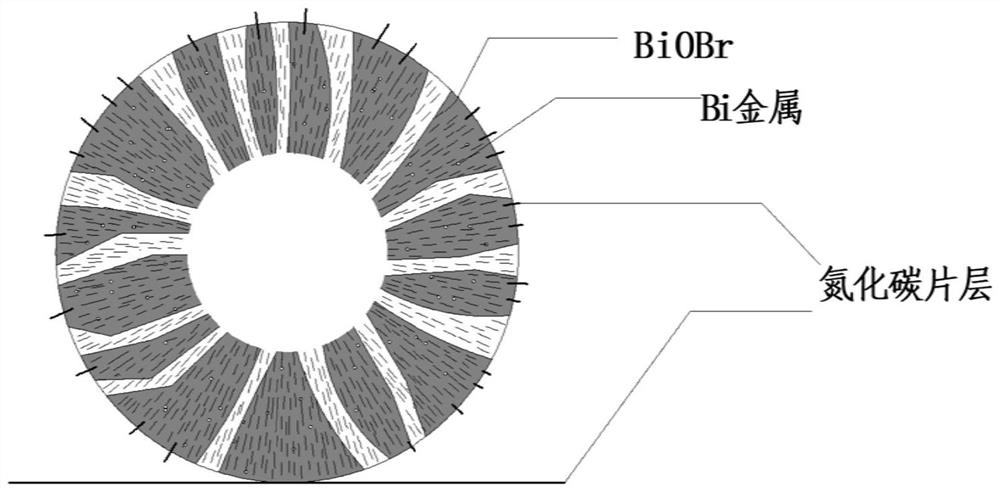

A bi-modified biobr-g-c 3 n 4 Heterojunction photocatalyst and preparation method and application thereof

A photocatalyst, g-c3n4 technology, applied in the field of photocatalysis, can solve the problem of insufficient absorption of visible light and achieve the effect of reducing the band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This embodiment provides a Bi-modified BiOBr-g-C 3 N 4 A heterojunction photocatalyst, the preparation method of which comprises the following steps:

[0077] S1. Preparation of g-C 3 N 4

[0078] After weighing 10g of urea into a ceramic crucible with a lid, place the crucible in a muffle furnace, heat it up to 350°C at a heating rate of 5°C / min, perform calcination once, and keep it for 1 hour; then heat at a temperature of 5°C / min The rate of heating was increased to 550°C, followed by secondary calcination for 3h; cooled to room temperature (25-30°C), ground into powder, washed with water and ethanol respectively, and finally placed in an oven and dried at 60°C for 36h to obtain porous g-C 3 N 4 ;

[0079]S2. Preparation of Bi-modified BiOBr-g-C 3 N 4 Heterojunction Photocatalyst

[0080] S21. g-C prepared from S1 3 N 4 0.2g, 1mmol Bi(NO3) 3 and 0.3g of PVP were dissolved in a beaker containing 20mL of ethylene glycol (EG) to obtain solution A;

[0081...

Embodiment 2

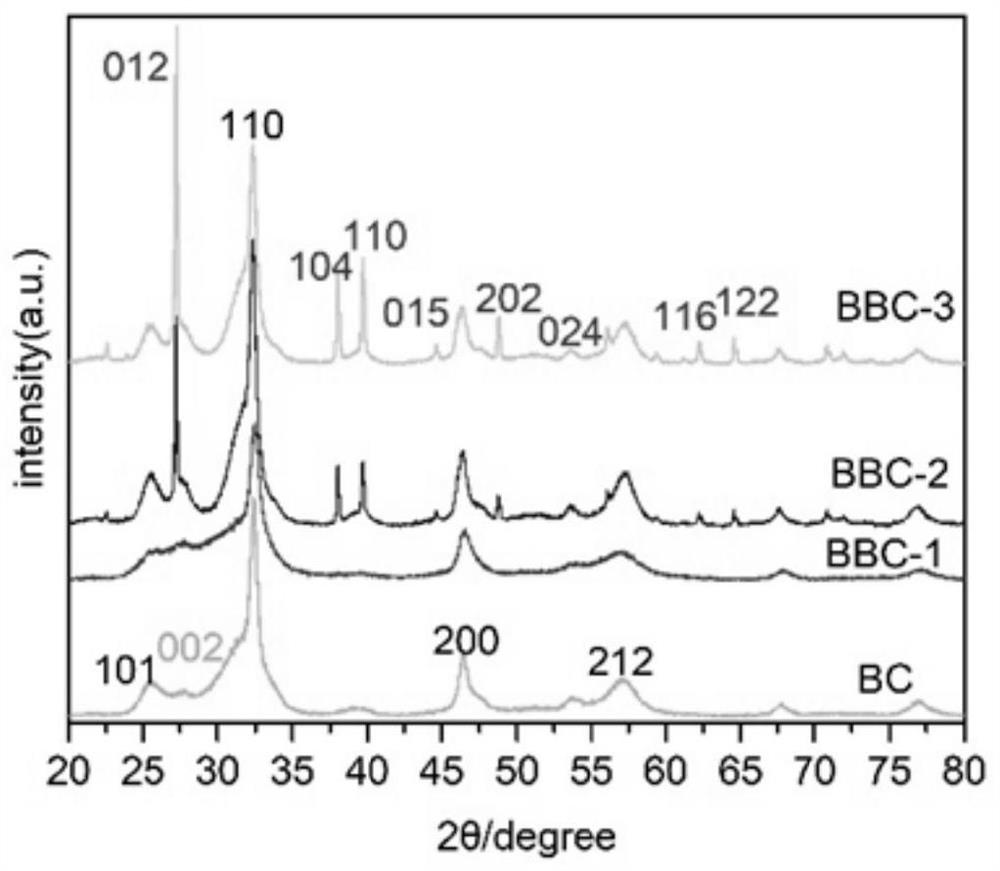

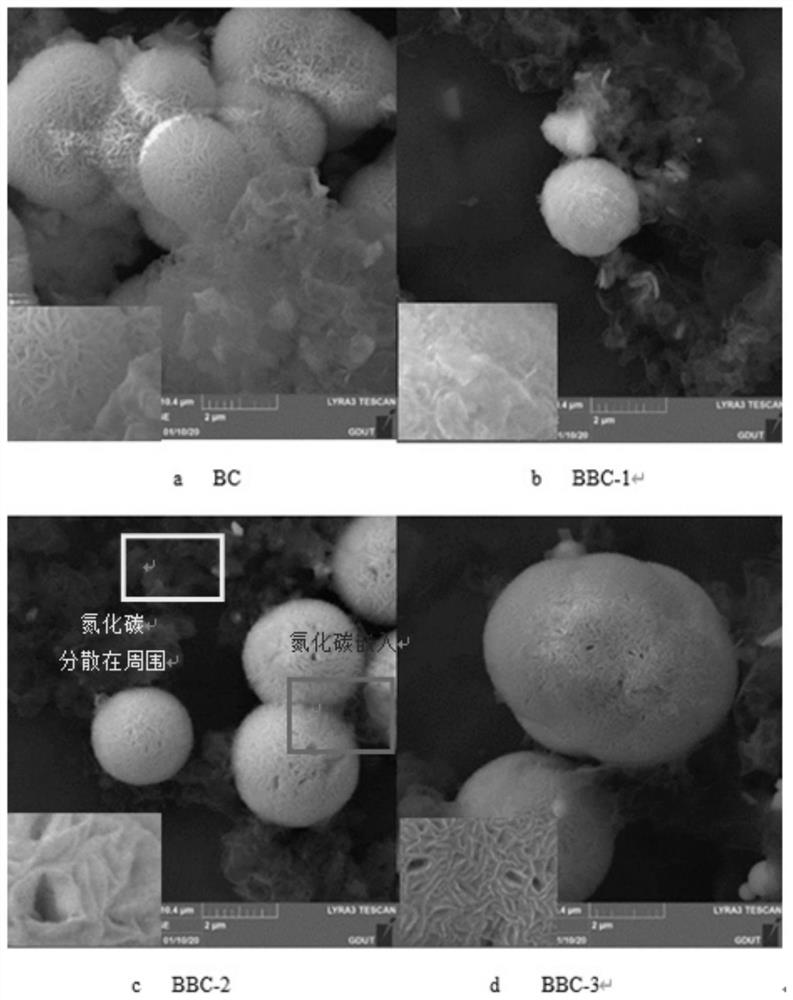

[0084] This embodiment provides a Bi-modified BiOBr-g-C 3 N 4 The difference between the heterojunction photocatalyst and Example 1 is that the amount of citric acid added in step S22 is 2 mmol, and the final prepared Bi-modified BiOBr-g-C 3 N 4 Heterojunction photocatalyst, denoted BBC-2, where Bi, BiOBr and g-C 3 N 4 The mass ratio of 0.27:1.14:1.

Embodiment 3

[0086] This embodiment provides a Bi-modified BiOBr-g-C 3 N 4 The difference between the heterojunction photocatalyst and Example 1 is that the amount of citric acid added in step S22 is 3 mmol, and the Bi-modified BiOBr-g-C prepared finally 3 N 4 Heterojunction photocatalyst, denoted as BBC-3, where Bi, BiOBr and g-C 3 N 4 The mass ratio of 0.41:1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com