VOC (volatile organic compound) waste gas treatment system

A technology for waste gas treatment and waste gas source, which is applied in the use of liquid separation agents, combined devices, and dispersed particle separation. It can solve the problems of VOCs desorption, exceeding standards, and on-site monitoring results exceeding standards, and achieves good effects, high efficiency, and operating costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

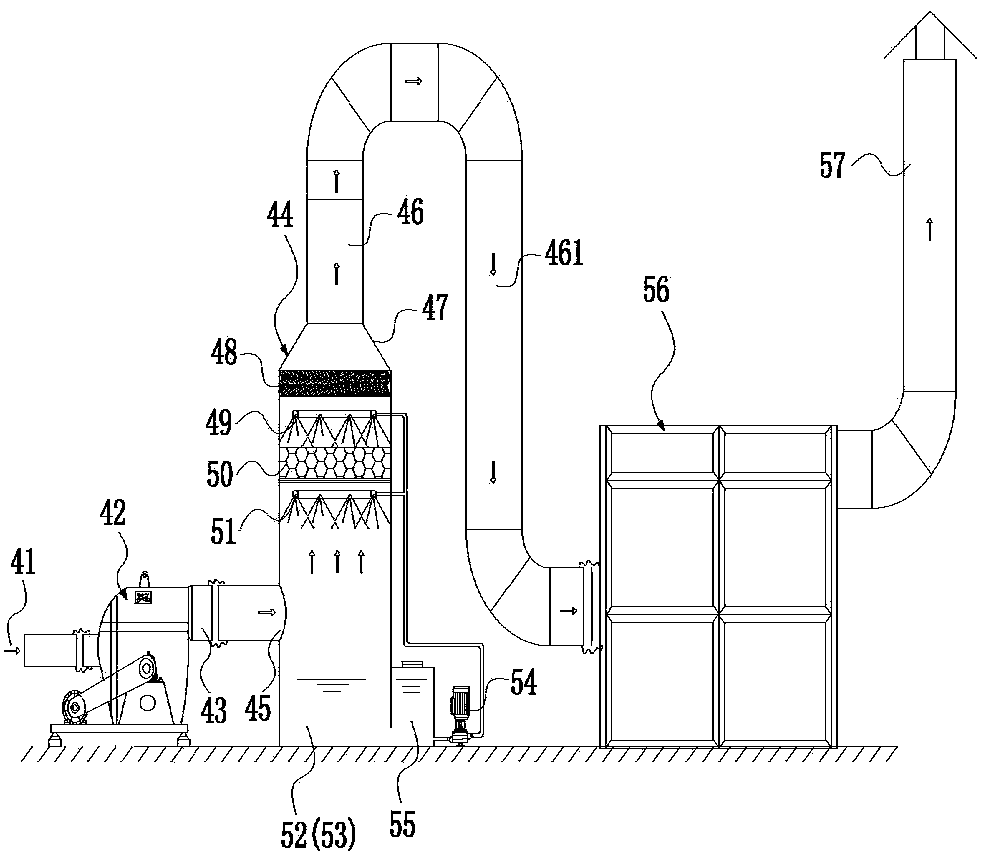

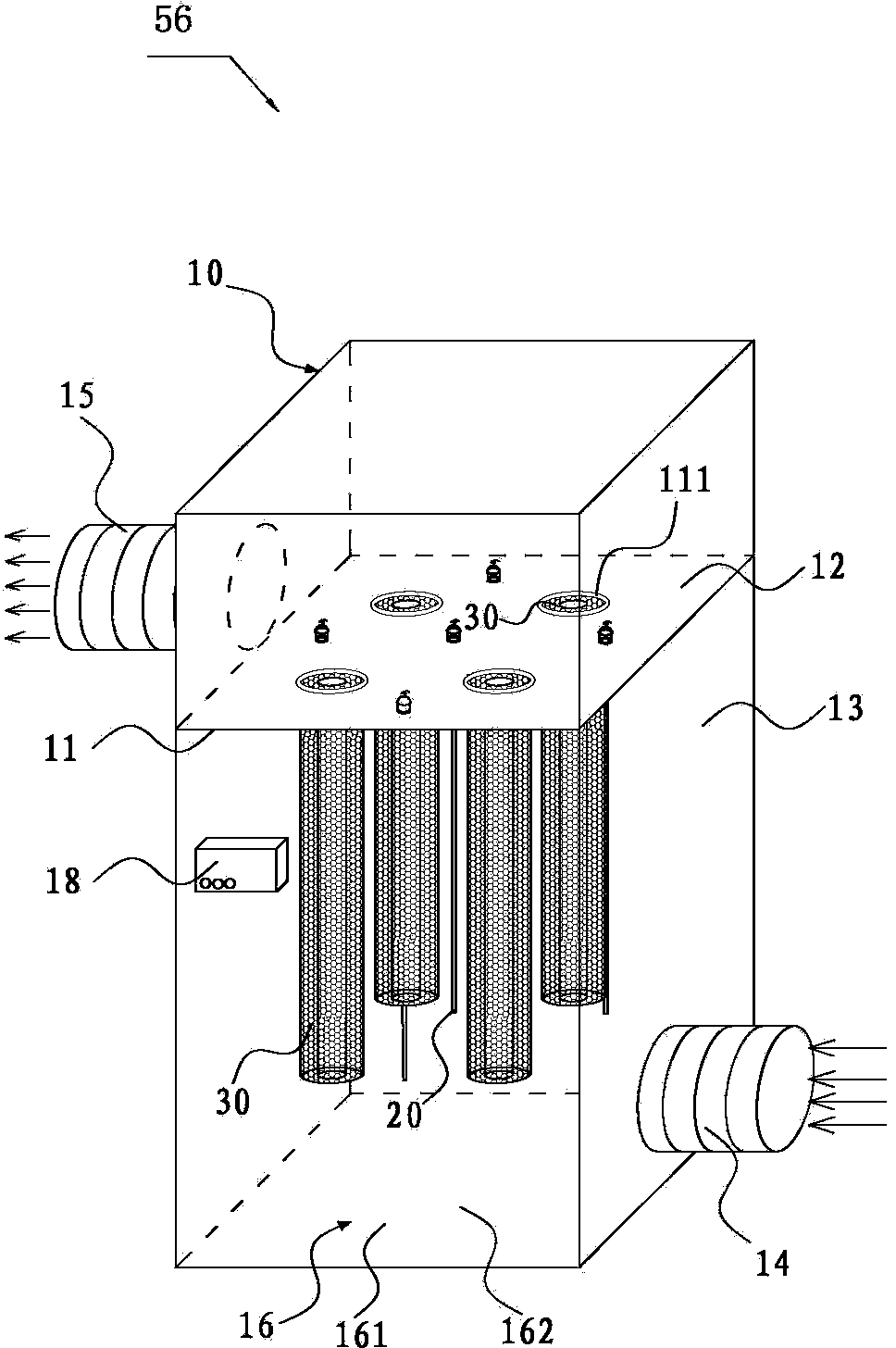

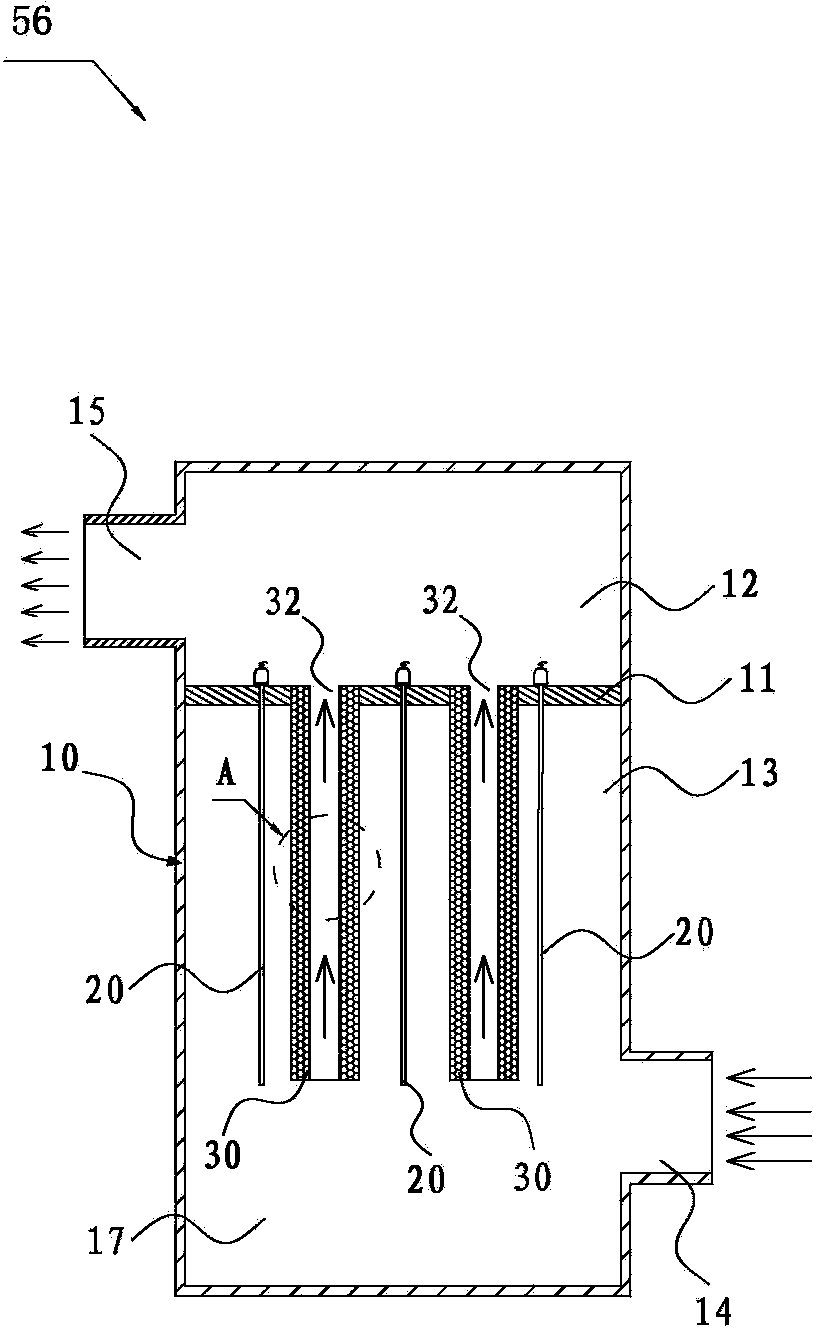

[0042] Please refer to figure 1 and Figure 6 Shown, it has shown the concrete structure of preferred embodiment of the present invention,

[0043] Such as figure 1 As shown, the VOC waste gas treatment system sequentially includes a fan 42 for connecting the VOC waste gas source 41, a packing spray tower device 44 connected to the air outlet 43 of the fan 42, and a packing spray tower device 44 along the waste gas treatment process. The ultraviolet activated carbon integrated device 56 of the air outlet 46, and the purification gas discharge port 57 that is connected on the ultraviolet activated carbon integrated device 56;

[0044] This packing spray tower device 44 comprises hollow tower body 47, and this hollow tower body 47 has top air outlet 46 and side air inlet 45, and its air inlet 45 is connected with the air outlet 43 of aforementioned blower fan 42; The demister layer 48, the upper sprayer 49, the packing layer 50, the lower sprayer 51 and the purification liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com