Plastic barrel cover

A technology of plastic buckets and bucket lids, applied in the field of plastic bucket processing, can solve the problems of inconvenient use and handling, lack of handling handles for plastic buckets, and difficulty in opening and closing the bucket lids. The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

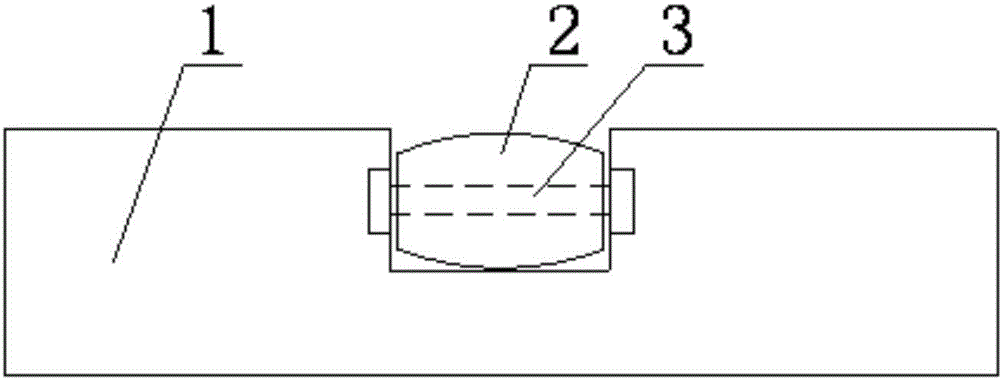

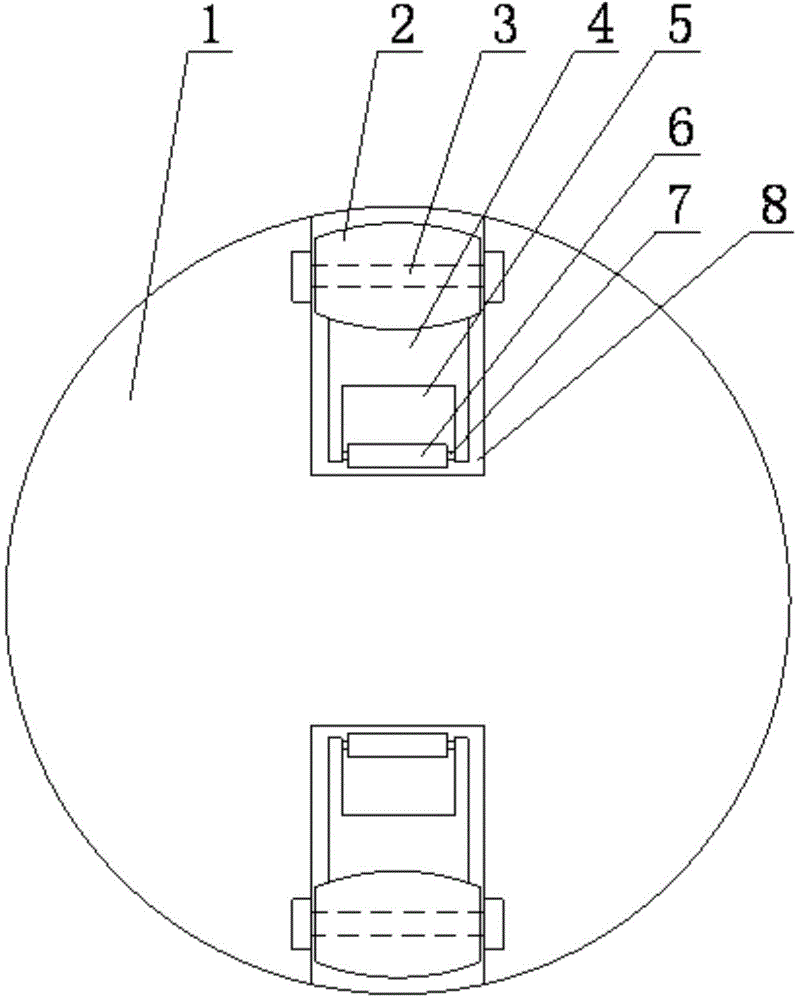

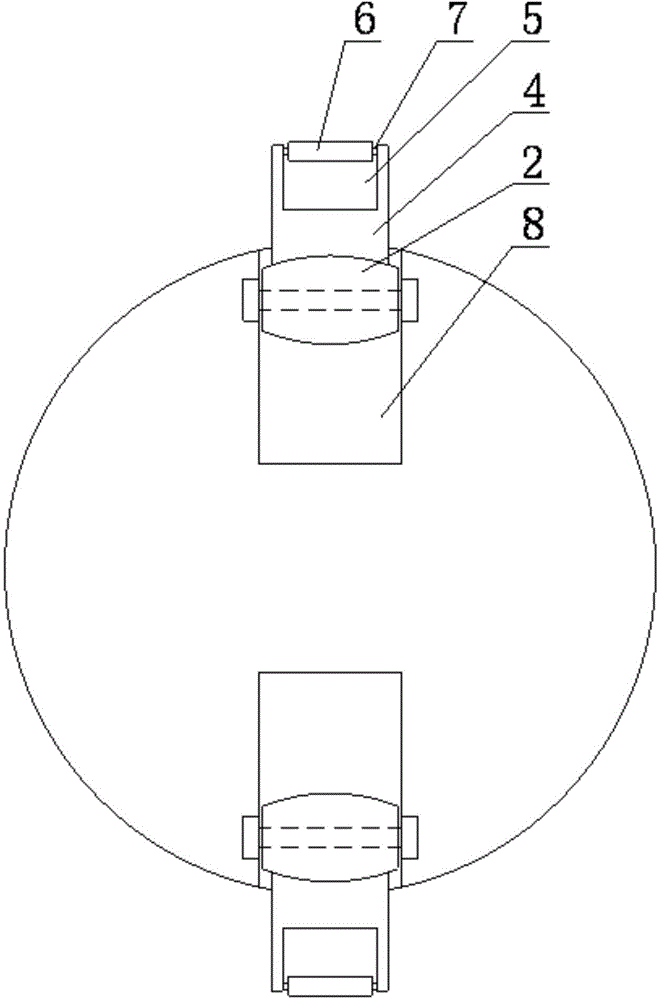

[0021] A plastic barrel cover, including a barrel cover body 1, its innovation is that a pair of installation grooves 8 are symmetrically formed on both ends of the upper surface of the barrel cover body, and a screwing mechanism is installed in the installation grooves. This screwing mechanism is made up of movable head 2, screwing handle 4 and bearing pin 3, and described movable head is fixedly mounted on one end of twisting handle, is shaped on the other end of twisting handle with an opening 5, and the end of opening passes through Gripping bar 7 is housed, and described movable head is installed in the installation groove by the rotation of pin shaft.

[0022] A grip sleeve 6 is also sleeved on the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com