Deduster

A technology of dust collector and spinner, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, combined devices, etc., can solve the problems of poor dust removal effect of dust collector, unsuitability for continuous production, poor dust removal effect, etc., and achieve saving Energy, clogging prevention, and workload reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

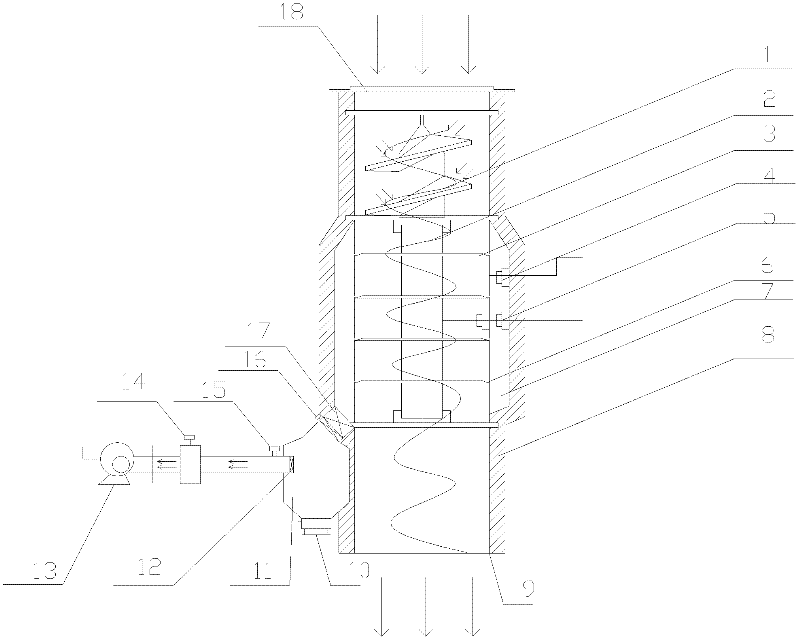

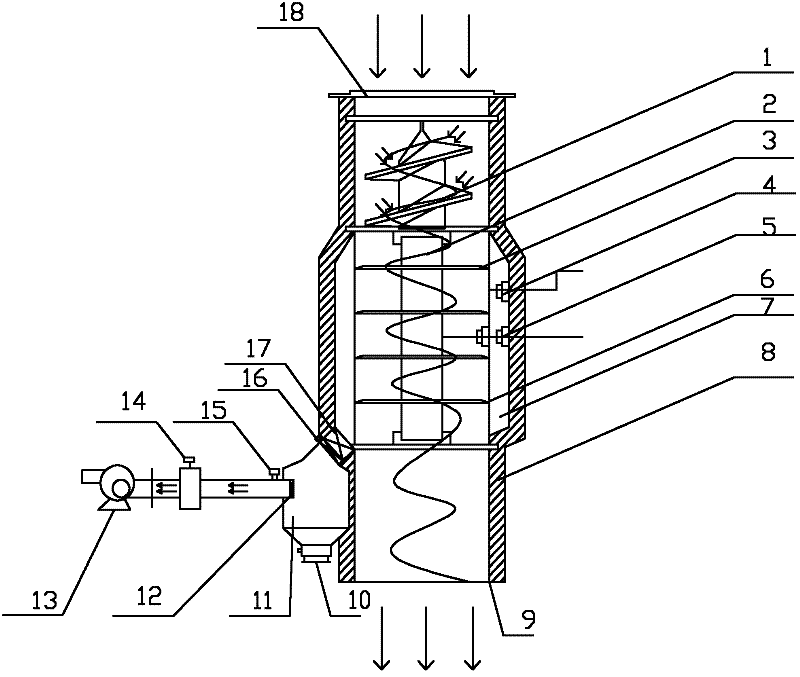

[0014] The technical solutions implemented in the present invention will be clearly and completely described below with reference to the accompanying drawings.

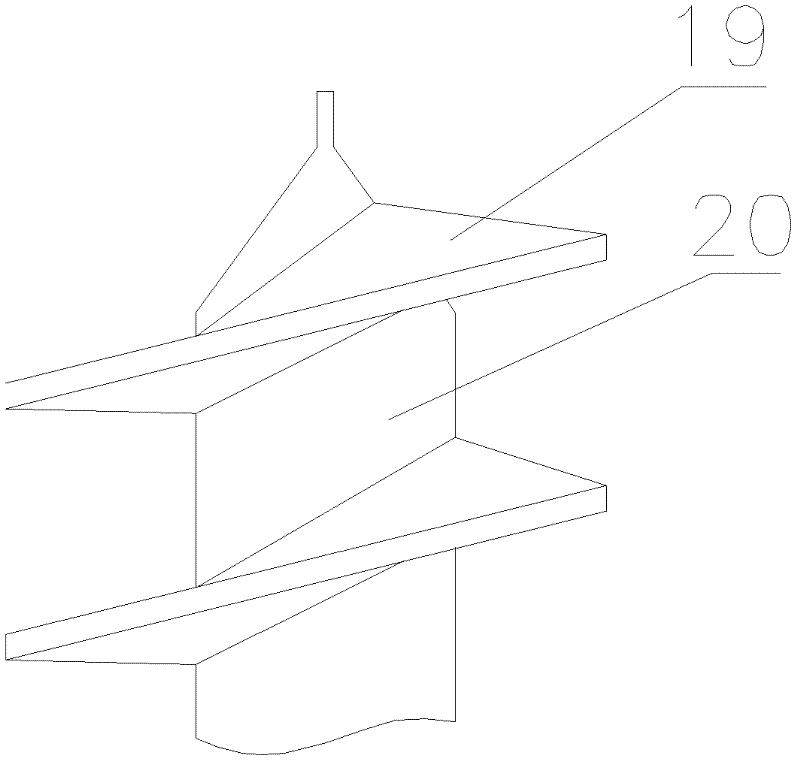

[0015] In order to achieve the above object, the technical solution adopted by the present invention to solve its technical problems is as follows: figure 1 : It is composed of two parts: a dust particle and flue gas separation device and an ash discharge device. The dust particle and flue gas separation device spinner 1 is located above the built-in cylindrical electrode 2, and the middle bracket is fixed around the device wall. The built-in cylindrical A number of soot traps 3 are evenly distributed on the electrode 2. The edges of the soot traps 3 are in contact with the cylinder wall. The edges of the soot traps 3 are chamfered and contact with the cylinder wall to form a circle of chute. The corresponding chute is evenly distributed on the cylinder wall. Circle the ash discharge hole 6, wherein the built-in cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com