Preparation method of titanium dioxide biomorphic material with high catalytic activity

A high catalytic activity, titanium dioxide technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of low cost, simple preparation method and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Rice husk—TiO 2

[0040] The experimental drugs used in the experiment were all analytically pure.

[0041] (1) acid pretreatment

[0042] Acid treatment: configure concentrated hydrochloric acid (mass fraction: 36.5%) into a dilute hydrochloric acid solution with a mass fraction of 1%, add rice husks to the prepared solution, install an oil bath reflux device, heat to boiling and reflux for 3 hours, then cool to room temperature , filtered with suction, washed repeatedly with deionized water until the pH value is neutral (PH=7±0.1), and dried at 50° C. for 24 hours.

[0043] (2) Preparation of TiO 2 Alcoholic solution

[0044] Tetrabutyl titanate (Ti(OBu) 4 ) was dissolved in absolute ethanol, and a tetrabutyl titanate ethanol solution with a volume fraction of 6.3% was prepared, and then acetylacetone was added according to the volume ratio tetrabutyl titanate ethanol solution: acetylacetone=128:0.4, and stirred in a magnetic stirrer for 20 min , and the obtained ...

Embodiment 2

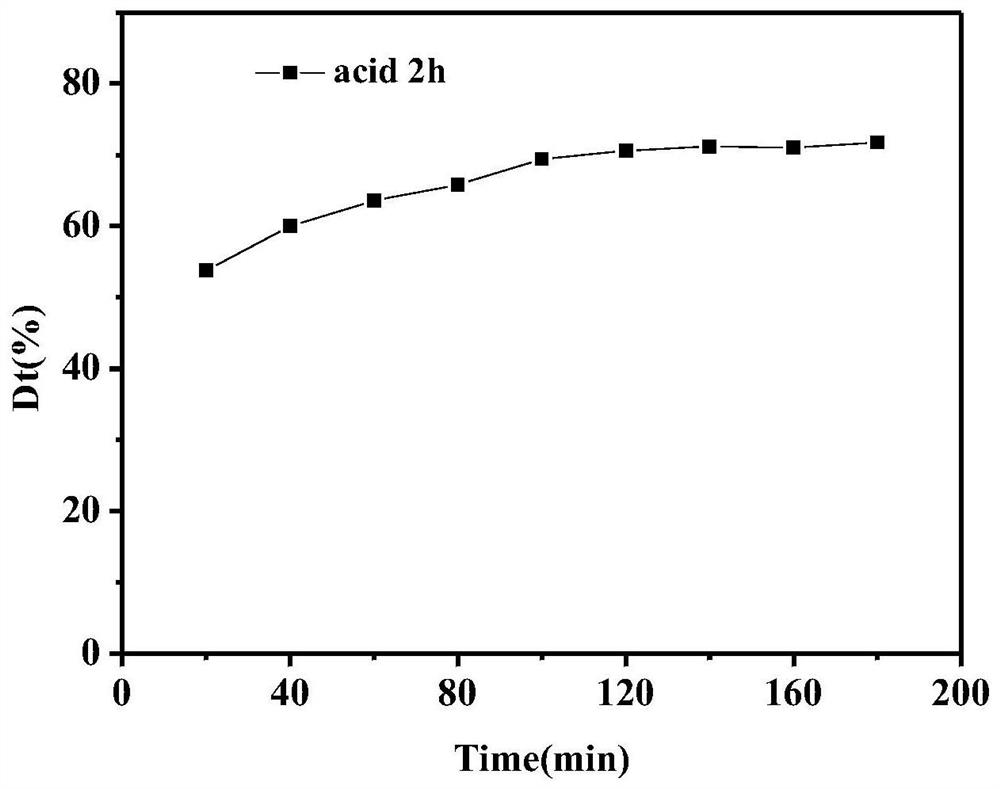

[0052] Begonia leaves—TiO 2 Material

[0053] Using crabapple leaves as natural biological templates to prepare residual TiO by solution impregnation method 2 .

[0054] The experimental drugs used in the experiment were all analytically pure.

[0055] (1) Pretreatment

[0056] Weigh three parts of crabapple leaves that are cleaned and dried in a vacuum drying oven, each part of 10g.

[0057] Acid treatment: configure concentrated hydrochloric acid (mass fraction: 36.5%) into a dilute hydrochloric acid solution with a mass fraction of 2%, add a portion of crabapple leaves to the dilute hydrochloric acid, install an oil bath reflux device, heat to boiling and reflux for 2 hours and cool to room temperature, Suction filtration, repeated washing with deionized water until the pH value is neutral (PH=7±0.1), and drying in a vacuum oven at 55° C. for 16 hours.

[0058] (2) Preparation of TiO 2 Alcoholic solution

[0059] Tetrabutyl titanate (Ti(OBu) 4 ) into absolute ethano...

Embodiment 3

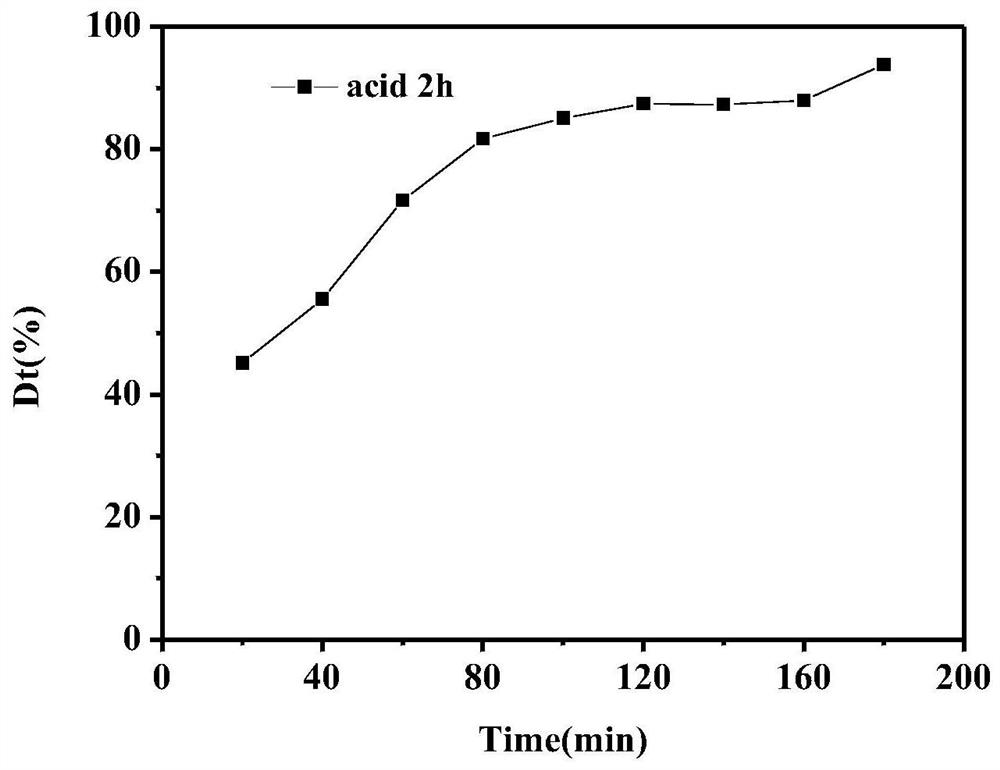

[0067] Hemp fiber—TiO 2

[0068] The experimental drugs used in the experiment were all analytically pure.

[0069] (1) acid pretreatment

[0070] Use concentrated hydrochloric acid (mass fraction: 36.5%) to configure a dilute hydrochloric acid solution with a mass fraction of 3%, add hemp fiber in the prepared dilute hydrochloric acid solution, install an oil bath reflux device, heat to boiling, and cool to room temperature after reflux for 1h , after repeated suction filtration, washed with deionized water until the pH value is neutral (PH=7±0.1), and dried in a blast drying oven at 60° C. for 14 hours.

[0071] (2) Configure Ti(OBu) 4 Alcoholic solution

[0072] Tetrabutyl titanate (Ti(OBu) 4 ) was dissolved in absolute ethanol, and a tetrabutyl titanate ethanol solution with a volume fraction of 7.7% was prepared, and then acetylacetone was added according to the volume ratio tetrabutyl titanate ethanol solution: acetylacetone=128:0.6, and stirred in a magnetic stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com