Carbonyl fluoride purifying method

A purification method and carbonyl fluoride technology, applied in the direction of carbonyl chloride, fractionation, etc., can solve the problems of high impurity gas content, low carbonyl fluoride purity, and difficulty in separating and purifying carbonyl fluoride.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0030] Among the following examples 1-10:

[0031] The pressures are absolute pressures;

[0032] The purified gas test method is as follows:

[0033] The gas was introduced into gas chromatography-mass spectrometry (GC-MS) (model: Shimadzu Corporation GC-2014) and Fourier transform infrared spectrometer (FT-IR) (model: Nicolet6700) to analyze the gas composition. It is determined by GC-MS and FT-IR that the main component of the gas is carbonyl fluoride, and the purity and yield of carbonyl fluoride are calculated according to the integrated area of carbonyl fluoride as a result of gas chromatography data.

[0034] The gas chromatographic determination uses He gas as the carrier gas and TCD detector, the He carrier gas flow rate is 100mL / min, the column temperature is 40°C, the inlet temperature is 100°C, and the TCD temperature is 100°C. The maximum peak on the gas chromatogram It is the chromatographic peak of carbonyl fluoride.

Embodiment 1

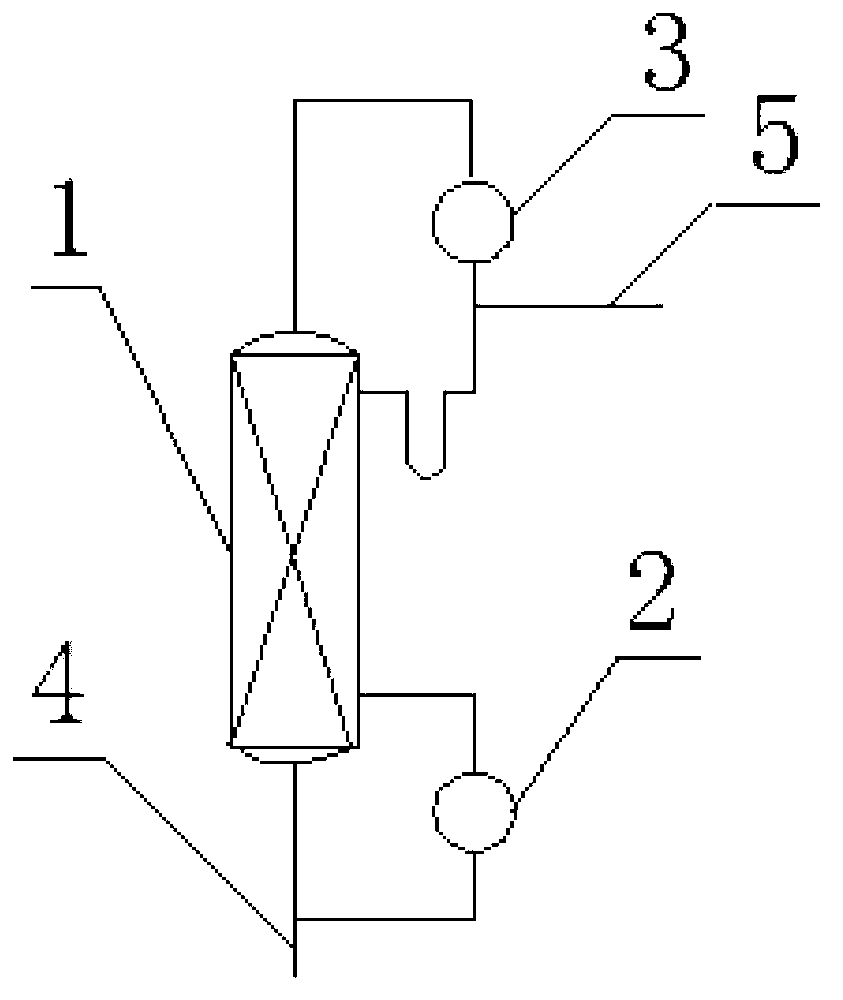

[0036] The purification device used in this example is as figure 1 The rectification tower shown includes a reboiler 2, a rectification column 1, a condenser 3, an inlet pipe 4 and a product take-off pipe 5. Wherein, the reboiler 2, the rectification column 1, and the condenser 3 are arranged sequentially from bottom to top, and the inlet pipe 4 is connected with the bottom of the reboiler 2 of the rectification tower and the bottom of the rectification column 1 respectively, and the reboiler of the rectification tower 2 The top is connected with the lower part of the rectification column 1, the top of the rectification column 1 is connected with the top of the condenser 3, the bottom of the condenser 3 is connected with the upper part of the rectification column 1, and the product extraction pipe 5 is located at the bottom of the condenser 3 and the rectification column 1 between the tops. The inlet pipe 4 is used for feed, and the product take-out pipe 5 is used for taking ...

Embodiment 2

[0048] The specific surface area of the filler in the purification device used in this embodiment is 2500m 2 / m 3 , all the other are with embodiment 1.

[0049] COF 2 The crude product gas enters the rectification tower through the inlet pipe 4 of the rectification tower for purification, and the COF 2 The specific components of the crude product gas and the volume percentage of each component are shown in Table 2.

[0050] Step 1. Preliminary distillation and purification

[0051] During light removal treatment, the temperature of the reboiler 2 of the rectification tower is -48°C, the pressure is 0.6MPa, the temperature of the condenser 3 is 0.5°C lower than that of the reboiler 2, and the low-boiling point impurities accumulate in the condenser 3 at the top of the tower. By vacuuming, the low-boiling impurities accumulated in the condenser 3 at the top of the tower are removed; during weight removal, the temperature of the reboiler 2 of the rectification tower is 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com