Purification method of low concentration phosphine waste gas

A phosphine, low-concentration technology, applied in chemical instruments and methods, separation methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high catalyst cost, difficult separation and recovery of products and catalysts, etc. Achieve the effects of easy separation and recovery, small and uniform bubbles, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

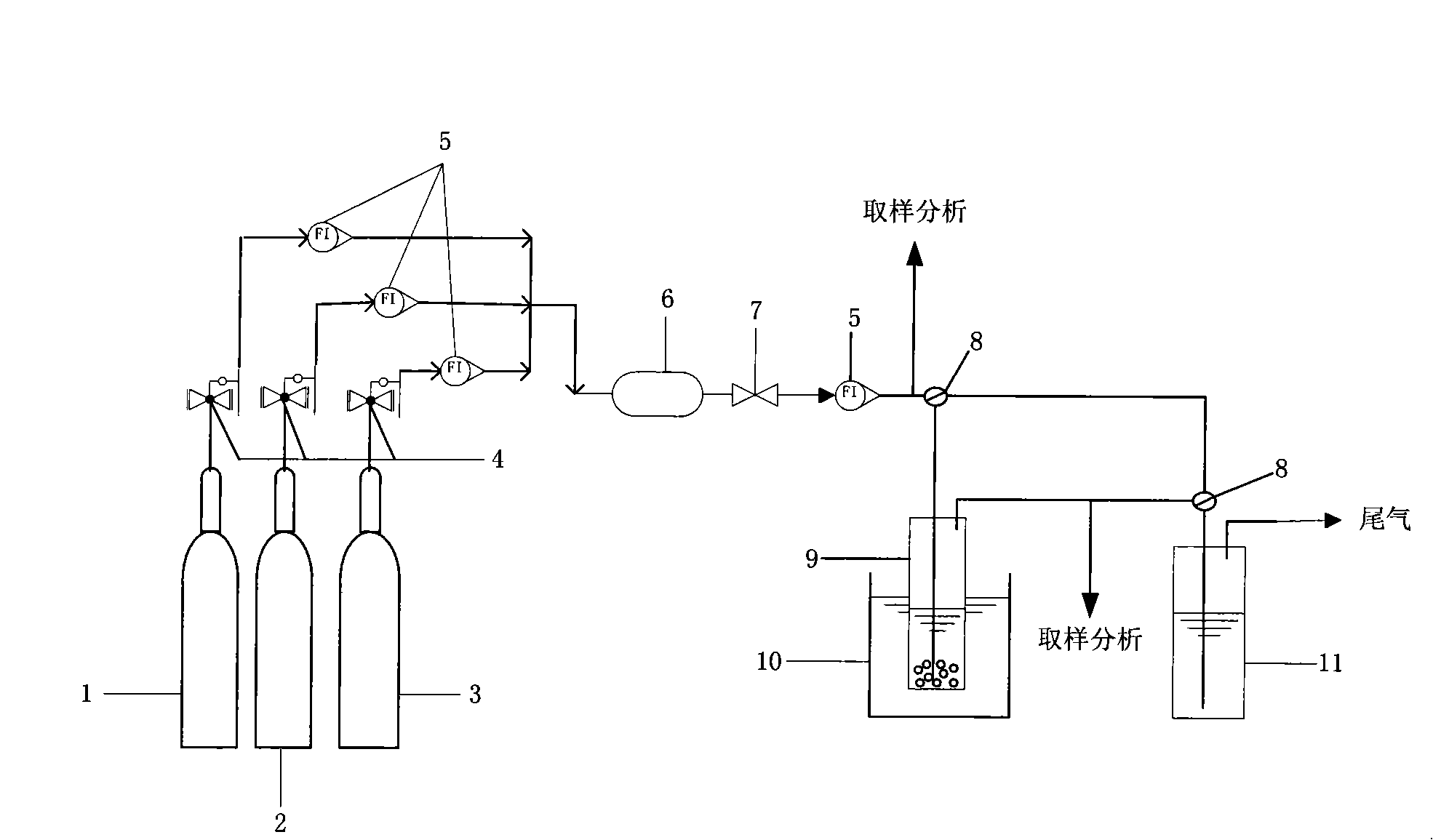

Method used

Image

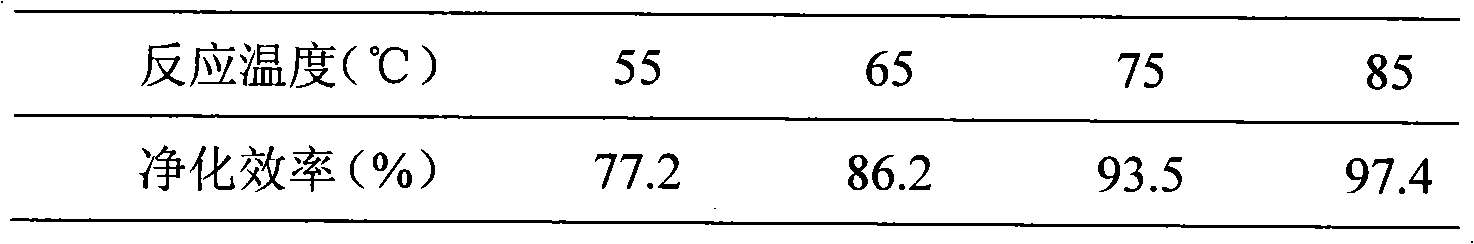

Examples

Embodiment 1

[0028] Preparation of catalyst: Weigh aluminum nitrate and copper nitrate according to the molar ratio of the elements at 1:1, dissolve aluminum nitrate with distilled water, add ammonia water with a volume fraction of 5% to prepare aluminum hydroxide sol; dissolve copper nitrate with distilled water, add In the aluminum sol, then add ammonia water with a volume fraction of 5% until no precipitation occurs, leave it to age for 6 hours after high-speed stirring, wash the resulting precipitation with distilled water, filter it three times and then dry it. The dried solid is ground at 400 °C for 3 hours.

[0029] Preparation of absorption solution: Take 10 ml of 1mol / L copper sulfate solution, add 4 to 5 drops of ammonia water with a volume fraction of 5% in the copper sulfate solution, so that the copper sulfate is just completely transformed into copper hydroxide precipitation, and the copper hydroxide precipitation is used Washing and filtering with distilled water for 3 to 4 ...

Embodiment 2

[0033] Catalyst preparation: Weigh iron nitrate and copper nitrate according to the element molar ratio of 1:2, dissolve them in distilled water to prepare iron nitrate solution and copper nitrate solution, mix the two solutions, and add 10% carbonic acid in the mixed solution Sodium solution until the precipitation is complete, wash the precipitate with distilled water and filter, repeat the operation 3 to 4 times, then dry the precipitate and grind it, and roast the obtained particles at 400°C for 4 hours to obtain the catalyst.

[0034] Preparation of absorption solution: Take 10 ml of 1mol / L copper sulfate solution, add ammonia water with a volume fraction of 10% to the copper sulfate solution, so that the copper sulfate is just completely transformed into copper hydroxide precipitate, wash the copper hydroxide precipitate with distilled water, pump Filter for 3 to 4 times; dry the copper hydroxide precipitate after washing and filtering, then use 10% ammonia water by volum...

Embodiment 3

[0038]Catalyst preparation: take aluminum nitrate, copper nitrate and cerium nitrate by weighing aluminum nitrate, copper nitrate and cerium nitrate according to the element molar ratio of 100:100:1, dissolve aluminum nitrate with distilled water to prepare copper nitrate solution, add ammonia water with a volume fraction of 10% to prepare aluminum hydroxide sol; Copper nitrate and cerium nitrate were dissolved in distilled water, respectively, and added to the aluminum hydroxide sol in turn, and ammonia water with a volume fraction of 10% was added until no precipitation was produced. After high-speed stirring, it was left to age for 6 hours, and the obtained precipitation was washed with distilled water and pumped. After filtering three times, it was dried, and the dried solid was finely ground and calcined at 350°C for 4h.

[0039] Preparation of absorption solution: Take 10 ml of 1mol / L copper sulfate solution, add ammonia water with a volume fraction of 5% to the copper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com