Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

893results about "Halogen/halogen-acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

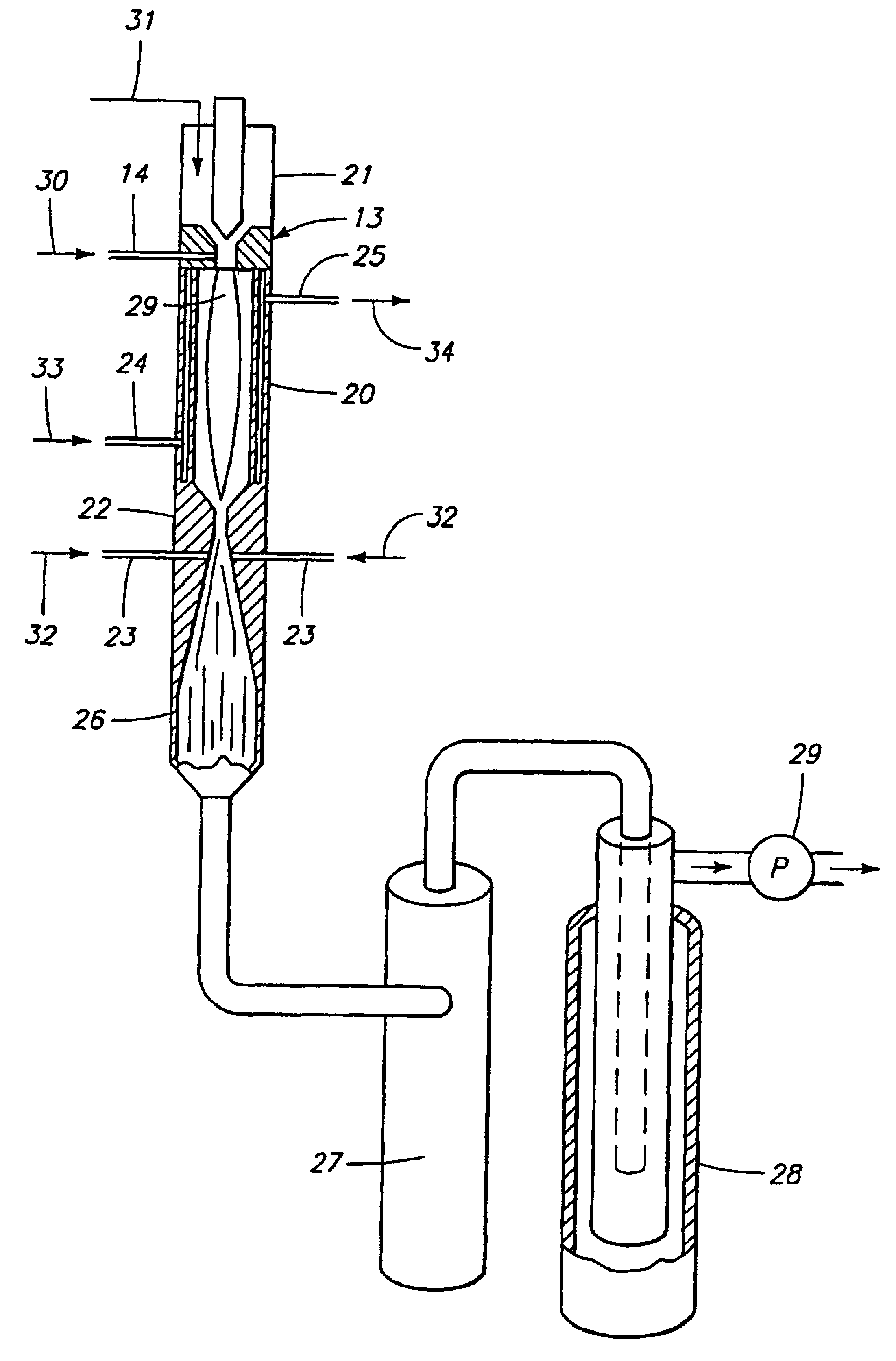

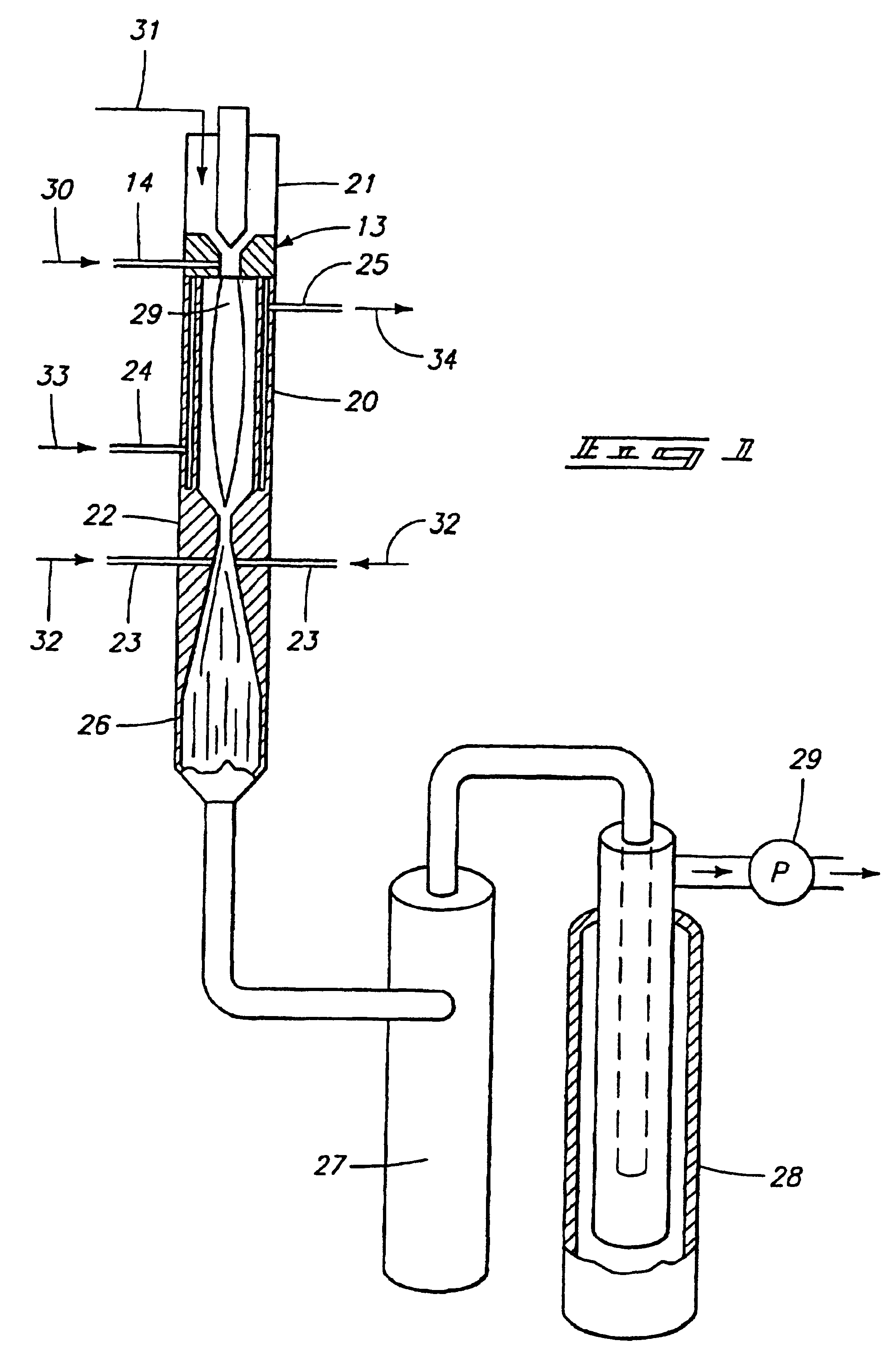

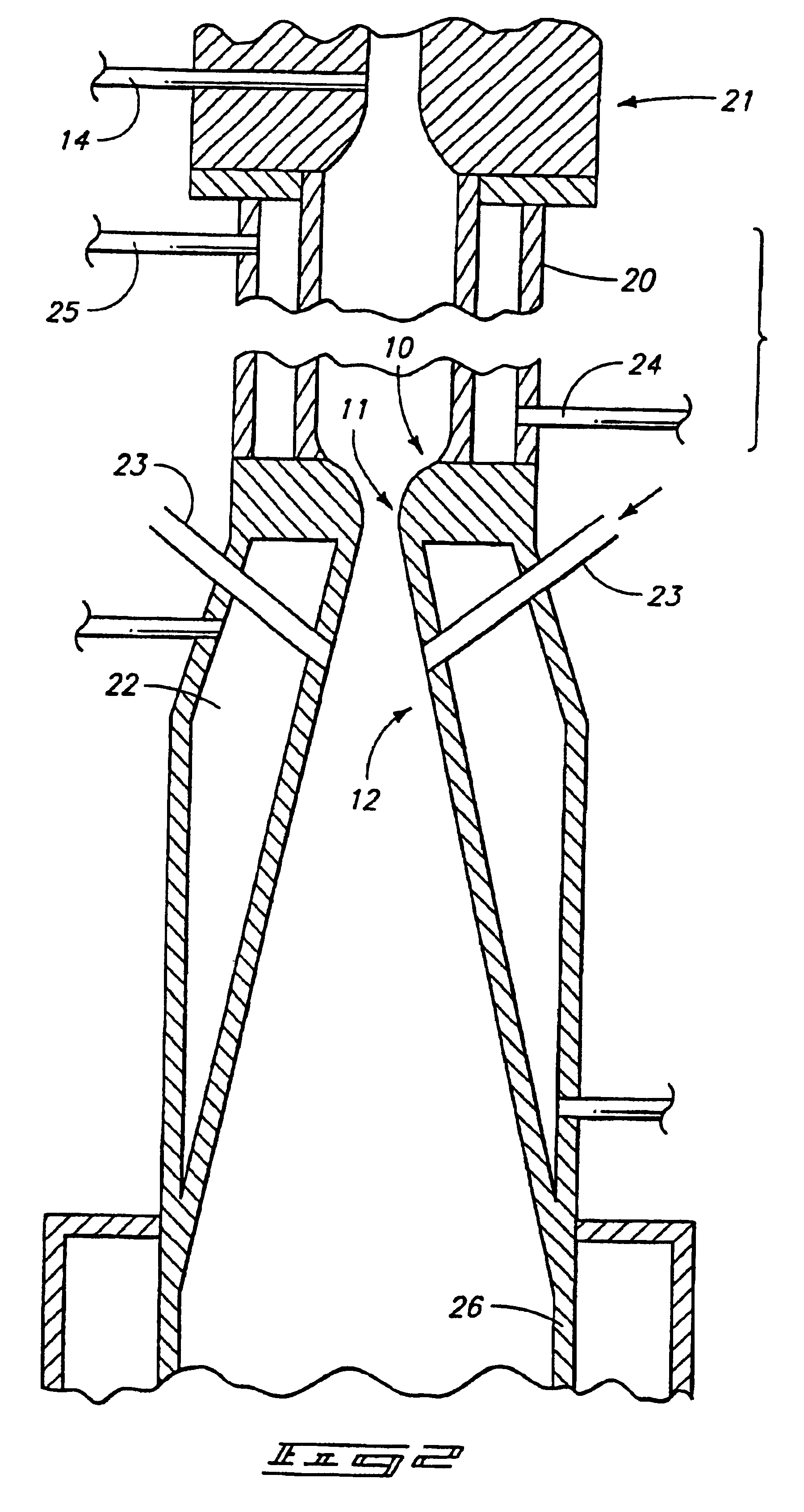

Fast quench reactor and method

InactiveUSRE37853E1Minimizing back reactionRapid coolingMaterial nanotechnologyIndirect heat exchangersThermodynamicsProcess engineering

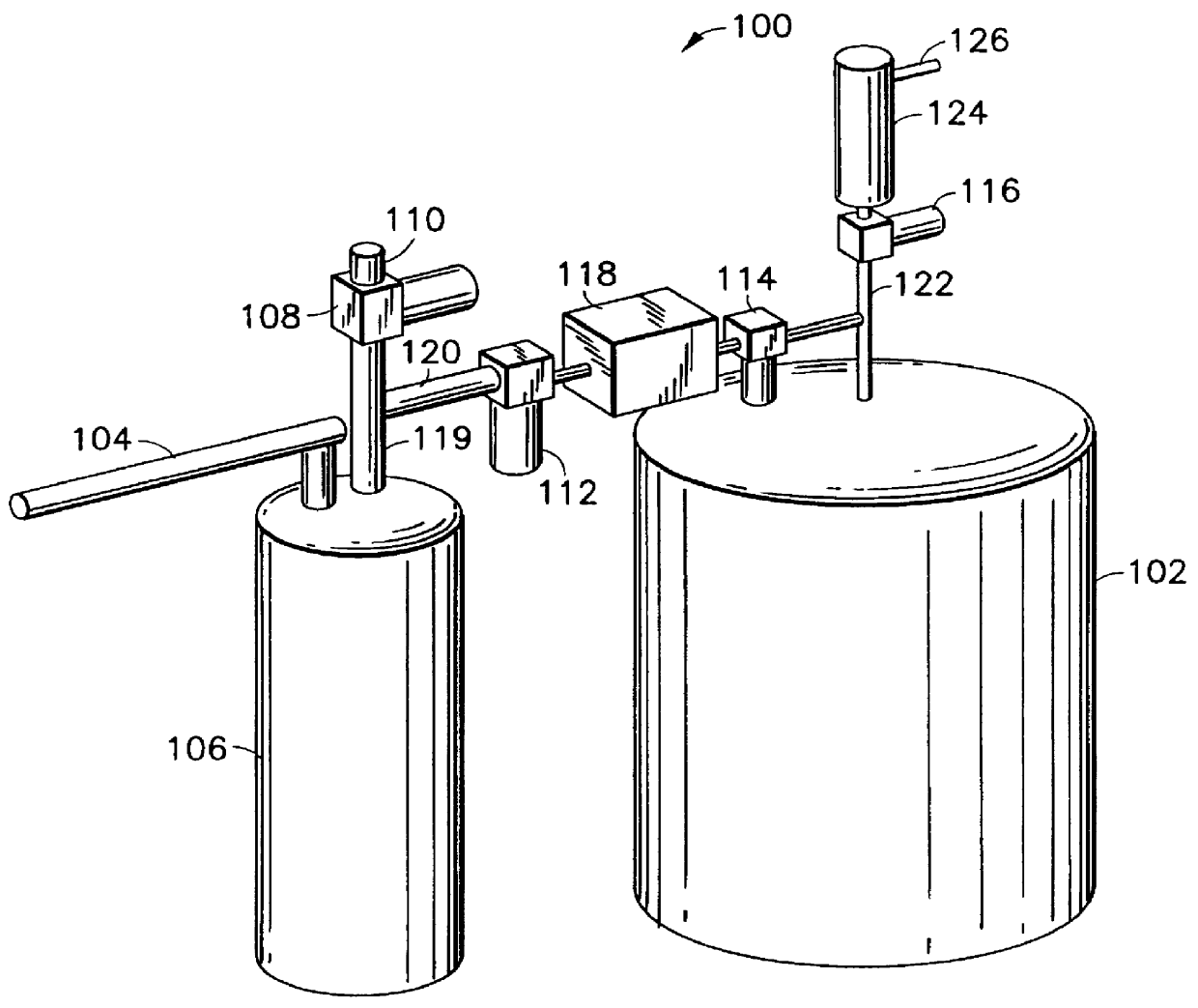

A fast quench reaction includes a reactor chamber having a high temperature heating means such as a plasma torch at its inlet and a restrictive convergent-divergent nozzle at its outlet end. Reactants are injected into the reactor chamber. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle. This "freezes" the desired end product(s) in the heated equilibrium reaction stage.

Owner:BATTELLE ENERGY ALLIANCE LLC

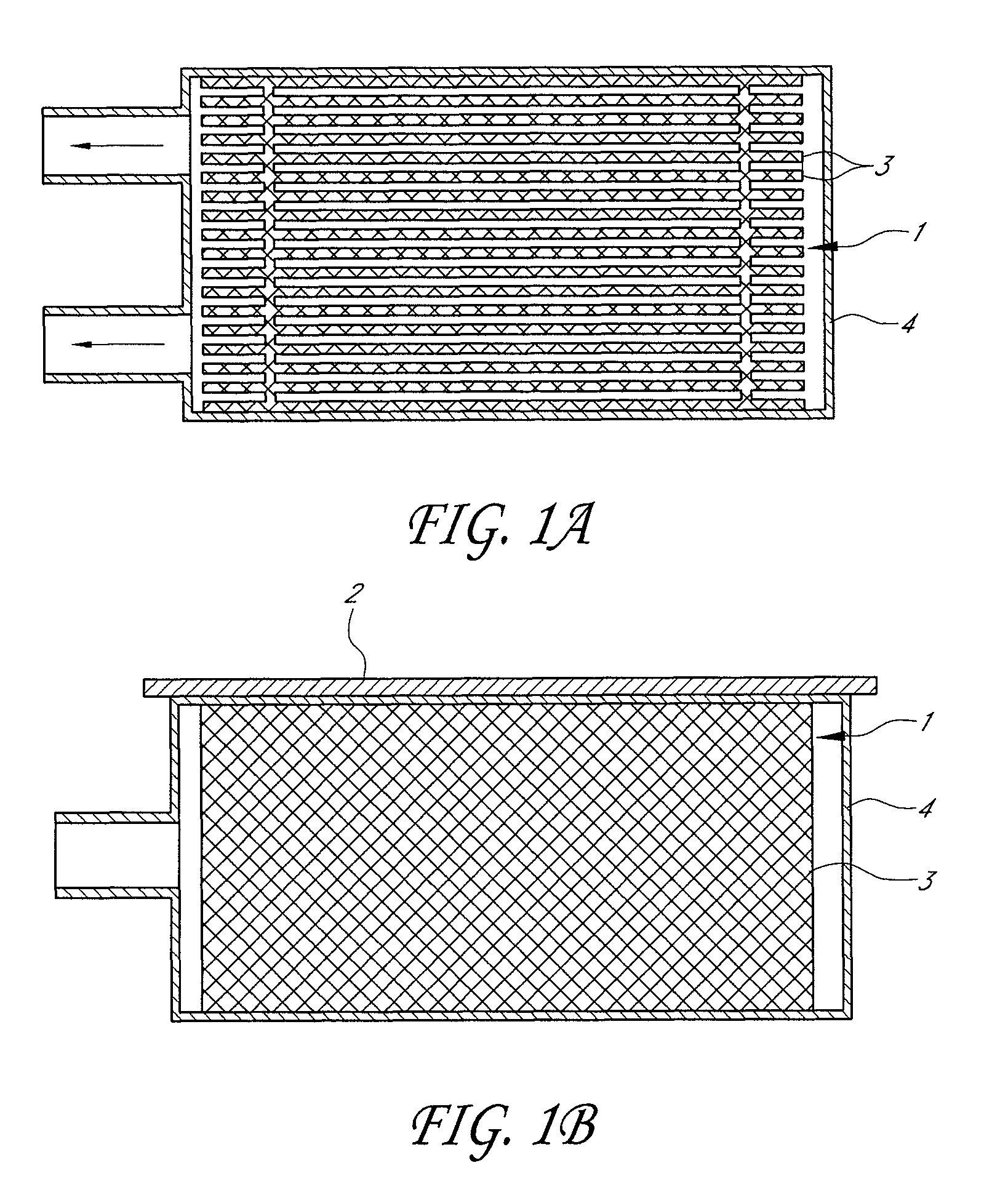

Method and apparatus for removing substances from gases

InactiveUS7799300B2Simple and reliable technicalEliminate the problemAuxillary pretreatmentEnergy based chemical/physical/physico-chemical processesSurface reactionGas phase

The present invention concerns a method and an apparatus for removing substances from gases discharged from gas phase reactors. In particular, the invention provides a method for removing substances contained in gases discharged from an ALD reaction process, comprising contacting the gases with a “sacrificial” material having a high surface area kept at essentially the same conditions as those prevailing during the gas phase reaction process. The sacrificial material is thus subjected to surface reactions with the substances contained in the gases to form a reaction product on the surface of the sacrificial material and to remove the substances from the gases. The present invention diminishes the amount of waste produced in the gas phase process and reduces wear on the equipment.

Owner:ASM INTERNATIONAL

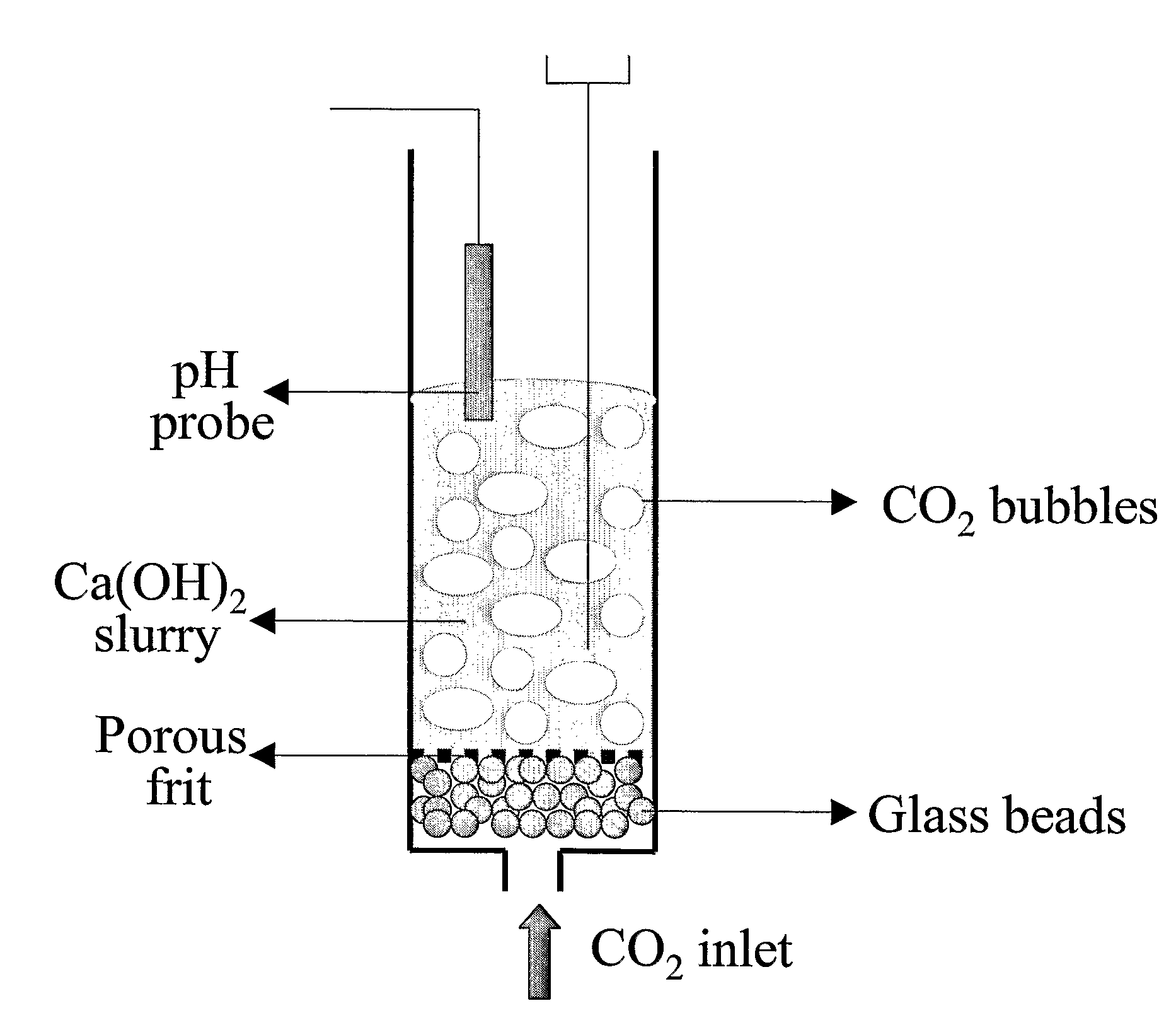

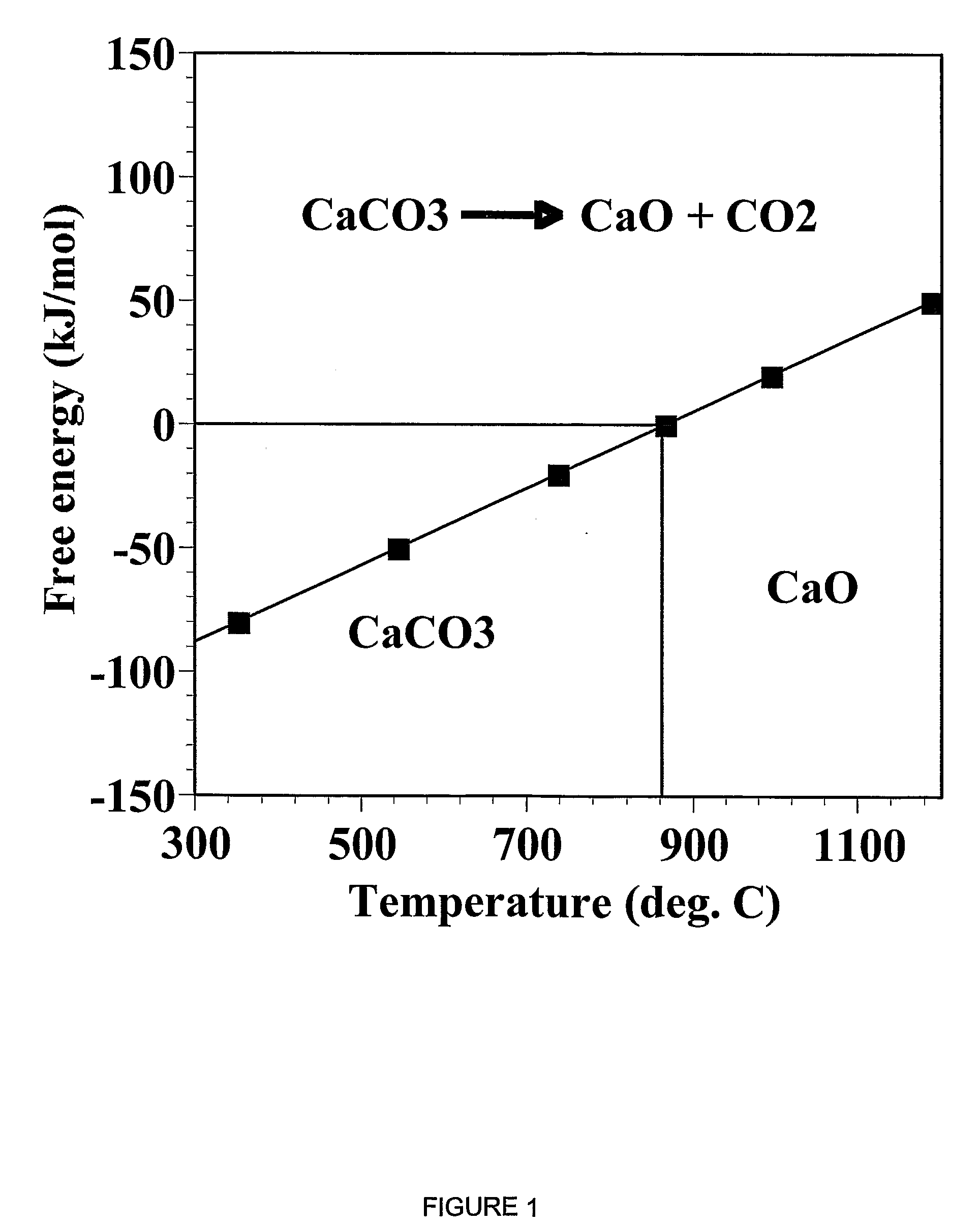

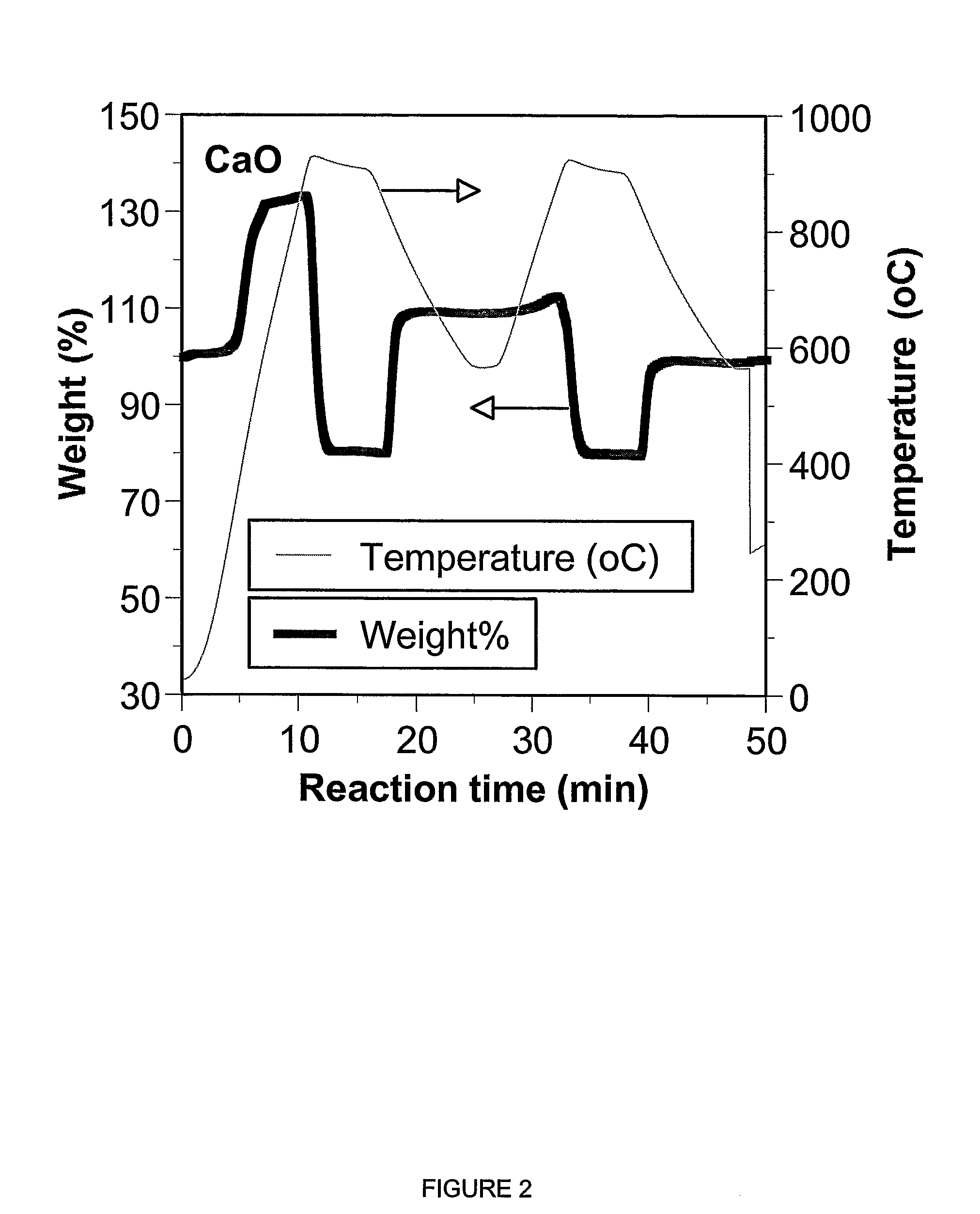

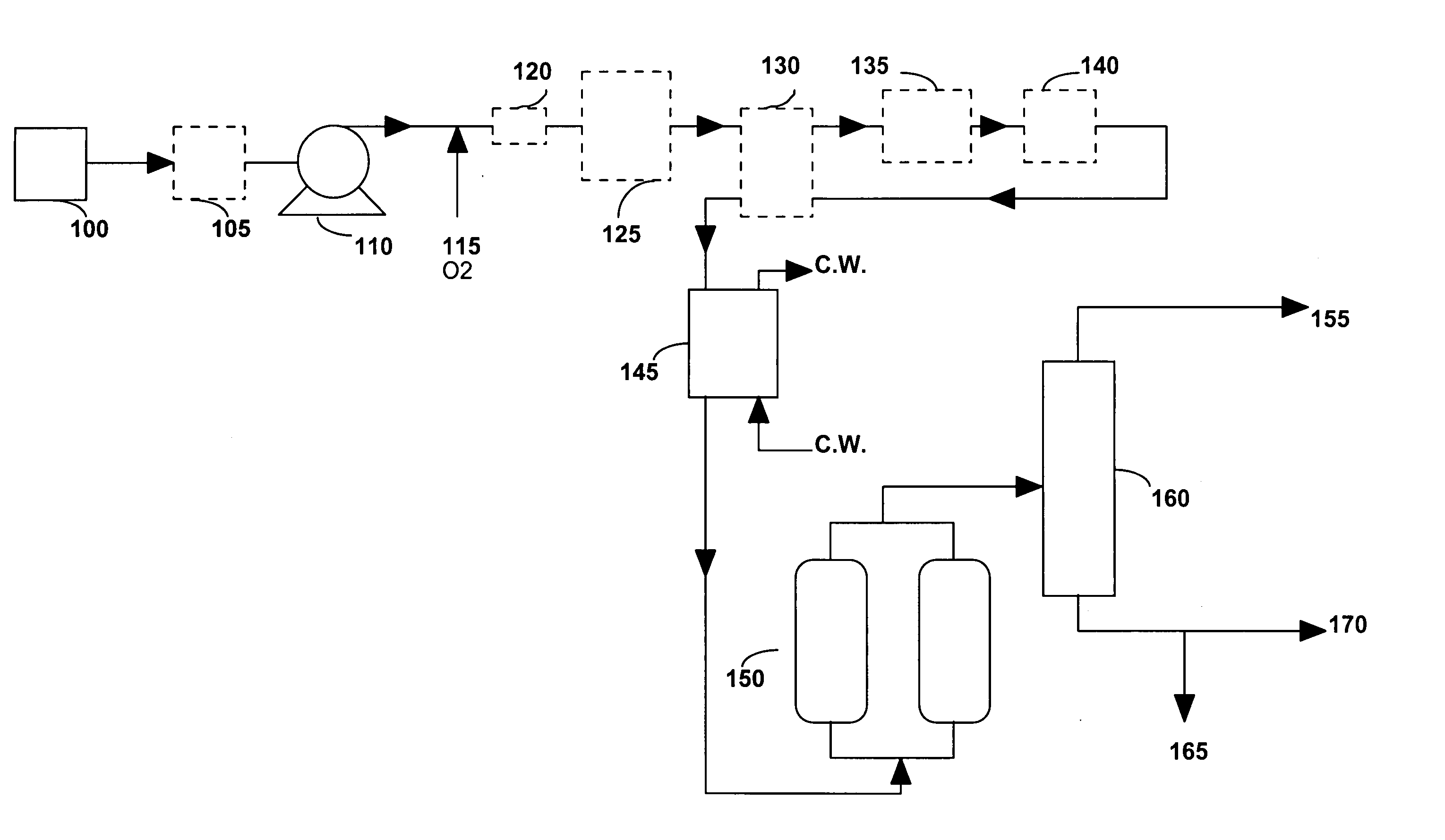

Separation of Carbon Dioxide (Co2) From Gas Mixtures By Calcium Based Reaction Separation (Cars-Co2) Process

InactiveUS20080233029A1Good repeatabilityMaterial nanotechnologyCombustible gas catalytic treatmentSorbentTransformation ratio

A reaction-based process has been developed for the selective removal of carbon dioxide (CO2) from a multicomponent gas mixture to provide a gaseous stream depleted in CO2 compared to the inlet CO2 concentration in the stream. The proposed process effects the separation of CO2 from a mixture of gases (such as flue gas / fuel gas) by its reaction with metal oxides (such as calcium oxide). The Calcium based Reaction Separation for CO2 (CaRS—CO2) process consists of contacting a CO2 laden gas with calcium oxide (CaO) in a reactor such that CaO captures the CO2 by the formation of calcium carbonate (CaCOa). Once “spent”, CaCO3 is regenerated by its calcination leading to the formation of fresh CaO sorbent and the evolution of a concentrated stream of CO2. The “regenerated” CaO is then recycled for the further capture of more CO2. This carbonation-calcination cycle forms the basis of the CaRS—CO2 process. This process also identifies the application of a mesoporous CaCO3 structure, developed by a process detailed elsewhere, that attains >90% conversion over multiple carbonation and calcination cycles. Lastly, thermal regeneration (calcination) under vacuum provided a better sorbent structure that maintained reproducible reactivity levels over multiple cycles.

Owner:THE OHIO STATES UNIV

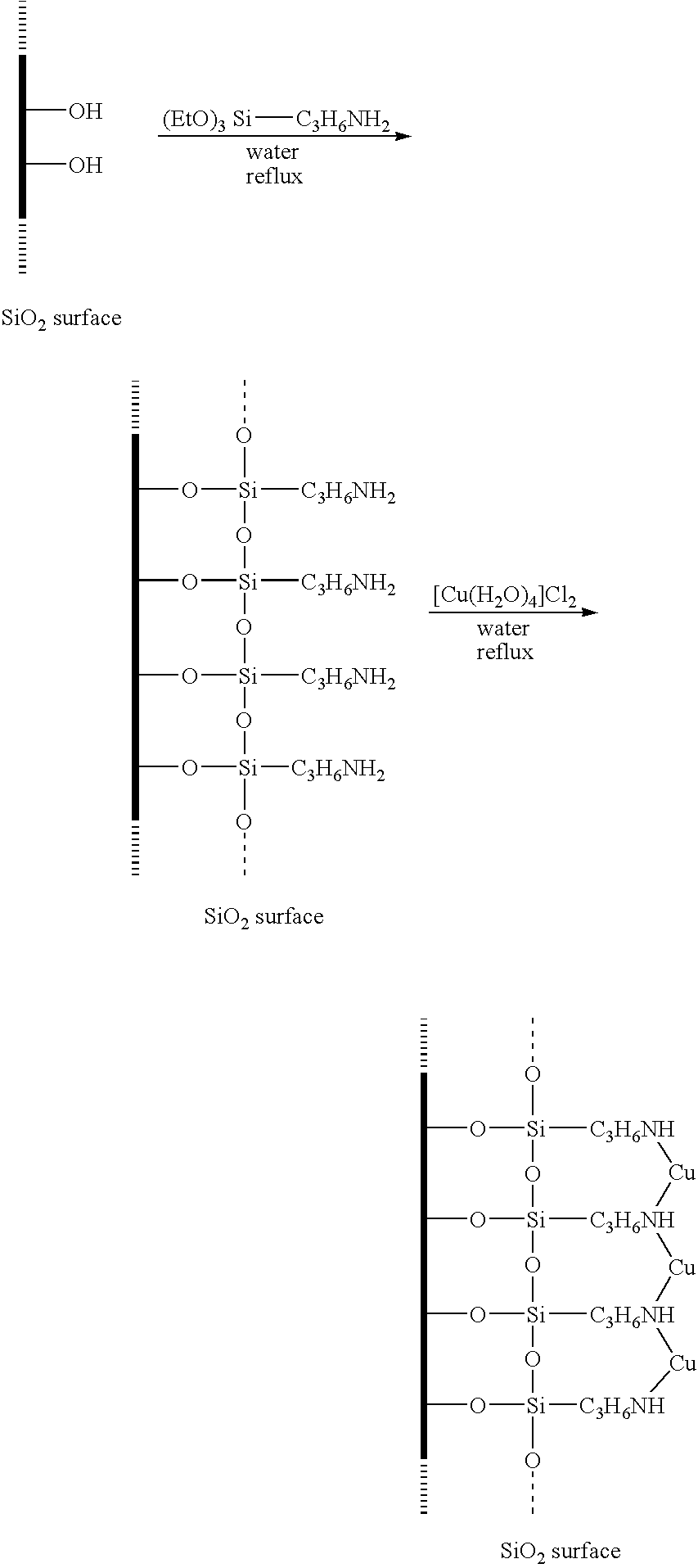

Method for reducing odor using metal-modified silica particles

ActiveUS20050084438A1Stability can be compromisedAmeliorate pH-lowering affectMaterial nanotechnologyNon-fibrous pulp additionSilica particleCompound (substance)

A method for reducing odor is provided. In one embodiment, the method comprises modifying the surface of silica particles with a transition metal so that the silica particles are bonded to the transition metal through a covalent or coordinate bond. The method further comprises contacting the modified silica particles with an odorous compound, the transition metal facilitating the capture of the odorous compound.

Owner:KIMBERLY-CLARK WORLDWIDE INC

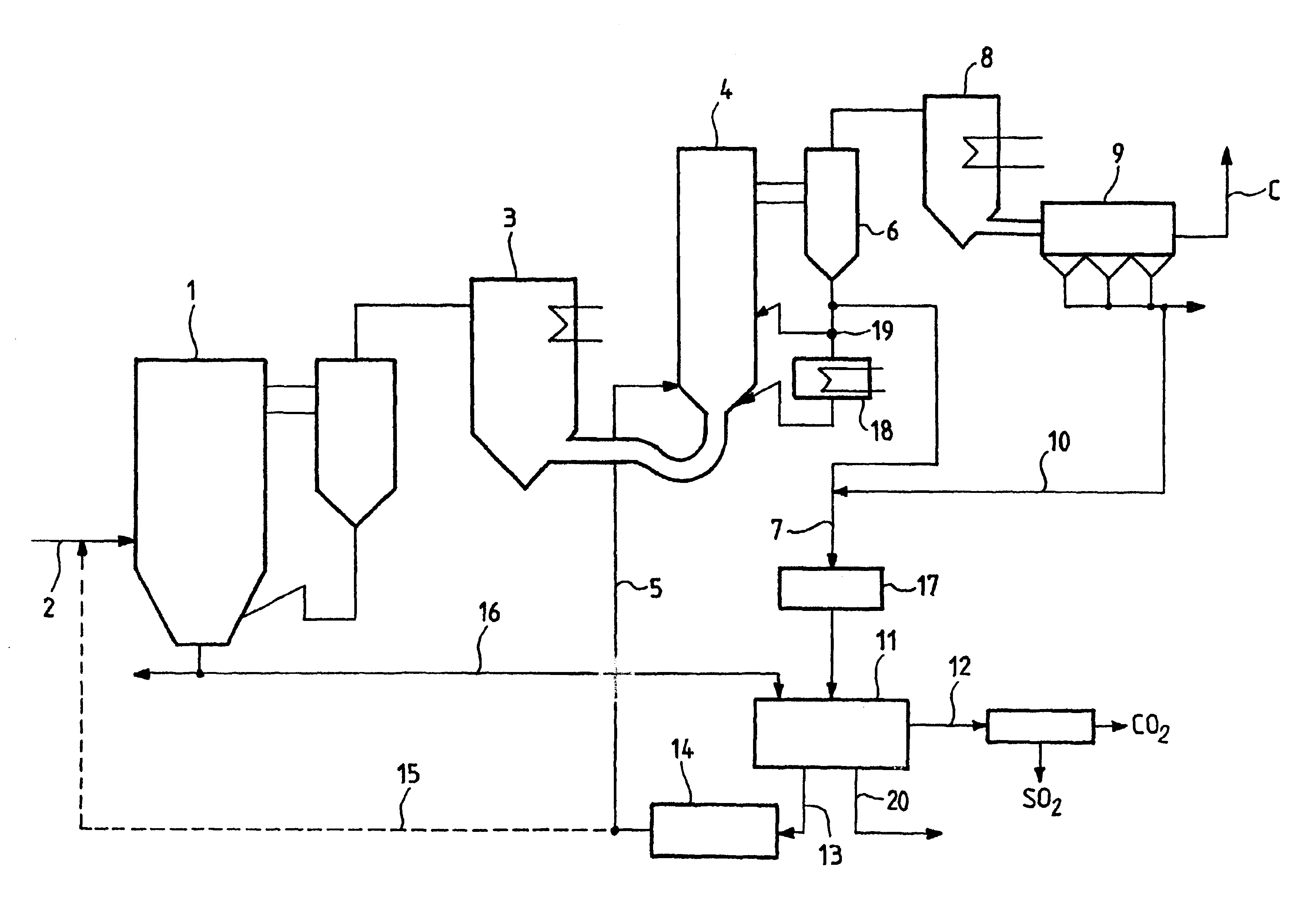

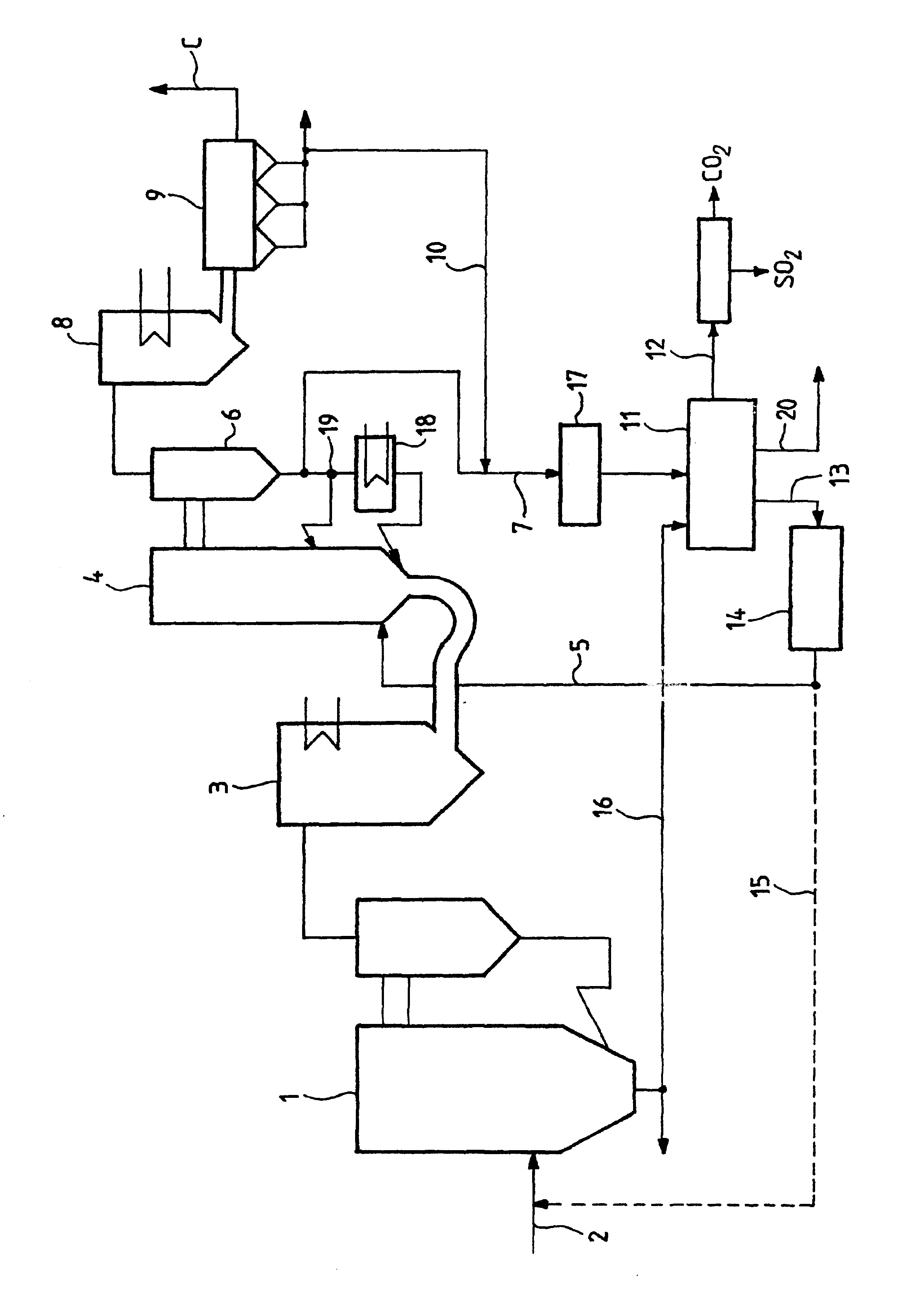

Method of simultaneously reducing CO2 and SO2 emissions in a combustion installation

InactiveUS6737031B2Reduce carbon dioxide emissionsFluidized bed combustionGas treatmentCombustionFlue gas

The method of simultaneously reducing carbon dioxide (CO2) emissions and sulfur dioxide (SO2) emissions produced by the combustion of carbon-containing matter in a hearth consists in injecting into the hearth a calcium-based agent, a fraction of which absorbs SO2 after decarbonization, and then, after the flue gases have been subjected to intermediate cooling, in causing them to transit via a first reactor and in putting them in contact therein with the other fraction of the absorbant that has not reacted with SO2 so as to capture CO2 from the flue gases by carbonization, then, in a separator, in extracting the solids contained in the flue gases output from the first reactor so as to subject them to heat treatment in a second reactor in order to extract CO2 therefrom by decarbonization and in order to recycle the resulting regenerated CO2 absorbant to the first reactor.

Owner:GENERAL ELECTRIC TECH GMBH

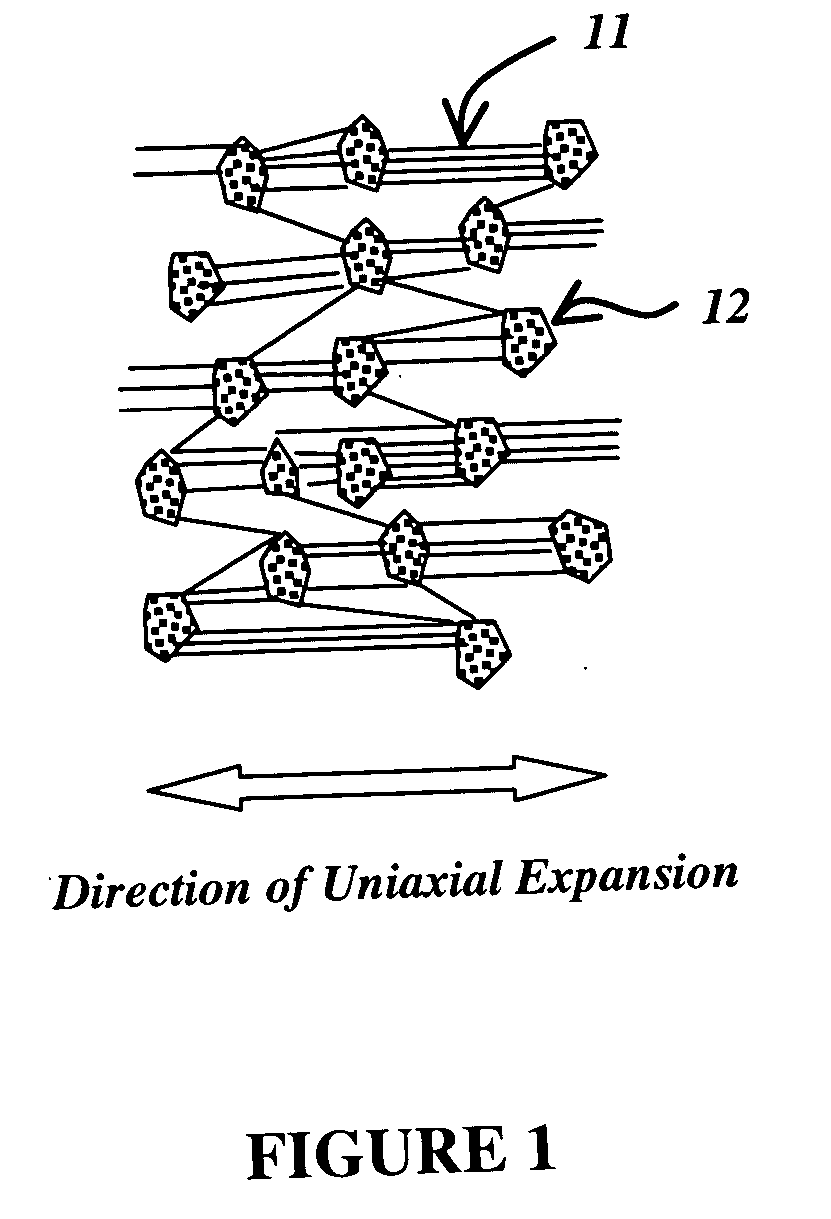

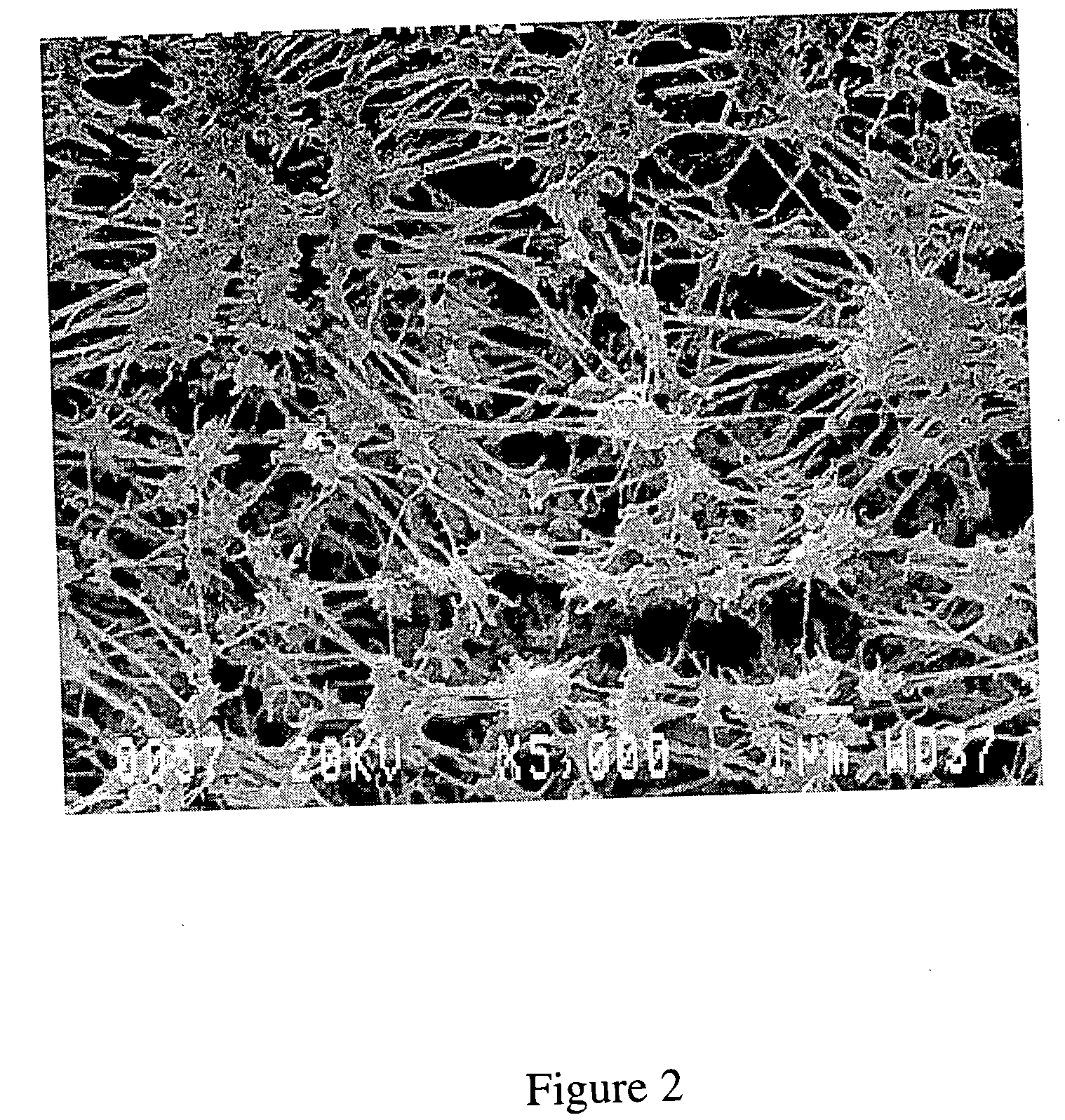

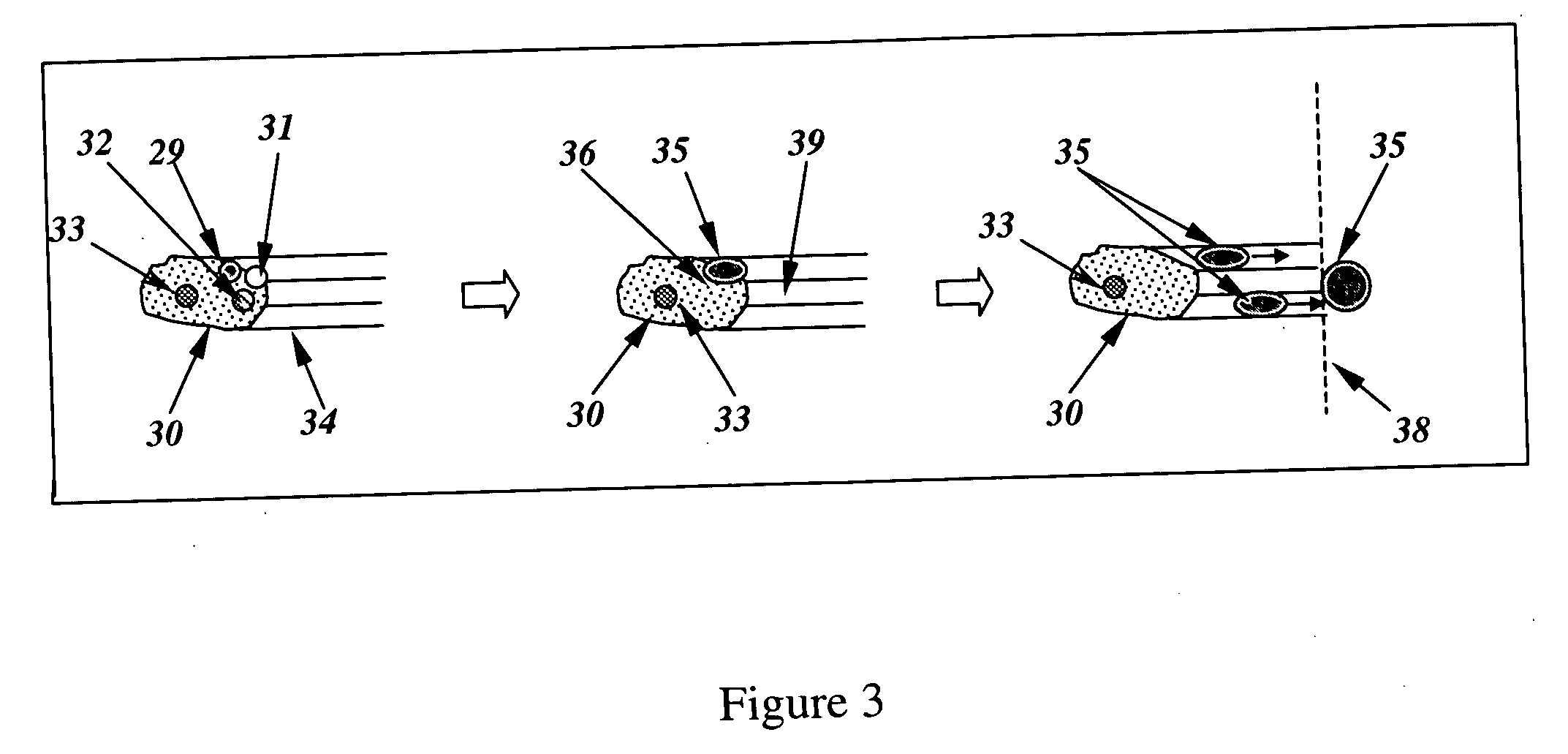

Flue gas purification process using a sorbent polymer composite material

ActiveUS20050019240A1Easy to fixImprove removal efficiencyGas treatmentNitrogen compoundsSorbentFluoropolymer

This invention provides a process of removing sulfur oxides, mercury vapor, and fine particulate matters from industrial flue gases that contain such pollutants. The pollutants are removed by modules, which contain microporous adsorbent (i.e., sorbent) material that is held within a polymer matrix. The preferred polymers are fluoropolymers. The composite material that contains the microporous absorbent material held within a polymer matrix removes sulfur oxides by converting them into high concentration sulfuric acids. It also removes mercury vapor by chemically adsorbing the mercury into the matrix. It also removes fine particulate matters by surface filtration. The sulfuric acid that is produced inside the composite material is automatically expelled onto the external surfaces of the composite material and is drained into an acid reservoir together with the fine particulate matters which are washed from the external surfaces of the composite material by the constant dripping of the sulfuric acid along the external surfaces of the composite material.

Owner:WL GORE & ASSOC INC

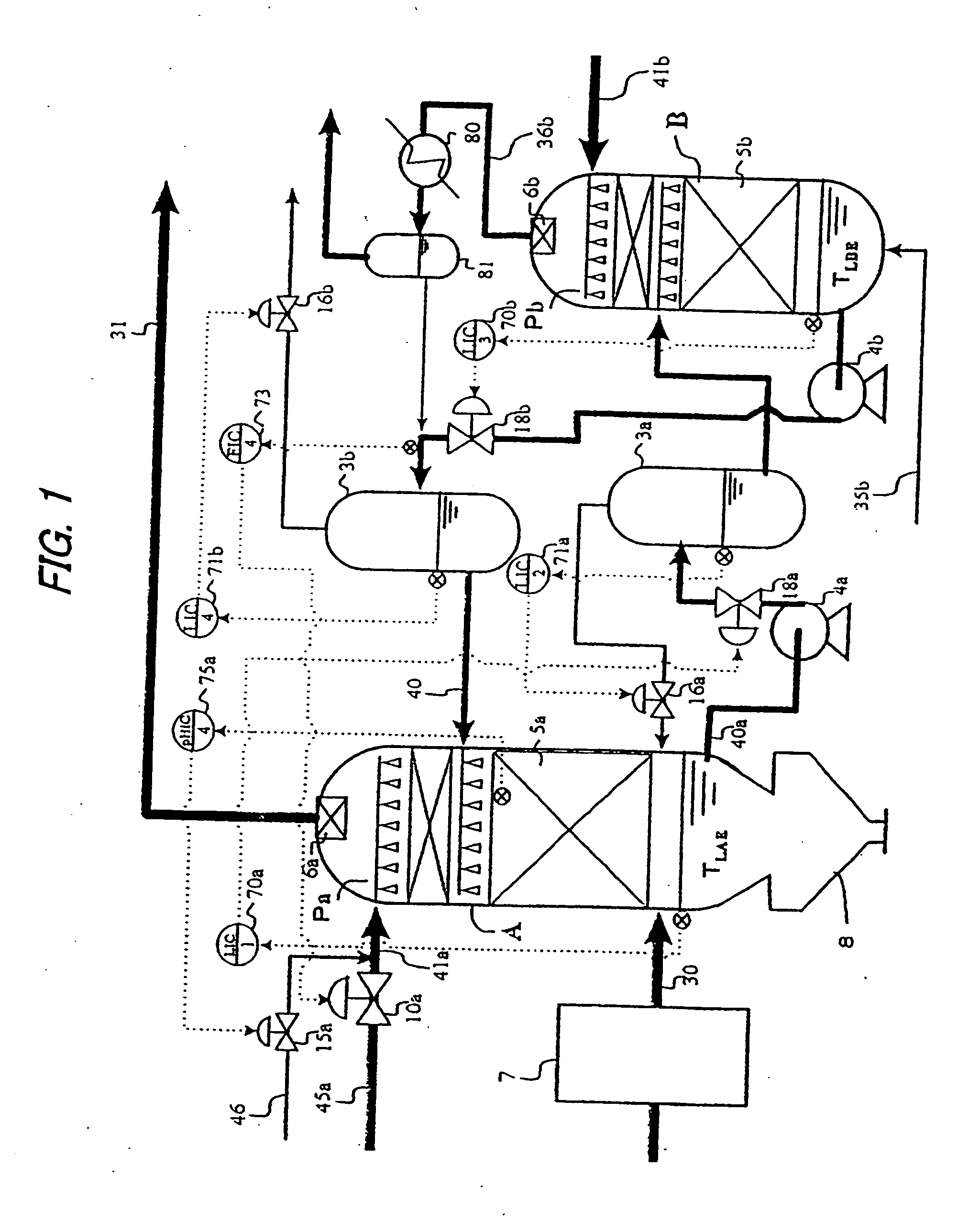

Acid gas scrubbing apparatus and method

InactiveUS20050132883A1Improve energy efficiencyImprove acid gas removal capabilityUsing liquid separation agentCombustible gas catalytic treatmentScrubberCarbon dioxide

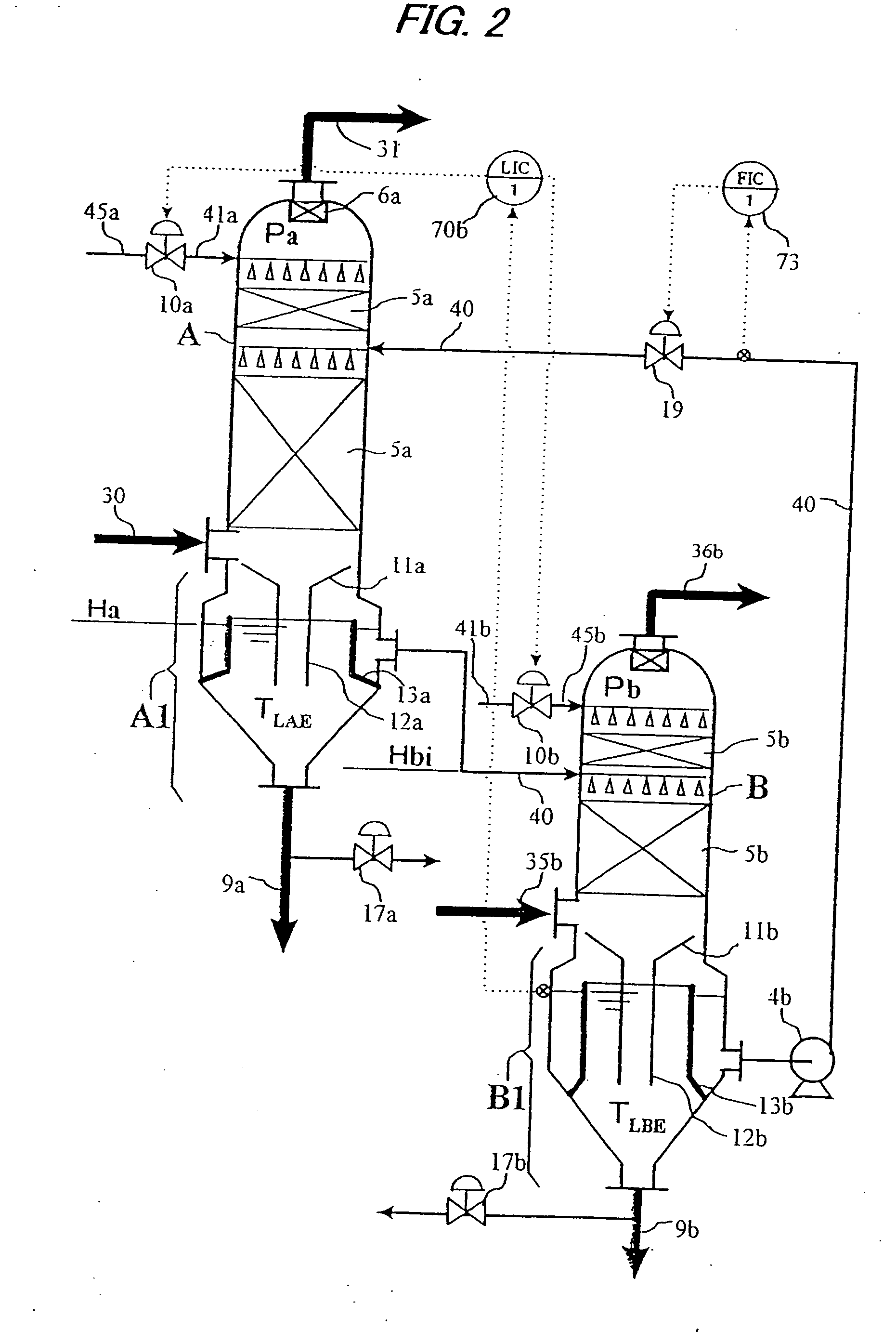

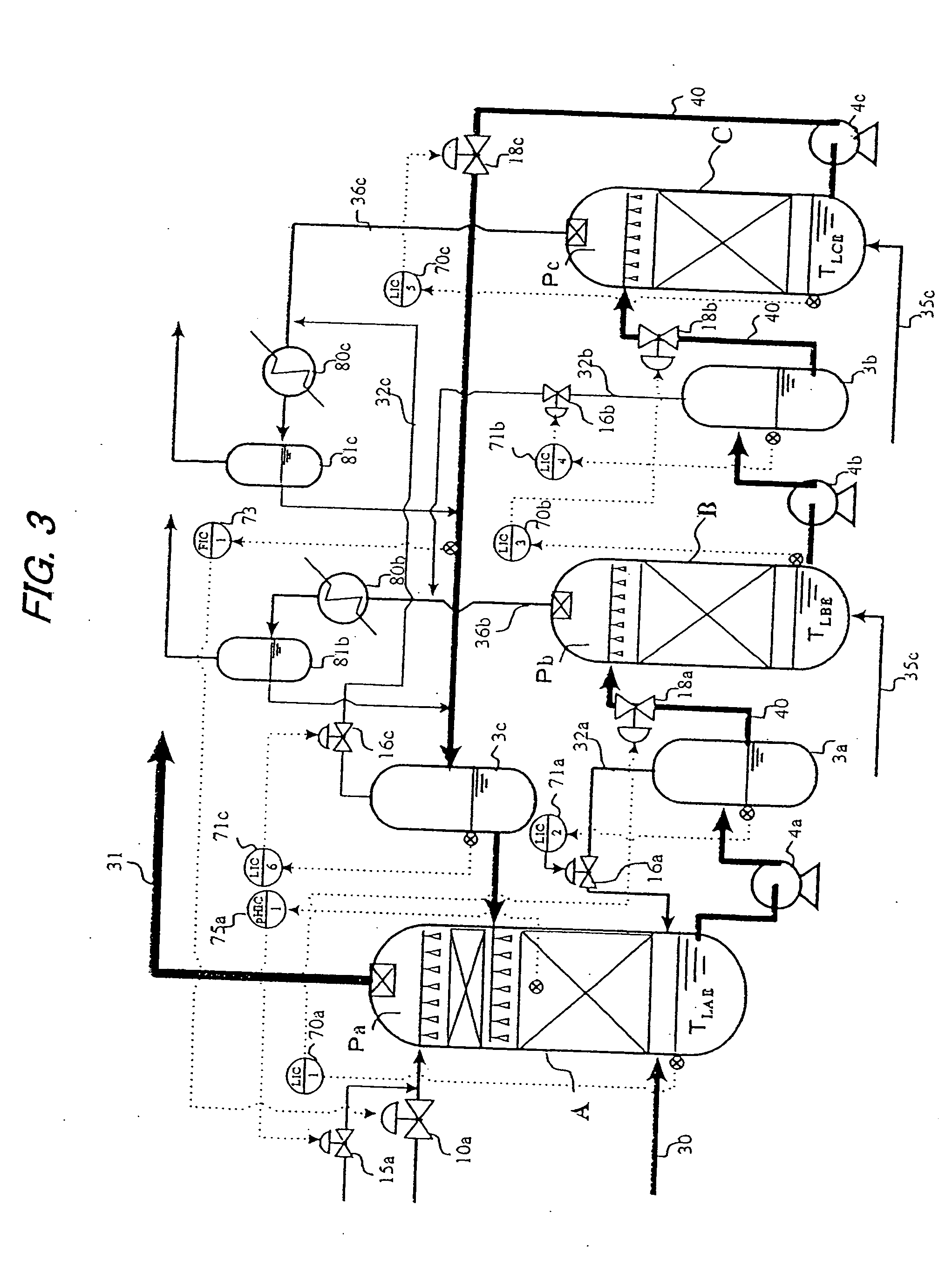

An acid gas scrubbing apparatus and method brings a gas, to be scrubbed, containing carbon dioxide into contact with a gas scrubbing liquid containing alkaline agent and cooled, and acid gases in the gas are removed. A gas scrubber removes acid gases in a gas, to be scrubbed, containing carbon dioxide by bringing the gas to be scrubbed into contact with a gas scrubbing liquid containing alkaline agent. A scrubbing liquid regenerator regenerates and cools the gas scrubbing liquid by bringing the gas scrubbing liquid into contact with a regenerating gas having components different from the gas scrubbing liquid and the gas to be scrubbed. A circulating device is provided between the gas scrubber and the scrubbing liquid regenerator for circulating the scrubbing liquid.

Owner:SU QINGQUAN +4

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

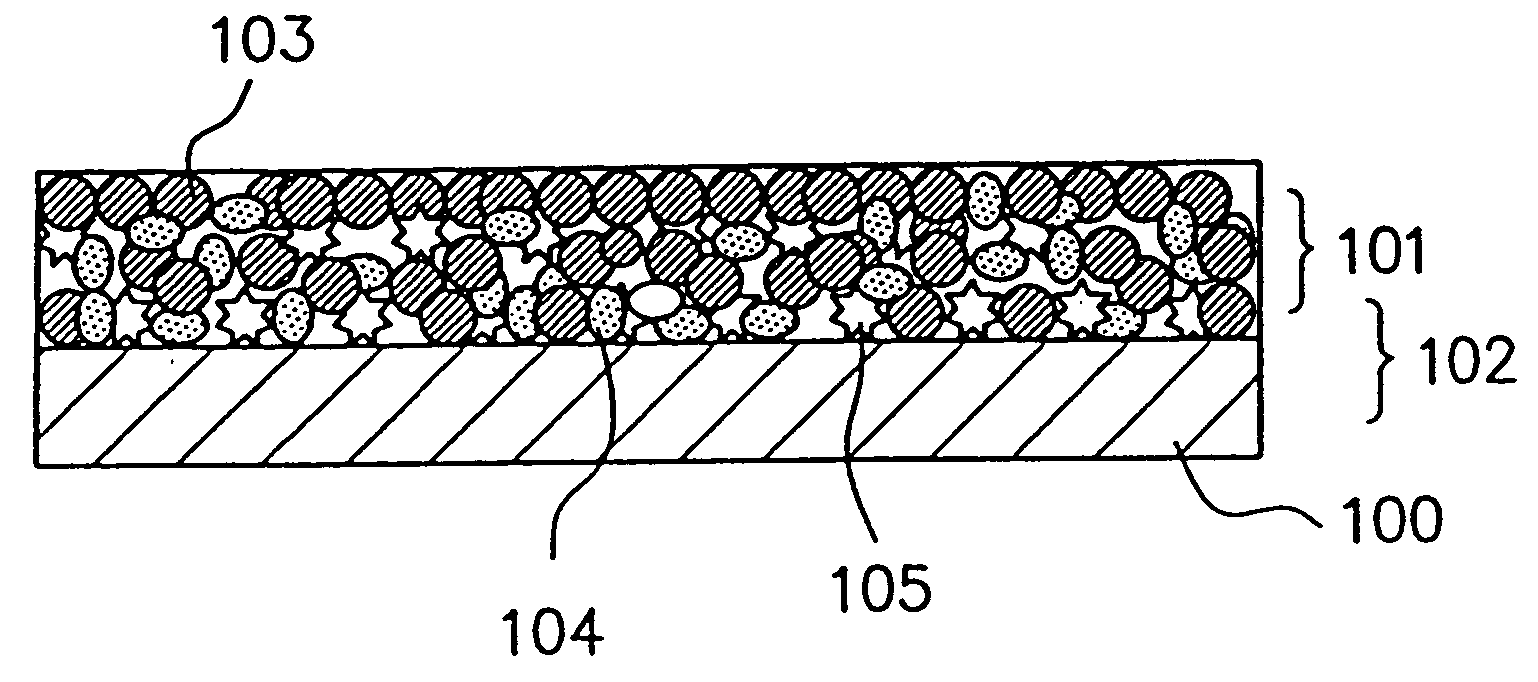

Diesel particulate filters having ultra-thin catalyzed oxidation coatings

The present invention is directed to an exhaust gas treatment system and method for removing particulate matter and nitrogen oxides from diesel engine exhaust streams. More specifically, the present invention relates to an emission treatment system that effectively provides simultaneous treatment of the particulate matter, as well as the NOx and other gaseous components of diesel engine exhaust. The emission treatment system uses an integrated soot filter coated with a catalyst washcoat composition comprising sub-micron particles, thereby providing an ultra-thin sub-micron washcoat layer showing improved catalyst performance without causing excessive backpressure.

Owner:ENGELHARD CORP

Methods of operating a coal burning facility

ActiveUS20070168213A1Improve balanceIncrease valueSustainable waste treatmentSolid fuel pretreatmentHalogenSorbent

Methods involve adding sorbent components, such as calcium oxide, alumina, and silica, as well as optional halogens as part of environmental control. Use of the sorbents leads to significant reductions in sulfur and mercury emissions that otherwise would result from burning coal. Use of the sorbents leads to production of waste coal ash that, while higher in mercury, is nevertheless usable as a commercial product because the mercury in the ash is non-leaching and because the coal ash has a higher cementitious nature by virtue of the increased content of the sorbent components in the ash. Thus, the methods involve adding powders having qualities that lead to the production of a cementitious coal ash while at the same time reducing emissions from a coal burning facility.

Owner:NOX II LTD

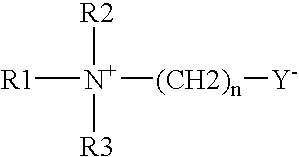

Disinfecting composition and process for disinfecting surfaces

InactiveUS6841090B1Immediate and long lasting disinfectionBiocideOrganic detergent compounding agentsHydrogenEther

Liquid disinfecting compositions comprise an effective amount of a disinfecting material and a poly (alkylene glycol) ether having the following formula: R1—O—(CH2—CHR2O)n—R3, wherein R1 and R2 are each independently hydrogen or a substituted or unsubstituted, saturated or unsaturated, linear or branched hydrocarbon chain having from 1 to 30 carbon atoms or a hydroxy bearing linear or branched hydrocarbon chain having from 1 to 30 carbon atoms. R3 is a substituted or unsubstituted, saturated, or unsaturated, linear or branched hydrocarbon chain having from 1 to 30 carbon atoms or a hydroxy bearing linear or branched hydrocarbon chain having from 1 to 30 carbon atoms, and n is greater than 2. Processes of disinfecting and hard-surface employ such a composition.

Owner:THE PROCTER & GAMBLE COMPANY

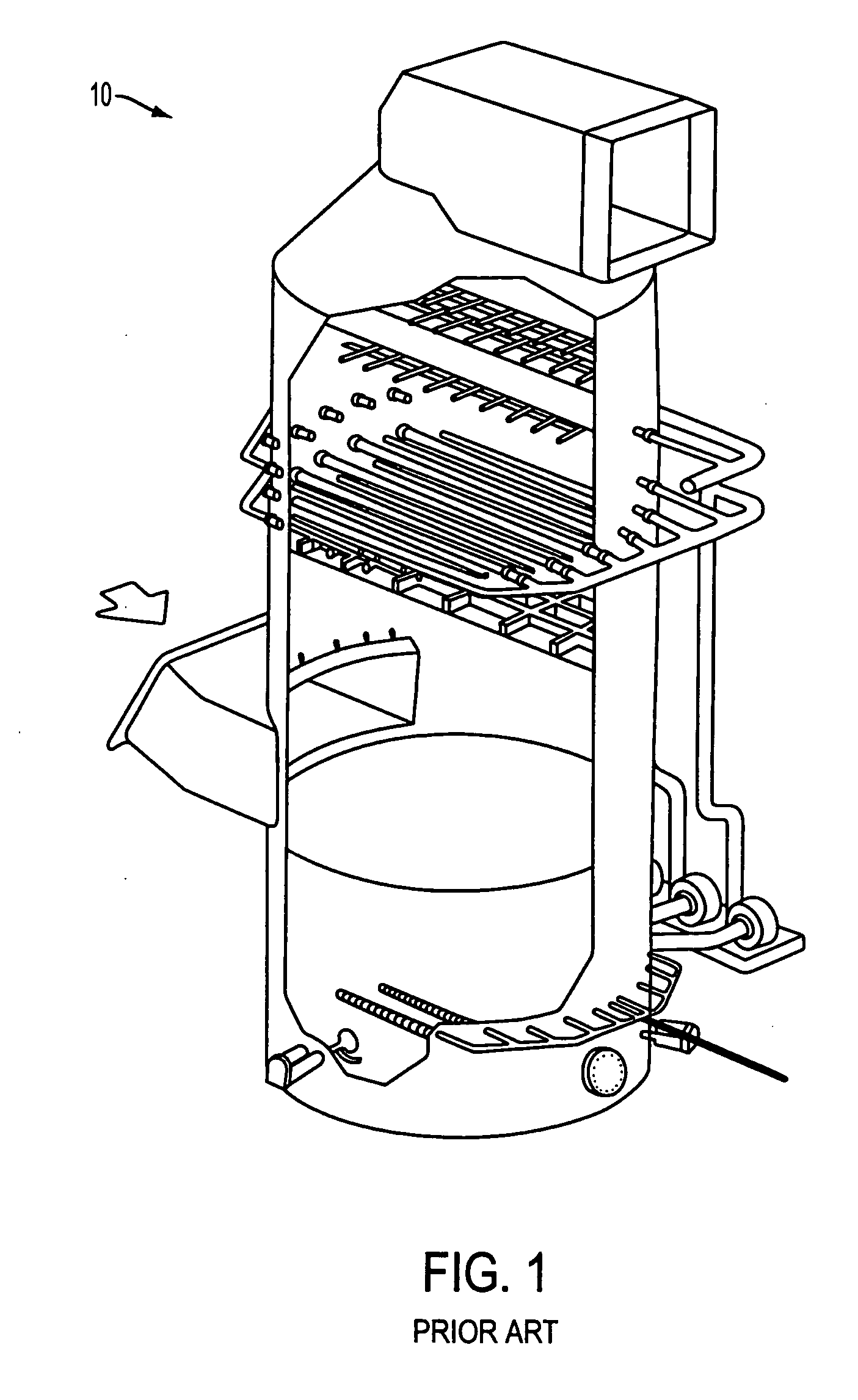

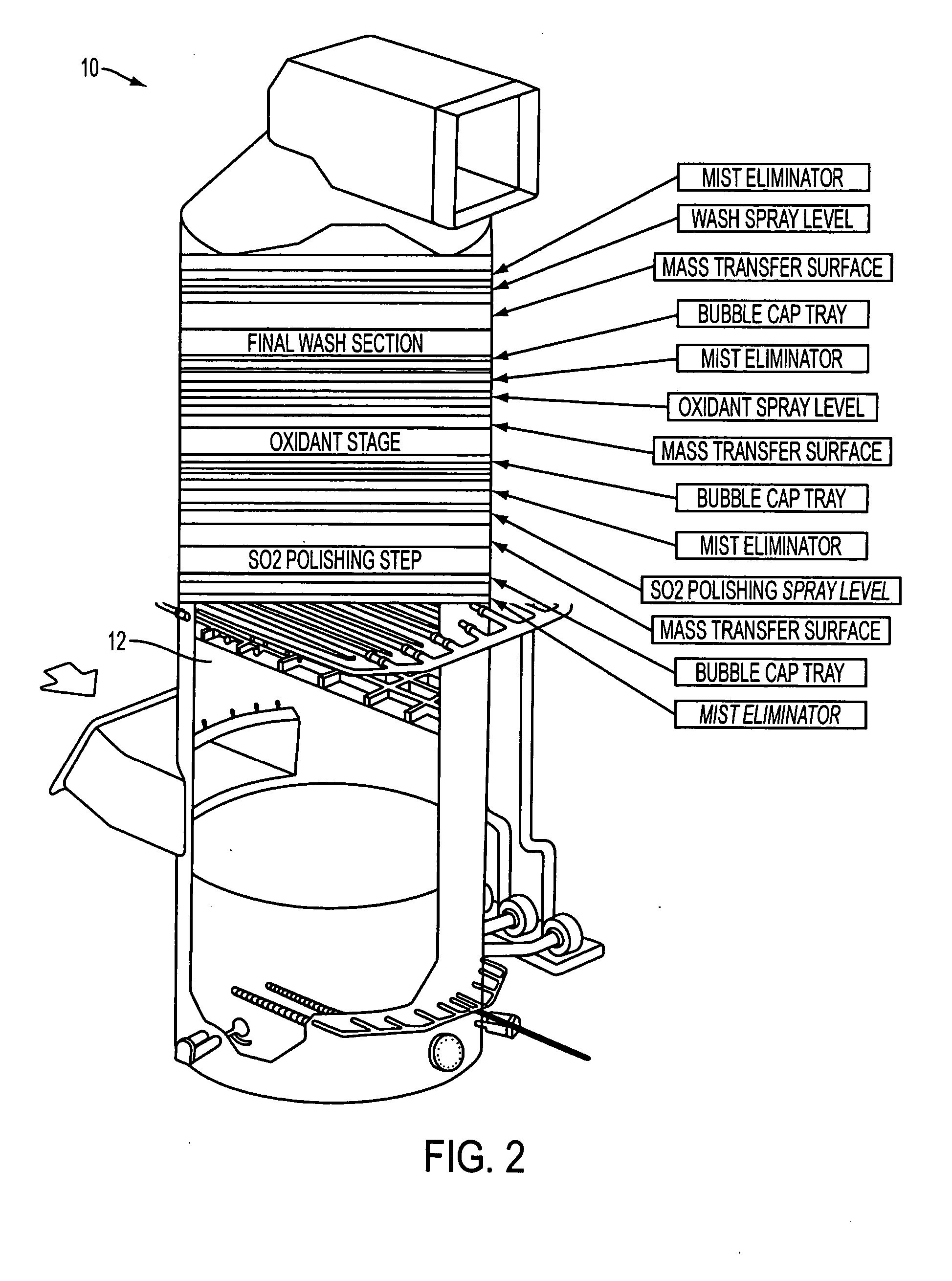

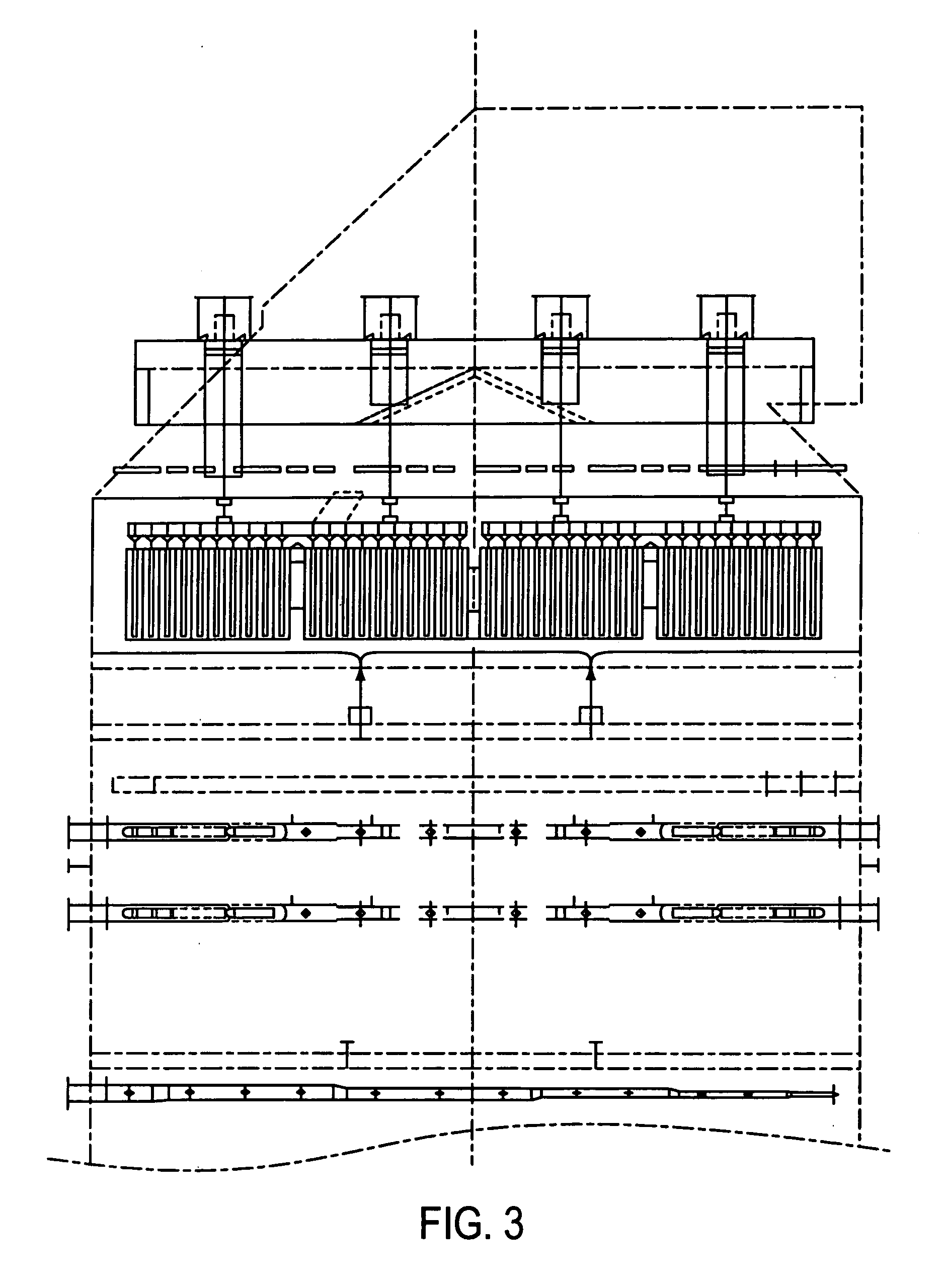

Removal of Hg, NOx, and SOx with using oxidants and staged gas/liquid contact

InactiveUS20050214187A1Simple methodHigh removal rateGas treatmentNitrogen compoundsNitrogen oxidesSorbent

A method of scrubbing mercury compounds and nitrogen oxides from a gas stream employing a scrubbing operation. The method involves the contact of the stream which contains mercury, SOx and NOx compounds with a sorbent to remove at least a portion of the latter compounds. This results in a partially cleaned stream. The method further involves contacting the latter stream with an oxidant to oxidize and remove substantially all residual nitrogen oxides, mercury and mercury compounds remaining in the stream.

Owner:AIRBORNE IND MINERALS INC CA

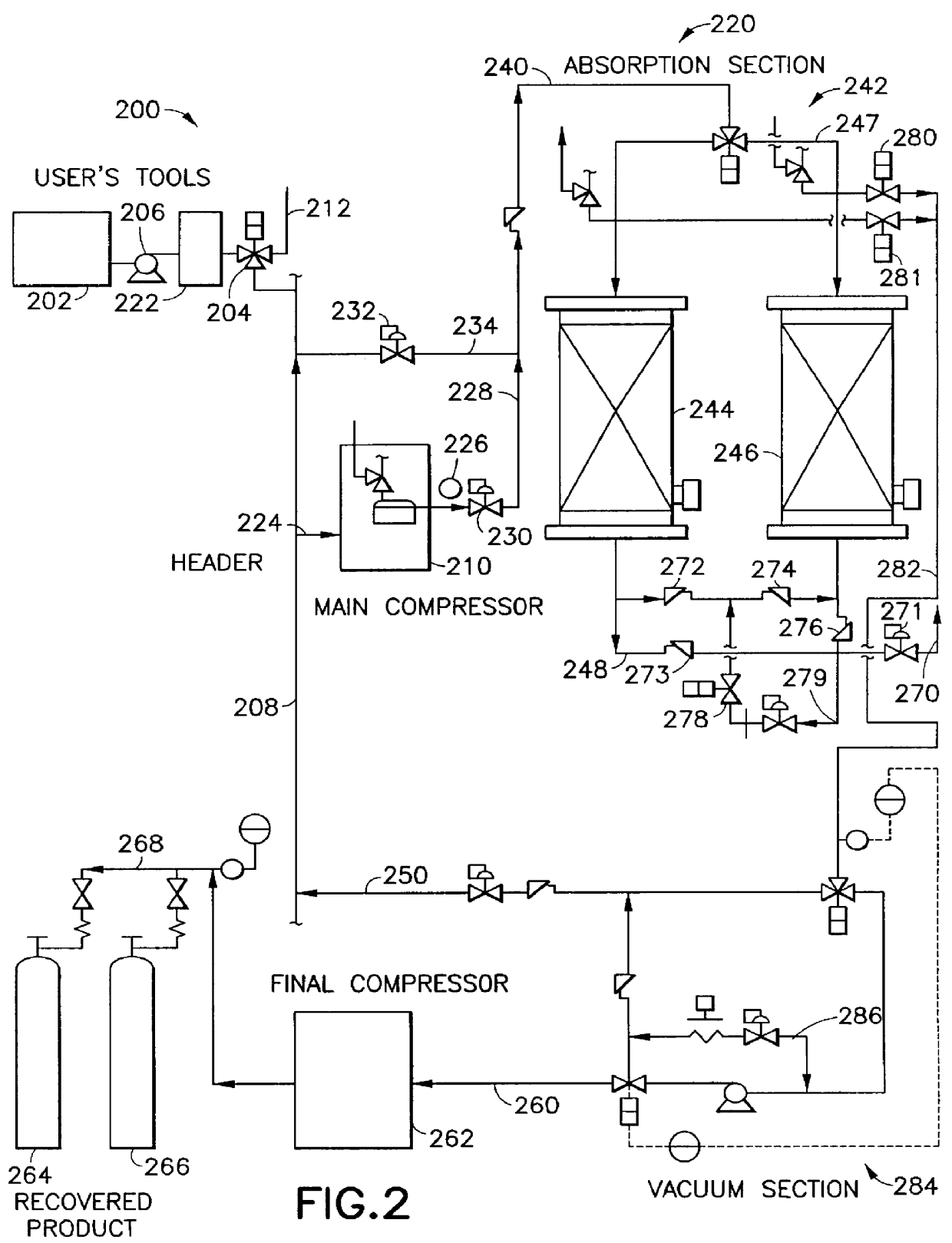

Process for removing and recovering halocarbons from effluent process streams

A process for recovery of fluorocompound gas from an effluent gas stream containing the fluorocompound gas and other gas components, in which at least one of the other gas components is removed, e.g., by oxidation or contacting of the effluent stream with a dry material such as an adsorbent or scrubber medium, to yield a first effluent gas mixture containing the fluorocompound gas. The fluorocompound gas is removed from the first effluent gas mixture and recovered as a concentrated fluorocompound gas, by a process such as cryogenic processing, membrane separation, and / or adsorption.

Owner:ADVANCED TECH MATERIALS INC

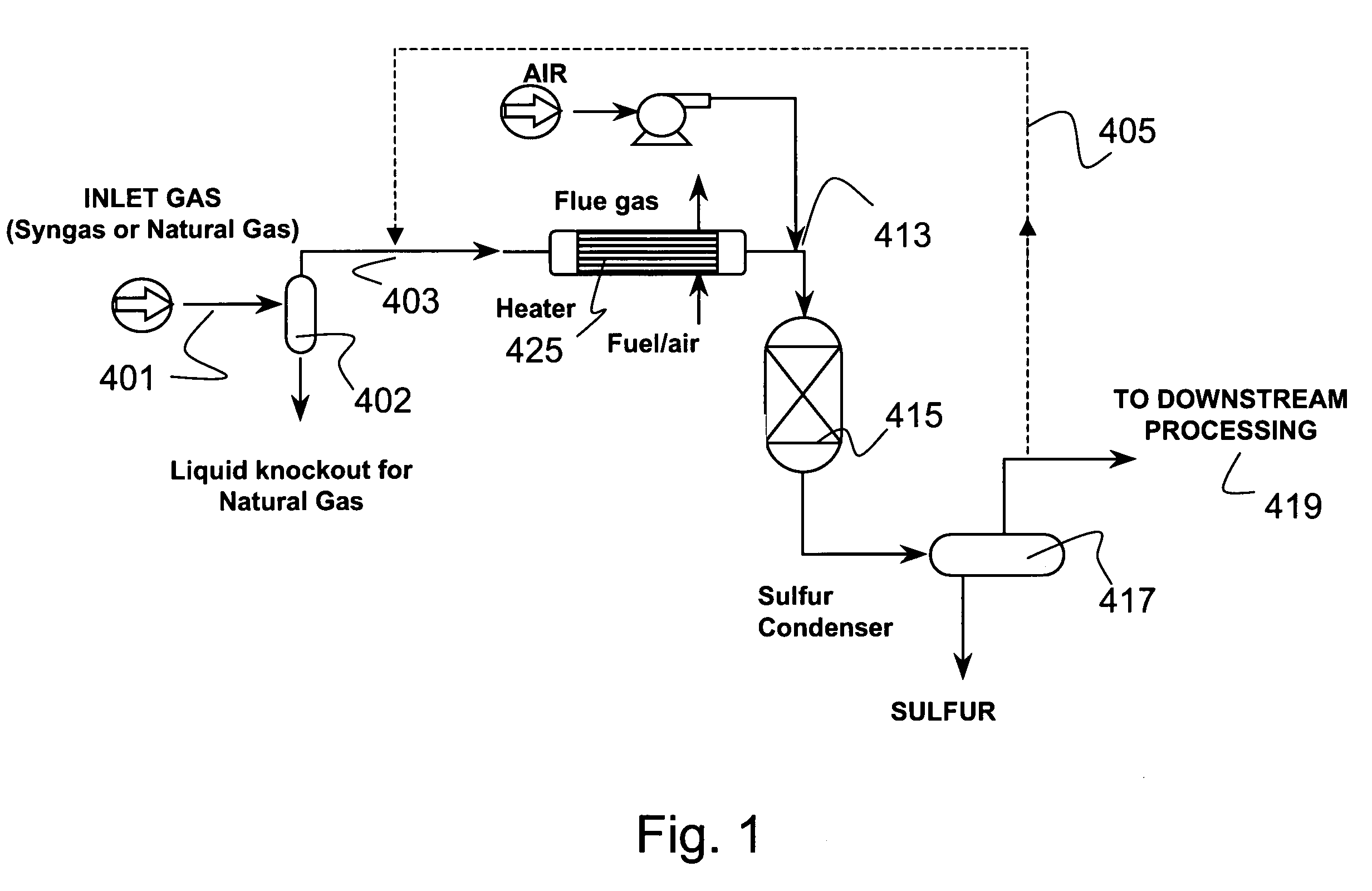

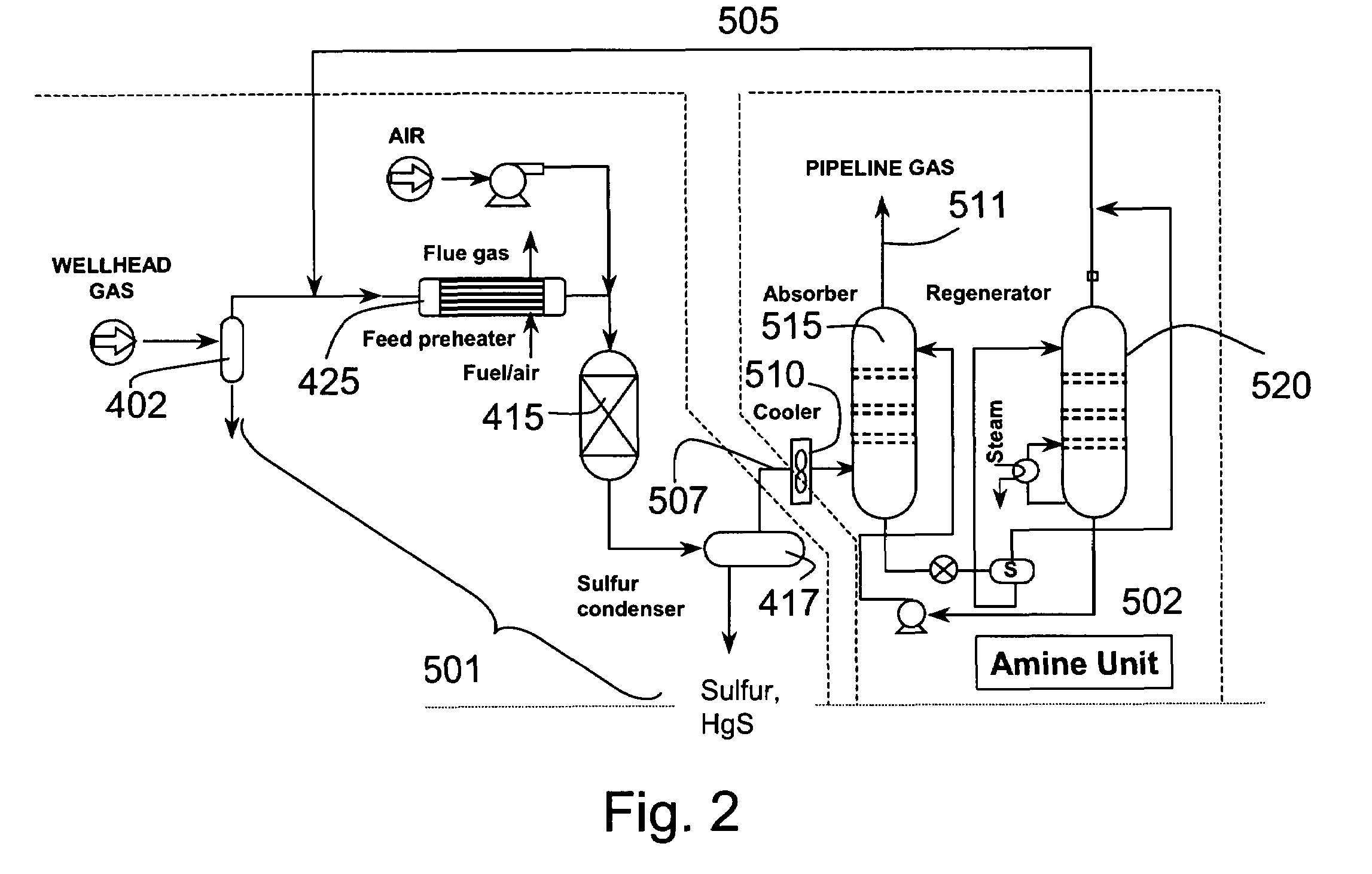

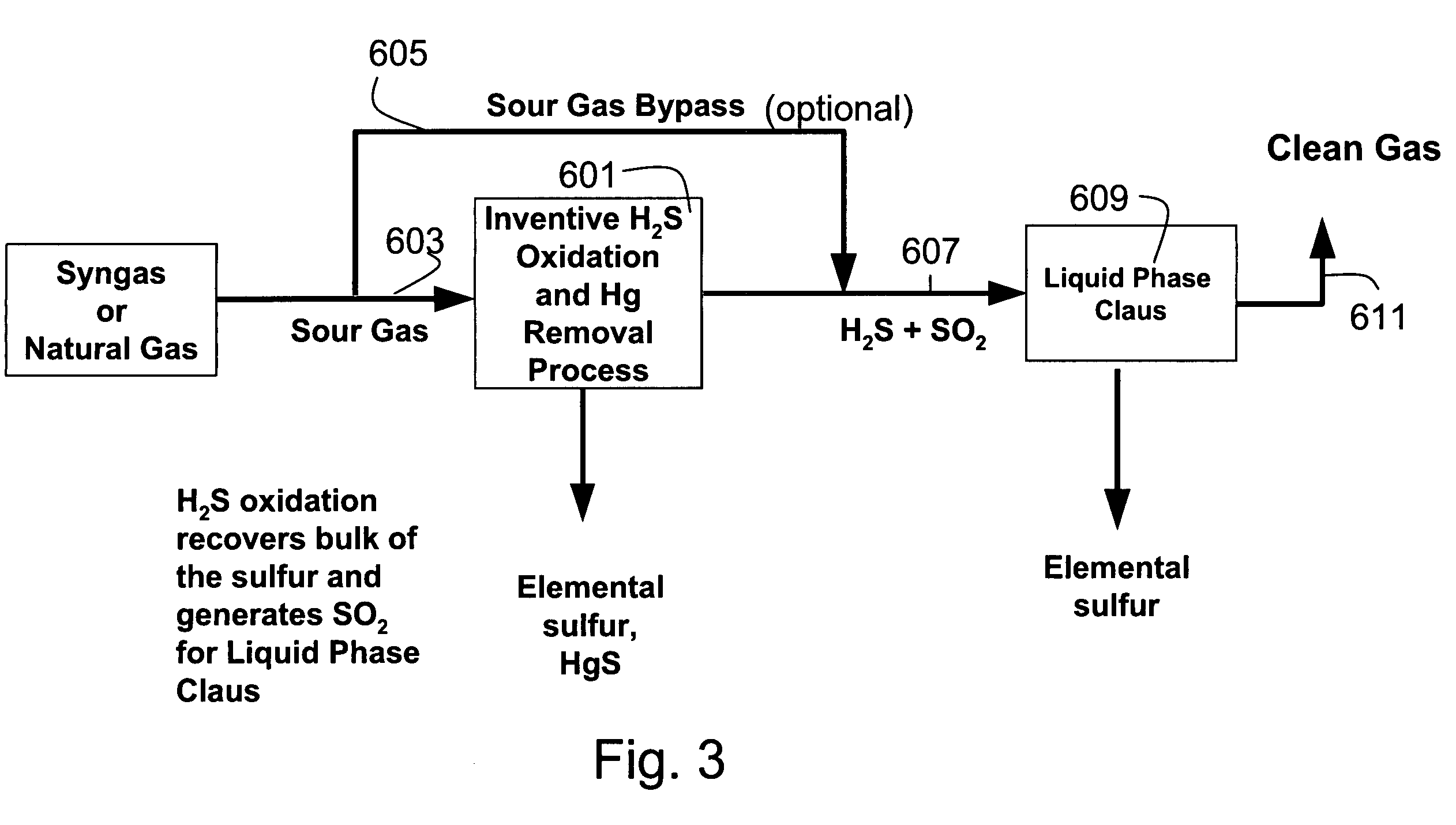

Process for the simultaneous removal of sulfur and mercury

InactiveUS7060233B1Lower capitalReduce operating costsGas treatmentUsing liquid separation agentSulfur containingInorganic sulfide

A process for removing hydrogen sulfide, other sulfur-containing compounds and / or sulfur and mercury from a gas stream contaminated with mercury, hydrogen sulfide or both. The method comprises the step of selective oxidation of hydrogen sulfide (H2S) in a gas stream containing one or more oxidizable components other than H2S to generate elemental sulfur (S) or a mixture of sulfur and sulfur dioxide (SO2). The sulfur generated in the gas stream reacts with mercury in the gas stream to generate mercuric sulfide and sulfur and mercuric sulfide are removed from the gas stream by co-condensation.

Owner:TDA RES

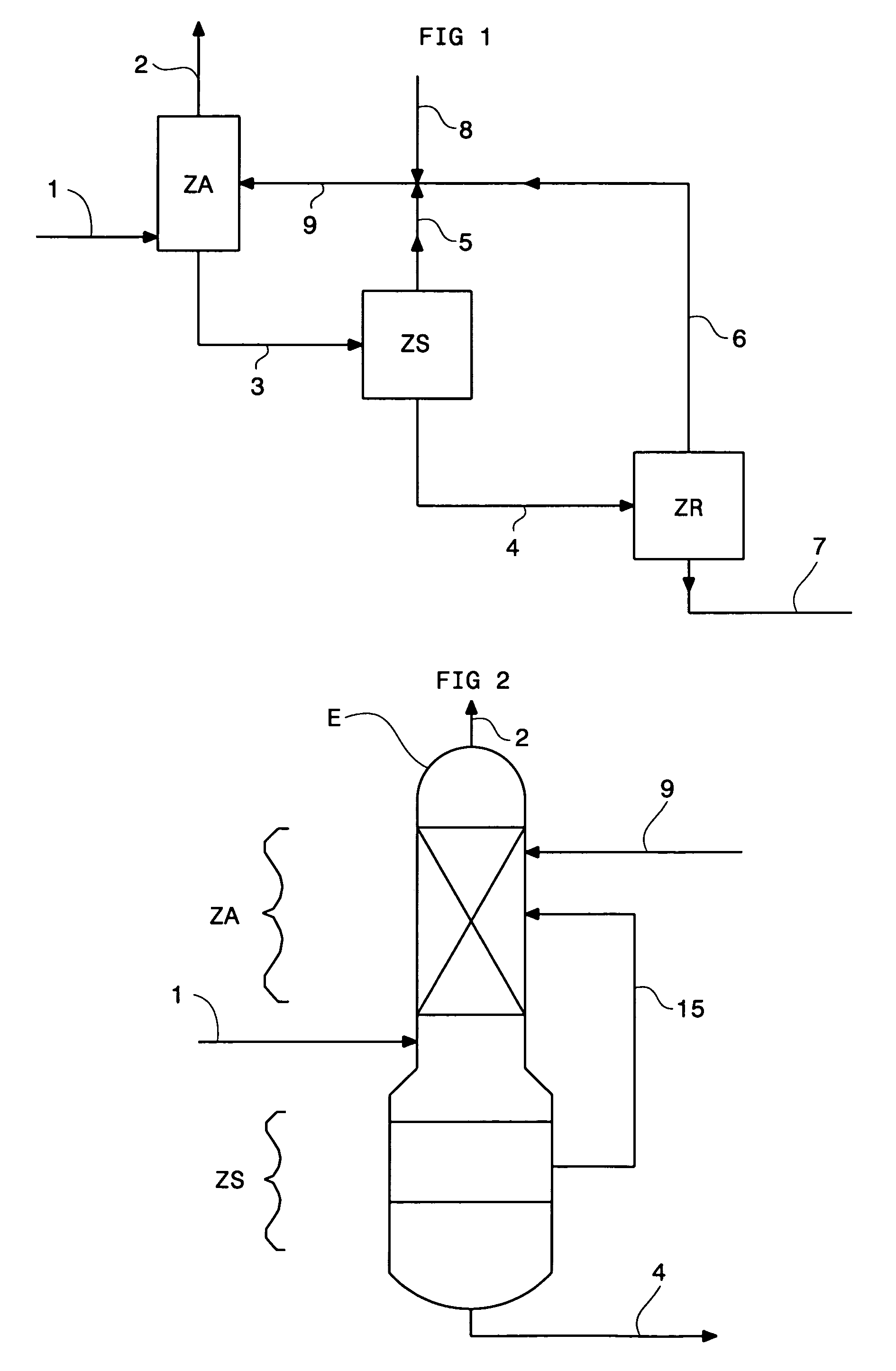

Method of deacidizing a gas with a fractional regeneration absorbent solution

The gaseous effluent flowing in through line 1 is contacted in absorption zone ZA with the liquid absorbent solution flowing in through line 9. The gaseous effluent depleted in acid compounds is discharged through line 2. The absorbent solution laden with acid compounds is discharged through line 3. The absorbent solution once laden with acid compounds comprises two phases: a first phase poor in acid compounds and a second phase rich in acid compounds. The two phases are separated in zone ZS. The first phase is recycled through lines 5 and 9 to absorption zone ZA. The second phase is fed through line 4 into regeneration zone ZR. In zone ZR, the acid compounds are separated from the absorbent solution. The acid compounds are discharged through line 7. The regenerated absorbent solution is recycled through lines 6 and 9 to zone ZA.

Owner:INST FR DU PETROLE

Oxygen scavenging compositions and packaging comprising said compositions

InactiveUS20060180790A1Removing hazeRecord information storageOrganic/inorganic per-compounds compounding agentsOxidation stateCompound (substance)

The instant invention concerns a composition comprising a base polymer, at least one compound of the formula E-(L-E)x wherein: E is and L is a linking group; and at least one transition metal in a positive oxidation state. The invention also concerns packages containing walls comprising such compositions, methods of forming such packages, and methods of packaging an oxygen-sensitive item within such a package

Owner:PLASTIPAK PACKAGING

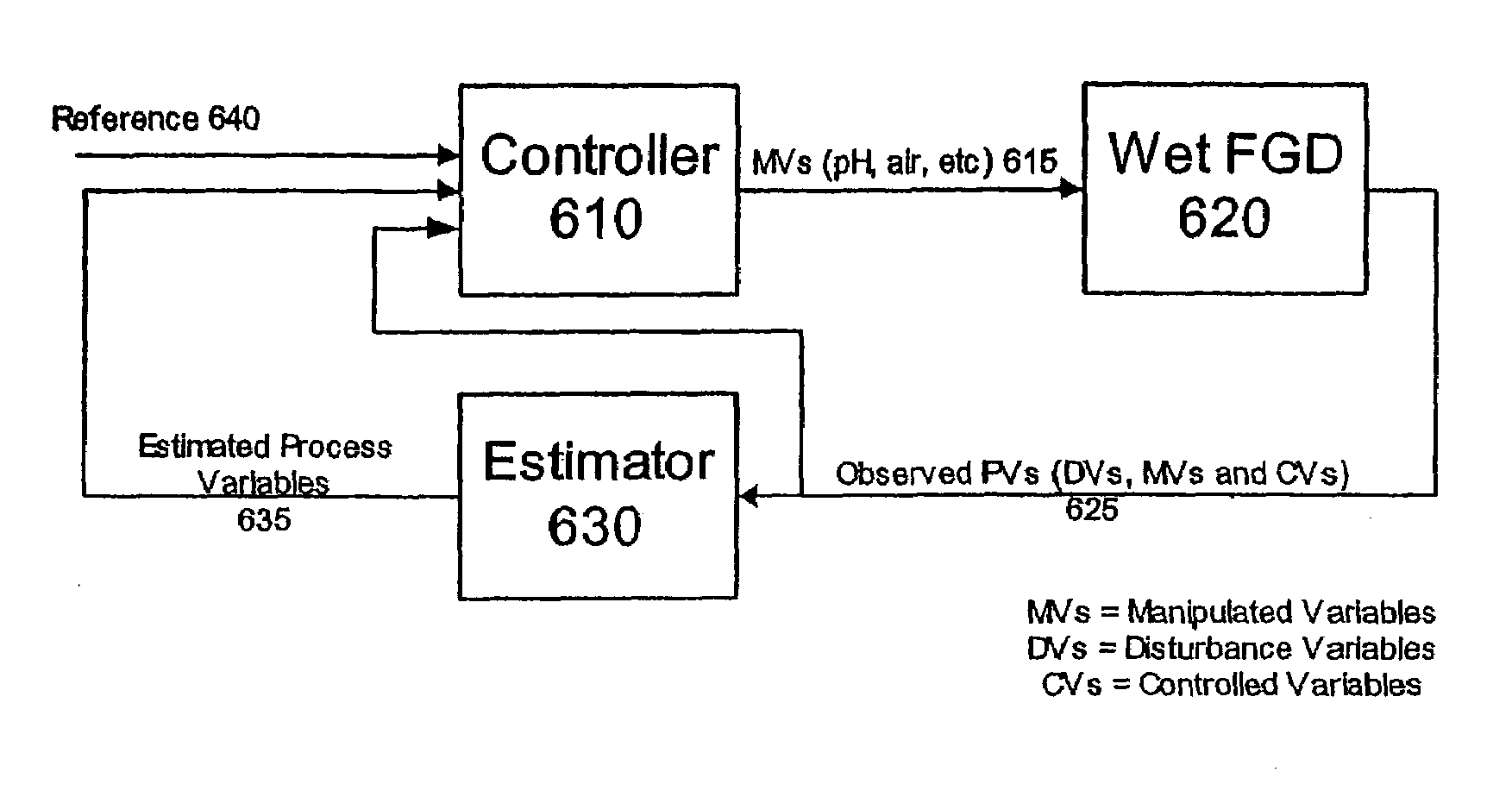

Cascaded control of an average value of a process parameter to a desired value

ActiveUS7117046B2Improve controlCombination devicesSolid sorbent liquid separationComputer scienceSet point

At least one of the multiple process parameters (MPPs) is a controllable process parameter (CTPP) and one is a targeted process parameter (TPP). The process also has a defined target limit (DTV) representing a first limit on an actual average value (AAV) of the TPP. A first logical controller predicts future average values (FAVs) of the TPP based on the AAVs of the TPP over a first prior time period and the DTV. A second logical controller establishes a further target limit (FTV) representing a second limit on the AAV of the TPP based on one or more of the predicted FAVs, and also determines a target set point for each CTPP based on the AAVs of the TPP over a prior time period and the FTV. The second logical controller directs control of each CTPP in accordance with the determined target set point.

Owner:GENERAL ELECTRIC TECH GMBH

Methods and devices for reducing hazardous air pollutants

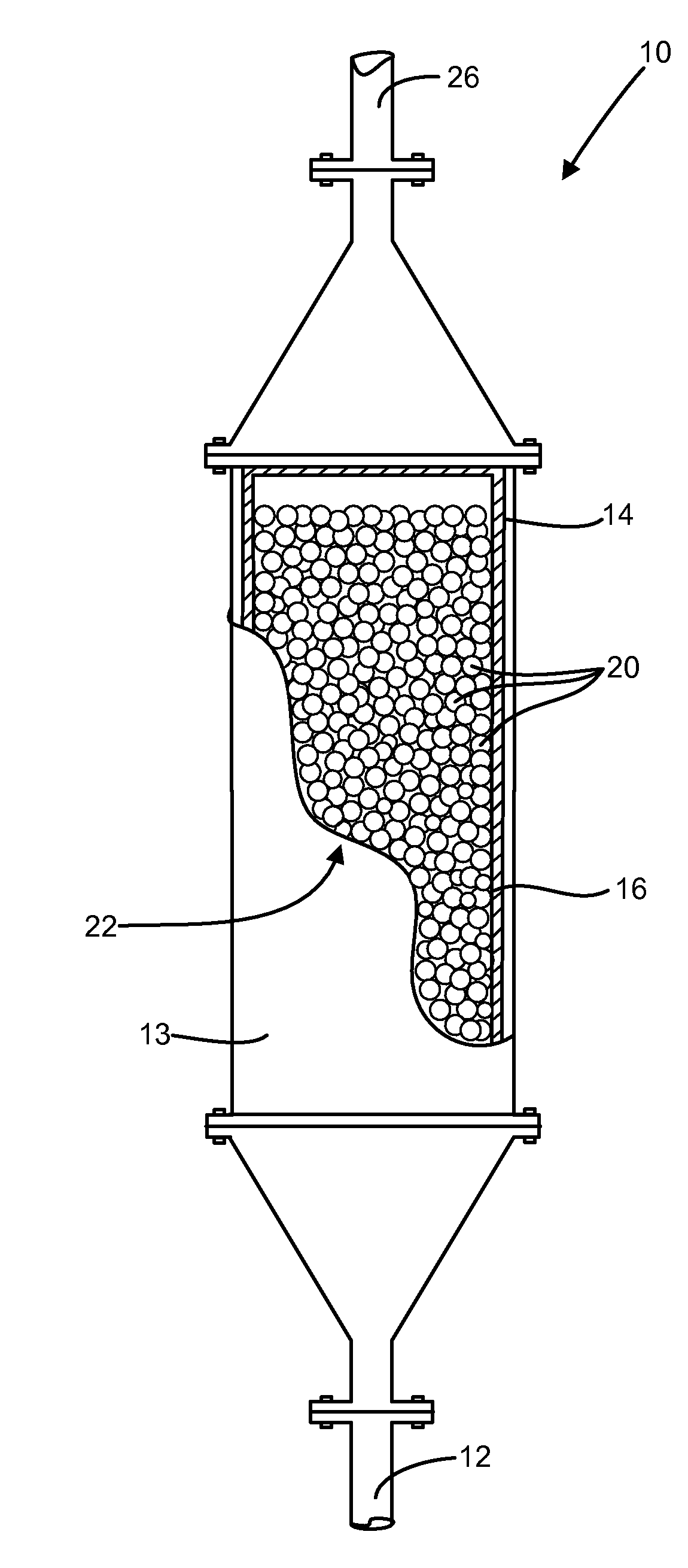

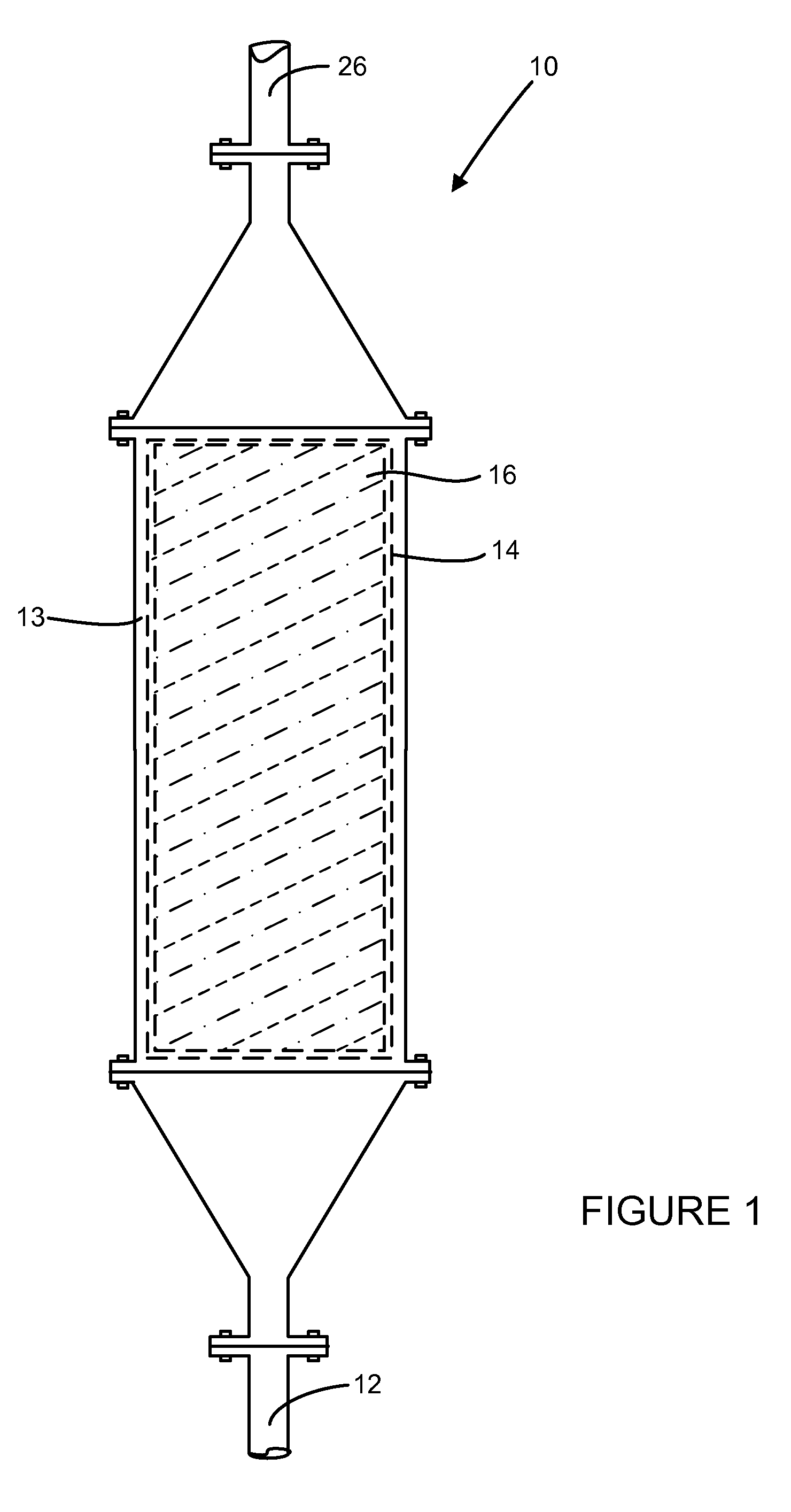

ActiveUS20090081093A1Reduce pollutionReduce the amount requiredCombination devicesCyanogen compoundsSlagSolid particle

The disclosure provides methods and systems for sequestering and / or reducing sulfur oxides, nitrogen oxides and / or carbon dioxide present in industrial effluent fluid streams. A solid particulate material comprising a slag component, a binder component (distinct from the slag component), and optionally water is formed and then contacted with the effluent fluid stream to reduce at least one of the sulfur oxides, nitrogen oxides, and / or carbon dioxide. The contacting of the effluent stream may occur in a packed bed reactor with the solid dry particulate material. Methods of reducing pollutants from exhaust generated by combustion sources, lime and / or cement kilns, iron and / or steel furnaces, and the like are provided.

Owner:C QUEST TECH

Control of rolling or moving average values of air pollution control emissions to a desired value

ActiveUS7113835B2Easy to planCombination devicesSolid sorbent liquid separationMoving averageEngineering

A controller directs performance of a process having multiple process parameters (MPPs), including a controllable process parameter (CTPP), a targeted process parameter (TPP), a defined target value (DTV) representing a limit on an actual average value (AAV) of the TPP over a defined moving time period of length TPLAAV. A storage device stores historical data representing the AVs of the TPP at various times over a prior time period (PTP) having a length of at least TPLAAV. A processor predicts future average values (FAVs) of the TPP over a future time period (FTP) based on the stored historical data and the current values of the MPPs. The processor also determines a target set point for each CTPP based on the predicted FAVs, the current values of the MPPs and the DTV, and directs control of each CTPP in accordance with the determined target set point for that CTPP.

Owner:GENERAL ELECTRIC TECH GMBH

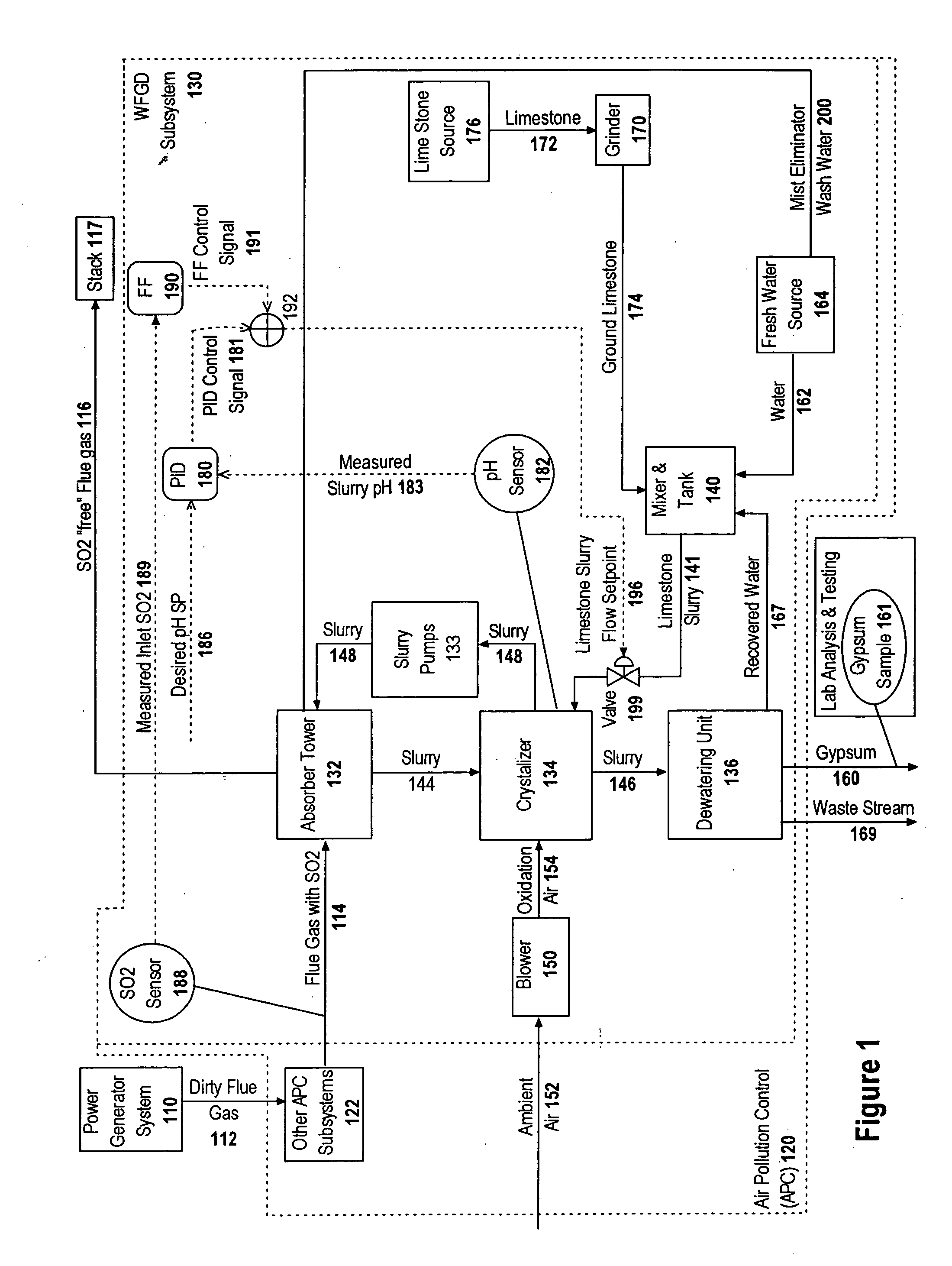

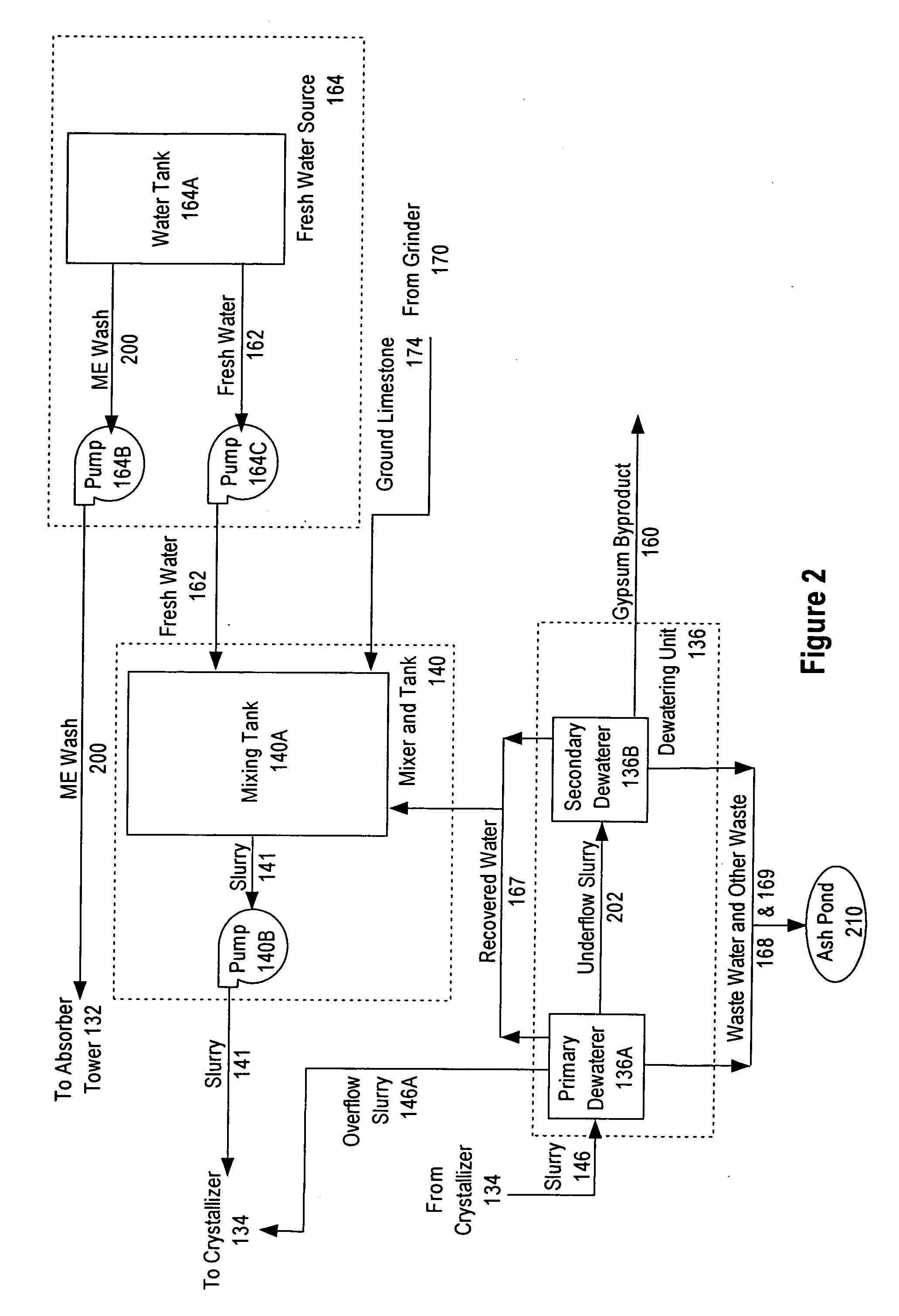

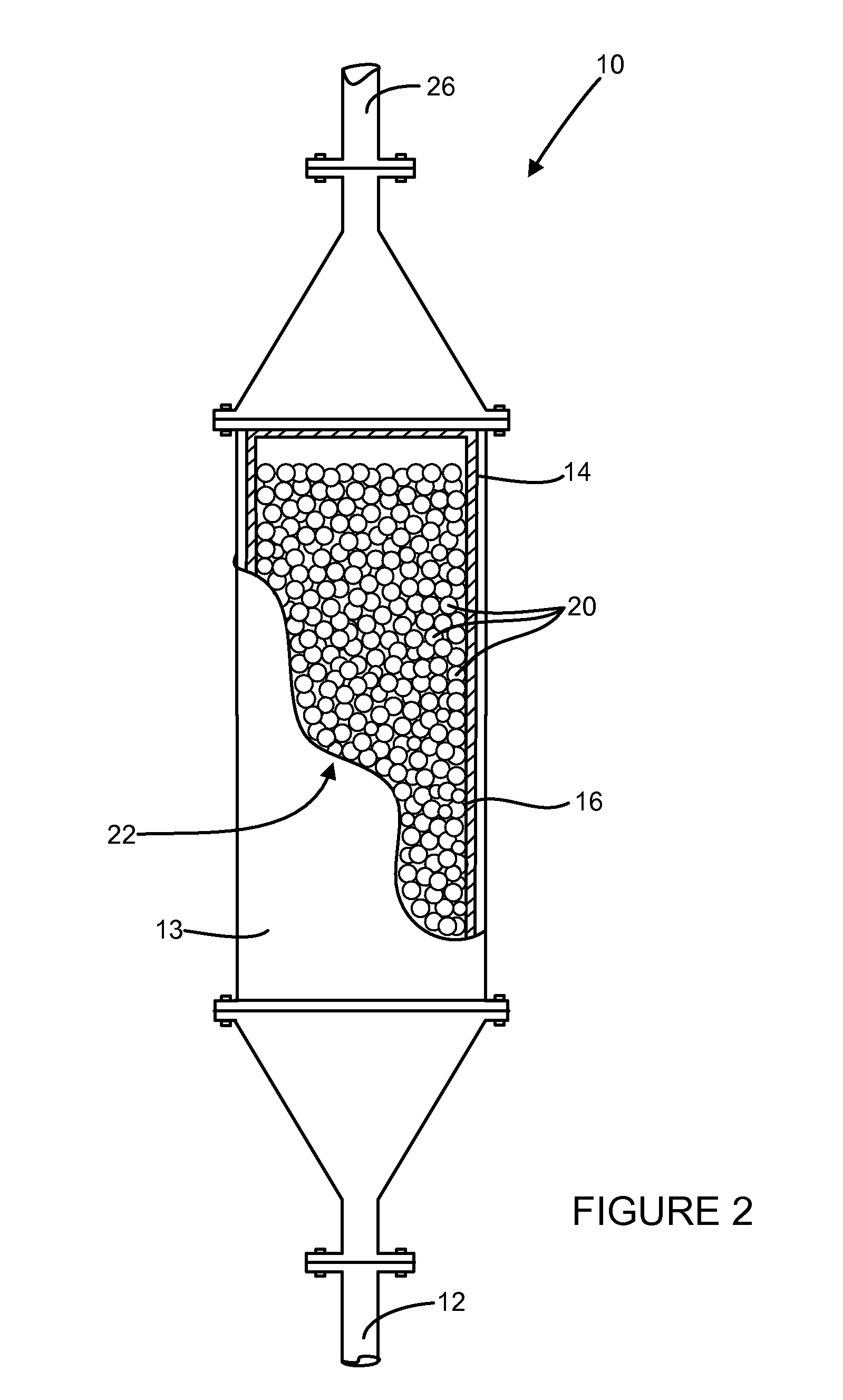

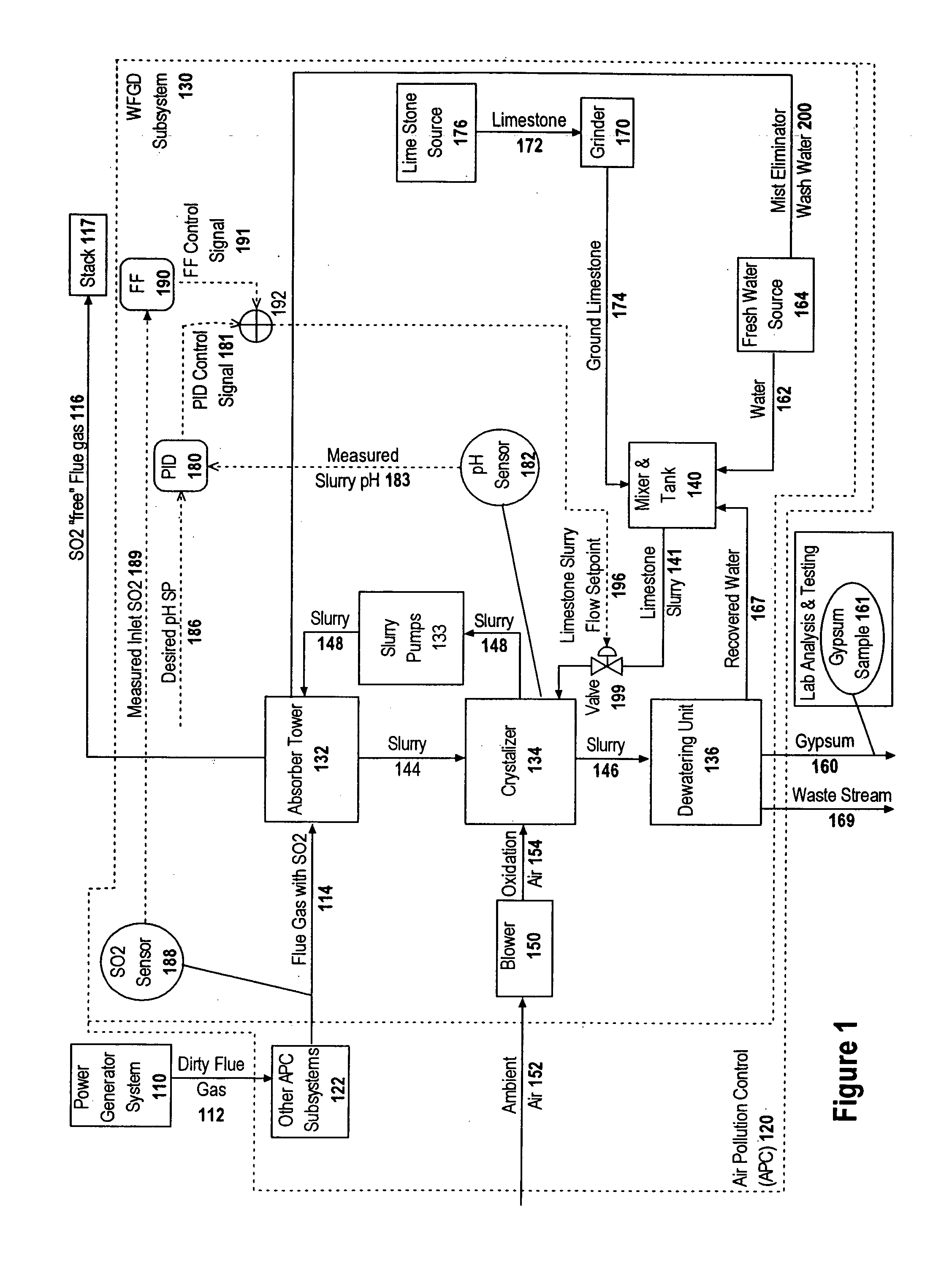

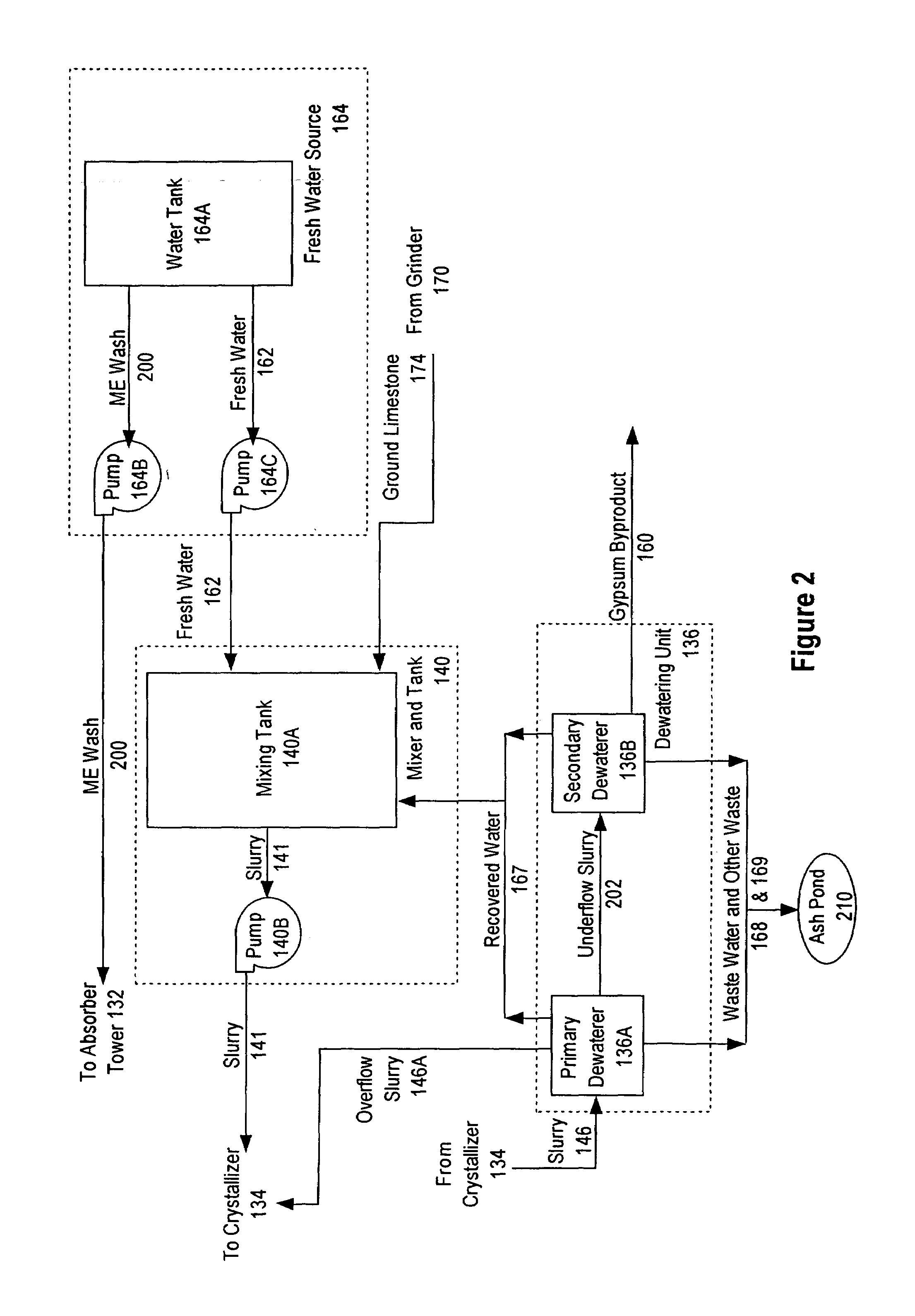

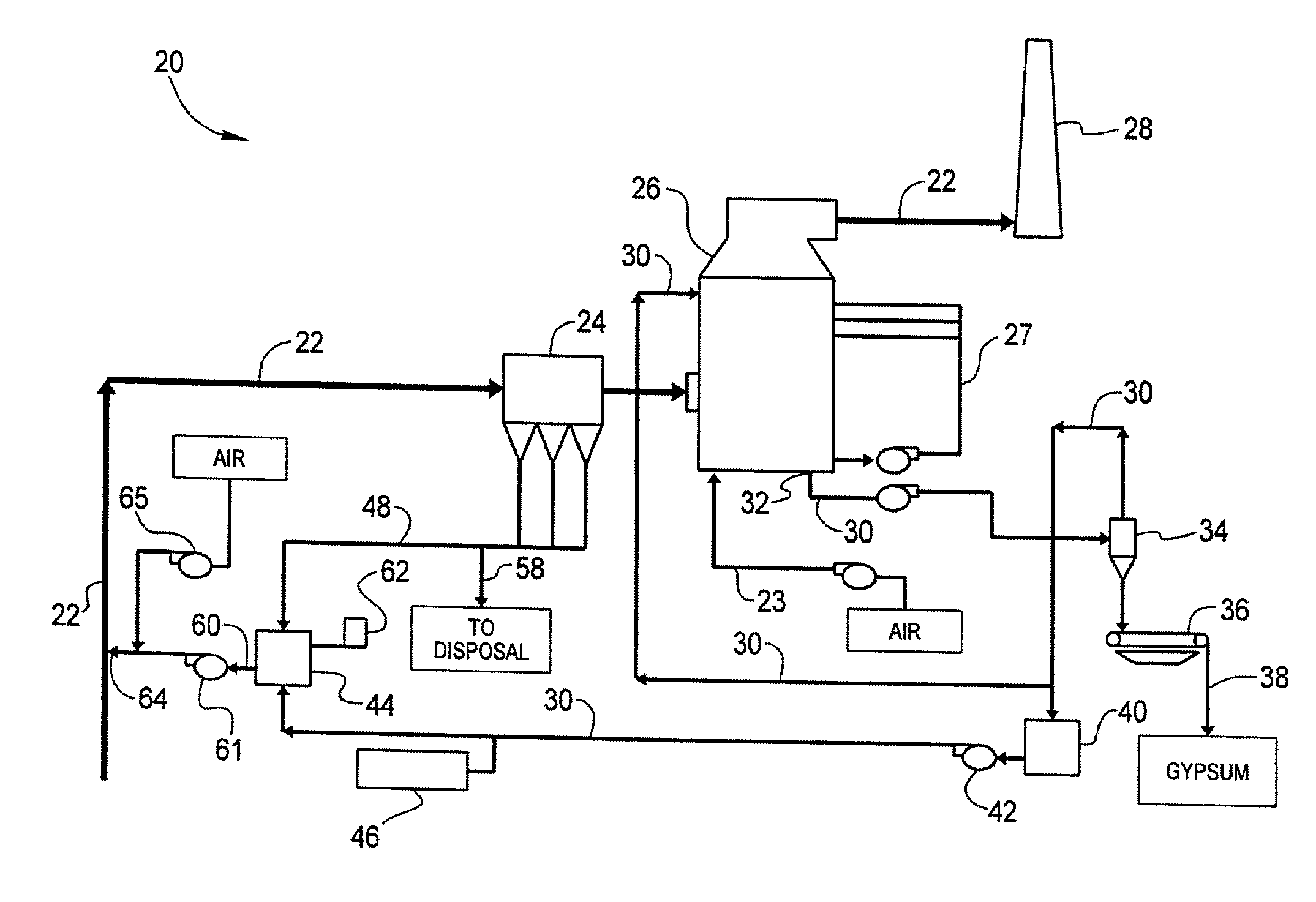

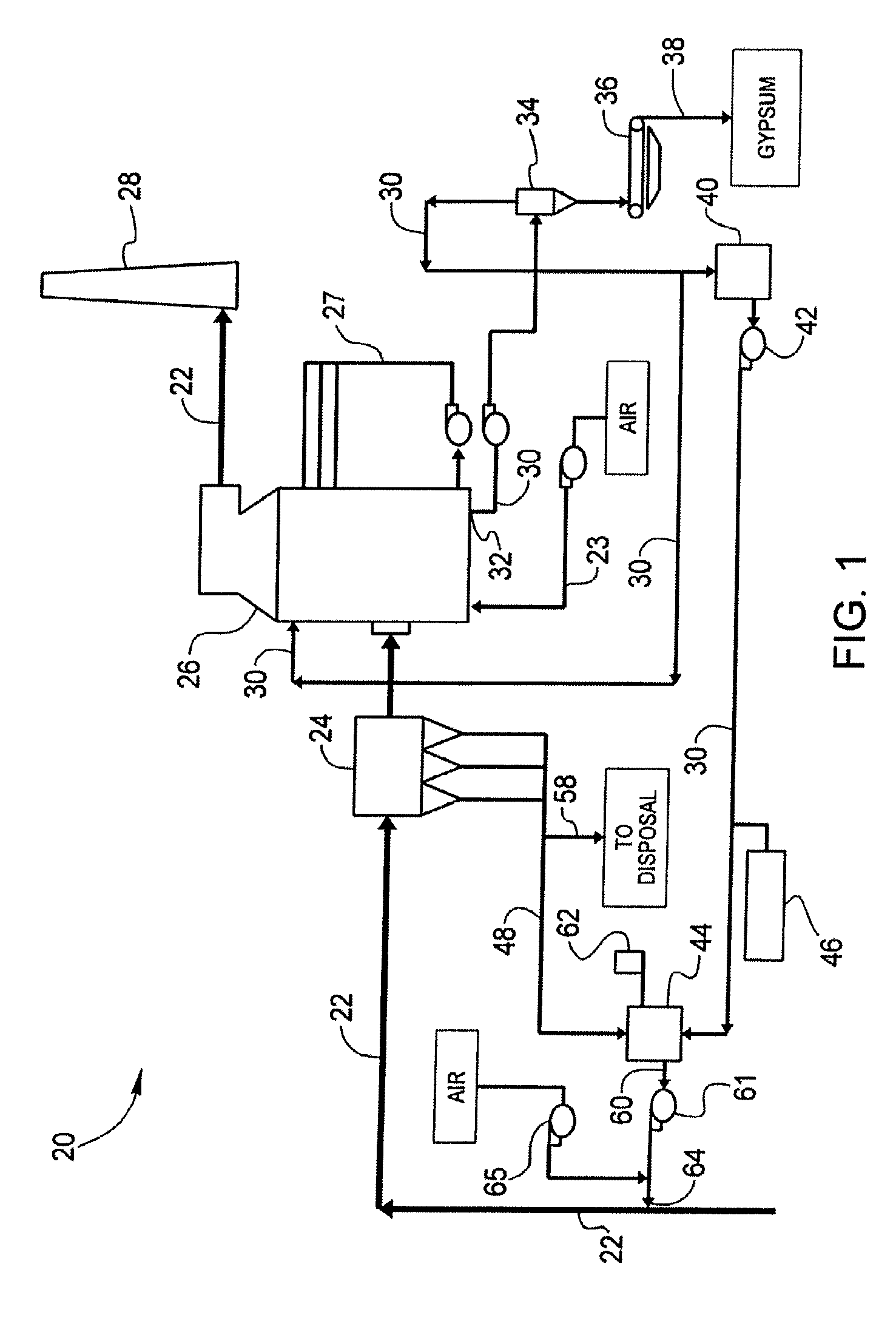

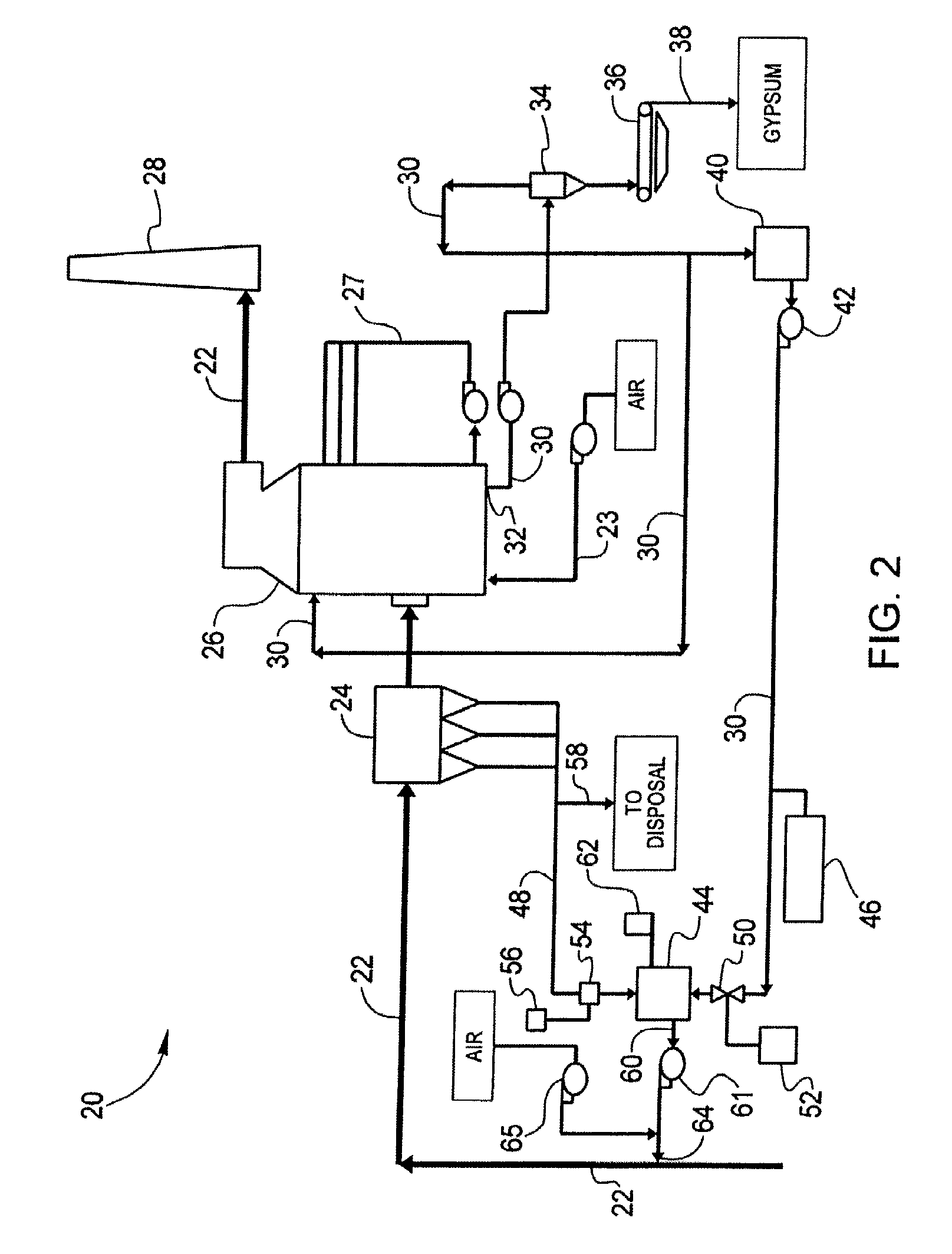

Reduced liquid discharge in wet flue gas desulfurization

One aspect of the invention relates to a method for removing contaminants from a flue gas stream (22). The method includes: removing fly ash from a flue gas stream (22) utilizing a particle collector (24); contacting the flue gas stream with an alkaline reagent in a wet scrubber (26); discharging a purge liquid (30) from the wet scrubber (26); and, combining at least a portion of the purge liquid with at least a portion of fly ash circulating within a dry circulating fluid bed scrubber (48) to form moistened fly ash (60).

Owner:GENERAL ELECTRIC TECH GMBH

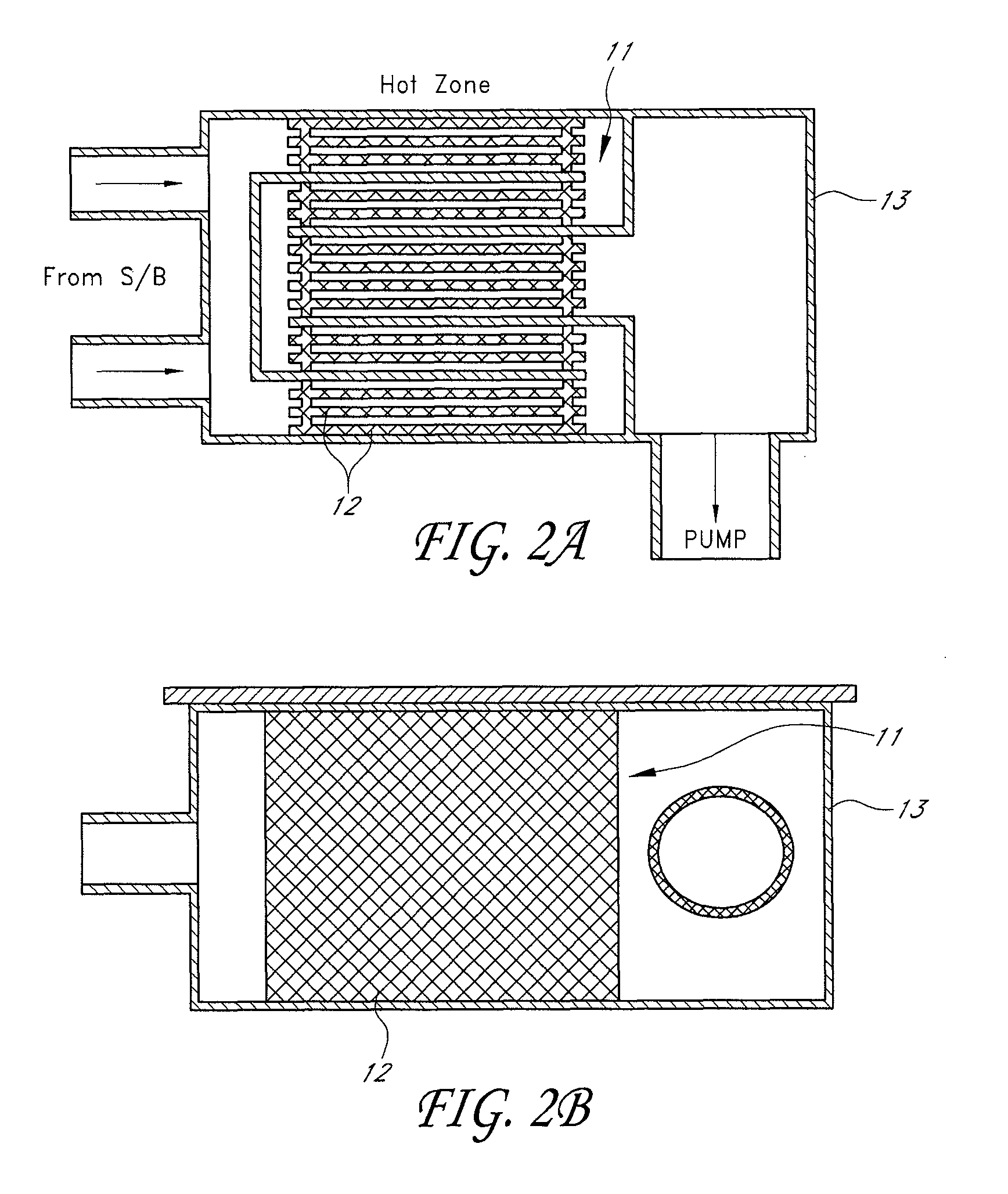

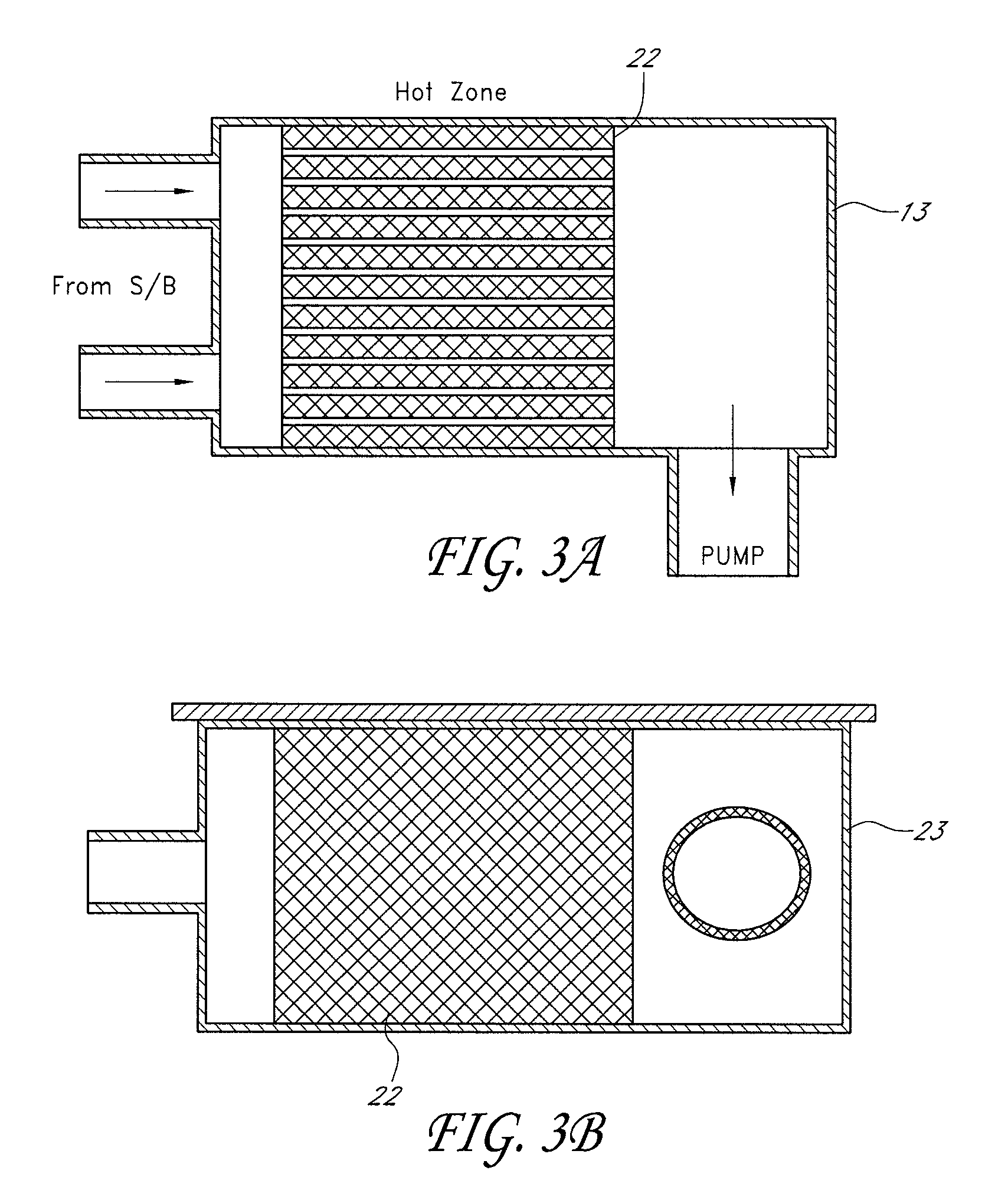

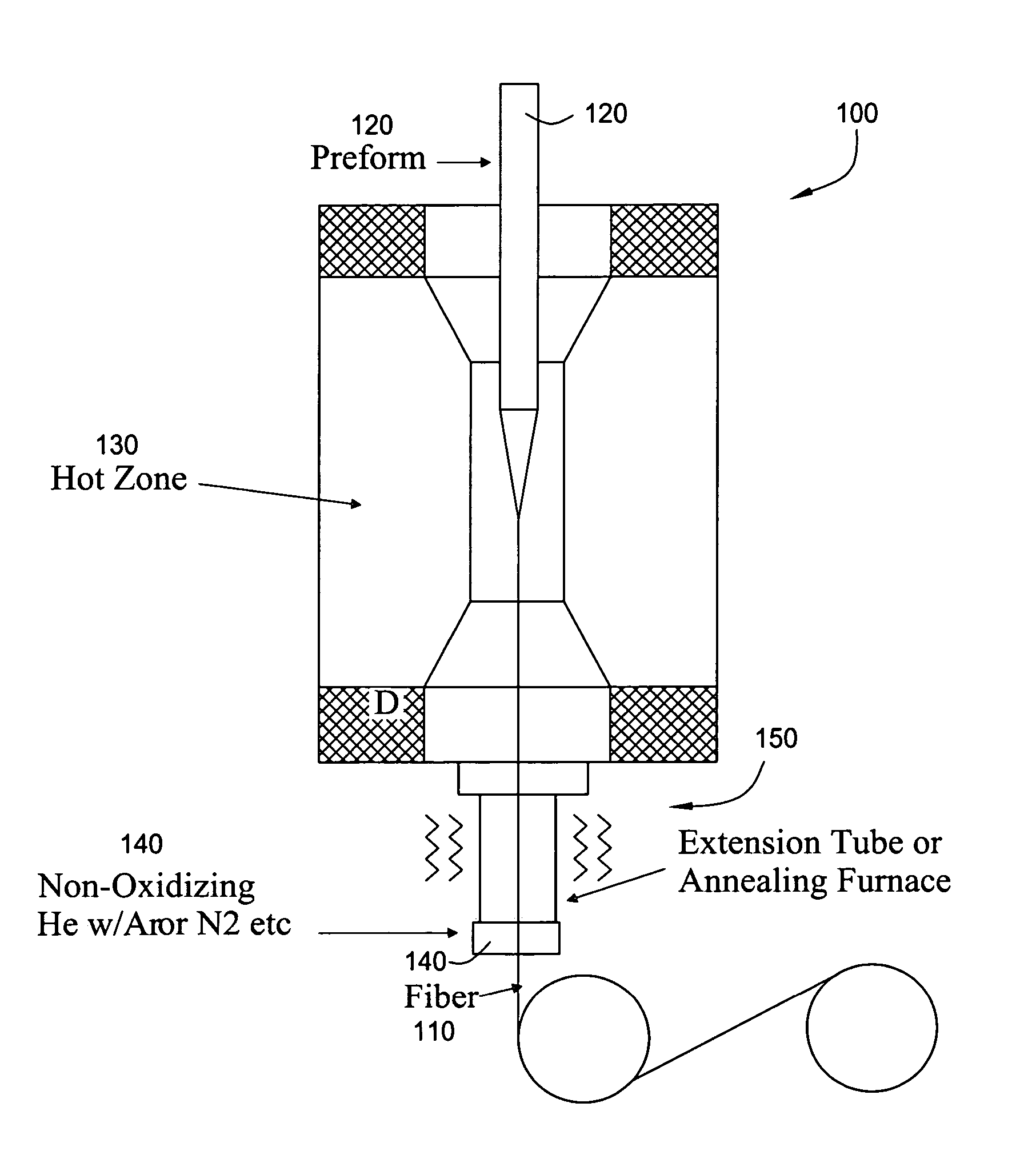

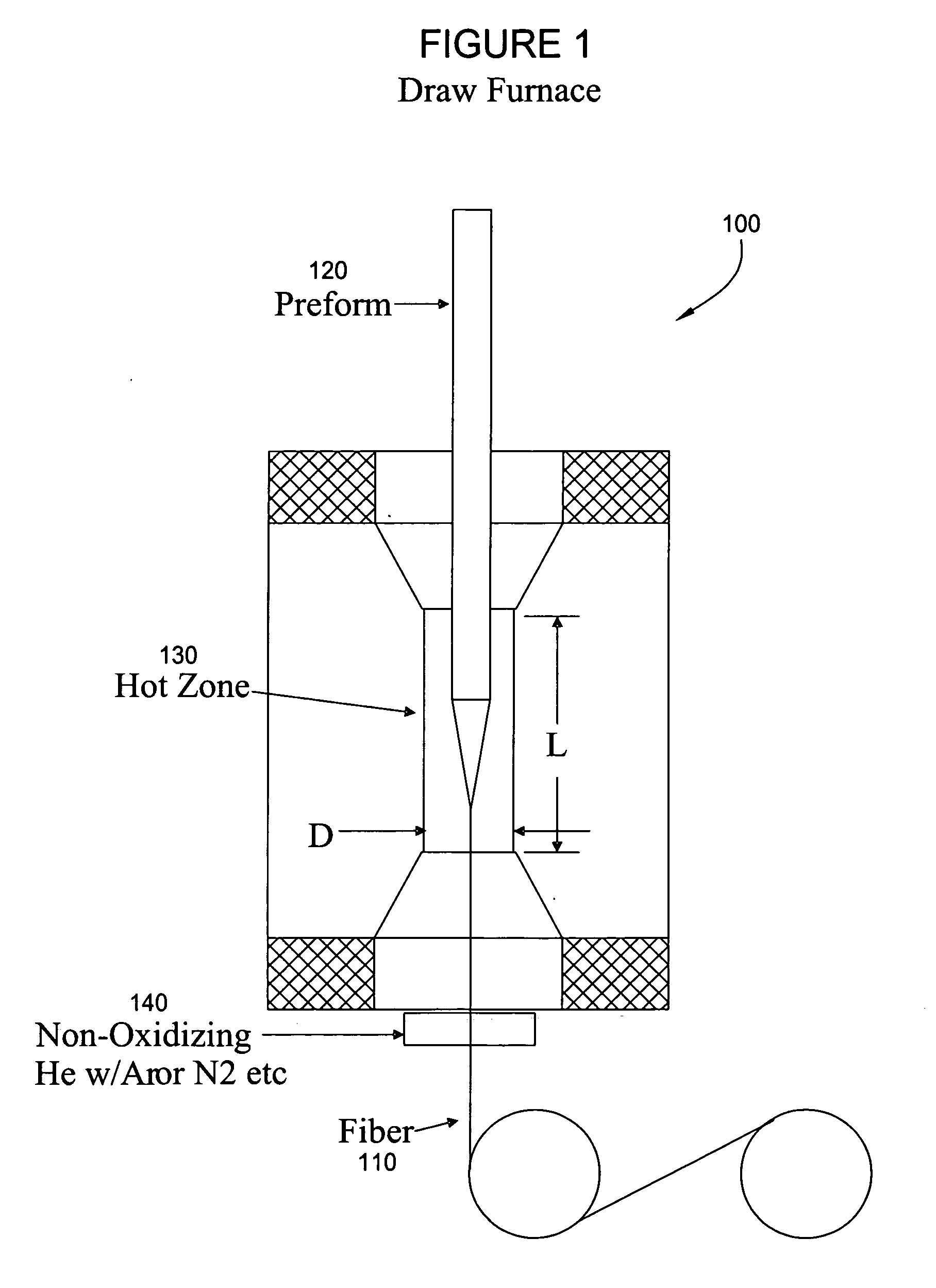

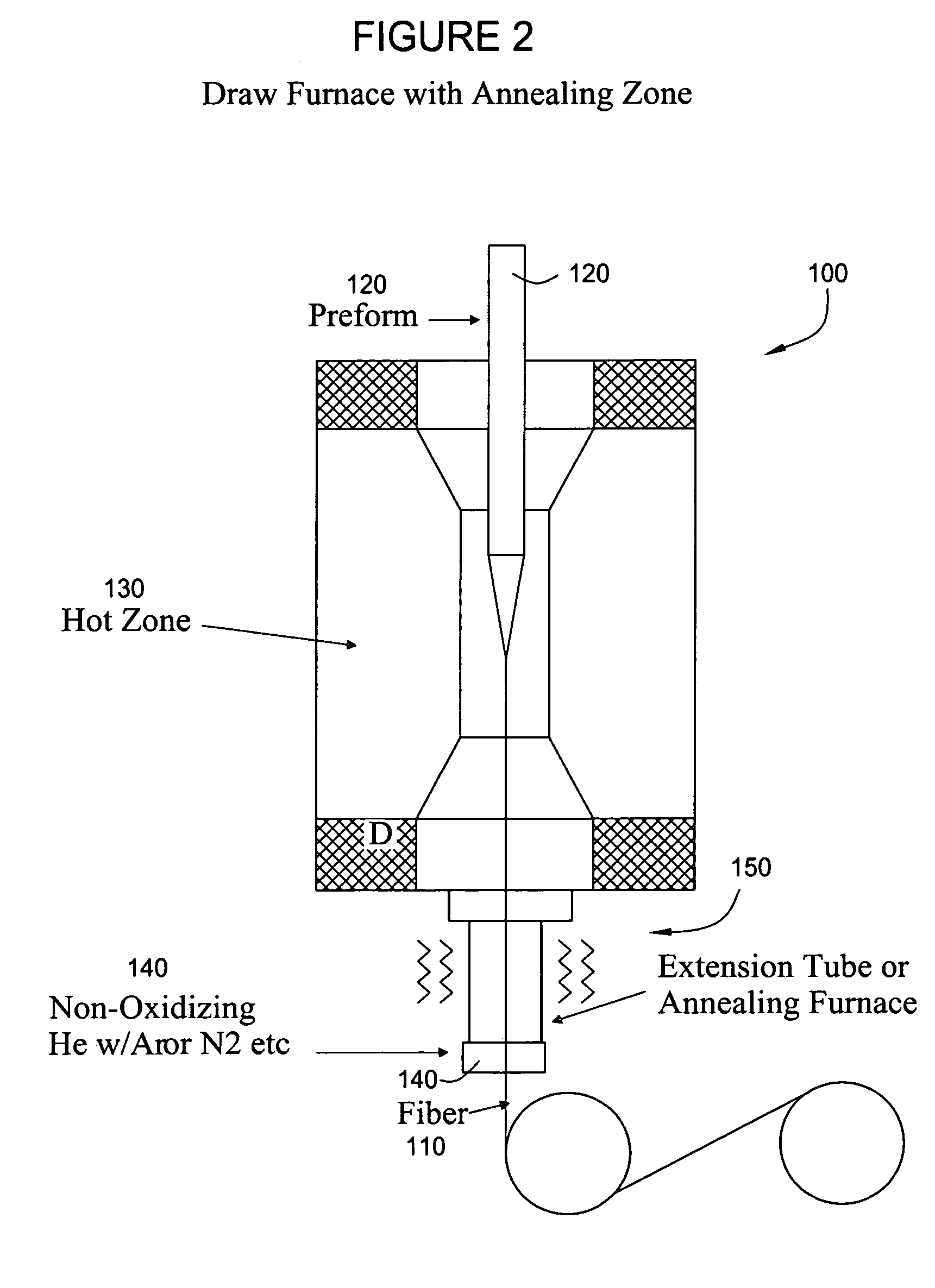

Furnace and process for drawing radiation resistant optical fiber

Apparatus and methods to fabricate a radiation hardened optical fiber from a preform are provided. Various parameters affecting the draw process are controlled to optimize the radiation resistance of the resulting fiber. An annealing zone may be provided to allow a drawn fiber exiting a primary hot zone to undergo an annealing process which may increase radiation resistance.

Owner:WEATHERFORDLAMB

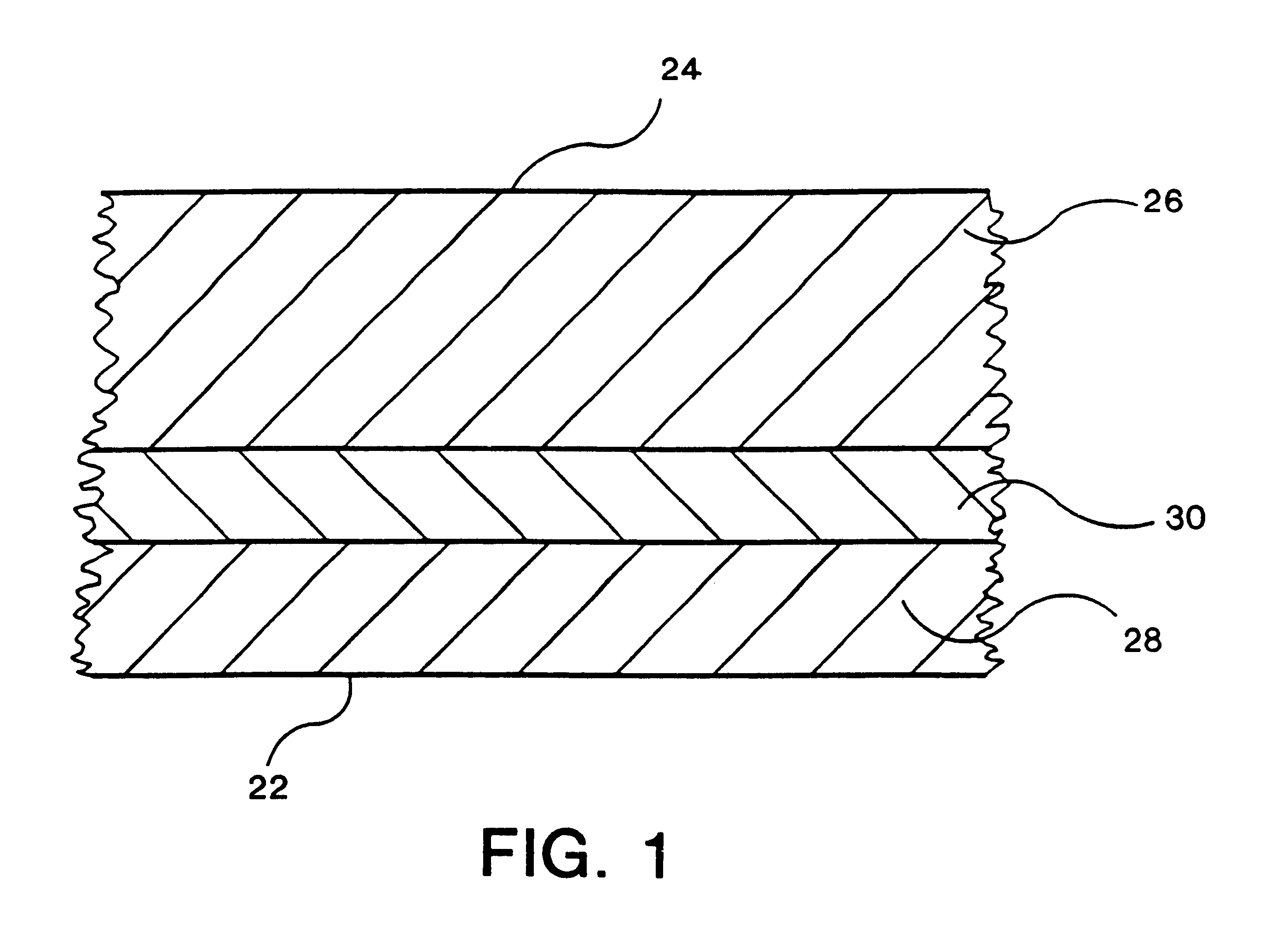

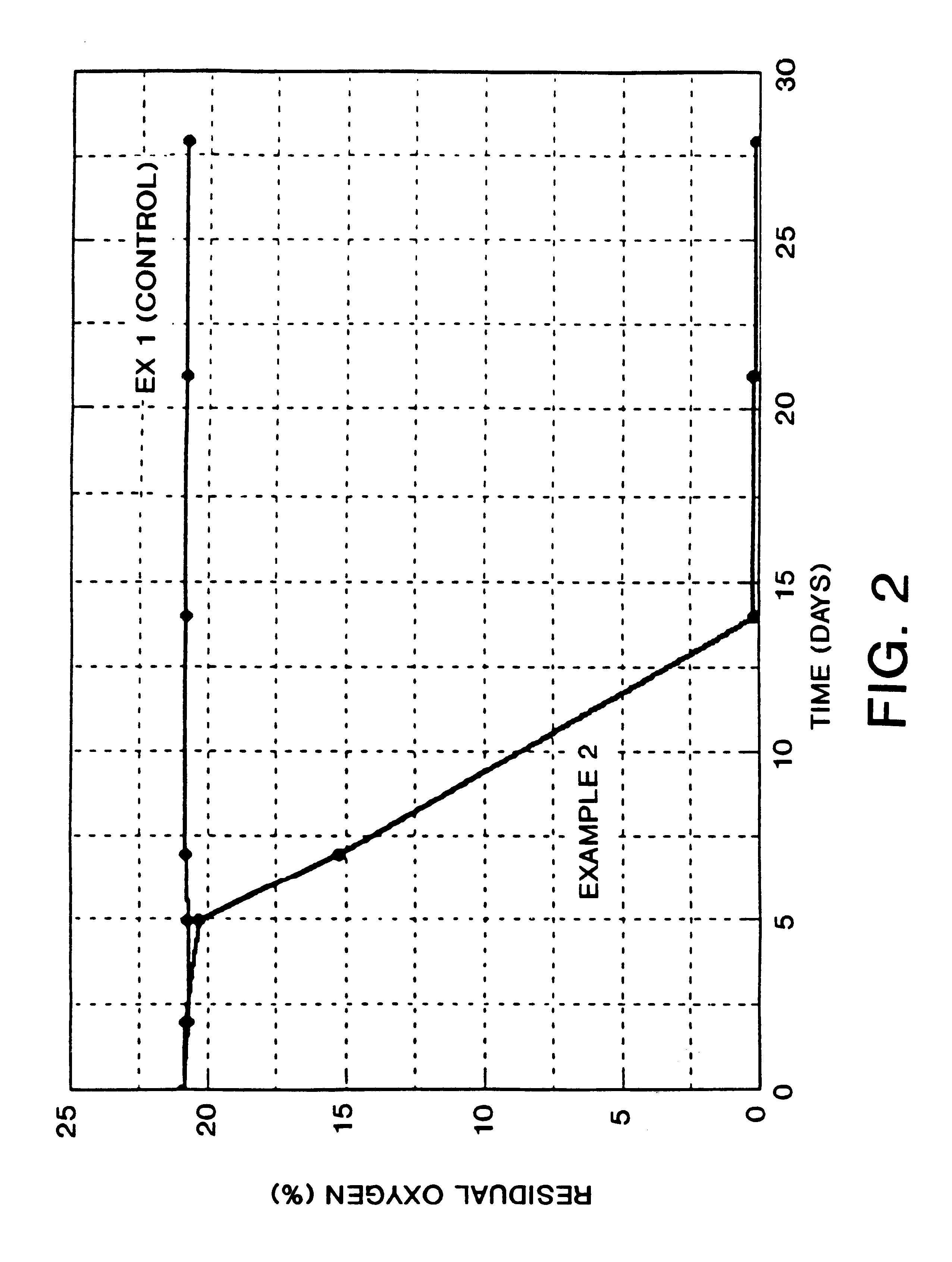

Active oxygen scavenger compositions and their use in packaging articles

Active oxygen scavenging compositions and their use in packaging articles are disclosed. The compositions are all plastic materials and are typically deployed as at least one layer in a multi-layered wall of a packaging article such as a bottle, can or film. The compositions are usually used in conjunction with added transition metal catalyst to enhance the uptake of oxygen. Use of the compositions and package constructions disclosed serves to lengthen the shelf life of packaged oxygen sensitive substances and / or diminish the need for refrigeration of the packages.

Owner:COLORMATRIX HLDG

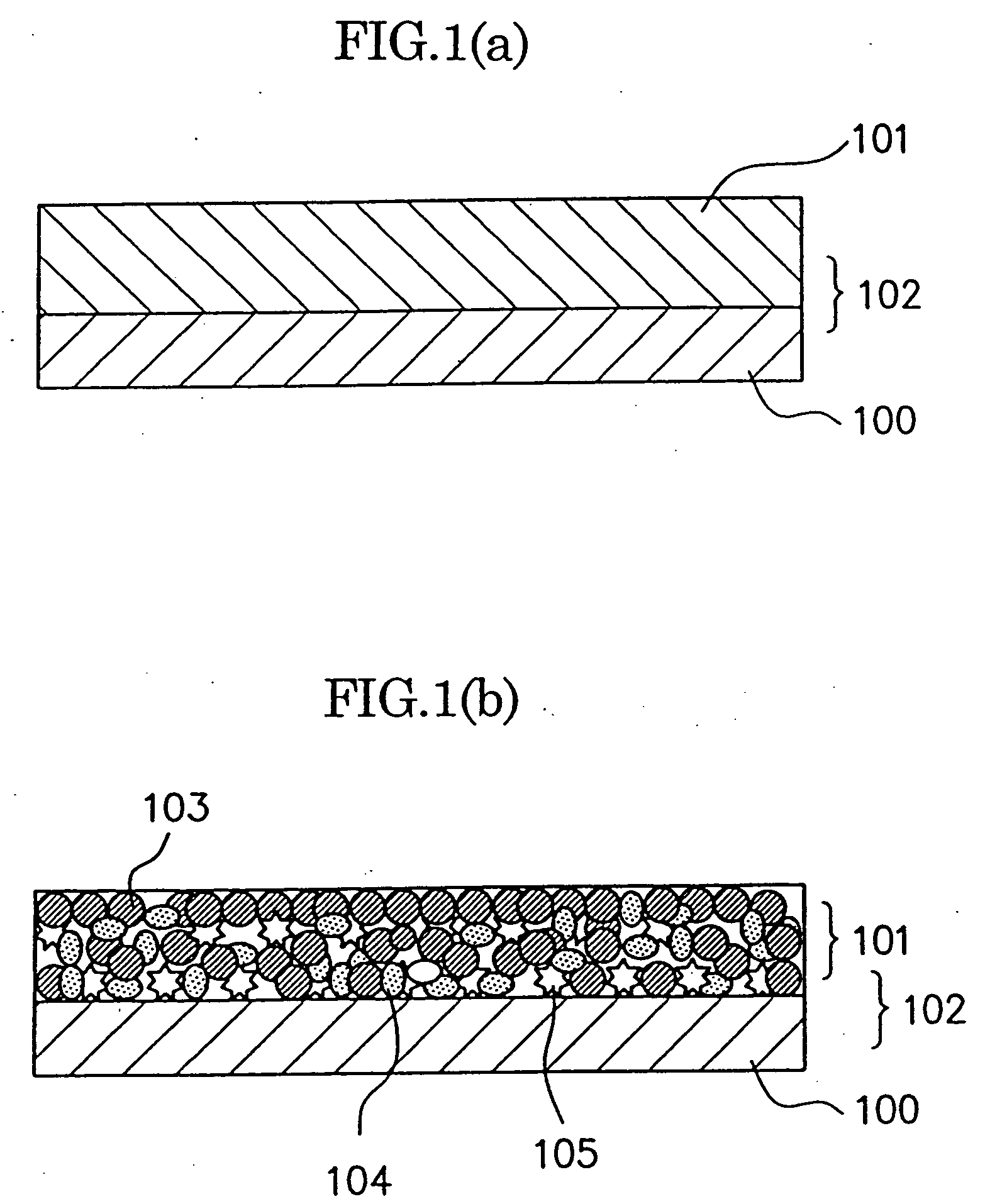

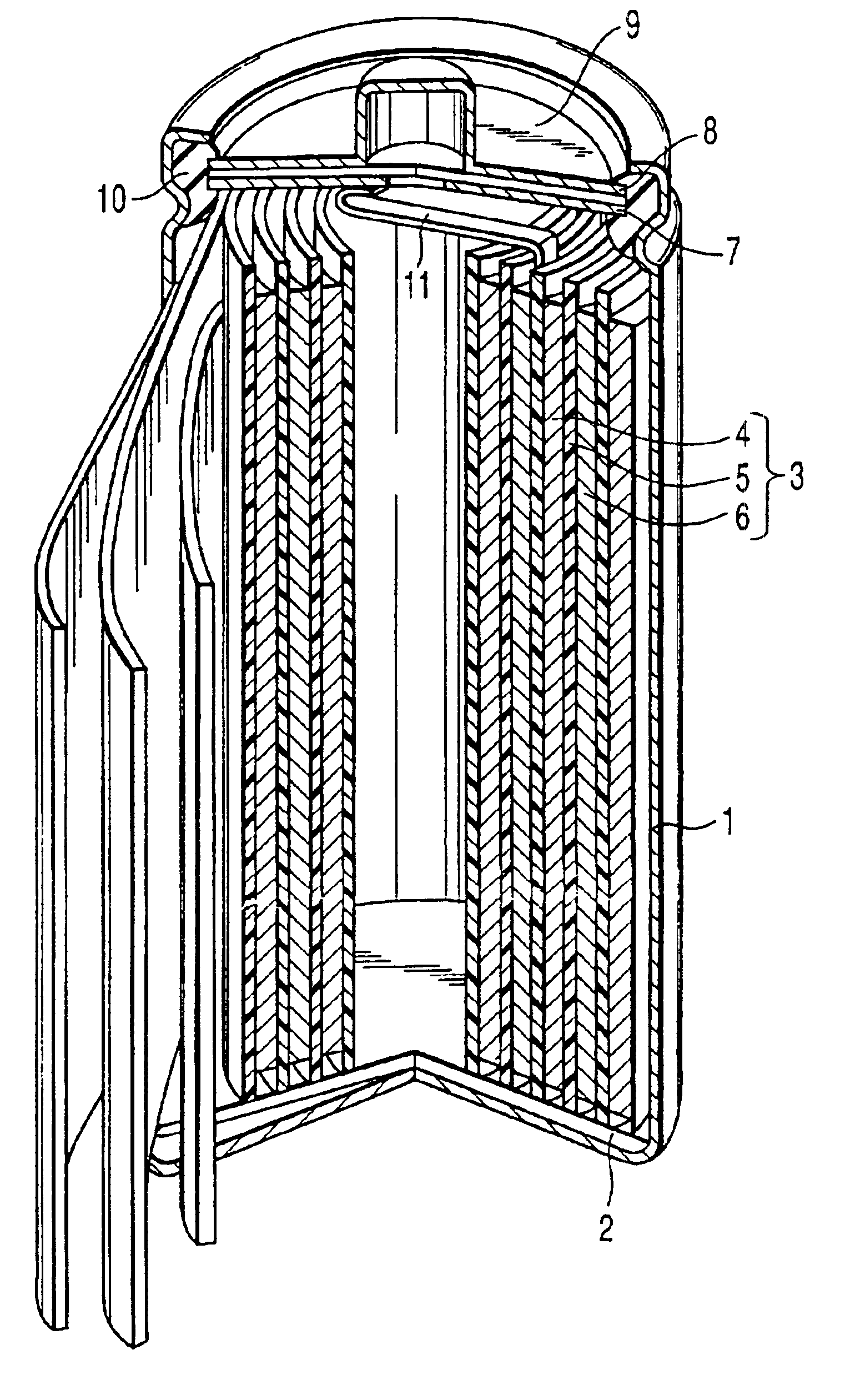

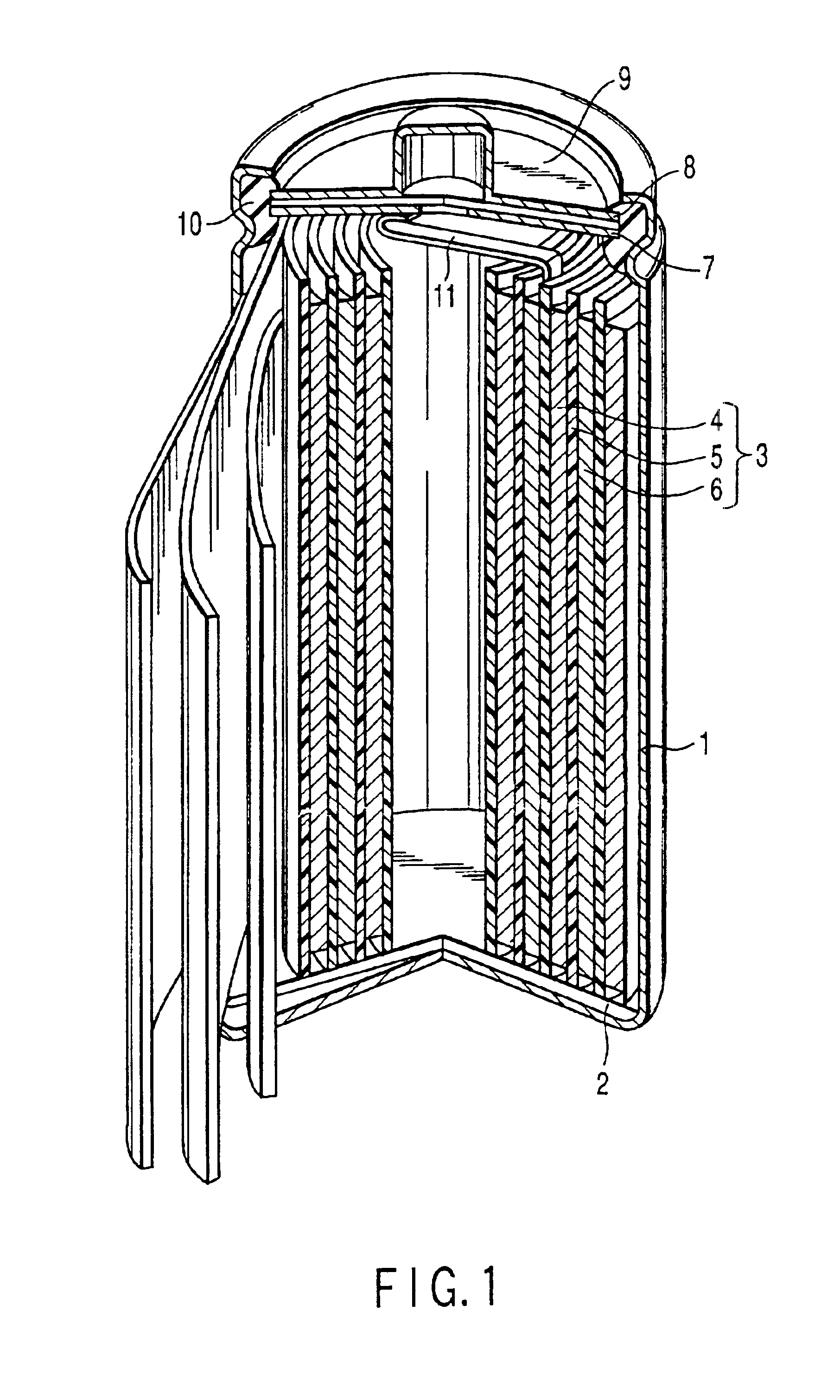

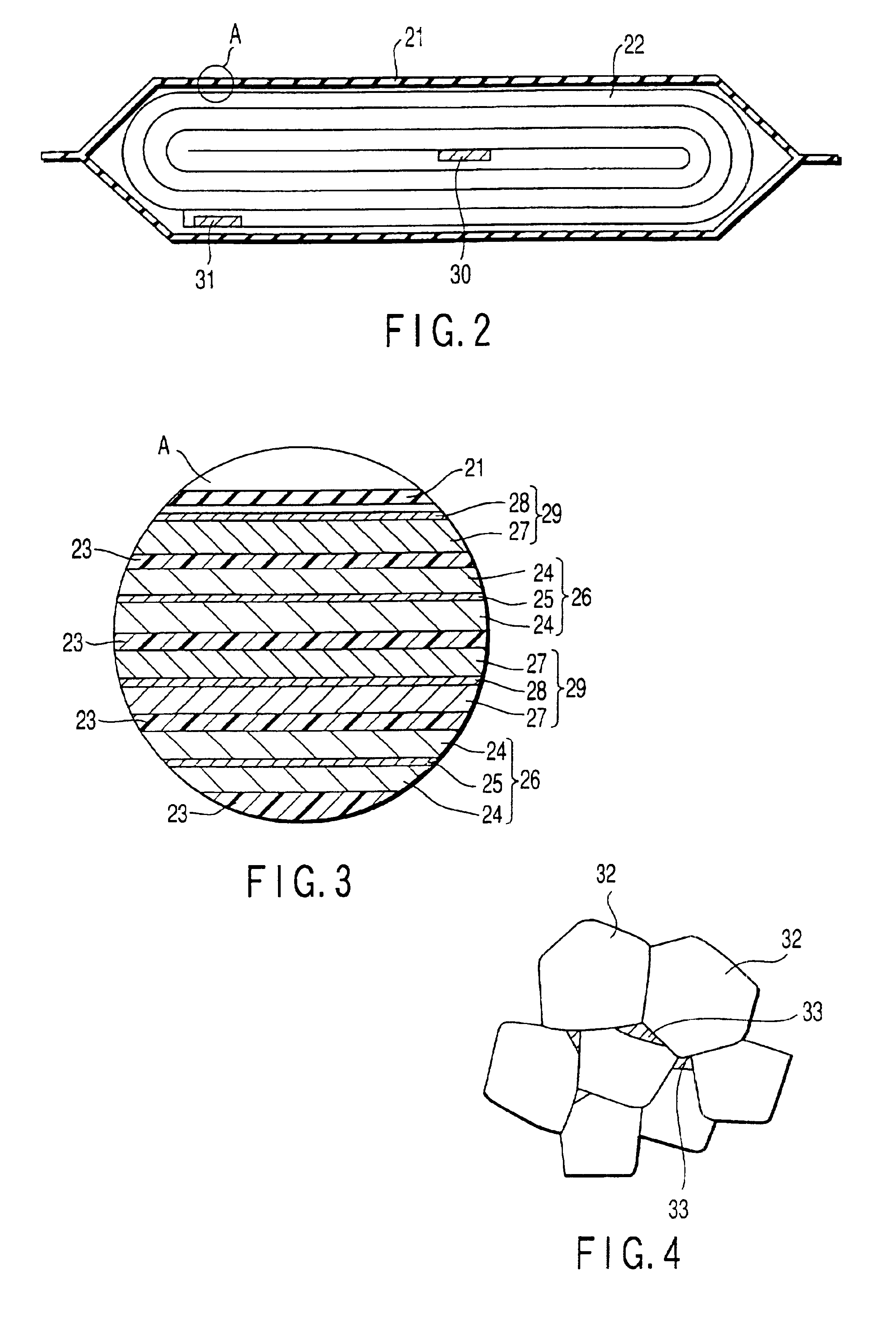

Electrode material for anode of rechargeable lithium battery, electrode structural body using said electrode material, rechargeable lithium battery using said electrode structural body, process for producing said electrode structural body, and process for producing said rechargeable lithium battery

InactiveUS20050175901A1Prolonged discharging cycle lifeLarge capacityNitrogen compoundsSelenium/tellurium compundsElectrochemical responseParticulates

An electrode material for an anode of a rechargeable lithium battery, containing a particulate comprising an amorphous Sn.A.X alloy with a substantially non-stoichiometric ratio composition. For said formula Sn.A.X, A indicates at least one kind of an element selected from a group consisting of transition metal elements, X indicates at least one kind of an element selected from a group consisting of O, F, N, Mg, Ba, Sr, Ca, La, Ce, Si, Ge, C, P, B, Pb, Bi, Sb, Al, Ga, In, Tl, Zn, Be, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, As, Se, Te, Li and S, where the element X is not always necessary to be contained. The content of the constituent element Sn of the amorphous Sn.A.X alloy is Sn / (Sn+A+X)=20 to 80 atomic %. An electrode structural body for a rechargeable lithium battery, comprising said electrode material for an anode and a collector comprising a material incapable of being alloyed with lithium in electrochemical reaction, and a rechargeable lithium battery having an anode comprising said electrode structural body.

Owner:CANON KK

Reducing mercury emissions from the burning of coal

ActiveUS7758827B2Reduce waste disposal costsReduce concrete costsSolid waste managementUsing liquid separation agentCombustionHalogen

Sorbent components containing calcium, alumina, silica, and halogen are used in combination during coal combustion to produce environmental benefits. Sorbents are added to the coal ahead of combustion and / or are added into the flame or downstream of the flame, preferably at minimum temperatures to assure complete formation of the refractory structures that result in various advantages of the methods. When used together, the components ● reduce emissions of mercury and sulfur; ● reduce emissions of elemental and oxidized mercury; ● increase the efficiency of the coal burning process through de-slagging of boiler tubes; ● increase the level of Hg, As, Pb, and / or Cl in the coal ash; ● decrease the levels of leachable heavy metals (such as Hg) in the ash, preferably to levels below the detectable limits; and ● make a highly cementitious ash product.

Owner:NOX II LTD

Hydrated lim kiln dust recirculation method for gas scrubbing

ActiveUS20050031515A1Effectively self-cleaningEffective sorbentGas treatmentIsotope separationFlue gasSorbent

Owner:GRAYMONT PA INC

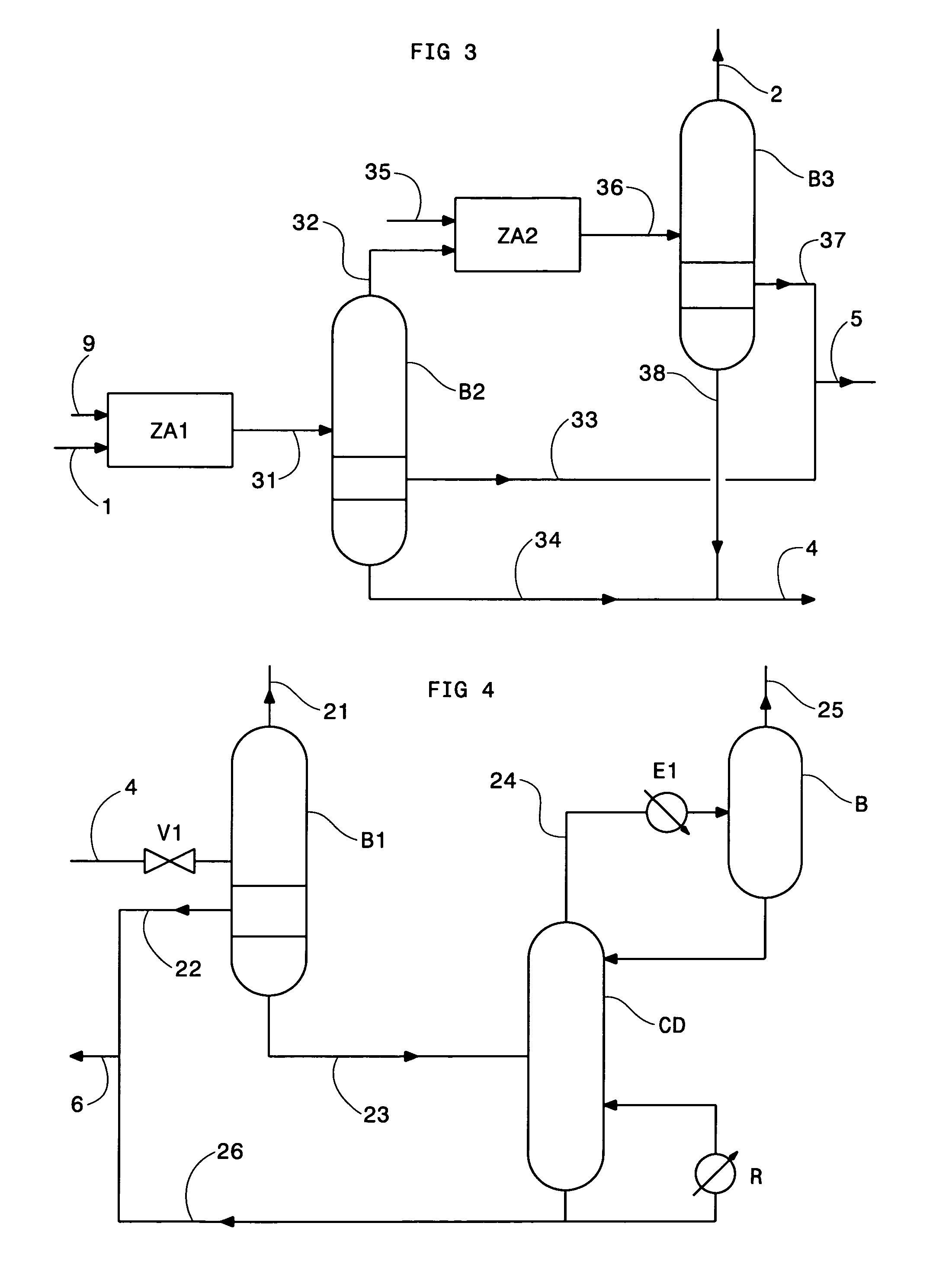

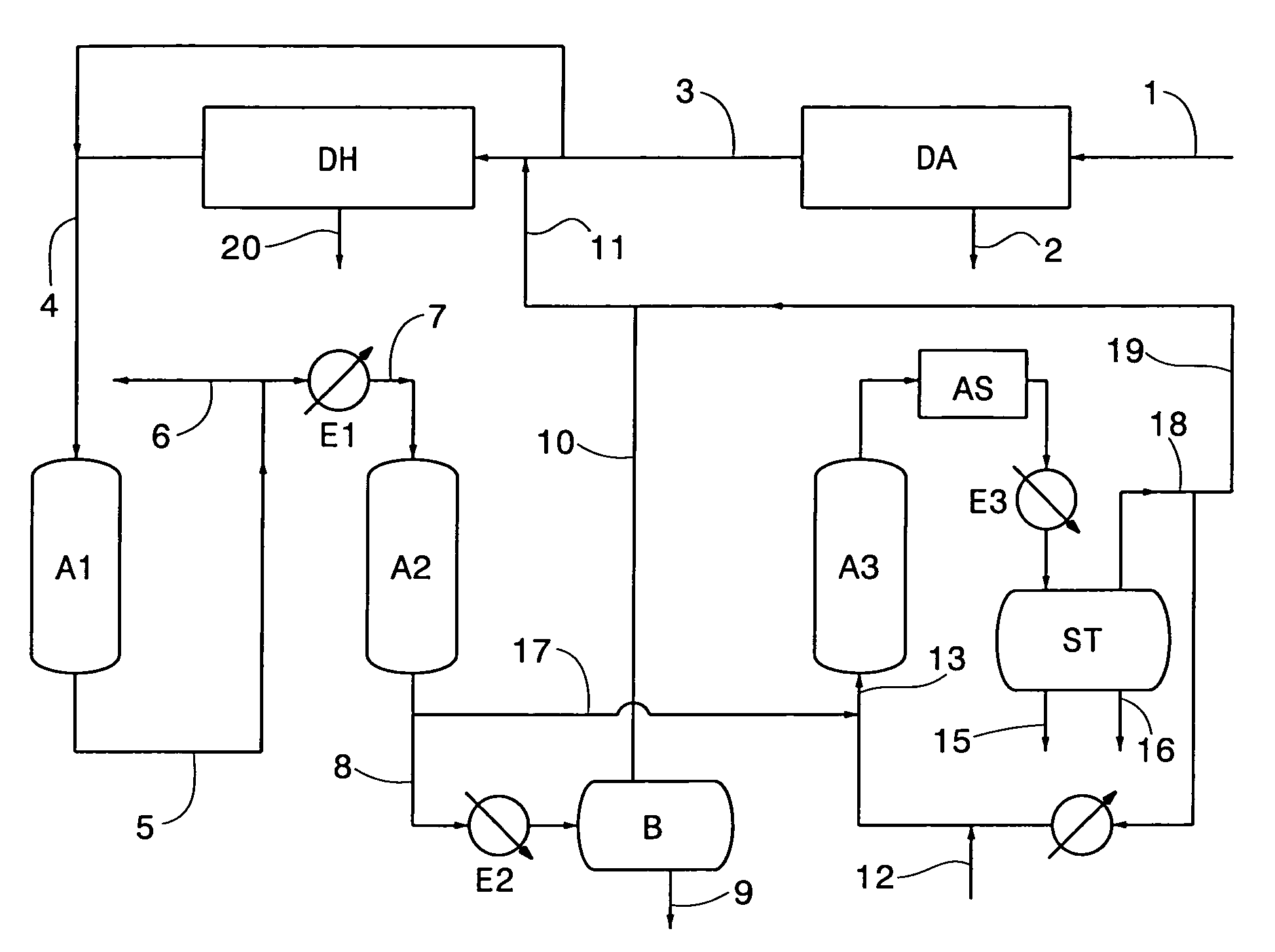

Method of purifying a natural gas by mercaptan adsorption

InactiveUS7449049B2Limit losses of purified natural gasHeavy hydrocarbon losses are minimizedGas treatmentUsing liquid separation agentThiolSorbent

The raw natural gas is deacidized and dehydrated in units DA and DH. The treated gas is then purified by adsorption of the mercaptans in first enclosure A1. Part of the purified gas is heated in E1, then fed into second enclosure A2 so as to discharge the water adsorbed by the adsorbent material contained in this second enclosure. A steam-rich stream is fed into third enclosure A3 containing a mercaptan-laden adsorbent material. In A3, the mercaptans are desorbed and replaced by the steam.

Owner:INST FR DU PETROLE

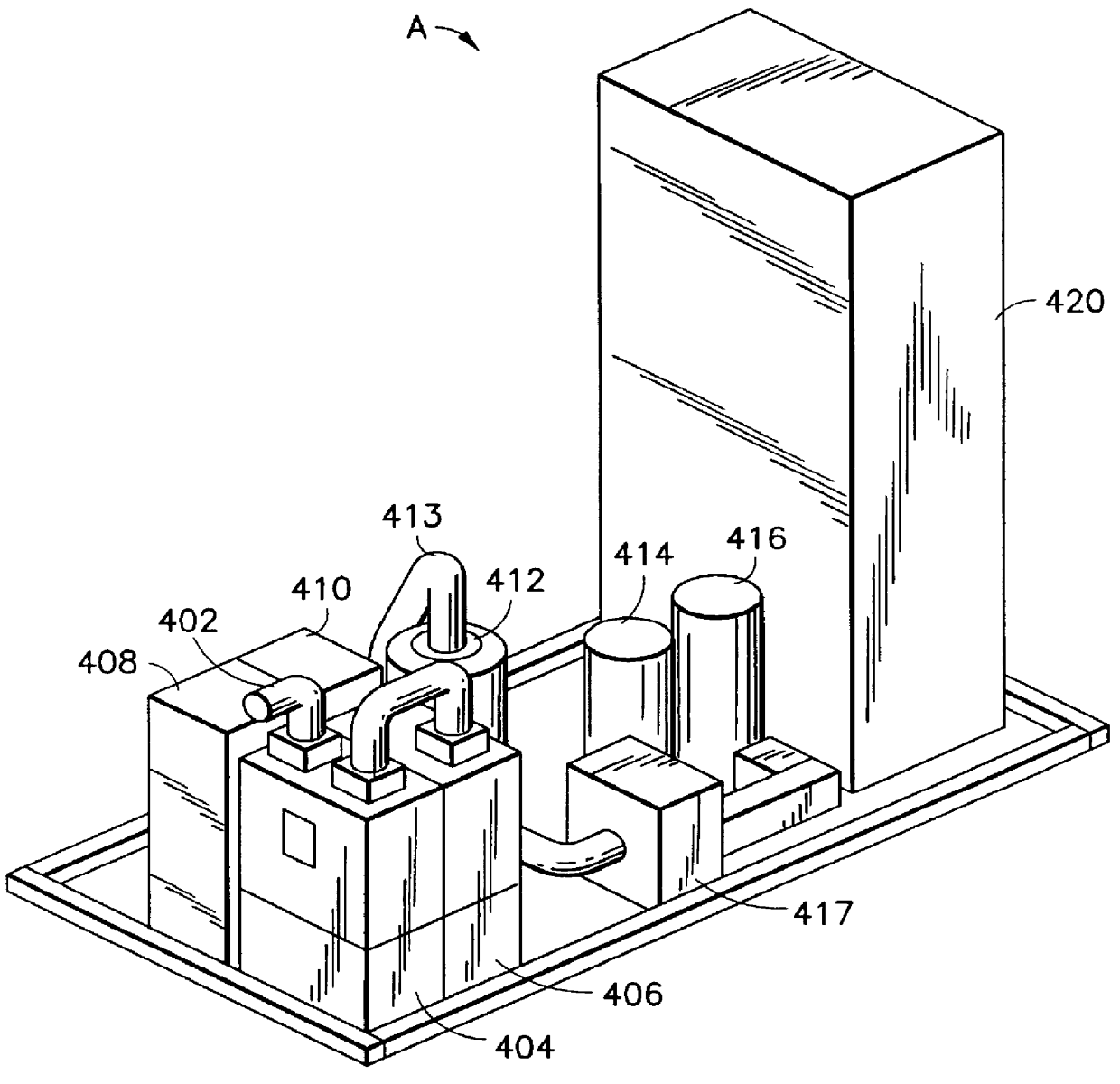

Method and apparatus for purifying a gas

The present invention provides for a method and apparatus for purifying carbon dioxide. Sulfur species and other impurities are removed from the carbon dioxide by a series of steps which include heater means, impurity adsorption means and catalysis means. Economical on-site analytical capabilities are also provided for by concentrating the impurities prior to their analysis.

Owner:BOC GRP INC

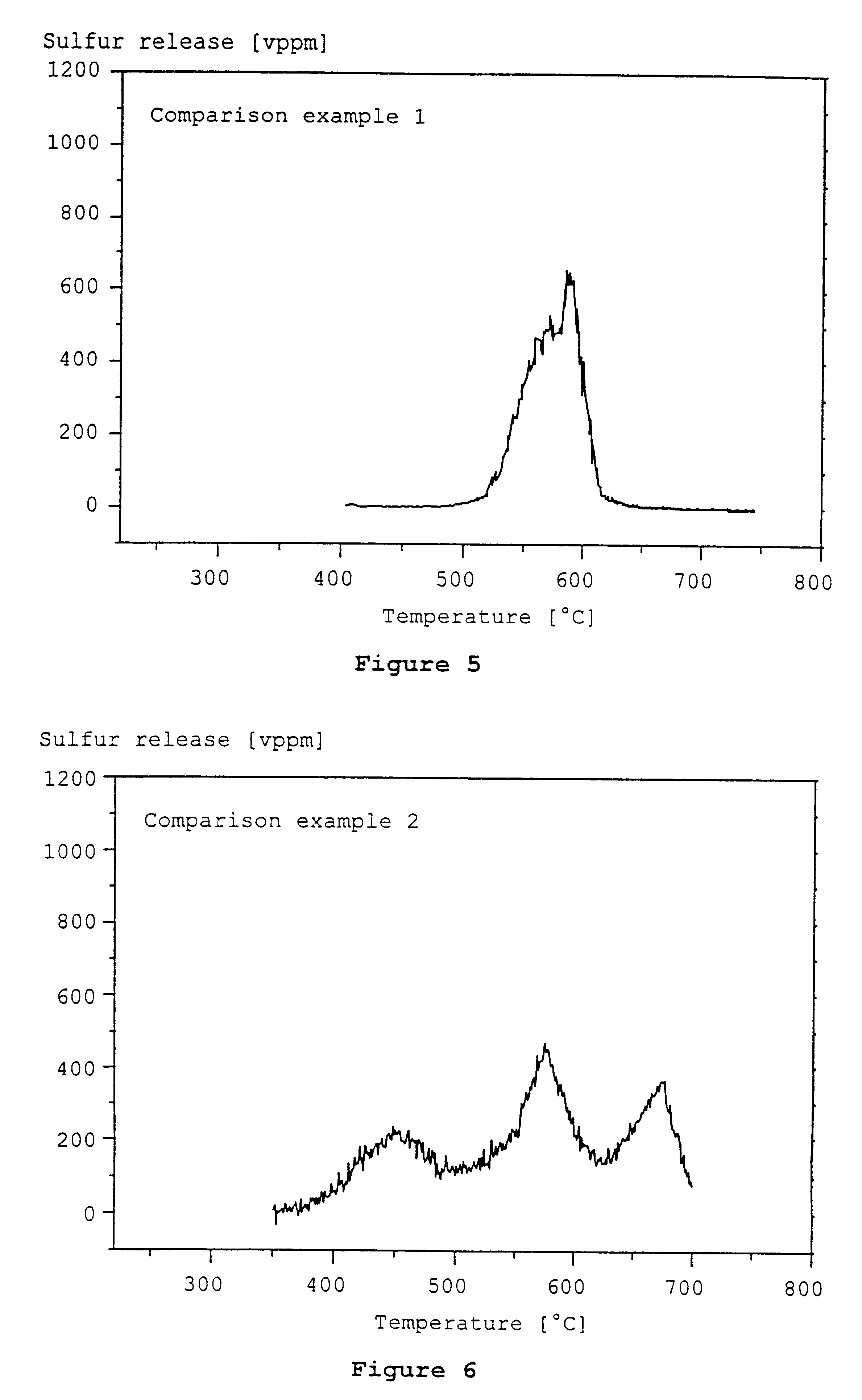

Storage material for sulfur oxides

InactiveUS6338831B1Improve the immunityRestores original storage capacityNitrogen compoundsExhaust apparatusOxygenInternal combustion engine

A sulfur oxide storage material contains a magnesium-aluminum spinel (MgO.Al2O3) and can be used as a so-called "sulfur trap" to remove sulfur oxides from oxygen-containing exhaust gases of industrial processes. In particular, it can be used for the catalytic purification of exhaust gas from internal-combustion engines to remove the sulfur oxides from the exhaust gas in order to protect the exhaust gas catalysts from sulfur poisoning. The material displays a molar ratio of magnesium oxide to aluminum oxide in the range of over 1.1:1, and the magnesium oxide present in stoichiometric excess is homogeneously distributed in a highly disperse form in the storage material.

Owner:DMC2 DEGUSSA METALS +1

Flue Gas Scrubbing

ActiveUS20110123422A1Reduce its mercury concentrationGas treatmentMolecular sieve catalystsCalcium hydroxideFlue gas

Herein is disclosed a flue gas scrubbing composition, a method of using the flue gas scrubbing composition, and a method of entombing mercury collected with the flue gas scrubbing composition. The flue gas scrubbing composition includes an admixture of a mercury sorbent material that comprises a clay, copper, and sulfur; and lime that comprises calcium oxide and / or calcium hydroxide. The method of collecting mercury from a flue gas includes injecting the flue gas scrubbing composition of any one of the preceding claims into a flue duct comprising the flue gas; reacting the mercury sorbent material with mercury in the flue gas to form a mercury-sorbed material and thereby reducing the concentration of mercury in the flue gas; reacting the lime with SO2, SO3, and / or HCl in the flue gas to form a calcium sulfate and / or a calcium chloride; and collecting a mixture that includes the mercury-sorbed material. The method of entombing mercury includes mixing the collected mixture of any one of claims 6 to 9 with water to form a freshly mixed concrete; and casting the freshly mixed concrete into a form.

Owner:AMCOL INTERNATIONAL CORPORATION

Positive electrode active material and lithium ion secondary battery

InactiveUS6872491B2Eliminate cracksLarge dischargeFluoride preparationFinal product manufactureStructural formulaComposite oxide

The present invention provides a positive electrode active material containing a composite oxide having a composition represented by a structural formula (1) given below:Lix(Ni1-yMe1y)(O2-zXz)+A (1)

Owner:KK TOSHIBA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com