Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

439results about "Ammonium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

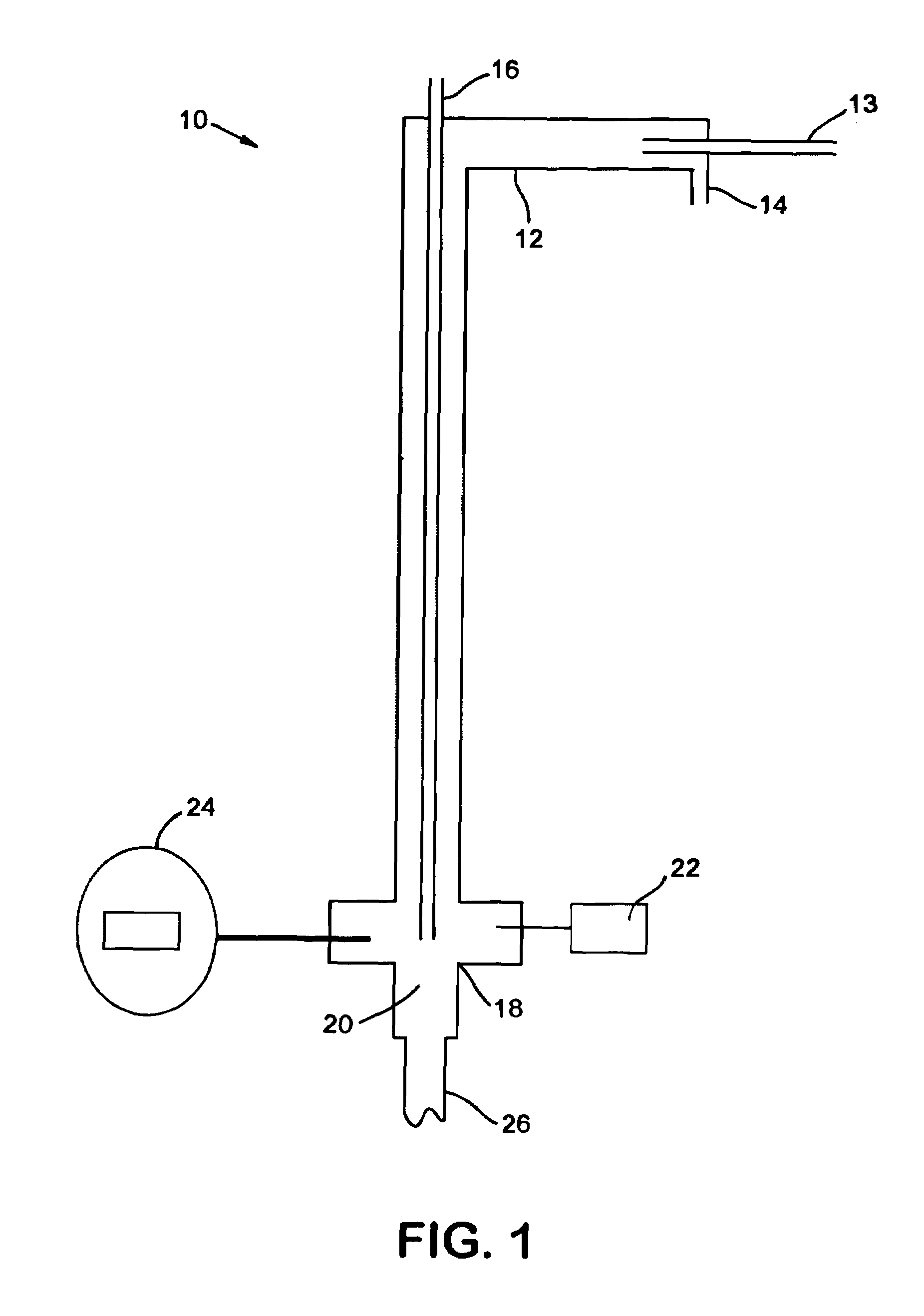

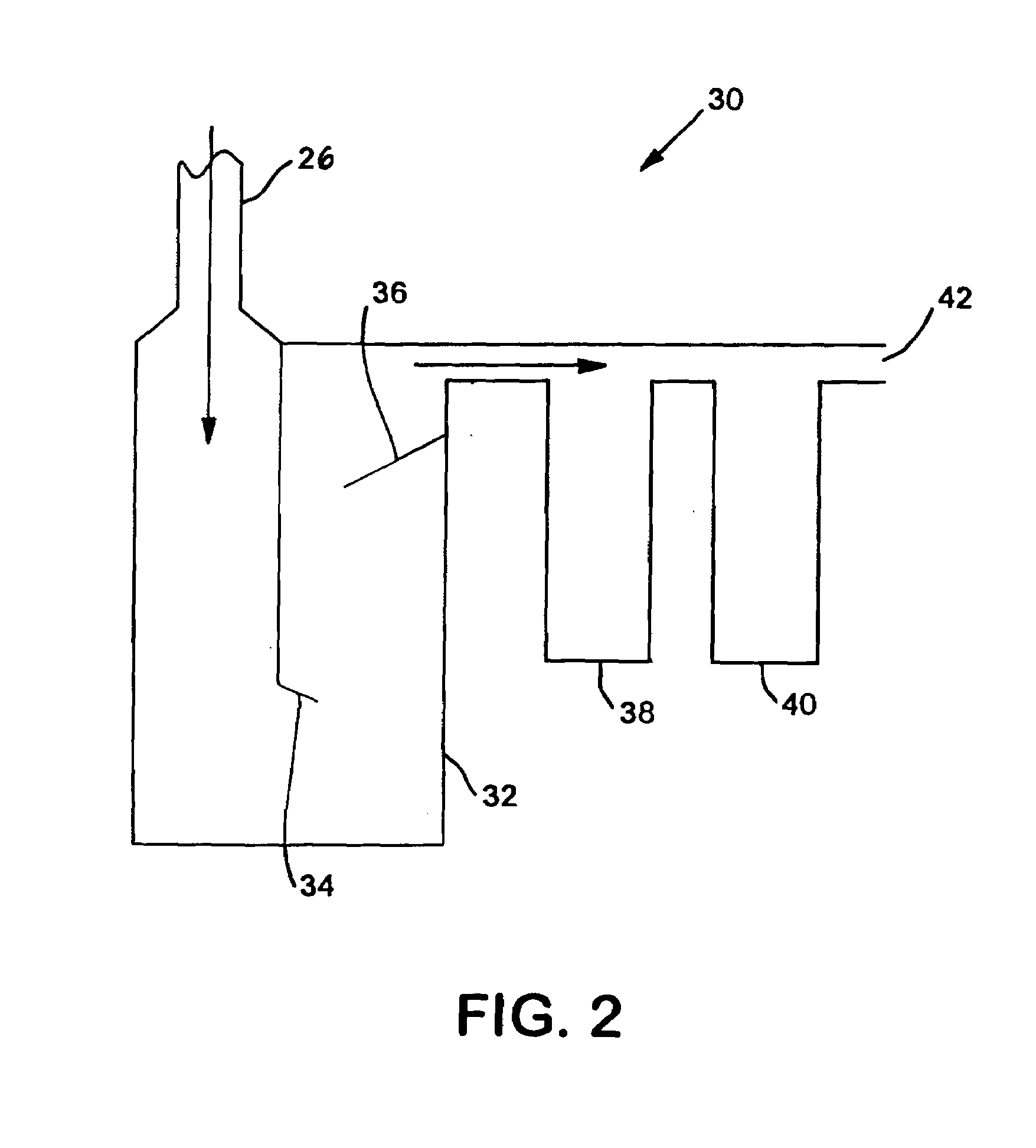

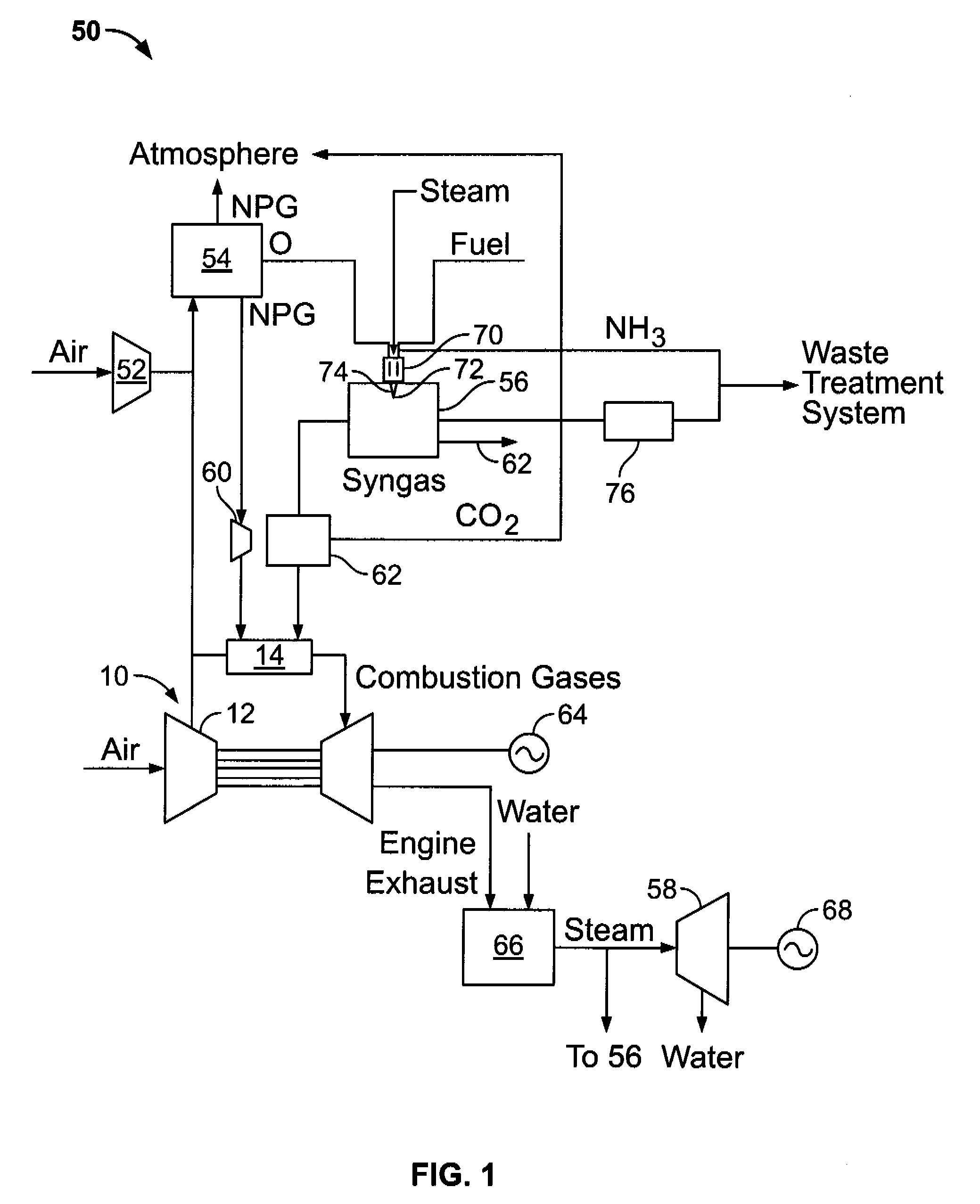

Methods and systems for zero discharge water treatment

ActiveUS20100172819A1Treatment involving filtrationDialysis systemsParticulatesWater treatment system

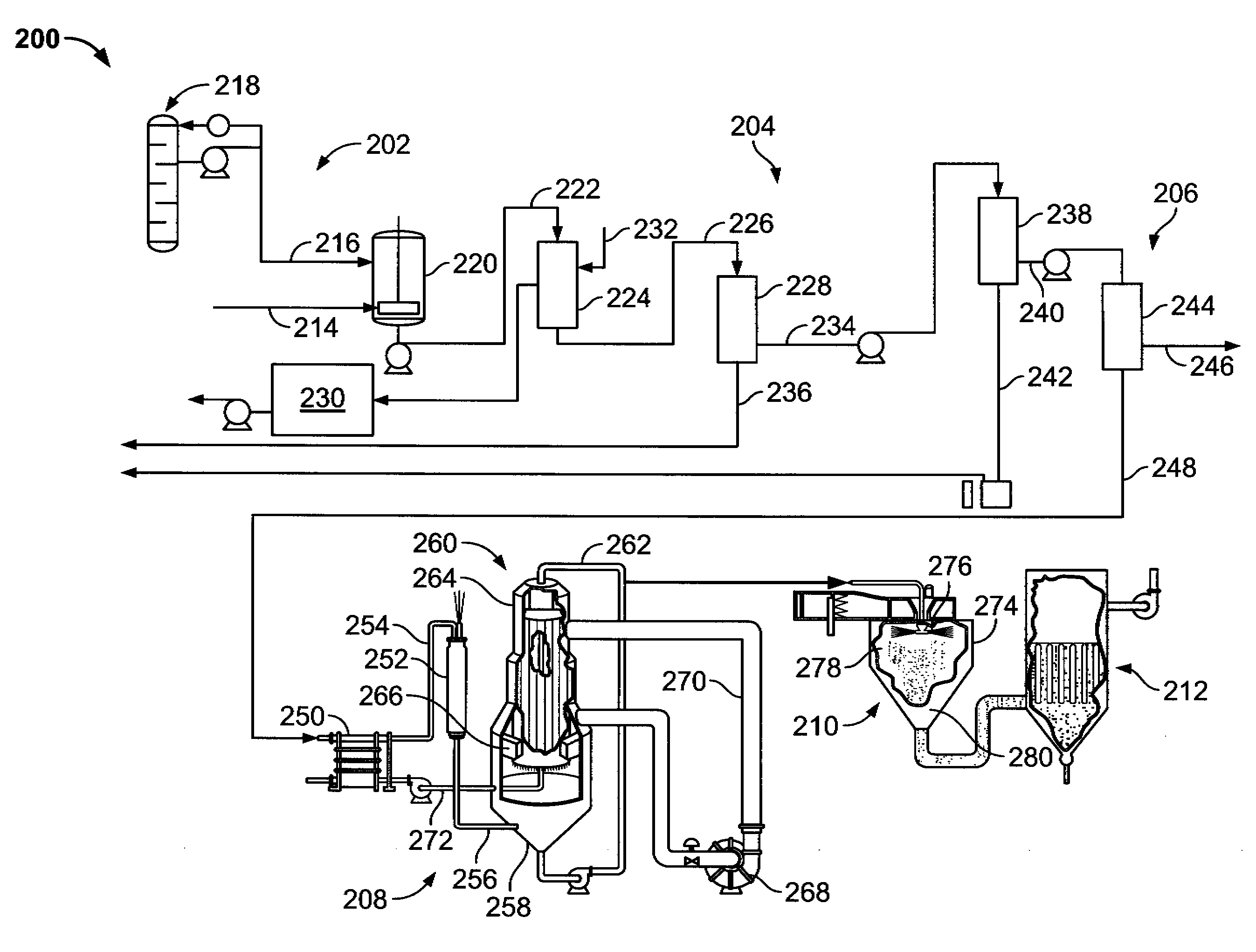

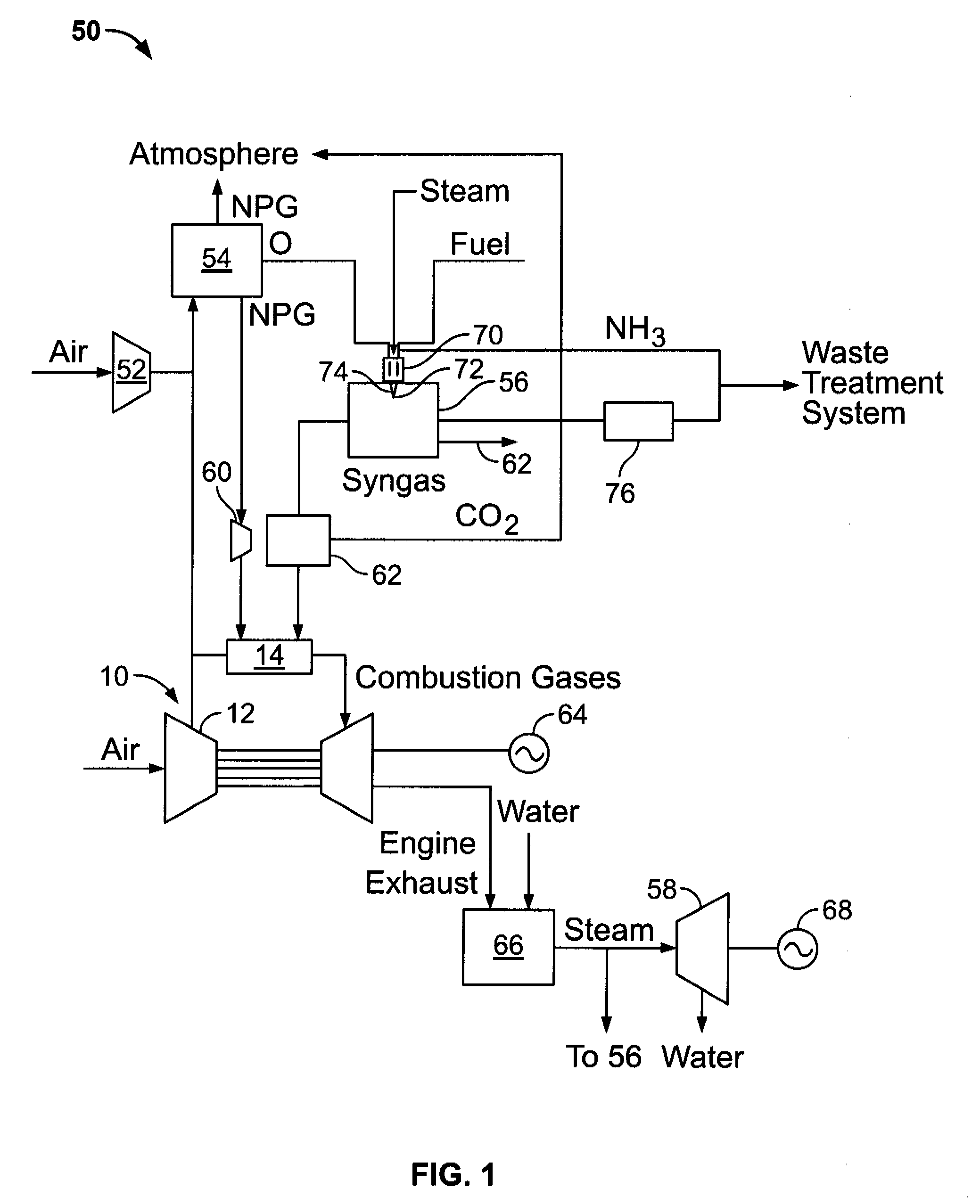

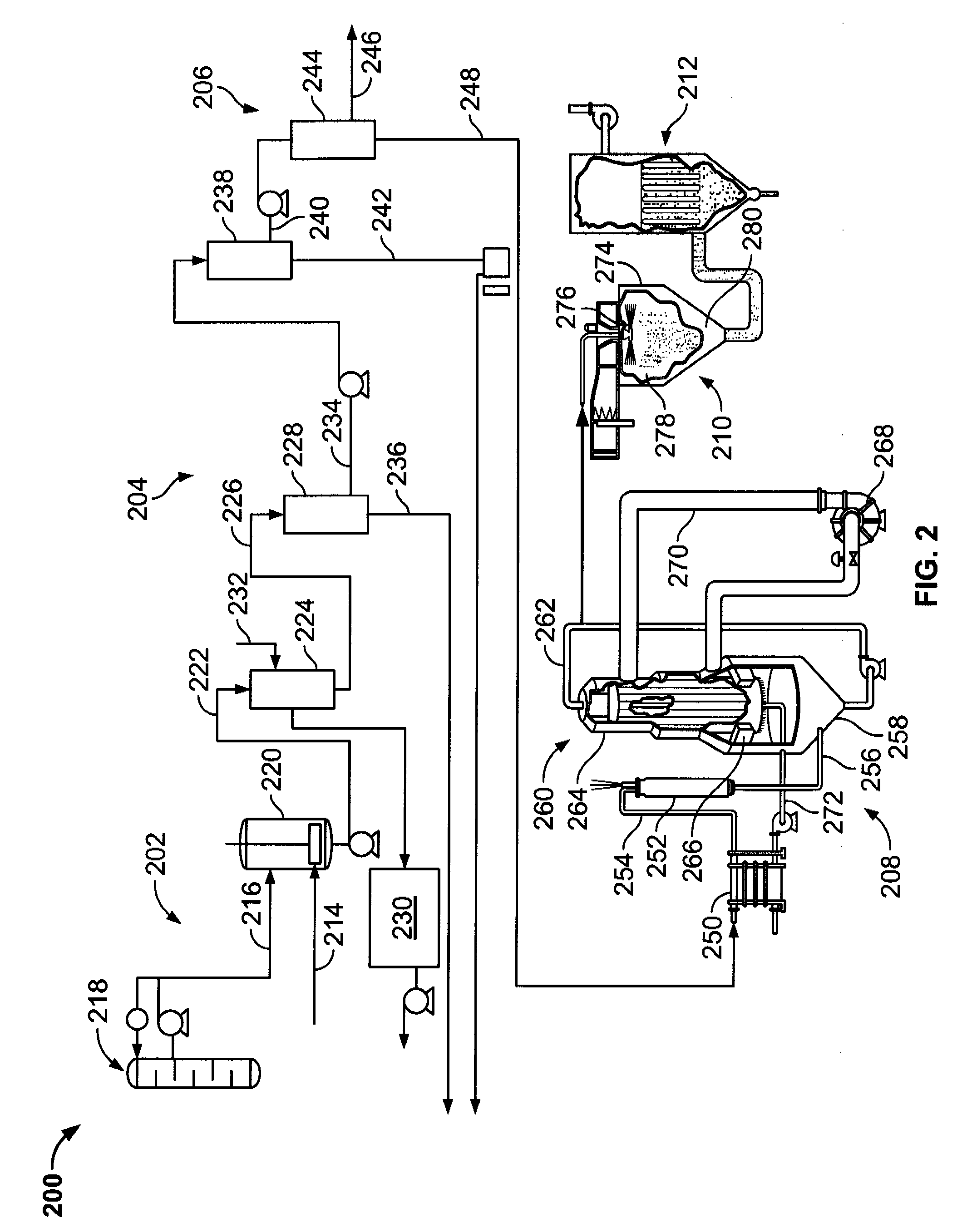

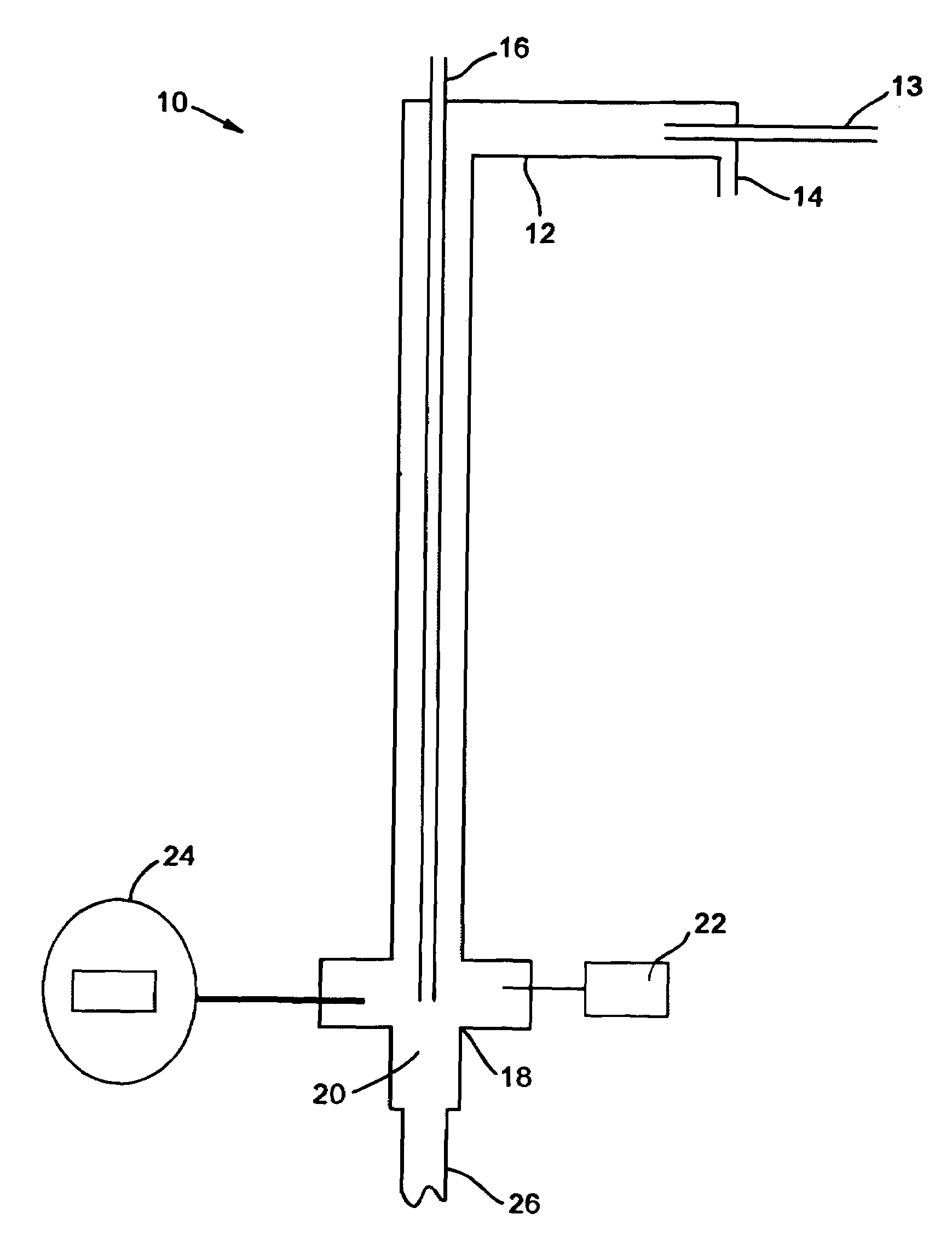

Methods and systems for a zero discharge waste water treatment system are provided. The system includes a filtration train including filter media having successively smaller diameter filtration elements, a reverse osmosis apparatus including a pump and a membrane coupled in flow communication with said filtration train, a vapor compressor coupled in flow communication with said reverse osmosis apparatus, and a spray dryer coupled in flow communication with said vapor compressor, said spray dryer configured to separate moisture in a brine solution from particulate suspended in the brine solution.

Owner:AIR PROD & CHEM INC

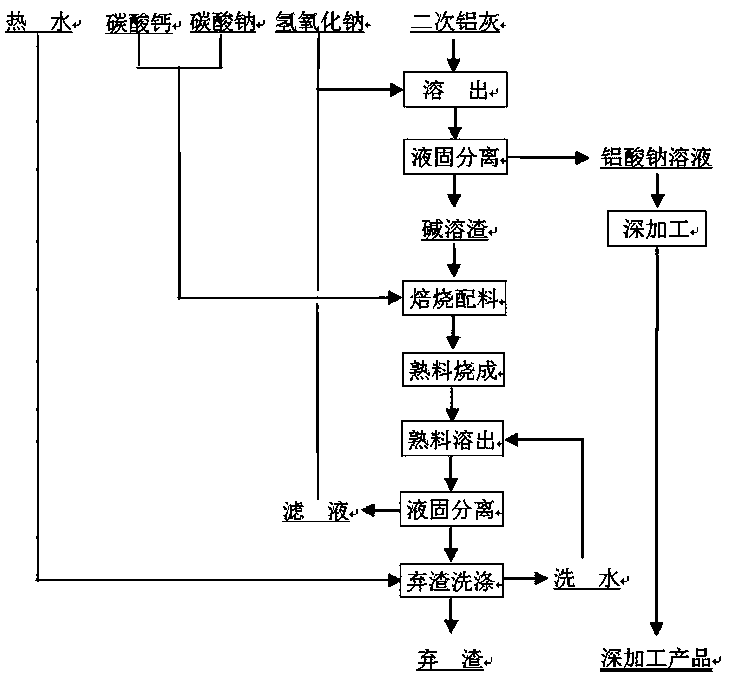

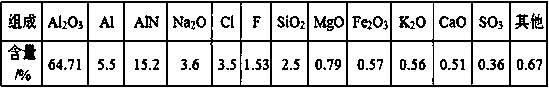

Method for preparing magnesium aluminate spinel by using secondary aluminum ash

ActiveCN108585826ARealize impurity removalQuick responseAmmonium chlorideElectric arc furnaceWater immersion

The invention discloses a method for preparing magnesium aluminate spinel by using secondary aluminum ash. The method comprises the following steps: (1) preparing the secondary aluminum ash as a raw material; (2) calcining for 1-3 h in 900-1200 DEG C, after cooling, ball-milling and preparing secondary aluminum ash fine powder; (3) adding the secondary aluminum ash fine powder to water, under theconditions of a temperature of 50-98 DEG C and stirring, and performing water leaching by applying an ultrasonic wave; feeding an ammonia gas generated by the water leaching to a reaction tank and generating ammonium chloride with hydrochloric acid; (4) filtering and separating a leaching residue, after washing and drying, mixing with a material containing magnesium oxide, and levigating; (5) pressing as pellets; and (6) sintering the pellets in a high temperature or smelting in an electric arc furnace so as to prepare the magnesium aluminate spinel. The method is rapid in reaction speed, andcapable of enabling nitrogen to be converted to the ammonia gas which is discharged and recycled, enabling soluble impurities to enter a liquid phase, and realizing the further impurity removal. The prepared magnesium aluminate spinel is high in purity, and less in impurity content.

Owner:NORTHEASTERN UNIV

Technique for extracting copper ions from industrial wastewater

ActiveCN104355474AHigh extraction rateGood removal effectWater contaminantsWater/sewage treatment by ion-exchangeIon exchangeIon-exchange resin

The invention discloses a technique for extracting copper ions from industrial wastewater, which comprises the following steps: 1) respectively pretreating an acidic coppery etching waste liquid and an alkaline coppery etching waste liquid; 2) neutralization and precipitation: carrying out neutralization reaction on the acidic coppery etching waste liquid and alkaline coppery etching waste liquid in a neutralizing tank, and precipitating to obtain a basic copper chloride precipitate and a filtrate; 3) adding the basic copper chloride precipitate into a reaction tank, and adding sulfuric acid to obtain a copper sulfate crystal; 4) sending the filtrate into an ion exchange resin tower to adsorb the rest unrecovered copper ions, thereby obtaining ammonia nitrogen wastewater; and 5) carrying out evaporative concentration on the ammonia nitrogen wastewater by a vapor recompression technique, crystallizing the concentrate to produce an ammonium chloride product, treating the condensation water by an ion-exchange process, and discharging after reaching the standard. The technique can greatly enhance the extraction rate of copper ions, solves the problem of environmental pollution caused by heavy metal ions, and can produce other products from the waste liquid to implement cyclic utilization, thereby saving the resources and protecting the environment.

Owner:清远市中宇环保实业有限公司

Circuit board acid-base etching waste liquid recycling treatment technology

InactiveCN108862365AImprove protectionEasy to operateCopper sulfidesCopper sulfatesEconomic benefitsCopper oxide

The invention discloses a circuit board acid-base etching waste liquid recycling treatment technology. Acidic etching waste liquid and alkaline etching waste liquid are neutralized to generate copperoxychloride, copper oxychloride reacts with an alkaline solution to generate copper oxide, copper oxide reacts with concentrated sulfuric acid to generate copper sulfate, and filtrate and washing water in the reactions are collected. The circuit board acid-base etching waste liquid recycling treatment technology makes copper ions precipitate to generate different copper-containing products througha plurality of steps, operation is easy, the cost is low, etching waste liquid ca be treated on a large scale, meanwhile, the treated filtrate is sufficiently utilized to prepare etching liquid again, the economic benefit is enhanced, emission is reduced, and environmental protection is facilitated.

Owner:广东省博罗县湘澧精细化工有限公司

Production of gaseous chloramine

InactiveUS7070751B2Prevent scalingSimple streamlined designCombination devicesExhaust apparatusChloramine BGas phase

The present invention provides a reactor for the gas-phase reaction of commercially available gases in the presence of an inert carrier gas to form product gas. The reactor has a streamlined, compact configuration and at least one solids collection and removal system downstream of the reactor, where solids are efficiently removed from the product gas stream, leaving high purity product gas. The removal system allows for a simple reactor design, which is easy to clean and operates continuously over longer periods of time.

Owner:BRISTOL MYERS SQUIBB CO

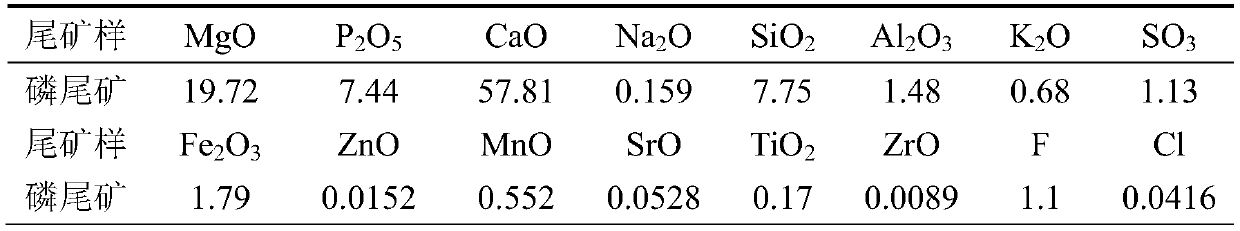

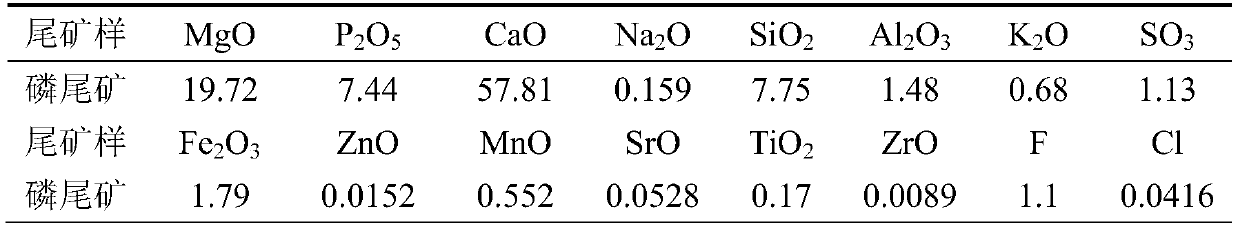

Method for preparing gypsum whiskers, magnesium chloride, ammonium magnesium phosphate and ammonium chloride from phosphate tailings

ActiveCN110817911AHigh recovery rateSolve the bottleneck problem that cannot be consumed in large quantitiesPolycrystalline material growthFrom normal temperature solutionsMagnesium phosphatePhosphoric acid

The invention provides a method for preparing gypsum whiskers, magnesium chloride, ammonium magnesium phosphate and ammonium chloride from phosphate tailings. The method comprises the following steps:adding an acidizing fluid into phosphate tailings in batches, dropwise adding hydrochloric acid to react, separating silicon slag and an acidolysis solution, and cooling and crystallizing the acidolysis solution to obtain calcium chlorophosphate and acidolysis solution; adding concentrated sulfuric acid into the acidizing fluid, dropwise adding the acidolysis fluid for reaction, and performing centrifugal separation after reaction to obtain gypsum whiskers and the acidizing fluid; heating and concentrating the acidizing fluid, crystallizing to obtain a magnesium chloride solution, and centrifugally separating the magnesium chloride solution to obtain magnesium chloride hexahydrate and a magnesium chloride mother liquor; adding ammonium sulfate and calcium chlorophosphate into the magnesium chloride mother liquor for reaction, filtering to obtain gypsum and a filtrate after the reaction is finished, dropwise adding ammonia water into the filtrate, cooling and filtering to obtain ammonium magnesium phosphate and an ammonium chloride solution; heating, concentrating, and cooling the ammonium chloride solution to obtain ammonium chloride crystals and a crystallization mother liquor, and after centrifugal separation, preparing a 5 to 20% ammonia water solution from the crystallization mother liquor and ammonia water. According to the technical scheme, the recovery rate of phosphorus reaches 99%, and the recovery rate of calcium reaches 95%.

Owner:三峡公共检验检测中心

Harmless treatment and utilization method for aluminum ash

InactiveCN107697884ASlightly affectedTake advantage ofSolid waste disposalAluminium oxide/hydroxide preparationSolid phasesChemistry

The invention discloses a harmless treatment and utilization method for aluminum ash. On the basis of a conventional process, the method comprises the following steps: additionally pretreating an aluminum ash raw material, namely performing primary disliquid washing treatment on the aluminum ash with a diluted alkali liquid or water, performing gas-water separation on a gas with ammonia gases, hydrogen and acetylene in the disliquid washing process, collecting the gas, recycling the ammonia gases with a diluted acid liquid for preparing an ammonium salt, and utilizing a combustible gas after ammonia removal as fuel of later procedures; dissolving cyanide, dissoluble fluoride and chloride in the aluminum ash into a liquid phase in disliquid washing to form an alkali pretreatment liquid, thereby separating the dissoluble substances from insoluble solid phases in the aluminum ash. Due to addition of a specific procedure of harmless treatment on environment danger sources, main danger sources, namely cyanide and dissoluble fluoride in the aluminum ash are separated from the aluminum ash, convenience is brought to later harmless treatment, meanwhile the chloride in the aluminum ash is dissolved, and the situation that later disliquid process is affected by the chloride is avoided; and therefore, the purpose that potential danger is eliminated while the aluminum ash is recycled is achieved.

Owner:上海添瑞环保科技有限公司

Methods and systems for zero discharge water treatment

Methods and systems for a zero discharge waste water treatment system are provided. The system includes a filtration train including filter media having successively smaller diameter filtration elements, a reverse osmosis apparatus including a pump and a membrane coupled in flow communication with said filtration train, a vapor compressor coupled in flow communication with said reverse osmosis apparatus, and a spray dryer coupled in flow communication with said vapor compressor, said spray dryer configured to separate moisture in a brine solution from particulate suspended in the brine solution.

Owner:AIR PROD & CHEM INC

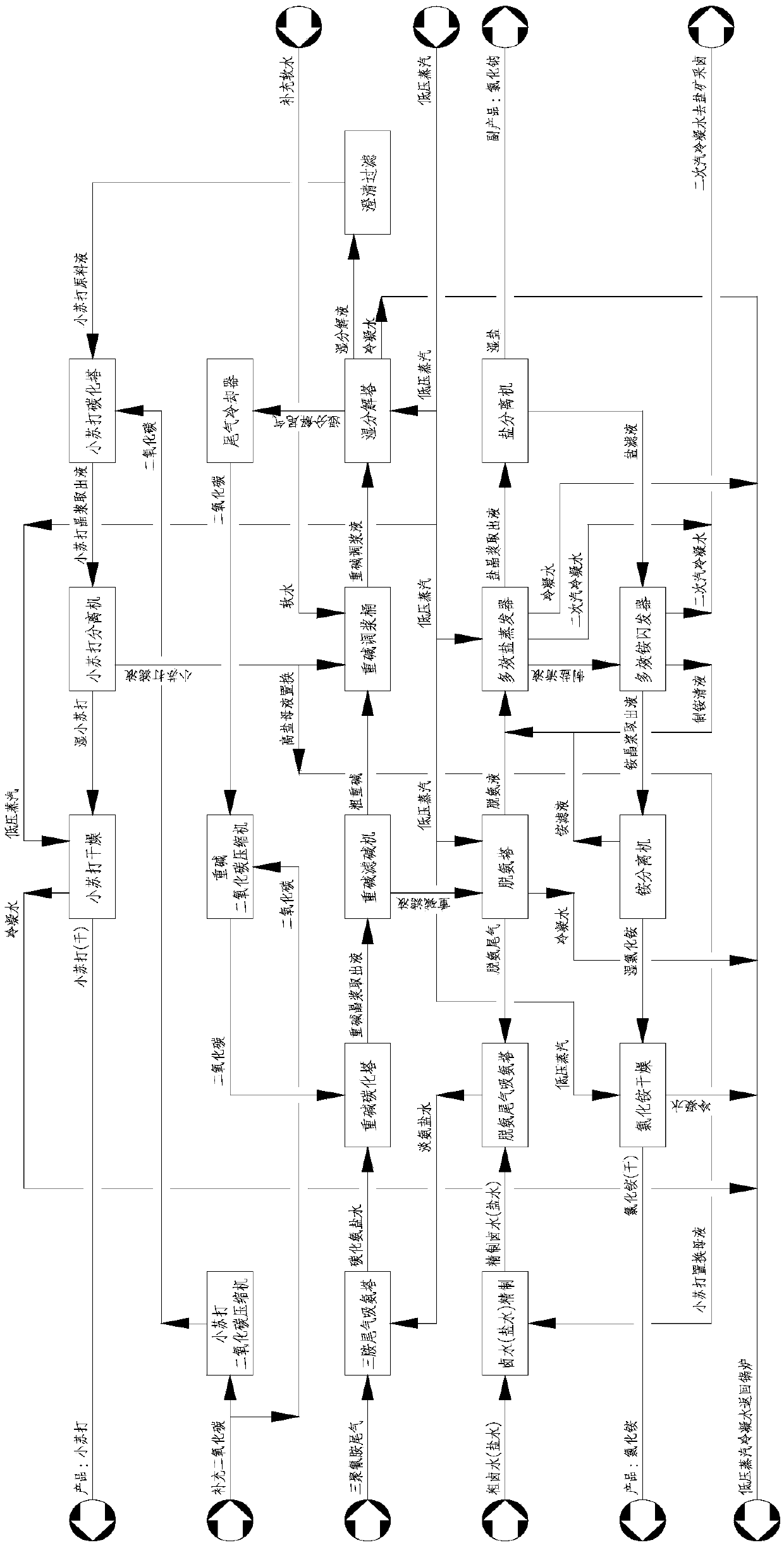

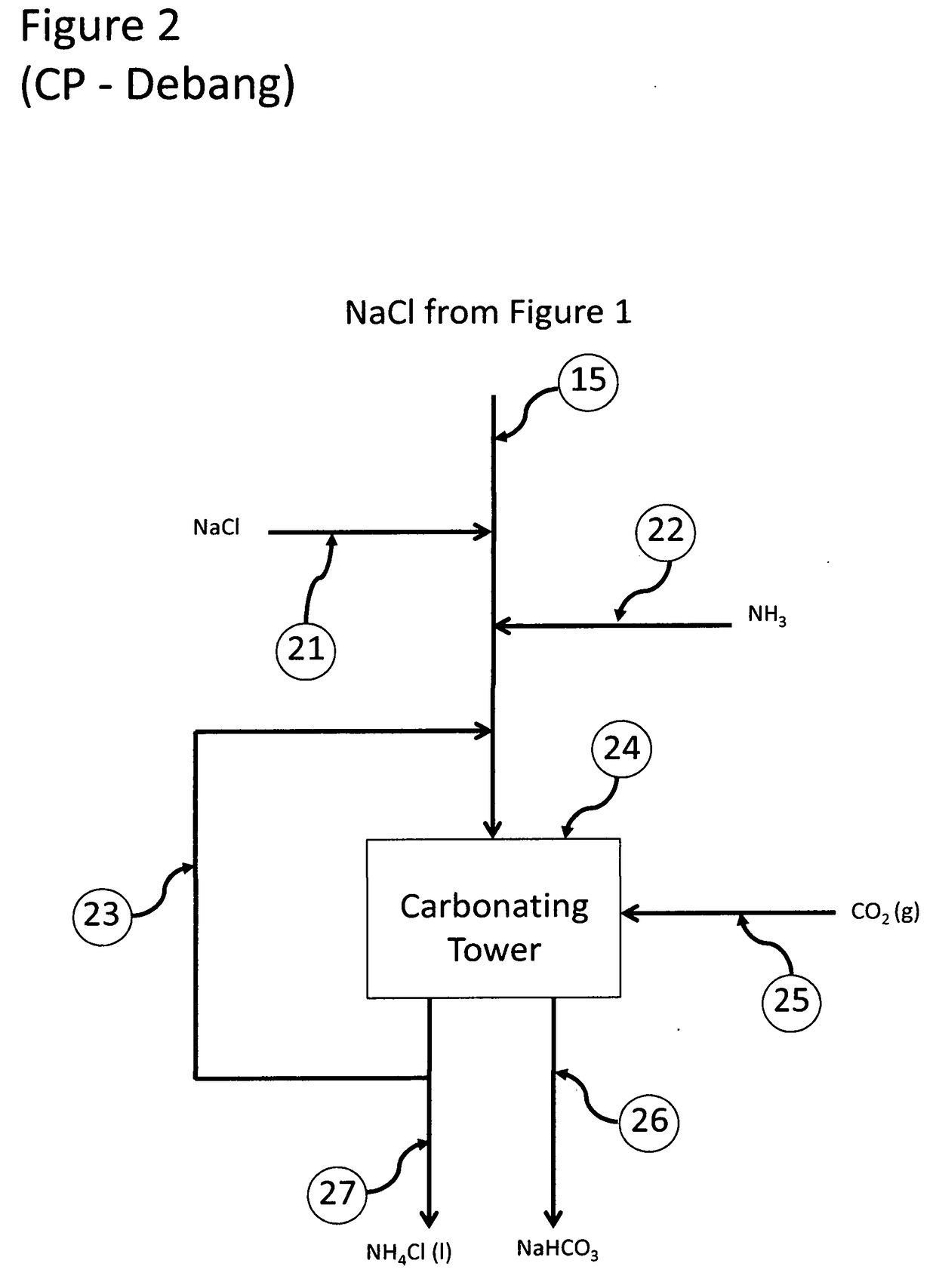

Technology for producing sodium bicarbonate and ammonium chloride by using triamine tail gas

InactiveCN107934996AIncrease profitNot dischargedAlkali metal chloridesAmmonium chlorideSodium bicarbonateFiltration

The invention discloses a technology for producing sodium bicarbonate and ammonium chloride by using triamine tail gas. The technology takes ammonia and carbon dioxide-containing melamine tail gas aswell as bittern or brine as raw materials, and adopts the technical processes of bittern or brine purification, tail gas deamination, triamine tail gas ammonia suction, ammoniacal brine carbonation, sodium bicarbonate separation, sodium bicarbonate pulp-mixing, wet decomposition, clarification and refined filtration, alkali liquor re-carbonation, sodium bicarbonate centrifugal drying, sodium bicarbonate filtrate deamination, multiple-effect evaporation and concentration salt manufacturing, multiple-effect flash vaporization ammonium manufacturing and separating and drying and the like to enable the tail gas generated through melamine production by urea is effectively used. The technology provided by the invention overcomes the defects that the spent liquor discharge amount of an ammonia-soda process is large and the mother solution of a combined alkaline manufacturing method is difficult to balance, the floor space of a device is small, and only low grade steam is used.

Owner:DALIAN RES & DESIGN INST OF CHEM IND +1

Device for treating biurea condensation sewage generated from preparation of ADC (Azodicarbonamide) foaming agent with urea method and use method of device

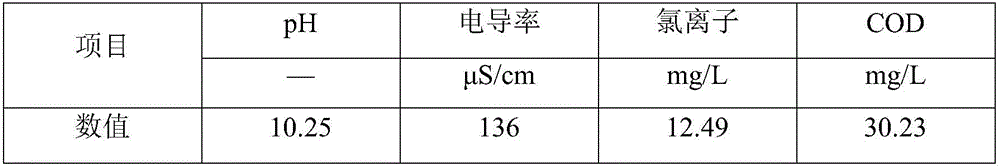

ActiveCN106698561AImprove recycling rateWater contaminantsDispersed particle separationBiureaChemical oxygen demand

The invention discloses a device for treating biurea condensation sewage generated from preparation of an ADC (Azodicarbonamide) foaming agent with a urea method and a use method of the device, relates to a sewage treatment device and a use method thereof, and aims to solve the problem that COD (Chemical Oxygen Demand) in effluent of the biurea condensation sewage generated when the ADC foaming agent is prepared by using the urea method is hard to meet standards. The device consists of an evaporation crystallizer, a high-temperature salt bath decomposition and gas absorption system and a pressure hydrolysis-flash evaporation system. The use method disclosed by the invention comprises the following steps: feeding sewage into the evaporation crystallizer, performing cooling crystallization on concentrated liquid, feeding into an ammonia distillation tower for ammonia distillation, discharging the bottom liquid of the ammonia distillation tower into the pressure hydrolysis-flash evaporation system for decomposition treatment, and feeding salt generated from evaporation crystallization into the high-temperature salt bath decomposition and gas absorption system for purification treatment. By adopting the device and the use method, urea and hydrazine hydrate of the ADC condensation sewage can be recycled, sodium chloride can be purified, the water circulation utilization rate can be increased, and standards of indexes such as COD in the effluent can be met.

Owner:HARBIN ENG UNIV

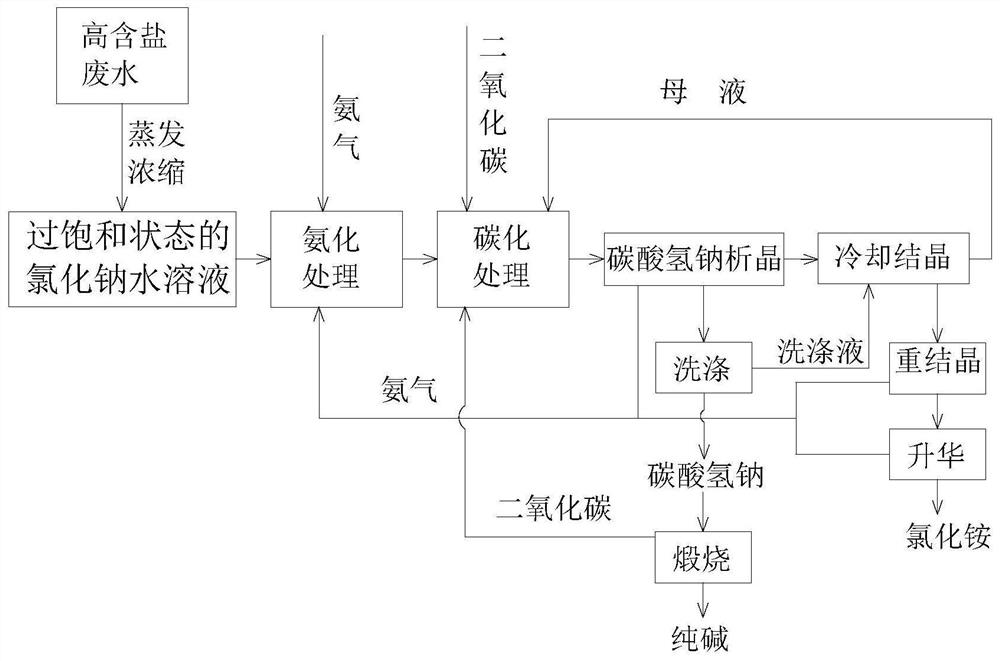

Production method for coproducing sodium carbonate and ammonium chloride from sodium chloride

PendingCN113135582AIncrease conversion rate per passQuality improvementProductsReagentsSodium bicarbonateProcess engineering

The invention belongs to the technical field of secondary utilization of sodium carbonate and resources, and particularly provides a production method for coproducing sodium carbonate and ammonium chloride from sodium chloride, which comprises the following steps: sequentially carrying out ammonification treatment, carbonization treatment and crystallization on a sodium chloride aqueous solution in a supersaturated state to obtain a sodium bicarbonate crude product and an ammonium chloride crude product; and carrying out washing, recrystallization and other post-treatments to obtain sodium carbonate and ammonium chloride. According to the method, the conversion per pass of sodium chloride is increased by 80% or above, the total conversion rate of sodium chloride exceeds 95%, the total conversion rate of ammonia reaches 98% or above, the yield of sodium carbonate is larger than 90%, and the yield of ammonium chloride is larger than 90%, so that circulating materials are reduced by 80% or above, energy consumption is greatly reduced, economic benefits are improved, and the method is environmentally friendly. Another advantage of the method is that the sodium carbonate and the ammonium chloride are good in quality and high in purity.

Owner:CHANGZHOU UNIV

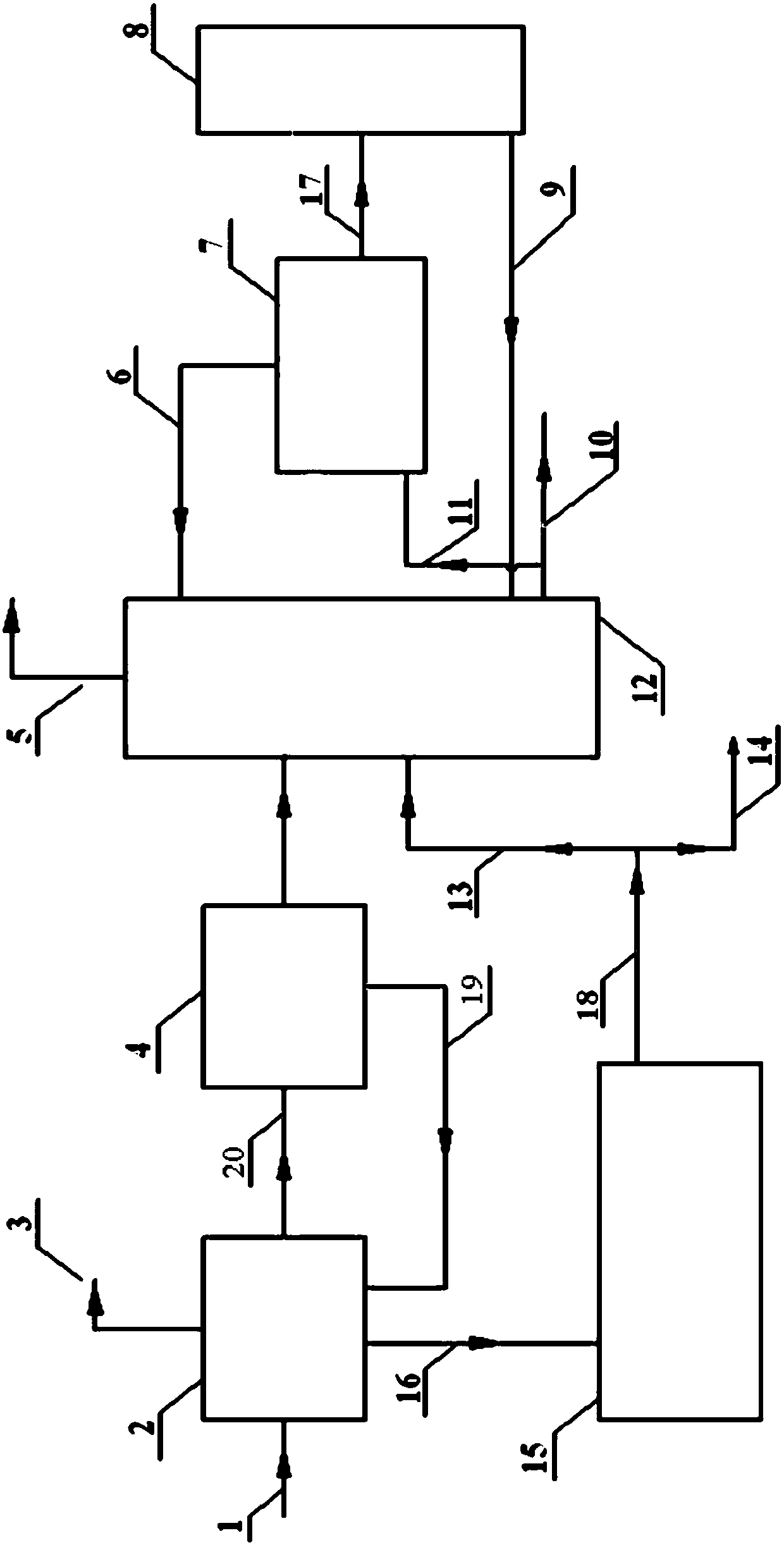

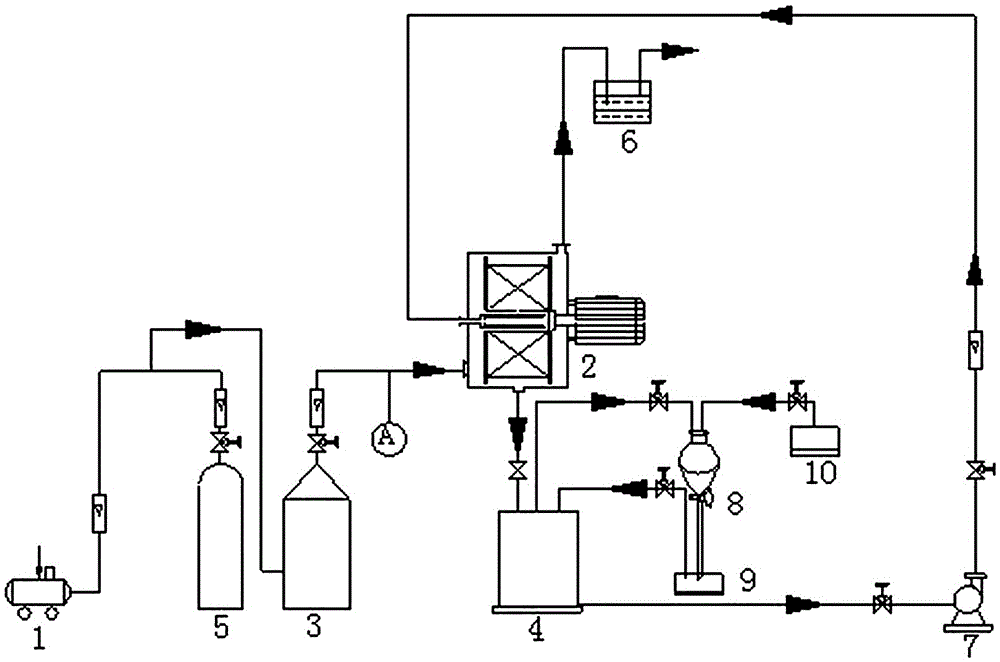

Deep hydrolysis method of aluminum nitride in aluminum ash

ActiveCN108217688AHydrolysis achievedImprove hydrolysis efficiencySolid waste disposalAmmonium chlorideResource utilizationEvaporation

The invention discloses a deep hydrolysis method of aluminum nitride in aluminum ash. The deep hydrolysis method comprises the following steps of 1) crushing the aluminum ash to form aluminum ash withthe particle size being 10mm or below, then heating the aluminum ash to a certain temperature, and uniformly mixing the heated aluminum ash and water according to a certain ratio; 2) performing grinding and hydrolyzing on obtained high-temperature slurry, and collecting ammonia gas produced by hydrolyzing at the same time to obtain corresponding ammonia water or ammonium salt; and 3) performing dewatering and filtering on the slurry after hydrolyzing to obtain a filter cake and a filtrate, and performing evaporation to recover industrial salt after circulating enrichment of the filtrate. According to the deep hydrolysis method provided by the invention, through the hydrolysis process of high temperature grinding and strengthening the aluminum nitride, deep hydrolysis of the aluminum nitride is realized, ammonia recovery is realized at the same time, so that a new way of harmless and resource utilization of the aluminum nitride in the aluminum ash is opened up.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Recycling using method of aluminum ash at last time

InactiveCN108103321AQuality is not affectedReduce investmentAmmonium nitratesProcess efficiency improvementCatalytic decompositionSlurry

The invention discloses a recycling using method of aluminum ash at the last time. The recycling using method has the steps that 1, water and a catalyst are added to the aluminum ash at the last timeunder stirring and turning over conditions, a pasty fluid is formed, heating and catalytic decomposition deamination are conducted on the pasty fluid, and escape ammonia generated by catalytic decomposition deamination enters an ammonia absorption tower; 2, in the ammonia absorption tower, spraying water or dilute acid are used to conduct collection to the escape ammonia, and ammonia water or ammonium salt serous fluid are obtained; ammonia water is in cyclic utilization, the generated ammonium salt serous fluid falls into a settling pond in the bottom of the ammonia absorption tower, the ammonium salt serous fluid is sent into a filter press through a pump to be conducted filter pressing dehydration; and the ammonium salt solid obtained after dehydration is recycled and used; 3, drying isconducted; the obtained materials after deamination in the step 1 are added to shoe cover materials, the obtained materials after deamination in the step 1 and the shoe cover materials enter into anelectrolytic cell together; calcinations is conducted by using the electrolytic cell temperature, and calcinations material mixture is formed; and 4, after the calcinations material mixture is crushed, the calcinations material mixture enters into the electrolytic cell to be used as raw materials.

Owner:湛卫华

Method for producing silicon nitride powder

The invention discloses a method for producing silicon nitride powder. The method comprises the following steps: 1) reacting silicon tetrachloride and ammonia which are used as raw materials in order to synthesize a silicon nitride precursor Si(NH)2 solid, and obtaining pure Si(NH)2 powder; 2) transferring the Si(NH)2 into a high temperature furnace, and calcining the Si(NH)2 to obtain amorphous silicon nitride powder; and 3) refining and briquetting the obtained silicon nitride powder, transferring the briquetted powder into a high temperature crystallization furnace, and performing calcination to obtain crystalline silicon nitride powder. The method can continuously synthesize the silicon nitride precursor, and can flexibly control the particle size, the shape and the phase composition of the final product silicon nitride powder by adopting two calcination treatments which are low temperature decomposition of the Si(NH)2 and high-temperature crystallization of the amorphous silicon nitride powder; no organic solvents participate in the whole process, so carbon impurities in the silicon nitride powder are avoided; and the raw materials used for the product are produced in large scale in China, so low-cost production of high-purity sub-micron isometric silicon nitride powder is achieved.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

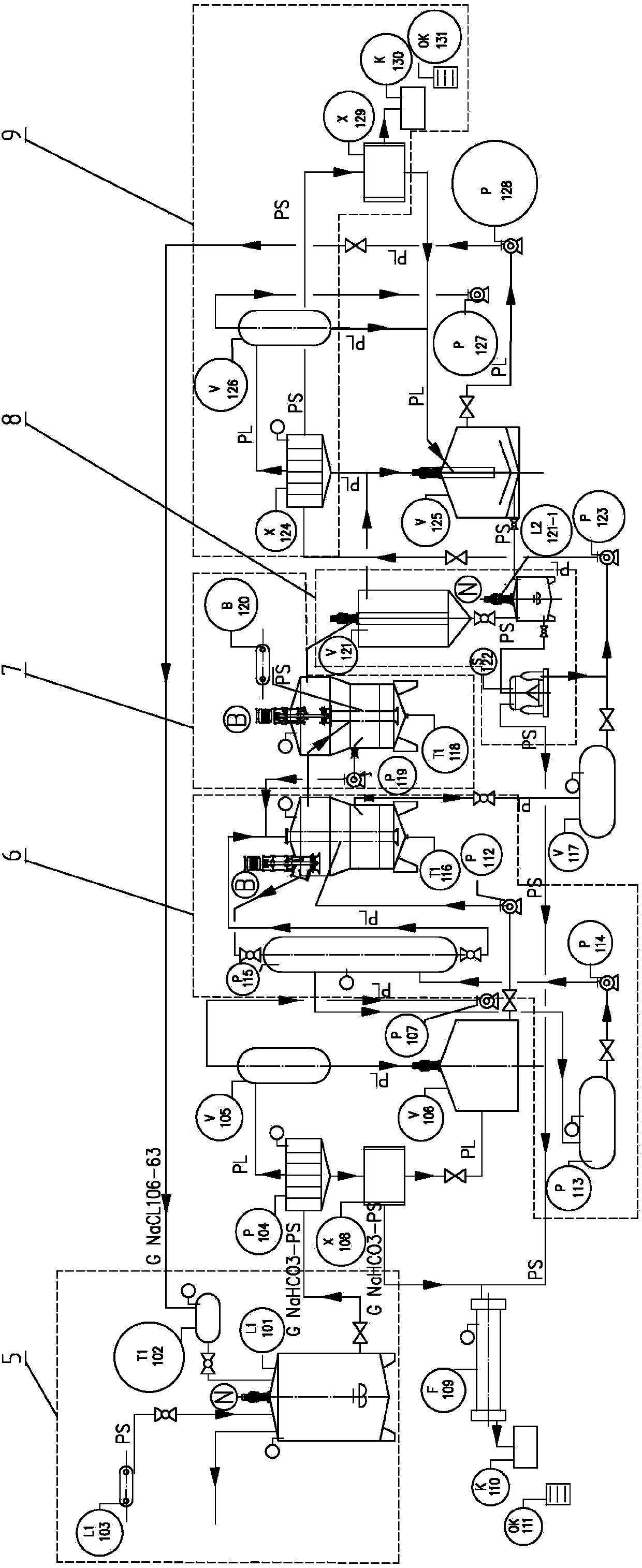

Cyclic manufacturing device for coproduction of baking soda and ammonium chloride

PendingCN109534364AHigh yieldHigh nitrogen contentChemical industryAmmonium chlorideChemistryAmmonium chloride mixture

The invention provides a cyclic manufacturing device for coproduction of baking soda and ammonium chloride. The cyclic manufacturing device comprises a primary-precipitating baking soda device, a coldprecipitation device, a salt precipitation device, a mother liquor cycle device which sequentially communicate, and secondary-precipitating baking soda device, one end of the secondary-precipitatingbaking soda device communicates with the salt precipitation device, and the other end of the secondary-precipitating baking soda device communicates with the mother liquor cycle device. By adopting the cyclic manufacturing device, energy saving and time saving can be achieved during ammonium chloride recovering at the cold precipitation stage, meanwhile, the baking soda and the ammonium chloride can further be produced efficiently, full cycle of motor liquor generated in the manufacturing process in the production process is achieved, the process is easy, and the production cost is low.

Owner:刘松林

Process for preparing organosilazanes

InactiveUS6051729ASilicon organic compoundsCoded identity card or credit card actuationSolventAmmonium chloride mixture

A process for preparing organosilazane and ammonium chloride, by reaction of an organochlorosilane with ammonia in the presence of organosilazane as solvent, wherein ammonium chloride is removed from the resulting organosilazane and ammonium chloride-containing mixture, the improvement comprising adding an antiblocking agent to the mixture before removal, or to the ammonium chloride after its removal, such that a non-blocking, reusable ammonium chloride product is obtained.

Owner:WACKER CHEM GMBH

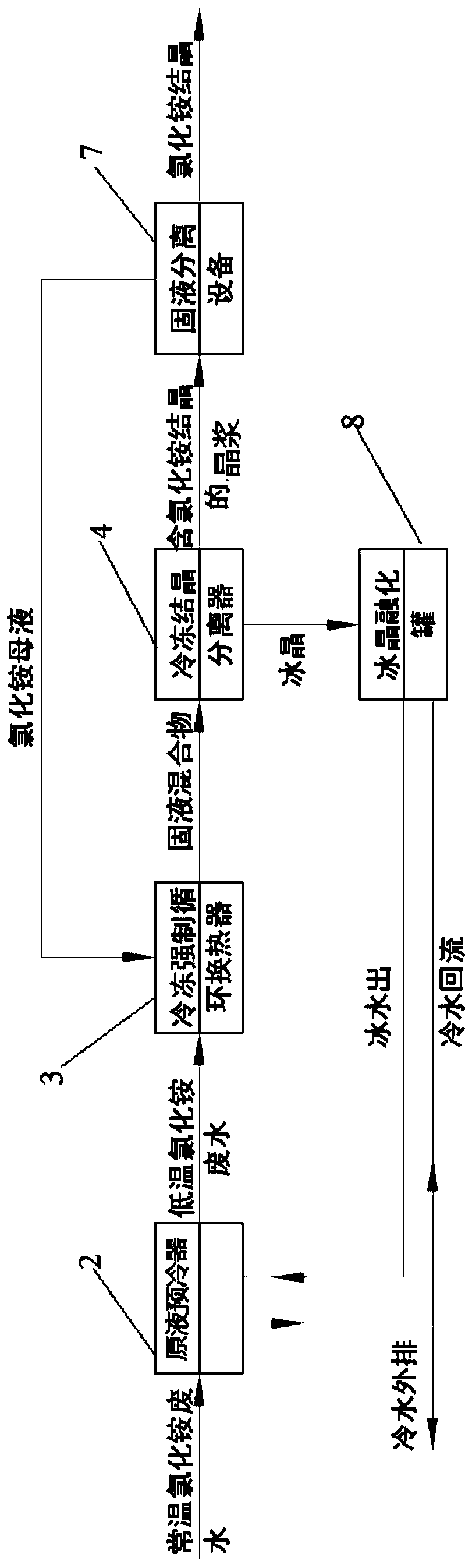

Energy-saving ammonium chloride wastewater freeze-concentration crystallizing system and technology thereof

InactiveCN110563067ARealize continuous freeze concentration and crystallization treatmentReduce dependenceChemical industryAmmonium chlorideChemistryTreatment effect

The invention relates to an energy-saving ammonium chloride wastewater freeze-concentration crystallizing system and a technology thereof. The system comprises a stock solution precooler, a freezing forced circulation heat exchanger, a freezing crystallization separator and a solid-liquid separation device which are connected in sequence, an ice crystal melting tank is connected between the freezing crystallization separator and the stock solution precooler, and the solid-liquid separation device is connected with the freezing forced circulation heat exchanger. The system is an energy-saving and emission-reducing apparatus, and has a high heat efficiency and a low power consumption; compared with an existing ammonium chloride evaporative crystallization technology, the technology of the invention has the advantages of low temperature and normal pressure conditions, no consumption of steam, reduction of the dependence on a boiler, reduction of pollutants, energy saving and environmentalfriendliness; and compared with conventional technologies, the technology provided by the invention has the advantages of realization of the continuous wastewater treatment effect, low energy consumption, freeness of steam consumption, few pollutants, greenness and environmental friendliness.

Owner:SHENZHEN SUNEVAP TECH

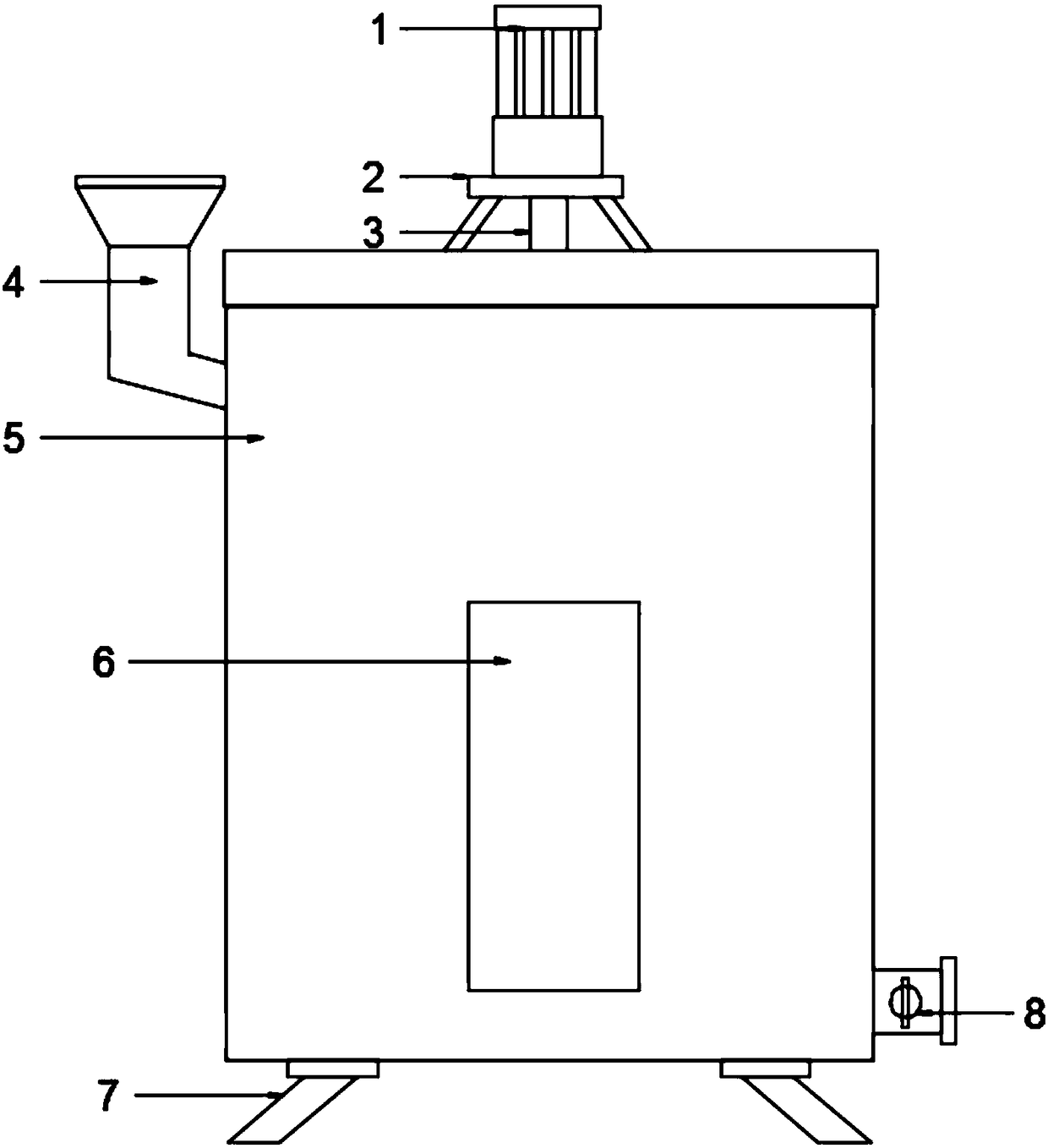

Ammonium chloride crystal storage device capable of preventing tank wall crystallization

InactiveCN108264061AAvoid decompositionWell mixedRotary stirring mixersTransportation and packagingEngineeringDirect heating

The invention discloses an ammonium chloride crystal storage device capable of preventing tank wall crystallization. The ammonium chloride crystal storage device comprises a storage tank and an innergear, wherein a glass window is arranged on the front end surface of a storage tank; the bottom of the storage tank is provided with four support legs in rectangular array distribution; a separation plate is arranged inside the storage tank; the bottom of the storage tank is divided into a discharging cavity by the separation plate; a discharging pipe is arranged at the right side of the discharging cavity; an electromagnetic valve is arranged in the center position of the separation plate; a feeding pipe is arranged at the upper end of the left side of the storage tank; a sealing cover is arranged at the upper end of the feeding pipe; the top of the storage tank is provided with a top plate; the inner gear is arranged inside the storage tank; a fixing pin is arranged between the inner gear and the storage tank. The ammonium chloride crystal storage device capable of preventing tank wall crystallization has the advantages that the problem that crystals attached to the inner wall of thestorage tank are difficult to clean is solved; the condition that ammonium chloride is decomposed when a heating device is used for direct heating is avoided.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

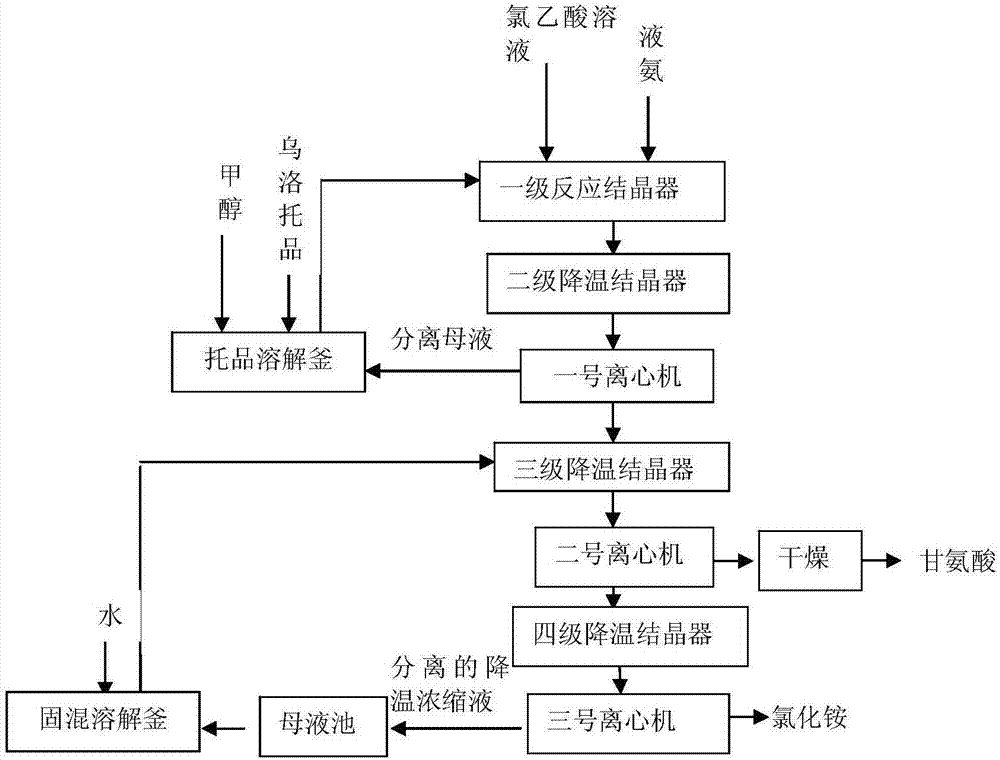

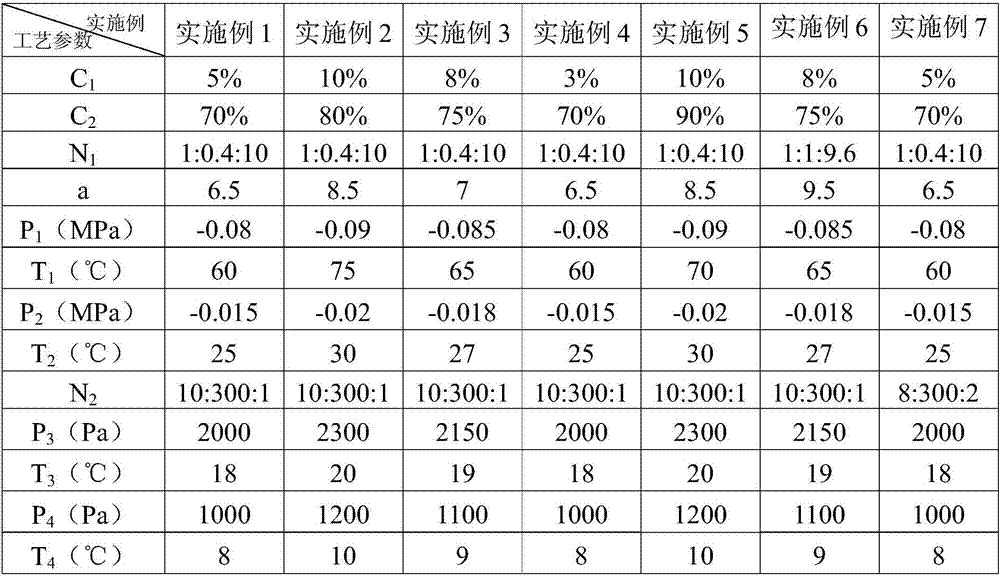

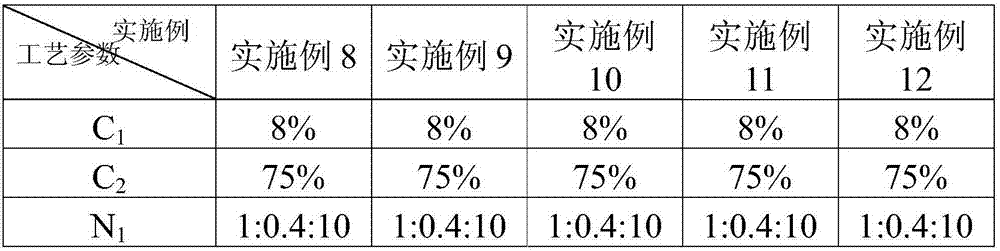

Process for producing glycine byproduct ammonium chloride

ActiveCN107089922ARealize continuous productionIncrease productivityOrganic compound preparationOrganic chemistry methodsHexamethylenetetramineChloroacetic acids

The invention provides a process for producing glycine byproduct ammonium chloride. The process comprises the following steps: by taking a chloroacetic acid solution as a raw material, carrying out an ammonolysis reaction with ammonia through catalysis of urotropine; performing negative pressure condensation on the reaction solution, cooling and crystallizing to obtain a mixture of glycine and ammonium chloride; and performing gradient cooling on the mixture so as to obtain glycine and high-purity ammonium chloride, and recycling the mother solution. According to the process disclosed by the invention, continuous production of glycine is realized, the production efficiency is improved, the labor intensity is reduced, the equipment input is reduced, and the catalyst, urotropine, can be recycled in the reaction by adopting the recycling process for the alcohol-phase reactive mother solution. Moreover, the ammonium chloride is separated by adopting the concentrating, cooling and crystallizing process, the usage amount of methanol is reduced, the energy consumption is reduced, and residual liquor is avoided.

Owner:闫小玉 +1

Cyclic manufacturing method for coproduction of baking soda and ammonium chloride

ActiveCN109534365APromote crystallizationReduce energy consumptionAmmonium chlorideCarbonate preparationEnergy consumptionPrecipitation

The invention relates to a cyclic manufacturing method for coproduction of baking soda and ammonium chloride. The cyclic manufacturing method comprises the steps of primary precipitating of baking soda, cold precipitation crystallization, salt precipitation crystallization and mother liquor cycling which are conducted sequentially; and the cyclic manufacturing method further comprises the step that the step of secondary precipitating of baking soda is arranged between the salt precipitation crystallization step and the mother liquor cycle step, and the step of secondary precipitating of bakingsoda is used for further precipitating the baking soda from baking soda mother liquor (I-II) generated after salt precipitation crystallization. By adopting the cyclic manufacturing method, energy consumption of ammonium chloride recovering through cold precipitation crystallization can be decreased, the baking soda and the ammonium chloride are efficiently produced, meanwhile, full cycle of motor liquor generated in a reaction in the production process is achieved, the process is easy, and the production cost is low.

Owner:衡阳爱洁科技股份有限公司

Method for treating mother liquid discharged in glycine production

InactiveCN104193751AProtective ingredientsEasy to handleOrganic compound preparationAmino-carboxyl compound preparationHigh concentrationHexamethylenetetramine

The invention belongs to methods for treating wastewater of chemical production, and in particular provides a method for treating a mother liquid discharged in glycine production. The method comprises the following steps: (1) performing reduced pressure distillation on the mother liquid so as to obtain an amino-containing methanol solution from a top tower layer and an aqueous solution containing ammonium chloride, urotropin and glycine from a bottom tower layer; (2) blowing off the ammonia gas of the amino-containing methanol solution, so as to obtain high-concentration ammonia water; (3) performing vacuum flashing on the solution obtained from the tower bottom, and concentrating the ammonium chloride solution at the tower bottom; and (4) continuously cooling the ammonium chloride solution, thereby separating ammonium chloride. An environment-friendly treatment method for recycling the mother liquid discharged in the glycine production process is adopted, effective recycling and repeated use of ammonia water, sodium hydroxide and urotropin are achieved, and thus the standard of zero sewage discharge is met.

Owner:沈美忠

Comprehensive recycling utilization method of potassium-containing wastewater generated in synthesis process of dicamba

ActiveCN106830478ARealize the big cycleImprove competitive advantageTreatment involving filtrationOxygen compounds purification/separationIon exchangePotassium

The invention discloses a comprehensive recycling utilization method of potassium-containing wastewater generated in a synthesis process of dicamba. The comprehensive recycling utilization method comprises the following steps: adding acid into potassium-containing wastewater I generated in the synthesis process of the dicamba, and naturally depositing; conveying a water layer obtained by layering into a macroporous adsorption resin bed through a pump; adsorbing and recycling dicamba intermediates, namely 2,5-dichlorophenol and 3,6-dichlorosalicylic acid, in the water layer through the macroporous adsorption resin bed; adding active carbon and stirring and filtering; adding alkali liquid to adjust the pH (Potential of Hydrogen); adding active carbon into potassium-containing wastewater IV; stirring and filtering; conveying the wastewater into a chelating resin bed through the pump; removing high-valent metal cations in the alkaline potassium-containing wastewater IV through ion exchange; conveying the wastewater into a cation exchange resin bed through the pump; carrying out the ion exchange to obtain a potassium hydrogen carbonate solution and an ammonium chloride solution respectively; and drying an obtained potassium hydrogen carbonate wet product to obtain potassium hydrogen carbonate, or calcining the potassium hydrogen carbonate wet product at a high temperature to obtain potassium carbonate.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

Low-grade mixed rare earth ore concentrate chemical dressing and chemical dressing waste water resource comprehensively recycling method

ActiveCN105668888ADissolution inhibitionImprove leaching effectWaste water treatment from quariesWater contaminantsDistilled waterMineralogy

The invention relates to a low-grade mixed rare earth ore concentrate chemical dressing and chemical dressing waste water resource comprehensively recycling method, which is characterized by comprising the steps of: A) performing mixed chemical dressing to the low-grade ore concentrate (REO -50%, 8% <= CaO <= 15%) with a hydrochloric acid solution and an enhanced impurity remover; B) adding a sulfuric acid solution to chemical dressing waste water to remove Ca<2+> to form calcium sulphate dihydrate; C) treating the low-grade mixed rare earth ore concentrate with the chemical dressing waste water after calcium removal; D) after the calcium removal of the cyclic chemical dressing waste water, neutralizing the waste water with ammonia water or liquid ammonia step-by-step to respectively recycle iron, rare earths, a phosphorus enriched product and a crude calcium fluoride side product; and E) evaporating and concentrating the waste water to obtain ammonium chloride crystal and distilled water. In the method, through enhanced chemical dressing technology, the low-grade mixed rare earth ore concentrate is enriched according to 62% <= REO grade <= 70% and CaO <= 2.5%. With the difference of physical and chemical properties of the salts in the mixture liquid and the characters of the rare earth ore treatment process, the method enriches the ore and achieves resource comprehensive utilization easily and high-effectively.

Owner:BAOTOU RES INST OF RARE EARTHS

Method for efficiently separating fluorine, chlorine and nitrogen components from aluminum ash for co-production of aluminum oxide concentrate

ActiveCN110304646AAchieve step-by-step separationEasy to separateCalcium/strontium/barium fluoridesAluminates/aluminium-oxide/aluminium-hydroxide purificationFiltrationEvaporation

The invention discloses a method for efficiently separating fluorine, chlorine and nitrogen components from aluminum ash for co-production of aluminum oxide concentrate. The method comprises the following steps: putting aluminum ash and water into a reaction kettle, performing desalination denitrification treatment, performing solid-liquid separation on slurry after desalination denitrification treatment, sufficiently mixing a solid phase obtained after separation with an alkali liquid, performing a defluorination reaction, performing filtration, washing and separation on a defluorination slurry so as to obtain a solid phase and a liquid phase, wherein the obtained solid phase is aluminum oxide concentrate; performing a neutralization reaction on the liquid phase by using a diluted acid, and adjusting the pH value of the solution to be neutral; performing a solution defluorination reaction on the blended neutral solution with the liquid phase obtained after desalination denitrification; performing a sufficient defluorination reaction on the solution, and performing solid-liquid separation so as to obtain a solid phase, namely a fluorine salt; and performing evaporation crystallization on the liquid phase after solid-liquid separation, so as to obtain a crystallization product, namely a chlorine salt. Due to the desalination denitrification process and the defluorination process, products such as ammonium hydroxide, the chlorine salt, the fluorine salt and the high-purity aluminum oxide concentrate can be prepared, and efficient separation of aluminum oxide, salts and toxicand harmful components in the aluminum ash can be achieved.

Owner:郑州中科新兴产业技术研究院 +1

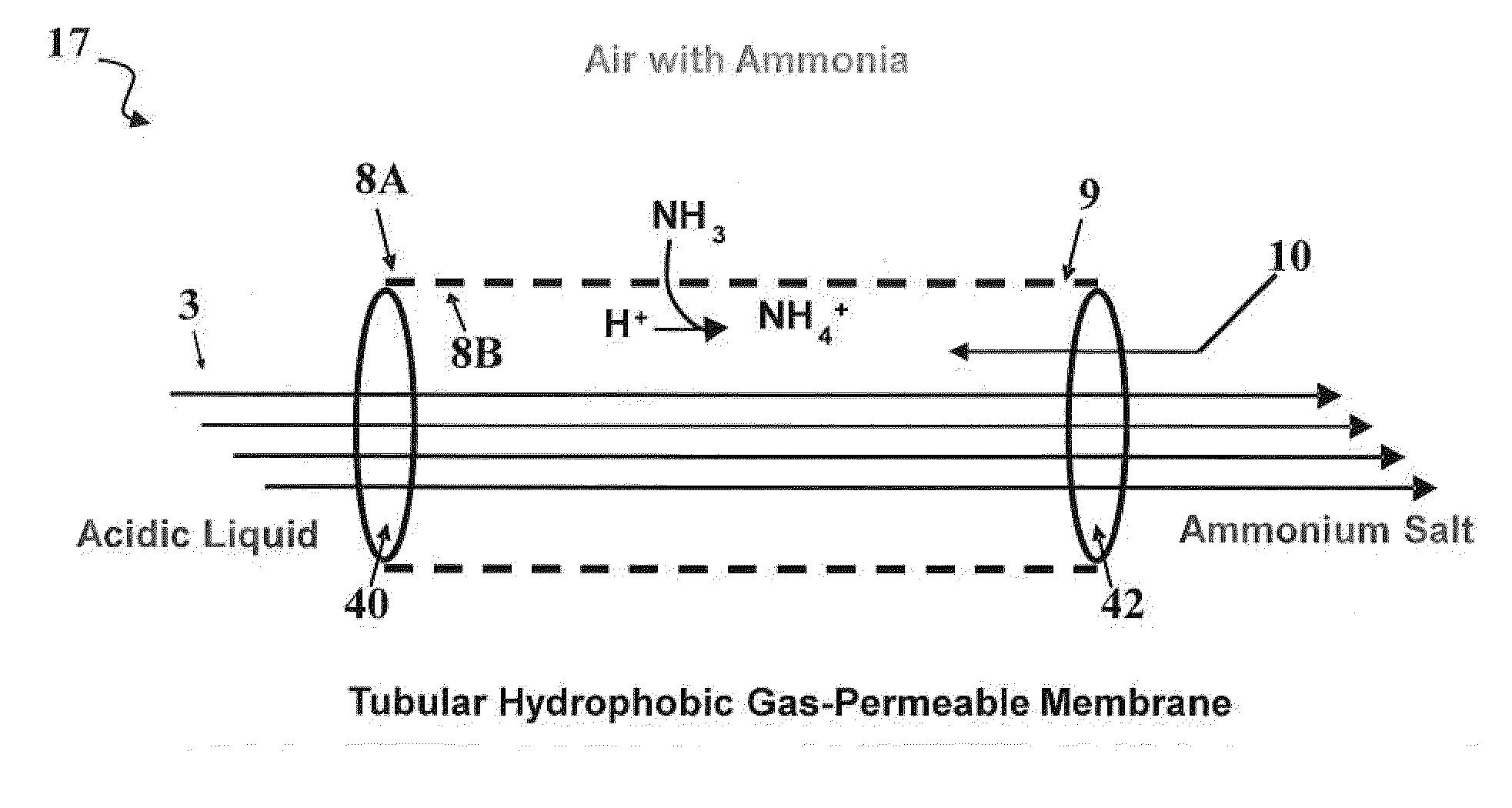

Gaseous Ammonia Removal System

ActiveUS20110229403A1Lower Level RequirementsGas treatmentOrganic compound preparationGaseous ammoniaNH3 compound

A system and method for passive capture of ammonia in an enclosure containing material that gives off ammonia. The invention allows for the passage of gaseous NH3 through microporous hydrophobic gas-permeable membranes and its capture in a circulated acidic solution with concomitant production of a concentrated non-volatile ammonium salt.

Owner:US SEC AGRI

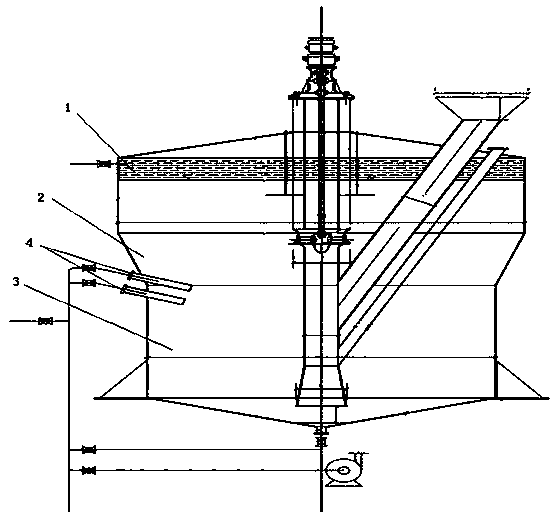

Device and process for treating ammonium chloride wastewater by supergravity carbonization reaction

ActiveCN105668753AIncrease contact areaEnhanced mass transferWater contaminantsWater/sewage treatmentHigh concentrationFiltration

The invention belongs to the technical field of treating industrialammonium chloride wastewater, and provides a device and a process for treating the ammonium chloride wastewater by a supergravity carbonization reaction, aiming at solving the problems that the current common electro-osmotic method for treating the ammonium chloride wastewater cannot realize an electrodialysis technology which is not only economical but also effective, the high-concentration ammonium chloride wastewater is hardly treated in an effective way by a membrane separation technology, and the cost is overhigh, etc. Ammonium chloride, organic amine and carbon dioxide react in a supergravity rotary packed bed to generate a mixed hydrochloric acid solution of ammonium bicarbonate and organic amine; after the ammonium bicarbonate and the organic amine are separated in a separating funnel, an organic amine solution reacts with ammonium hydroxide to regenerate organic amine; an obtained ammonium chloride solution through the regeneration is subjected to concentration, crystallization, filtration, and drying to obtain industrial grade ammonium chloride. The carbonization effect is improved; the carbonization reaction time is shortened; the treatment effect is improved; energies are saved; environment protection is realized; by adopting the method provided by the invention, reaction equipment can be minimized, the carbonization time can be shortened, the treatment effect can be improved, and the operation cost can be reduced.

Owner:ZHONGBEI UNIV

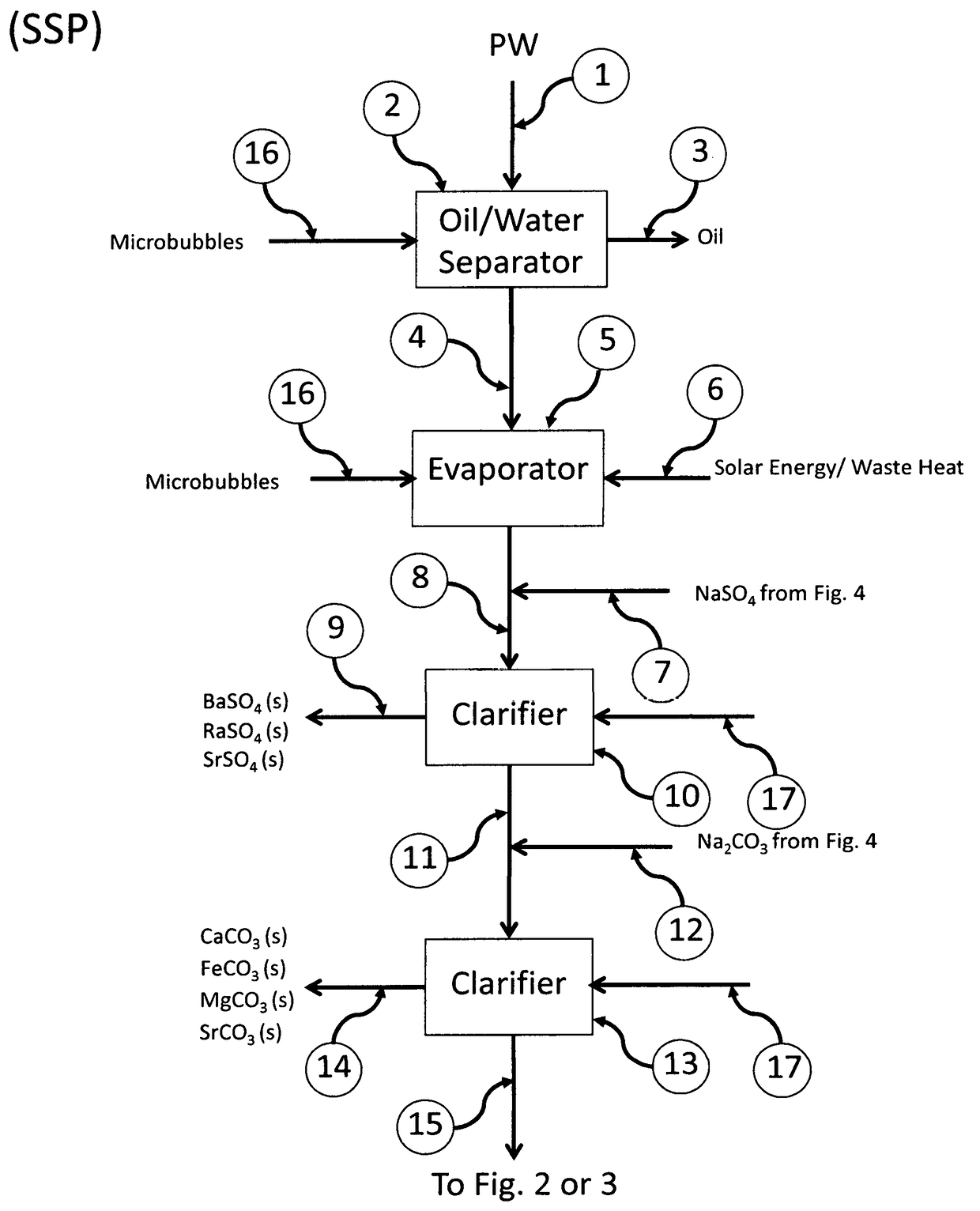

Recovery of Valuable Resources from Produced Water and Coal Combustion Products

ActiveUS20180022617A1Increase valueIncrease wasteWaste water treatment from quariesStrontium carbonatesFlue gasWaste stream

The present invention relates to processes employing water produced from wells that, after suitable purification steps, is processed to recover resources that can be used to treat other waste streams, such as flue gases and ashes from combustion of fossil fuels.

Owner:CORT STEVEN L

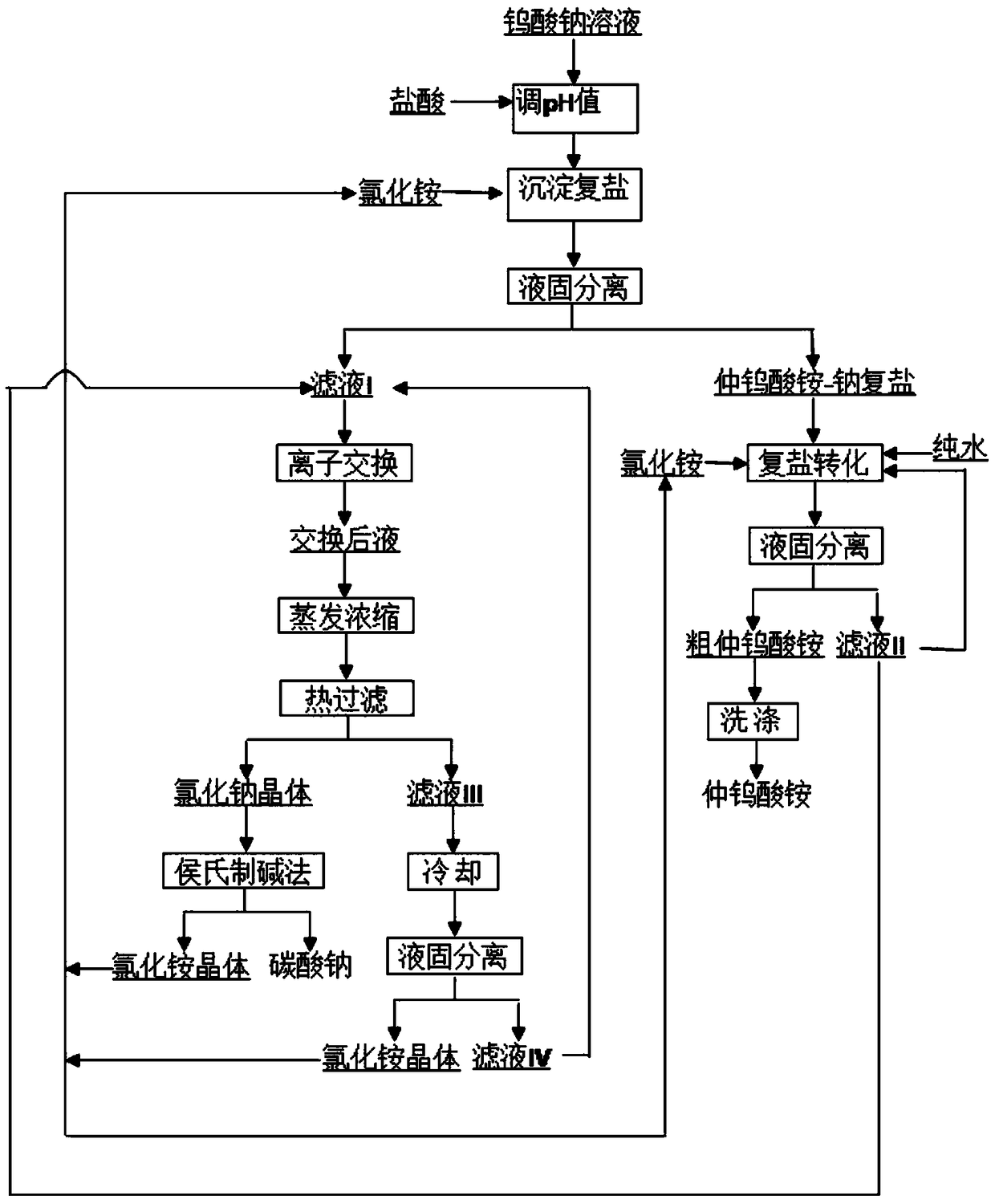

Preparation method of ammonium paratungstate

ActiveCN108557890AControl the sodium ion impurity contentReduce volumeAlkali metal halide purificationAmmonium chlorideHigh concentrationLiquid waste

The invention discloses a preparation method of ammonium paratungstate and belongs to the technical field of tungsten metallurgy. The ammonium paratungstate is prepared by taking high-concentration sodium tungstate solutions as raw material, WO3 concentration in the sodium tungstate solutions can reach 100-500g / L, a great deal of dilute water is reduced as compared with that in a traditional ion exchange method, and salt bearing liquid waste obtained in preparation of the ammonium paratungstate is small in size, high in concentration and convenient in treatment. By setting up a plurality of processes of 'internal microcirculation' to treat wastewater effluent, ammonium chloride and sodium chloride are separated and recycled through 'evaporative crystallization-hot filtration', sodium chloride is converted into ammonium chloride cyclically used in the production process and sodium carbonate used for high pressure leaching of sodium carbonate from tungsten minerals by introducing a 'Hou's process for soda production', preparation of the ammonium paratungstate directly by high-concentration sodium tungstate solutions is realized, the salt bearing liquid waste generated during the process is effectively reclaimed, pollution of the wastewater and waste salt on environment is removed, waste is turned into wealth, and cleaning production is realized.

Owner:CENT SOUTH UNIV

Potassium nitrate crystallization system and process through double-decomposition method

ActiveCN104261435AQuality assuranceGuaranteed outputAlkali metal nitrate preparationAmmonium chloridePotassium nitrateChloride

The invention relates to a potassium nitrate crystallization system and process through a double-decomposition method. The potassium nitrate crystallization system comprises a dissolving tank, a potassium nitrate vacuum crystallization device, a thickener, a first centrifuge, a mixing tank, a concentration device, a potassium chloride crystallization device and a second centrifuge. The potassium nitrate crystallization process comprises the following steps: adding circulating mother liquid, water and potassium chloride into the dissolving tank, sequentially feeding material liquid into the potassium nitrate vacuum crystallization device, the thickener and the first centrifuge, separating potassium nitrate crystals from the first centrifuge, drying and cooling, thereby obtaining the finished product potassium nitrate; adding potassium nitrate crystal mother liquid into the mixing tank, adding ammonium nitrate, uniformly mixing, and sequentially feeding the mixture into the concentration device, the ammonium chloride crystallization device and the second centrifuge; separating ammonium chloride crystals from the second centrifuge, drying and cooling, thereby obtaining the finished product ammonium chloride. A set of novel potassium nitrate crystallization system and process through the double-decomposition method are disclosed by the invention, the stability of potassium nitrate crystallization is improved, and the production quality and the yield are effectively ensured.

Owner:KINGENTA ECOLOGICAL ENG GRP

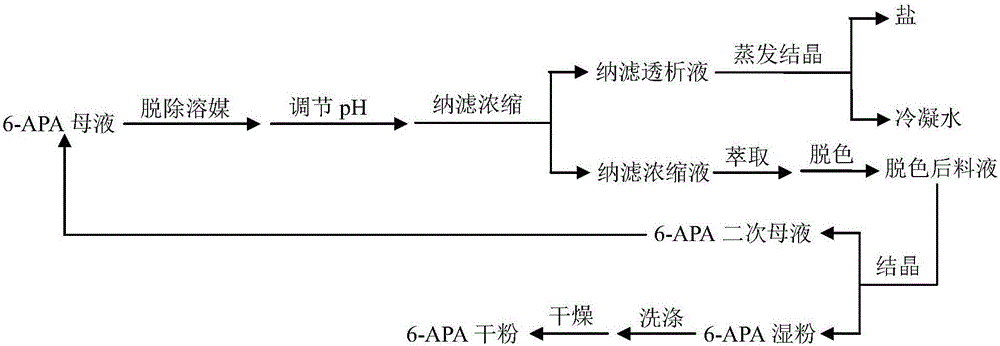

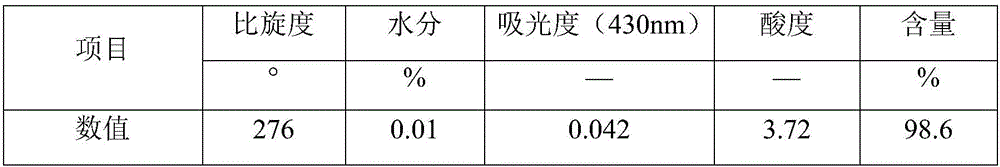

Process for recovering 6-APA and salt from 6-APA mother liquor

ActiveCN105732662ARealize resource utilizationOrganic chemistryAlkali metal chloridesSteam condensationResource utilization

The invention relates to a method for recovering 6-APA and salt from a 6-APA mother liquor, belongs to the technical field of pharmaceuticals. The process comprises the following steps: using a nanofiltration membrane for concentrating the 6-APA mother liquor; recovering 6-APA from a nanofiltration concentrate; recovering ammonium chloride or sodium chloride from a 6-APA nanofiltration dialyzate; meanwhile, recovering condensation water in an evaporative crystallization process. Compared with the prior art, the invention has the advantages that 6-APA and sodium chloride or ammonium chloride are recovered from the 6-APA mother liquor, steam condensation water of feed liquid is obtained while evaporating the recovered salt, the condensation water can be recycled into the workshop, to achieve the resource utilization of 6-APA mother liquor.

Owner:INNER MONGOLIA CHANGSHENG PHARMA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com