Preparation and applications of photocatalyst CNU-BA

A CNU-BA, photocatalyst technology, applied in the field of photocatalytic materials, can solve the problems of limited increase in photocatalytic efficiency of modified catalysts, inability to meet industrial requirements, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

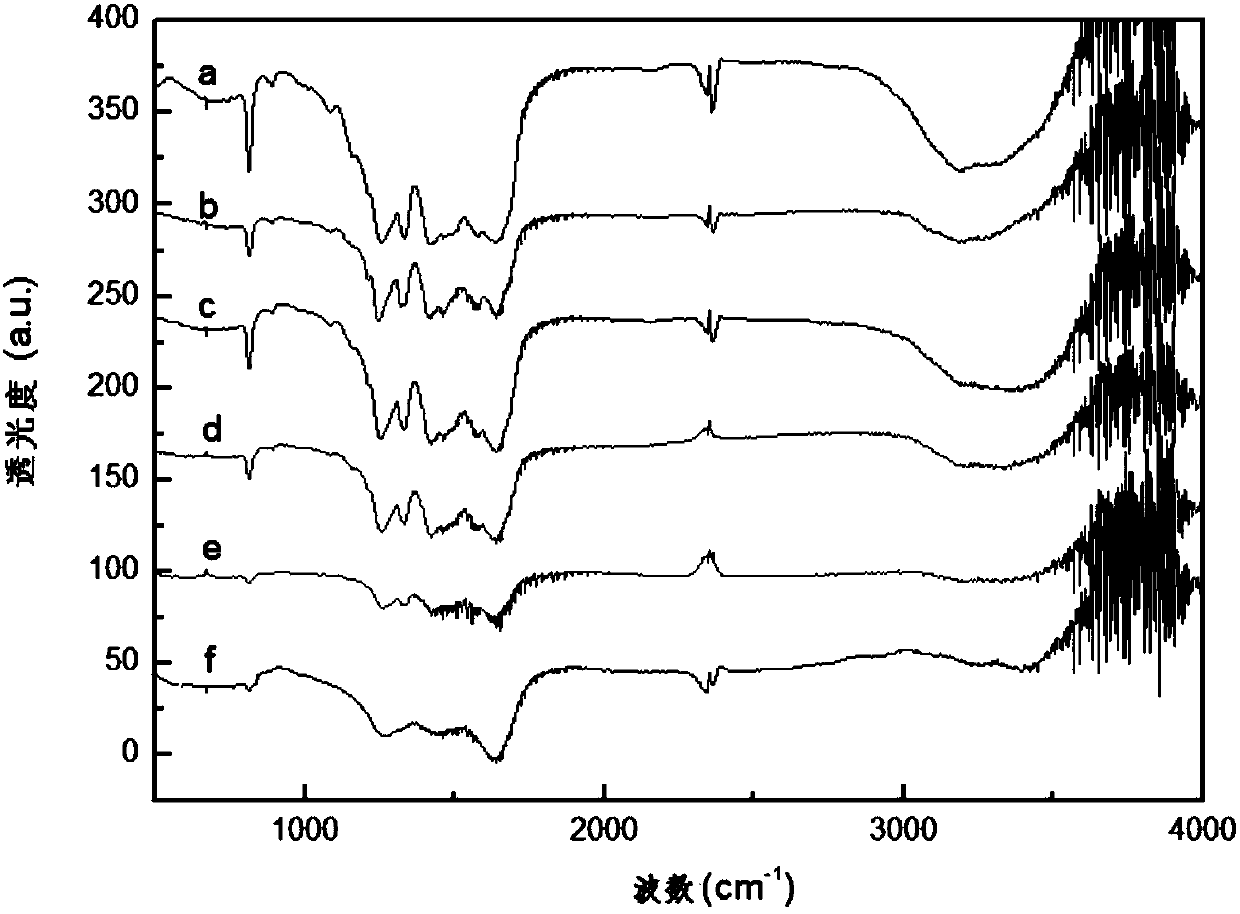

Image

Examples

Embodiment 1

[0060] (1) Accurately weigh 0.01g of barbituric acid with an electronic balance and dissolve it in a beaker containing 10mL of distilled water, then weigh 10g of urea and add it to the above beaker, put a small magnet into the beaker, and place the beaker on a magnetic Stir on a stirrer to speed up the dissolution of the mixture. Then place the beaker in a constant temperature water bath at 100°C to evaporate to dryness, and grind it into powder in an agate mortar to obtain solid I;

[0061] (2) Then the above-mentioned solid I is transferred to a dry and clean porcelain crucible, placed in a muffle furnace, heated to 550°C at a speed of 10°C / min, and ground to powder in an agate mortar after roasting for 2h. Then put it in a sealed bag and seal it for storage. The product number is CNU-BA 0.01 .

Embodiment 2

[0063] The experimental procedure is the same as in Example 1, except that the amount of barbituric acid used is different. In this example, the amount of barbituric acid is 0.03g, and the product number is CNU-BA 0.03 .

Embodiment 3

[0065] The experimental procedure is the same as in Example 1, except that the amount of barbituric acid used is different. In this example, the amount of barbituric acid is 0.05g, and the product number is CNU-BA 0.05 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com