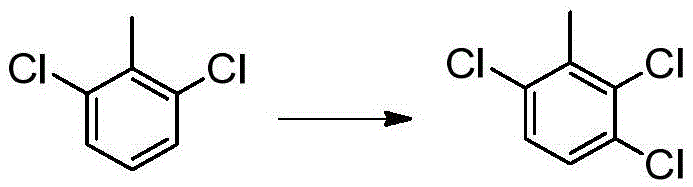

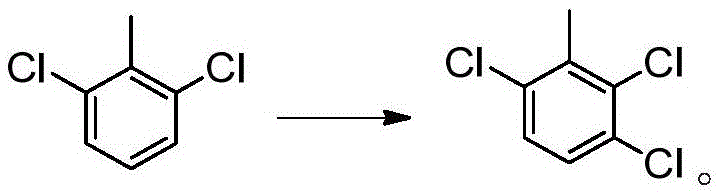

Synthetic method of 2,3,6-trichlorotoluene

A technology of trichlorotoluene and a synthetic method, which is applied in two fields, can solve the problems of low selectivity, cumbersome preparation methods, and high production costs, and achieve the effects of simple preparation methods, cheap and easy-to-obtain raw materials, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 100g of 2,6-dichlorotoluene and 0.5g of antimony trichloride into the round-bottomed flask, feed 39.7g of chlorine gas under normal pressure at 25°C, control the reaction temperature at 25-30°C, and pass chlorine at a rate of 10g / h, about Hours later, the GC detection reaction conversion rate was 80%, and the chlorine flow was stopped. 117.6 g of reaction liquid was obtained, and the composition was 20% of 2,6-dichlorotoluene, 77.2% of 2,3,6-trichlorotoluene, 0.7% of 2,4,6-trichlorotoluene, 2.1% of tetrachlorotoluene and impurities. The reaction solution was rectified to obtain 94.6 g of 2,3,6-trichlorotoluene, with a yield of 78.0% (94.6% after recovery of 2,6-dichlorotoluene), and a GC area content of 99%.

Embodiment 2

[0029] Add 100g of 2,6-dichlorotoluene, 100g of 1,2-dichloroethane, 0.5g of antimony trichloride into the round bottom flask, feed 39.7g of chlorine gas under normal pressure at 25°C, and control the reaction temperature at 25-30°C , Chlorine flow rate 10g / h, after about 4 hours, GC detection reaction conversion rate is 80%, stop to pass chlorine. Atmospheric pressure distillation reclaims solvent 1,2-dichloroethane to obtain 117.5 g of still residue, consisting of 20% 2,6-dichlorotoluene, 77.5% 2,3,6-trichlorotoluene, 2,4,6- Trichlorotoluene 0.6%, tetrachlorotoluene and impurities 1.9%. After further rectification, 95.0 g of 2,3,6-trichlorotoluene was obtained, with a yield of 78.3% (94.9% after recovery of 2,6-dichlorotoluene), and a GC area content of 99%.

Embodiment 3

[0031] Add 100g of 2,6-dichlorotoluene and 0.5g of antimony trichloride into the round bottom flask, feed 59.6g of chlorine gas under normal pressure at 25°C, control the reaction temperature at 25-30°C, and pass chlorine at a rate of 10g / h, approx. After 6 hours, GC detected that the reaction of 2,6-dichlorotoluene was complete, and the chlorine flow was stopped. 124.1 g of the reaction solution was obtained, and the composition was 85.4% of 2,3,6-trichlorotoluene, 1.9% of 2,4,6-trichlorotoluene, 12.7% of tetrachlorotoluene and impurities. The reaction solution was rectified to obtain 104.7 g of 2,3,6-trichlorotoluene with a yield of 86.3% and a GC area content of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com