Recycling method of ferronickel slag

A technology of ferronickel slag and slag, which is applied in the field of slag recycling and regeneration, can solve problems such as loss of strength, easy pulverization, and instability, and achieve the effects of eliminating environmental impact, reducing reaction temperature, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

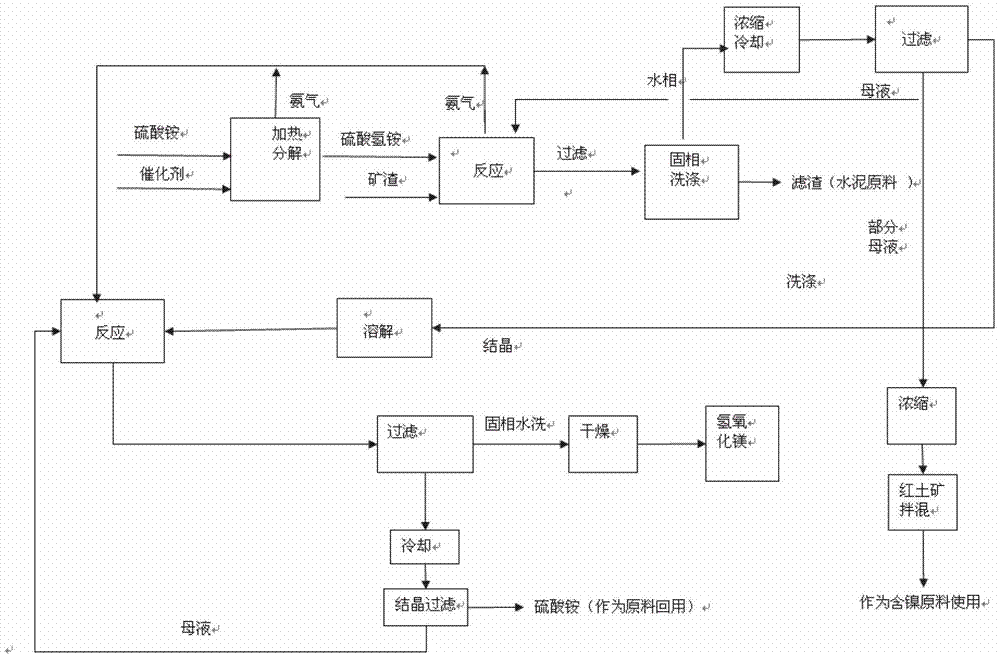

Image

Examples

Embodiment 1

[0050] In a 1000ml three-necked flask equipped with a thermometer, a stirrer, and an ammonia absorption device, add 400 grams of ammonium sulfate, 3 grams of powdered porous aluminum hydroxide, and 80 grams of water, heat up, start stirring, and the reaction temperature gradually rises to 220 ° C. Keep warm After 4 hours, it was cooled and tested by sampling, and the content of ammonium bisulfate was 99.03%.

[0051] Example 2:

[0052] Take 200g of ferronickel slag, after testing, the slag composition: magnesium (calculated as magnesium oxide): 23.00%; silicon (calculated as SiO 2 Nickel: 0.23%; Iron: 5.03%; crushed into more than 100 mesh, added to a 1000ml four-necked flask equipped with a thermometer, agitator, and ammonia absorption, added 500g of water, heated to 50°C, and batched Add 300g of ammonium bisulfate synthesized in Example 1, react for 6 hours, filter, and wash the solid phase with 200g of water for three times. The solid phase filter residue magnesium con...

Embodiment 3

[0054] Get the mother liquor of example two, get the same slag of example two, be ground into more than 200 orders, get 200 grams and add 1000ml and thermometer, stirrer are equipped with, in the four-necked flask of ammonia absorption, limit heat up, add the ammonium bisulfate of example one limit 200g, rise to 80°C within one hour, keep warm for 4 hours and filter, wash the solid phase with 200g of water three times, the solid phase filter residue has a magnesium content of 2.5% and a nickel content of 0.012%. The filter residue is used for cement production, and the filtrate is used for later use.

Embodiment 4

[0056] Take 500g of the mother liquor of Example 3, repeat the test of Example 3, take the mother liquor, concentrate and evaporate, cool to 20°C, crystallize and precipitate green crystals, filter, wash with water, and obtain 310g of crystals, the mother liquor can be used for reaction, or directly after mixing with laterite ore , as raw material ore for ferronickel production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com