Cyclic manufacturing device for coproduction of baking soda and ammonium chloride

A technology for manufacturing devices and circulating devices, applied in the direction of ammonium chloride, ammonium halide, sustainable manufacturing/processing, etc., can solve the problems of no process devices, difficult industrial application, pollution of river water sources, etc., to increase nitrogen content, promote Effects of crystal growth and precipitation promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

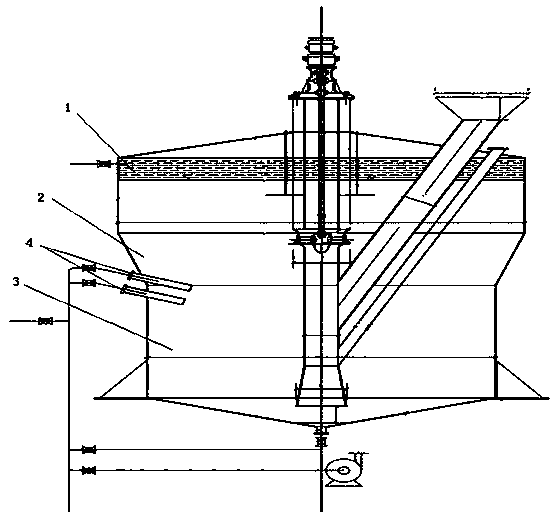

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] refer to Figure 1~2 , a cyclic manufacturing device for sodium bicarbonate co-production of ammonium chloride, said device comprises a first-stage separation of baking soda device 5, a cooling analysis device 6, a salting-out device 7 and a mother liquor circulation device connected in sequence, and a secondary separation of baking soda Device 8, one end of the secondary precipitation sodium bicarbonate device 8 communicates with the salting-out device 6, and the other end communicates with the mother liquor circulation device.

[0026] Specifically, the primary sodium bicarbonate precipitation device 5 includes a reaction kettle L101, a brine tank V102, and an ammonium bicarbonate feeding device N103, and the brine tank V102 and the ammonium bicarbonate feeding device N103 are connected to the reactor L101.

[0027] Also be provided with sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com