Gravity type air scrubbing filter pool

An air scrubbing and gravity-type technology, which is applied in the direction of gravity filter, filter separation, loose filter material filter, etc., can solve the problems of blockage of air washing mechanism, lower production efficiency, difficult to wash off, etc., and achieve the effect of ensuring cleaning , Reduce production costs and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

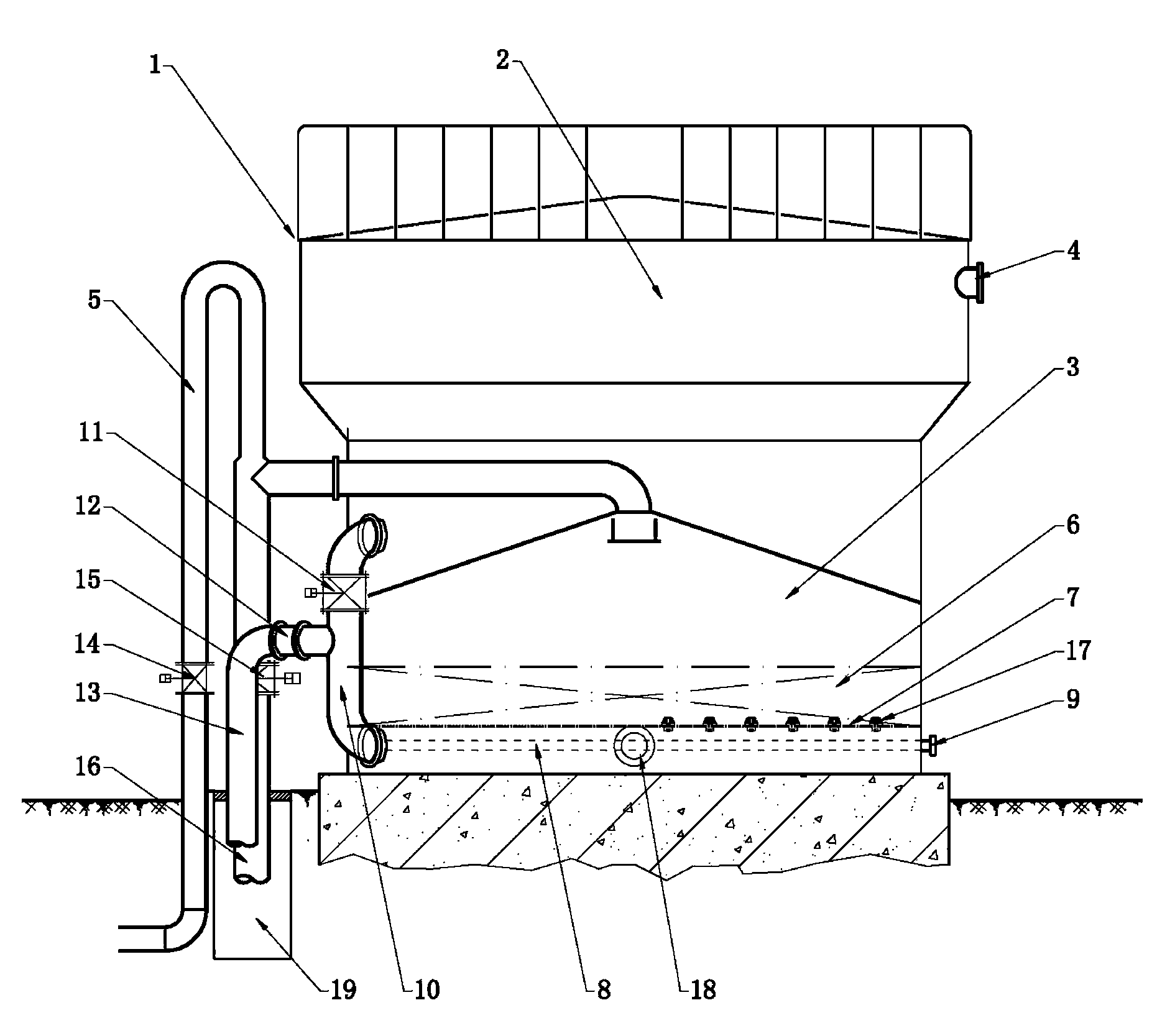

[0019] Such as figure 1 Shown: a gravity-type air scrubbing filter, including a pool body 1, a clear water bin 2 on the upper part of the pool body 1, and a filter bin 3 located on the lower side of the clear water bin 2. The clear water bin 2 is provided with an overflow port 4, and the filter bin 3 Connect with the external raw water pool through the water inlet pipe 5, the inlet of the water inlet pipe 5 is provided with a water inlet regulating valve 14, and the water inlet pipe 5 behind the water inlet regulating valve 14 is provided with a drainage branch pipe with a backwash drain valve 15 16. A filter layer 6 made of porcelain sand filter material is provided at the bottom of the filter chamber 3. The filter layer 6 is arranged on a porous filter plate 7, and the porous filter plate 7 is provided with evenly distributed filter caps 17. The porou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com