Fume purification system based on advanced oxygenation combining wet scrubbing

A flue gas purification system and wet scrubbing technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle separation, can solve problems such as low denitrification and mercury removal efficiency, inability to achieve desulfurization, denitrification and mercury removal, and slow research progress. , to achieve the effect of reducing initial investment and operating costs, high development and application value, and reducing complexity

Inactive Publication Date: 2011-08-24

SOUTHEAST UNIV

View PDF5 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Wet flue gas purification technology is a traditional flue gas treatment technology. It has the characteristics of small initial investment, simple process flow and easy removal of multiple pollutants at the same time. It is a very promising flue gas purification technology for development and application. , but the research progress of traditional wet flue gas purification technology has been relatively slow, the main reason is that nitrogen oxides and mercury elements contain more than 90% insoluble NO and 40-80% insoluble Hg 0

According to the double-membrane theory, the gas-phase molecules must first dissolve into the liquid phase through mass transfer and diffusion processes from the gas state, and then they can undergo chemical reactions and be fixed in the absorption liquid, while NO and Hg 0 The insoluble characteristics greatly increase the absorption and mass transfer resistance in the liquid phase, and it is difficult to significantly increase the NO and Hg levels only by adjusting the pH and temperature of the absorption liquid. 0 Solubility in the liquid phase, this characteristic has caused the traditional wet desulfurization, denitrification and mercury removal technology to generally have high desulfurization efficiency, but low denitrification and mercury removal efficiency, etc. In fact, it is impossible to achieve real simultaneous desulfurization, denitrification and mercury removal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

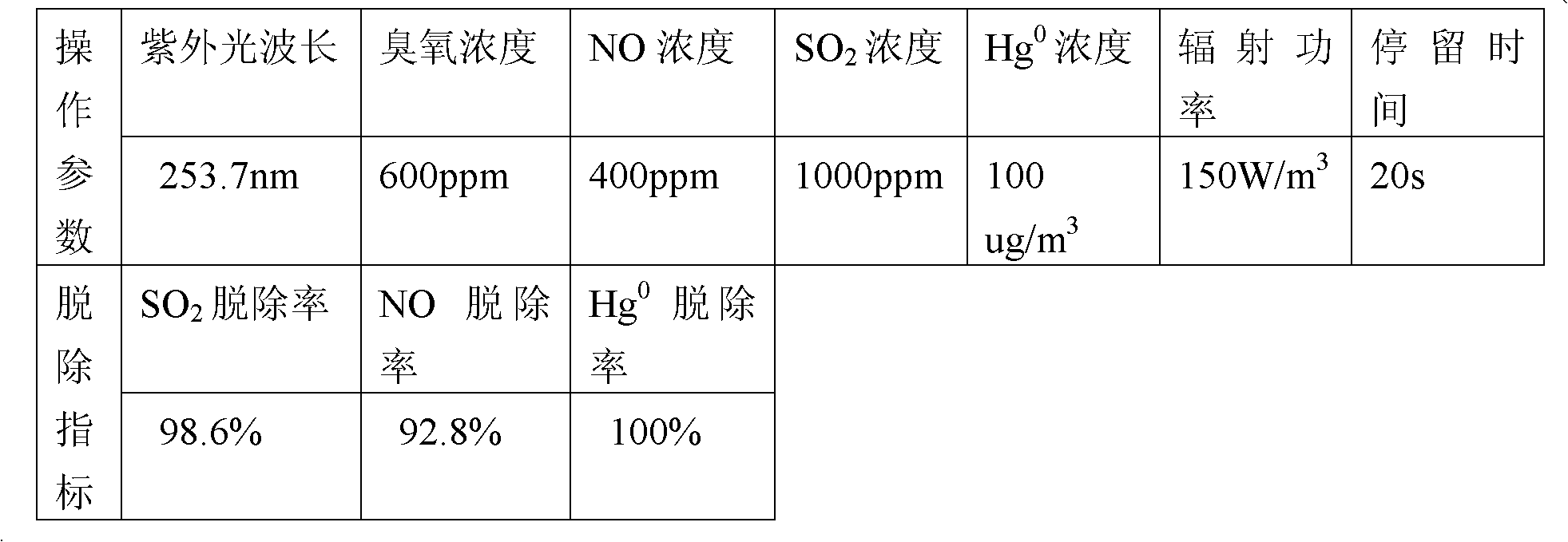

Embodiment 1

[0051]

Embodiment 2

[0053]

Embodiment 3

[0055]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

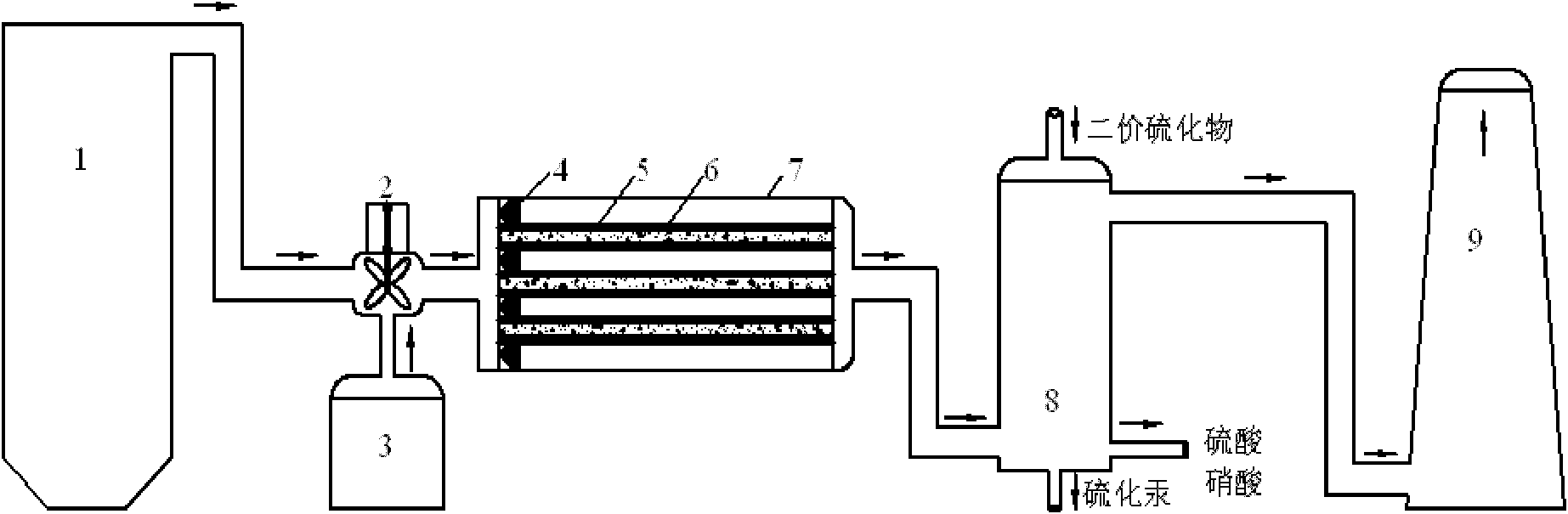

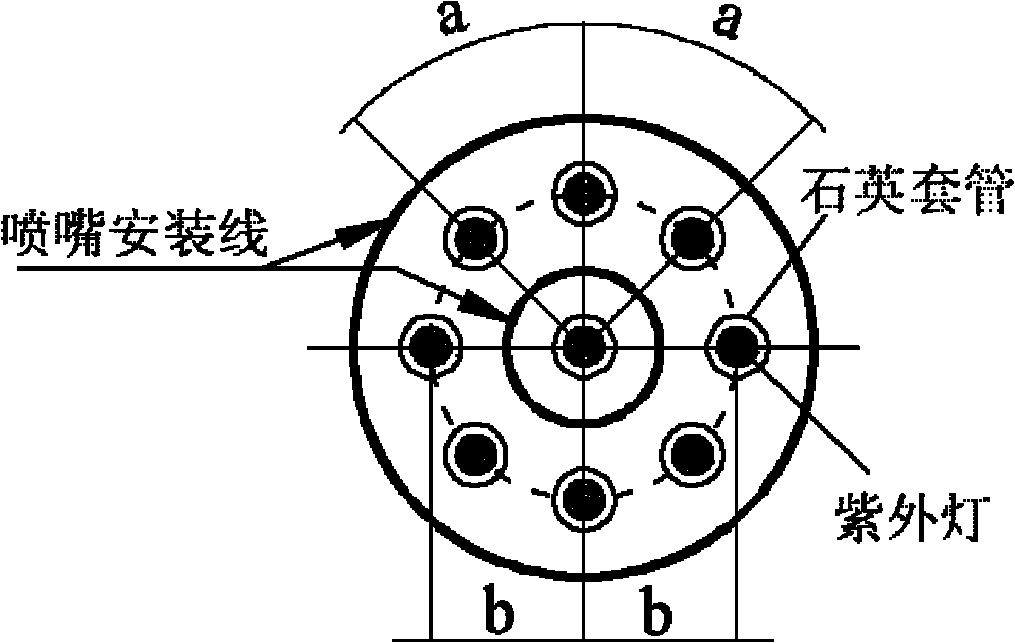

The invention provides a fume purification system based on advanced oxygenation combining wet scrubbing. The system is a combustion and exhaust system formed by a boiler, an ozone generator, a stirrer, a swirl nozzle, a reactor, a gas-liquid absorption tower and a chimney, wherein fume containing sulfur oxide, nitric oxide and mercury generated by combustion of the boiler and O3 generated by the ozone generator enter the stirrer together, are mixed, flow through the swirl nozzle, and are sprayed into the reactor with an ultraviolet lamp tube; and hydroxyl radical (.OH) with strong oxidability generated under excitation of ultraviolet radiation, SO2 in the fume, indissoluble NO and HgO are oxidized into gaseous products with higher dissolubility and enter the gas-liquid absorption tower to be absorbed and removed by water; Hg<2+> generated in the gas-liquid absorption tower captures and retrieves mercuric sulfide by adding sulfidion S<2-> in equal molar ratio; and the residual sulfuric acid and nitric acid mixed solution is used as an industrial raw material for recycling, and the cleaned fume enters the chimney so as to be exhausted.

Description

technical field [0001] The invention relates to the control of flue gas emission pollutants in the combustion process, in particular to a flue gas purification system based on advanced oxidation combined with wet scrubbing. Background technique [0002] Sulfur oxides, nitrogen oxides, and mercury produced during combustion can cause serious hazards such as acid rain, photochemical smog, and carcinogenicity and teratogenicity. Therefore, developing effective methods for flue gas desulfurization, denitrification and mercury removal is one of the important tasks of environmental protection scientists and technicians in various countries. In recent years, although people have developed a large number of flue gas desulfurization, denitrification and demercury technologies, due to the limitations of human understanding and the gradual development of science and technology, the existing desulfurization, denitration and demercury technologies were only developed for a single Pollut...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/76B01D53/60B01D53/64

Inventor 刘杨先张军盛昌栋张永春赵亮丁启忠

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com