Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

342results about How to "Easy to dope" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

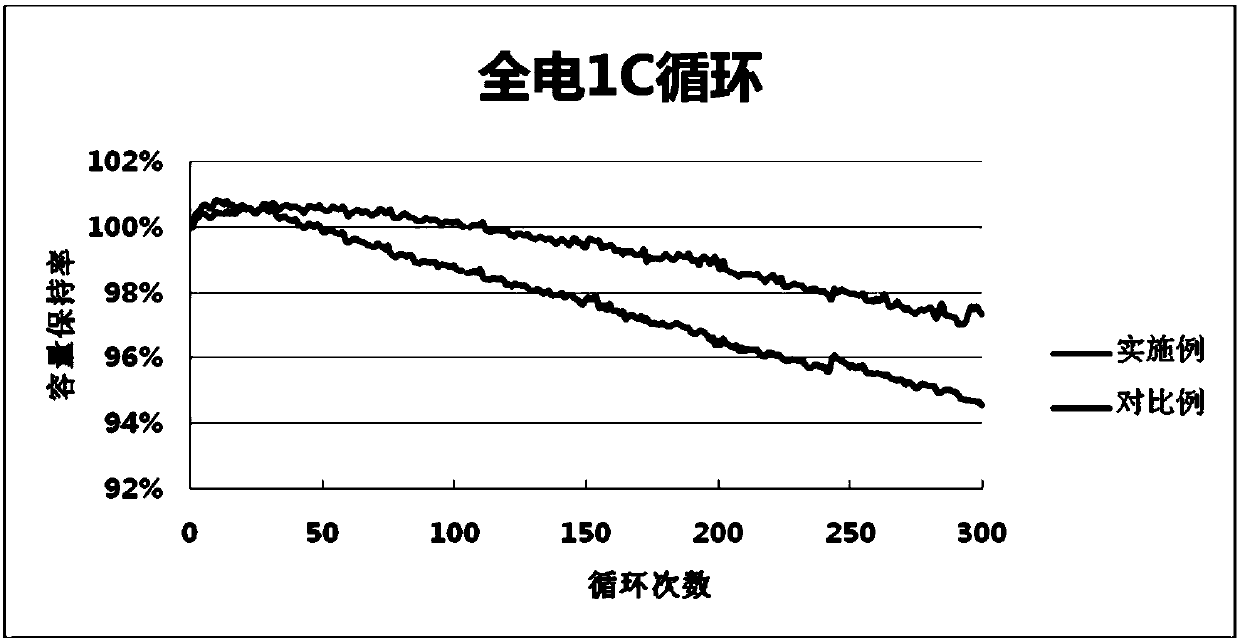

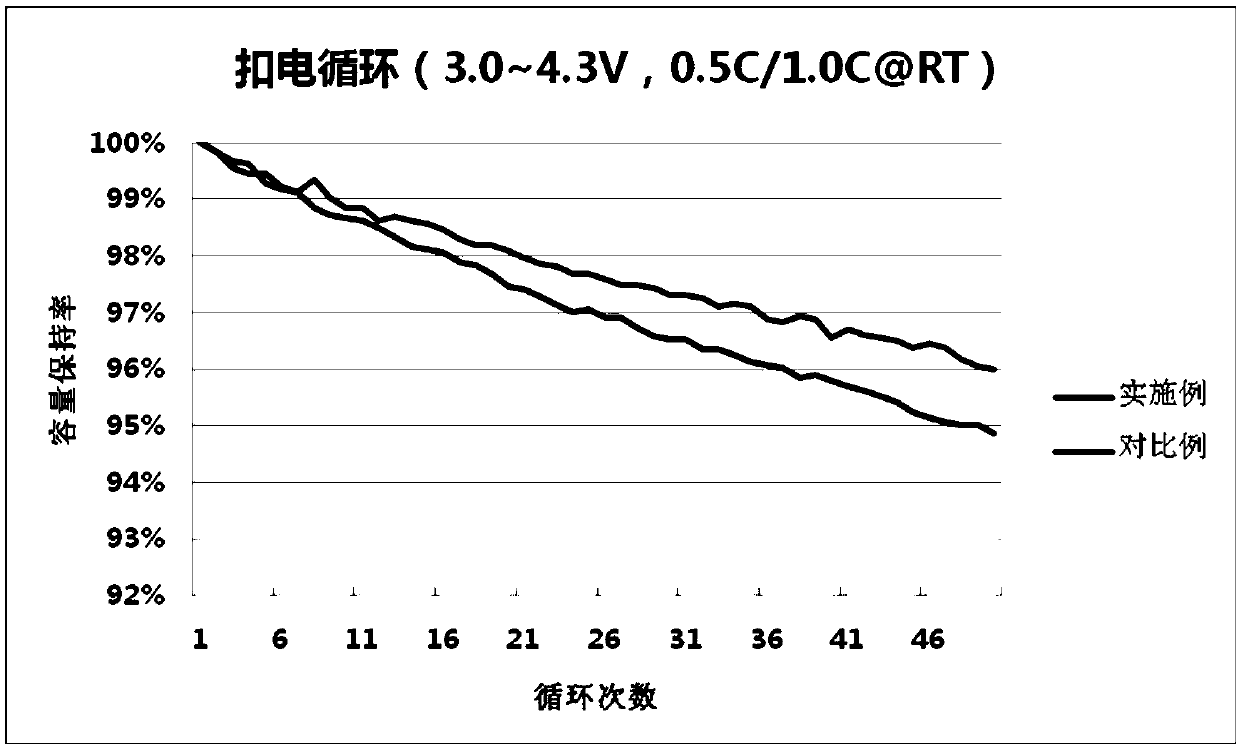

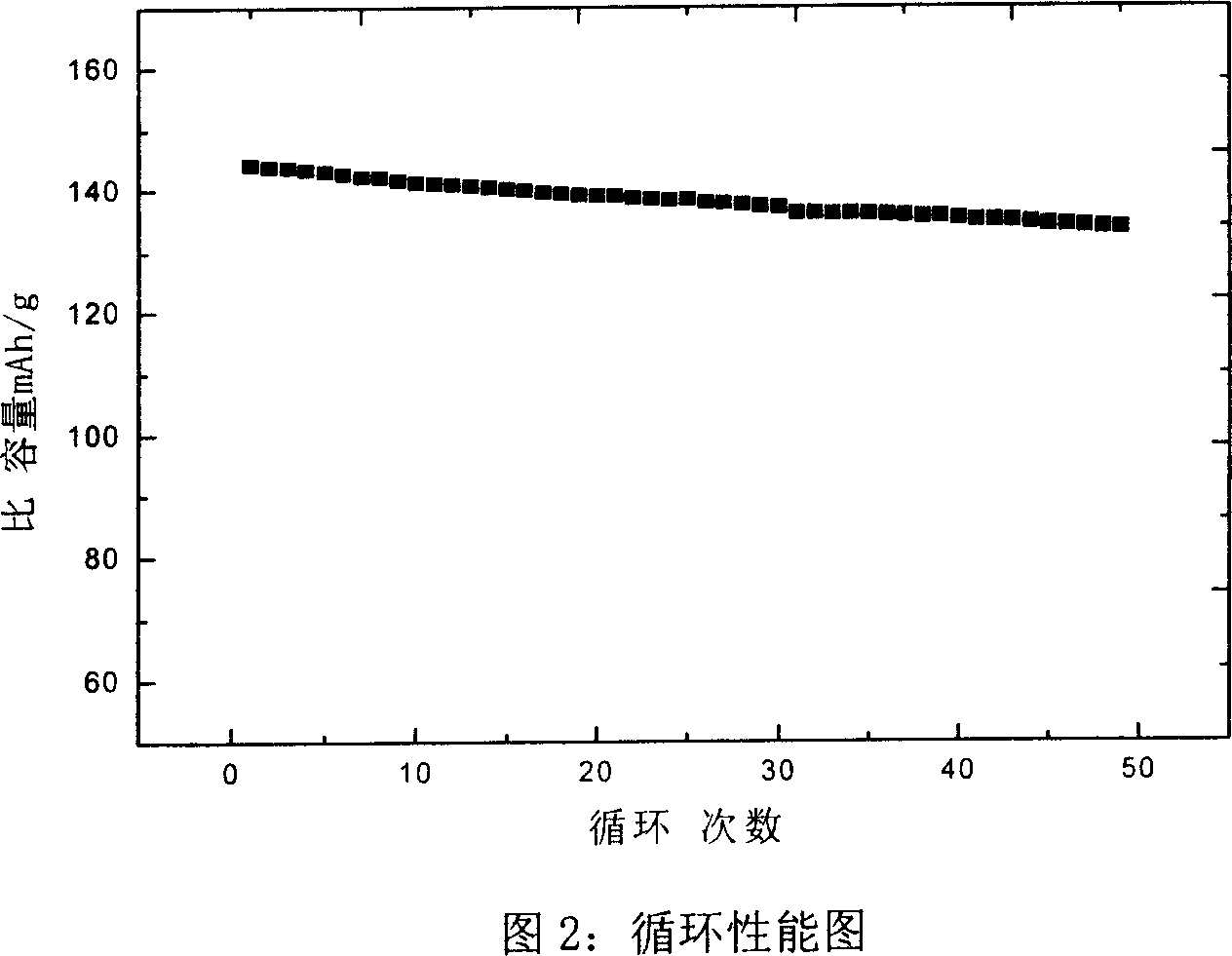

Modified high-nickel positive electrode material coated with fast ion conductor and preparation method of modified high-nickel positive electrode material

InactiveCN108023077AImprove cycle performanceImproved magnification performanceCell electrodesSecondary cellsElectrical conductorPhysical chemistry

The invention discloses a modified high-nickel positive electrode material coated with a fast ion conductor and a preparation method of the modified high-nickel positive electrode material. The high-nickel positive electrode material comprises a substrate, wherein the substrate is a compound LiNi<1-x-y>Co<x>Mn<y>M<z>O<2> shown in a formula I, in the formula I, x is more than 0 but less than or equal to 0.20, y is more than 0 but less than or equal to 0.20, z is more than 0 but less than or equal to 0.1, and M is arbitrary one or more of elements of Al, Mg, Ti, Zr, Mn, Ni, Sn, Co, Zn, W, Mo, Ru, Ca, Sr, Ba, B, Y, V and Nb. The preparation method comprises the following steps of washing and drying the high-nickel positive electrode material, uniformly mixing the high-nickel positive electrode material and an appropriate amount of coating agent, and performing sintering and sieving to obtain the modified high-nickel positive electrode material coated with the fast ion conductor. The fastion conductor is coated by washing and surface drying methods, the alkali amount of a surface of the positive electrode material is reduced, side reaction of the material and an electrolyte is reduced, and the high-temperature stability and the safety of the material are improved; and by doping and coating the surface with the fast ion conductor, the energy density, the rate performance and the cycle property of the material are improved, and the long cycle lifetime of a battery is finally prolonged.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

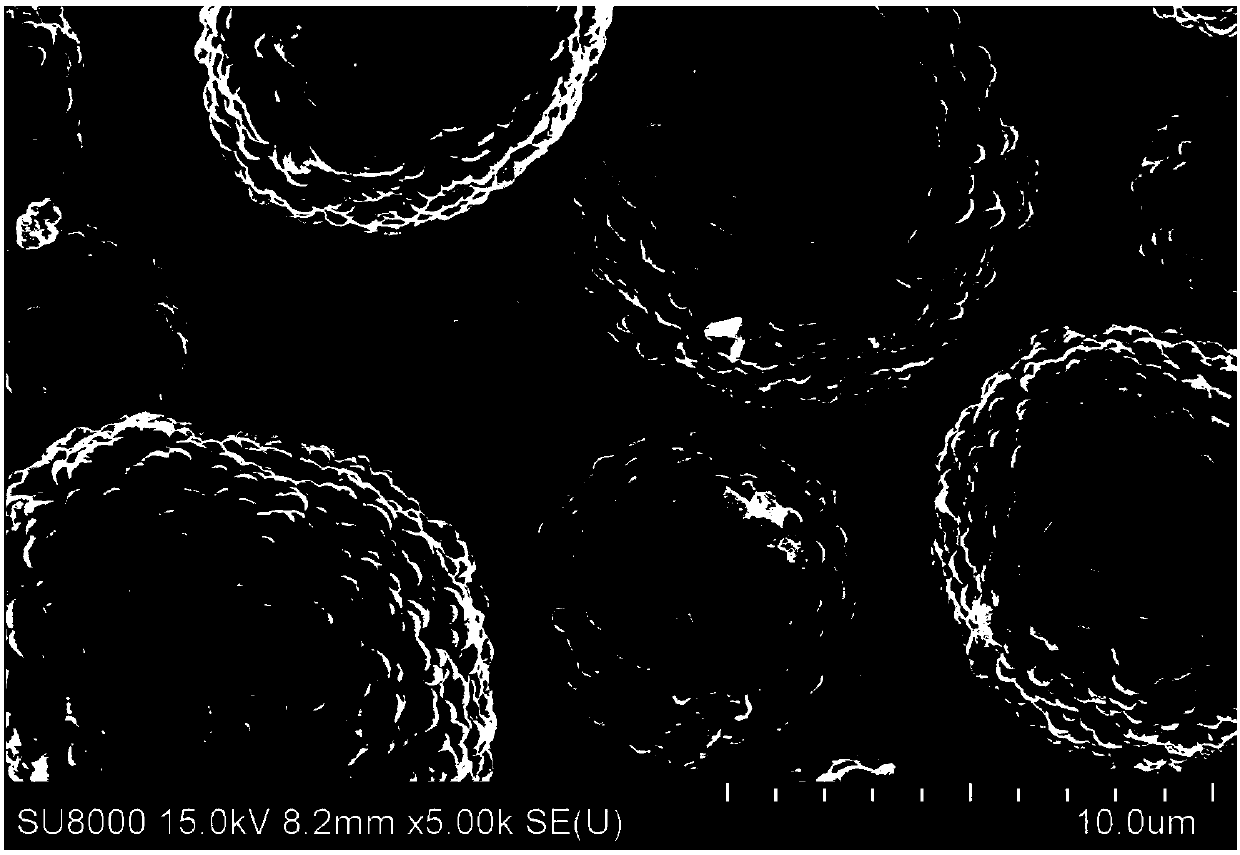

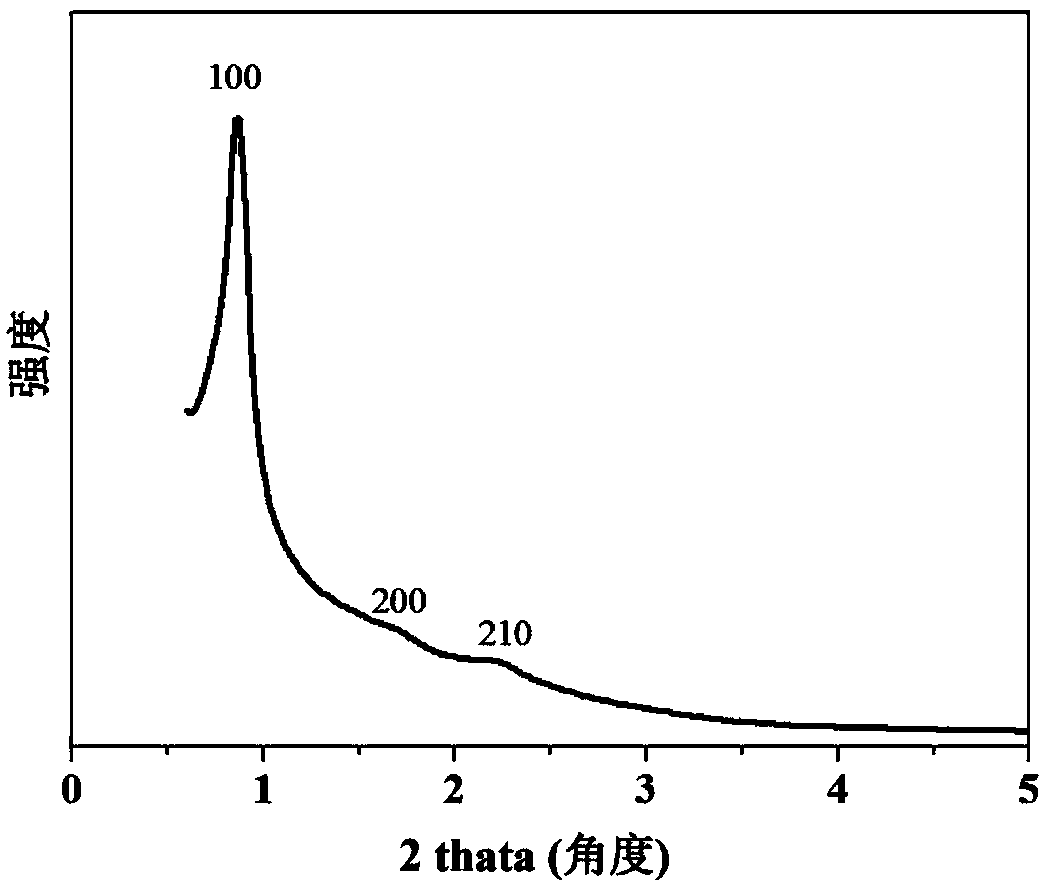

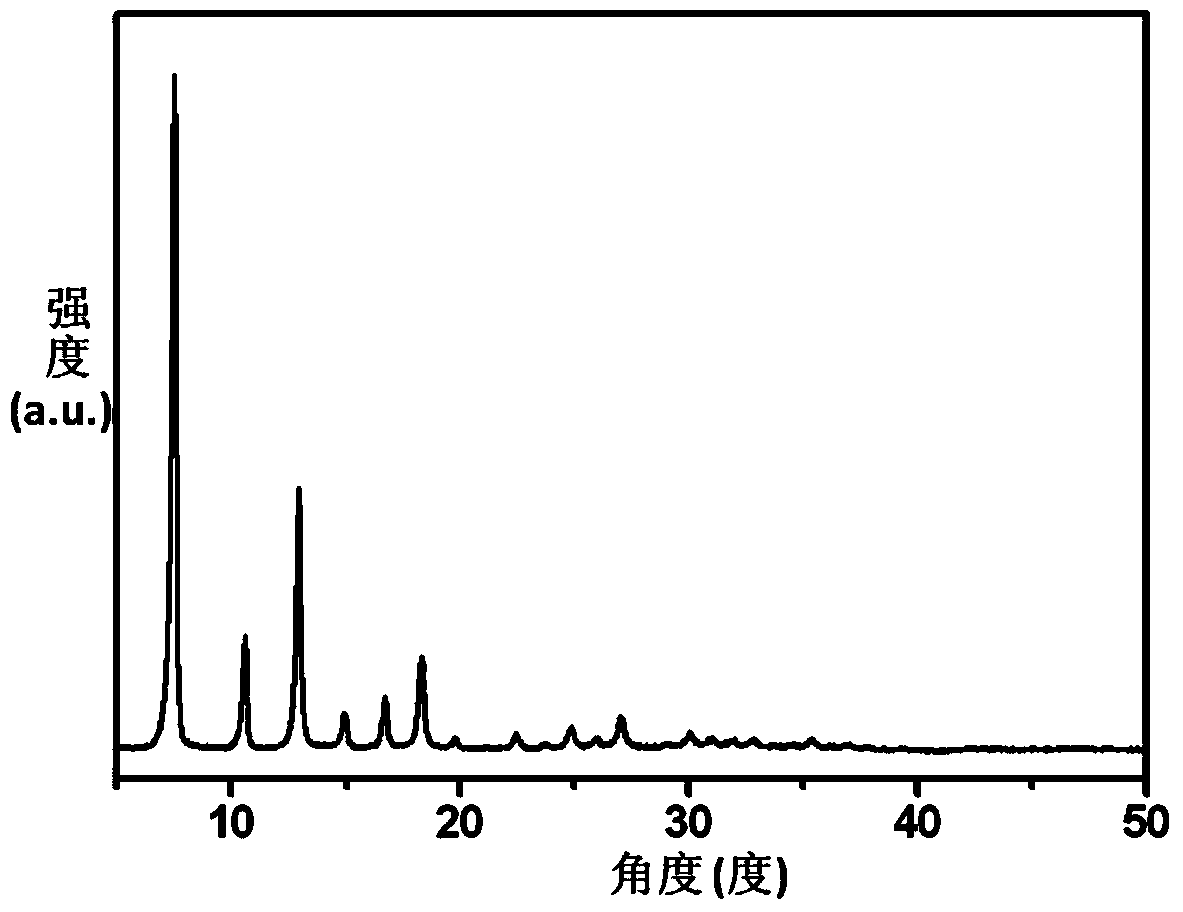

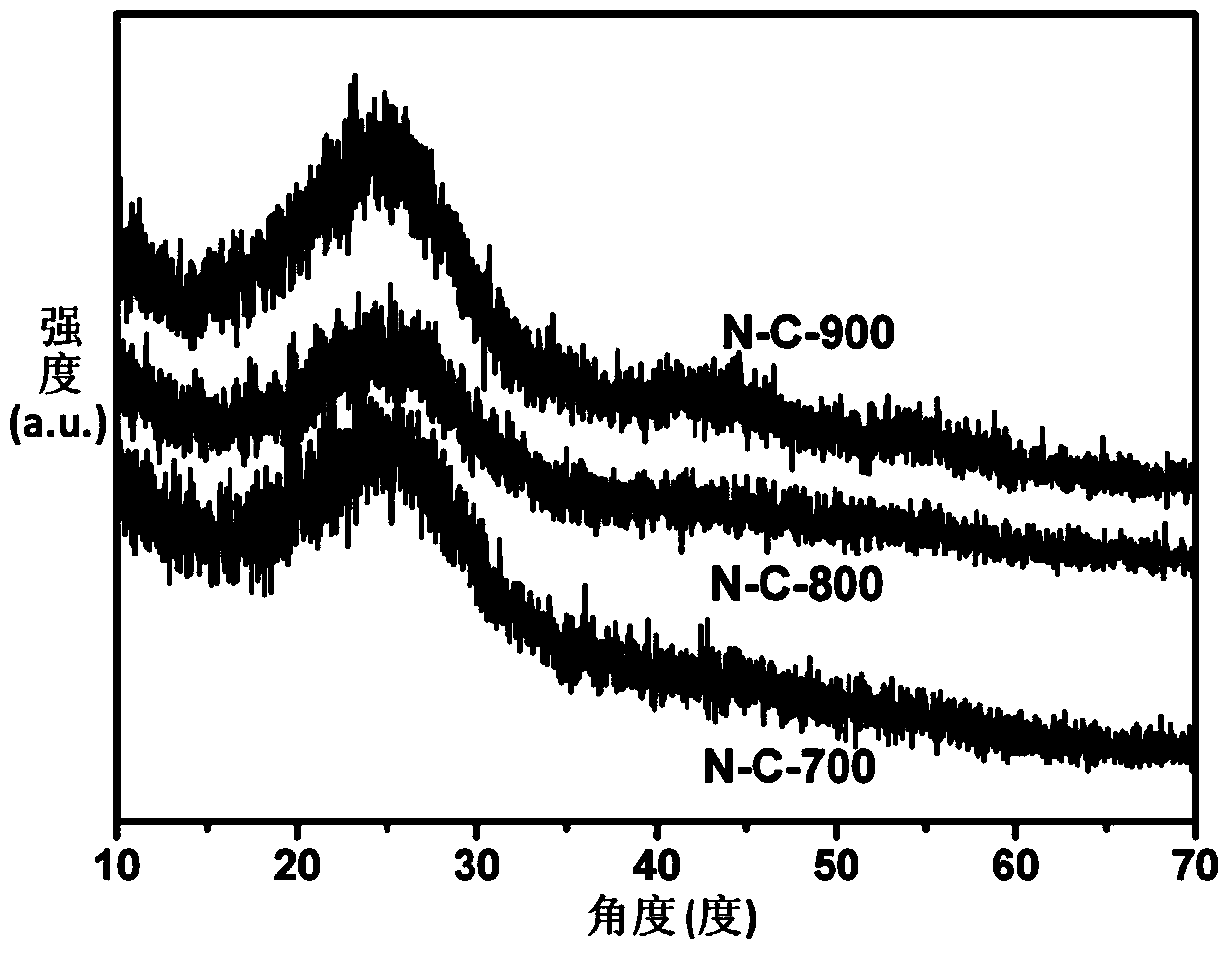

Solid-phase synthetic method of highly ordered mesoporous carbon material

InactiveCN103964414AIncrease the areaHigh pore volumeCarbon preparation/purificationPore diameterSelf-assembly

The invention discloses a solid-phase synthetic method of a highly ordered mesoporous carbon material. The solid-phase synthetic method comprises the following steps: 1) mixing a structure-directing agent with a high molecular monomer used as a carbon source, and grinding for 5-180 min at 10-100 DEG C; 2), heating for 0.5-120 h at 40-380 DEG C; 3) under the protection of inert gases, rising the temperature to 500-2,100 DEG C at the temperature rising speed of 1-40 DEG C / min, and roasting for 2-10 h at high temperature. The functionalization mesoporous carbon material is synthetized through the organic-organic self-assembly between the high molecular monomer and the structure-directing agent and between the low polymer of the high molecular monomer and the structure-directing agent, and the mechanical grinding. The solid-phase synthetic method is simple to operate, efficient, and low in cost, and the prepared mesoporous carbon material has a highly ordered mesoporous channel, high specific surface area (500-2,500 m<2> / g and large pore volume (pore diameter of 2.5-20 nm and pore volume of 0.1-2.5 cm <3> / g).

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

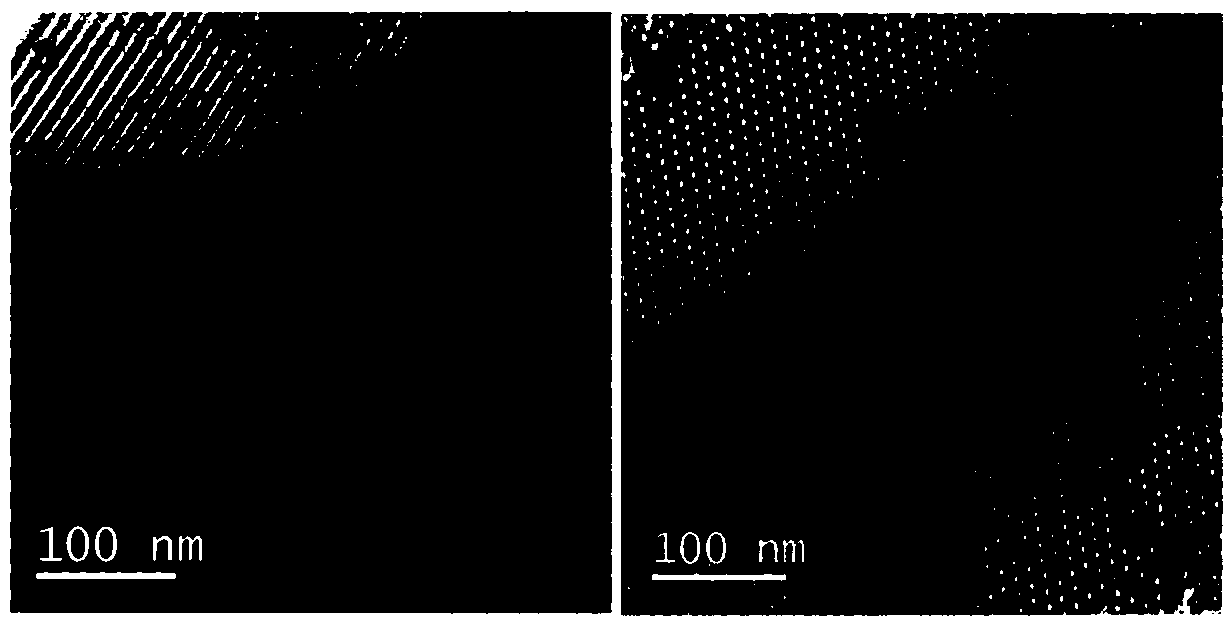

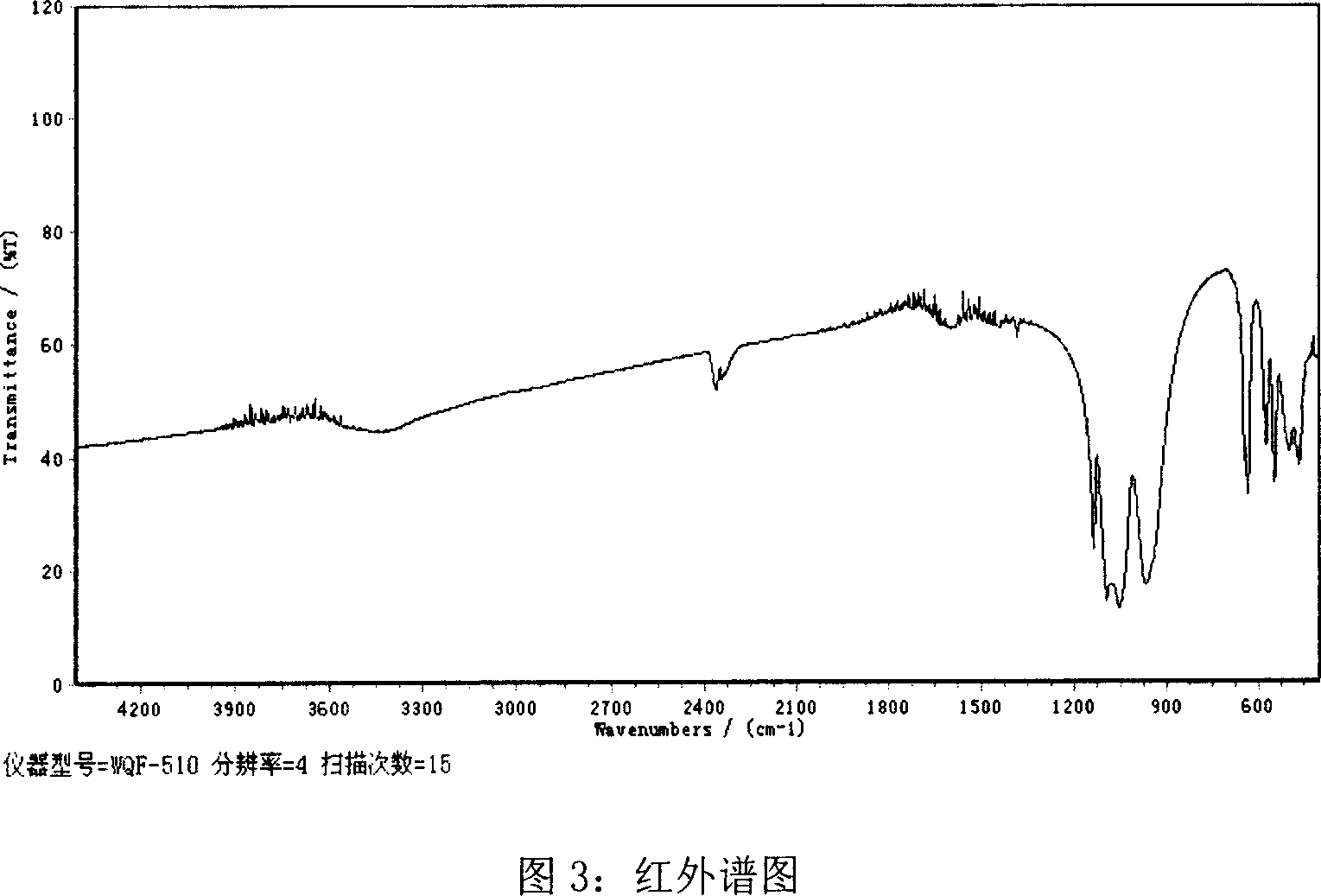

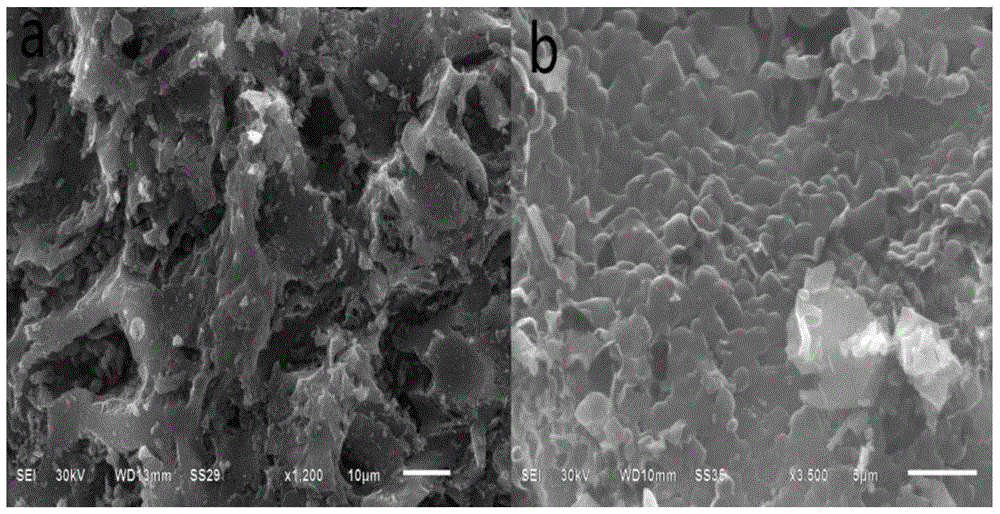

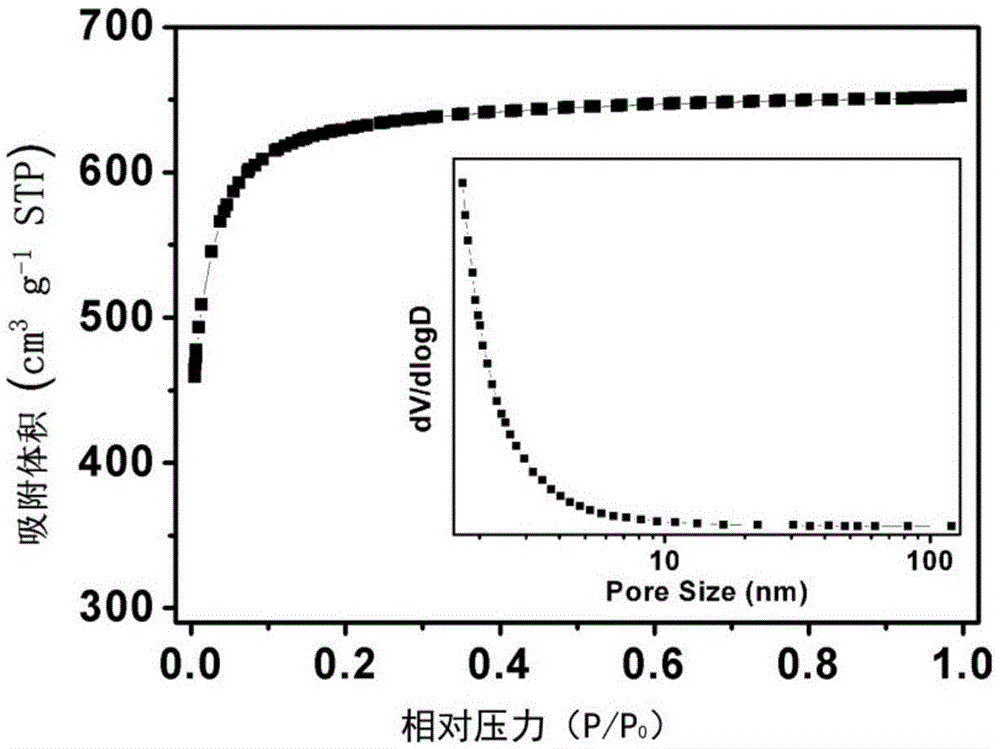

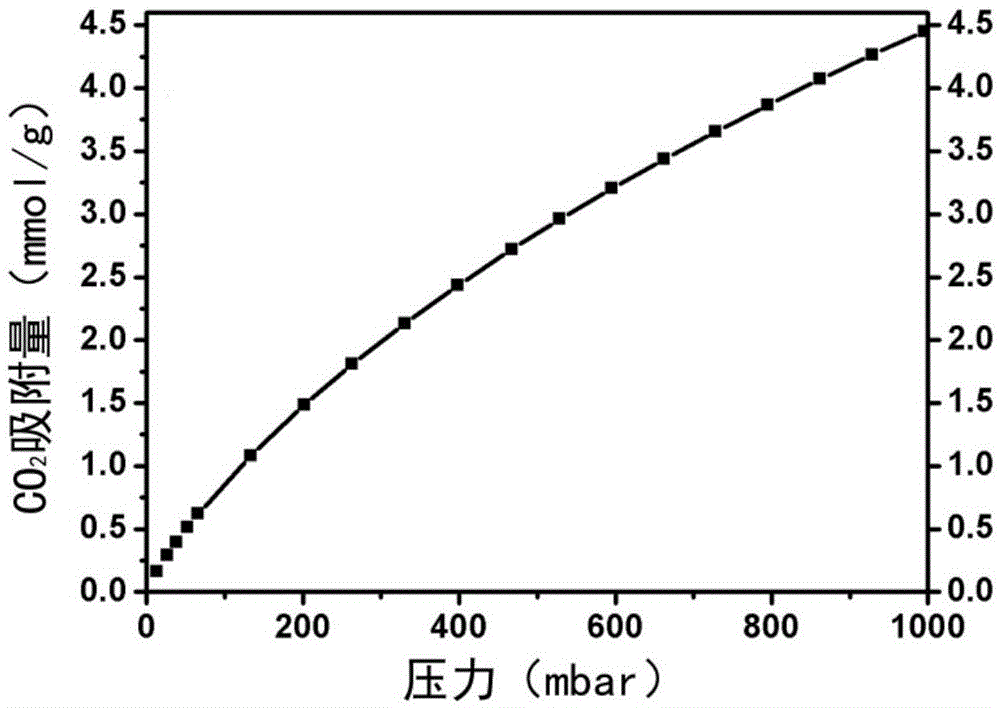

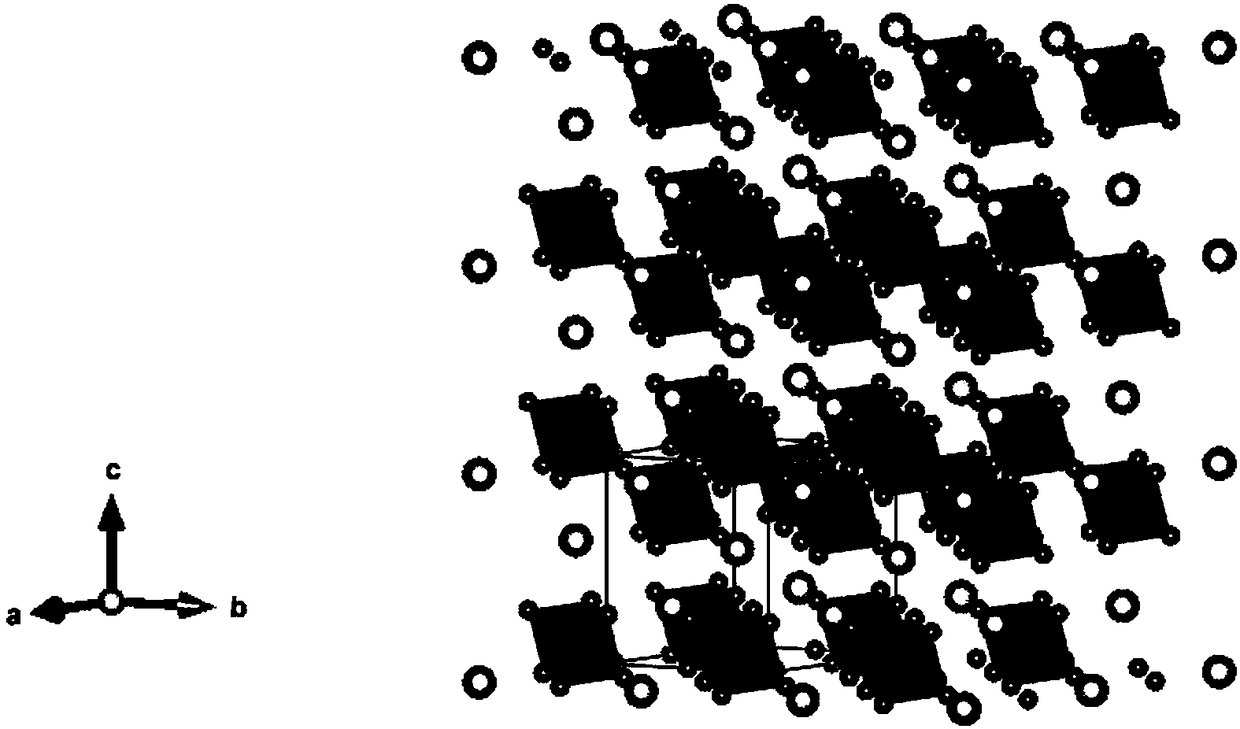

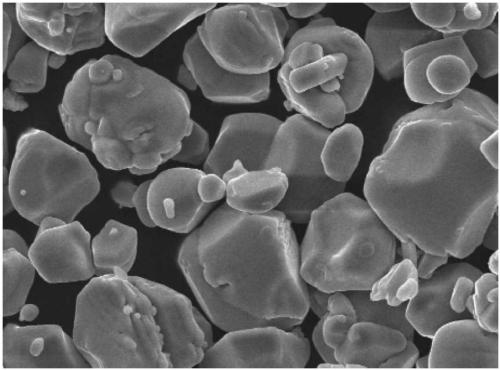

Preparation method of high-nitrogen-doped graphene nanoparticles and application of high-nitrogen-doped graphene nanoparticles as negative material of lithium ion battery

ActiveCN104201385AEasy to dopeHigh nitrogen contentMaterial nanotechnologyCell electrodesDoped grapheneZinc nitrate

The invention provides a preparation method of high-nitrogen-doped graphene nanoparticles and application of the high-nitrogen-doped graphene nanoparticles as a negative material of a lithium ion battery. The corresponding method comprises the following steps: slowly dropwise adding a preset quantity of zinc nitrate (Zn(NO3)) methanol solution into a methanol mixed solution which is prepared from a preset amount of 2-methylimidazole (C4H6N2) and a preset amount of polyvinylpyrrolidone (PVP), magnetically stirring and standing for preset time, carrying out centrifugal separation to obtain ZIF-8(a complex formed by zinc and 2-methylimidazole) nanoparticles; and putting the obtained ZIF-8 nanoparticles in a high-temperature furnace and calcining at 600-1,000 DEG C for preset time in the nitrogen atmosphere to obtain the high-nitrogen-doped graphene nanoparticles. The preparation process of the high-nitrogen-doped graphene nanoparticles is simple, and the high-nitrogen-doped graphene nanoparticles are uniform in shape, relatively large in specific surface and high in content of nitrogen, and have great application potentials in aspects of lithium ion batteries, electrochemical energy storage, catalysis and the like. The preparation method of the high-nitrogen-doped graphene nanoparticles is simple and efficient, safe and liable to implement, short in synthesis cycle, is capable of preparing a large quantity of high-nitrogen-doped graphene nanoparticles and is expected to be popularized and industrially applied.

Owner:UNIV OF SCI & TECH OF CHINA

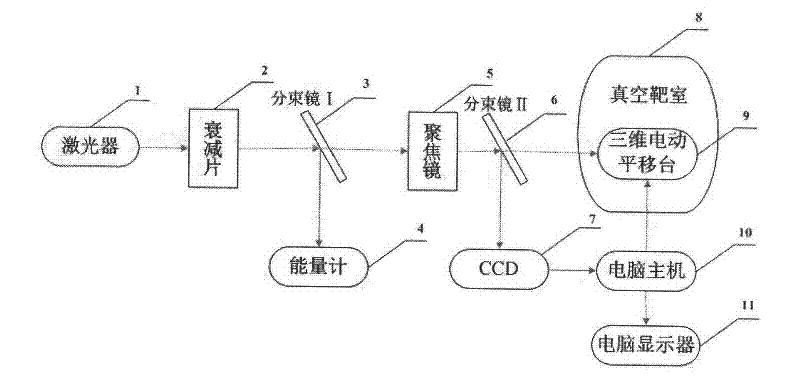

Preparation device for preparing functional micro-nano materials on silicon surfaces based on femtosecond laser and method

InactiveCN102500923AReduce heat damageEasy to processDecorative surface effectsChemical vapor deposition coatingField emission deviceSolar cell

The invention provides a preparation device for preparing functional micro-nano materials on silicon surfaces based on femtosecond laser and a method. When the device is used for preparation, scanning speed reaches 4mm / s, and is increased by 20 times as compared with scanning speed when micro-nano materials are prepared in a traditional method. Simultaneously, supersaturation doping of the silicon material surface and preparation of micro-nano structures of the surfaces are realized during preparation, prepared micro-nano materials can absorb 90% of light with wavelength ranging from 200nm to 2500nm, and silicon materials without scanning traces on surfaces can be obtained. The preparation device and the method are exquisite in design and easy to control, and the prepared materials can be applied to solar cells, detectors, field emission devices and the like in the photoelectric industry.

Owner:CHANGCHUN UNIV OF SCI & TECH

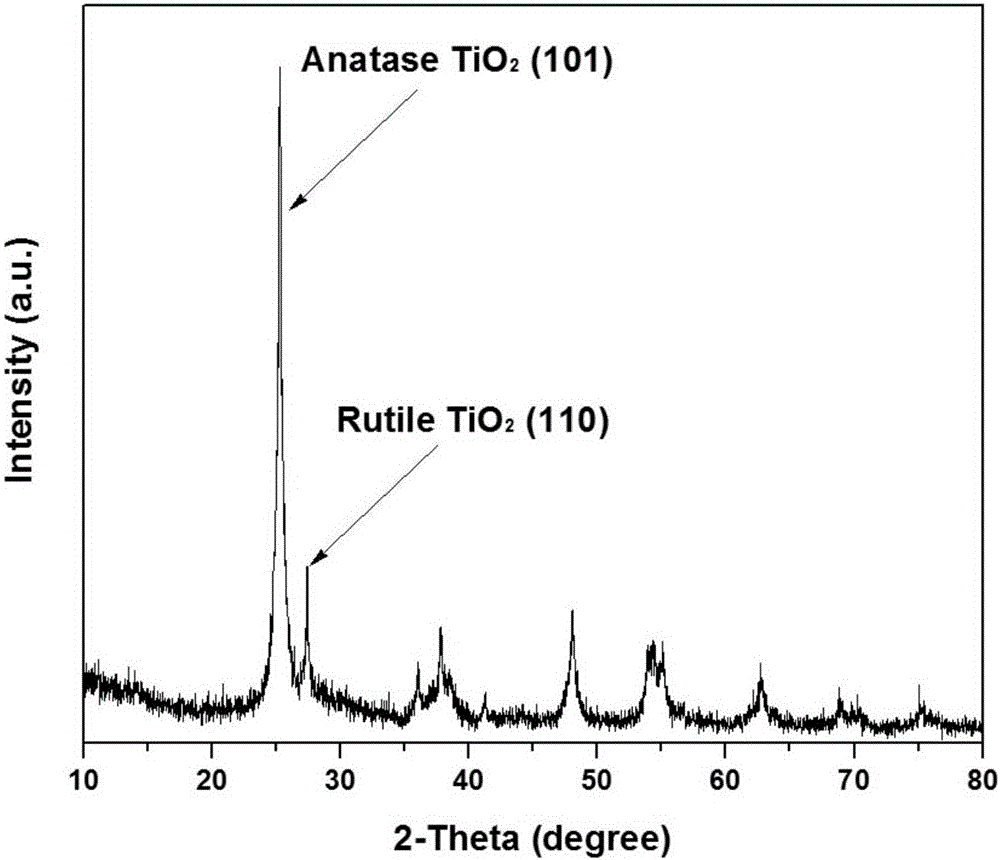

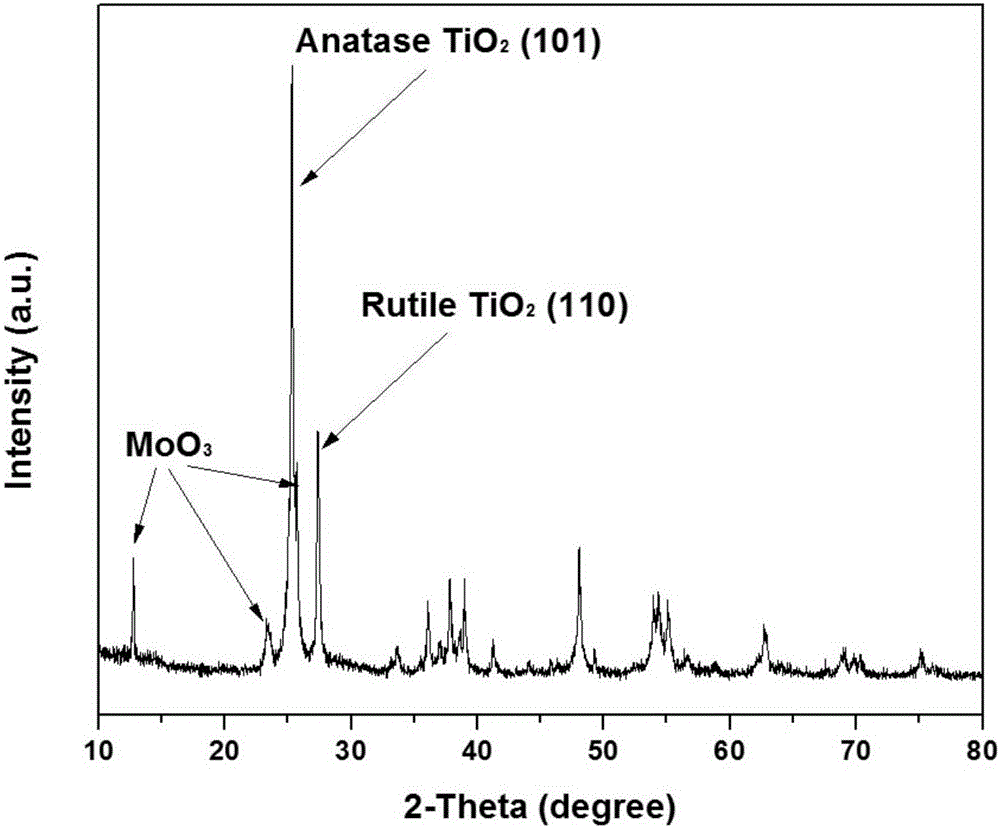

Molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle and preparation method and application thereof

InactiveCN105161700AGood transmission and diffusion effectImprove conductivityMaterial nanotechnologyCell electrodesHigh rateElectrochemistry

The invention relates to a molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle. The surface of a trivalent molybdenum ion doped titanium dioxide nano particle is coated with molybdenum trioxide, titanium dioxide is a mixed phase composed of an anatase phase and a rutile phase, and a sintered interface is arranged among titanium dioxide particles and is of a chain structure. A flame spraying combustion technology is adopted, and the molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle can be rapidly and continuously prepared; a synergistic effect is played to the greatest extent; and the conductivity of TiO2 is improved, an extra lithium insertion space is provided by the TiO2 and MoO3 grown on the surface, the specific capacity is improved, high electrochemical activity and high rate performance of a material are ensured, and the molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle has excellent rate performance and cyclic stability when applied to the field of an anode material of a lithium ion battery.

Owner:EAST CHINA UNIV OF SCI & TECH +1

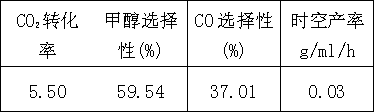

Catalyst for synthesising methanol by hydrogenation of carbon dioxide as well as preparation method and application thereof

ActiveCN103252241AEasy to prepareEasy to operateOrganic compound preparationHydroxy compound preparationMetalMethanol

The invention discloses a catalyst for synthesising methanol by hydrogenation of carbon dioxide. The catalyst is composed of oxides with the following molar ratio based on metal: 20-50% of La, 0-10% of M, 15-35% of Cu, and 2-15% of Zn, wherein M is one or more of Zr, Y, K, Ag, Ce, Pd, Mn, Mg, Fe, Co, Ni or Cr. The catalyst disclosed by the invention has the advantages that preparation is simple, operation is easy, catalyst performance repeatability is good, industrial amplification is easy to realize, and reaction conversion rate and reaction selectivity are high.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

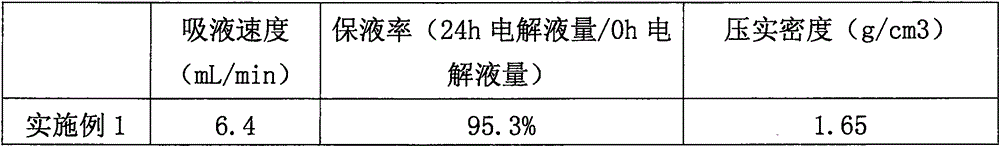

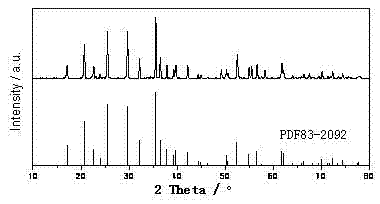

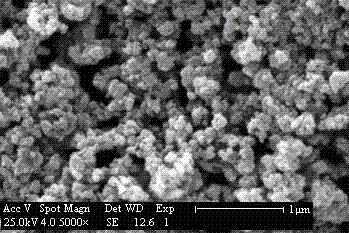

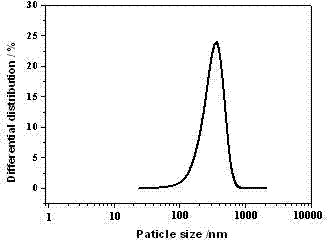

High density ultrafine composite ferric lithium phosphate anode material and preparation method

ActiveCN1907844AChemical composition is easy to controlEasy to dopeCell electrodesPhosphorus compoundsIron saltsOrganic compound

This invention belongs to battery field, which relates to ultra-micro compound lithium iron phosphate cathode material with high density and its fabrication method. Said cathode material is prepared by mixing iron salt, lithium salt and phosphates at a P / Li / Fe ratio of 1-1.1:1-1.1:1-1.1, adding conductive additives containing dopant element and carbon-bearing organic compound, adding organic acid as carrier, adjusting pH, controlling solution temperature in reactor to form sol, separating the sol to obtain nano-precursor and placing it into micorwave oven under protection of inert gas, and obtaining the final product. It is easy to control the chemical component, phase composition and particle size distribution. The conductive additive can be well-distributed. The method also has the advantages of short reaction time, low energy consumption during synthesis process and low cost. The obtained composite has high purity and good compatibility with electrolyte, excellent conductive property and charge and discharge property with large current, and good structure stability,thermal stability and cycle performance.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

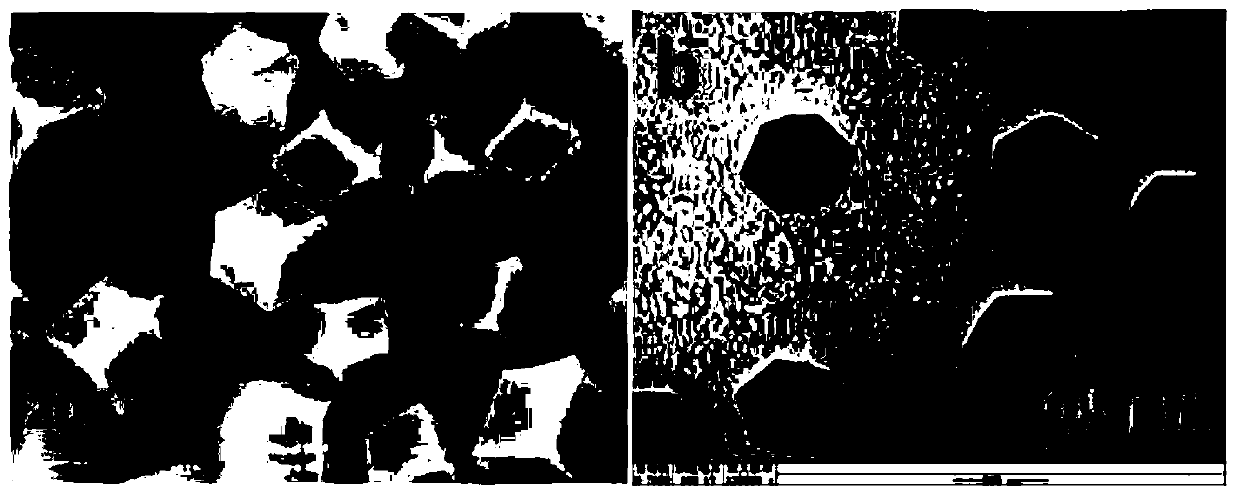

Process using date pits to prepare nitrogen-doped porous carbon material and preparation method of super-capacitor electrode

ActiveCN105645408AHigh cycle efficiency ratioImprove electrochemical performanceCarbon compoundsHybrid capacitor electrodesCapacitancePorous carbon

The invention belongs to the field of biomass carbon material preparation and particularly discloses a process using date pits to prepare nitrogen-doped porous carbon material and a preparation method of a super-capacitor electrode. The process includes the steps of firstly, preprocessing the date pits; secondly, preparing nitrogen-doped carbon material; thirdly, preparing the nitrogen-doped porous carbon material. The process is characterized in that the date pits are used as the carbon source and mixed with ammonia gas and steam in inert protecting gas, the nitrogen doping reaction is performed during the carbonization process, activated perforation is performed under the effect of activating agent, and the nitrogen-doped porous carbon material with high specific surface area and pore volume is prepared. The preparation method is simple, low in cost, high in preparation efficiency and energy saving. Experiments show that the super-capacitor electrode prepared by the nitrogen-doped porous carbon material has high specific capacitance, ideal pseudo-capacitance and high circulation stability, the performance of the super-capacitor electrode is better than the performance of commercial activated-carbon super-capacitors, and the performance of the nitrogen-doped porous carbon material is better than that of most nitrogen-doped porous carbon materials.

Owner:XIANGTAN UNIV

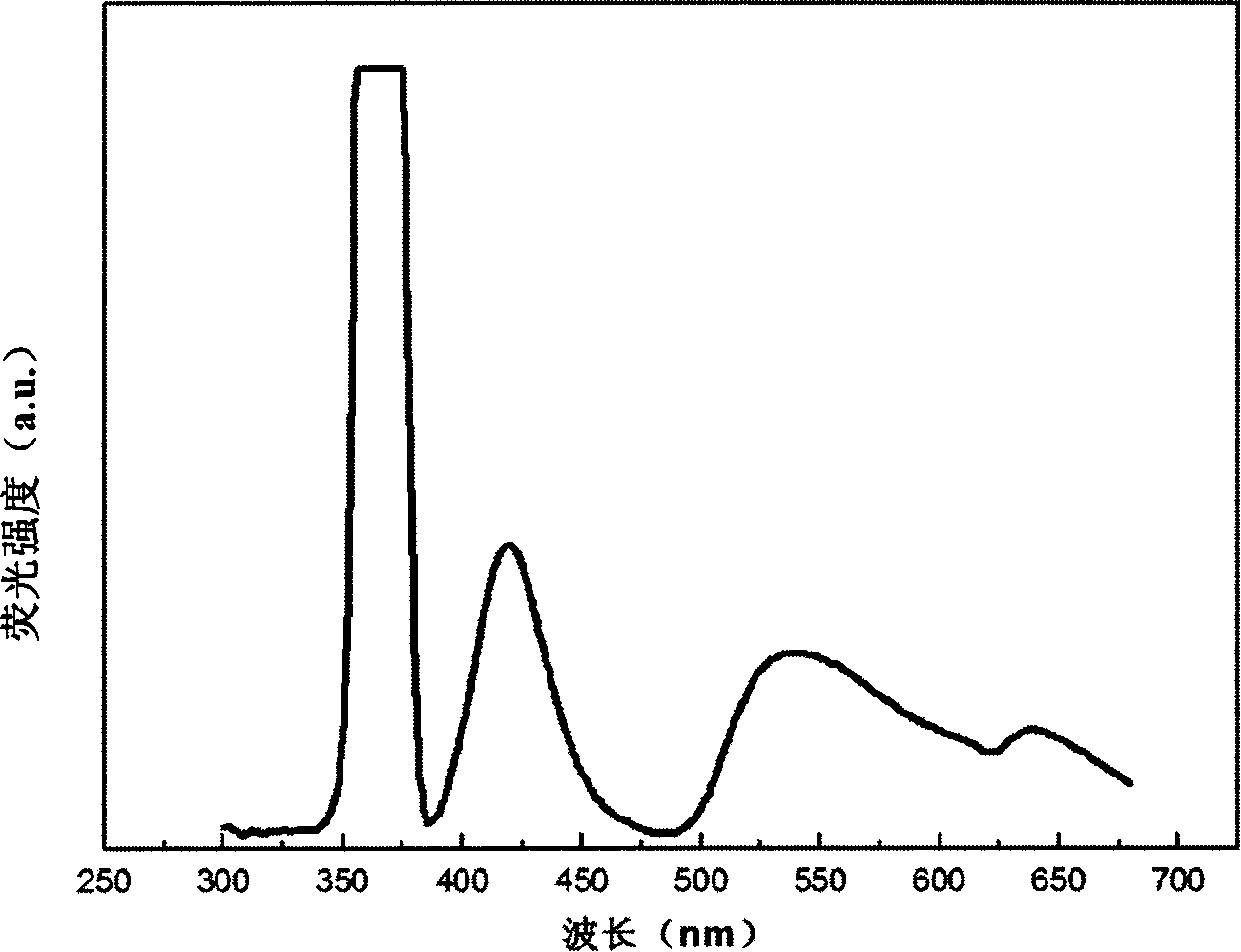

Method for increasing fluorescence yield and stability of non-lead halogen perovskite material

InactiveCN108329912AChange the degree of distortionHigh fluorescence quantum yieldLuminescent compositionsRare-earth elementHalogen

The invention discloses a method for increasing fluorescence yield and stability of a non-lead halogen perovskite material. The method is characterized by comprising steps as follows: rare earth elements RE are introduced into non-lead halogen perovskite A3B2X9, and rare earth element doped non-lead halogen perovskite is formed; B is one of Bi and Sb, and X is one of Cl, Br and I. According to themethod, by means of improvement of the addition quantity and substitution sites of the rare earth elements RE in a non-lead halogen perovskite material product, whole process design of the preparation method as well as parameters and conditions of each step, rare earth ions are utilized to regulate metal-halogen octahedron distortion degree of non-lead perovskite and change the metal ion crystalfield environment, and compared with the prior art, fluorescence yield and stability of the non-lead halogen perovskite material can be increased effectively.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of composite conductive fabric with spray polymerization

InactiveCN102312376AImprove conductivityStable conductivityVegetal fibresAnimal fibresSolventChemistry

The invention which relates to a preparation method of a composite conductive fabric with spray polymerization belongs to the technical field of textiles. An atomization mode is adopted in the invention to atomize a monomer solution into particles, and an in situ polymerization reaction is initiated on a monomer under the effect of an oxidant deposited in the fabric to prepare the composite conductive fabric. The preparation method of the invention which has the advantages of easy controlled condition, simple operation, low raw material cost, and less energy consumption is suitable for the large scale and industrial production. Compared with routine products prepared with a liquid-phase oxidation method, the adhesion between a conducting layer and a fabric matrix of the composite conductive fabric prepared in the invention is substantially improved, the conducting layer is more compacted, and protrude wear resistances and solvent resistances are possessed; the surface resistor of the preparative composite conductive fabric is 10-10<5>omega / cm<2>, the conductivity is good, the electromagnetic shielding property and the flexibility of a product (the composite conductive fabric) are good, and the surface resistor of the product in the invention is sensitive to the change of pressure, elasticity and the like, so the product can be widely applied to the sensor field, the antistaticfield, the anti-electromagnetic shielding field and the like.

Owner:WUHAN TEXTILE UNIV

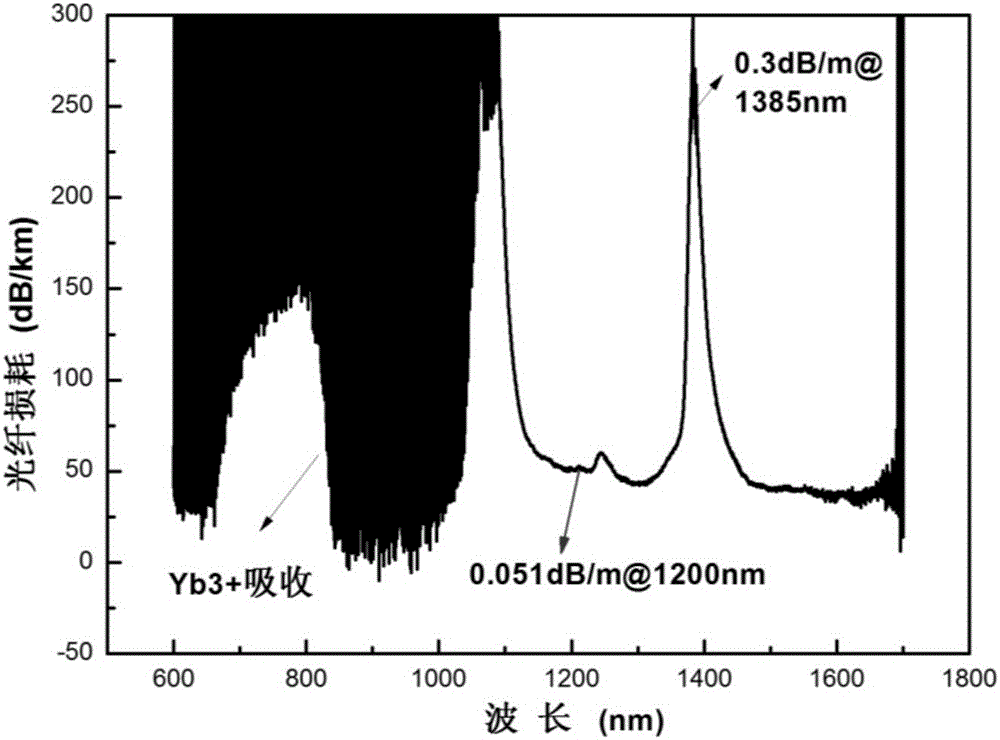

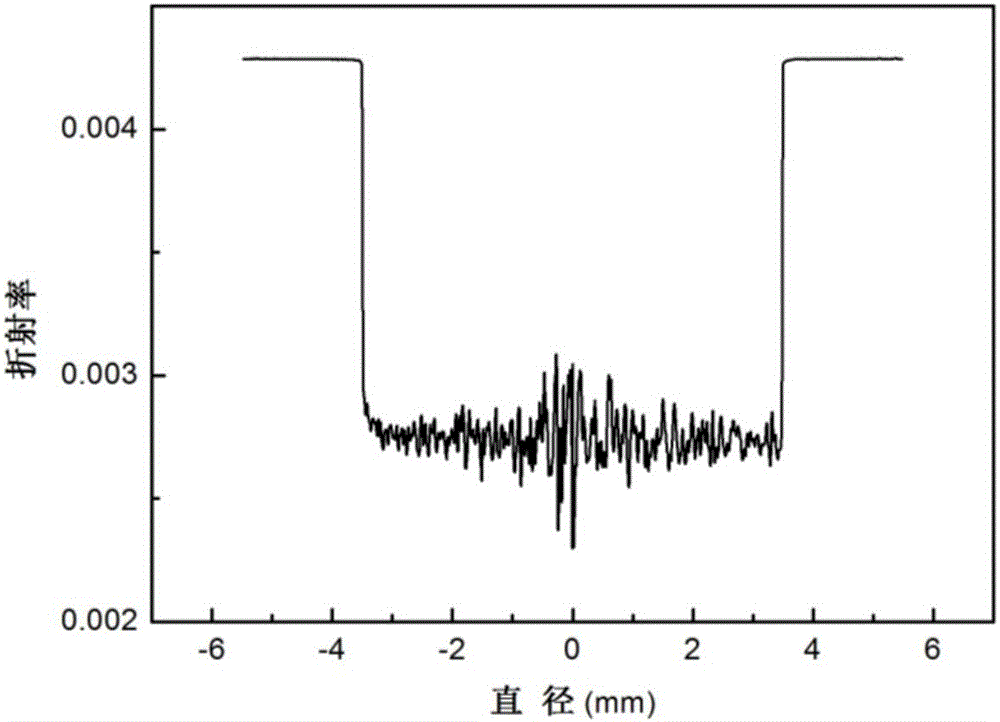

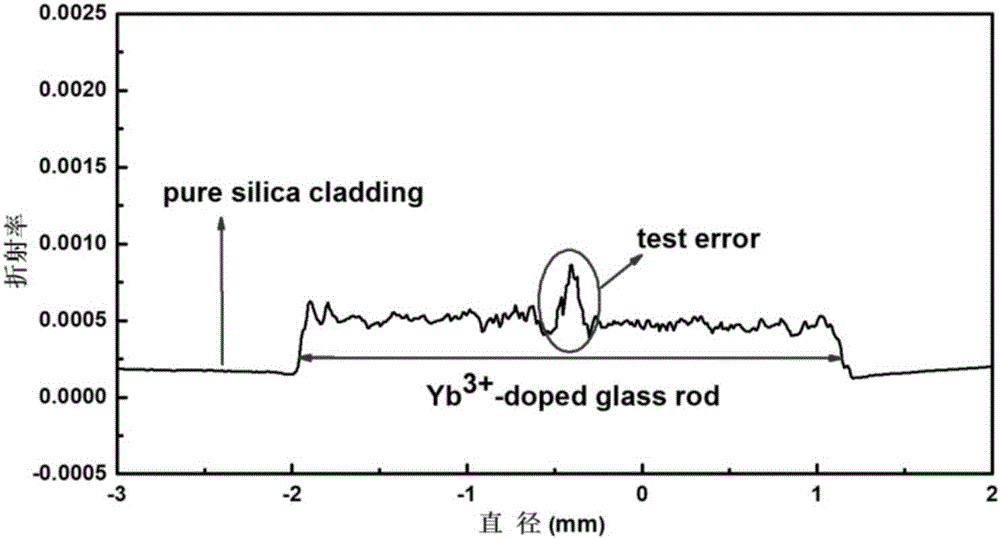

Preparation method of low-mass Yb3+ doped silica fiber preform mandrel

ActiveCN106007352AEasy to dopeLow hydroxyl contentGlass making apparatusSilica fiberRefractive index

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Preparation method of tin oxide fiber precursor and tin oxide crystal fibers

ActiveCN103556303AUniform diameterGood whitenessInorganic material artificial filamentsTin oxidesElectrospinningPhotocatalysis

The invention relates to a preparation method of a tin oxide fiber precursor and tin oxide crystal fibers. The preparation method comprises the following steps: carrying out a replacement reaction on halides of tin and potassium (sodium) acetate to synthesize the tin oxide fiber precursor which takes acetic acid as a ligand; concentrating a precursor solution to obtain a spinning solution and carrying out centrifugal silk spinning to obtain tin oxide precursor fibers; and carrying out procedures of special atmosphere pre-treatment, high-temperature heat treatment and the like on the precursor fibers to obtain the tin oxide crystal fibers. According to the preparation method, the long-diameter ratio of the tin oxide crystal fibers is greater than 1000, the tensile strength of the fibers is 0.8GPa-1.1GPa, the whiteness of the fibers is good and the color and luster of the fibers are soft. The preparation method is simple in preparation process, moderate in condition and stable in quality of fibers in batches; spinning sol does not go bad after being placed for a long time. The tin oxide crystal fibers can be applied to the fields of photocatalysis, air sensitivity, humidity sensitivity and the like. The tin oxide fiber precursor can also be used for preparing oxide thin films, nano powder and nano wires or preparing tin-containing functional materials including nano tin oxide fibers and the like by an electrostatic spinning method.

Owner:SHANDONG UNIV

Method for preparing large-size optical fiber preform

ActiveCN102757179ALow costEasy to dopeGlass making apparatusDeposition processChemical vapor deposition

The invention relates to a method for preparing a large-size optical fiber preform, comprising the following steps: a mandril is prepared by the intra-tube chemical vapor deposition method, and the mandril comprises a fiber core layer, or a fiber core layer and part of inner cladding layer; the mandril is used as a target rod, a SiO2 loose body is prepared on the target rod by the VAD (Vapor Axial Deposition) method, and an inner cladding layer or part of inner cladding layer is formed; a primary optical fiber preform with uniform structure is obtained; and the primary optical fiber preform is used as the target rod, a SiO2 outer cladding layer is deposited on the primary optical fiber preform through the OVD (Outside Vapor Deposition) method, after the deposition is finished, and the primary optical fiber preform is sintered into a transparent optical fiber preform. The method is combined with the advantages of various deposition techniques, the disadvantages of the techniques are reasonably avoided, and the unification of high deposition rate, high performance and low cost is realized. The method is not only suitable for preparing a common single-mode optical fiber with a simple section, but is also suitable for preparing special optical fibers with precise and complicated sections.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

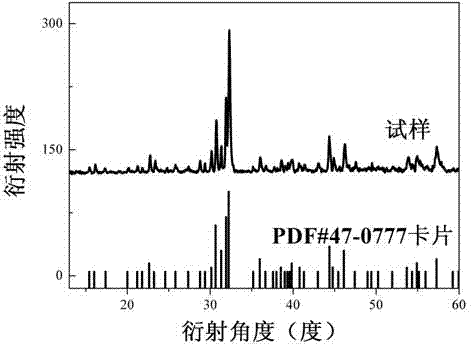

Cerium-doped nanometer barium ferrite thin film and method for making same

InactiveCN101452756AImprove absorbing performanceAdjust the magneticMagnetic layersCerium nitrateCerium nitrate hexahydrate

The invention relates to a cerium-doped nanometer barium ferrite film and a preparation method thereof. The film is characterized in that the formula comprises 1.48 to 1.60g / 100ml of glycol, 2.51 to 2.71g / 100ml of citric acid, 1.74g / 100ml of ferric nitrate, 0.125g / 100ml of barium nitrate, and 0.04 to 0.125g / 100ml of cerium nitrate. The preparation method comprises: a crystalline nanometer barium ferrite film is prepared on a quartz substrate; the cerium-doped nanometer barium ferrite film with high purity is obtained through the optimization of preparation technology; and the film can be used for preparing magnetic recording materials and wave-absorbing materials. The method has the advantages that the method has simple process flow and low cost, is convenient for preparing films on various substrates with different shapes, is easy to obtain an uniform and multi-component oxide film, is easy for quantitative doping, and can effectively control the constituents and a microscopic structure of the film.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

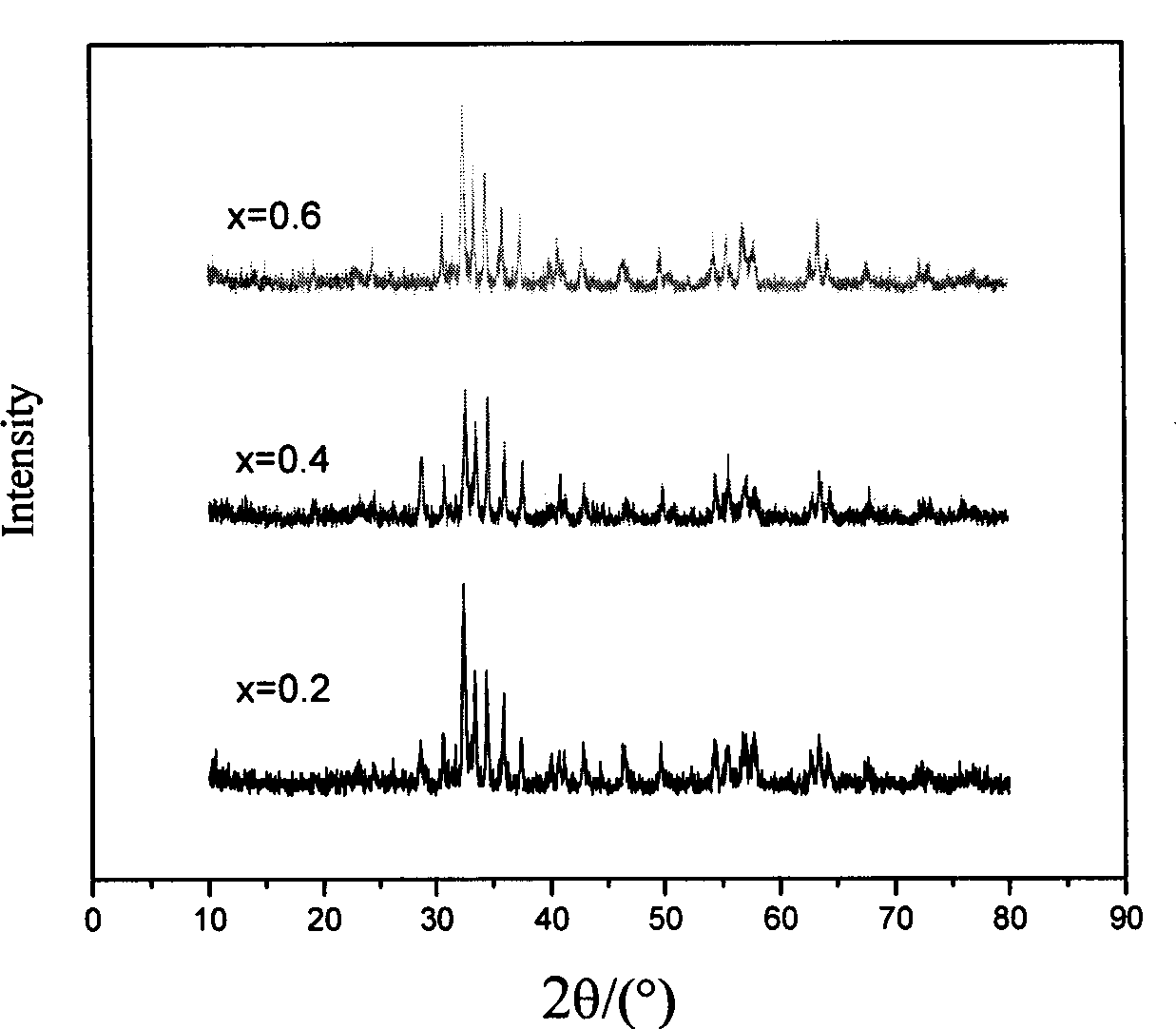

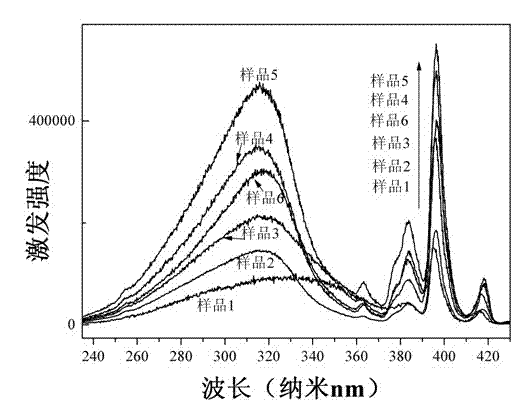

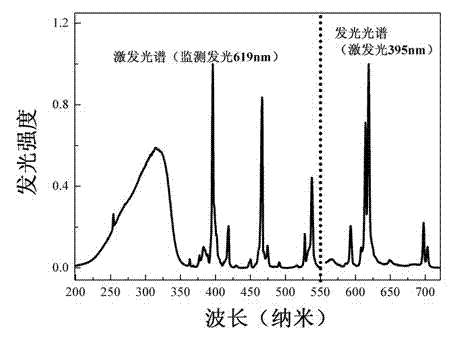

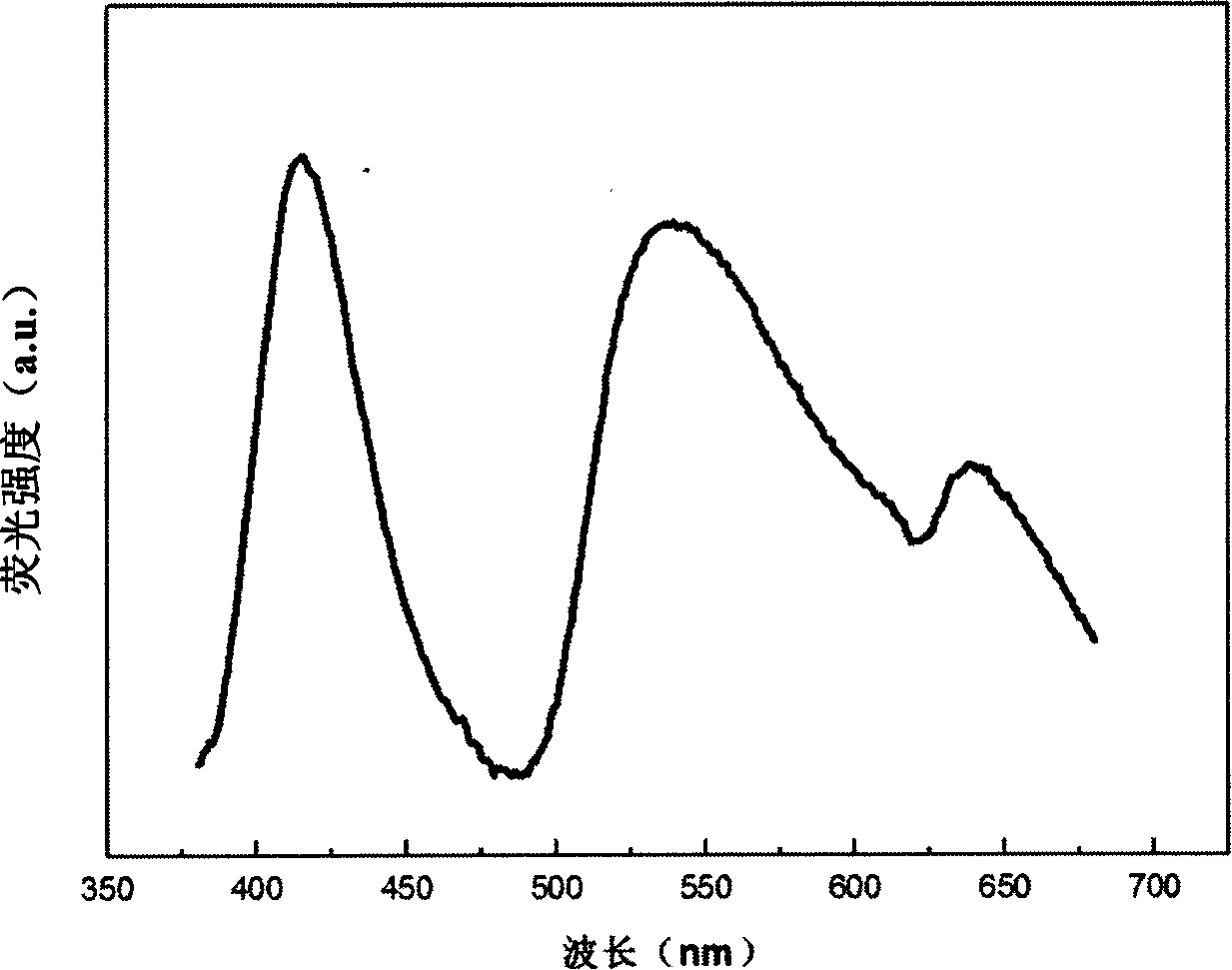

Vanadate red phosphor, preparation method and application

ActiveCN102399558AEasy to dopeNo quenching of luminescenceLuminescent compositionsSemiconductor devicesPhosphorLength wave

The invention discloses vanadate red phosphor, a preparation method and application. The molecular formula of Eu3<+>activated vanadate red phosphor is as follows: NaM<II>La1-x-y (VO4) 2: Eux, R<III>y, wherein M<II> is one or more than one of Mg<2+>, Ca<2+>, Sr<2+>, Ba<2+> and Zn<2+>, R<III> is at least one of Sm<3+>, Gd<3+>, Tb<3+>, Dy<3+>, Lu<3+> and Y<3+>, x is Eu<3+> doped mole percentage coefficient, which is greater than or equal to 0.0001 or less than and equal to 0.6, and y is R<III> replaced La<3+> mole percentage coefficient, which is greater than or equal to 0.0001 and less than or equal to 0.6. In the invention, the emission wavelength of the vanadate red phosphor is mainly 619nm, very strong excitation can be produced when the emission wavelength is about 400nm-450nm, the emission wavelength is fit with the emission wavelength of an LED (Light-emitting Diode) chip with near ultravoilet light and blue light, and the light-emitting efficiency is high. The invention has a simple manufacturing method and good repeatability. The obtained product has stable quality, and is easy for operation and industrial production.

Owner:扬州科丰高新产业投资开发集团有限公司

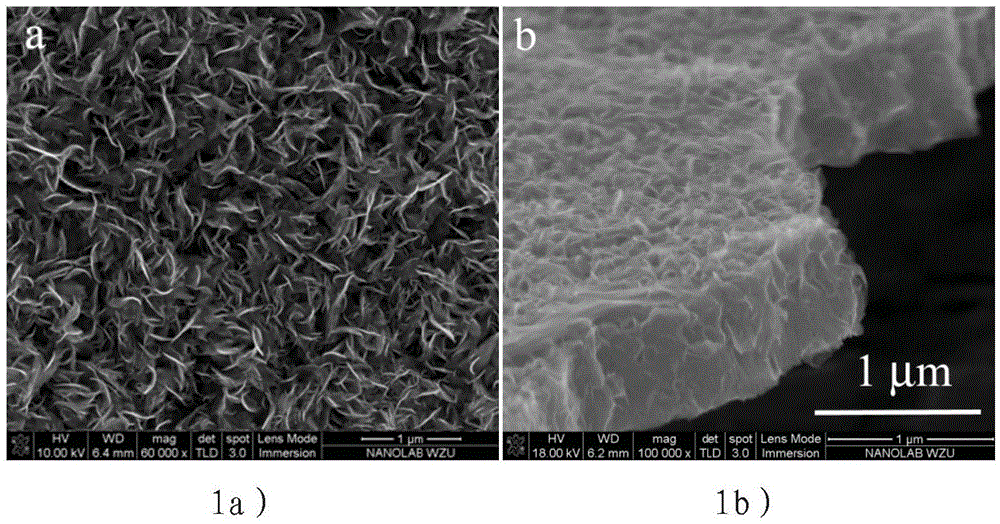

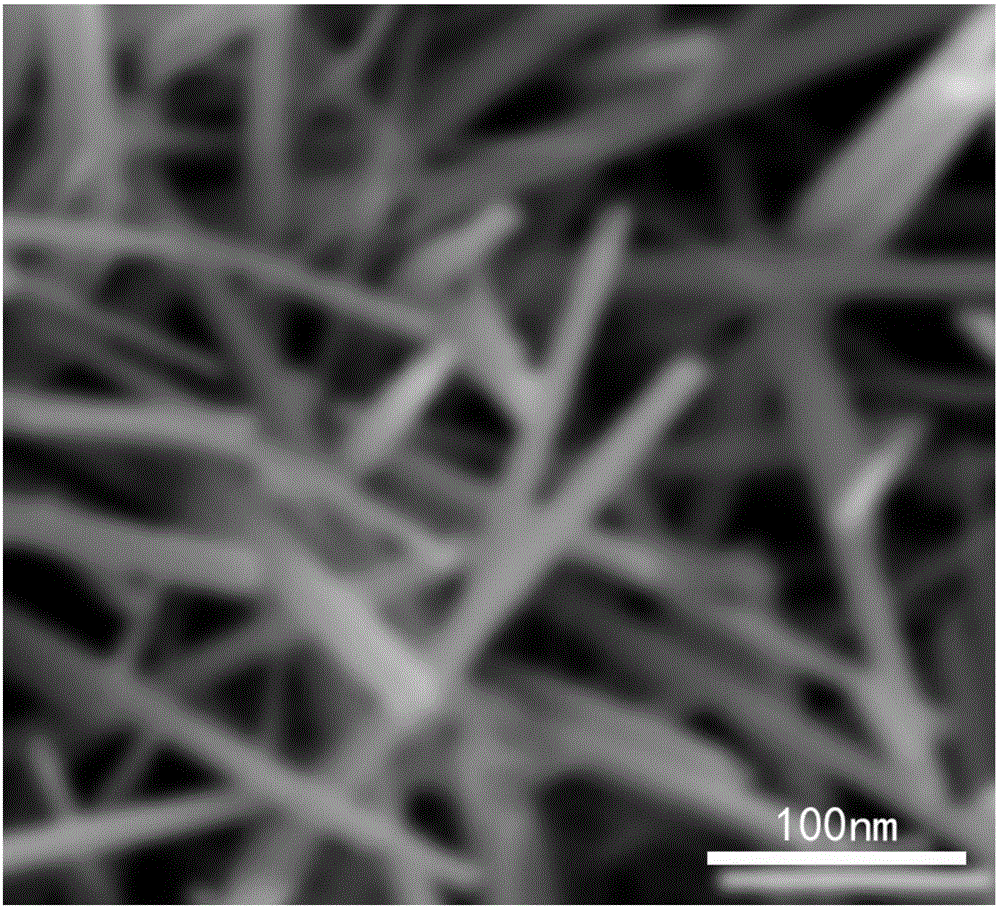

Method for preparing efficient copper-doped MoS2 nano-sheet array electrocatalyst

ActiveCN105597785AEasy to operateGood repeatabilityElectrolysis componentsPhysical/chemical process catalystsHydrogenDecomposition

The invention discloses a method for preparing an efficient copper-doped MoS2 nano-sheet array electrocatalyst. The preparing method includes the steps that a 2,300-mesh stainless wire mesh serves as a substrate material, Mo7O24.6 (NH4).4(H2O) and CH4N2S serve as raw materials, and a material is synthesized at the certain synthesis temperature and the certain synthesis time in a water phase system; the efficient electrocatalytic activity of the obtained MoS2 nano-sheet array material is further obtained by doping copper. By means of the method, the product is environmentally friendly, can be prepared in a large-scale mode and has the efficient water electrocatalytic decomposition hydrogen generation performance.

Owner:WENZHOU UNIVERSITY

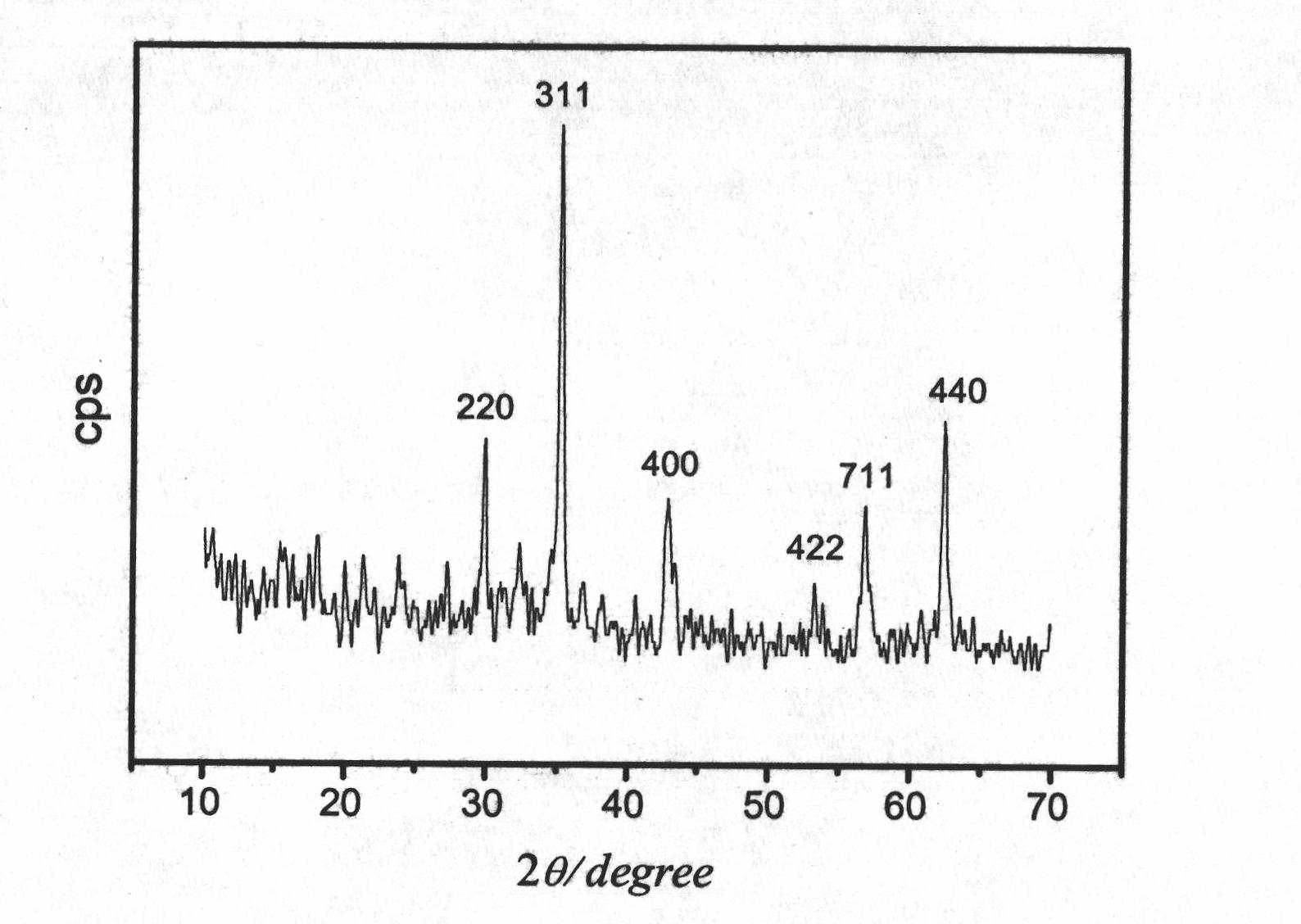

Low-temperature preparation method of Co ferrite Nano powder

The invention discloses a low-temperature preparation method of Co ferrite Nano powder. Co(CH3CO2)2.4H2O, Fe(NO3)3.9H2O and poly-hydroxyl carboxylic acid are used as raw materials, and analytically pure ethylene glycol methyl ether and water are mixed to be used as a solvent, wherein the volume ratio of the analytically pure ethylene glycol methyl ether to water is (7-9):1. The preparation method comprises the following steps of: firstly, dissolving Co(CH3CO2)2.4H2O and Fe(NO3)3.9H2O in the mixed solvent; secondly, adding poly-hydroxyl carboxylic acid to the solution, slowly dropping analytically pure ammonia water to the solution under a stirring condition, adjusting the pH value to approximate 6, and slowly evaporating the solution to form the brown sol in a water bath at 70 DEG C; thirdly, heating the sol to 130 DEG C or refluxing for 12h till the sol forms the brownish black xerogel, transferring the xerogel to an oven at 250 DEG C, wherein the xerogel can combust automatically to produce the dendritic and bulking products, and grinding the products to obtain the Co ferrite Nano powder. The low-temperature preparation method of the Co ferrite Nano powder has simple process, low cost, easily controllable chemical constituent, good repetition and easy doping; and the particle of the prepared product has good dispersibility, uniform size and good magnetic properties.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

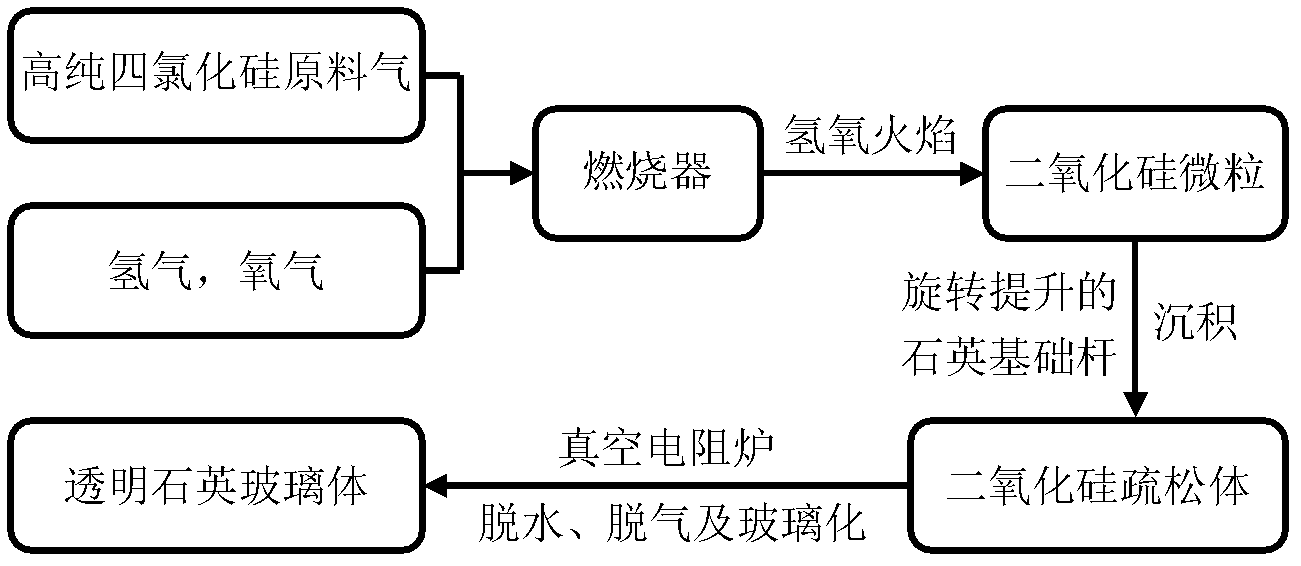

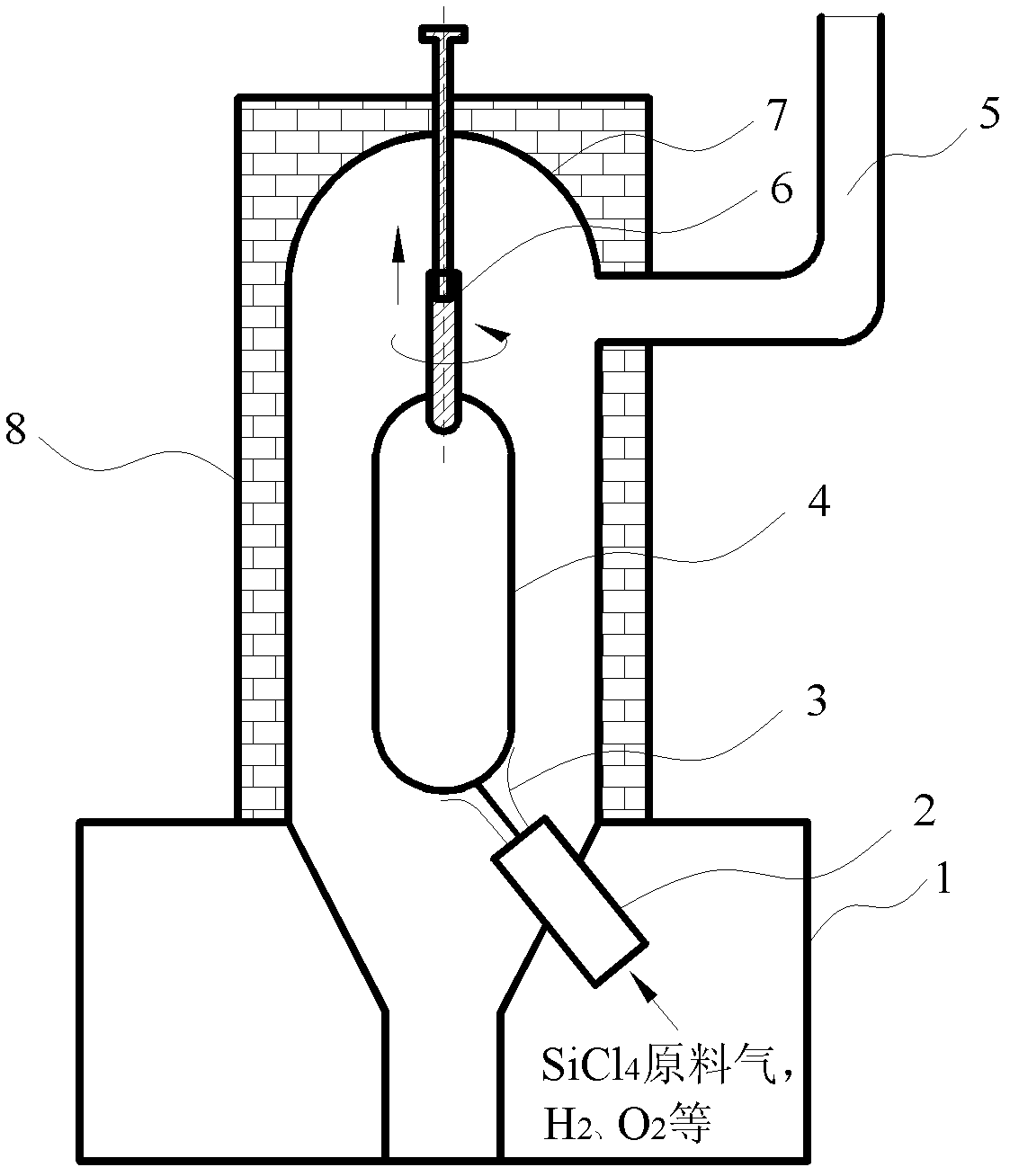

Method for indirect synthesis of quartz glass, special equipment used therein and quartz glass

ActiveCN102583977AReduce the temperatureHigh deposition efficiency and deposition rateSilicaGlass shaping apparatusPhotolithographySilicon tetrachloride

The invention provides a method for indirect synthesis of quartz glass, a special equipment used therein and a quartz glass, which belongs to the field of fabrication of glass. The method comprises the following steps: 1) allowing the feed gas of silicon tetrachloride to react in oxyhydrogen flame with a temperature of 600 to 1200 DEG C, enabling silicon tetrachloride to undergo hydrolysis or oxidation so as to produce nanometer silica particles and depositing the nanometer silica particles so as to obtain a silica loose body; and 2) carrying out dehydration, degassing and vitrification on the silica loose body at a temperature of 100 to 1600 DEG C under a vacuum degree of 0.01 to 500 Pa so as to obtain the quartz glass. According to the invention, a deposition rate in the method can reach 500 to 2000 g / h, and the obtained quartz glass has the following excellent characteristics: high transmittance is obtained at 200 to 3200 nm full spectrum (ultraviolet-visible-infrared bands), the content of metal impurities is less than 5 ppm, the content of hydroxyl groups is controlled to be within 20 ppm, a diameter is up to 50 to 200 mm, and the quartz glass can be used in the field of high and new technologies like precision optics, semiconductor photolithography and laser technology and has a wide application prospect.

Owner:CHINA BUILDING MATERIALS ACAD

Preparation method of cuprous sulfide powder, and cuprous sulfide powder

The invention discloses a preparation method of cuprous sulfide powder and the cuprous sulfide powder. The preparation method of the cuprous sulfide powder comprises the following steps: allowing cuprous oxide and a sulfurizing agent solution to react and filtering to obtain a cuprous sulfide precursor; calcining the cuprous sulfide precursor in vacuum to obtain the cuprous sulfide powder. According to the preparation method of the cuprous sulfide powder, the cuprous oxide and the sulfuring agent react, the cuprous sulfide precursor is prepared by adopting a precipitate transformation method and is calcined in vacuum to prepare the cuprous sulfide powder. The method is rich in cheap raw materials, low in cost, simple in preparation process, mild in condition, good in controllability, high in production efficiency, easy to realize industrialization, free of pollution and wide in development prospect in the field of preparation of superfine powder; the prepared cuprous sulfide powder is high in purity, good in crystal form, good in dispersity, stable in structure, easy to coat, dope, sinter and the like, and applicable to the fields of solar batteries, seawater batteries, sensors, catalysts and the like.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

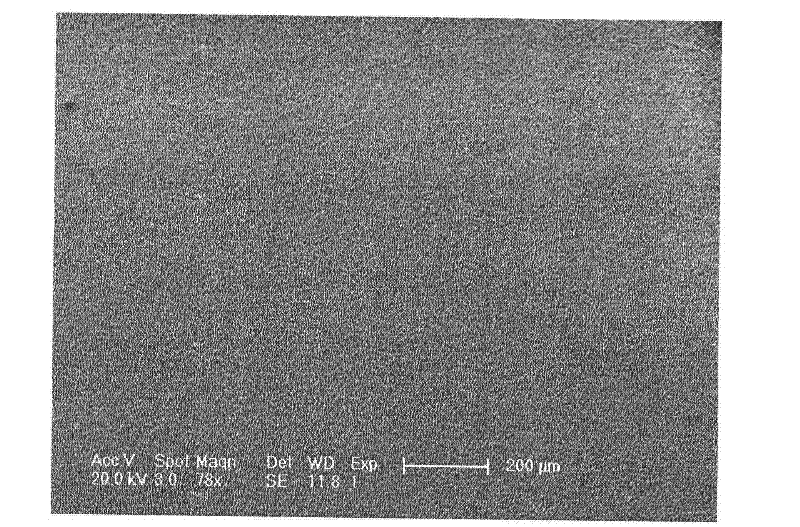

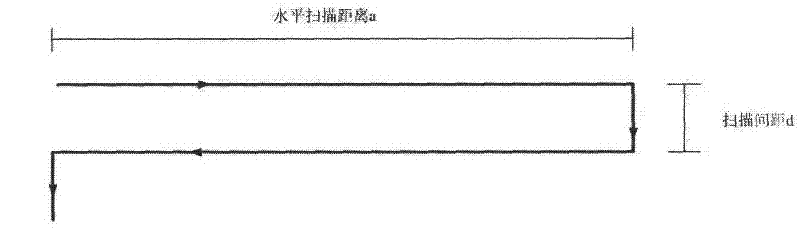

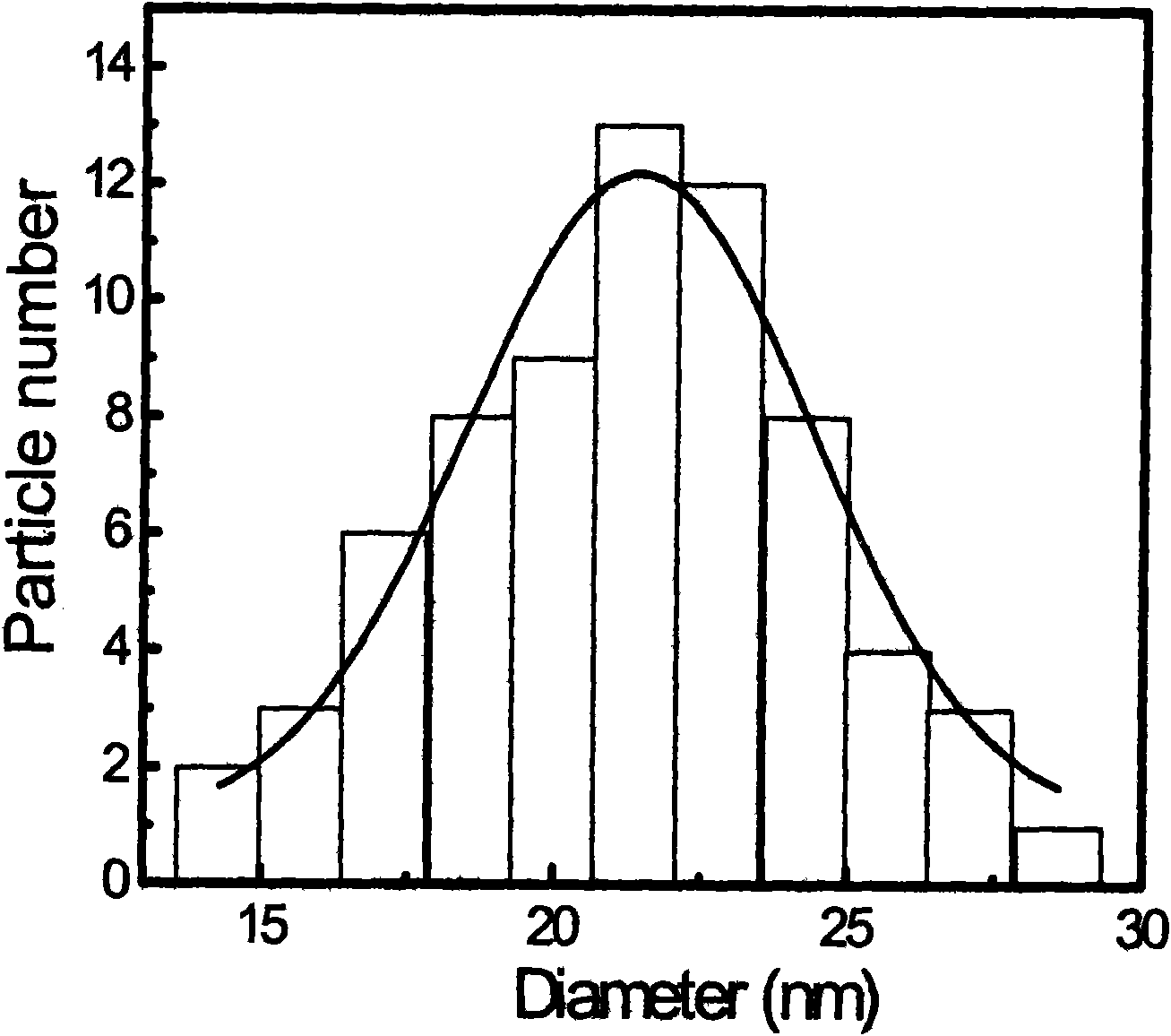

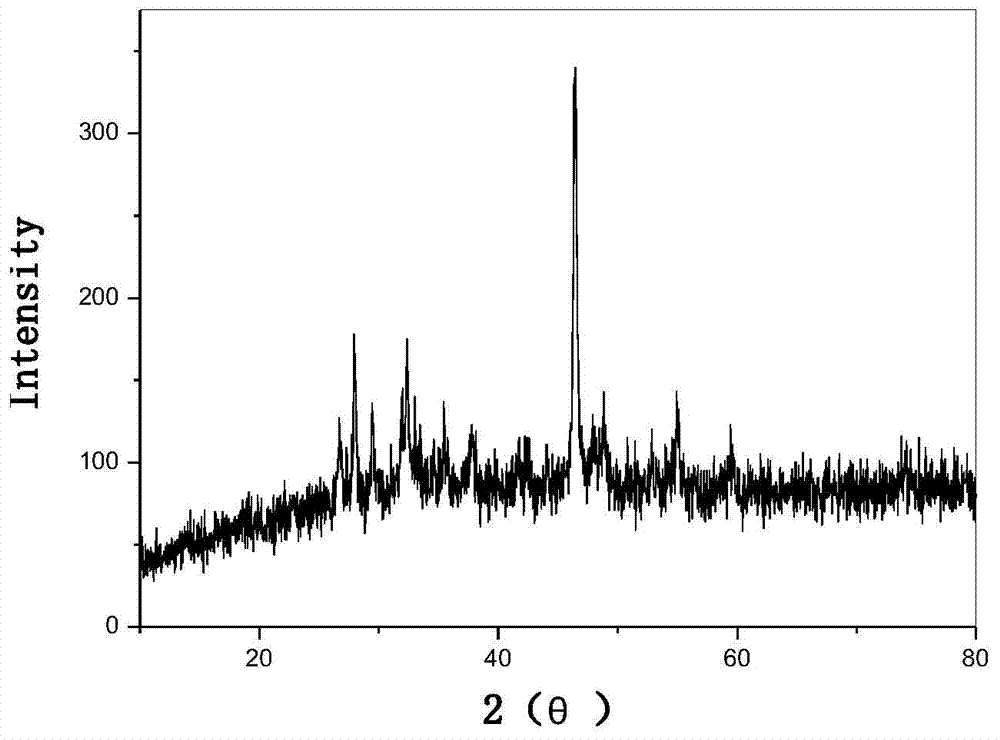

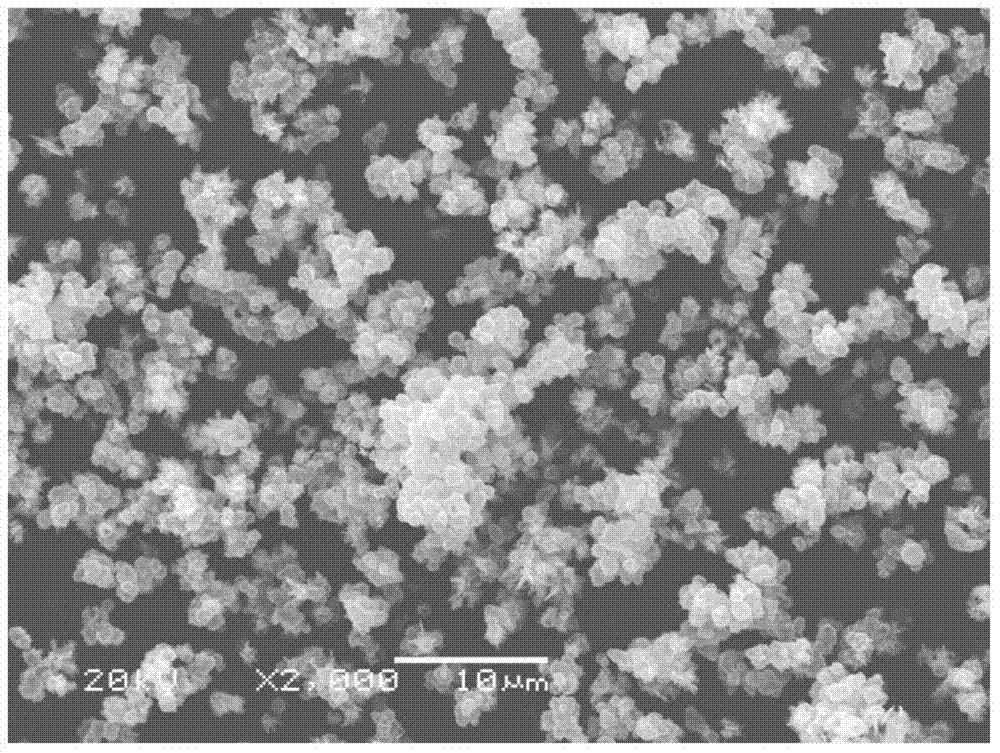

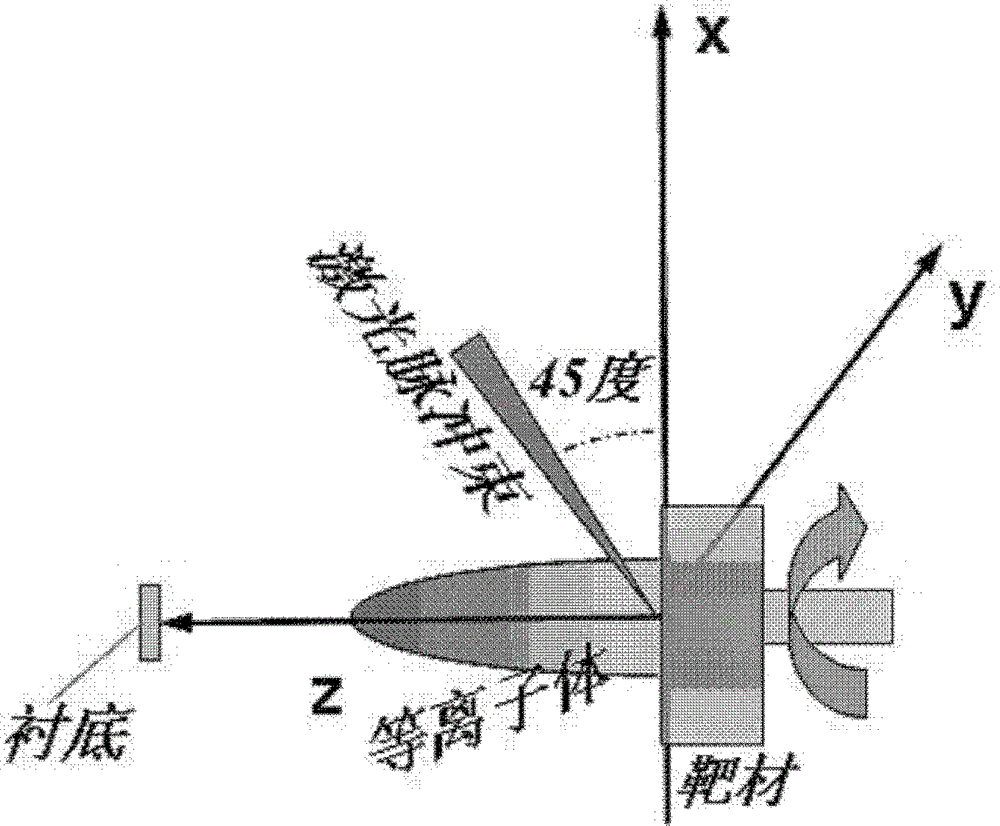

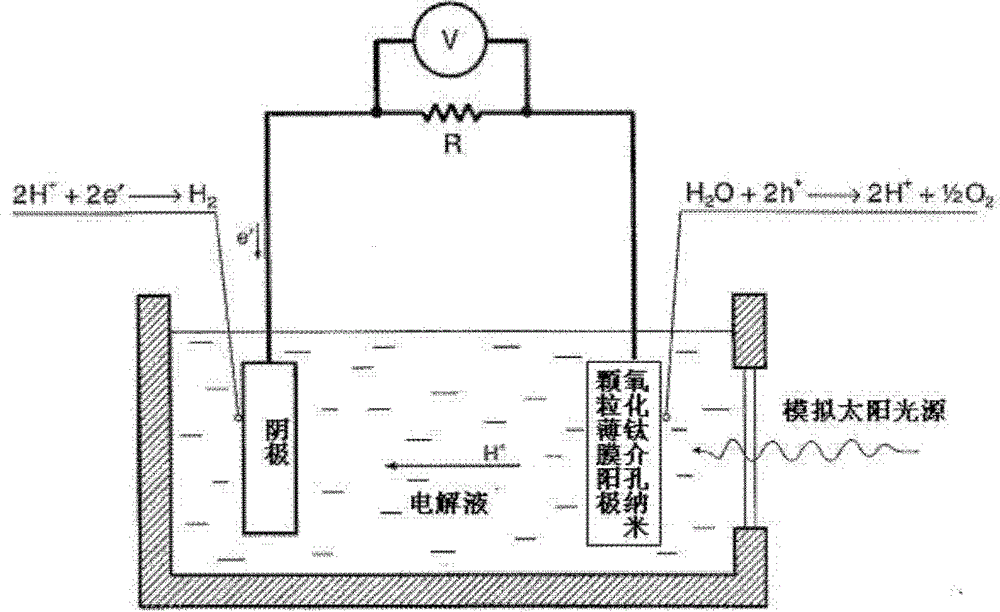

Femtosecond laser preparation method for uniform and thick mesoporous titanium oxide nanometer particle film

InactiveCN106148902AIncrease powerRandom sputteringVacuum evaporation coatingSputtering coatingHertzTitanium oxide

The invention discloses a preparation method of a mesoporous nanometer particle film and belongs to a technology for preparing films with special properties through femtosecond laser deposition. According to the preparation method, high-purity titanium oxide serves as a target, a laser vacuum deposition device characterized in that the pulse width is 300 femtoseconds, the center wavelength is 537 nanometers, the frequency is 33 hertz, and the maximum single pulse energy is 0.9 millijoules is adopted, and preparation of the uniform and thick mesoporous titanium oxide nanometer particle film is achieved. The preparation method is characterized in that when the deposition time is short, the average dimension of nanometer particles is about 20 nanometers; and after deposition is conducted for a long time, the cluster phenomenon is generated in particles, the film is thick, and the mesoporous clearance is obvious. The preparation method has the beneficial effects that the film parameters can be changed by controlling the pulse energy and the deposition time; the difference change of the film crystallization morphology can be achieved by controlling the target chamber air pressure and the air inflation type; doping or compounding of other materials is facilitated; the high solar conversion efficiency per unit thickness is high; and research on application of the different types of films which have the special properties and are prepared through femtosecond laser deposition to hydrogen production is facilitated.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Preparation method of NCM ternary cathode material doped with Al<3+> on surface

InactiveCN108123128AInhibition transitionEasy to dopeCell electrodesSecondary cellsHigh rateLithium hydroxide

The invention relates to a preparation method of an NCM ternary cathode material doped with Al<3+> on the surface and belongs to the field of chemical energy storage batteries. The preparation methodprovided by the invention has the benefits that aluminum nitrate is added in the mixing process of a nickel-cobalt-manganese hydroxide precursor and lithium hydroxide to realize the doping of the Al<3+> on a lithium layer on the surface; compared with the situation that the Al<3+> is doped on a transition metal layer in the preparation process of the nickel-cobalt-manganese hydroxide precursor, the Al<3+> exists on the lithium layer and can better play a supporting role, less Al<3+> can be used to achieve a structure stabilizing effect, and particularly, and the improvement effect on electrochemical performance at high voltage and high rate is significant. The preparation method provided by the invention is simple to operate, a process and a technology are easy to realize, the large-scalecommercial application can be realized, and the method can be used for Al<3+> doping on the surface of other ternary cathode materials or a lithium-rich cathode material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

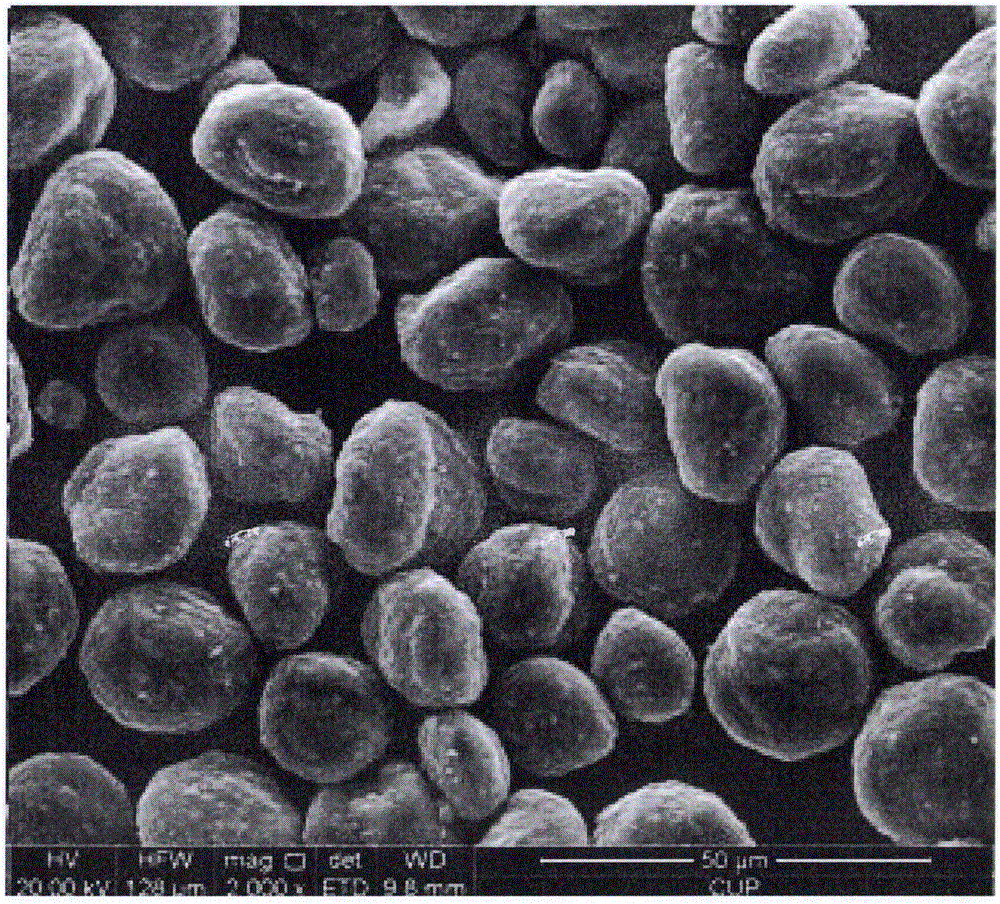

Composite catalyst for catalyzing formaldehyde decomposition and preparation method thereof

ActiveCN106238065AEasy to makeLow costHeterogenous catalyst chemical elementsDispersed particle separationRoom temperatureCatalytic decomposition

A composite catalyst for catalyzing formaldehyde decomposition and a preparation method thereof are disclosed. The preparation method comprises the following steps: successively dissolving permanganate, MnII salt, CuII salt, FeIII salt and CeIII salt in a solvent to obtain a primary mixed liquor, adding a proper amount of an auxiliary agent to obtain a secondary mixed liquor, letting the secondary mixed liquor react at high temperature and at high pressure, cleaning, filtering, and drying. The composite catalyst for catalyzing formaldehyde decomposition is nano-scale rodlike, and diameter is 10 nm. The preparation process of the composite catalyst is simple; and cost is low. The prepared composite catalyst has advantages of full doping of materials and high catalytic decomposition efficacy, and can spontaneously catalyze formaldehyde decomposition under the condition of room temperature.

Owner:NINGBO TAIAN NEW MATERIAL TECH CO LTD

Lithium ion battery positive electrode material additive, positive electrode material, positive electrode and battery

InactiveCN106654184AImprove performanceConducive to process applicationCell electrodesSecondary cellsEngineeringLithium-ion battery

The invention provides a lithium ion battery positive electrode material additive, a lithium ion battery positive electrode material prepared by the positive electrode material additive, a positive electrode and a battery. The additive includes a lithium-containing additive, the lithium-containing additive is Li2Mo1-0.75xBxO3, wherein 0.04<=x<=0.3, the problem of irreversible capacities of the lithium ion battery can be effectively solved, the additive is simple and convenient in process, lower in cost and higher in safety, and the energy density of the battery can be remarkably improved.

Owner:SHANGHAI BYD

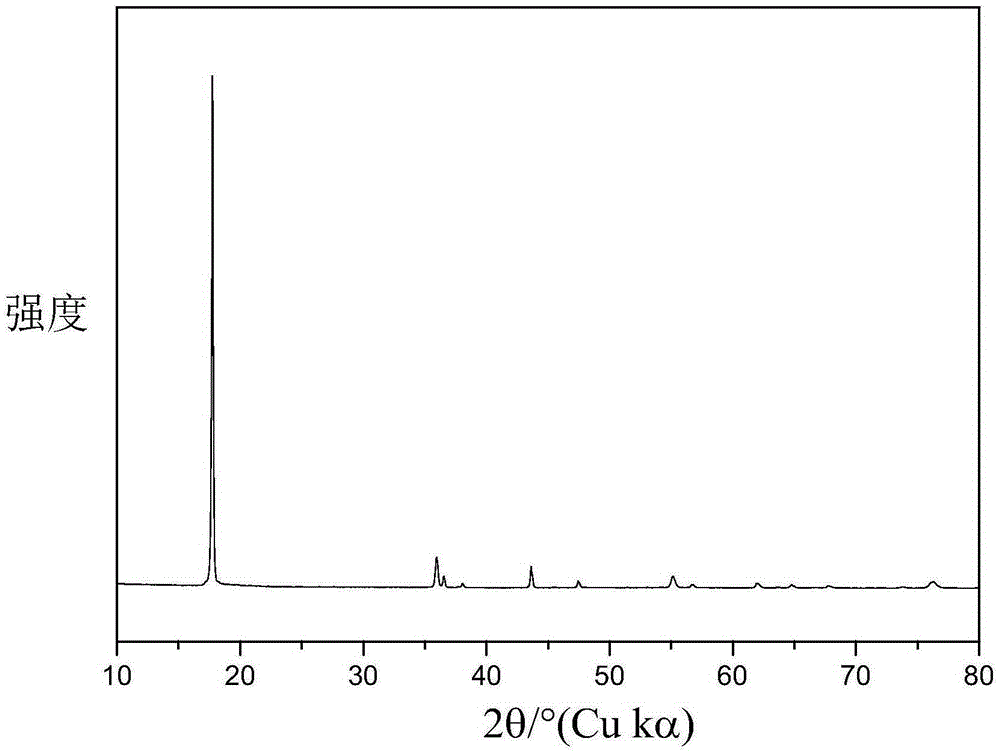

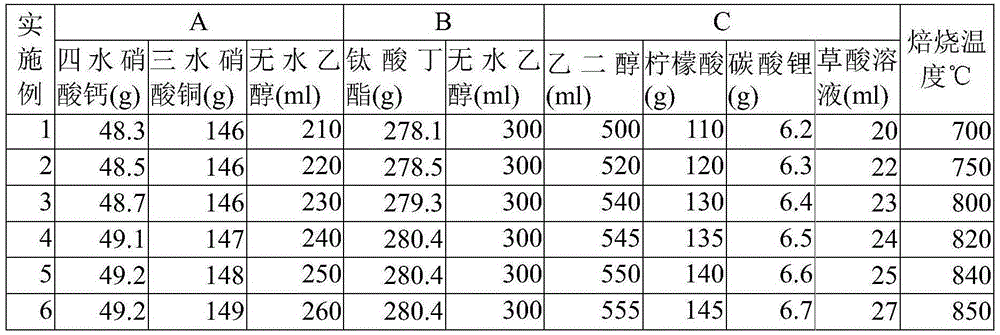

Method for preparing nano CaCu3Ti4O12 ceramic material with giant dielectric constant

InactiveCN105330286AShorten the timeShort reaction cycleMaterial nanotechnologyReaction temperatureCalcination

The invention relates to a method for preparing a nano CaCu3Ti4O12 ceramic material with a giant dielectric constant. The method comprises the steps of dissolving Cu(NO3)2.3H2O and Ca(NO3)2.4H2O in absolute ethyl alcohol to prepare a solution A; dissolving butyl titanate into absolute ethyl alcohol to prepare a solution B; mixing glycol, citric acid, lithium carbonate and an oxalic acid aqueous solution to prepare a solution C; dripping the solution B in the solution A and stirring, and controlling the reaction temperature to be 80 to 95 DEG C and the pH (Potential Of Hydrogen) value to be 5.0 to 6.0; then dripping the solution C into the obtained mixed solution of the solution A and the solution B, and controlling the pH value to be 3.0 to 4.0 and the temperature to be 75 to 85 DEG C; obtaining nano CaCu3Ti4O12 by carrying out aftertreatment and calcination on an obtained product, wherein the calcination temperature is 700 to 850 DEG C. According to the method for preparing the nano CaCu3Ti4O12 ceramic material, disclosed by the invention, the nano CaCu3Ti4O12 which is uniform in particle size distribution, high in chemical activity and easy to modify and dope and has a very high dielectric constant and very low dielectric loss is prepared, the reaction period is greatly shortened, the firing temperature is low, and the energy consumption is low.

Owner:胡晓鸿

Method for preparing composite cathode material by modification of graphite

InactiveCN105932320AImprove conductivityLarge specific surface areaCell electrodesSecondary cellsComposite cathodeOrganic solvent

The invention discloses a method for preparing a composite cathode material by the modification of graphite. The method comprises four processes of preparation of a solution A, preparation of a solution B, preparation of a solution C and preparation of the composite cathode material, wherein during the preparation process of the solution A, a polymer matrix, a pore forming agent, a conductive agent, an inorganic additive and an organic solvent are used; during the preparation process of the solution B, pitch and an organic solvent are used; during the preparation process of the solution C, the solution A and the solution B are used; and during the preparation process of the composite cathode material, the graphite, the solution C and a three-dimensional mixer are used. According to the method, the graphite is modified by the pore-forming technology and doping modification technology, the composite cathode material with high capacity, high specific surface area and good conductivity can be prepared, and liquid protection capabilities, rate performance and cycle performance of the composite cathode material in the lithium ion battery are improved, and the requirement of high-energy-density lithium ion battery on the cathode material is met.

Owner:赵晓锋

Low-temperature type lithium iron phosphate anode material and preparation method thereof

The invention provides a low-temperature type lithium iron phosphate anode material and a preparation method of the low-temperature type lithium iron phosphate anode material. The method comprises the following steps of: proportioning lithium carbonate, metallic oxide, iron phosphate and glucose according to the molar ratio as follows: Li: R: Fe: P: C= (1.1-x): x: 1: 1: 0.8, wherein x=0.01-0.03, C is C in the glucose, and R is a doped metal ion; directly mixing, adding absolute ethyl alcohol of which the gross weight is 2-3 times as heavy as the gross weight of the mixture; ball-milling by means of wetting phase, and evenly mixing; drying, smashing and pelleting the ball-milled sizing agent; calcinating for 2-5h under the temperature of 300-500 DEG C in an inert atmosphere furnace under the status of open setting; cooling to be room temperature; calcinating the power for 8-12h under the temperature of 500-800 DEG C in the inert atmosphere furnace under the compacting status that the surface pressure is 10kg / cm<3>; and secondarily sintering and synthesizing so as to obtain the lithium iron phosphate anode material. The synthesized material is classified and screened by means of fluid energy milling to obtain the nanometer-level lithium iron phosphate anode material, wherein the material is good in electrical conductivity, and the low-temperature performance of a manufactured battery can be effectively improved.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

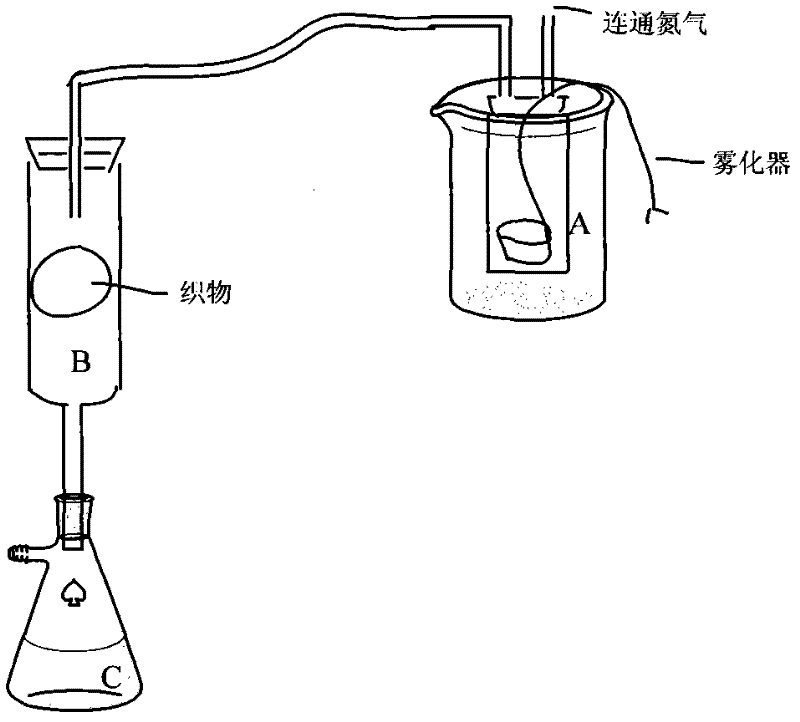

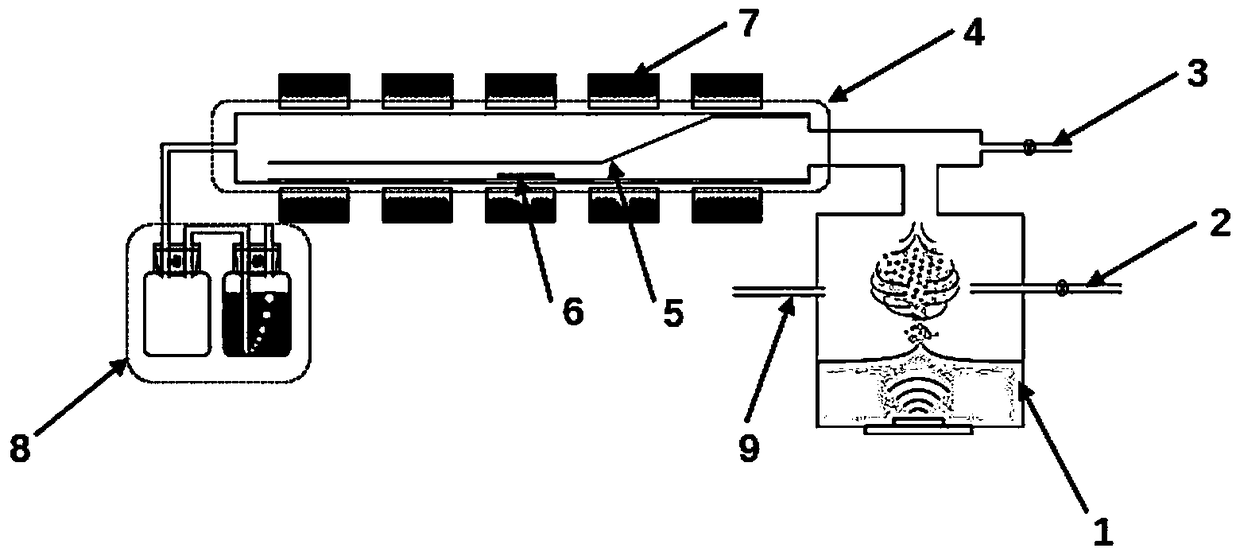

System for growth of gallium oxide by means of ultrasound-assisted fog-phase transport chemical vapor deposition

PendingCN109056066AEasy to dopeControl growth ratePolycrystalline material growthFrom chemically reactive gasesGas phaseNitrogen gas

The invention relates to a system for growth of gallium oxide by means of ultrasound-assisted fog-phase transport chemical vapor deposition. An ultrasound-assisted fog-phase transport chemical vapor deposition method adopts a water-soluble gallium salt ultrasonic atomization source as a raw material and is performed in a reaction chamber; the part, having gas flow, of a confinement device portionin the reaction chamber is used as a growth region, and the whole reaction chamber is used as a horizontal structure; after being atomized by using an ultrasonic atomizer, an aqueous solution of a gallium source is transported by using inert gas (nitrogen gas) as carrier gas, is mixed with dilution gas and then enters the reaction chamber; the reaction chamber is internally provided with a gas flow confinement structure; reaction products and unreacted raw materials are absorbed with water at an output position of the rear end of the reaction chamber, and an anti-inverse-suction structure is arranged at the output position; after a reaction is finished, the exhaust gas is treated by means of an exhaust gas treatment device.

Owner:NANJING UNIV

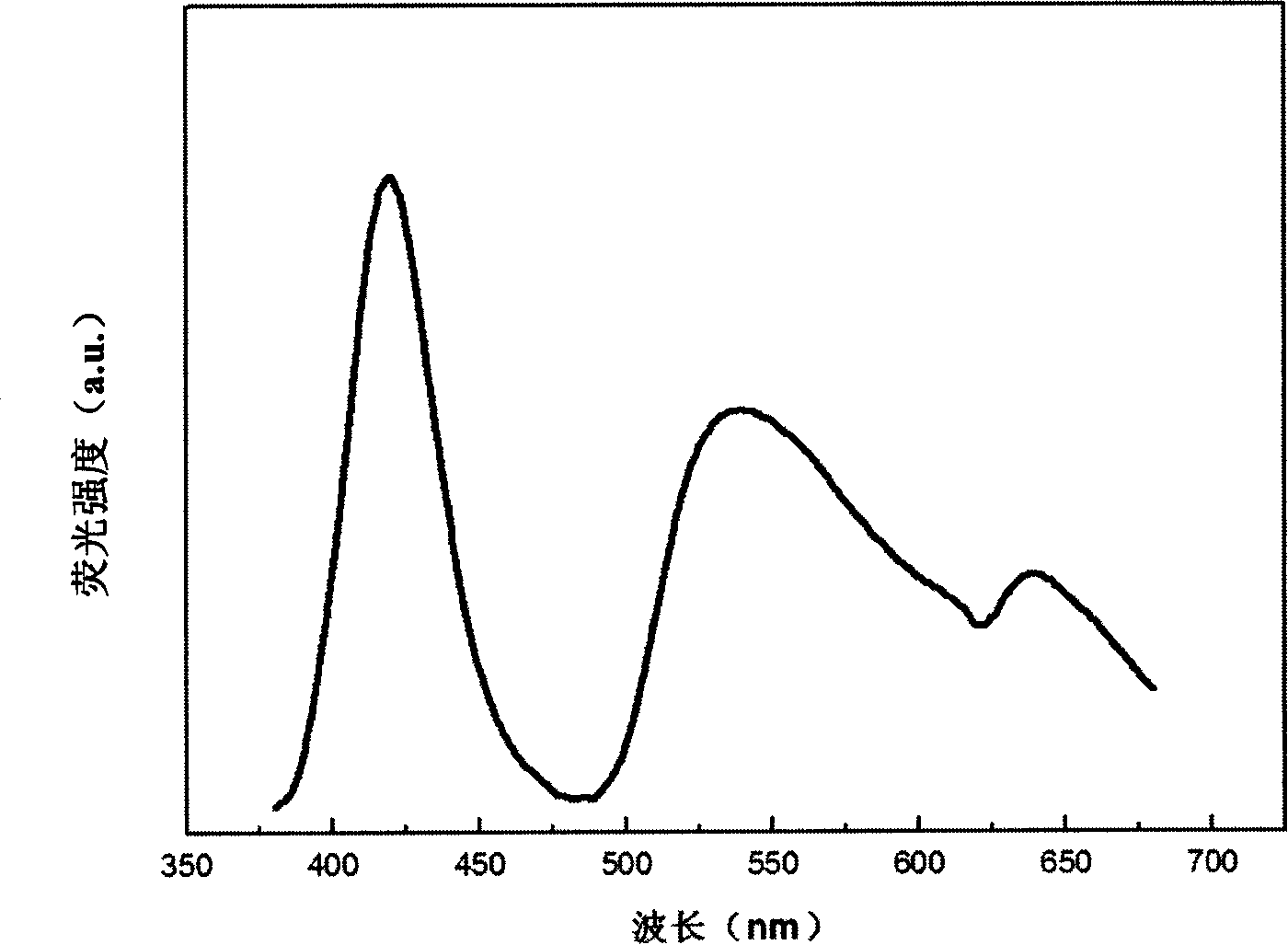

Aluminate red phosphor, preparation method and application

InactiveCN102492425AEasy to dopeQuenching does not occurLuminescent compositionsSemiconductor devicesAluminatePhosphor

The invention discloses an aluminate red phosphor, a preparation method and application. Activation ions of the aluminate red phosphor are trivalent europium ions Eu<3+>; the chemical formula of the aluminate red phosphor is M<II>3RE<III>1-xEuxAl2O7.5, wherein, M<II> is one or more selected from the group consisting of Mg<2+>, Ca<2+>, Sr<2+> and Ba<2+>, RE<III> is at least one selected from the group consisting of La<3+>, Ce<3+>, Pr<3+>, Nd<3+>, Sm<3+>, Gd<3+>, Tb<3+>, Dy<3+>, Ho<3+>, Er<3+>, Tm<3+>, Yb<3+>, Lu<3+>, Sc<3+> and Y<3+>, and x is mole percentage of doped Eu<3+> and is no less than 0.0001 and no more than 1.0. The aluminate red phosphor has strong excitation at a wavelength of about 400 nm, high luminous efficiency and good thermal stability and emits red fluorescence which mainly has a wavelength of 613 nm under the excitation of near ultraviolet light. The preparation method provided in the invention is simple, has good reproducibility, enables a product to have stable quality and is easy to operate and easily applicable in industrial production.

Owner:SUZHOU UNIV

Method for producing ultraviolet light excitated single phase white radiation fluorescent powder

InactiveCN101173171ARaw materials are easy to getOperational securityLuminescent compositionsSal ammoniacChemistry

The invention discloses a preparation method of ultraviolet excitation single white phosphor, belonging to the technical field of luminescent materials. The structural formula of the phosphor is Sr1-XEuXZn2-YMnY(PO4)2, 0.005 is less than or equal to x is less than or equal to 0.1, 0.005 is less than or equal to y is less than or equal to 0.1. According to the molar ratio of Sr, Eu, Zn, and Mn in the structural formula Sr1-XEuXZn2-YMnY(PO4)2, the materials of SrCO3, ZnO, MnCO3, and Eu2O3 are weighted and dissolved in excess concentrated nitric acid. The solution is well mixed, and salicylic acid complexing agent is added in; after even stirring, urea, PEG and NH4H2PO4 are added to the solution, which is then stirred evenly. The solution is heated until all the water in the solution is evaporated to dryness, and then a gel is formed. Ammonia is added to the solution during the heating process of the solution. The acquired gel is combusted, and precursor powder is obtained. The obtained precursor powder is sintered, and the needed phosphor is produced. The invention has the advantages of easy access to the materials needed by the preparation, safe operation, and low energy consumption.

Owner:SHANGHAI JIAO TONG UNIV

Lithium cobalt oxide positive electrode material of lithium ion battery with voltage of 4.45 V or above and preparation method of lithium cobalt oxide positive electrode material

ActiveCN111081987AStoichiometric balancePerformanceCell electrodesSecondary cellsElectrical batteryPhysical chemistry

The invention discloses a lithium cobalt oxide positive electrode material of a lithium ion battery with the voltage of 4.45 V or above. The lithium cobalt oxide positive electrode material comprisesa lithium cobalt oxide matrix (Mg, Ti and Al doped lithium cobalt oxide) and a coating layer (M and N doped lithium cobalt oxide) coating the surface of the matrix. The preparation method comprises the following steps that: (1) a Li source, a Co source, MgO, TiO2 and Al2O3 are uniformly mixed, an obtained mixture is sintered, jet milling is performed on a sintered product, so that a matrix lithiumcobalt oxide can be obtained; and (2) the matrix lithium cobalt oxide, CoCO3 containing doped metal elements M and N, and a Li source are uniformly mixed, secondary constant-temperature sintering isperformed, and sieving is performed, and the lithium cobalt oxide positive electrode material is obtained. The lithium cobalt oxide positive electrode material disclosed by the invention is assembledinto a whole battery; a test under the condition of 25 DEG C shows that the first discharge capacity of the battery of 4.5 V is not lower than 191mAh / g and the efficiency of the battery is not lower than 92.0%; and a test under the condition of 45 DEG C shows that the capacity retention ratio of the battery after 500 cycles under 4.48 V is not lower than 80.0%, and the capacity retention ratio ofthe battery after 350 cycles under 4.5 V is not lower than 80.0%.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com