Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

202 results about "Wet scrubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term wet scrubber describes a variety of devices that remove pollutants from a furnace flue gas or from other gas streams. In a wet scrubber, the polluted gas stream is brought into contact with the scrubbing liquid, by spraying it with the liquid, by forcing it through a pool of liquid, or by some other contact method, so as to remove the pollutants.

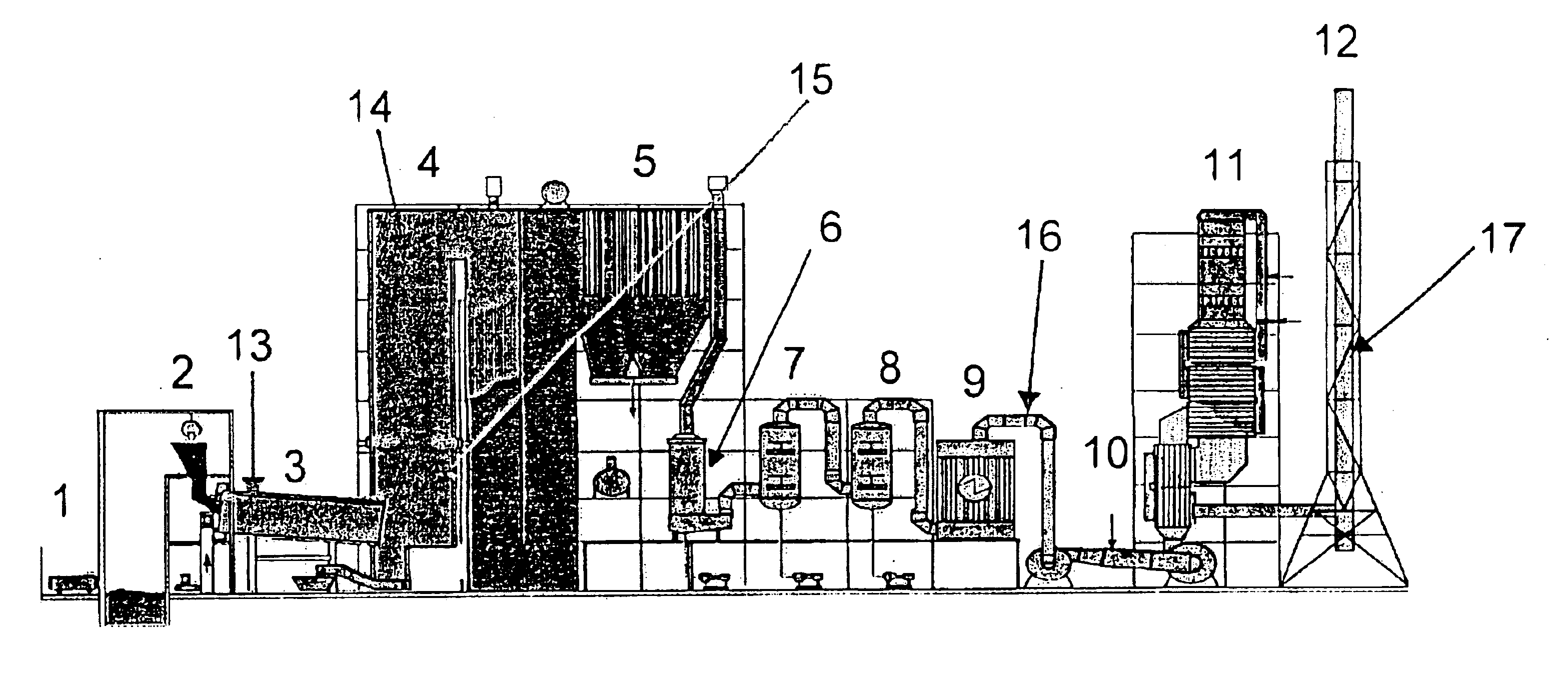

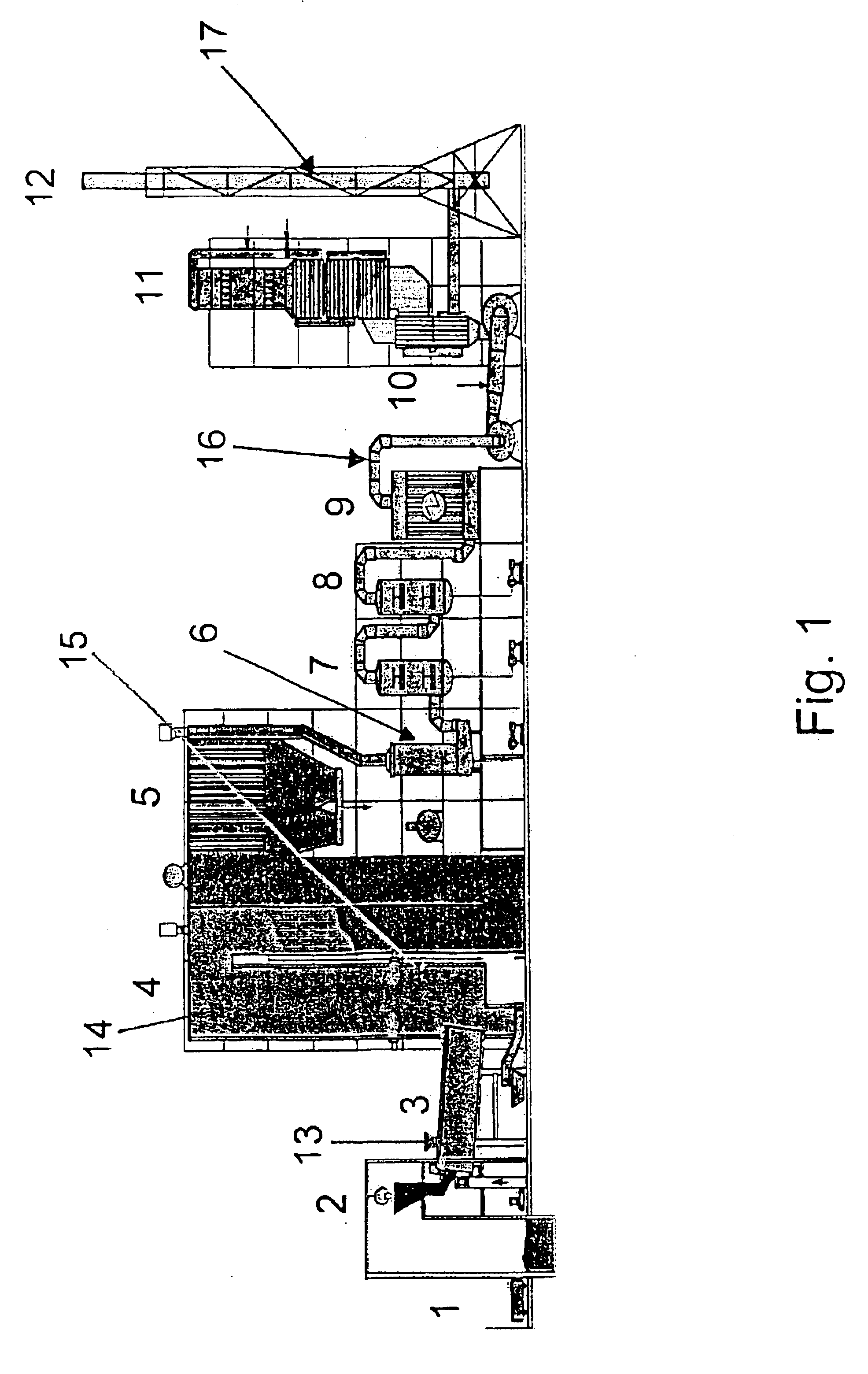

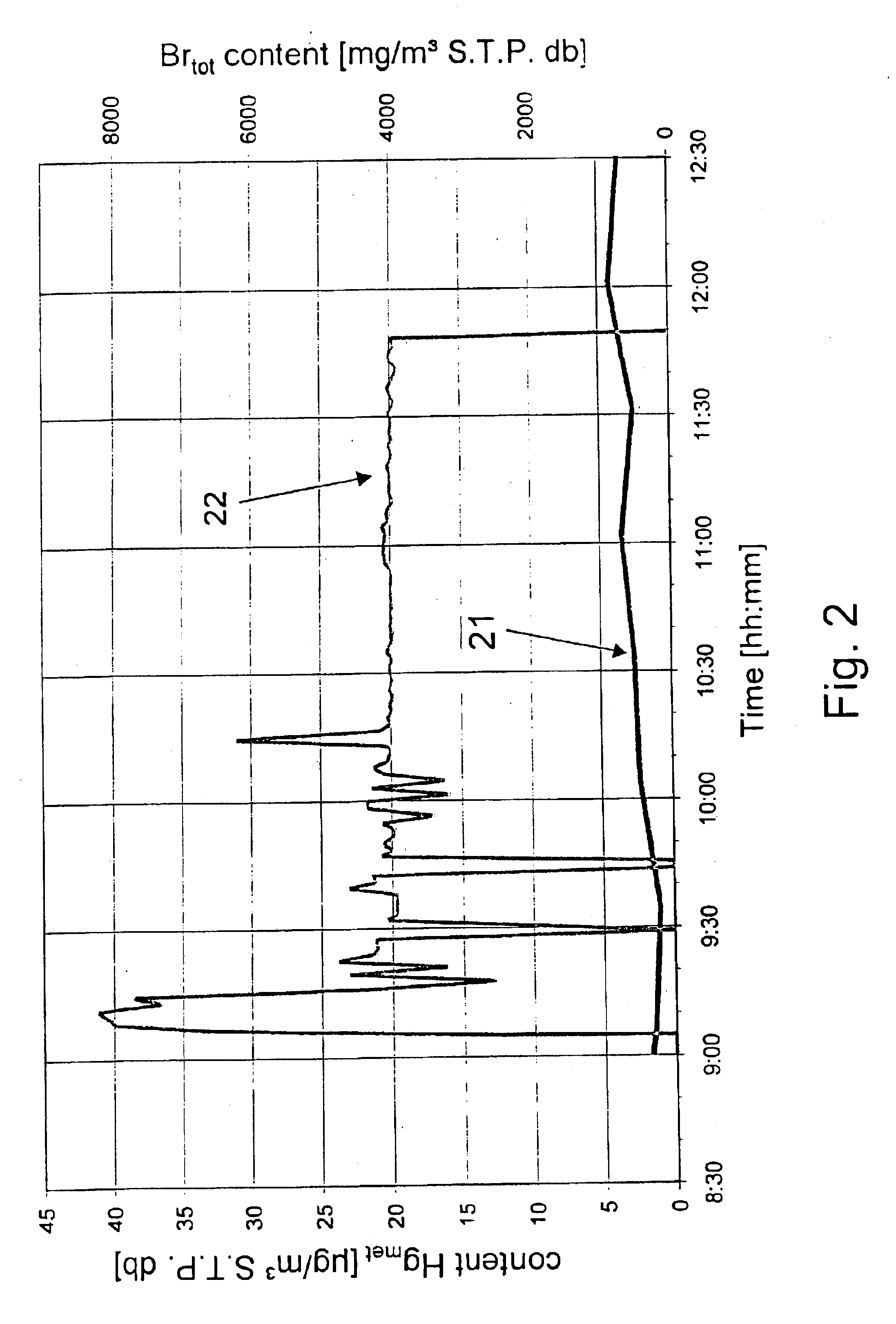

Process for removing mercury from flue gases

InactiveUS6878358B2Reduce operating costsSmall amountUsing liquid separation agentChemical/physical processesPower stationCombustion

Process for removing mercury from flue gases of high-temperature plants, in particular power stations and waste incineration plants in which a bromine compound is fed to the multistage furnace and / or the flue gas in a plant section downstream of the furnace, the temperature during contact of the bromine compound with the flue gas being at least 500° C., preferably at least 800° C. The combustion is carried out in the presence of a sulphur compound, in particular sulphur dioxide. Subsequently to the furnace, the flue gas is subjected to an optional multistage cleanup for removing mercury from the flue gas, which cleanup comprises a wet scrubber and / or a dry cleanup.

Owner:BROMERC

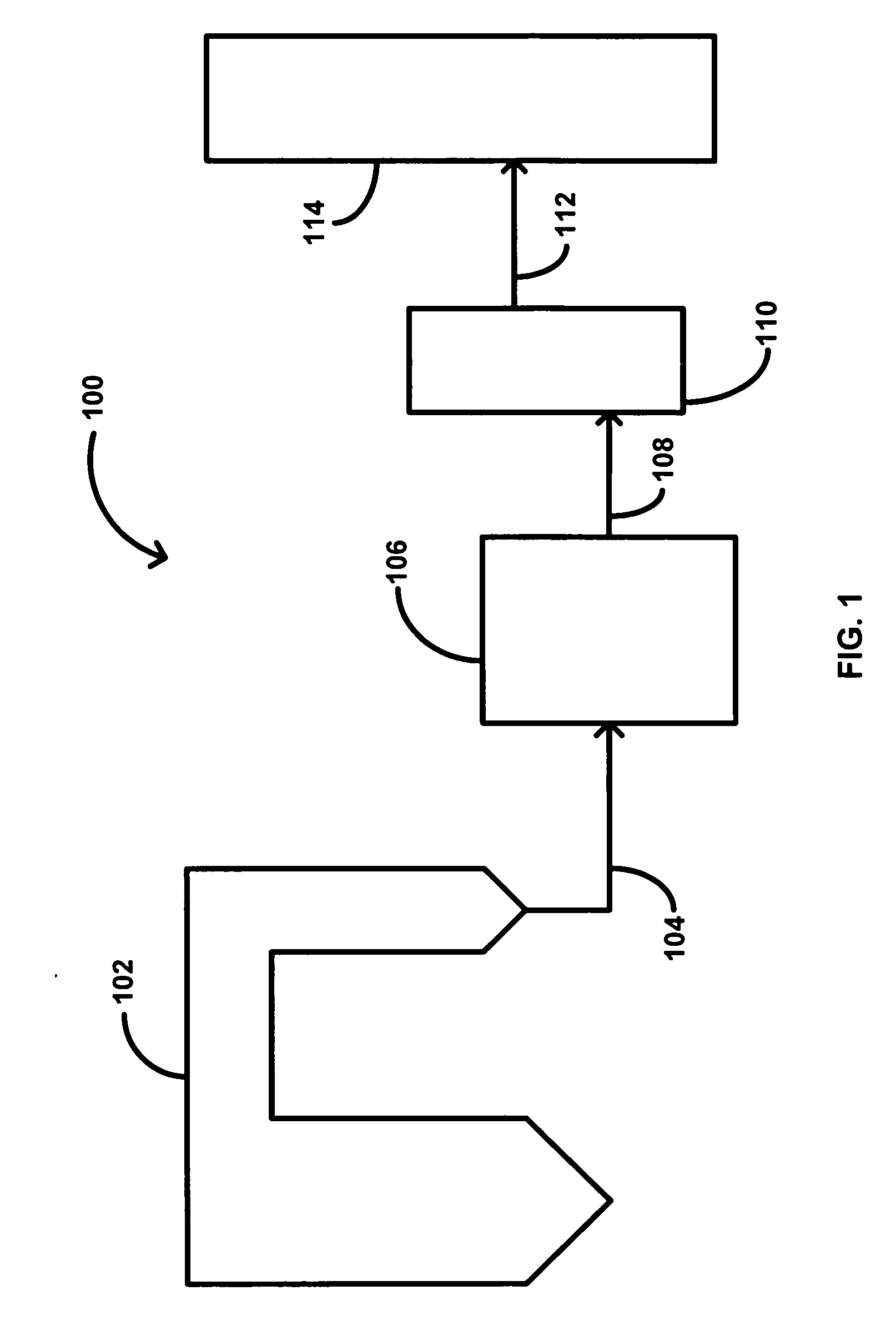

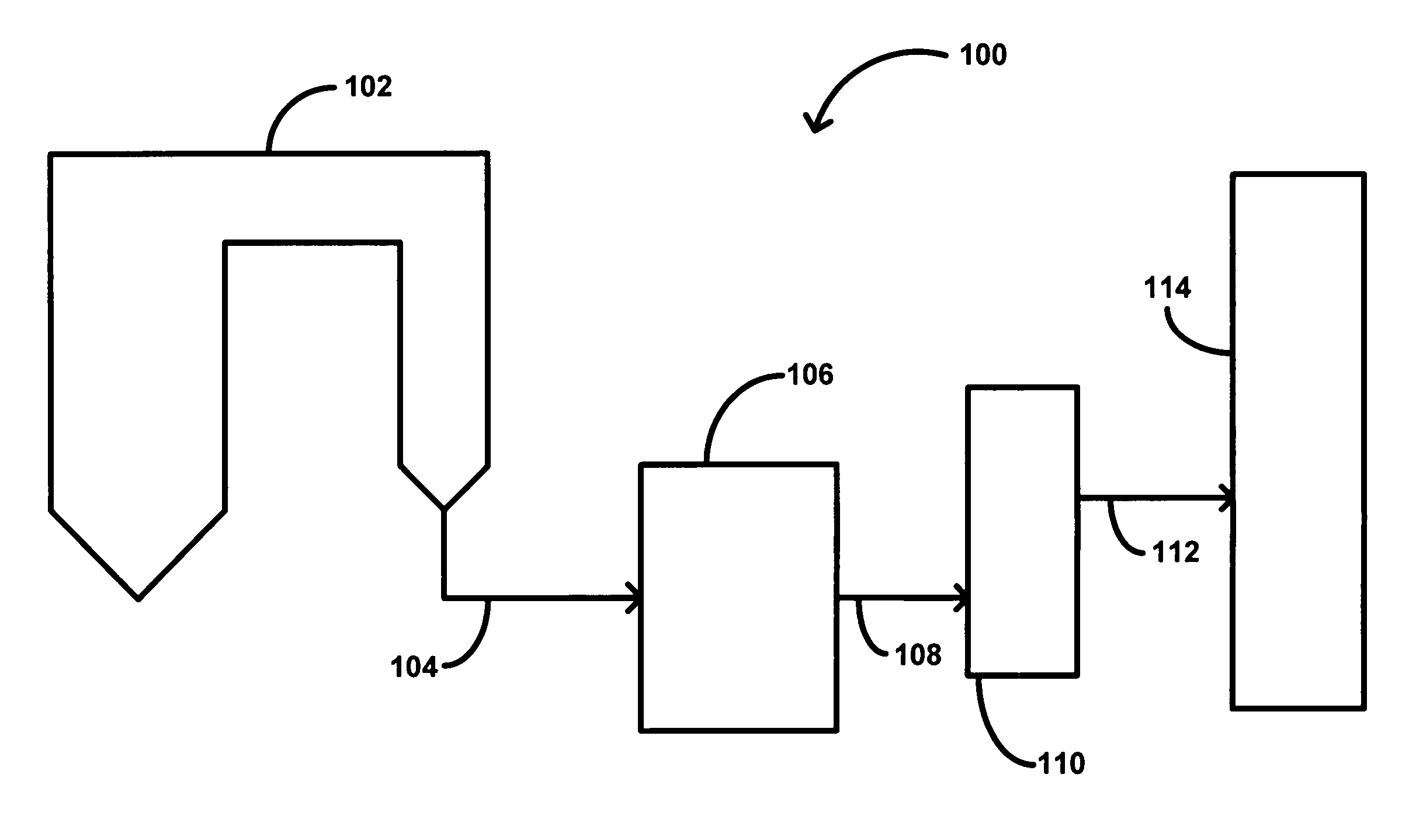

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

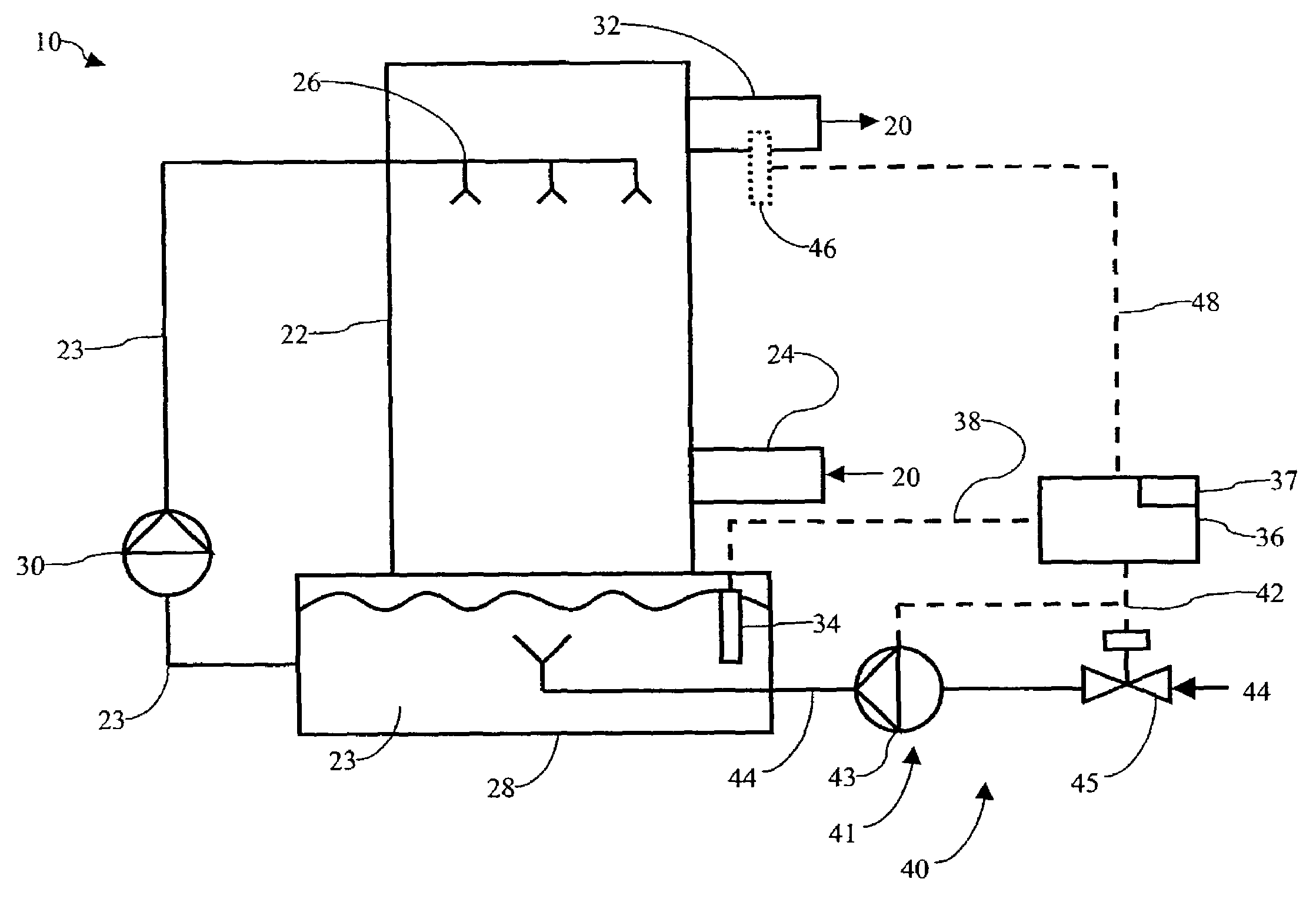

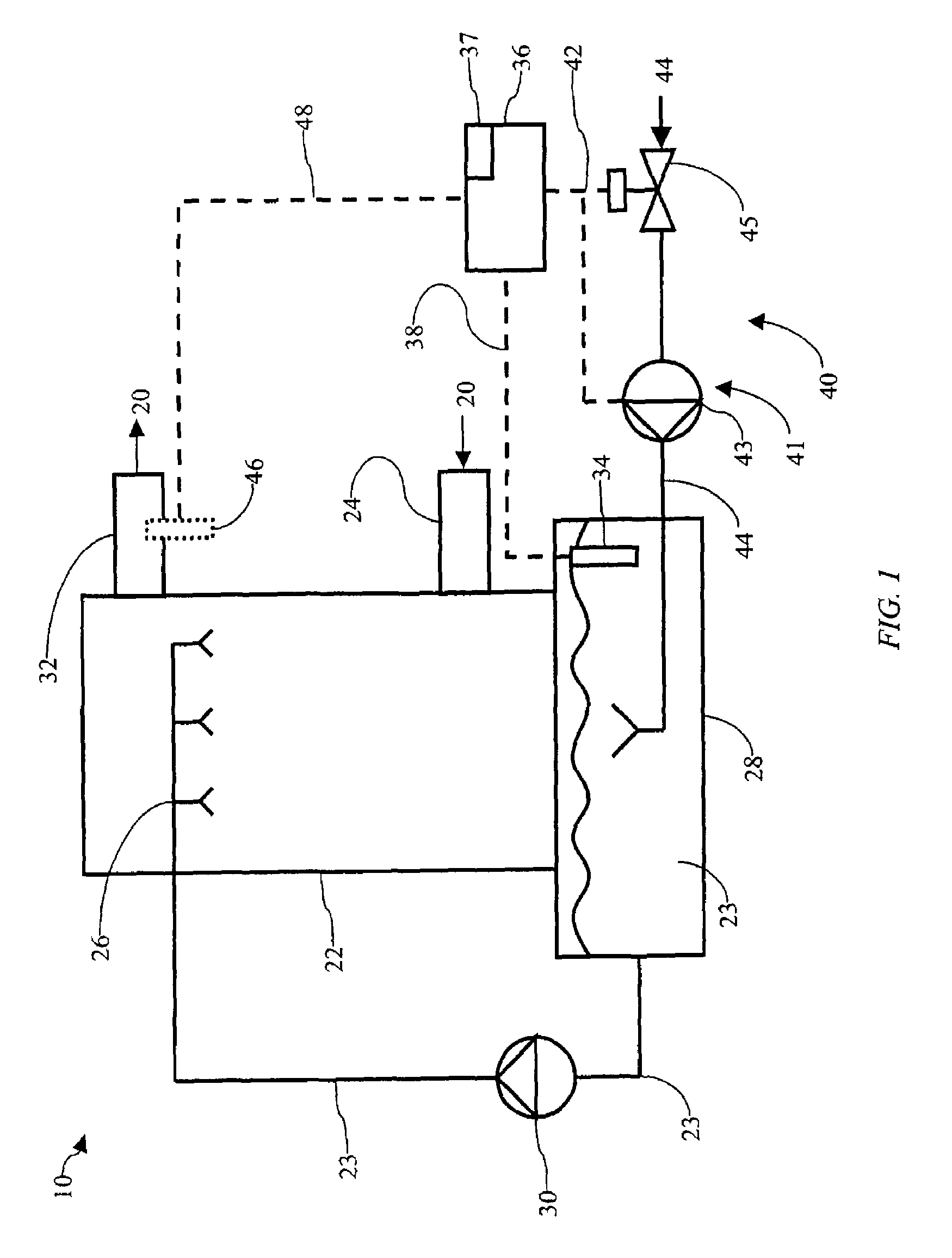

InactiveUS6322756B1Reduce sensitivityReduces water requiredCombination devicesExhaust apparatusOxygenOxidative treatment

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises an oxidation unit to which an oxygen-containing gas such as ozone may be added, with input of energy (e.g., thermal, radio frequency, electrical, microwave, etc.), to effect oxidation of oxidizable species in the effluent, such as halocompounds (e.g., chlorofluorocarbons, perfluorocarbons), CO, NF3, nitrogen oxides, and sulfur oxides). The effluent gas stream treatment system may include a wet scrubber associated with the oxygen-containing gas source, so that the gas stream is contacted with the oxygen-containing gas during the wet scrubbing operation, to enhance removal of oxidizable species in the gas stream during treatment.

Owner:BHT SERVICES PTE LTD

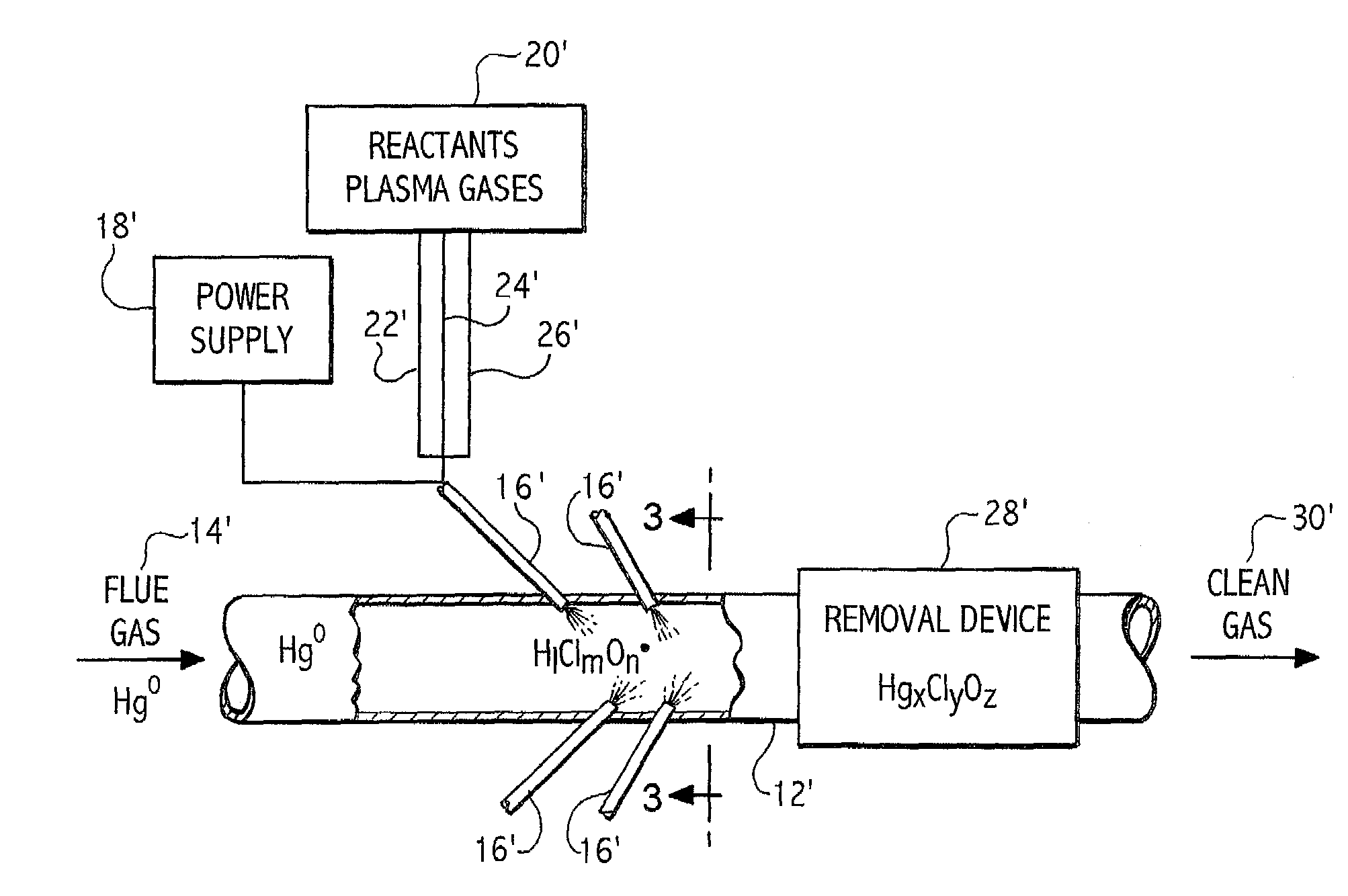

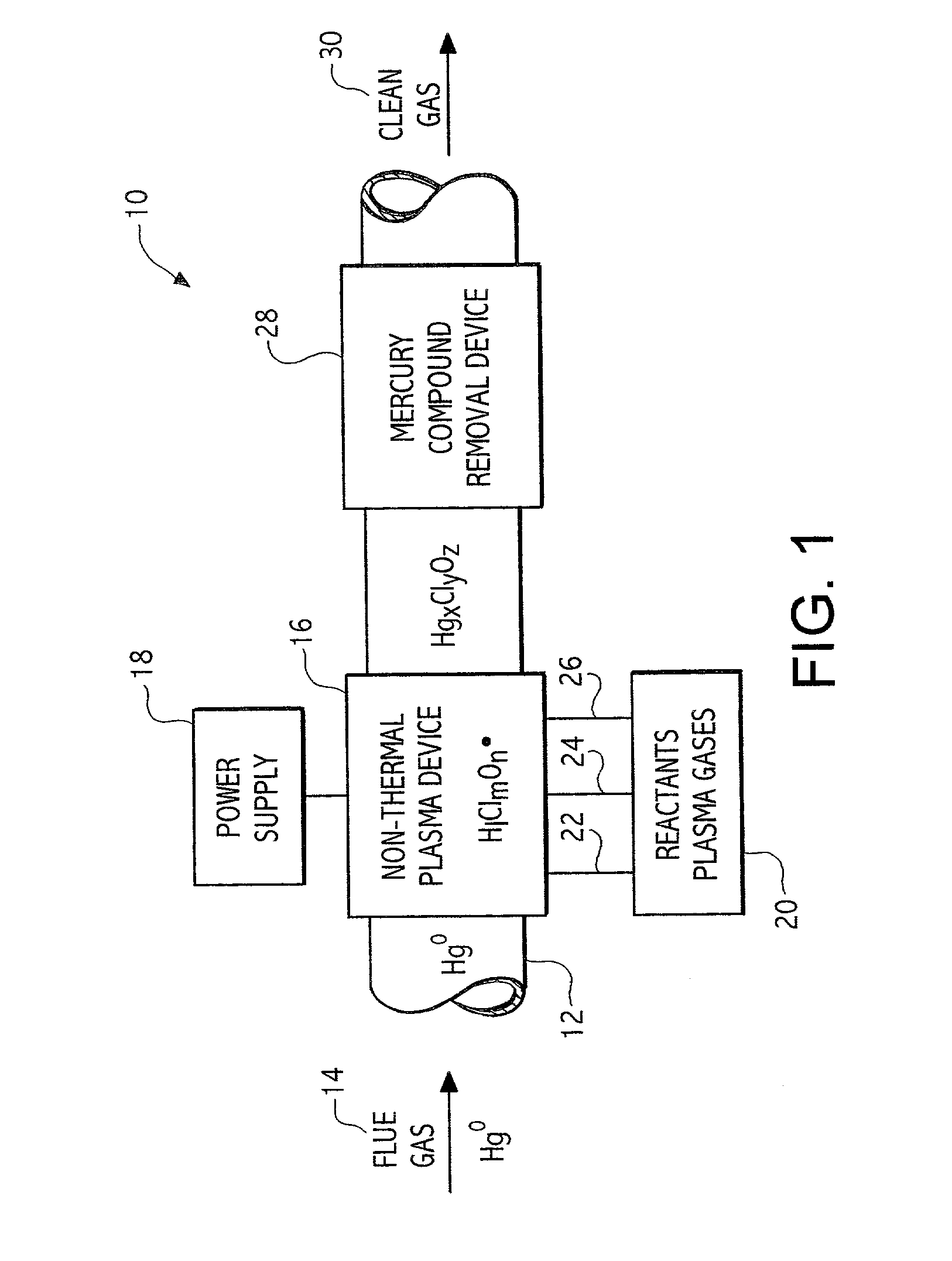

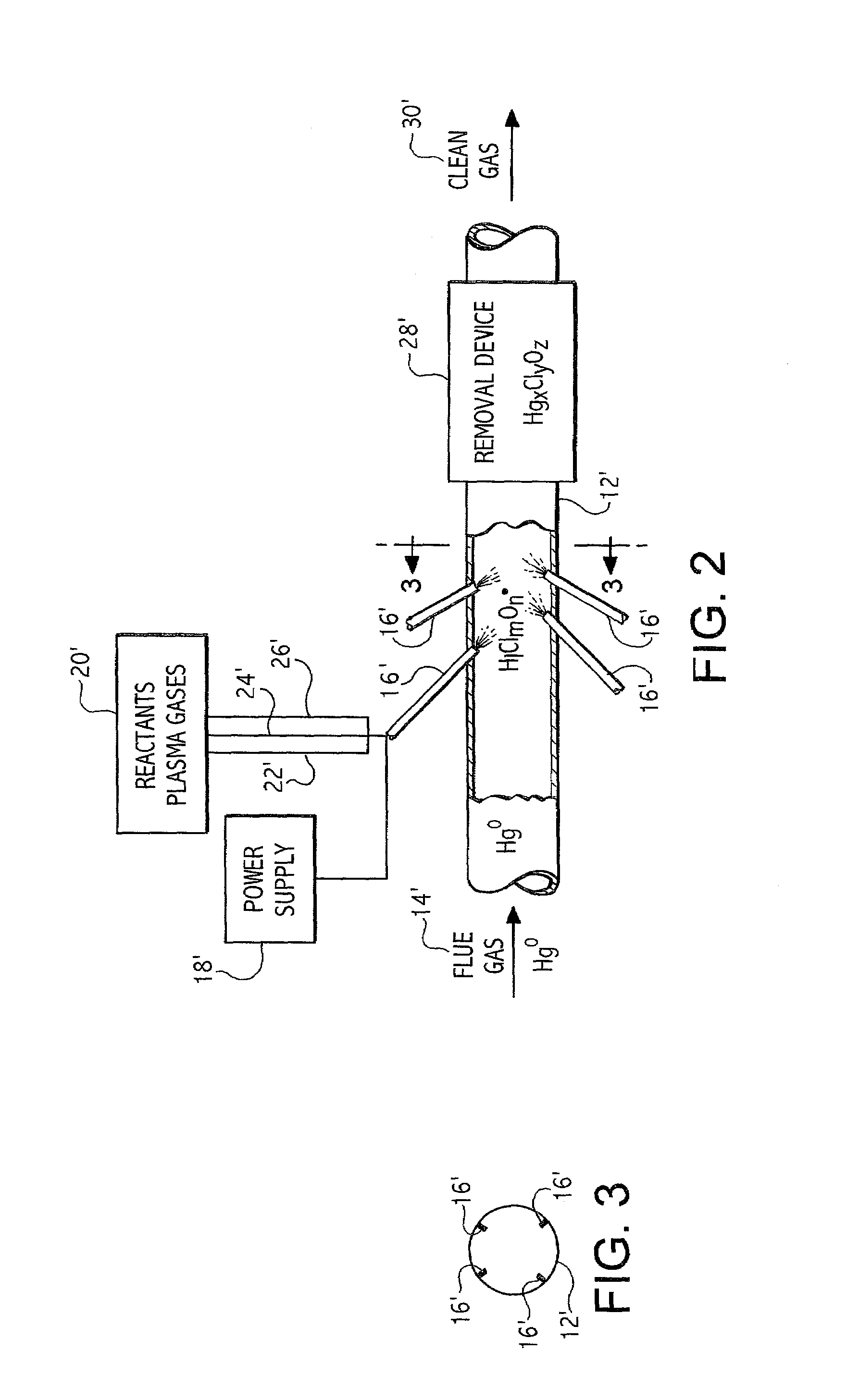

Plasma based trace metal removal apparatus and method

A system and method for the removal of metals such as mercury from a gas stream. The method involves contacting a gas stream containing the target metals with reactive chemical species generated in a plasma device. The metal to be removed is chemically converted into forms enabling capture in either conventional particulate removal devices or in a wet scrubber for the capture of a soluble chemical species.

Owner:CONTINENTAL RES & DEV

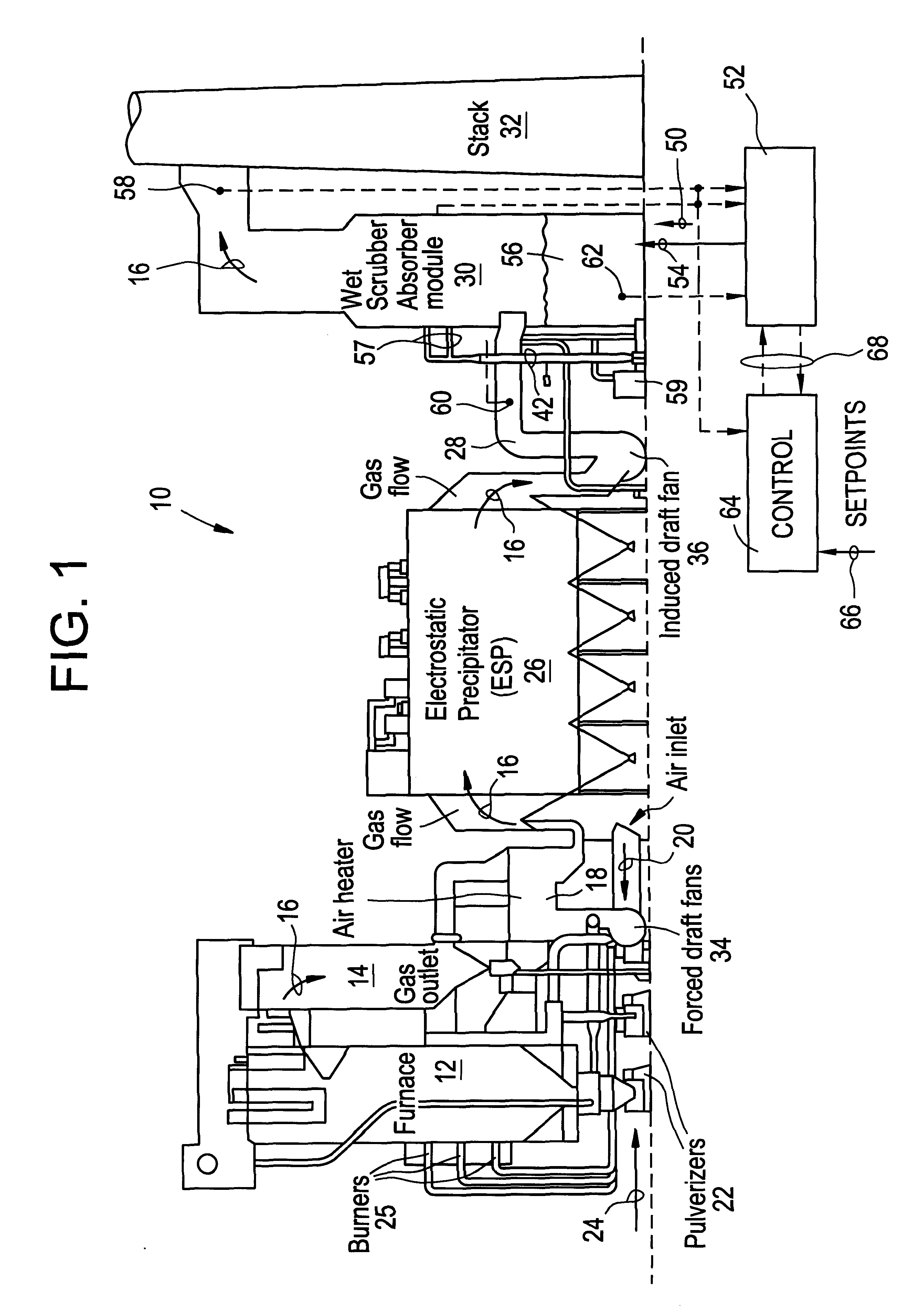

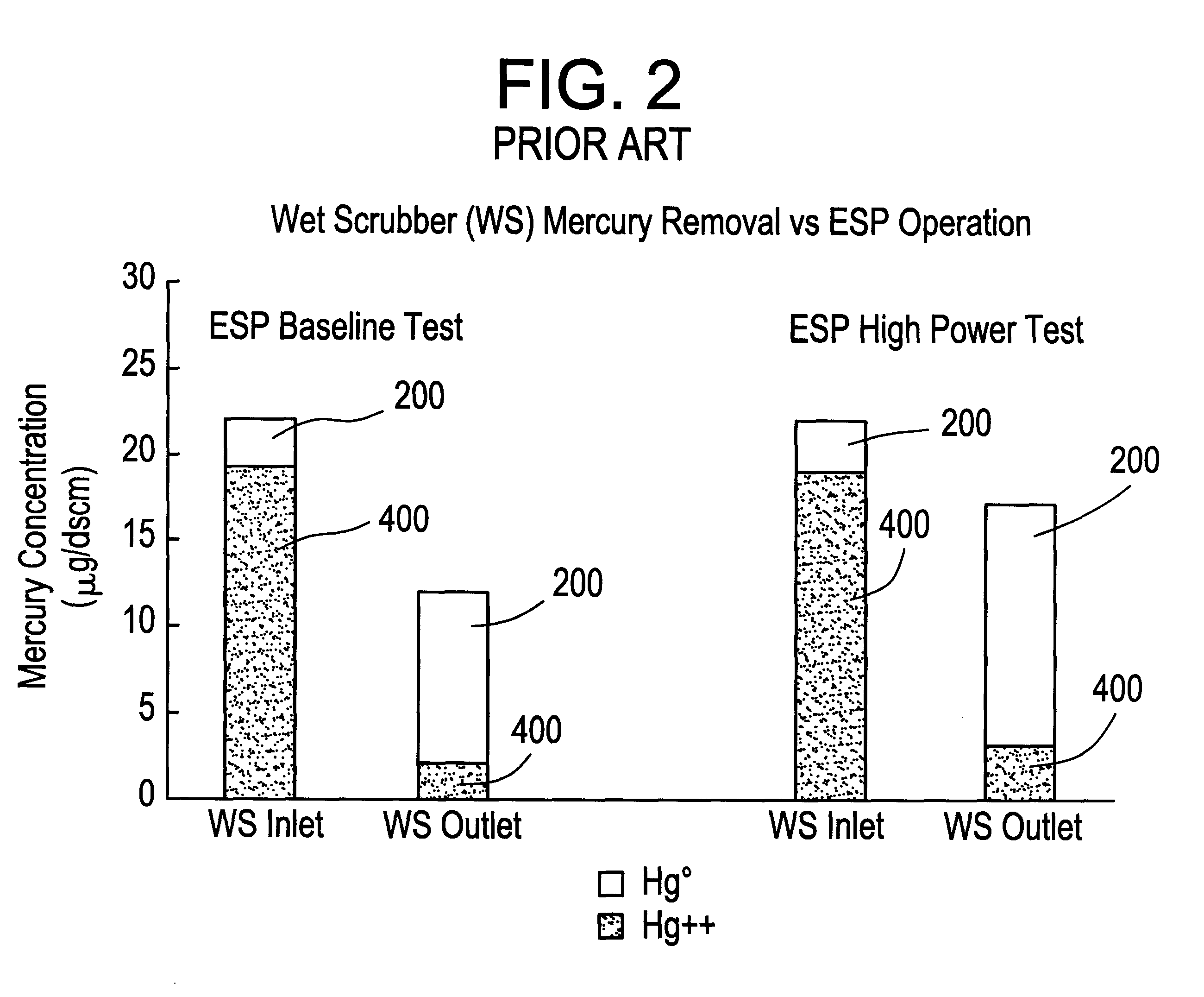

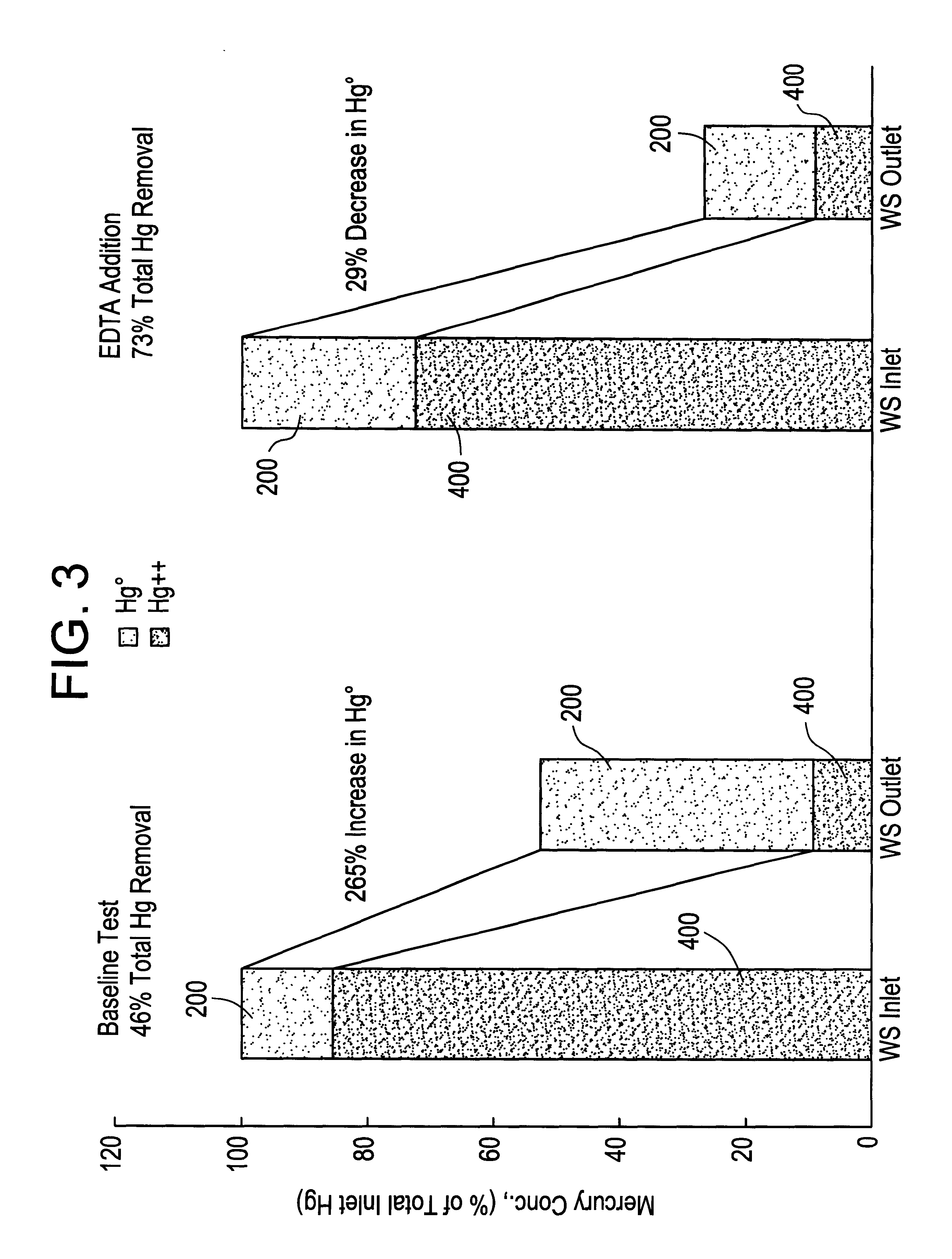

Mercury removal in utility wet scrubber using a chelating agent

InactiveUS6328939B1Degree of reductionReduce concentrationUsing liquid separation agentChemical/physical processesCombustionElemental mercury

A method for capturing and reducing the mercury content of an industrial flue gas such as that produced in the combustion of a fossil fuel or solid waste adds a chelating agent, such as ethylenediaminetetraacetic acid (EDTA) or other similar compounds like HEDTA, DTPA and / or NTA, to the flue gas being scrubbed in a wet scrubber used in the industrial process. The chelating agent prevents the reduction of oxidized mercury to elemental mercury, thereby increasing the mercury removal efficiency of the wet scrubber. Exemplary tests on inlet and outlet mercury concentration in an industrial flue gas were performed without and with EDTA addition. Without EDTA, mercury removal totaled 42%. With EDTA, mercury removal increased to 71%. The invention may be readily adapted to known wet scrubber systems and it specifically provides for the removal of unwanted mercury both by supplying S2- ions to convert Hg2+ ions into mercuric sulfide (HgS) and by supplying a chelating agent to sequester other ions, including but not limited to Fe2+ ions, which could otherwise induce the unwanted reduction of Hg2+ to the form, Hg0.

Owner:THE BABCOCK & WILCOX CO

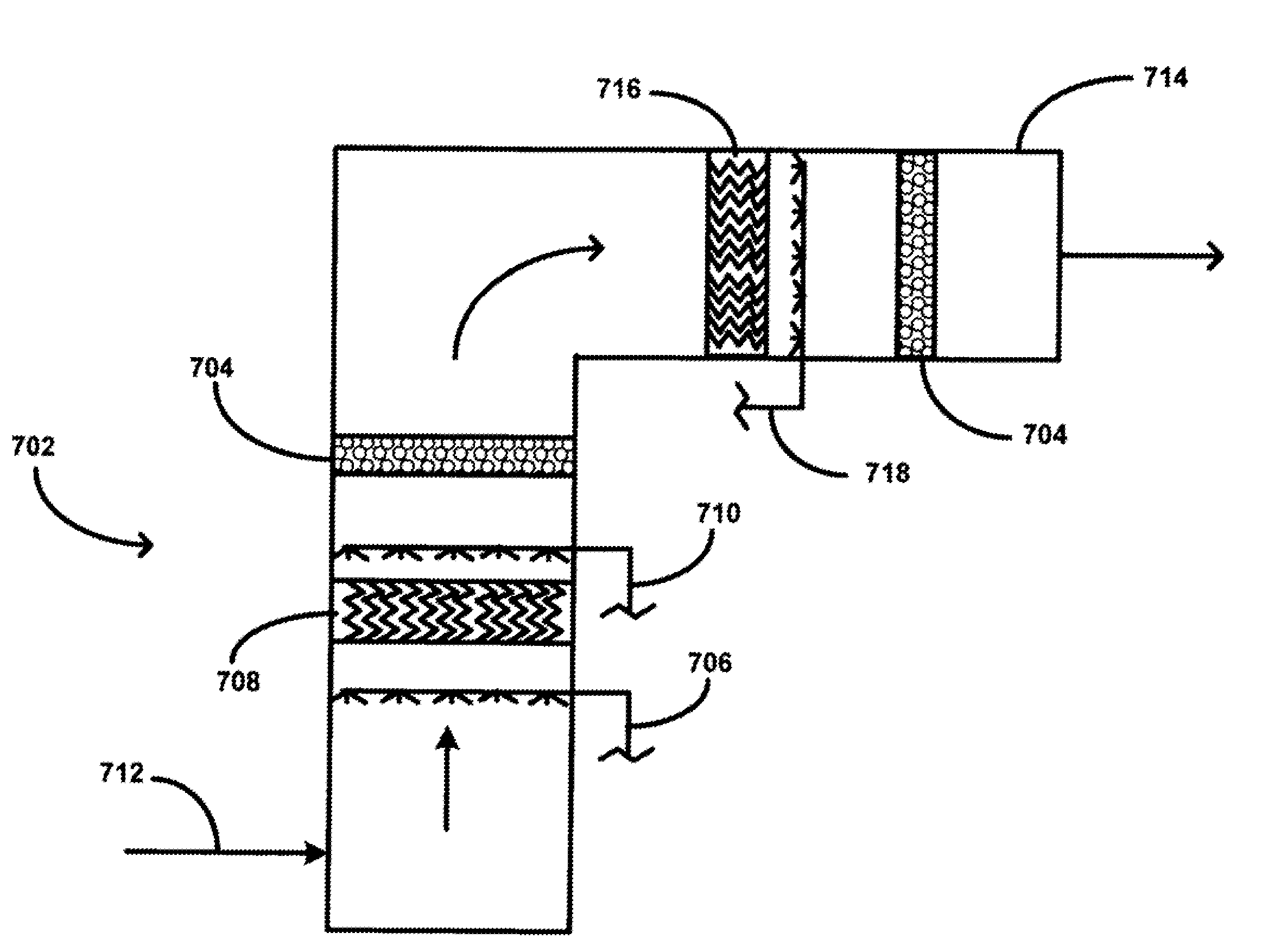

Sorbent Filter for the Removal of Vapor Phase Contaminants

Methods and apparatuses are described for removing a contaminant, such as a vaporous trace metal contaminant like mercury, from a gas stream. In one embodiment, a primary particulate collection device that removes particulate matter is used. In this embodiment, a sorbent filter is placed within the housing of the primary particulate collection device, such as an electrostatic precipitator or a baghouse, to adsorb the contaminant of interest. In another embodiment, a sorbent filter is placed within or after a scrubber, such as a wet scrubber, to adsorb the contaminant of interest. In some embodiments, the invention provides methods and apparatuses that can advantageously be retrofit into existing particulate collection equipment. In some embodiments, the invention provides methods and apparatuses that in addition to removal of a contaminant additionally remove particulate matter from a gas stream.

Owner:ELECTRIC POWER RES INST INC

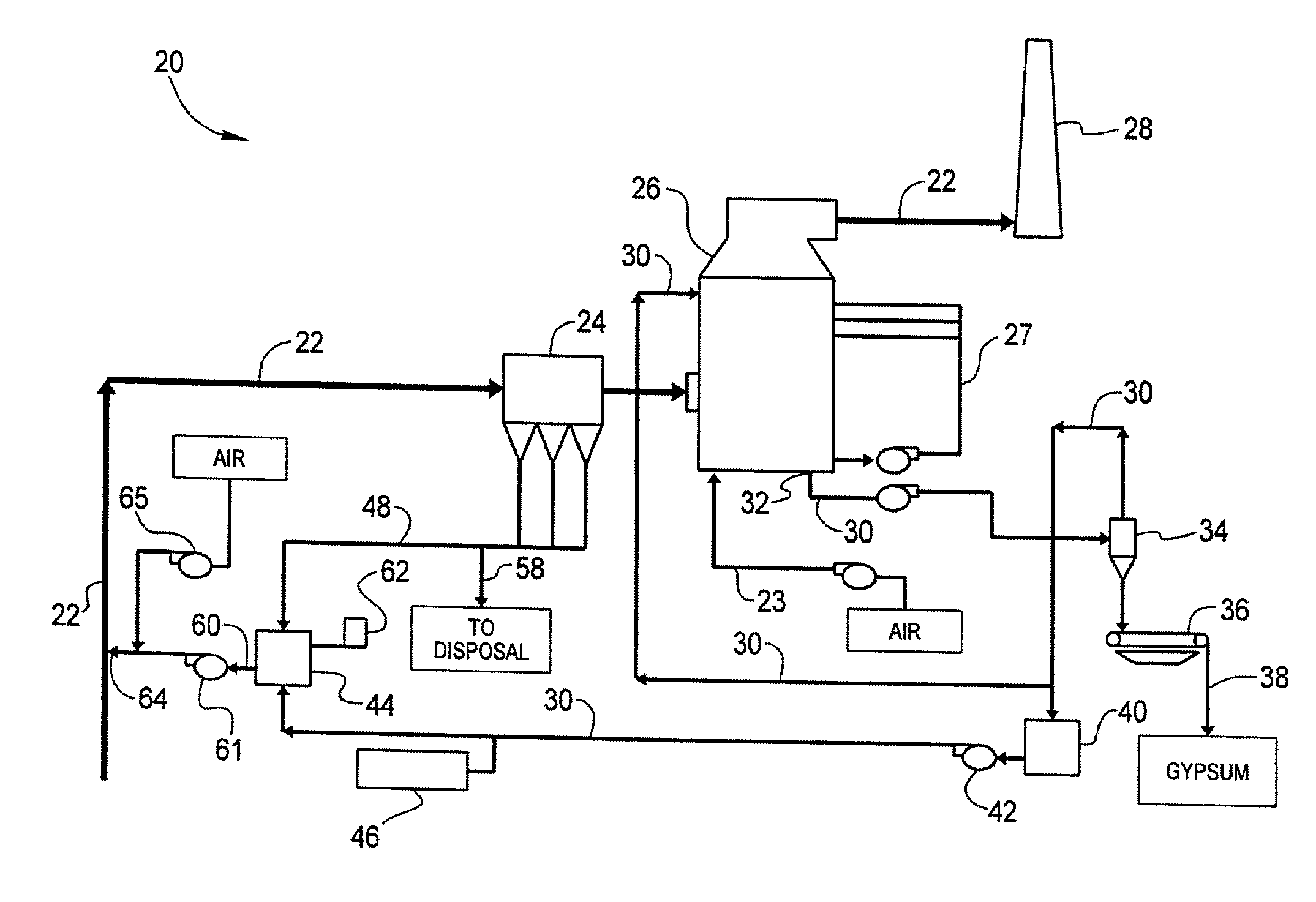

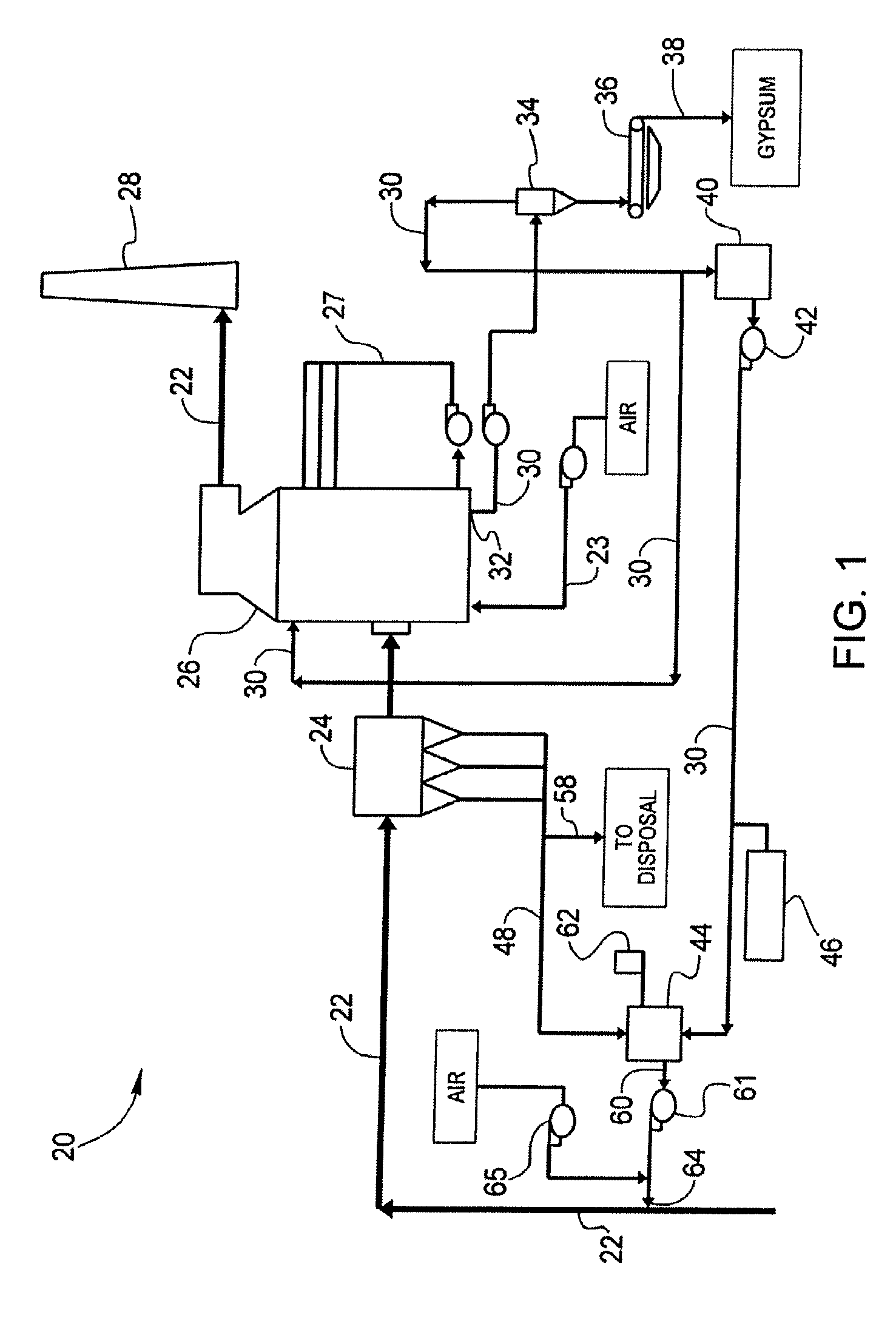

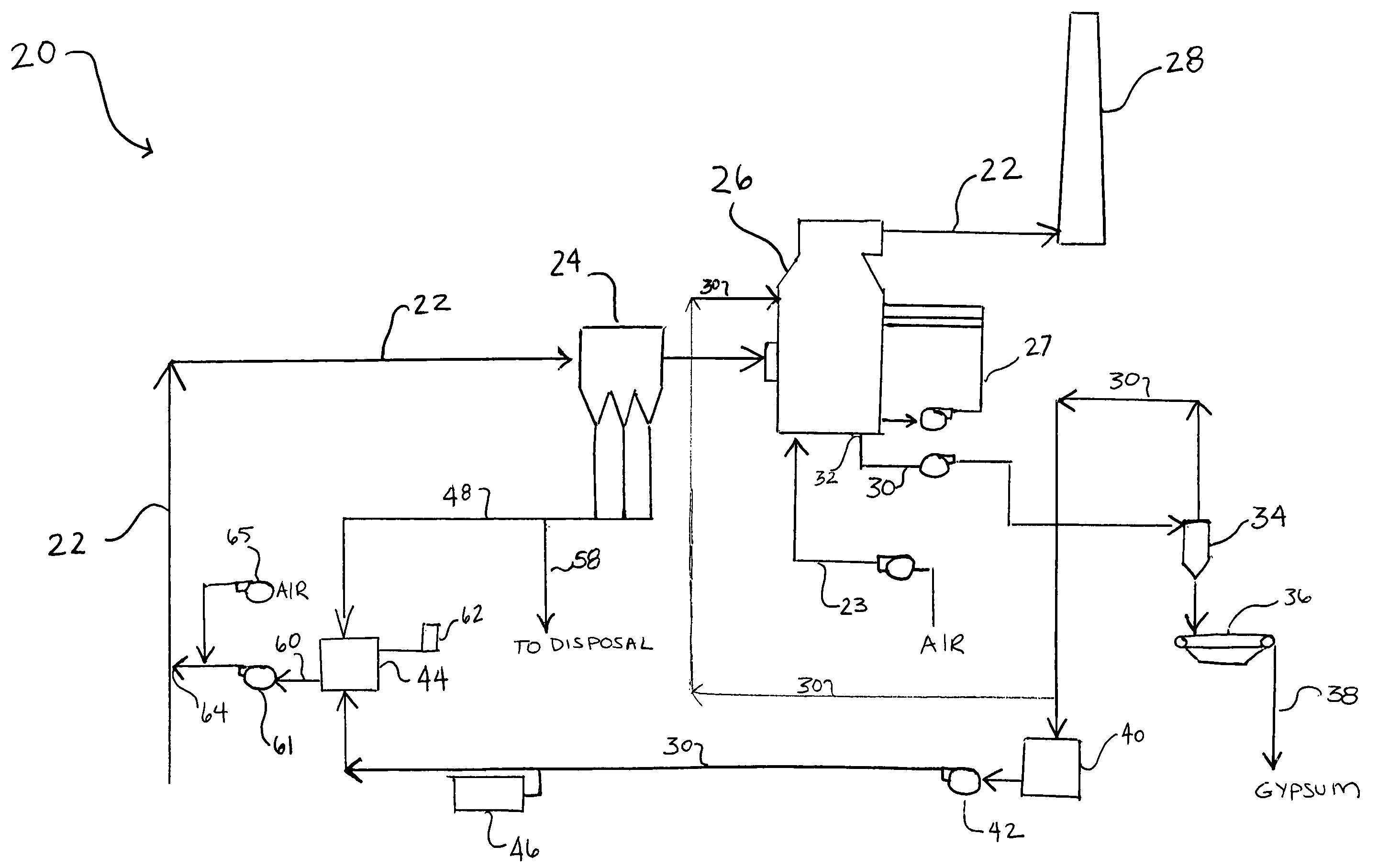

Reduced liquid discharge in wet flue gas desulfurization

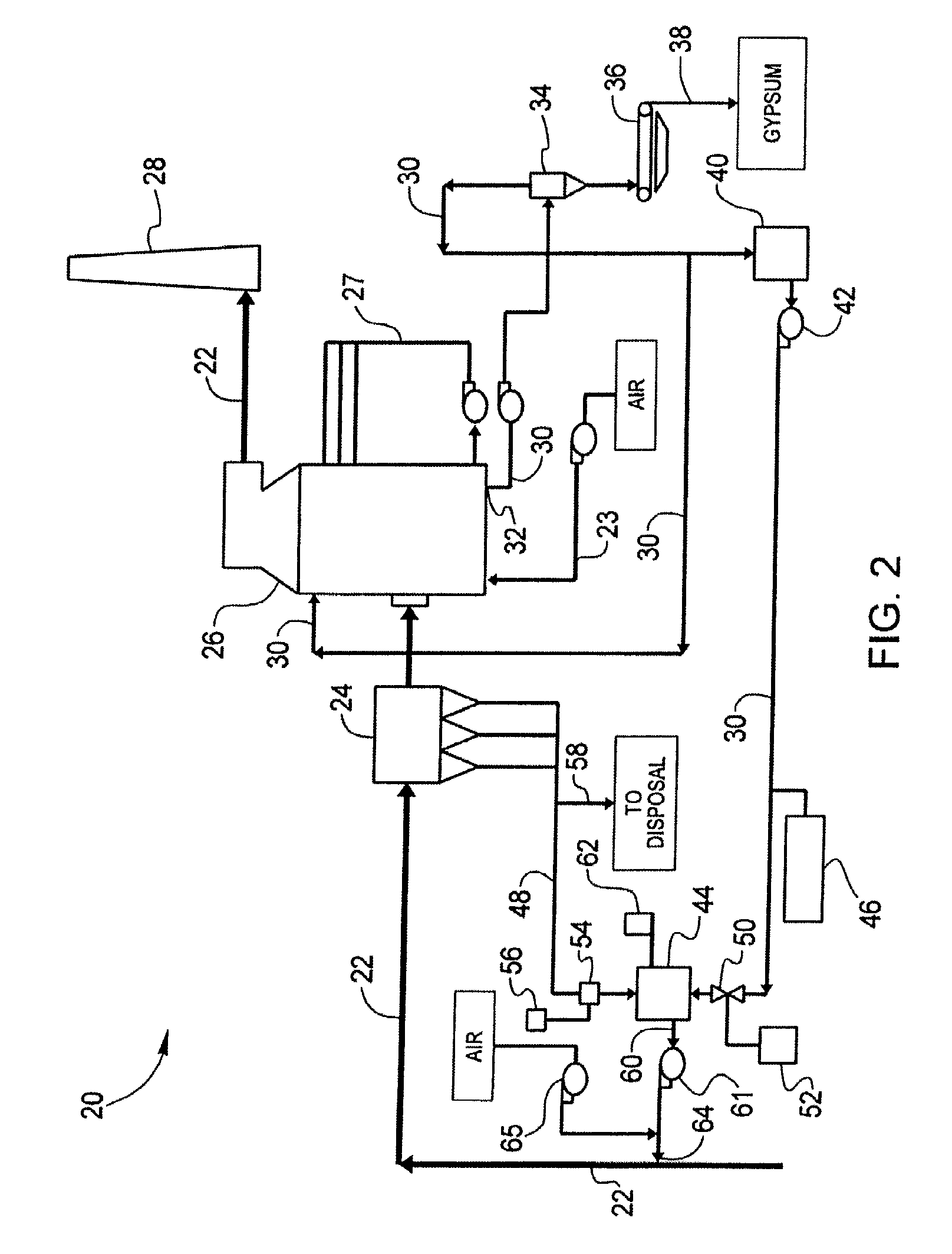

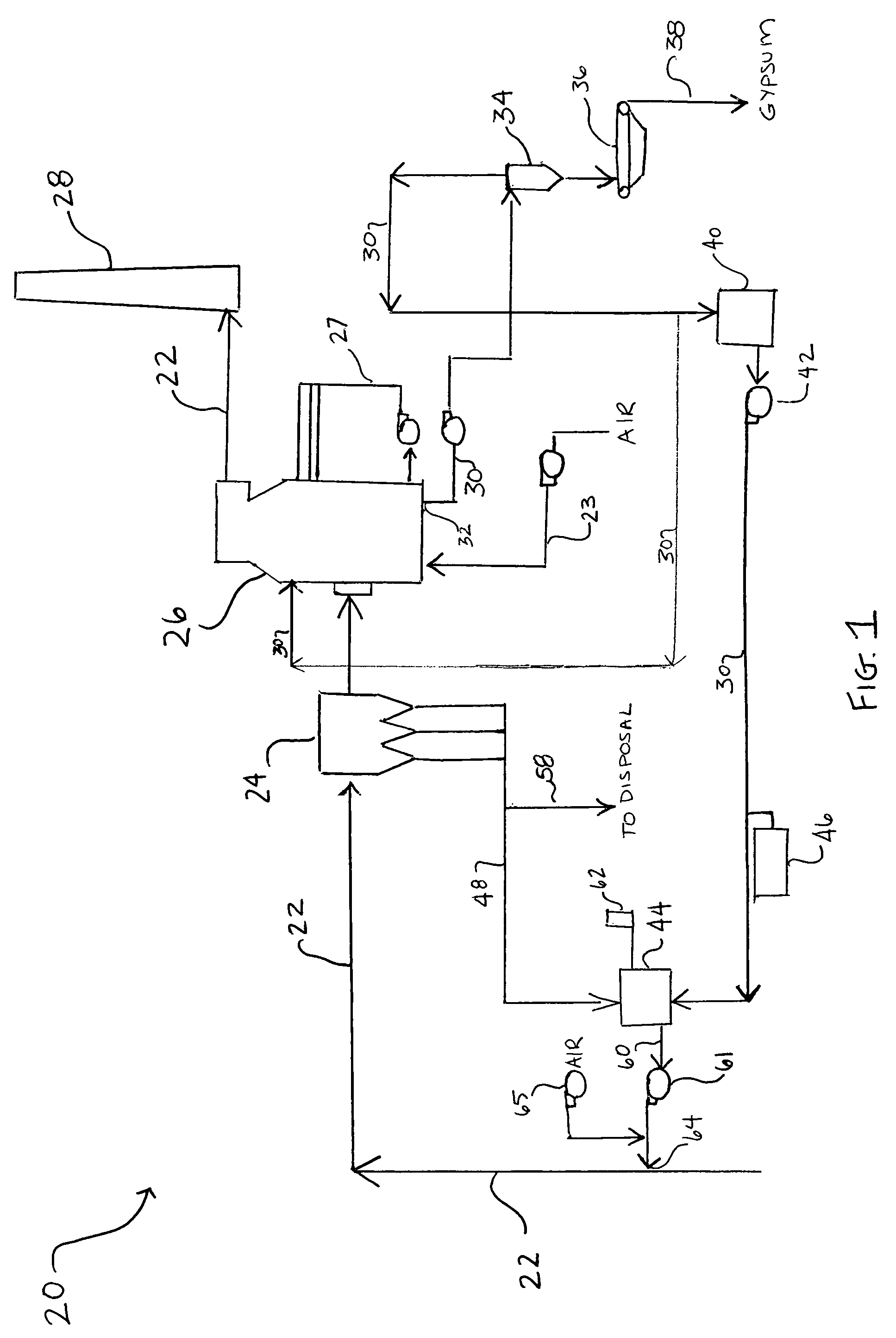

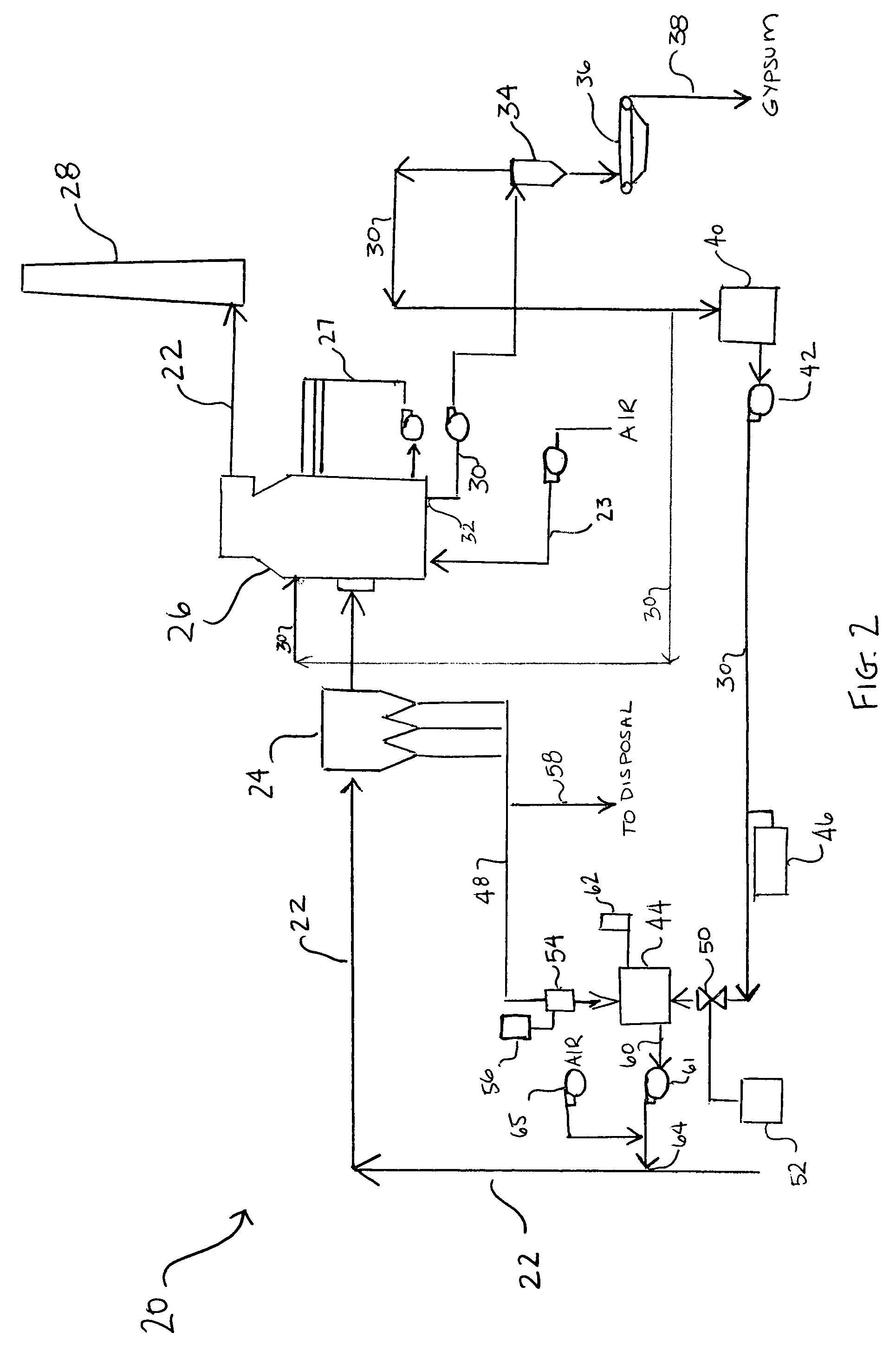

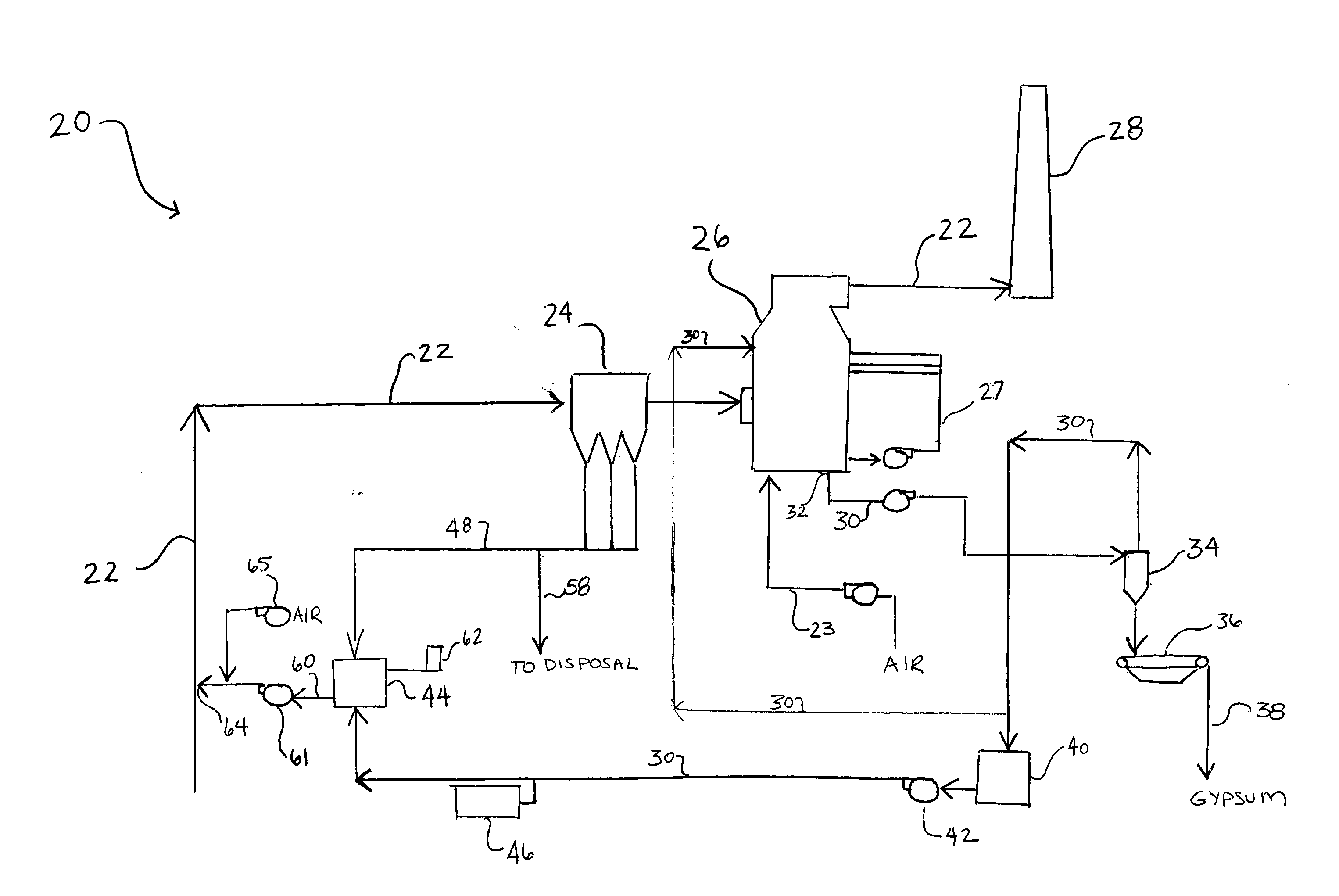

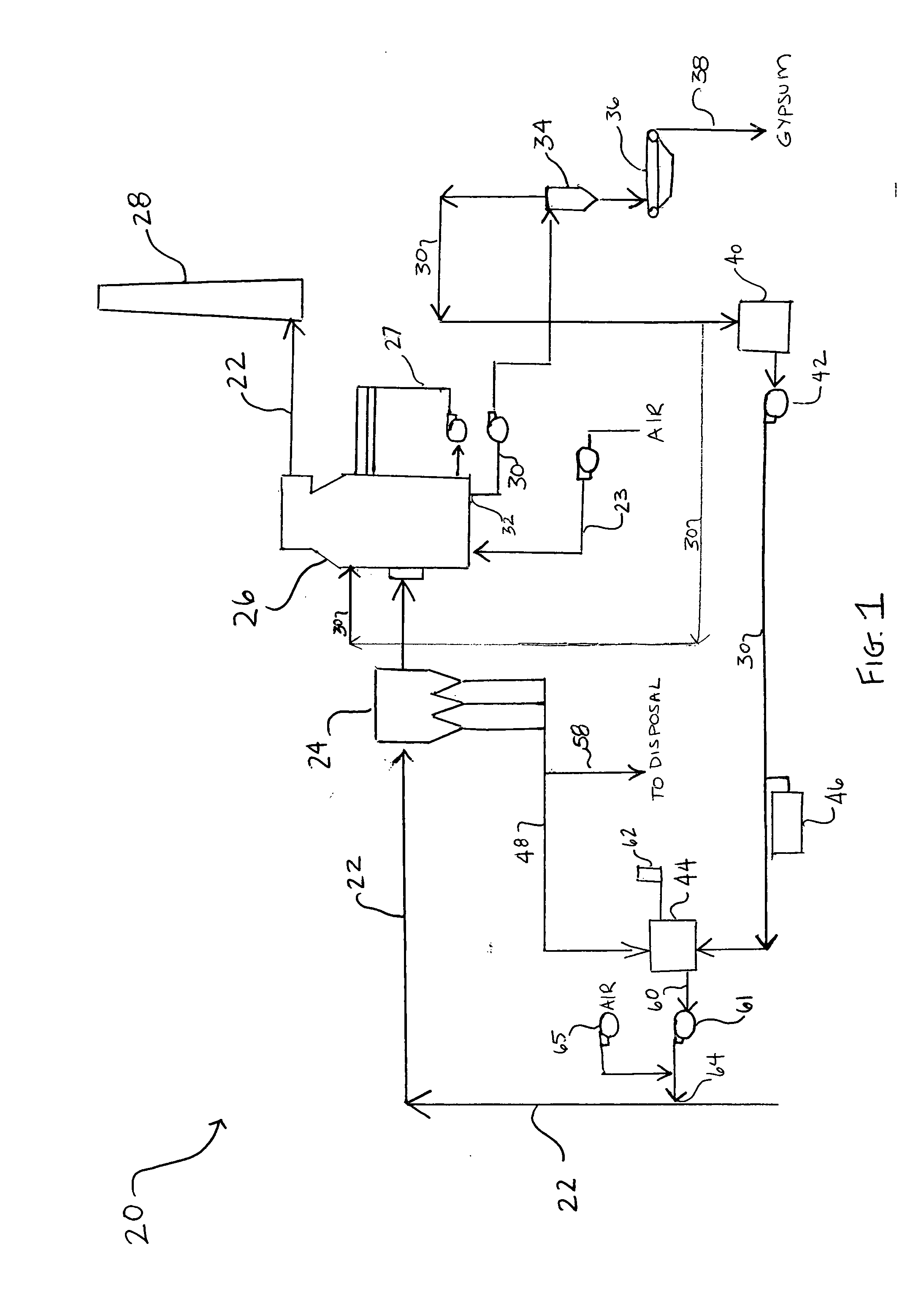

One aspect of the invention relates to a method for removing contaminants from a flue gas stream (22). The method includes: removing fly ash from a flue gas stream (22) utilizing a particle collector (24); contacting the flue gas stream with an alkaline reagent in a wet scrubber (26); discharging a purge liquid (30) from the wet scrubber (26); and, combining at least a portion of the purge liquid with at least a portion of fly ash circulating within a dry circulating fluid bed scrubber (48) to form moistened fly ash (60).

Owner:GENERAL ELECTRIC TECH GMBH

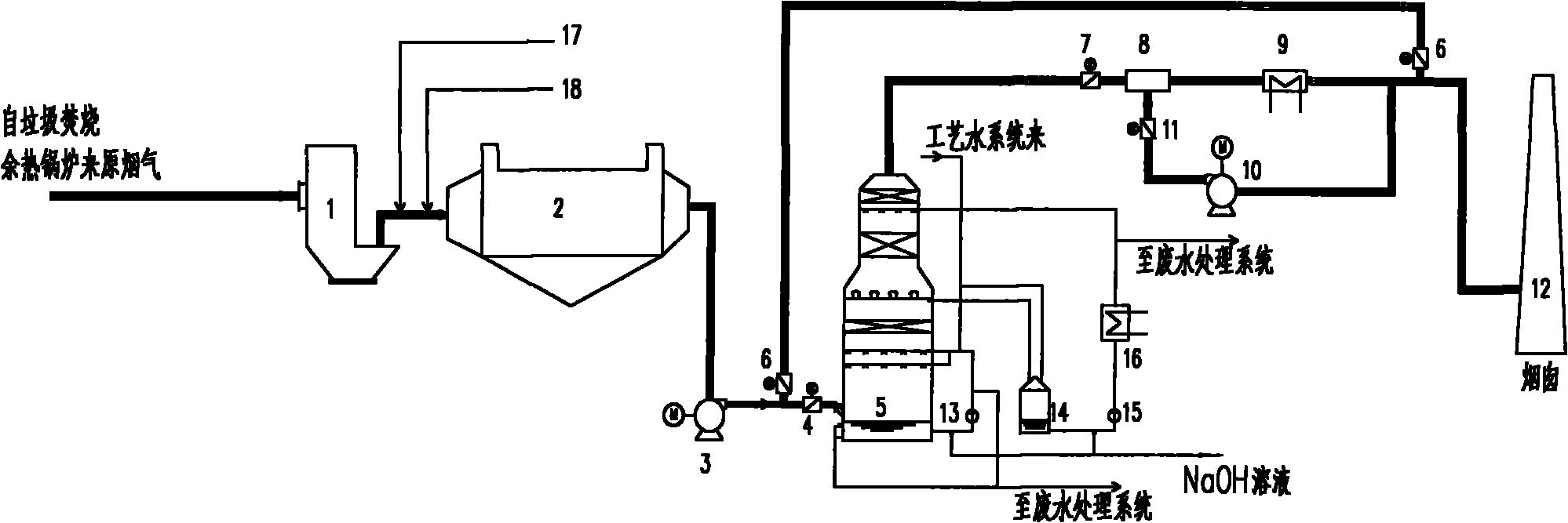

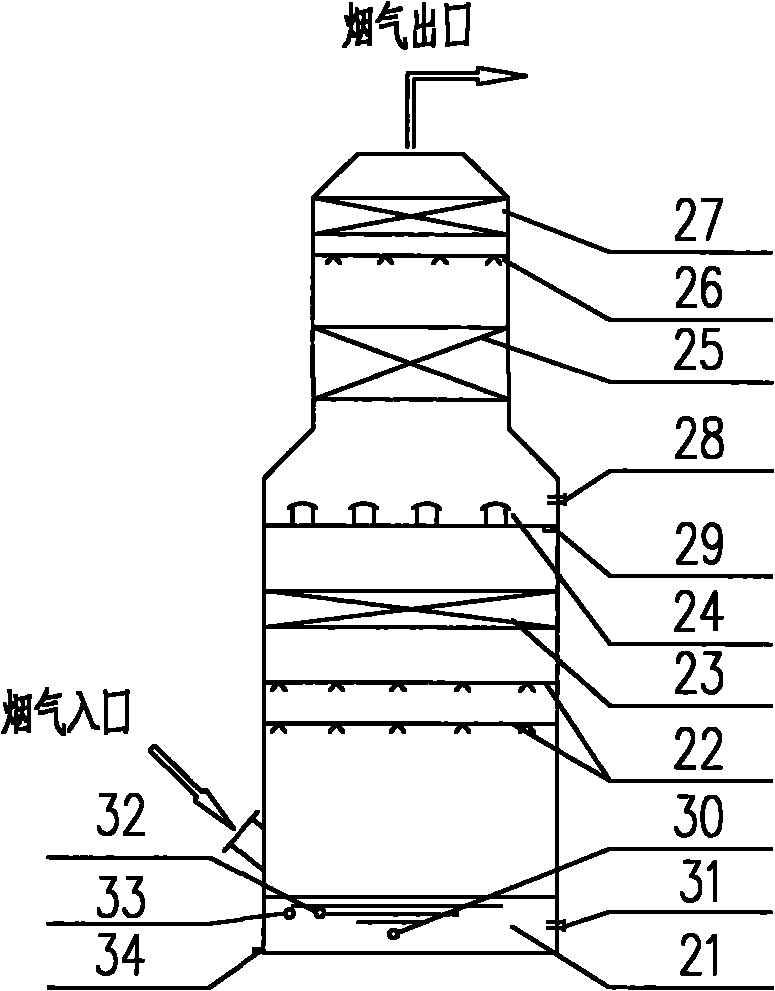

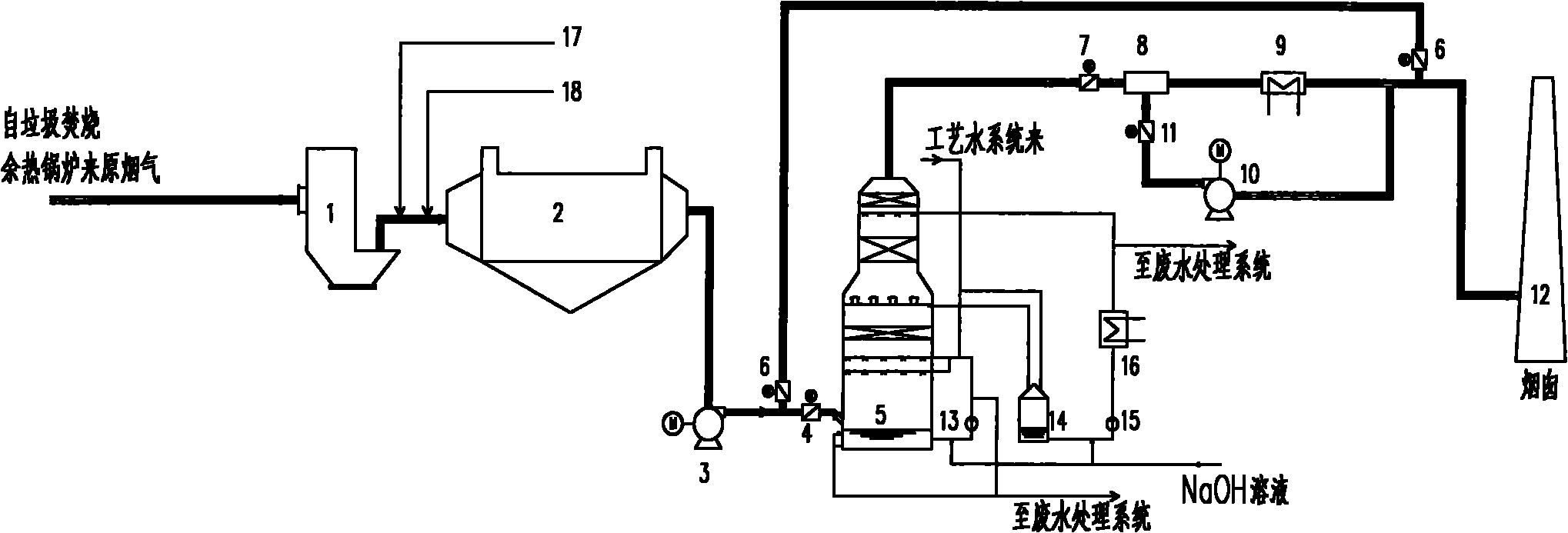

Flue-gas cleaning method and system for waste incineration

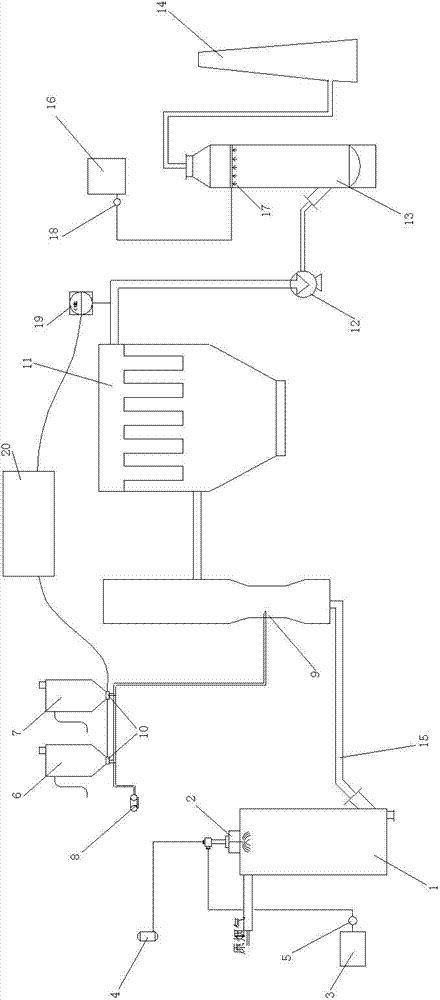

InactiveCN101829468AImprove removal efficiencyLarge load concentrationCombination devicesLighting and heating apparatusCooling towerHazardous substance

The invention discloses a flue-gas cleaning method for waste incineration, which comprises a dry process and a wet process. In the dry process, harmful substance in the flue gas is adsorbed by utilizing an adsorbent, and acid gas is neutralized by utilizing an alkaline absorbent, and in the wet process, a wet spray scrubber is utilized to purify the flu gas with higher efficiency. In addition, the invention also discloses a flue-gas cleaning system for waste incineration, which comprises a cooling tower, a bag-type dust collector, a wet washing tower and a glue-gas reheater. Flue gas from an exhaust-heat boiler enters the bag-type dust collector after being cooled by the cooling tower. Activated carbon and slaked lime powder are sprayed into the flue gas before the flue gas enters the bag-type dust collector to carry out preliminary purification on the flue gas; the purified flue gas is introduced to the wet washing tower through a draught fan for further processing; and the purified flue gas is discharged into the atomosphere by a chimney after the two-stage heating. The invention can effectively remove pollutant in flue gas and the quality of the purified flue gas can achieve the EU 2000 effluent standard.

Owner:山东三融环保工程有限公司

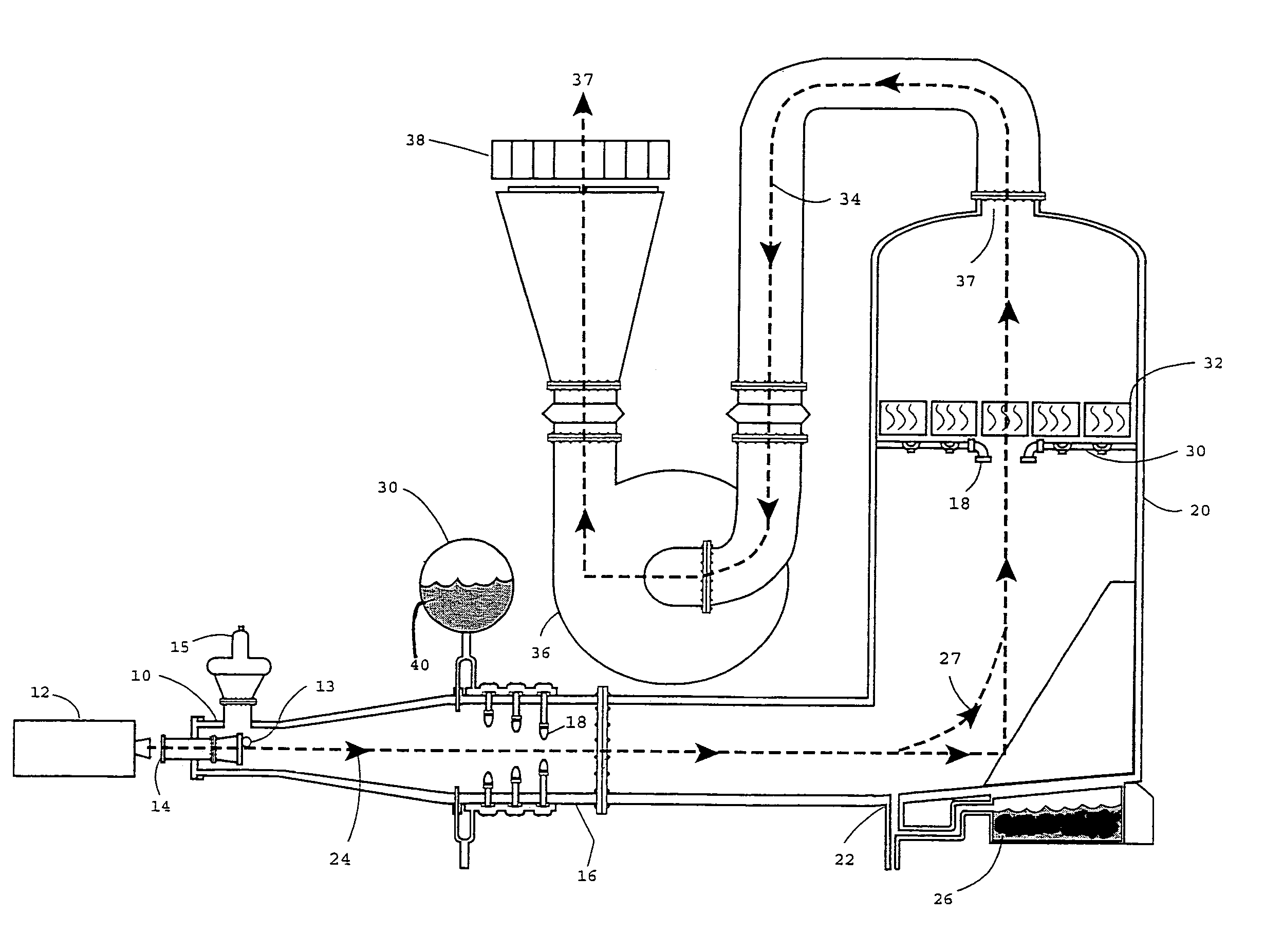

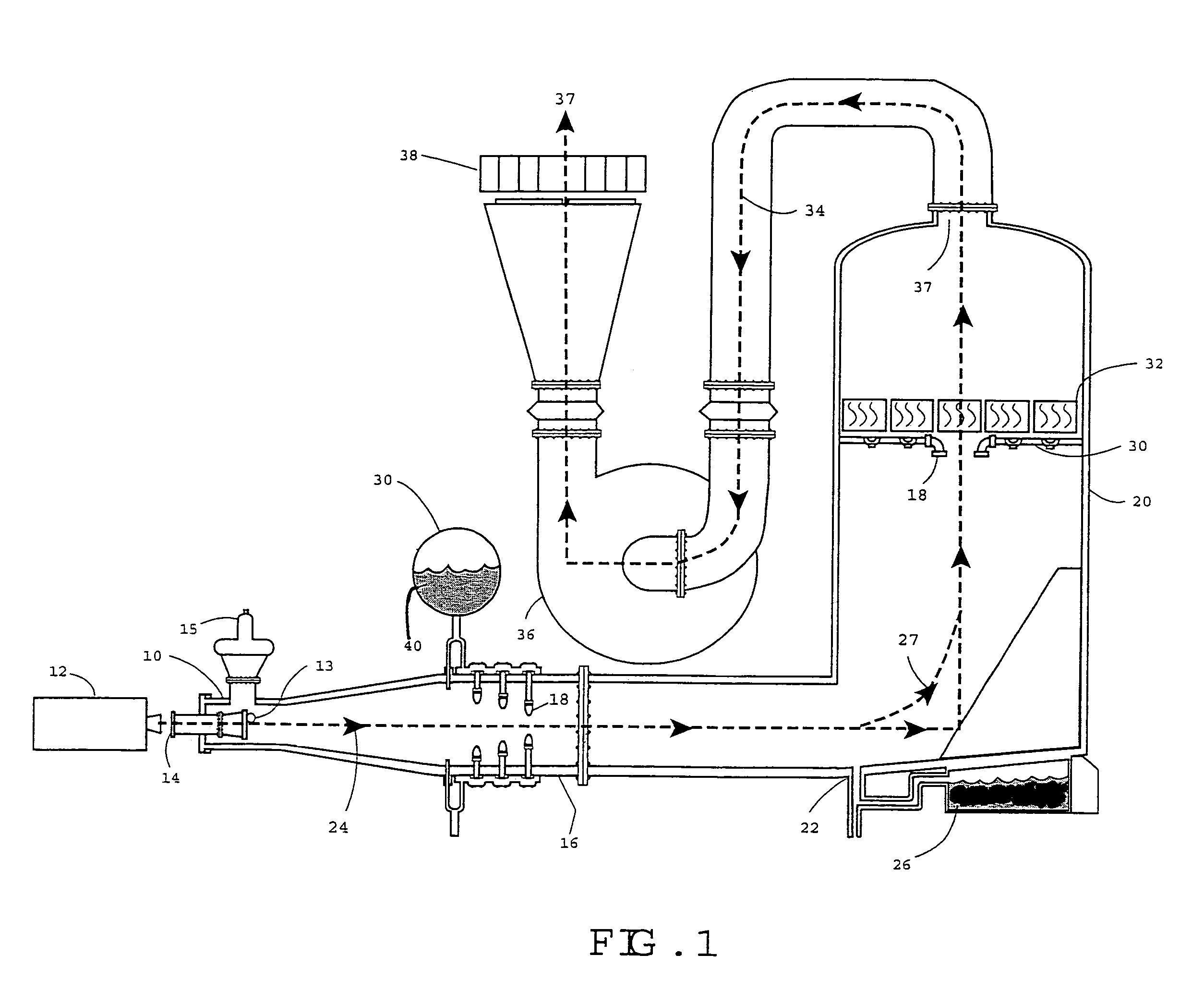

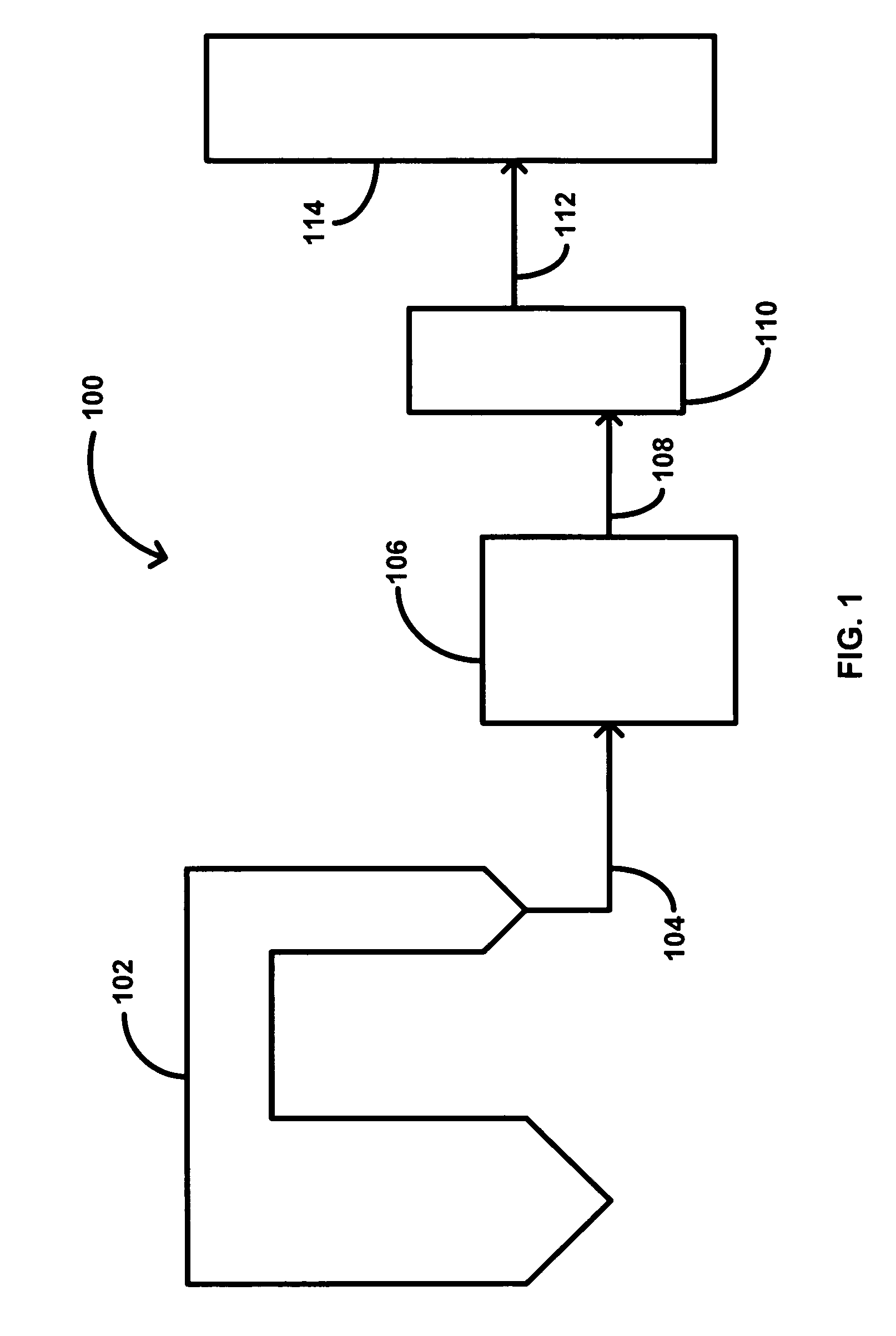

Rocket motor exhaust scrubber

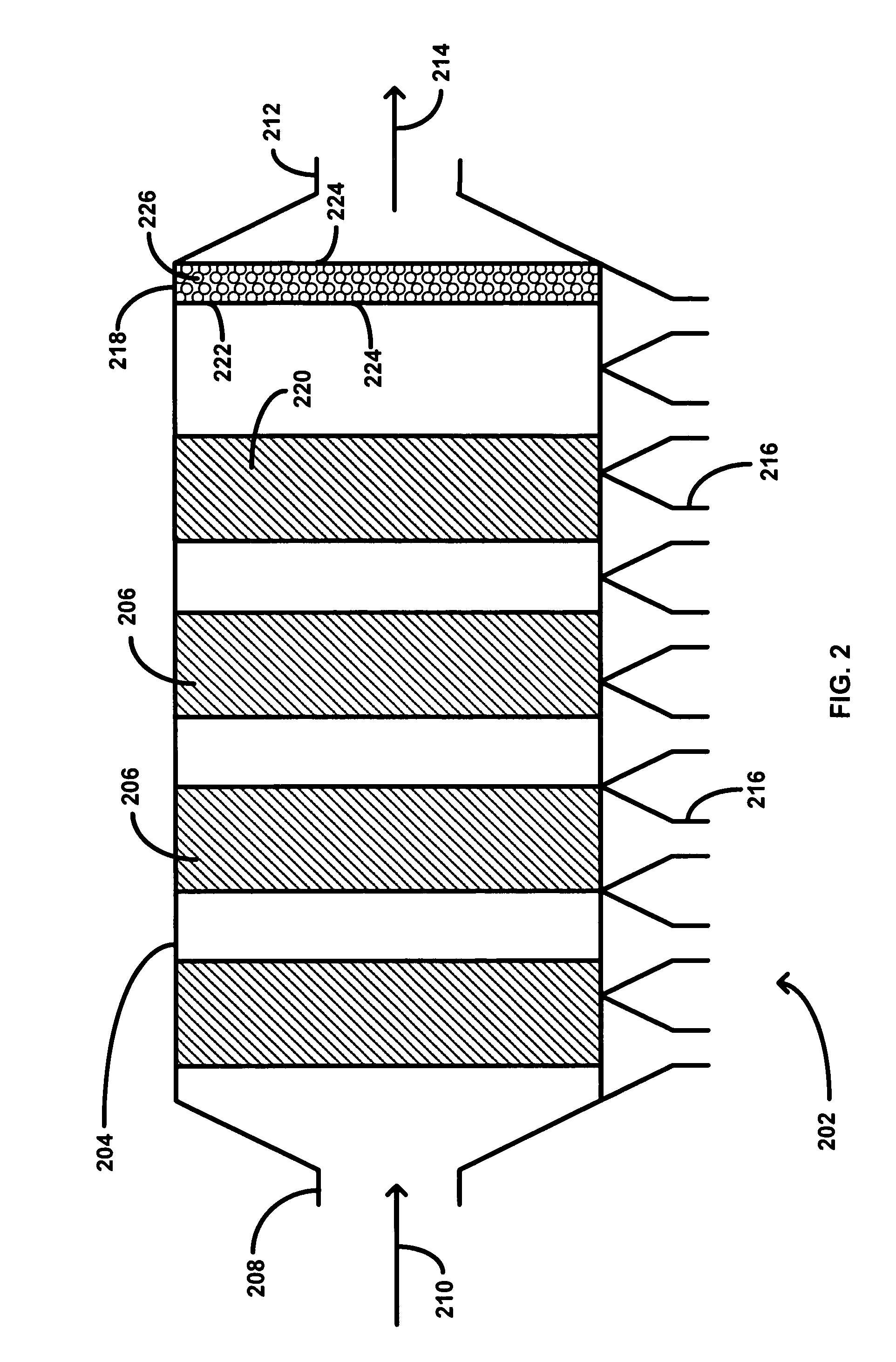

InactiveUS6964699B1Reduce probabilityEfficient captureCombination devicesGas treatmentGas passingEngineering

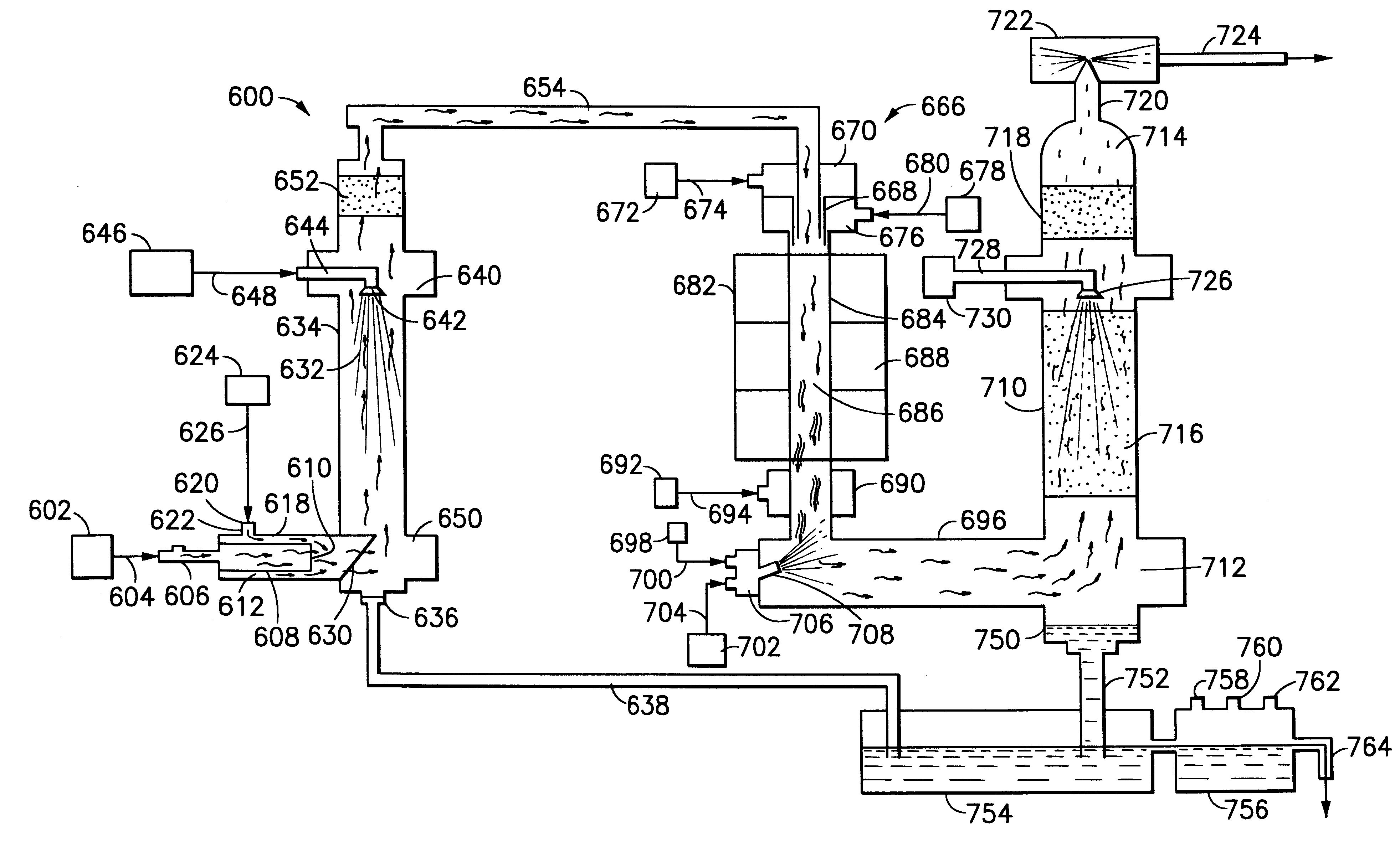

A wet scrubber having a series of chambers for capturing and cooling exhaust gases generated during static test firing of rocket motors. Exhaust gas enters an inlet to a first chamber and is cooled and slowed by a spray solution. HCL gas is condensed and absorbed by the spray solution and precipitates to a liquid slurry at the bottom of the device. The remaining exhaust products enter a demister chamber where nozzles continue to spray the gasses as they pass upward and through a mesh-style demister at the top of the vessel. The demister filters liquid and solid waste particles from the gas stream, and the clean, dry gases are accelerated through a centrifugal fan into the atmosphere. A deflector is positioned within the inlet to the first chamber for containing parts in the event of a motor mal-function.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

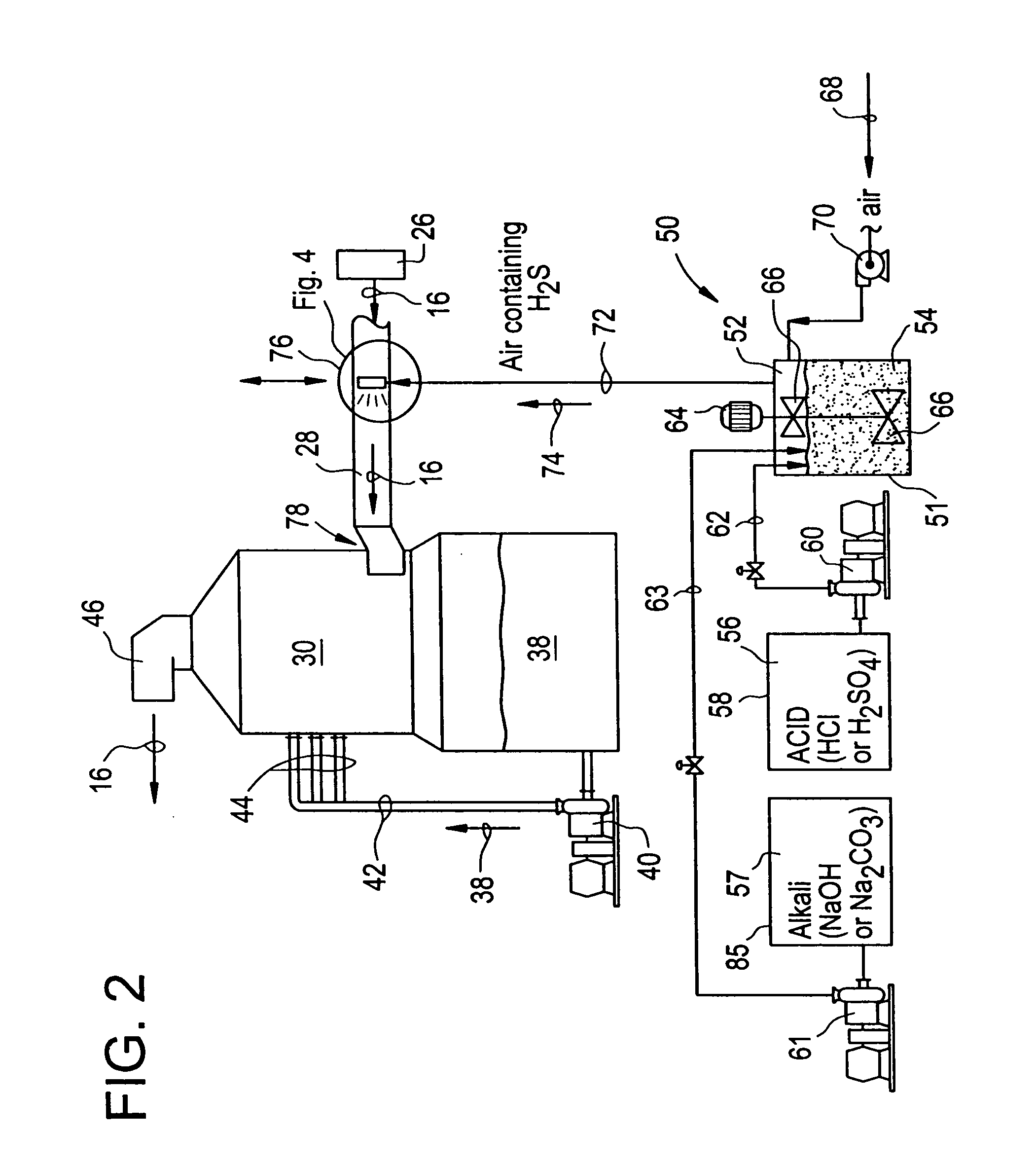

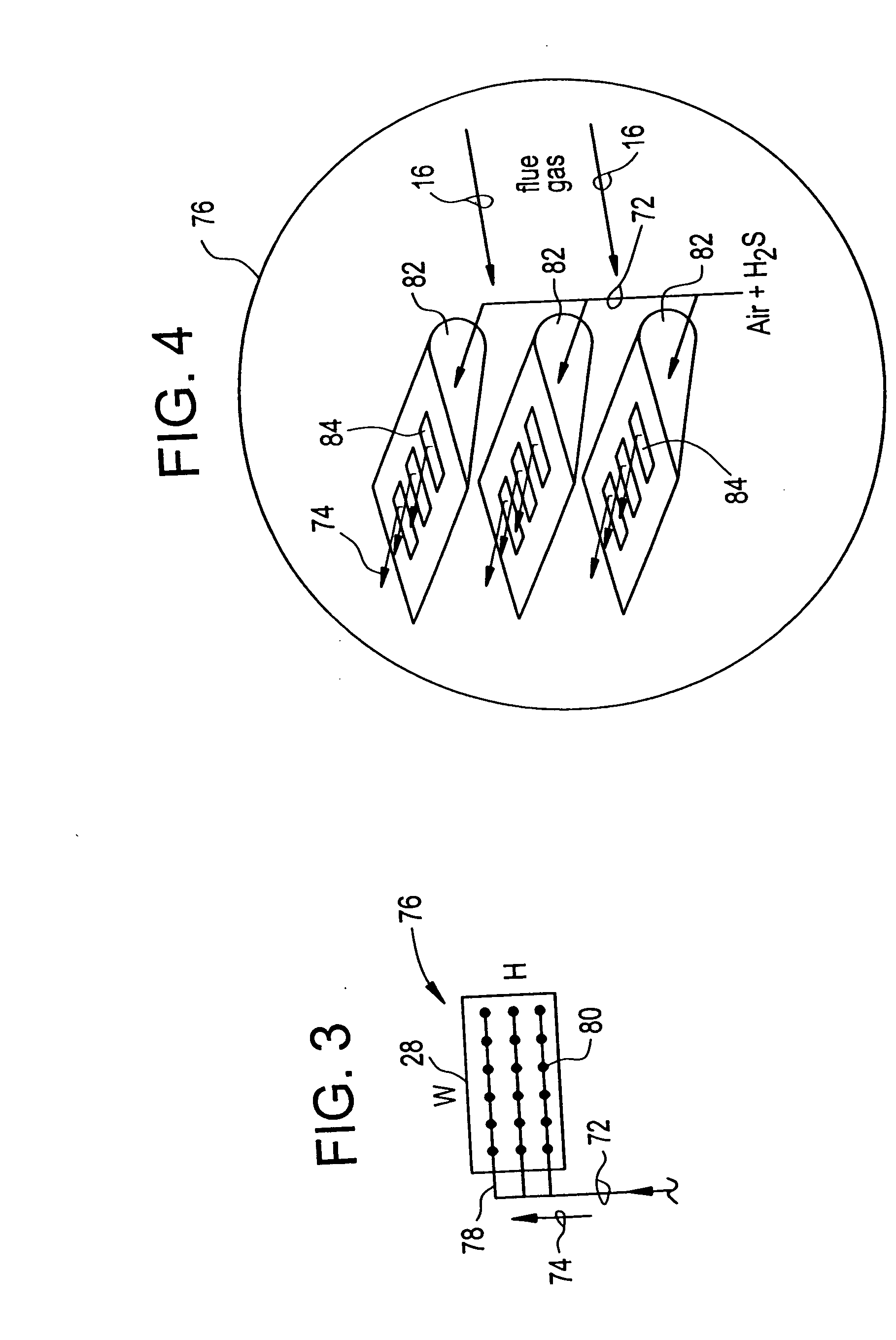

Method for control of mercury

InactiveUS20050169824A1Inherent safety advantageEfficient removalUsing liquid separation agentEmission preventionCoalWet scrubber

A method and apparatus for reducing mercury in industrial gases such as the flue gas produced by the combustion of fossil fuels such as coal adds hydrogen sulfide to the flue gas in or just before a scrubber of the industrial process which contains the wet scrubber. The method and apparatus of the present invention is applicable to installations employing either wet or dry scrubber flue gas desulfurization systems. The present invention uses kraft green liquor as a source for hydrogen sulfide and / or the injection of mineral acids into the green liquor to release vaporous hydrogen sulfide in order to form mercury sulfide solids.

Owner:DOWNS WILLIAM +1

Method of mercury removal in a wet flue gas desulfurization system

Controlling the reductive capacity of an aqueous alkaline slurry (23) in a wet scrubber makes it possible to accurately control the mercury emission from the scrubber to a desired value. One method of controlling the reductive capacity of the slurry is to measure the reduction-oxidation potential (“redox potential”) of the aqueous alkaline slurry (23) and to add or remove substances that affect the redox potential and thus the reductive capacity of the slurry. In wet scrubbers in which limestone is used for absorption of acid gases and where a gypsum slurry is circulated, it has been found to be an attractive solution to control the amount of oxidation air blown into the scrubber in order to control the redox potential and thereby the mercury emissions.

Owner:GENERAL ELECTRIC TECH GMBH

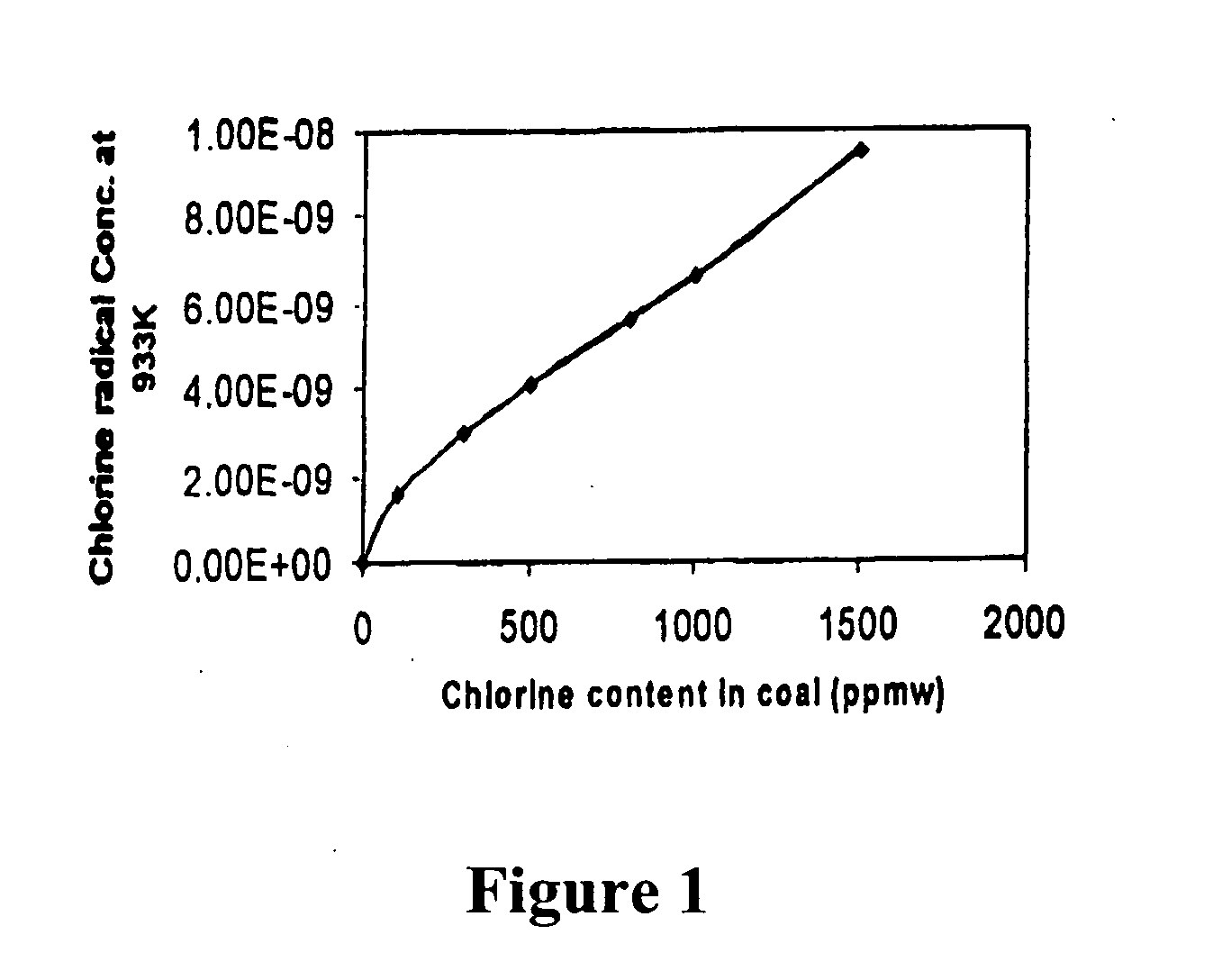

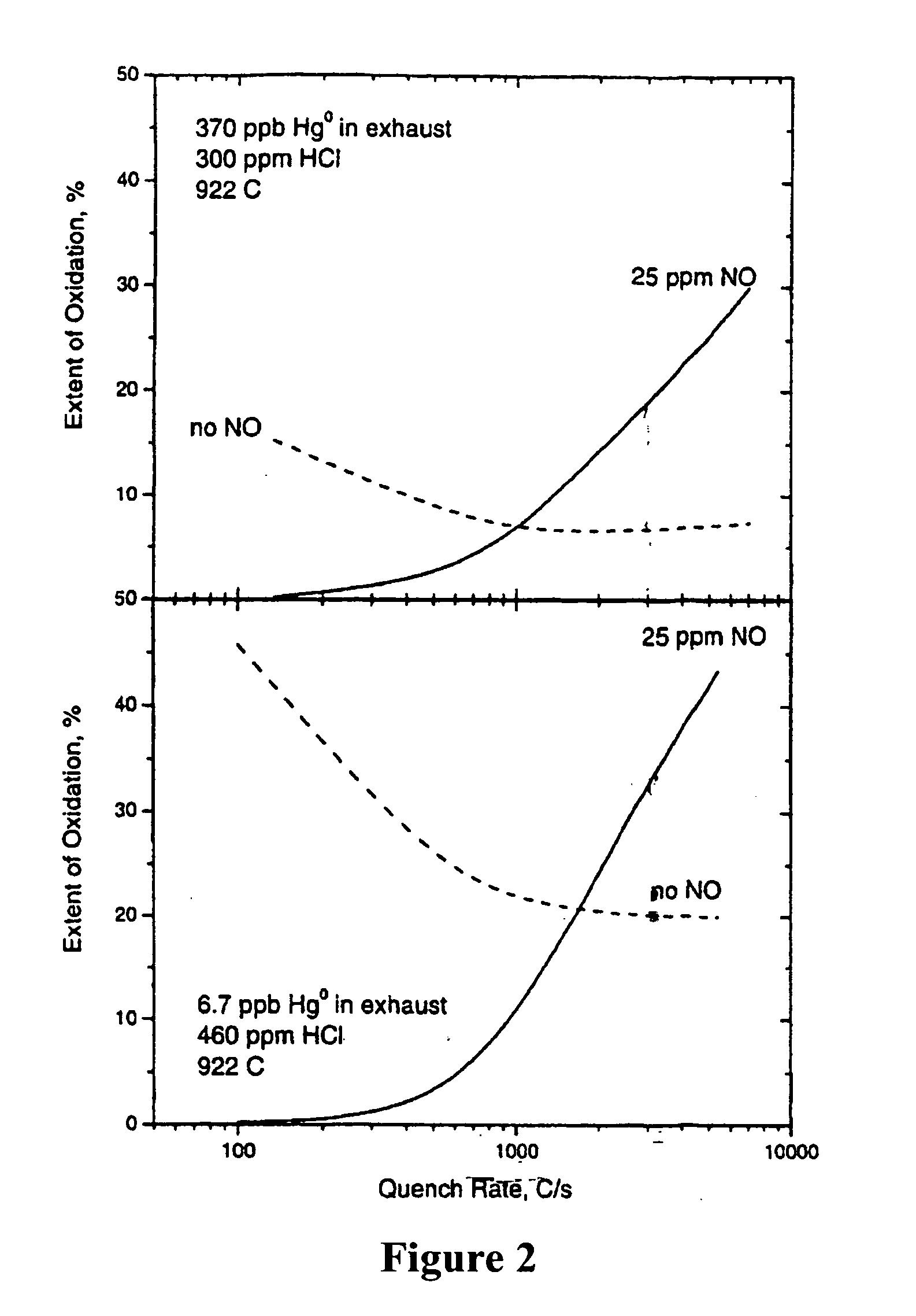

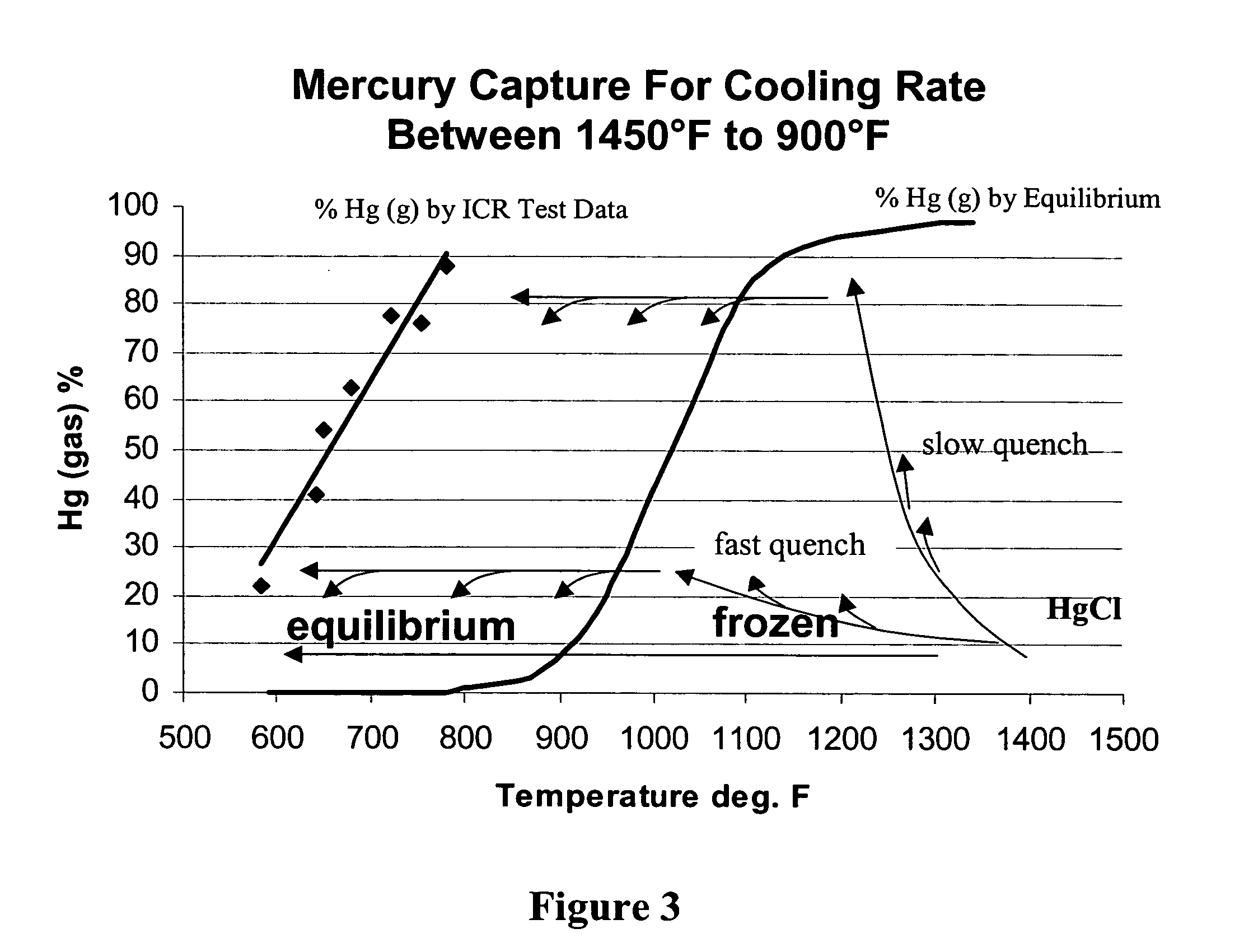

Method of removing mercury from flue gas through enhancement of high temperature oxidation

InactiveUS20060029531A1Increased formationIncrease volumeGas treatmentUsing liquid separation agentGas phaseWastewater

In a method for removing mercury from flue gas produced by combustion devices burning coal and other fuels that contain mercury and chlorine the combustion process is controlled to generate a flue gas comprising fly ash containing at least 0.25% unburned carbon, and preferably at least 5.0% unburned carbon. In addition the flue gas is rapidly cooled from a temperature within the range of 1450° F. to 900° F. to a temperature below 900° F. at a rate of at least 1000° F. per second. This step will enhance the concentrations of Cl-atoms and Cl2, which accelerates the rates of mercury oxidation in both the gas phase and on particle surfaces. Finally, the flue gas is directed to the particle removal device for removal of the fly ash to which some of the mercury is bound, and also directed to a wet scrubber for retention of the oxidized mercury vapor in wastewater and solid effluents.

Owner:BREEN ENERGY SOLUTIONS

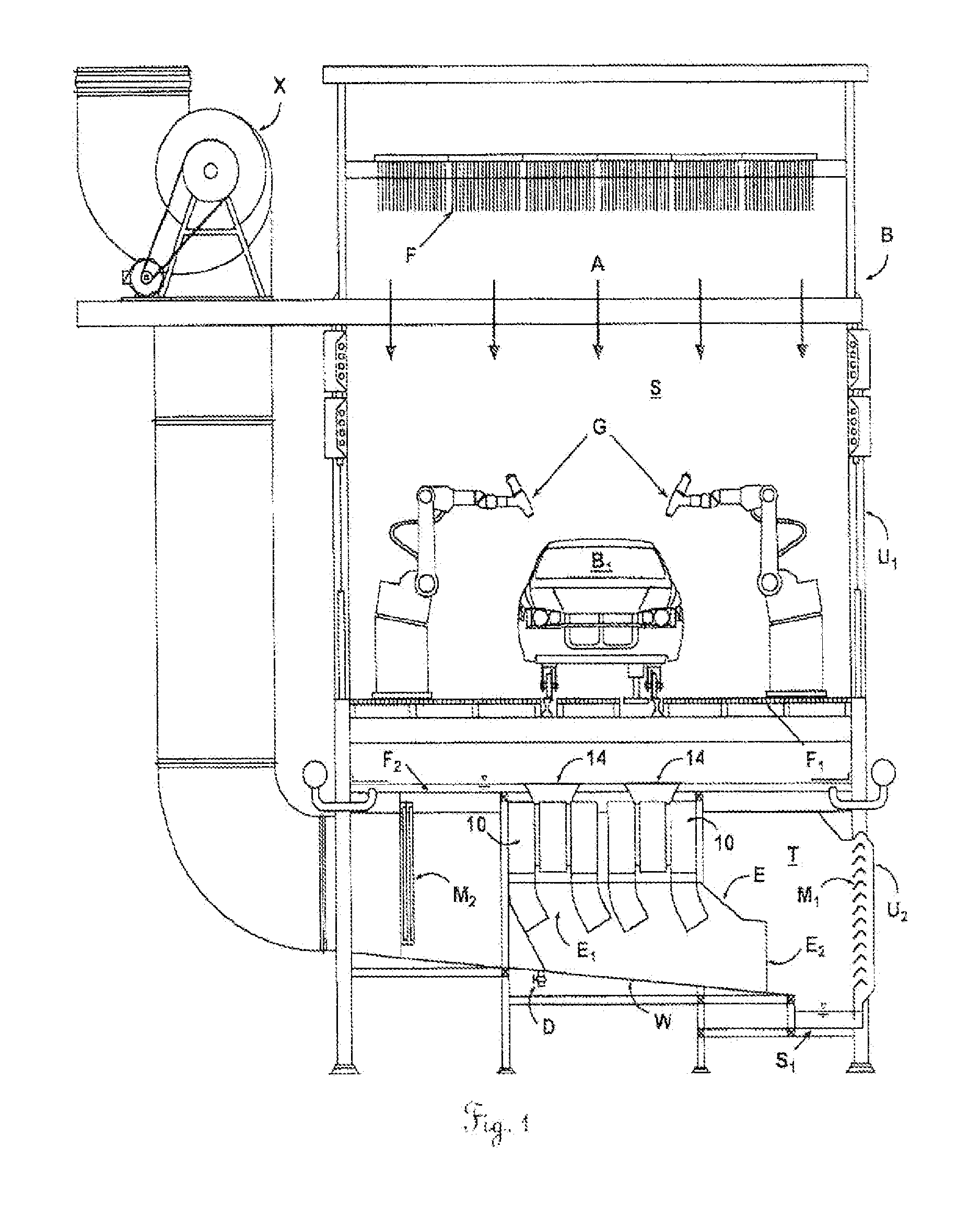

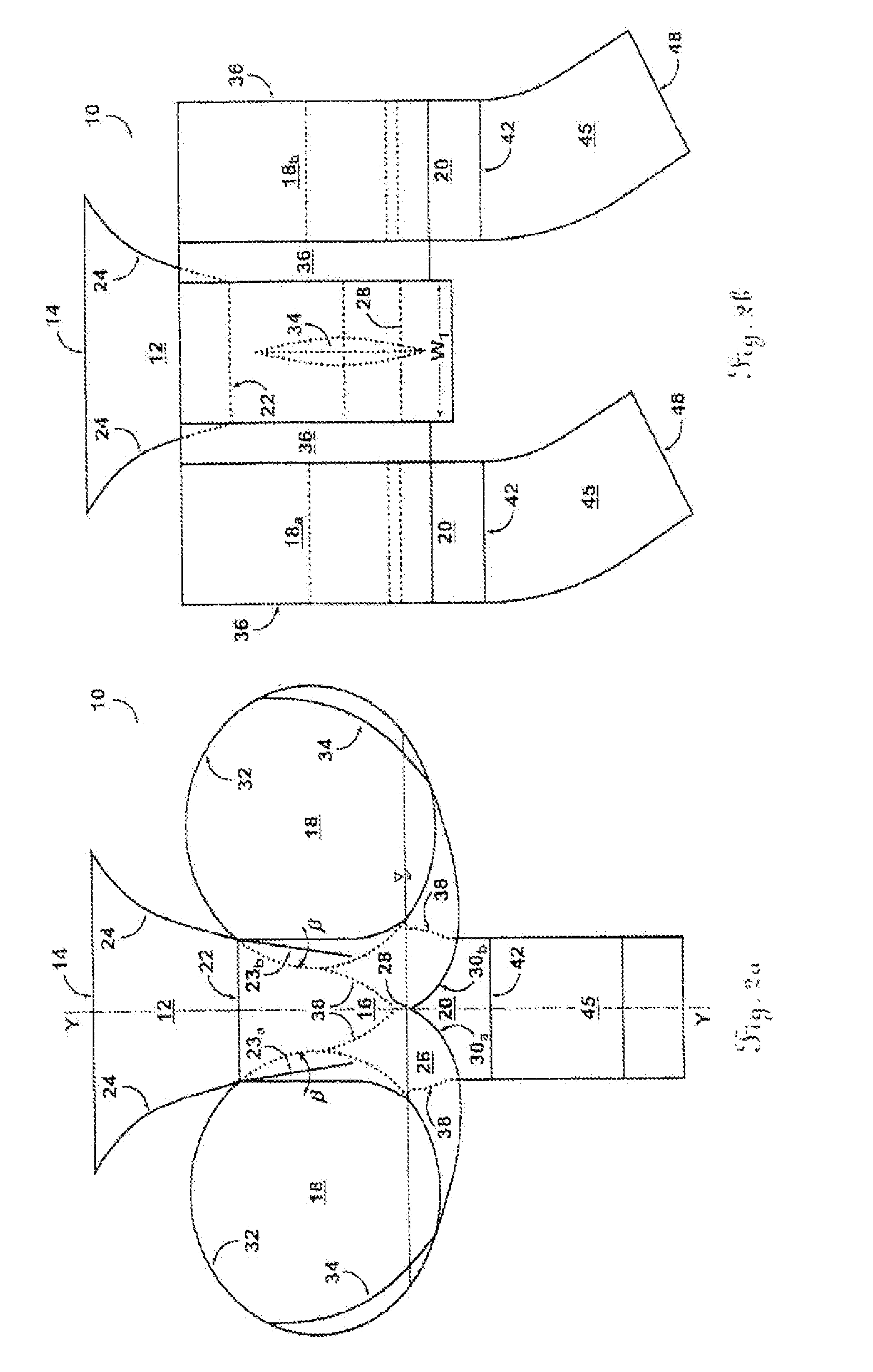

Fluid scrubber and spray booth including the fluid scrubber

ActiveUS20100212498A1Avoid recyclingLiquid surface applicatorsUsing liquid separation agentBiomedical engineeringWet scrubber

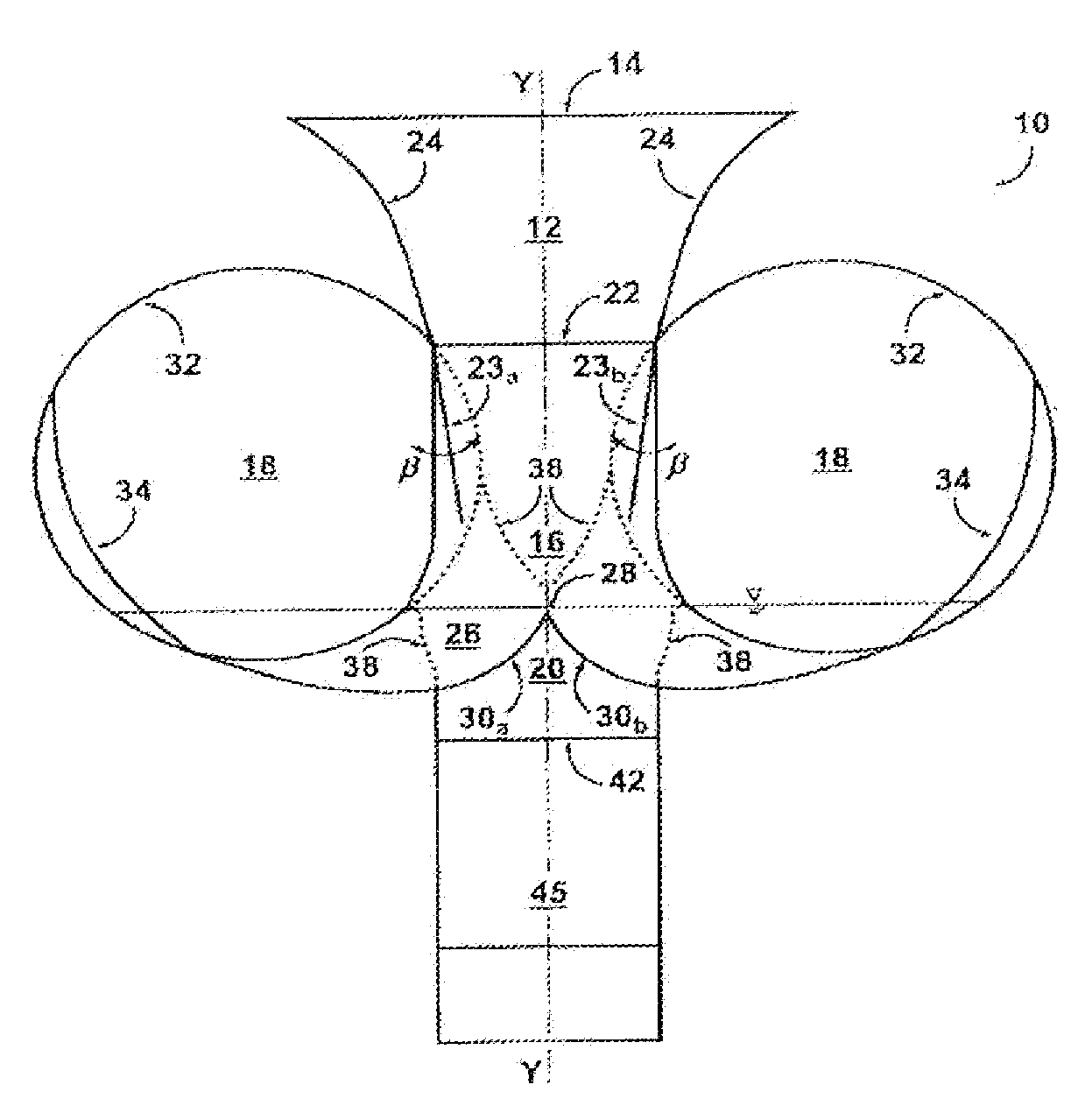

A wet scrubber for scrubbing a fluid. The wet scrubber may include an inlet for receiving the fluid and a vortex chamber, in communication with the inlet, for causing at least a portion of the fluid to circulate. The wet scrubber may also include at least one diffuser for exhausting the fluid from the vortex chamber, the diffuser configured to substantially prevent fluid exhausted from the diffuser from recirculating back into the diffuser. A paint booth and a method of scrubbing a fluid are also provided.

Owner:UNIV OF KENTUCKY RES FOUND

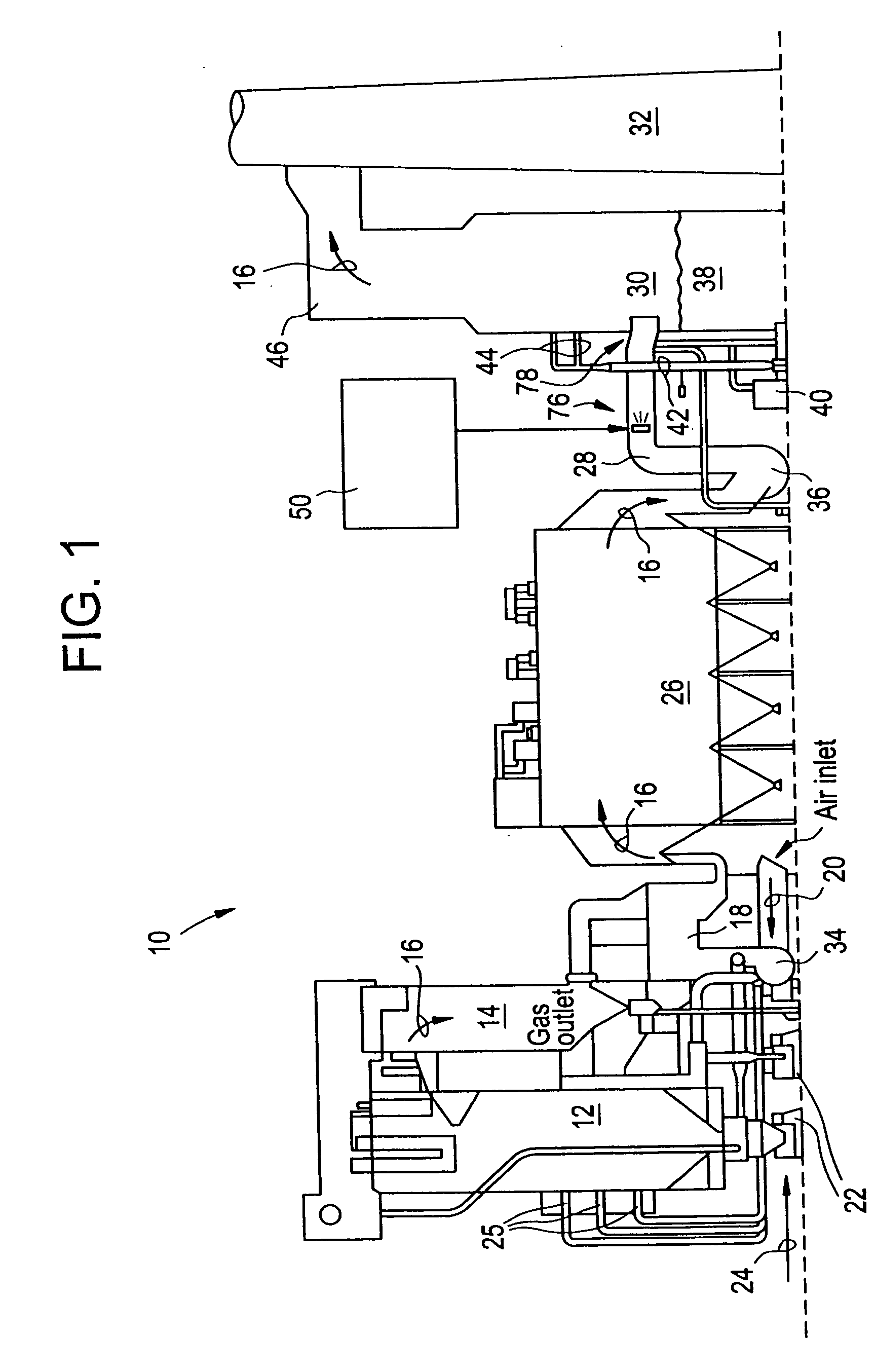

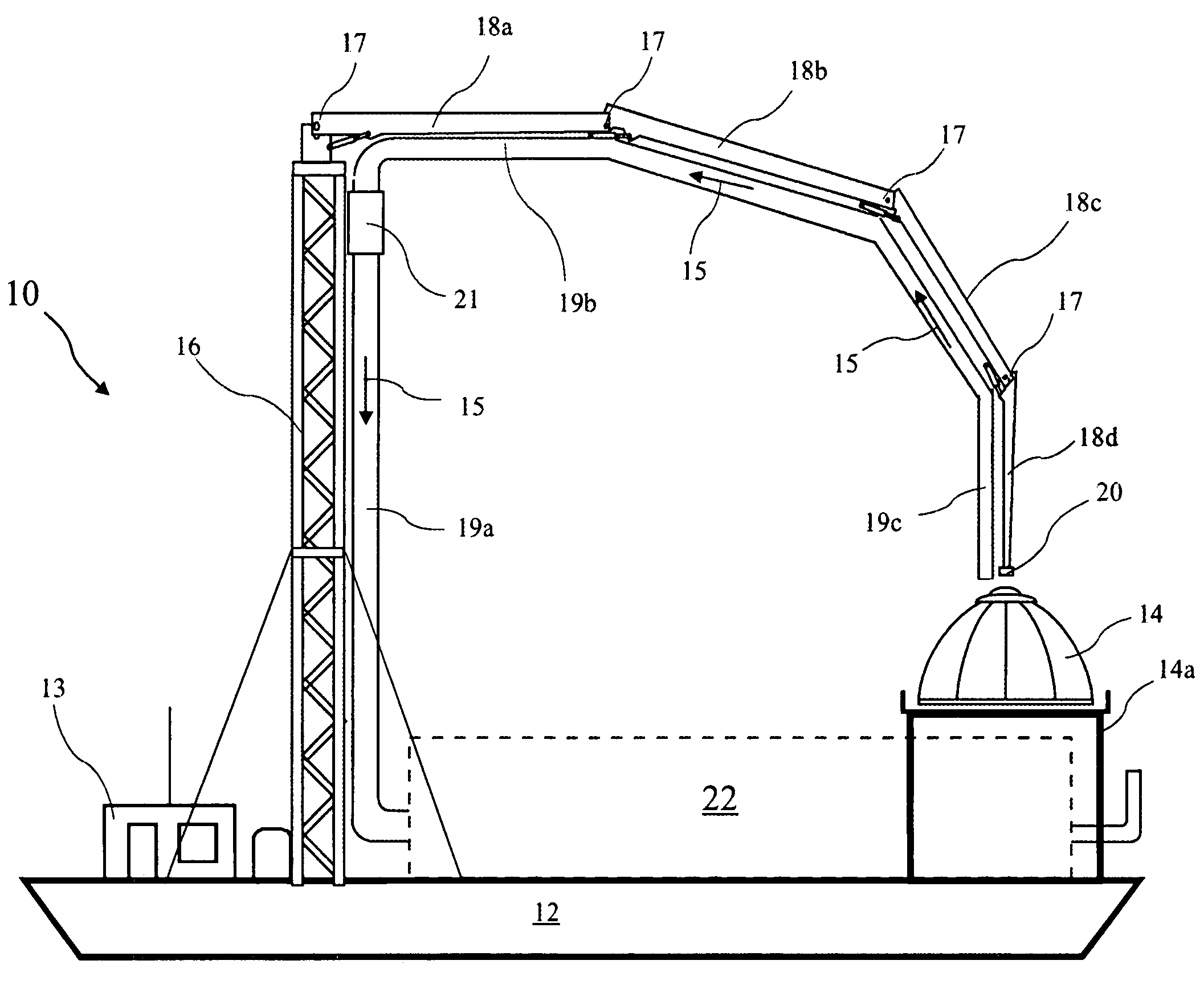

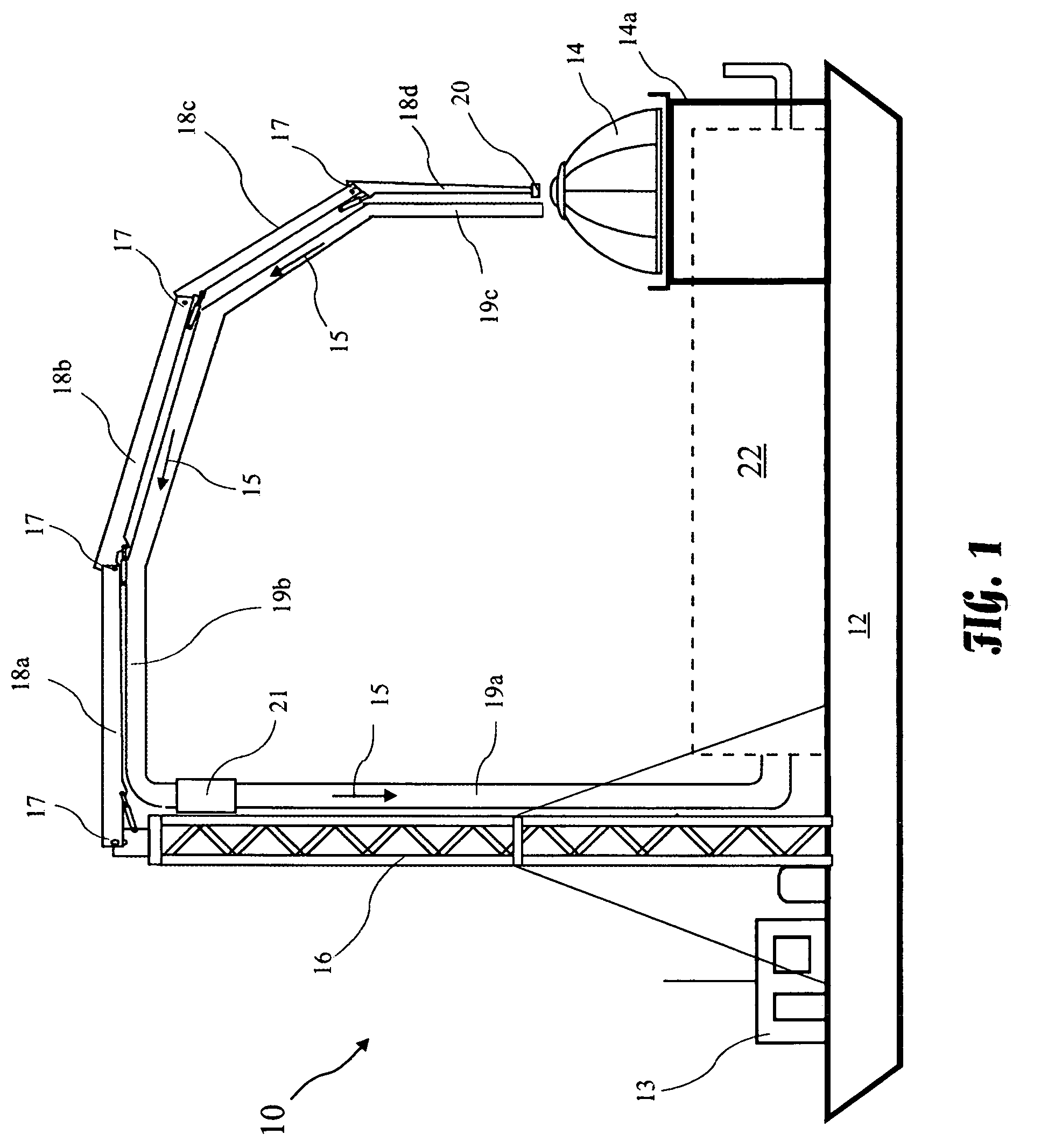

Air pollution control system for ocean-going vessels

ActiveUS20060213197A1Improve efficiencyExtended service lifeGas treatmentInternal combustion piston enginesParticulatesPollution

Owner:ADVANCED ENVIRONMENTAL GRP +1

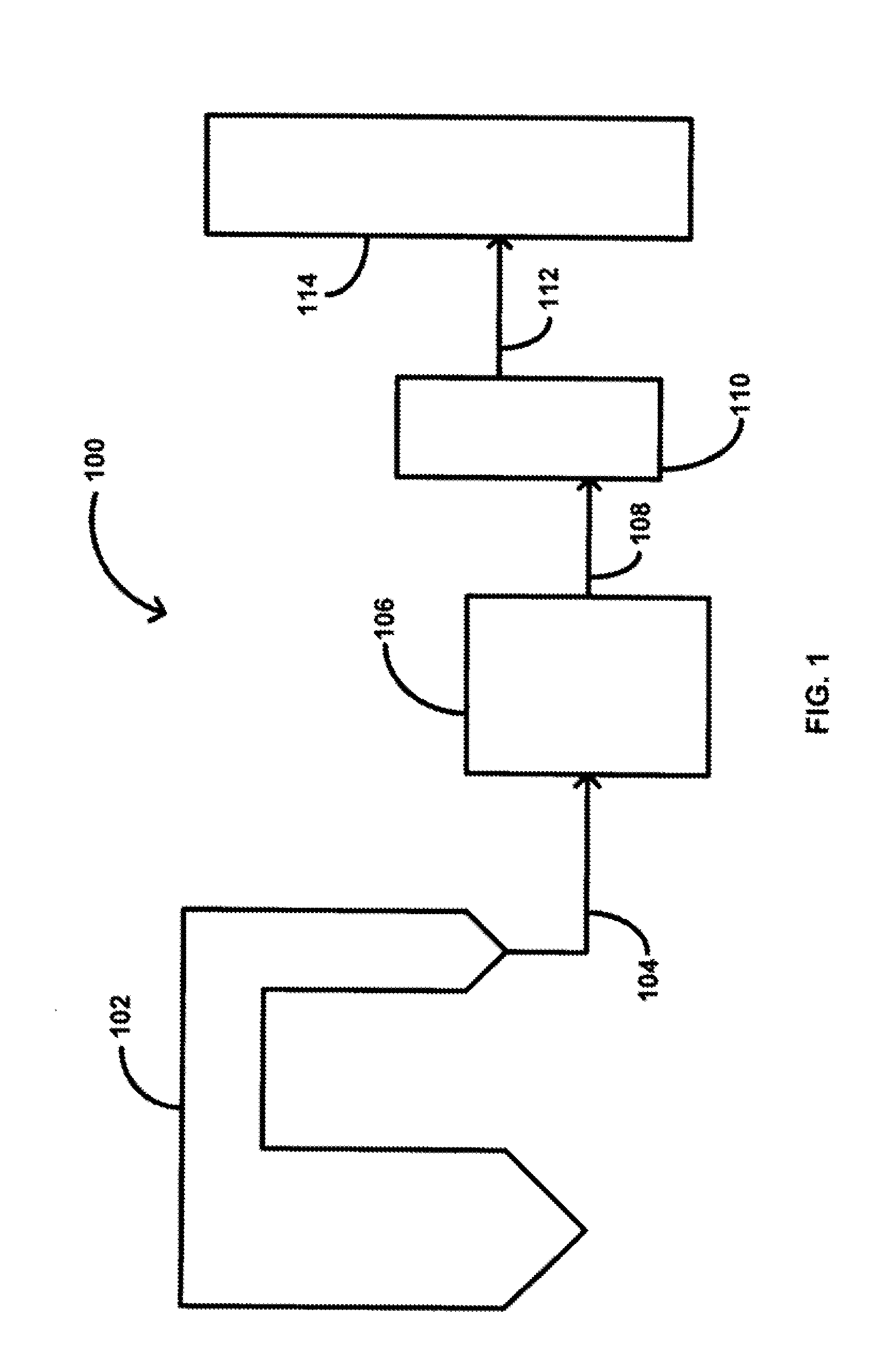

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

InactiveUS6333010B1Reduce sensitivityReduced water requirementsCombination devicesGas treatmentEnvironmental engineeringProduct gas

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises a pre-oxidation treatment unit, which may for example comprise a scrubber, an oxidation unit such an electrothermal oxidizer, and a post-oxidation treatment unit, such as a wet or dry scrubber. The effluent gas stream treatment system of the invention may utilize an integrated oxidizer, quench and wet scrubber assembly, for abatement of hazardous or otherwise undesired components from the effluent gas stream. Gas or liquid shrouding of gas streams in the treatment system may be provided by high efficiency inlet structures.

Owner:BHT SERVICES PTE LTD

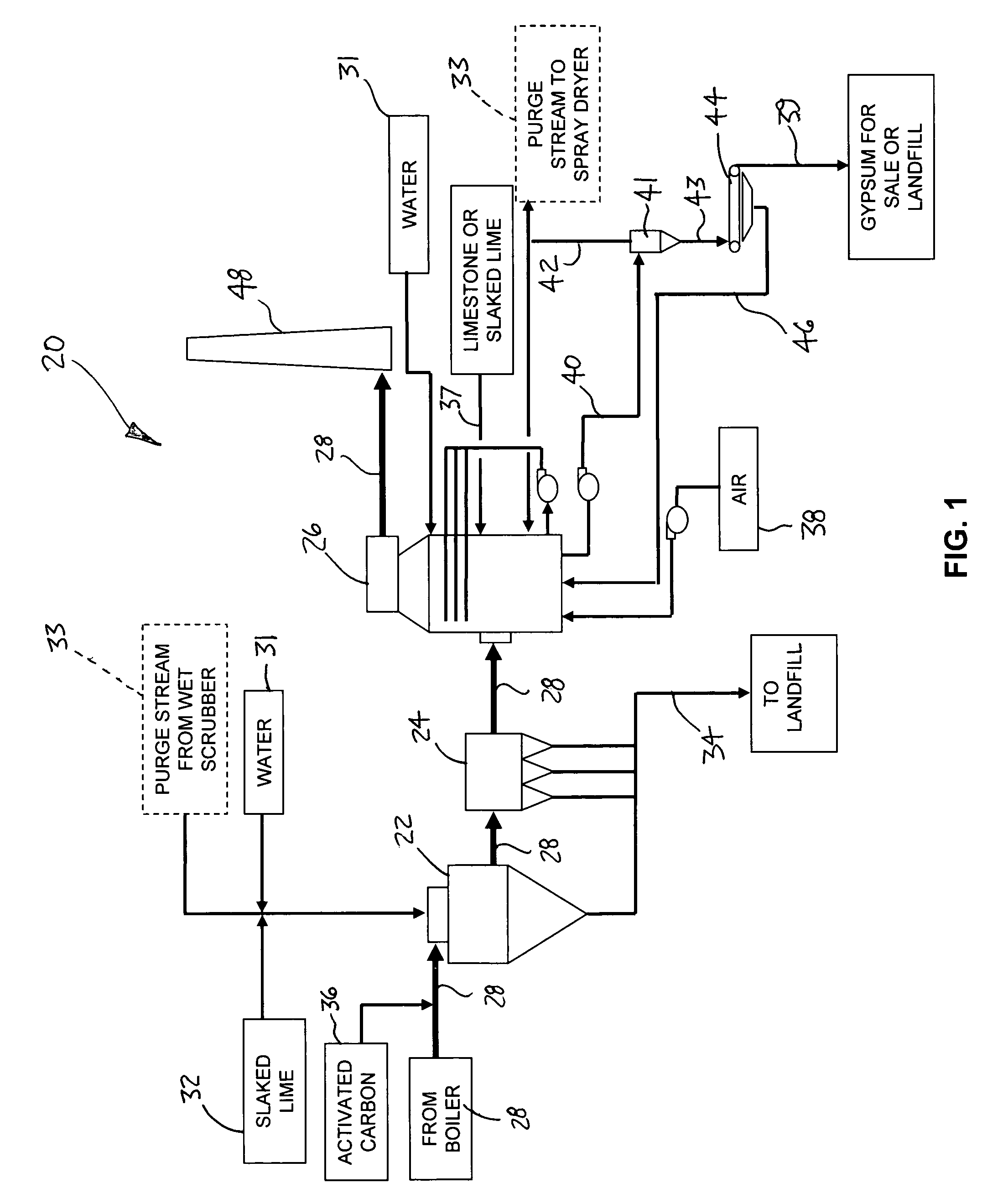

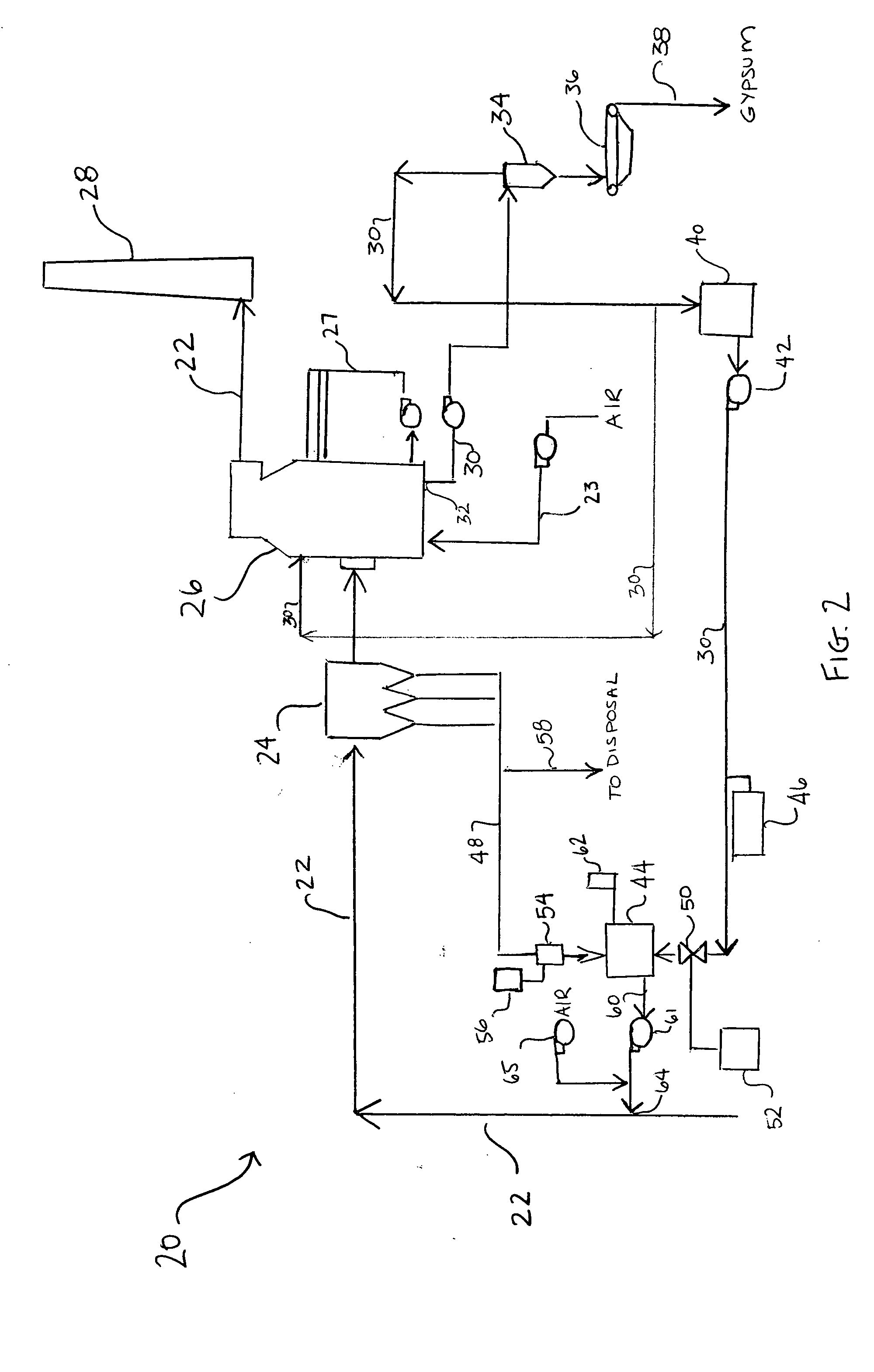

Integrated dry and wet flue gas cleaning process and system

A process and system for removing sulfur oxide, other gases, and particulate from a flue gas. The process includes treating flue gas with a slurry formed from water, an alkaline reagent, and the purge stream from a wet scrubber in a spray dryer, thereby producing a dry by-product. The process further includes filtering the flue gas to remove at least a portion of the dry by-product, wet scrubbing the flue gas exiting the filter in a wet scrubber, adding a lime or limestone reagent to the wet scrubber, and producing gypsum. Activated carbon may be injected into the flue gas upstream of the filtering step and particulate may be removed from the flue gas upstream of the spray dryer.

Owner:GENERAL ELECTRIC TECH GMBH

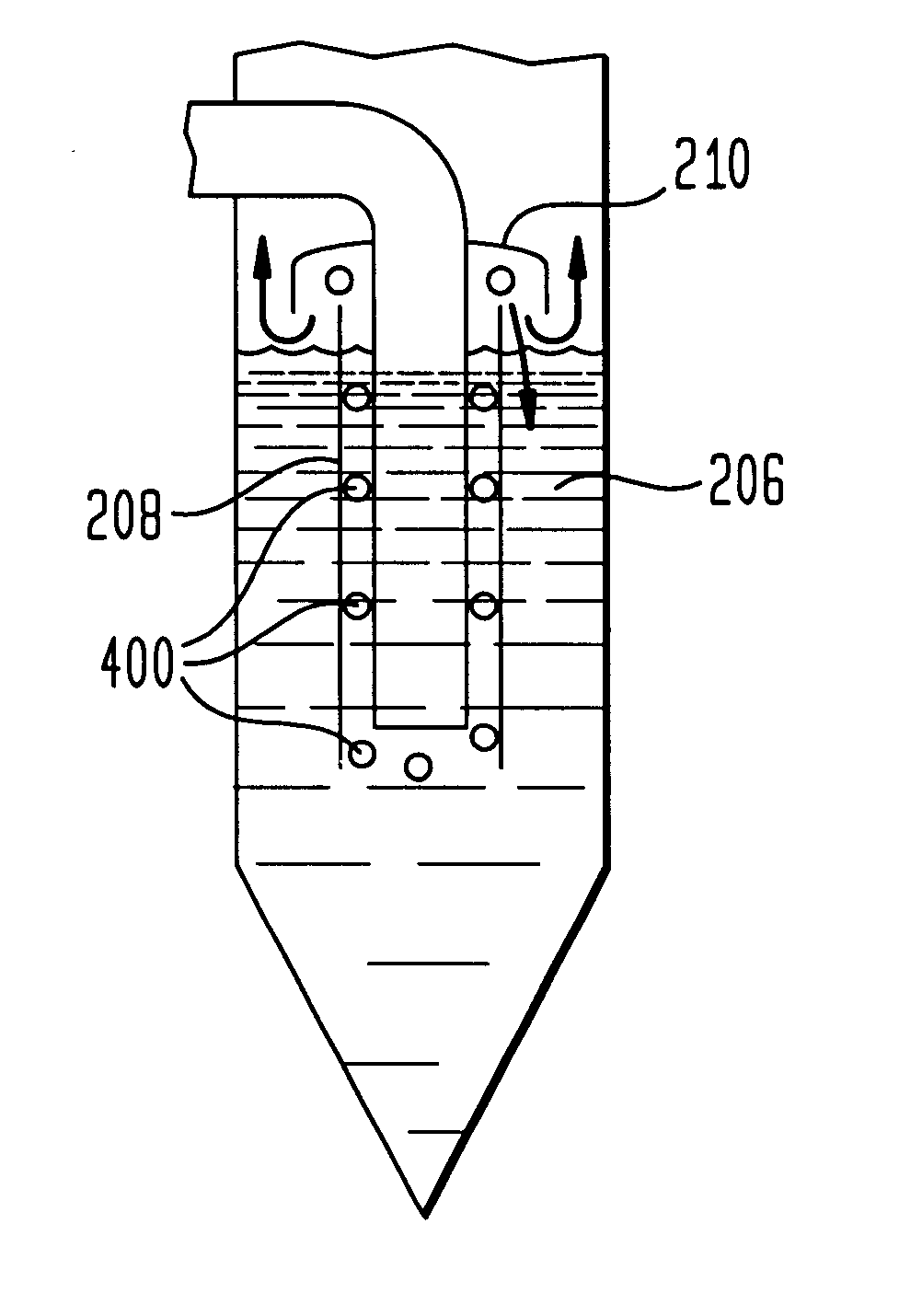

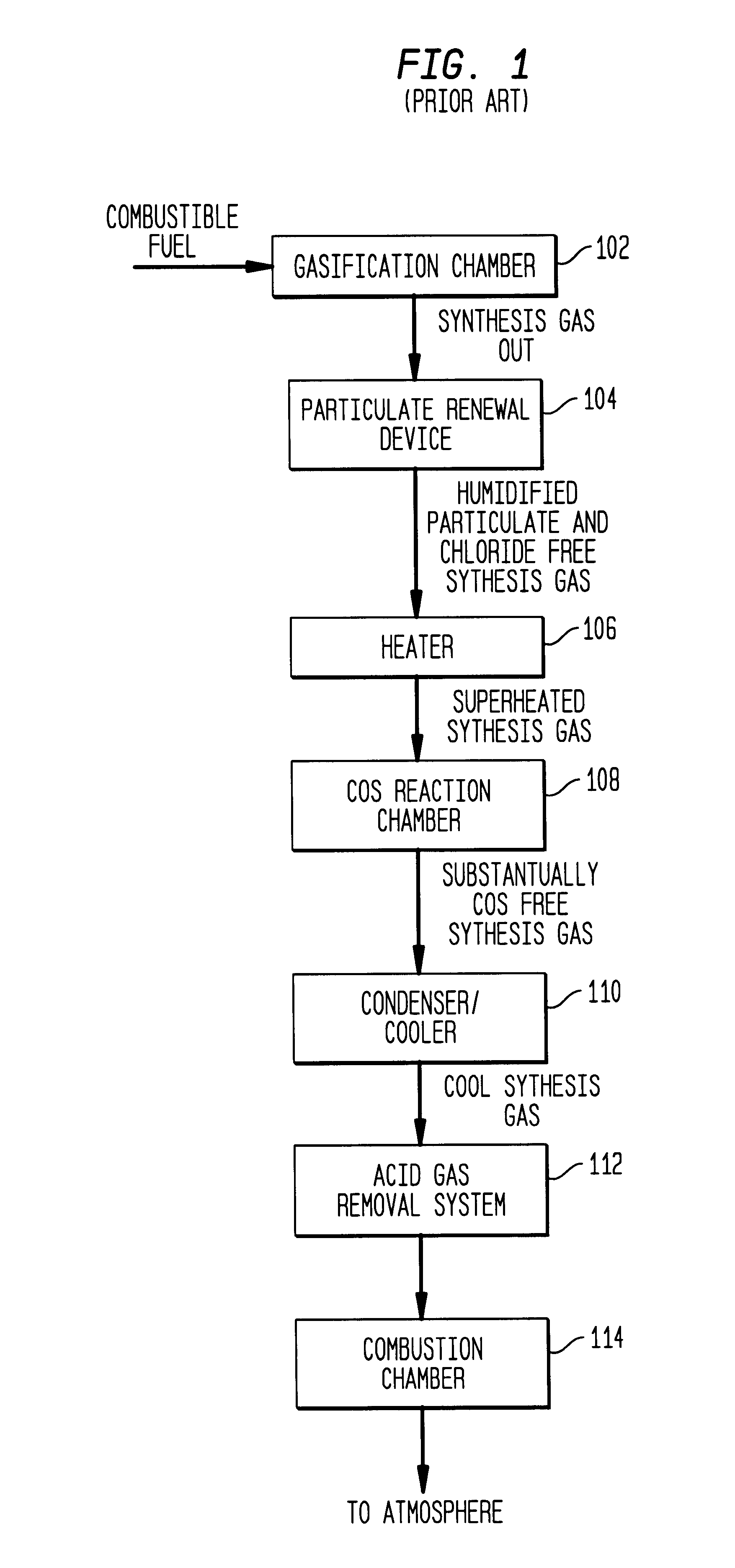

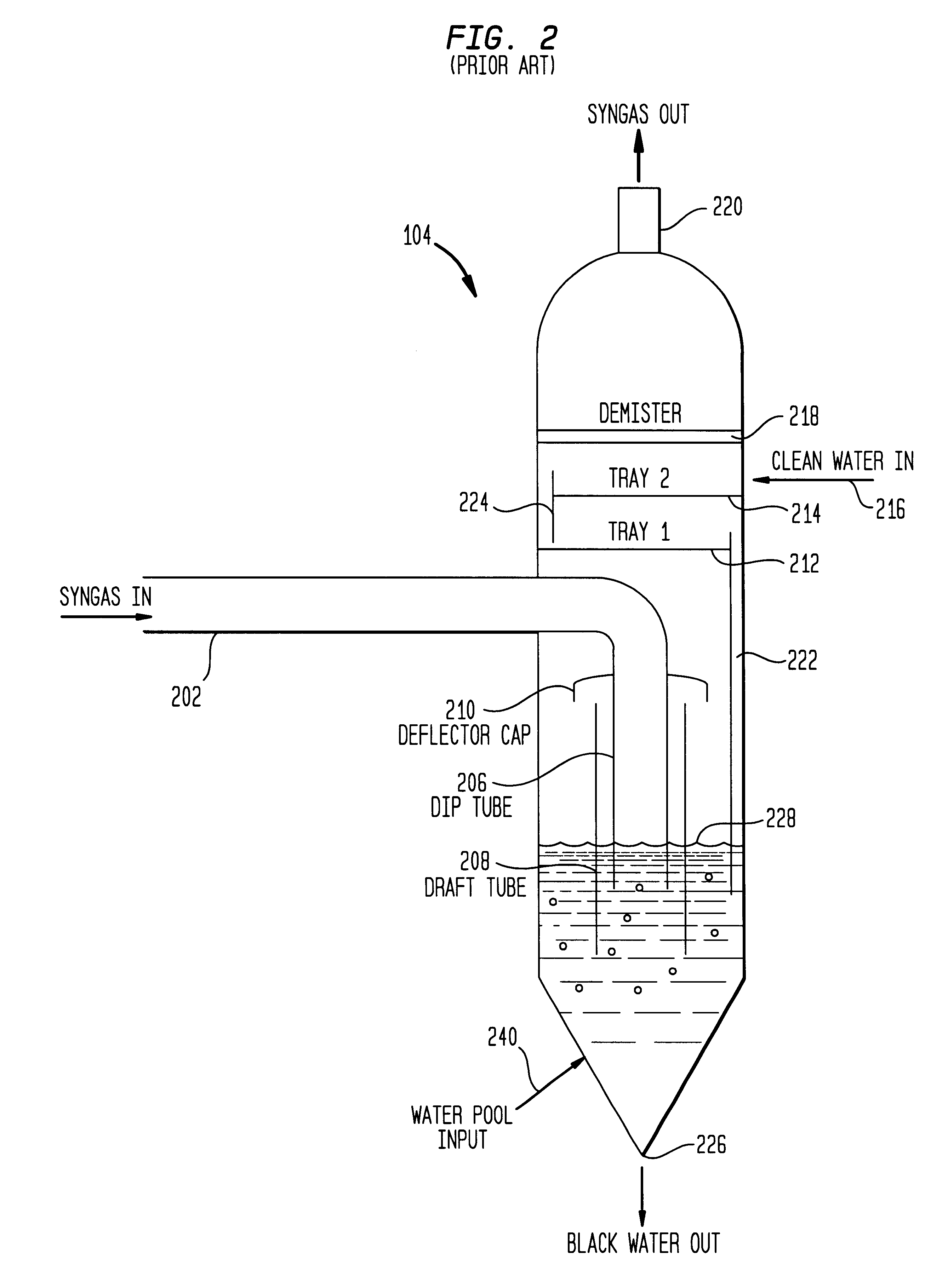

Method and apparatus for removing carbonyl sulfide from a gas stream via wet scrubbing

InactiveUS6322763B1Weaken energyLower Level RequirementsGas treatmentUsing liquid separation agentCarbonyl sulfideWater flow

Methods for removing carbonyl sulfide (COS) from a synthesis gas stream are disclosed. The method entails raising the water level of a wet scrubber so that hydrolysis of the COS may occur in the scrubber itself instead of a COS reduction chamber and no additional catalysts other than those naturally occurring in the production of the synthesis gas need be introduced into the scrubber. The water is raised, in one example, to a level such that water within an inner tube of the wet scrubber flows over an upper end of the inner tube. Raising the water level in the scrubber ensures intimate and vigorous interaction between the water, the COS, and the naturally occurring catalyst, and promotes the hydrolysis of the COS. In one example, the naturally occurring catalyst (e.g., alumina oxide) is present in the coal ash produced when coal is the fuel gasified that creates the synthesis gas stream.

Owner:MTI INSULATED PROD

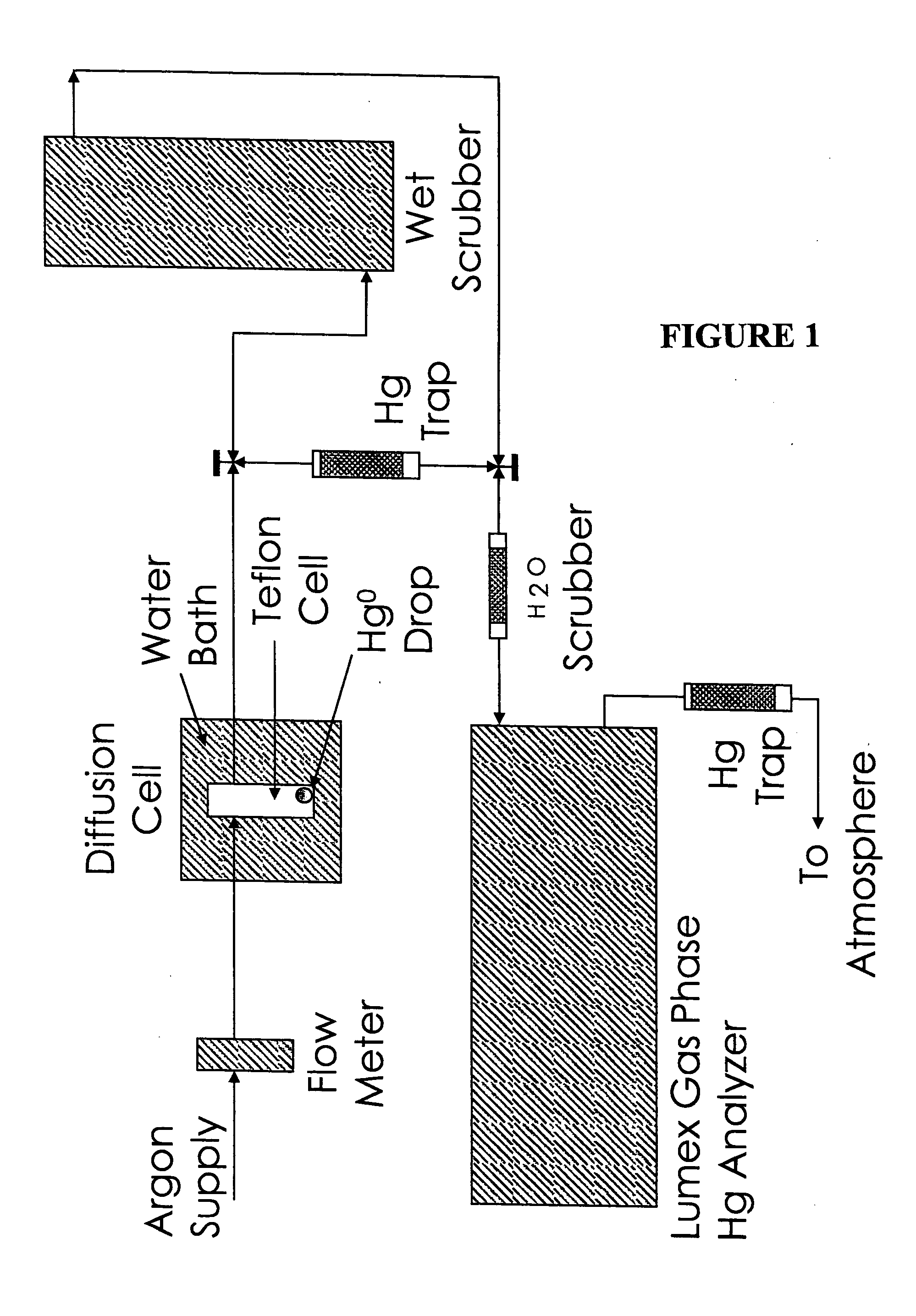

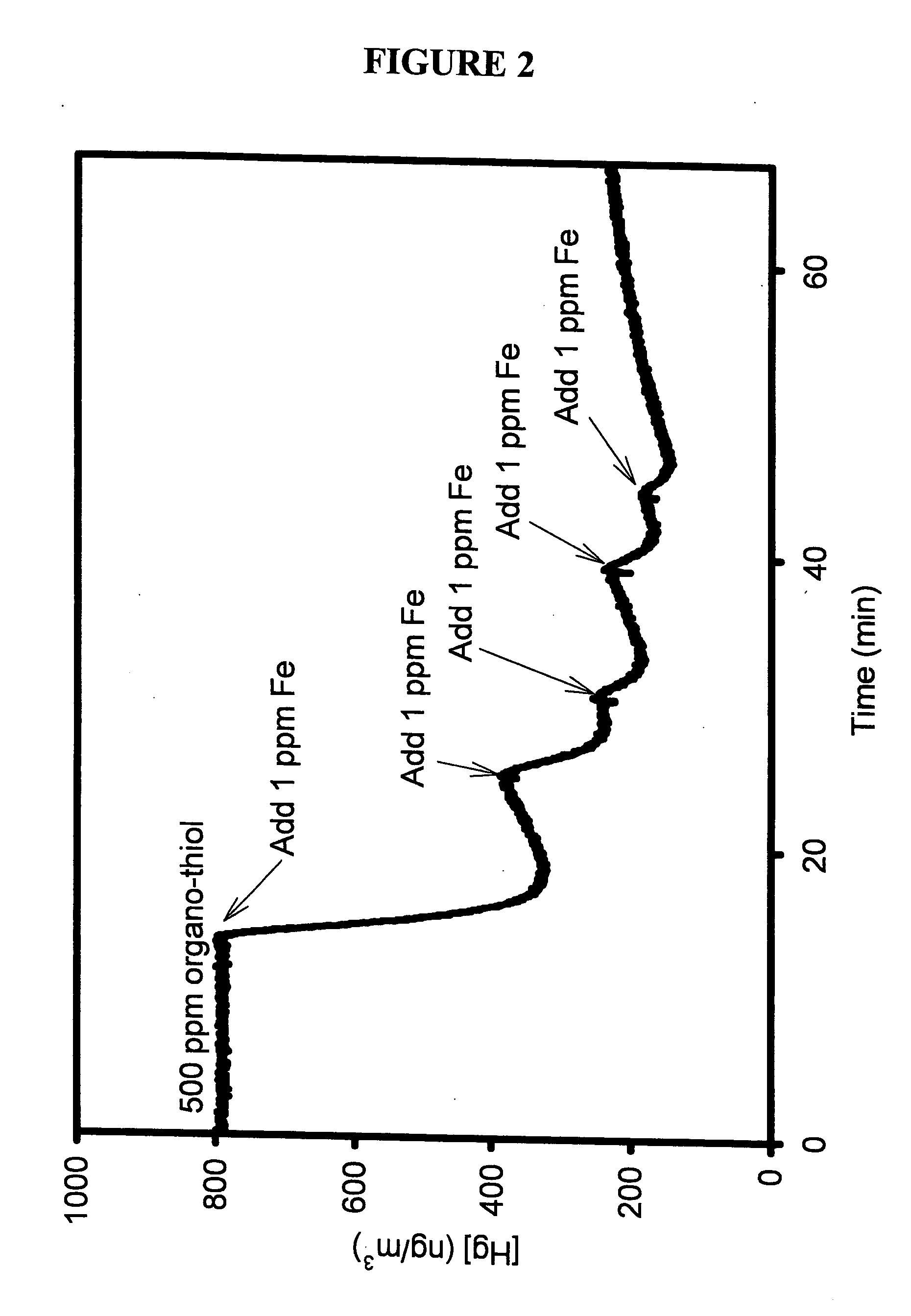

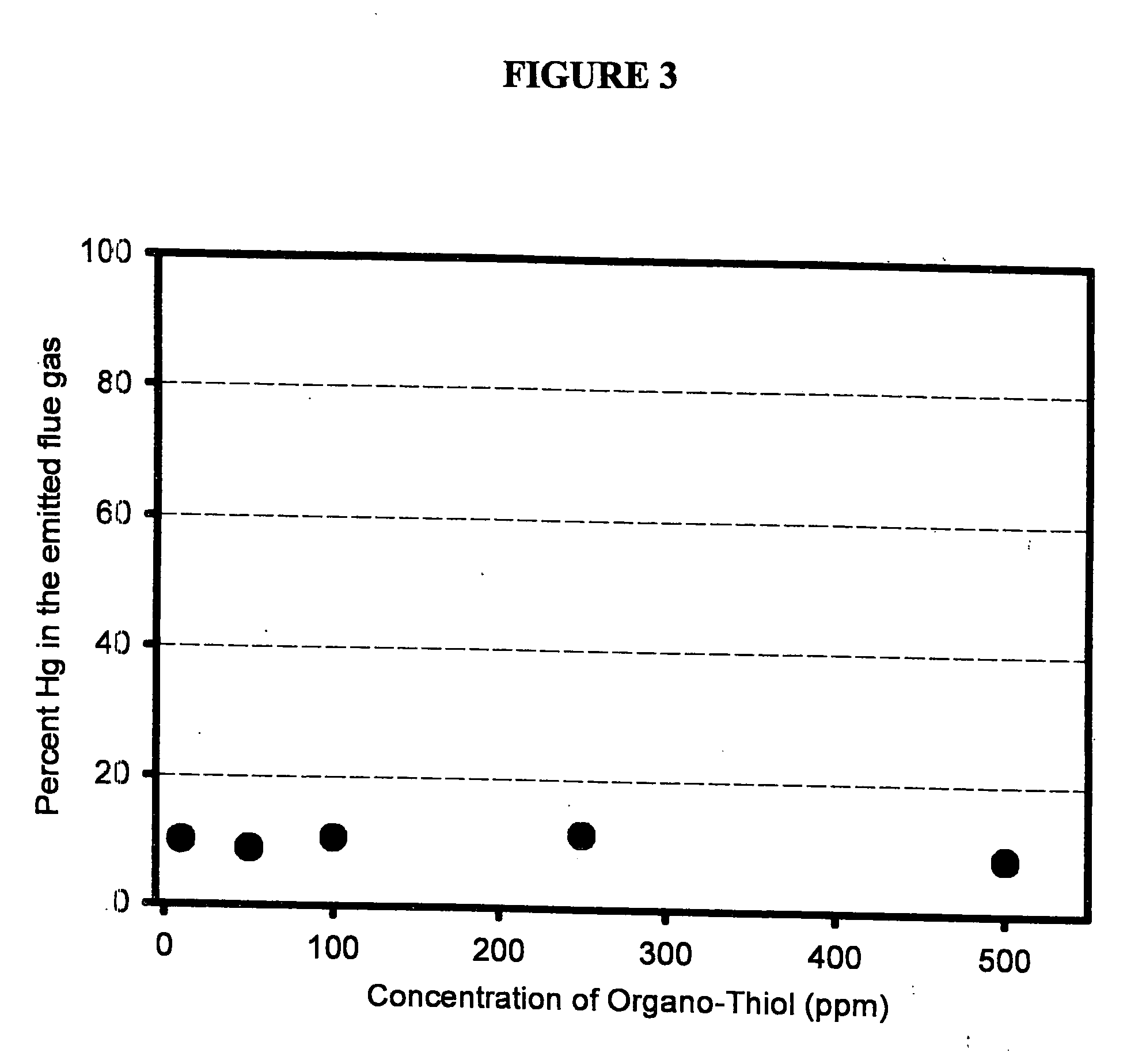

Removal of elemental mercury from gas by modifying wet scrubber systems with an organic compound

A method of removing elemental mercury from gas phase fluids by contacting the gas with an organic compound dissolved in a gas scrubbing liquid.

Owner:HENSMAN CARL E

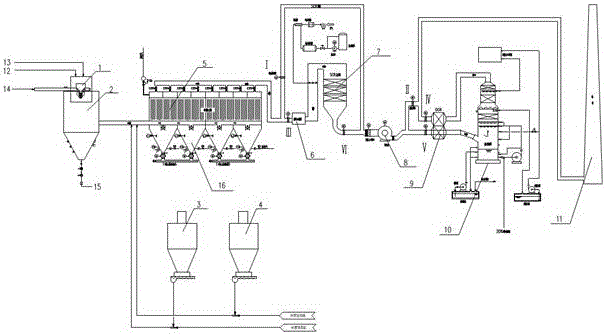

Garbage incineration fume ultralow emission purifying system

PendingCN106621754AImprove removal efficiencyAchieve cleanupCombination devicesGas treatmentActivated carbonPlate heat exchanger

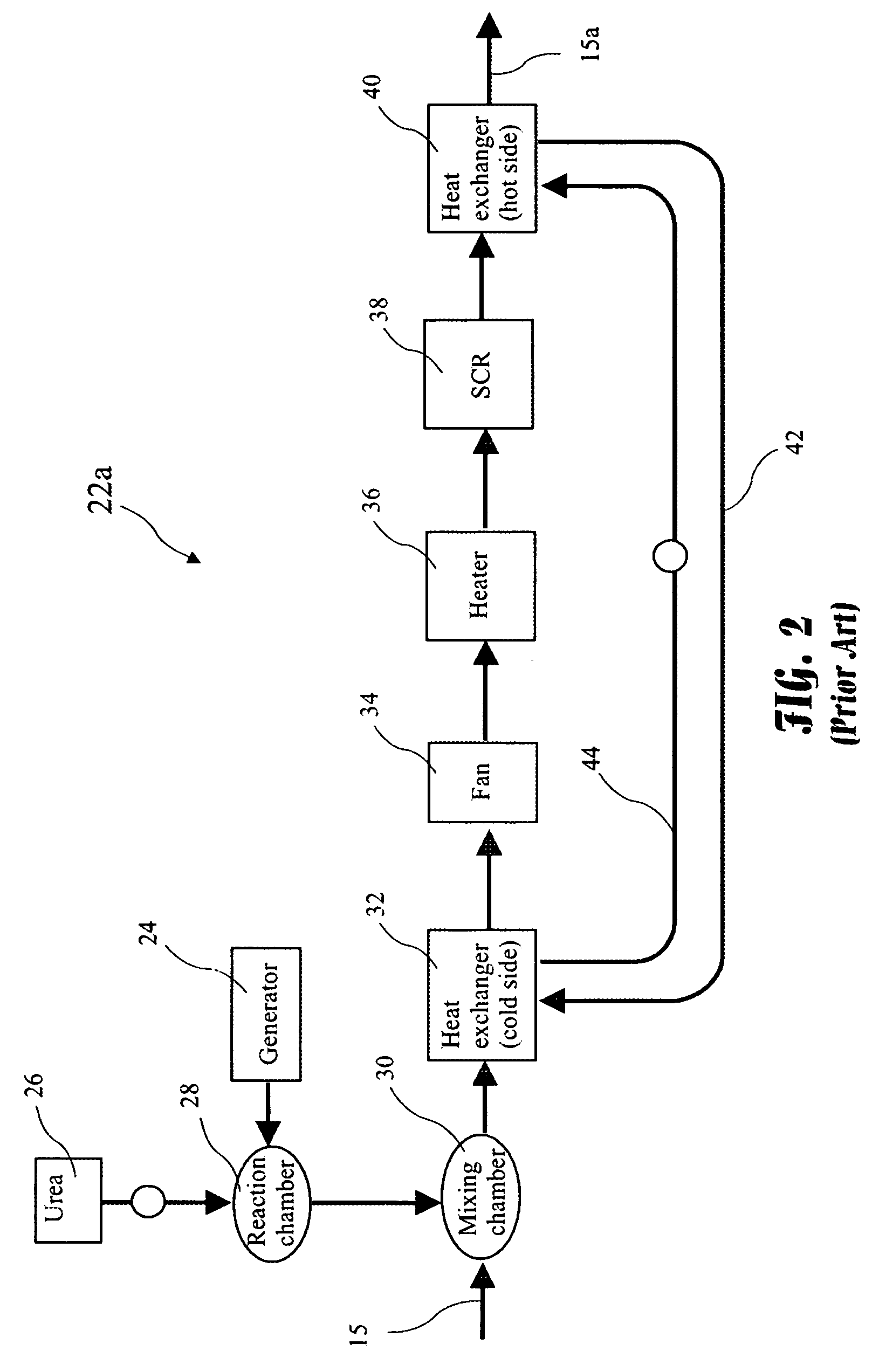

The invention discloses a garbage incineration fume ultralow emission system. A garbage incineration fume purifying treatment device comprises an SNCR (selective non-catalytic reduction) device, a semi-dry type reaction tower, a slaked lime spraying device, an activated carbon spraying device, a bag type deduster, a steam heater, an SCR (selective catalytic reduction) reaction tower, a fume / fume heat exchanger, a wet type scrubbing tower, an induced draft fan and a chimney. The low-temperature fume after washing is performed with heat exchange in the fume / fume heat exchanger, heated, and exhausted out of the chimney. The garbage incineration fume purifying treatment device has the advantage that the emission of the fume is superior to the European Union 2000 standard.

Owner:SHANGHAI SUS ENVIRONMENT

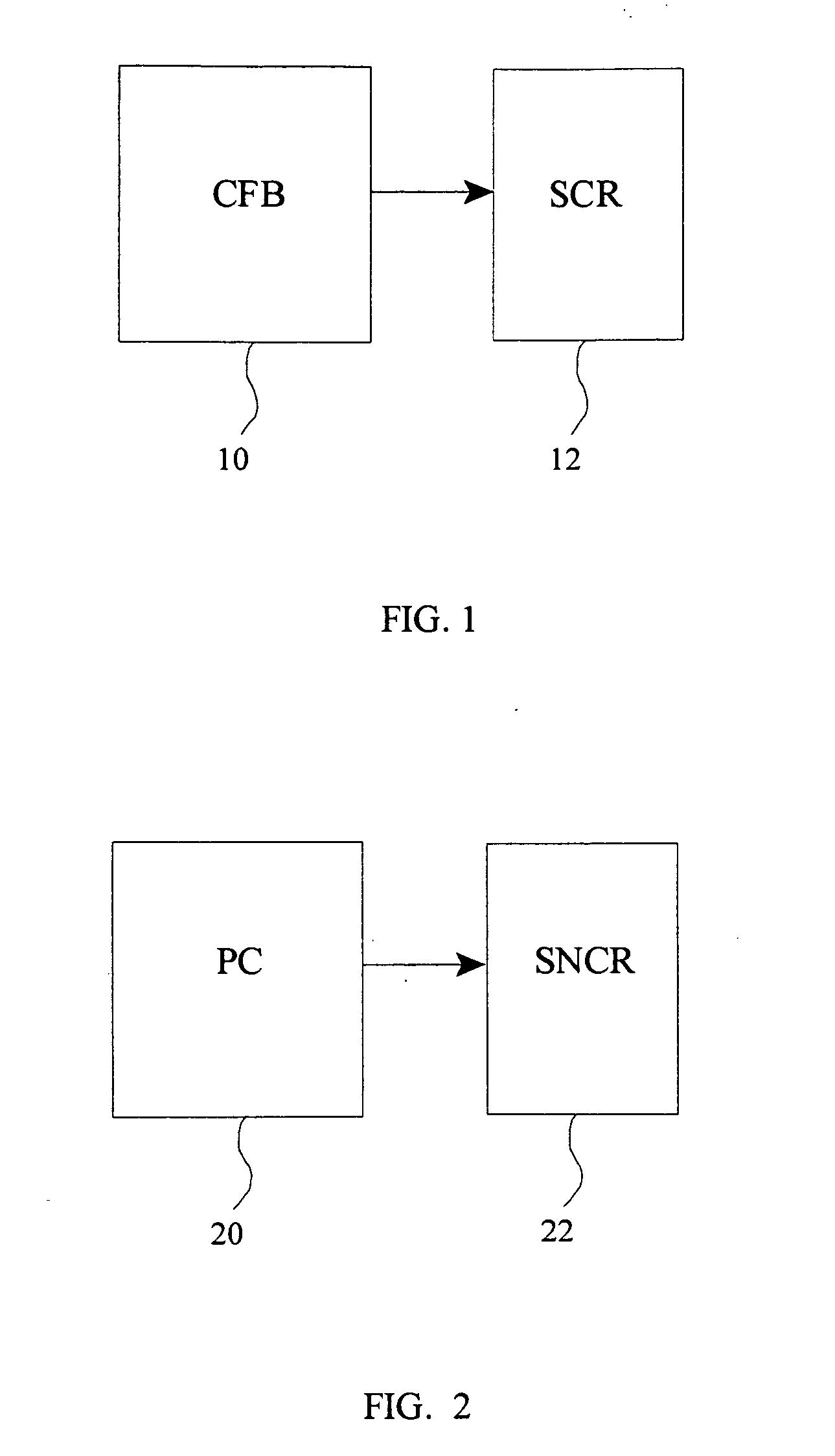

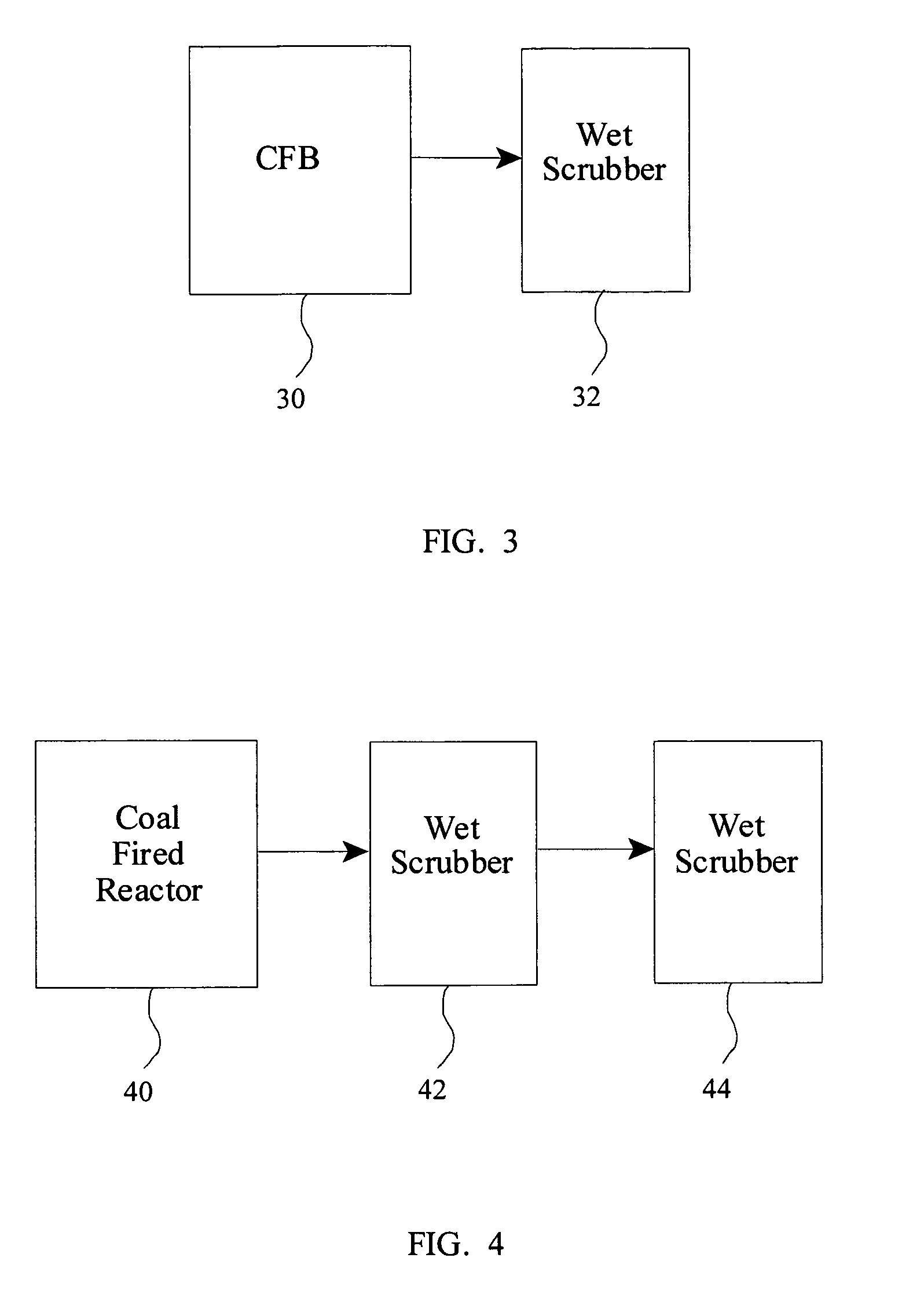

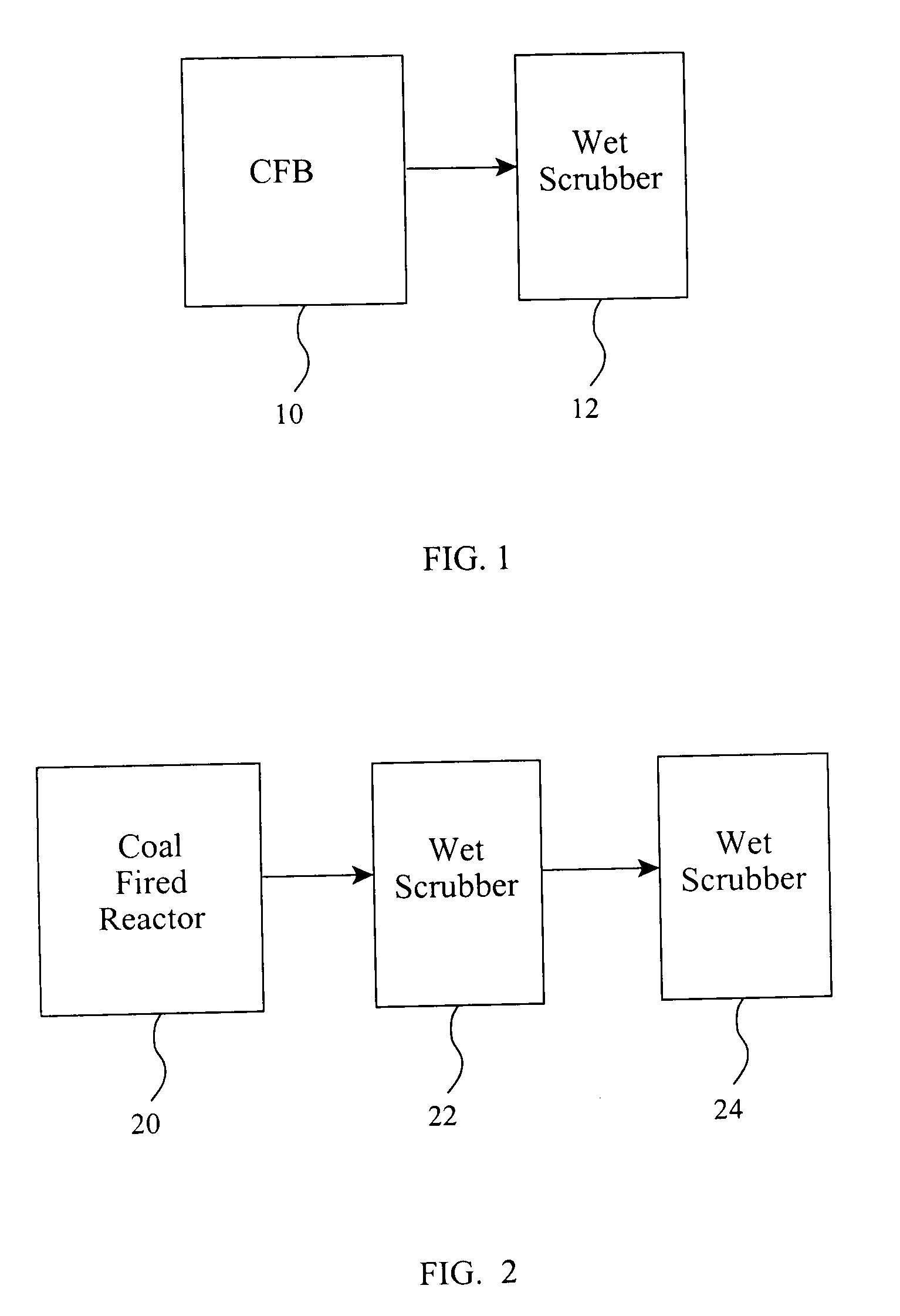

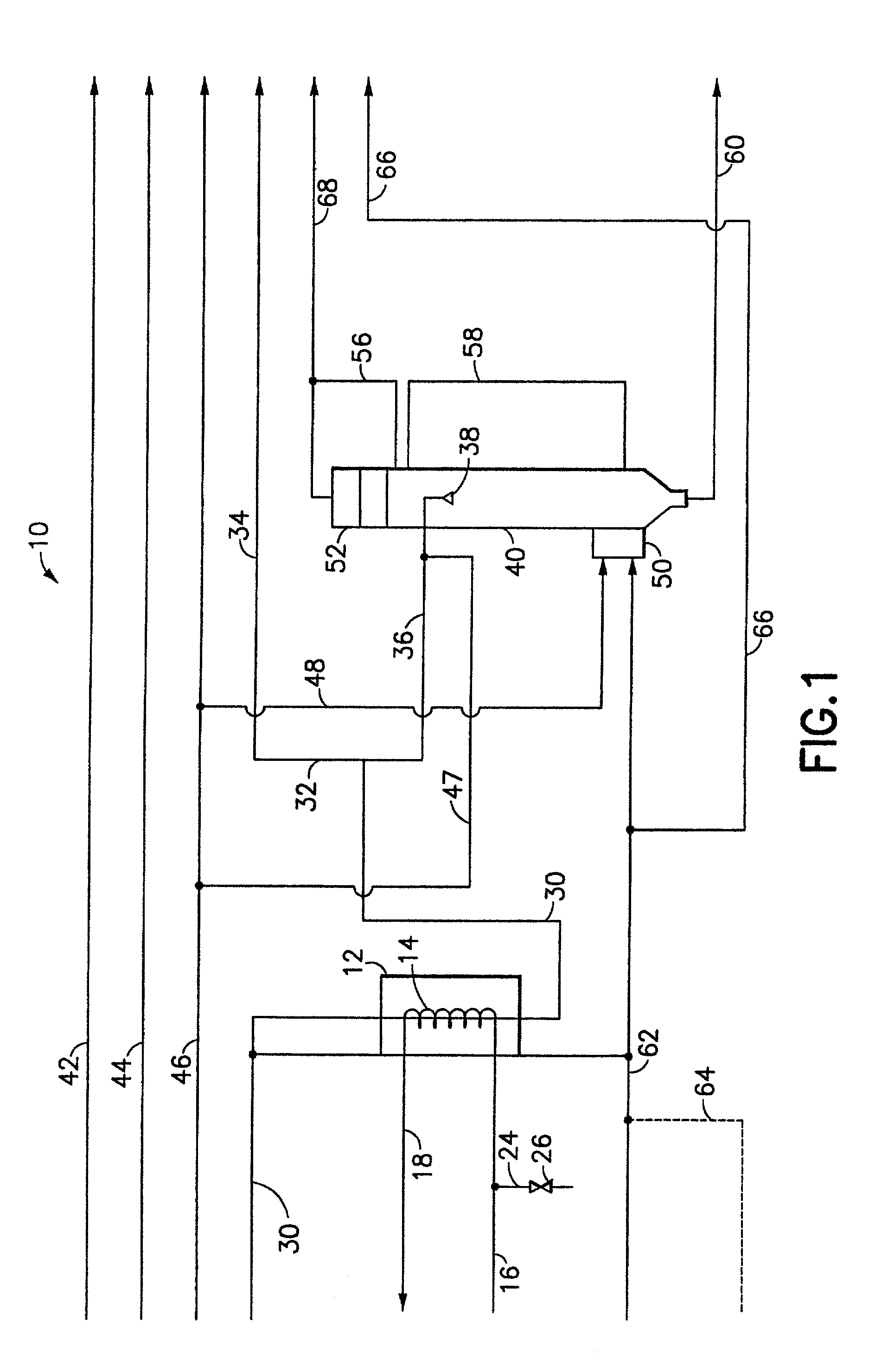

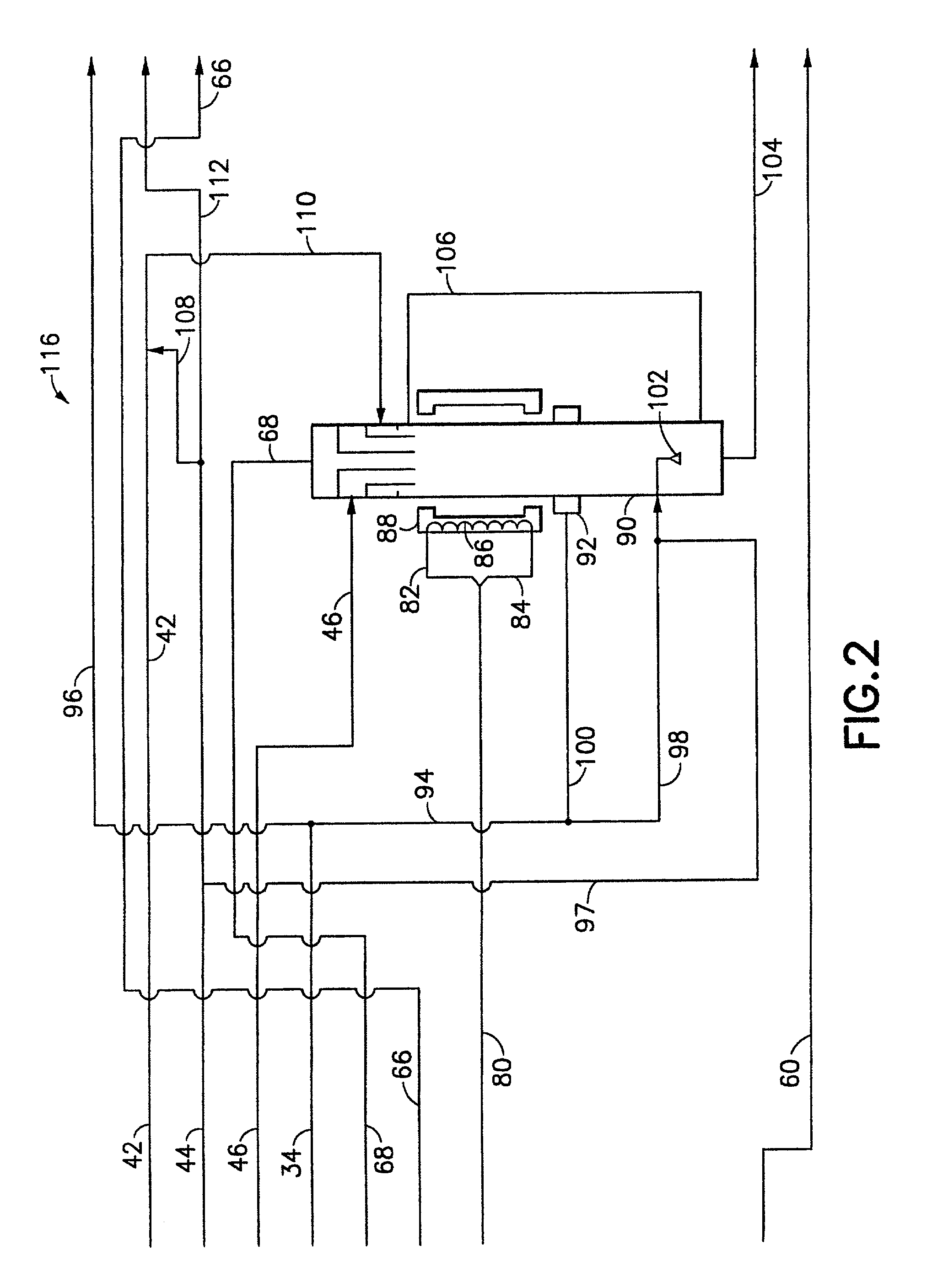

Scrubbing systems and methods for coal fired combustion units

InactiveUS20050084434A1Reduce nitrogen oxide emissionsHigh ppmCombination devicesFluidized bed combustionUnit systemWet scrubber

Systems and methods for removing toxic emissions from flue gas of coal fired combustions units can be achieved. Decreasing nitrogen oxide and sulfur emissions from a coal fired circulating fluidized bed reactor can include treating flue gas using a selective catalytic reduction system and a wet scrubber. Furthermore, reducing the nitrogen oxide emissions from a pulverized coal reactor can be accomplished with a selective non-catalytic reduction system. Additionally, the reduction of sulfur oxide emissions from a pulverized coal reactor can be enhanced using dry and / or wet scrubbers. Such systems and methods provide improved levels of toxic emissions over currently available technologies.

Owner:ENVIROSERVE ASSOCS

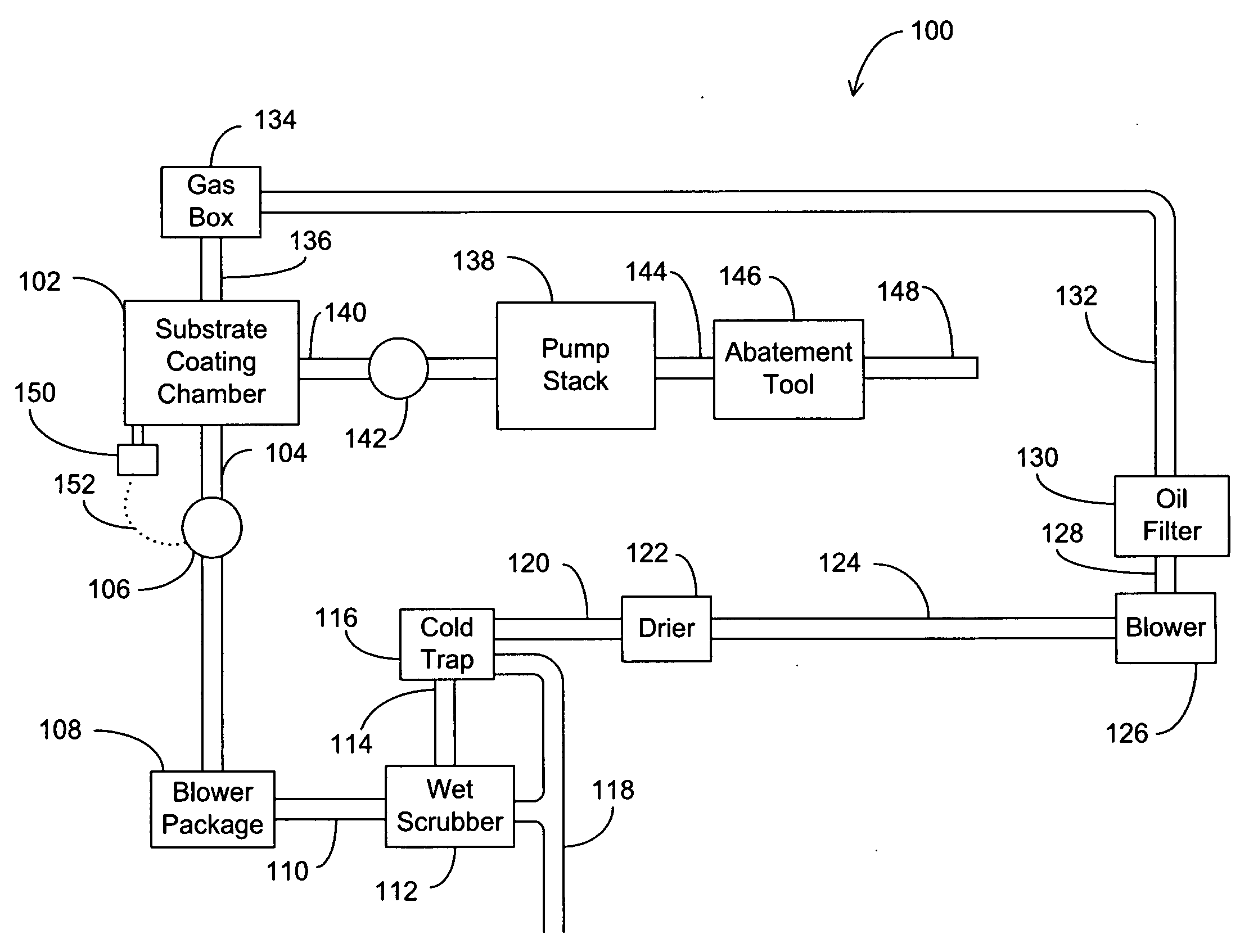

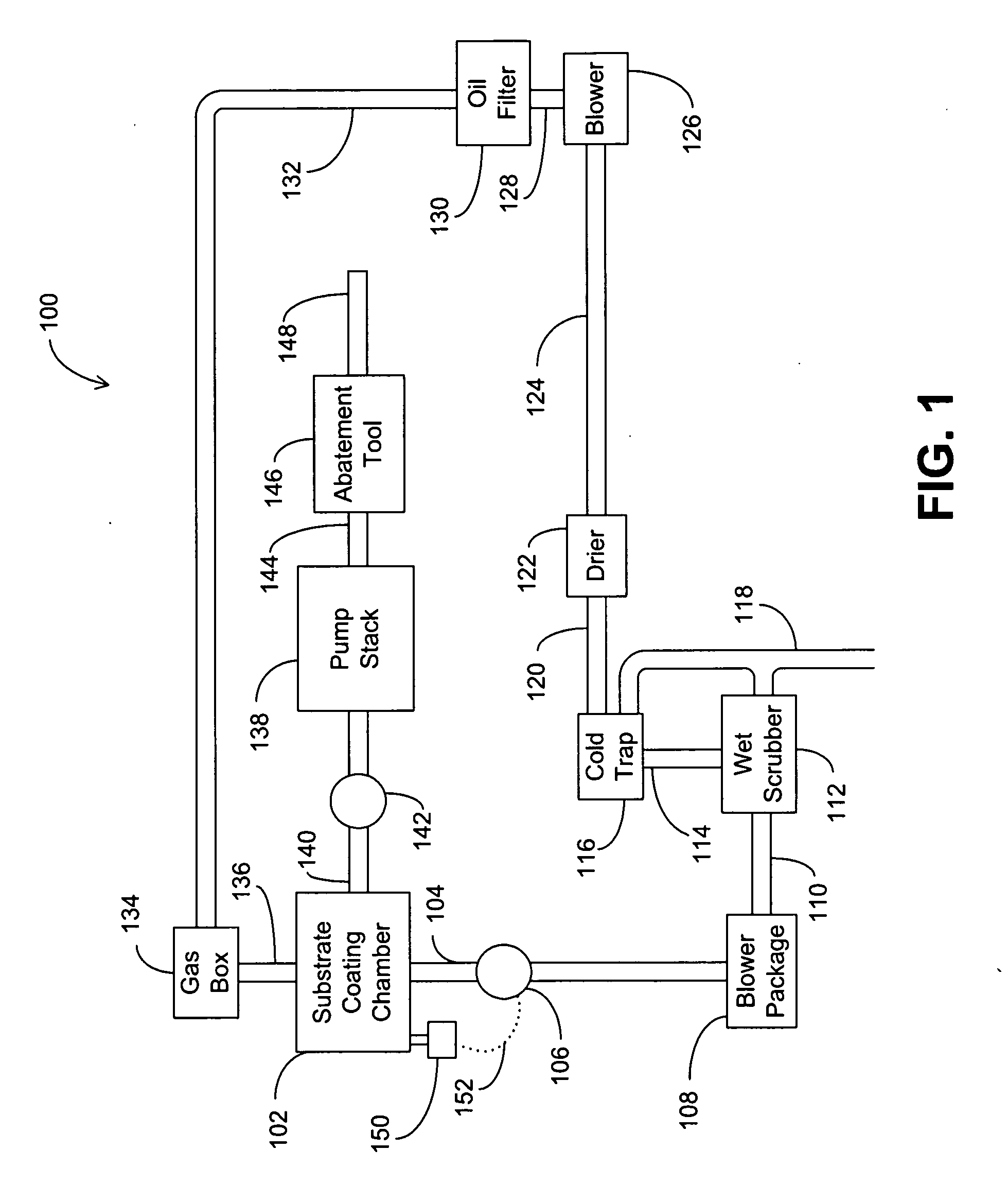

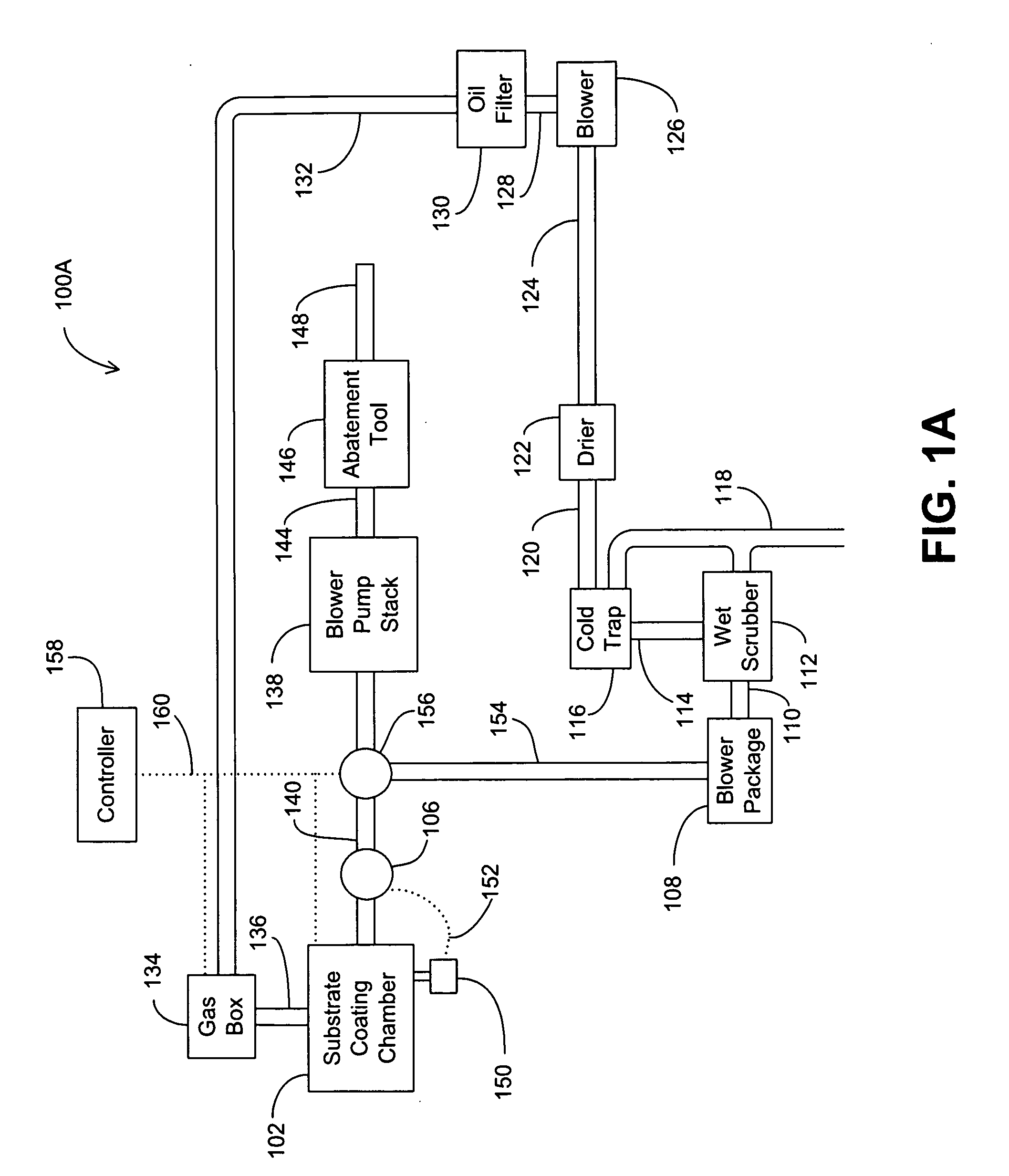

Methods and apparatus for reducing the consumption of reagents in electronic device manufacturing processes

A substrate coating system is provided which includes a substrate coating chamber; a gas box connected to the coating chamber and adapted to provide reagent gases to the coating chamber; and a reagent reclaim system connected to the substrate coating chamber and the gas box, wherein the reagent reclaim system includes a wet scrubber connected to the coating chamber; a polisher connected to the wet scrubber; and a dryer connected to the polisher and the gas box.

Owner:APPLIED MATERIALS INC

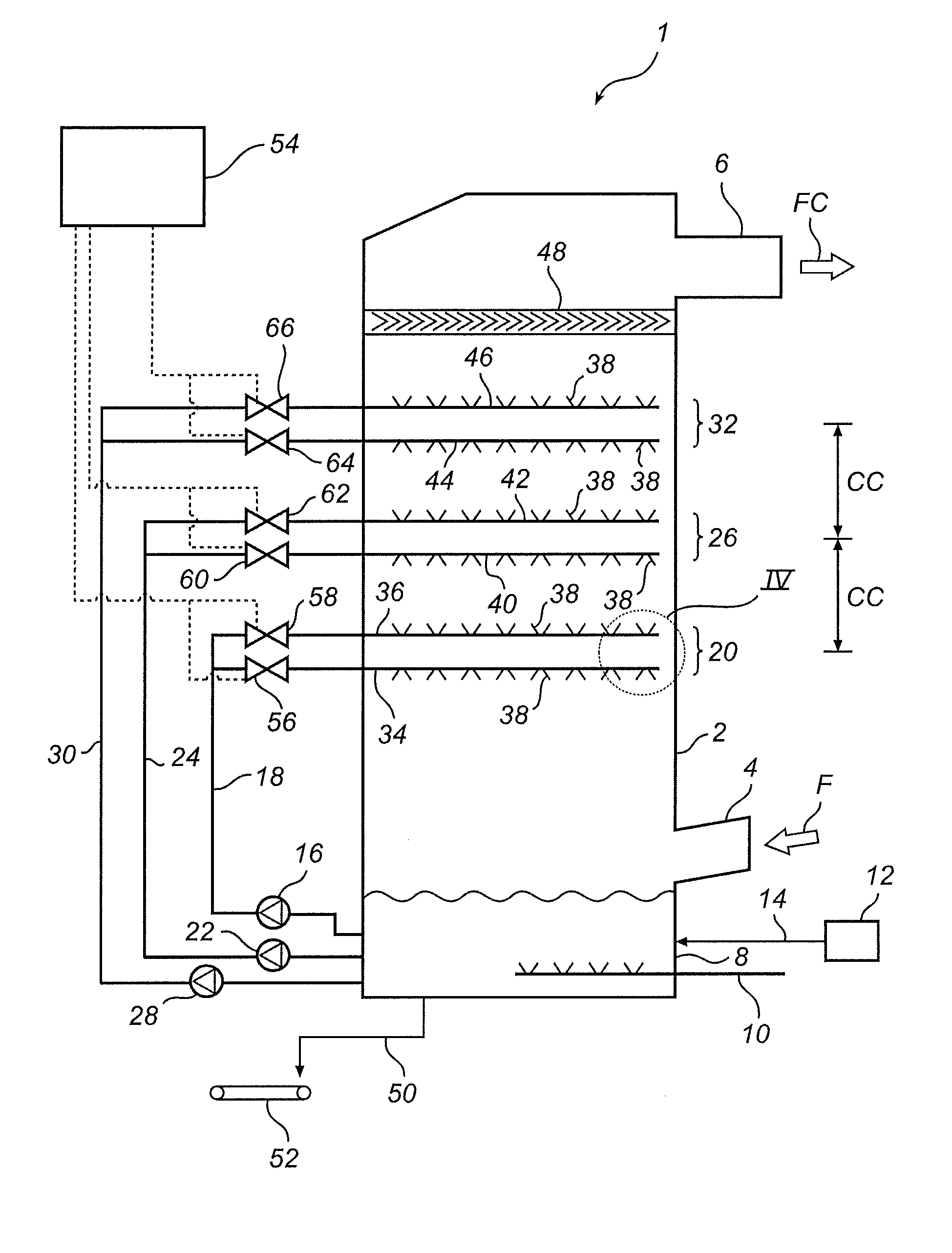

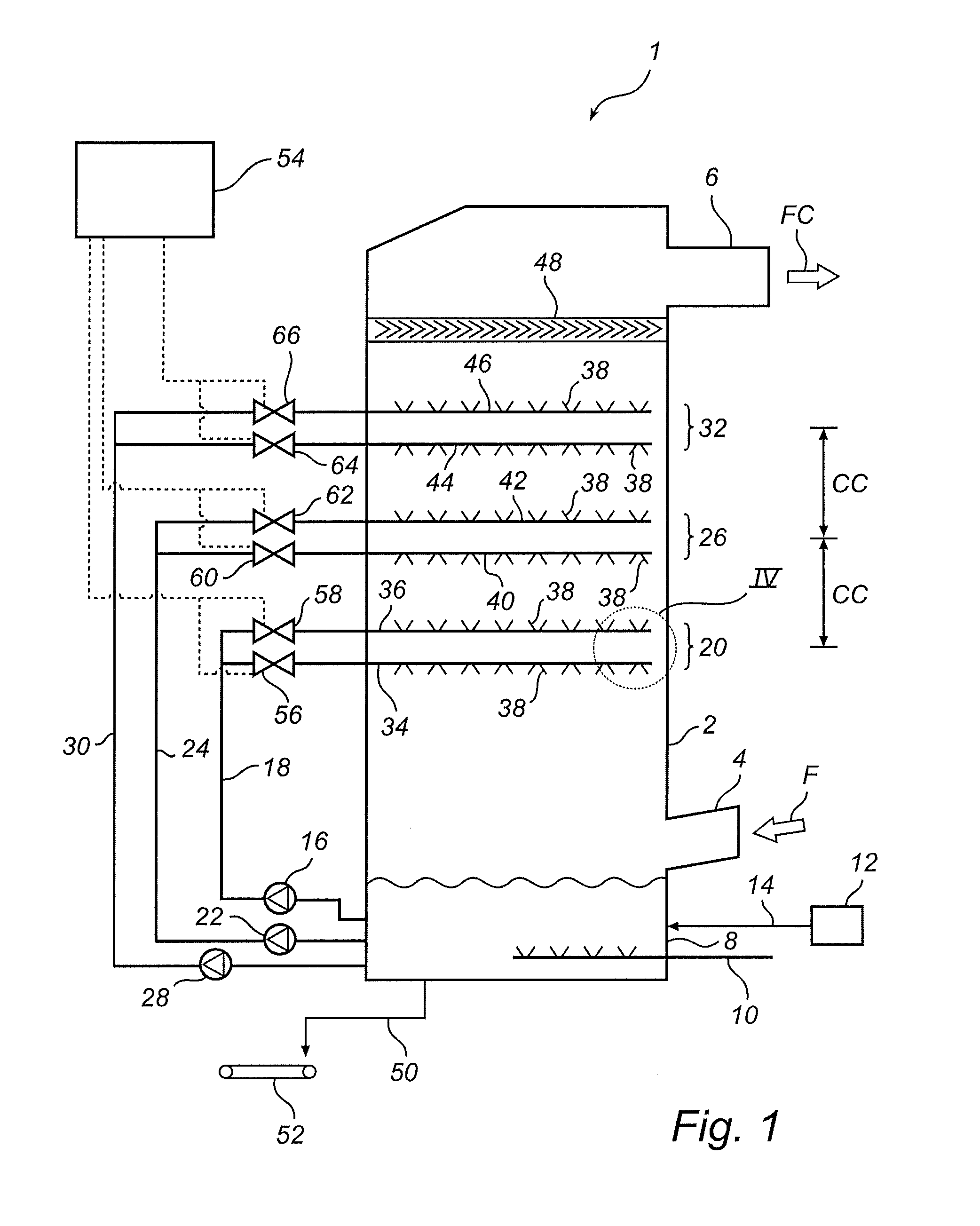

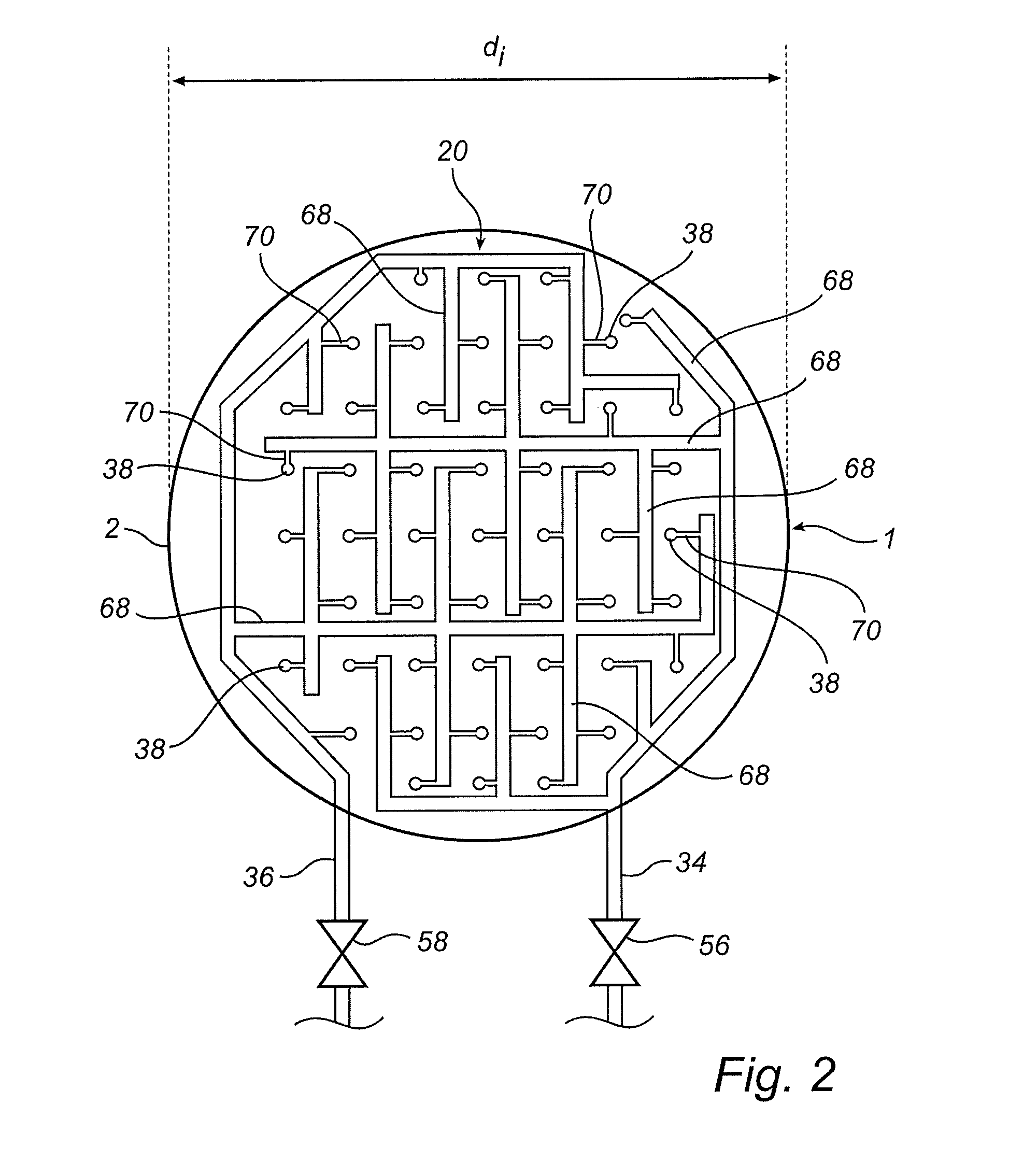

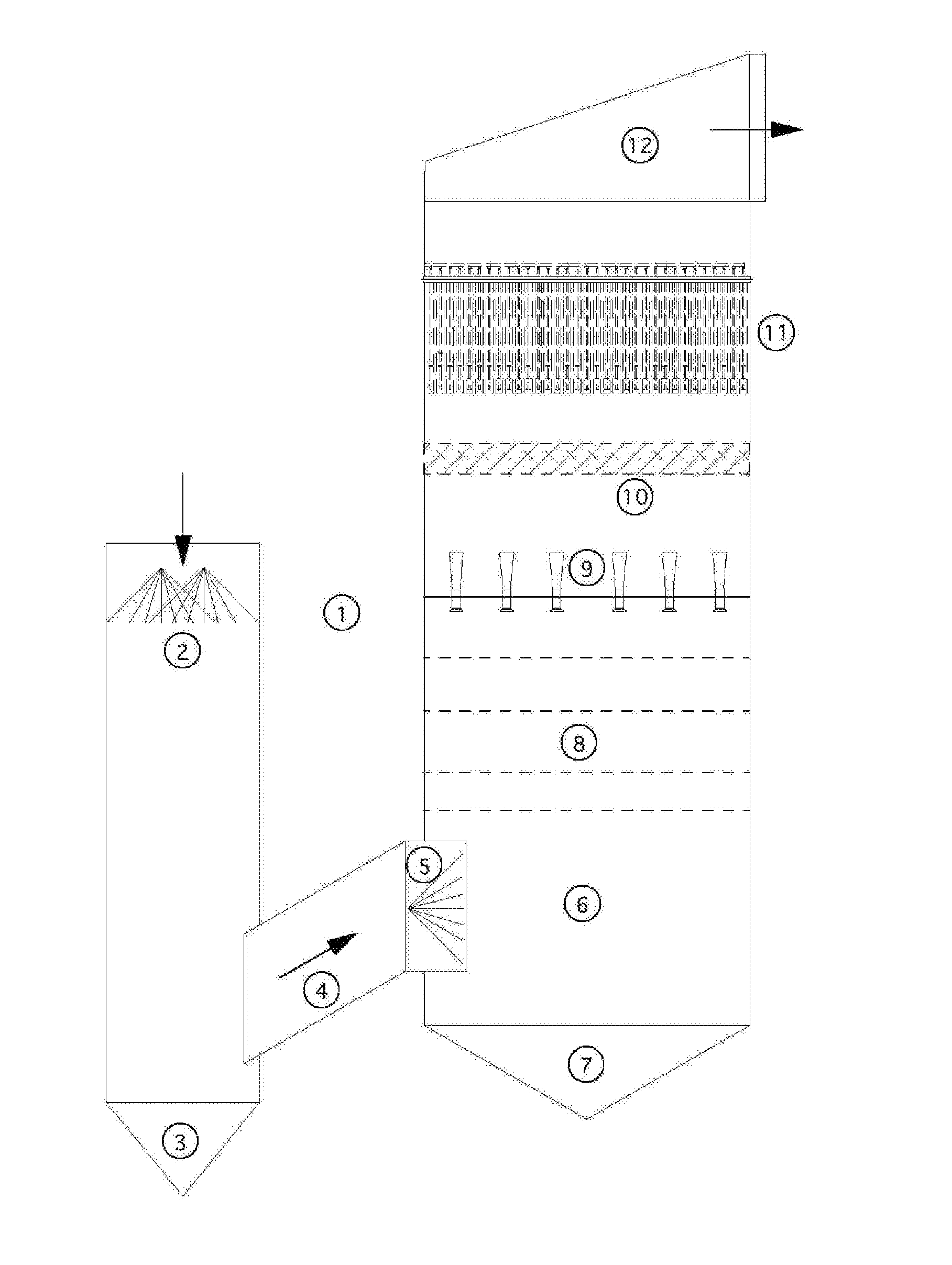

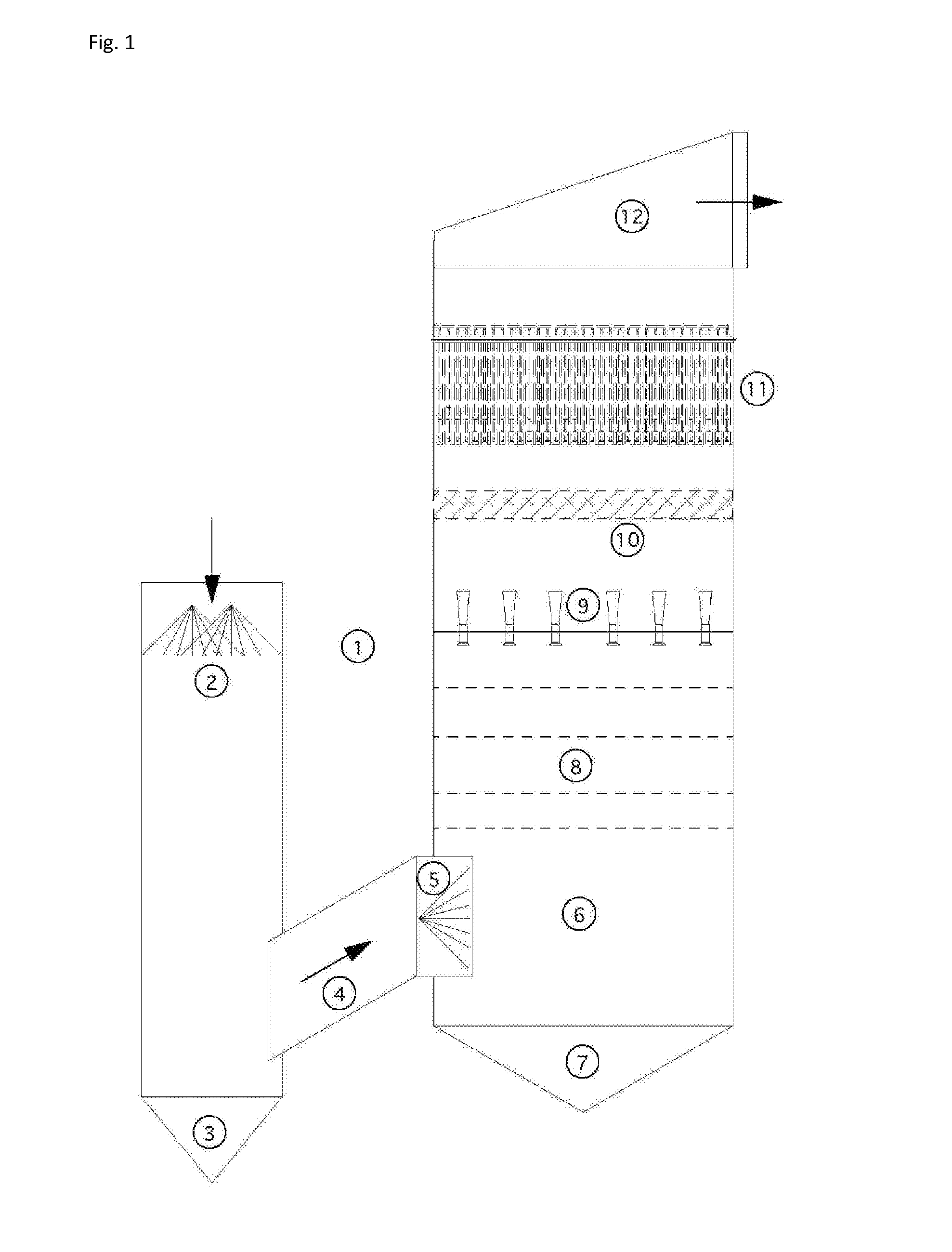

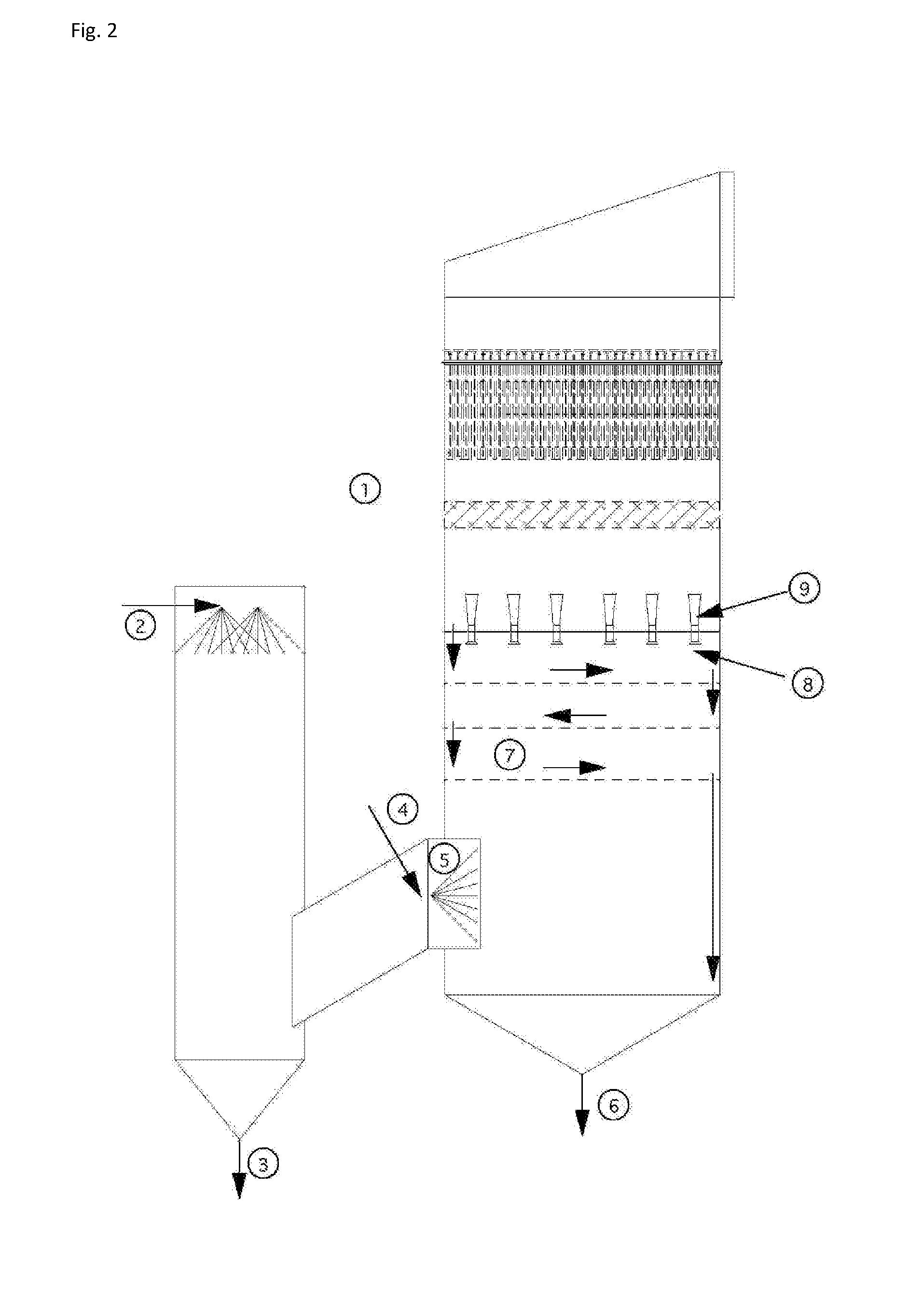

Wet scrubber and a method of cleaning a process gas

ActiveUS20110203456A1Efficient sulphur dioxide absorptionIncrease gas pressure dropGas treatmentExhaust apparatusProduct gasVolumetric Mass Density

A wet scrubber (1) and a method of using the wet scrubber to clean a process gas containing sulphur dioxide comprising at least one spray level system (20) with atomizing nozzles (38) to which an absorption liquid is supplied for atomization by the nozzles (38). The method comprises operating the spray level system (20) in at least a first operating mode with an active nozzle density of at least 0.7 nozzles / m2, an absorption liquid flow of at least 10 m3 / hour per nozzle and a Total Flow of at least 30 m3 / hour / m2.

Owner:GENERAL ELECTRIC TECH GMBH

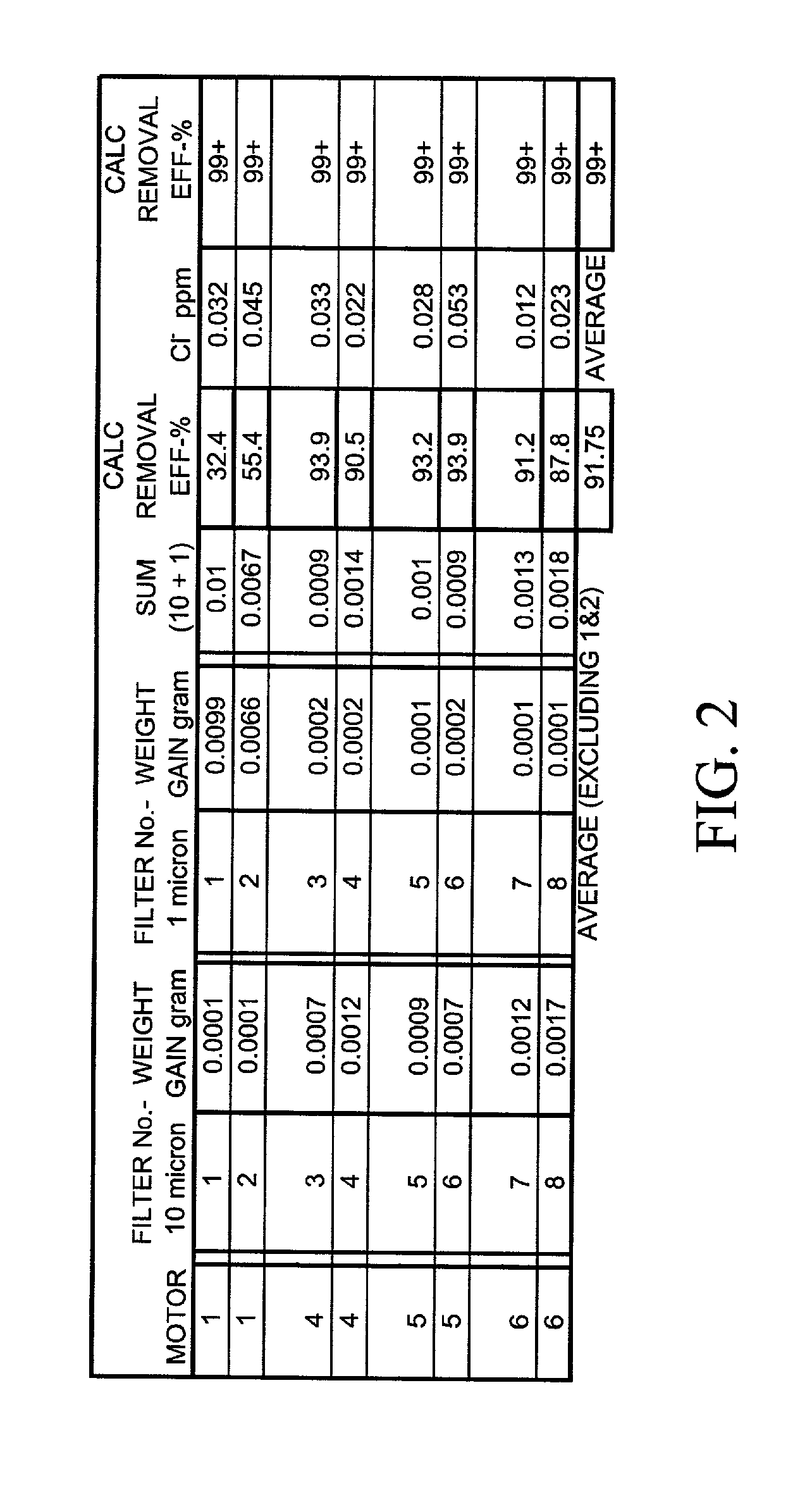

Sorbent filter for the removal of vapor phase contaminants

Methods and apparatuses are described for removing a contaminant, such as a vaporous trace metal contaminant like mercury, from a gas stream. In one embodiment, a primary particulate collection device that removes particulate matter is used. In this embodiment, a sorbent filter is placed within the housing of the primary particulate collection device, such as an electrostatic precipitator or a baghouse, to adsorb the contaminant of interest. In another embodiment, a sorbent filter is placed within a scrubber, such as a wet scrubber, to adsorb the contaminant of interest. In some embodiments, the invention provides methods and apparatuses that can advantageously be retrofit into existing particulate collection equipment. In some embodiments, the invention provides methods and apparatuses that in addition to removal of a contaminant additionally remove particulate matter from a gas stream.

Owner:ELECTRIC POWER RES INST INC

Purification system for flue gas generated in hazardous waste incineration

ActiveCN103611399AEasy to handleExcellent emission valueCombination devicesFilter systemProcess engineering

The invention provides a purification system for flue gas generated in hazardous waste incineration. According to the system, three deacidification filtering systems of dry dust removal, wet dust removal and cloth bag dust removal are combined; the disadvantages of the three deacidification filtering systems during the respective independent using processes are overcome; the treatment capability of acid gas in the flue gas generated by hazardous waste incineration is improved. The system comprises a quenching device, wherein the quenching device is provided with a flue gas inlet and a flue gas outlet; the flue gas outlet of the quenching device is communicated with a flue gas purification device through a pipeline; an outlet of the flue gas purification device is communicated with a chimney. The system is characterized in that the flue gas purification device specifically comprises a dry reactor, a bag dust remover and a wet washing tower, wherein the flue gas outlet of the quenching device is connected with a flue gas inlet of the dry reactor; a flue gas outlet of the dry reactor is connected with a flue gas inlet of the bag dust remover; a flue gas outlet of the bag dust remover is connected with a flue gas inlet of the wet washing tower; a flue gas outlet of the wet washing tower is communicated with the chimney.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

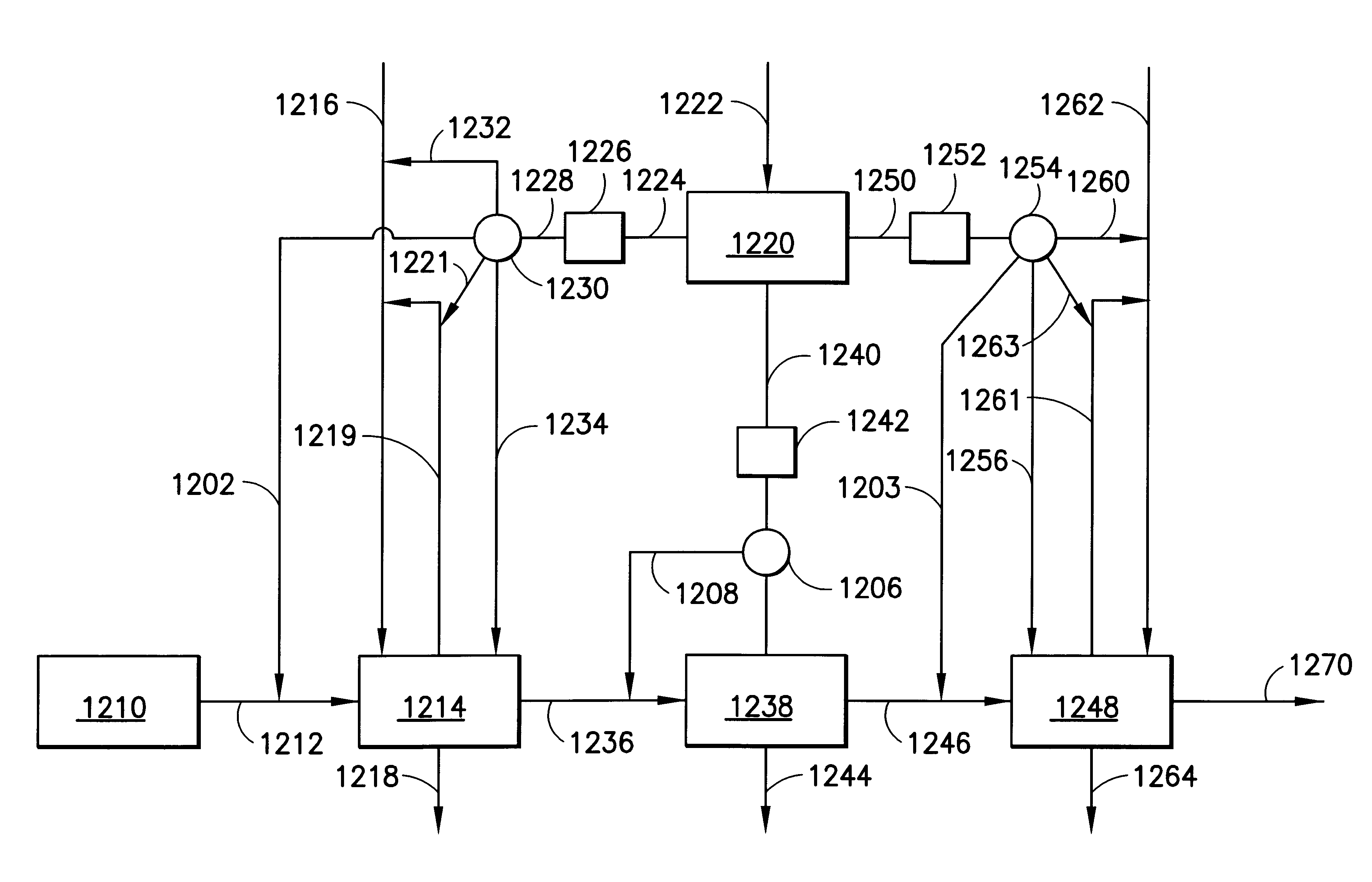

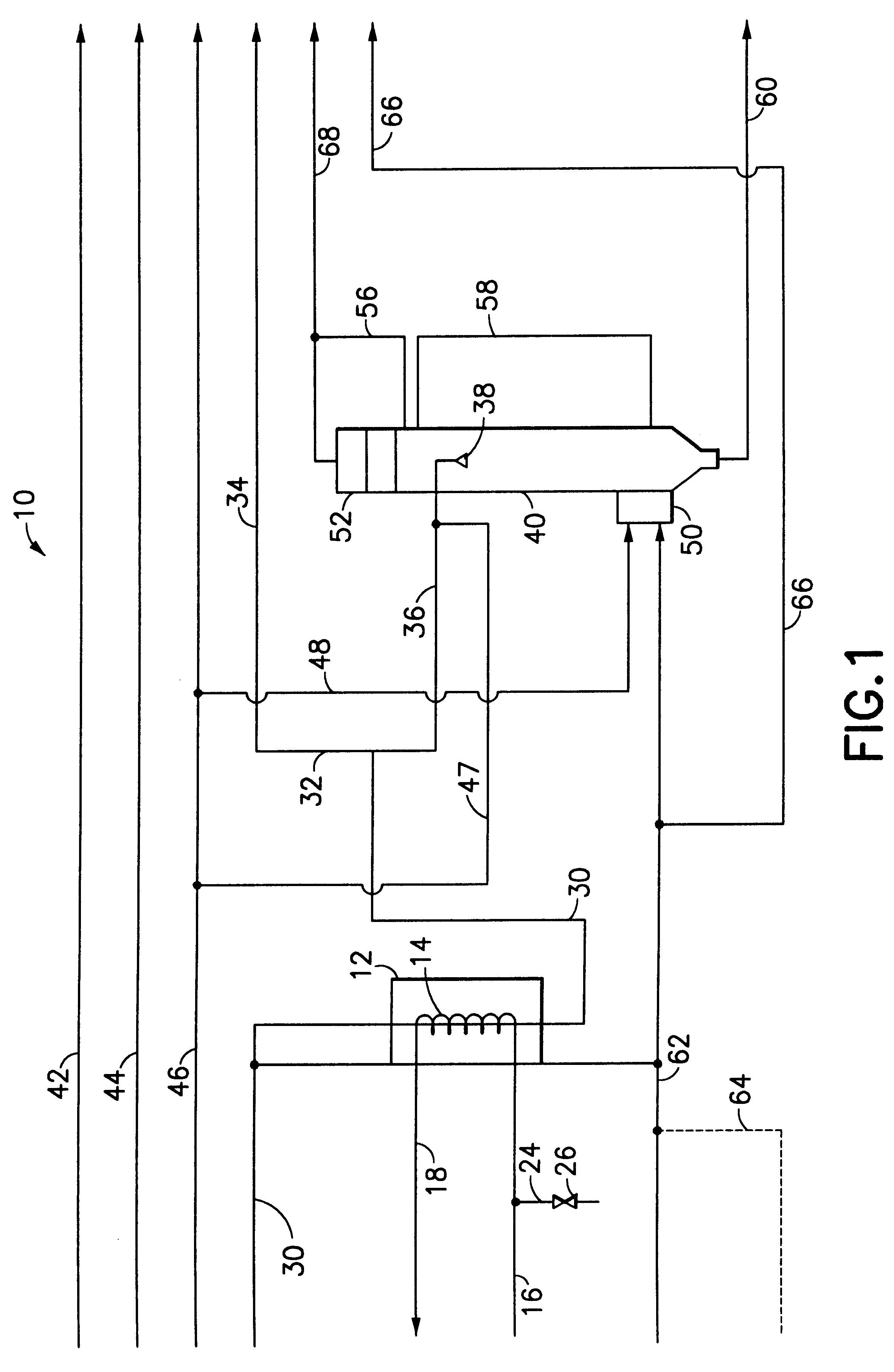

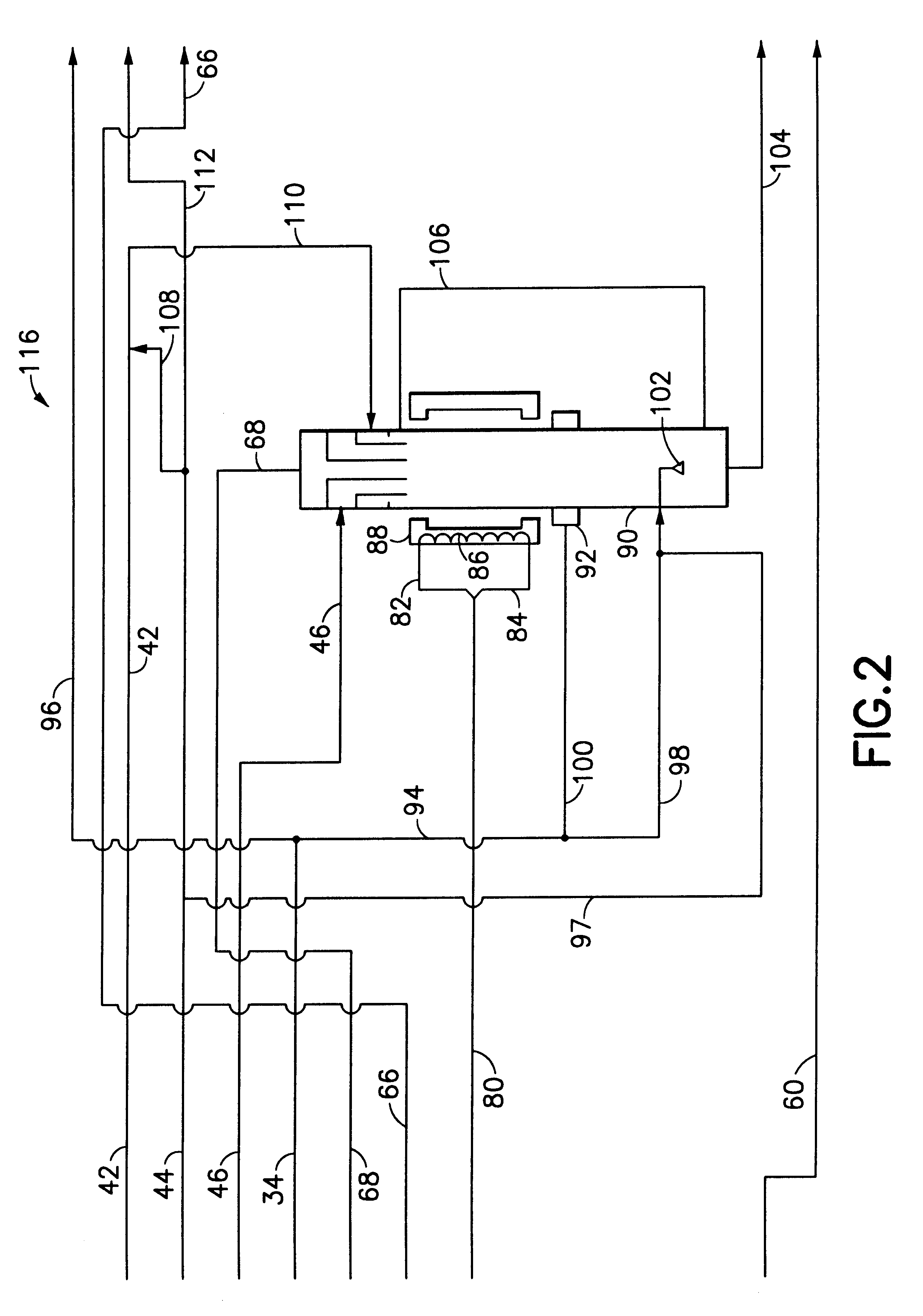

Reduced liquid discharge in wet flue gas desulfurization

One aspect of the invention relates to a method for removing contaminants from a flue gas stream (22). The method includes: removing fly ash from a flue gas stream (22) utilizing a particle collector (24); contacting the flue gas stream with an alkaline reagent in a wet scrubber (26); discharging a purge liquid (30) from the wet scrubber (26); combining at least a portion of the purge liquid (30) with at least a portion of the fly ash (48) to form moistened fly ash (60); and injecting at least a portion of the moistened fly ash (60) into the flue gas stream (22) upstream of the particle collector (24), whereby the moistened fly ash (60) removes at least a portion of contaminants present in the flue gas stream (22).

Owner:GENERAL ELECTRIC TECH GMBH

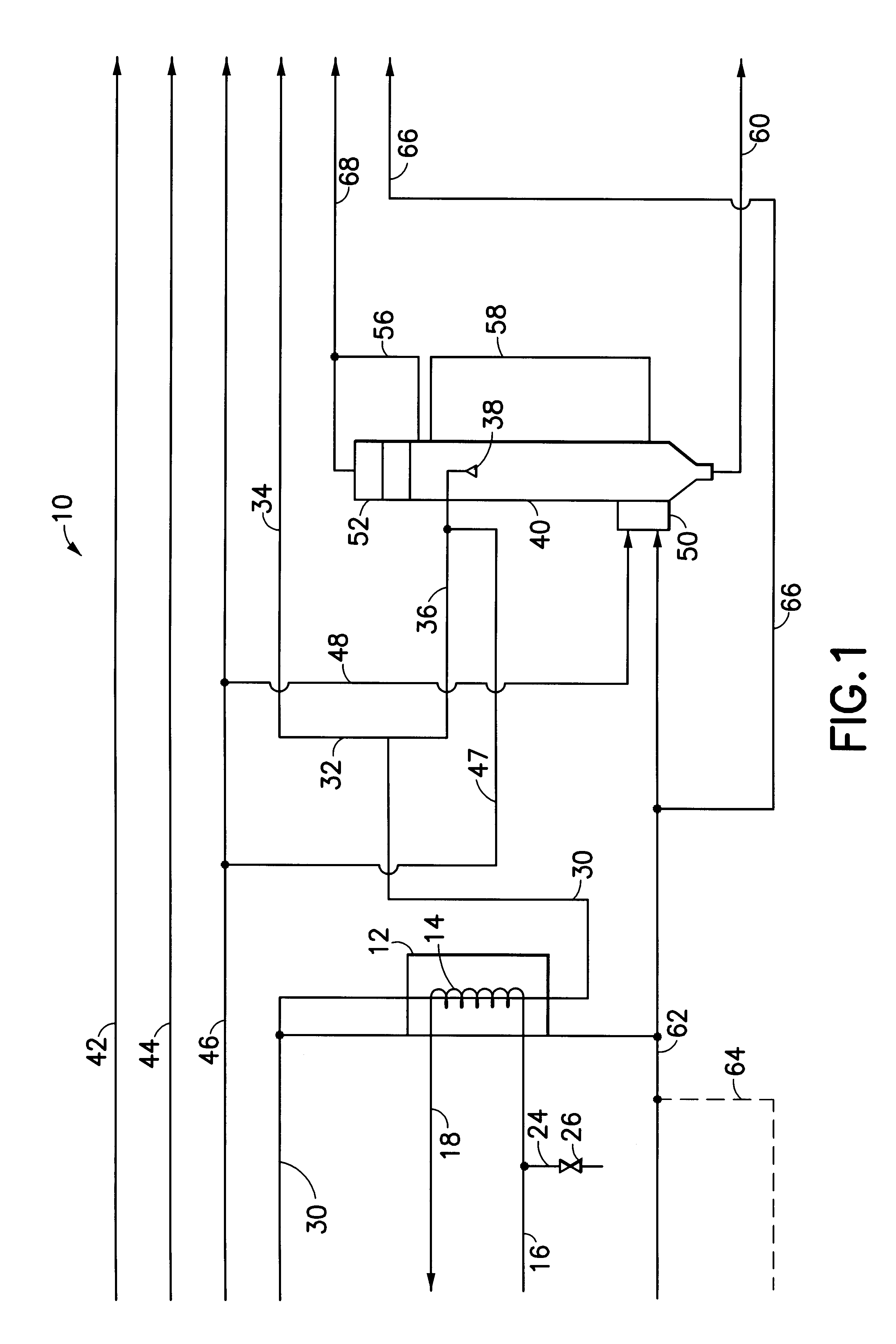

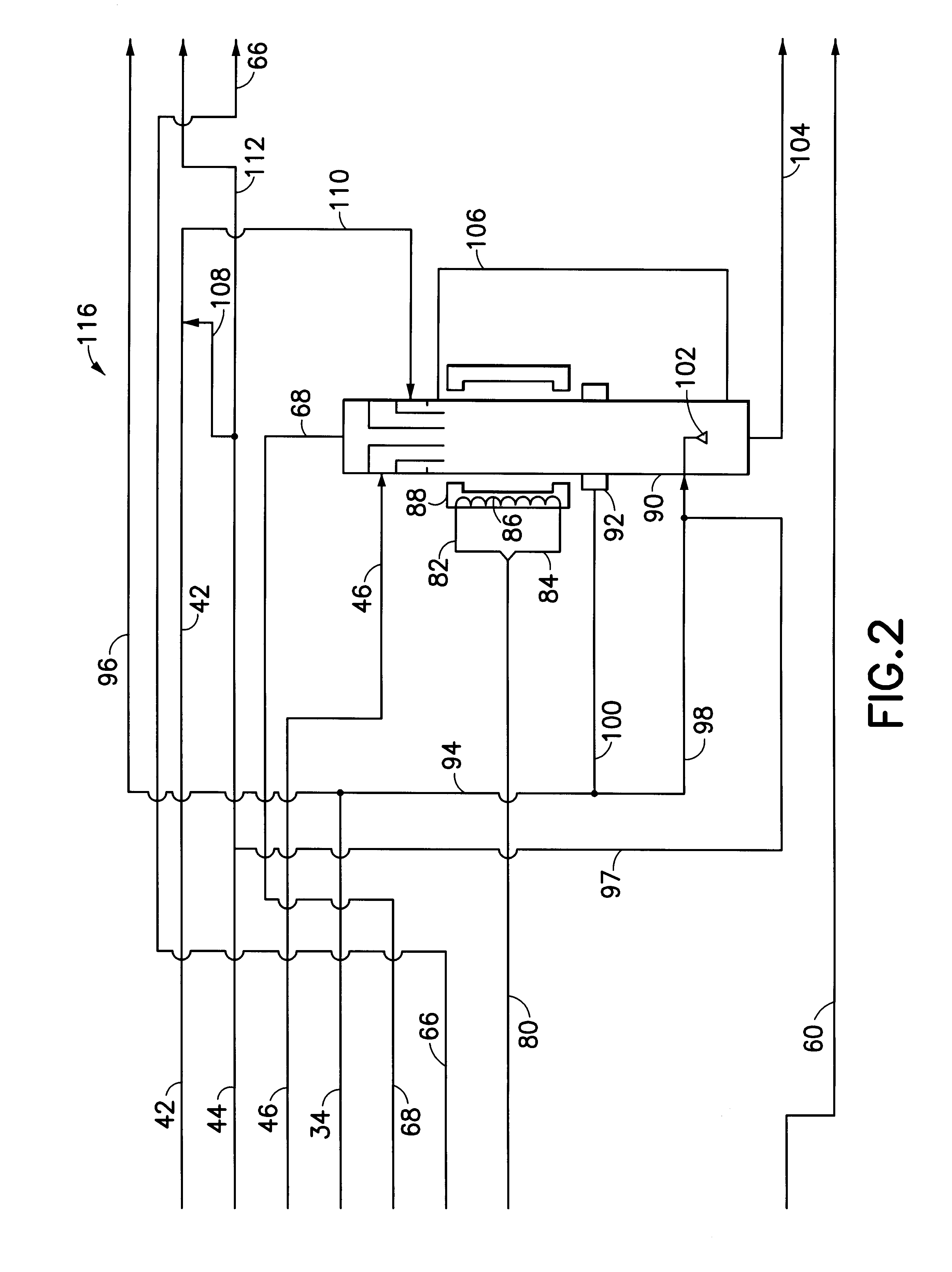

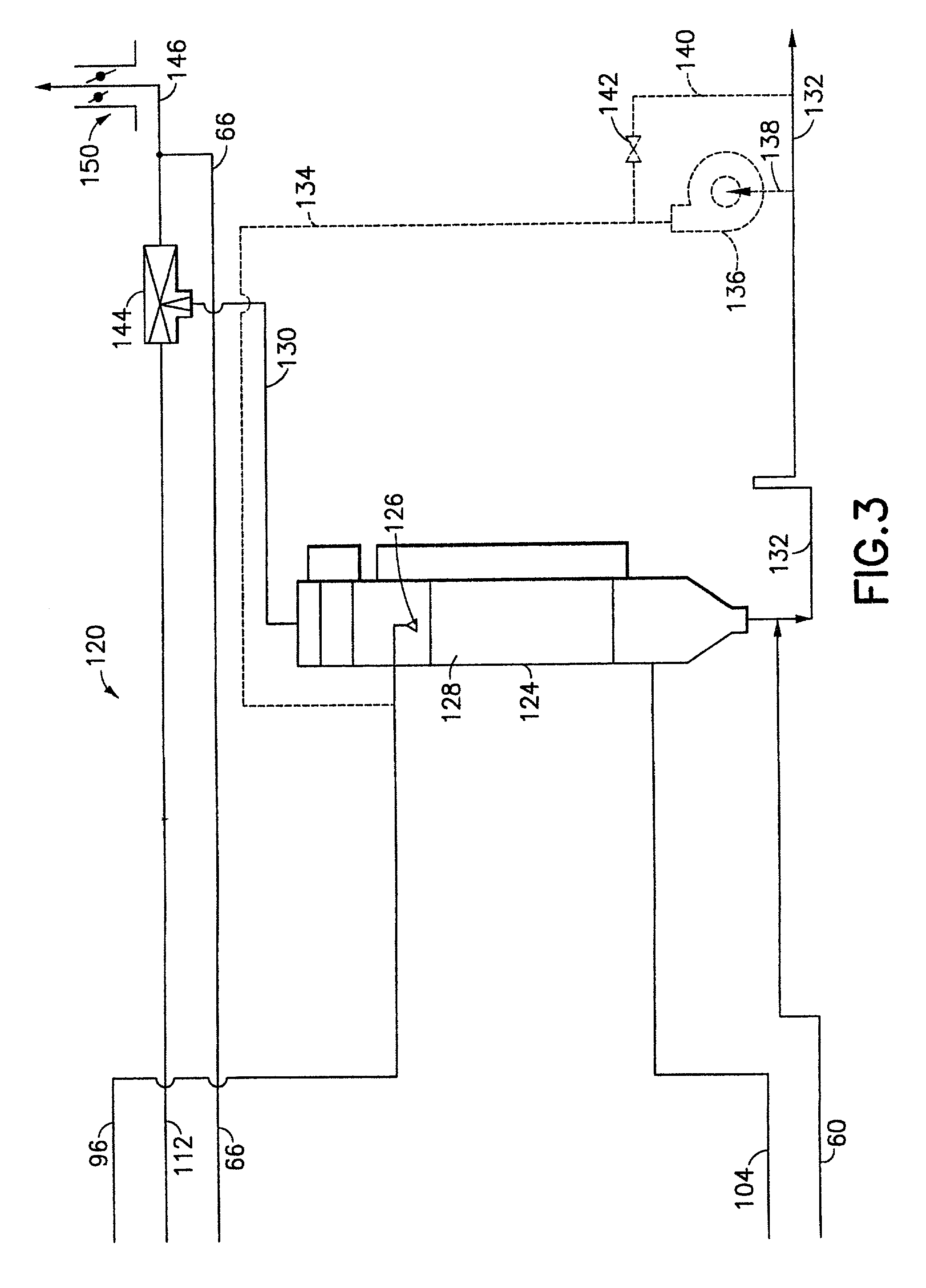

Reduced liquid discharge in wet flue gas desulfurization

ActiveUS20080011158A1Reduce amountCombination devicesDispersed particle filtrationFlue-gas stackFly ash

One aspect of the invention relates to a method for removing contaminants from a flue gas stream (22). The method includes: removing fly ash from a flue gas stream (22) utilizing a particle collector (24); contacting the flue gas stream with an alkaline reagent in a wet scrubber (26); discharging a purge liquid (30) from the wet scrubber (26); combining at least a portion of the purge liquid (30) with at least a portion of the fly ash (48) to form moistened fly ash (60); and injecting at least a portion of the moistened fly ash (60) into the flue gas stream (22) upstream of the particle collector (24), whereby the moistened fly ash (60) removes at least a portion of contaminants present in the flue gas stream (22).

Owner:GENERAL ELECTRIC TECH GMBH

Scrubbing systems and methods for coal fired combustion units

InactiveUS20050084437A1Emission reductionCombination devicesFluidized bed combustionParticulatesGas phase

Systems and methods for removing toxic emissions from flue gas of coal fired combustion units can be achieved. Decreasing sulfur oxide emissions from a coal fired circulating fluidized bed reactor can include treating flue gas unit using a wet scrubber. Wet scrubbers can include gas phase scrubbers, liquid phase scrubbers, and gas-liquid phase scrubbers. Additionally, toxic emissions can be reduced from coal fired combustion units such as circulating fluidized beds or pulverized coal units. Particulates can be removed from flue gas of the coal fired combustion unit. The flue gas can then be treated with at least two consecutive wet scrubbers to produce a low sulfur flue gas. In addition to sulfur oxides, a wide variety of toxic emissions can be removed such as nitrogen oxides, carbon monoxide, arsenic, beryllium, cadmium, hydrochloric acid, chromium, cobalt, hafnium, lead, manganese, mercury, nickel, selenium, benzo(a)pyrene, and combinations thereof. Such systems and methods provide improved levels of toxic emissions over currently available technologies.

Owner:ENVIROSERVE ASSOCS

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

InactiveUS20020018737A1Reduce sensitivityEliminate accumulationCombination devicesGas treatmentProduct gasOxidative treatment

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises a pre-oxidation treatment unit, which may for example comprise a scrubber, an oxidation unit such an electrothermal oxidizer, and a post-oxidation treatment unit, such as a wet or dry scrubber. The effluent gas stream treatment system of the invention may utilize an integrated oxidizer, quench and wet scrubber assembly, for abatement of hazardous or otherwise undesired components from the effluent gas stream. Gas or liquid shrouding of gas streams in the treatment system may be provided by high efficiency inlet structures.

Owner:APPLIED MATERIALS INC

An apparatus and method for particulate capture from gas streams and a method of removing soluble particulate from a gas

ActiveUS20160303502A1Reduce concentrationUrea derivatives preparationOrganic compound preparationHigh concentrationParticulates

Disclosed is a method for the removal of soluble particulate matter from a gas stream, such as urea dust from the off-gas of a finishing section of a urea production plant. The method comprises subjecting the off-gas to at least two quenching stages an aqueous quenching liquid. The quenching liquid used in a first, upstream quench stage, is allowed to have a higher concentration of dissolved particulate matter than the quenching liquid in the second, downstream quench stage. The quenched gas is led through a particle capture zone, typically comprising one or more of a wet scrubber, a Venturi scrubber, and a wet electrostatic precipitator.

Owner:STAMICARBON BV

Sorbent filter for the removal of vapor phase contaminants

Methods and apparatuses are described for removing a contaminant, such as a vaporous trace metal contaminant like mercury, from a gas stream. In one embodiment, a primary particulate collection device that removes particulate matter is used. In this embodiment, a sorbent filter is placed within the housing of the primary particulate collection device, such as an electrostatic precipitator or a baghouse, to adsorb the contaminant of interest. In another embodiment, a sorbent filter is placed within a scrubber, such as a wet scrubber, to adsorb the contaminant of interest. In some embodiments, the invention provides methods and apparatuses that can advantageously be retrofit into existing particulate collection equipment. In some embodiments, the invention provides methods and apparatuses that in addition to removal of a contaminant additionally remove particulate matter from a gas stream.

Owner:ELECTRIC POWER RES INST INC

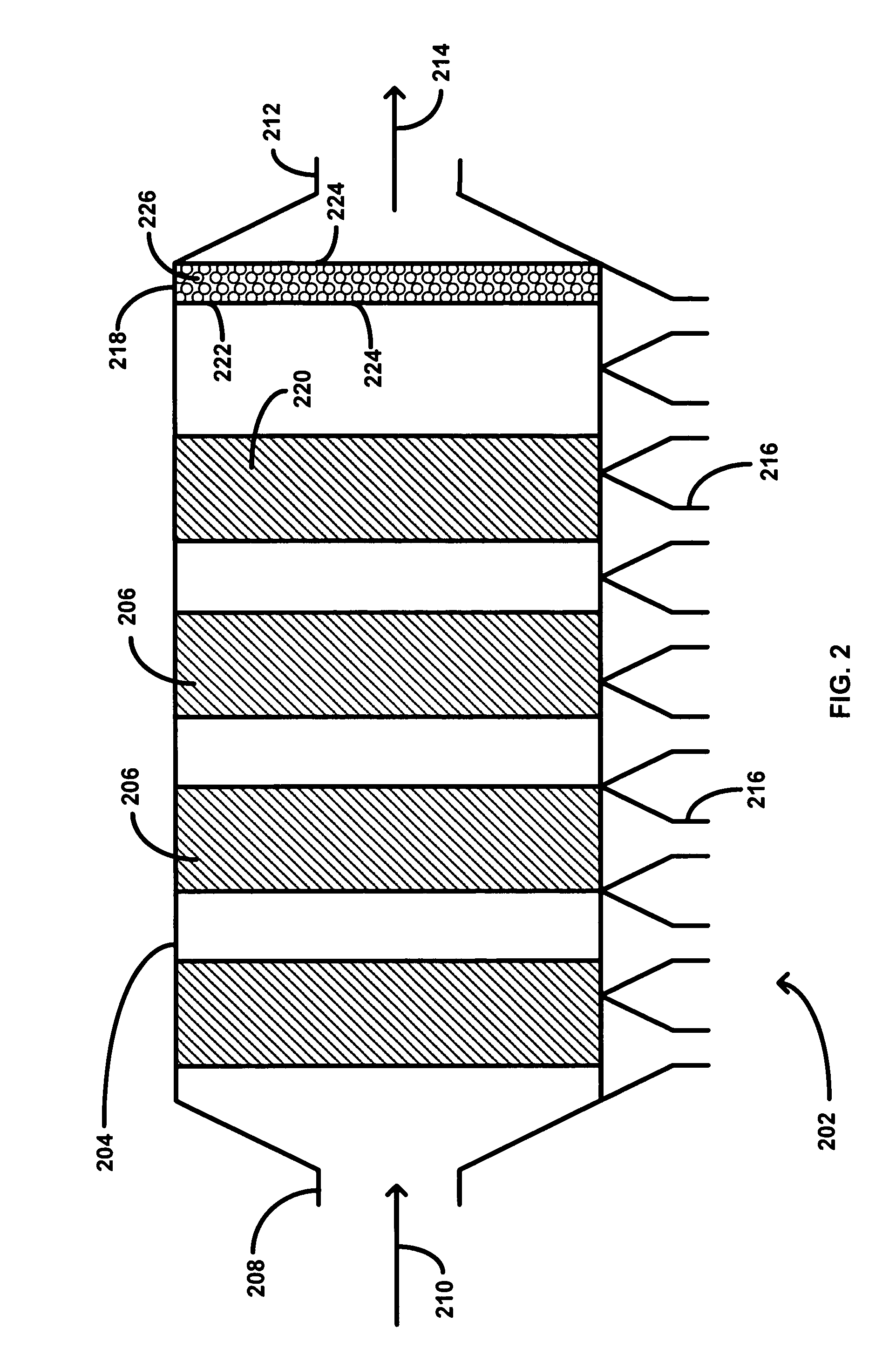

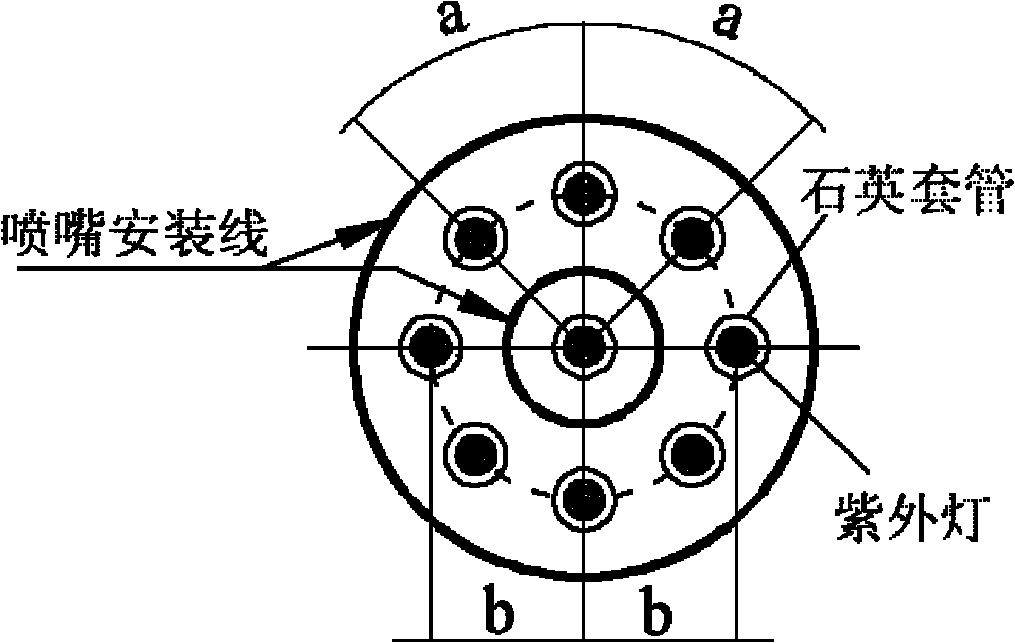

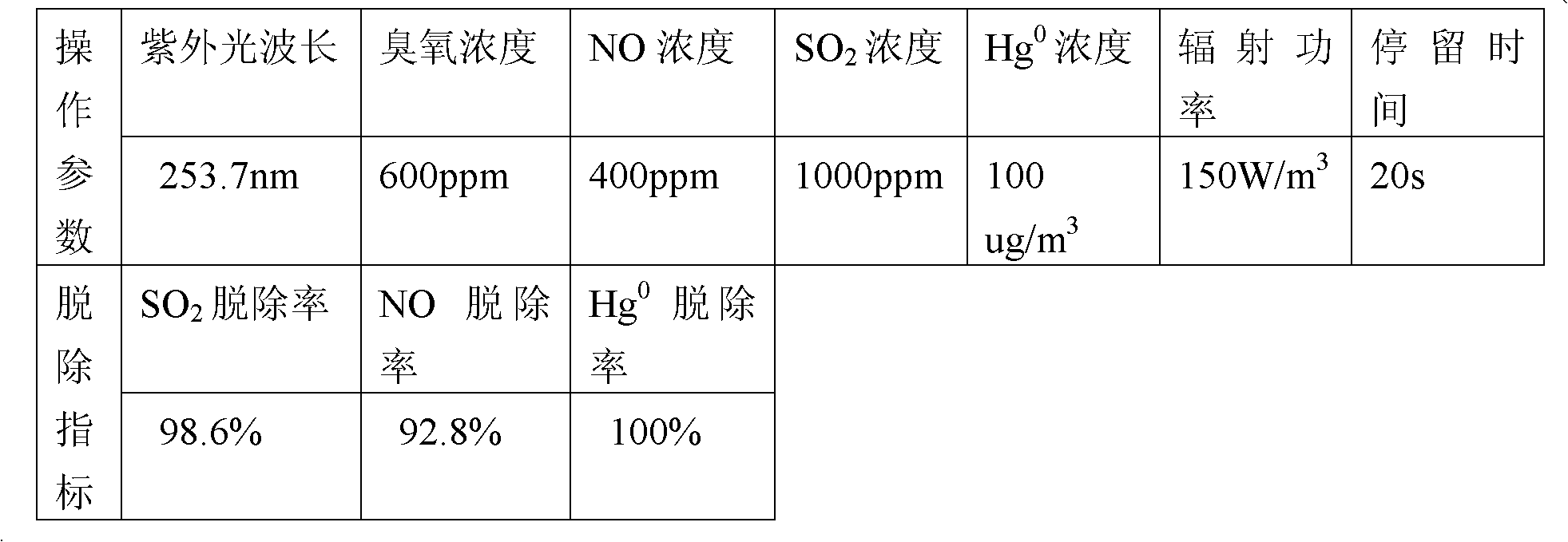

Fume purification system based on advanced oxygenation combining wet scrubbing

InactiveCN102160959AHigh reaction rate constantEasy attackDispersed particle separationSolubilityEngineering

The invention provides a fume purification system based on advanced oxygenation combining wet scrubbing. The system is a combustion and exhaust system formed by a boiler, an ozone generator, a stirrer, a swirl nozzle, a reactor, a gas-liquid absorption tower and a chimney, wherein fume containing sulfur oxide, nitric oxide and mercury generated by combustion of the boiler and O3 generated by the ozone generator enter the stirrer together, are mixed, flow through the swirl nozzle, and are sprayed into the reactor with an ultraviolet lamp tube; and hydroxyl radical (.OH) with strong oxidability generated under excitation of ultraviolet radiation, SO2 in the fume, indissoluble NO and HgO are oxidized into gaseous products with higher dissolubility and enter the gas-liquid absorption tower to be absorbed and removed by water; Hg<2+> generated in the gas-liquid absorption tower captures and retrieves mercuric sulfide by adding sulfidion S<2-> in equal molar ratio; and the residual sulfuric acid and nitric acid mixed solution is used as an industrial raw material for recycling, and the cleaned fume enters the chimney so as to be exhausted.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com