Cyclic manufacturing method for coproduction of baking soda and ammonium chloride

A manufacturing method, baking soda technology, applied in the direction of ammonium chloride, ammonium halide, carbonate preparations, etc., can solve the problems of difficult industrial application, high process cost, pollution of river water sources, etc., to increase yield and nitrogen content , improve yield and purity, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

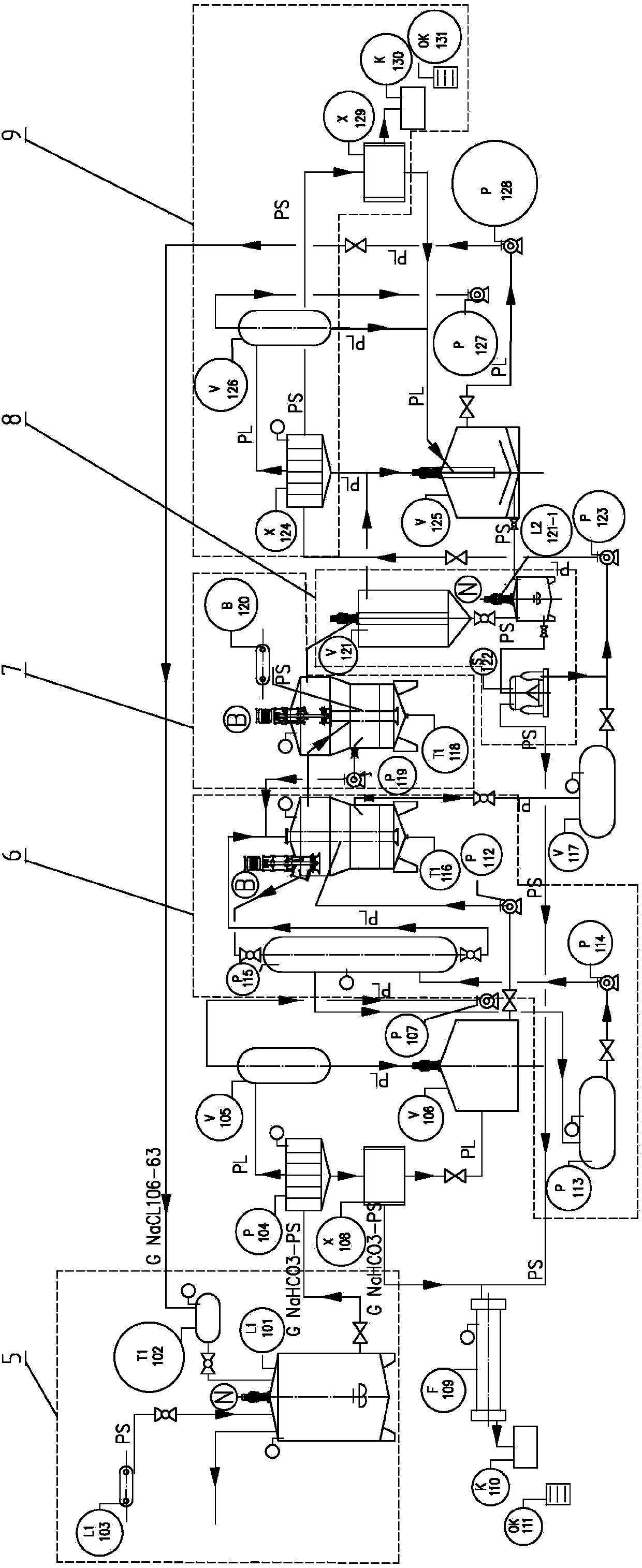

[0031] refer to Figure 1~2 , a cyclic manufacturing device for sodium bicarbonate co-production of ammonium chloride, said device comprises a first-stage separation of baking soda device 5, a cooling analysis device 6, a salting-out device 7 and a mother liquor circulation device connected in sequence, and a secondary separation of baking soda Device 8, one end of the secondary precipitation sodium bicarbonate device 8 communicates with the salting-out device 6, and the other end communicates with the mother liquor circulation device.

[0032] Specifically, the primary sodium bicarbonate precipitation device 5 includes a reaction kettle L101, a brine tank V102, and an ammonium bicarbonate feeding device N103, and the brine tank V102 and the ammonium bicarbonate feeding device N103 are connected to the reactor L101.

[0033]Also be provided with sodium bicarbonate treatment device between described one-stage separating out baking soda device 5 and cold analysis device 6, descr...

specific Embodiment 2

[0049] The difference between this example and Example 1 is that the ingredients in the baking soda mother liquor (I) are controlled to be NaCl 120 g / L, NH 4 HCO3 100g / L, NH 4 Cl 200g / L, SO 4 2- 8 g / L; the ingredients in the baking soda mother liquor (Ⅱ) are controlled as NaCl 230g / L, NH 4 HCO 3 70g / L, NH 4 Cl 120g / L, SO 4 2- 8g / L.

[0050] Calculate the productive rate of baking soda in the production process to be 96%, the productive rate of ammonium chloride to be 95%, and the content of nitrogen in the ammonium chloride product is 24%.

[0051] The working principle of the present invention: a cyclic manufacturing method for the preparation of baking soda and co-production of ammonium chloride in the present invention is based on the principle of phase equilibrium and solubility. The reason why the phase diagram in the system is difficult to balance is that the anions of complexed sodium and ammonium salts are all one Valence compounds make the molecular bonding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com