Process using date pits to prepare nitrogen-doped porous carbon material and preparation method of super-capacitor electrode

A nitrogen-doped porous carbon and nitrogen-doped carbon technology is applied in hybrid capacitor electrodes, chemical instruments and methods, carbon compounds, etc., and can solve problems such as increased experimental difficulty, high cost, and material performance has not been greatly improved. , to achieve the effect of being beneficial to industrialization, low cost, improving adsorption performance and capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Wash and dry the jujube stones, weigh 10 g of crushed jujube stones, put them into a porcelain crucible, and carbonize them at 600°C for 2 hours in a mixed gas of nitrogen, ammonia and water vapor to obtain nitrogen-doped carbon materials.

[0049] The mixed gas is made of nitrogen with 300mLmin -1 The flow rate was prepared by 75 °C, 1M ammonium nitrate solution. Control the volume ratio of the ammonia gas, water vapor and inert gas to 1:1-3:100-200 as much as possible, especially the volume ratio of 1:2:150 is better.

[0050] Take 1g of nitrogen-doped carbon material and 3g of KOH and add water to mix evenly, then dry it at 130°C, put the resulting mixture in a tube furnace and calcinate at 800°C for 2 hours in a nitrogen atmosphere, and wash the obtained nitrogen-doped porous carbon material with distilled water until neutral , dried at 100°C for later use.

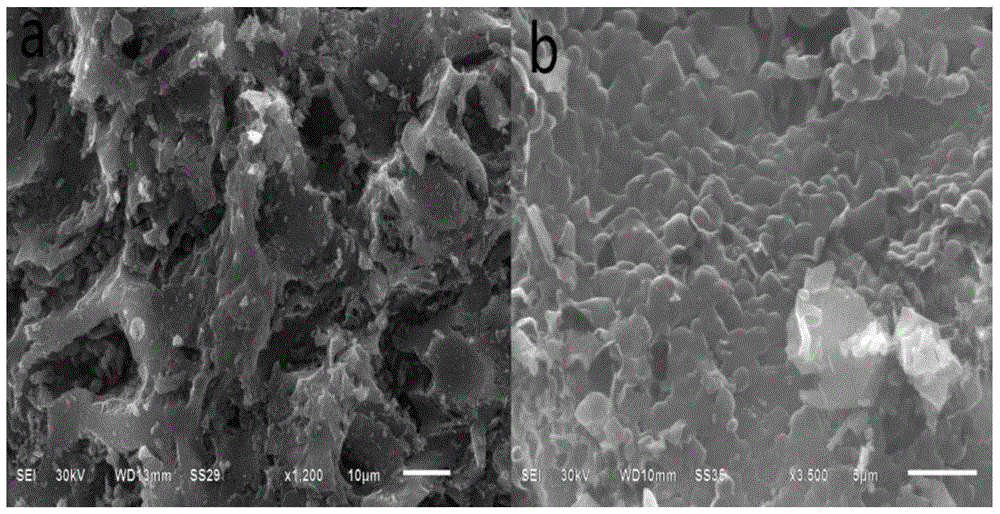

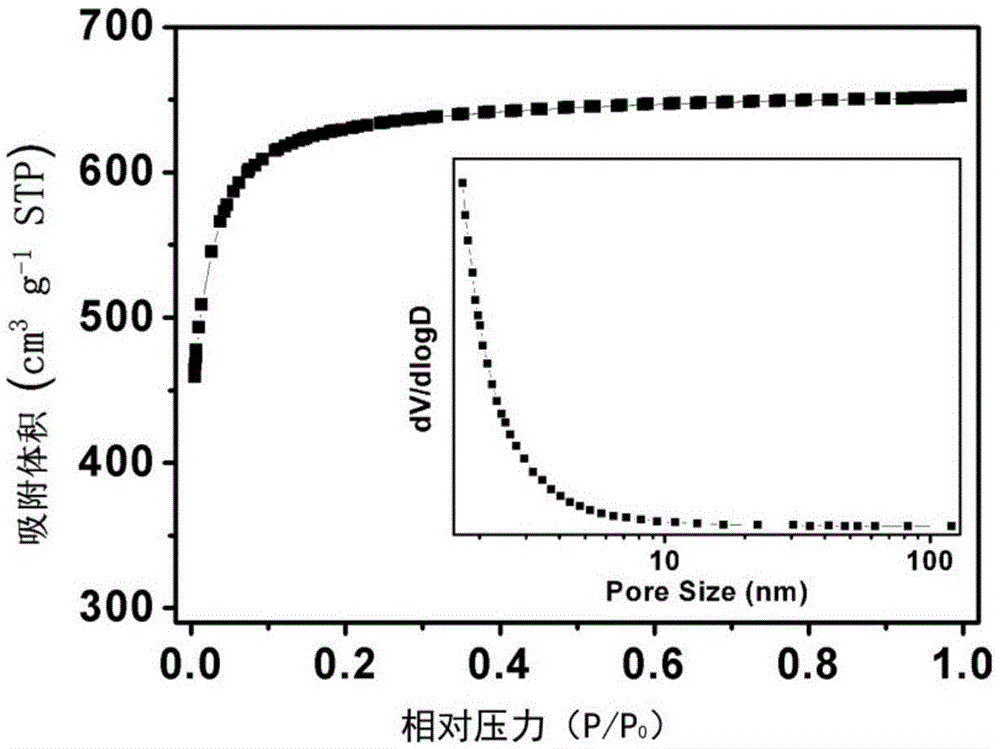

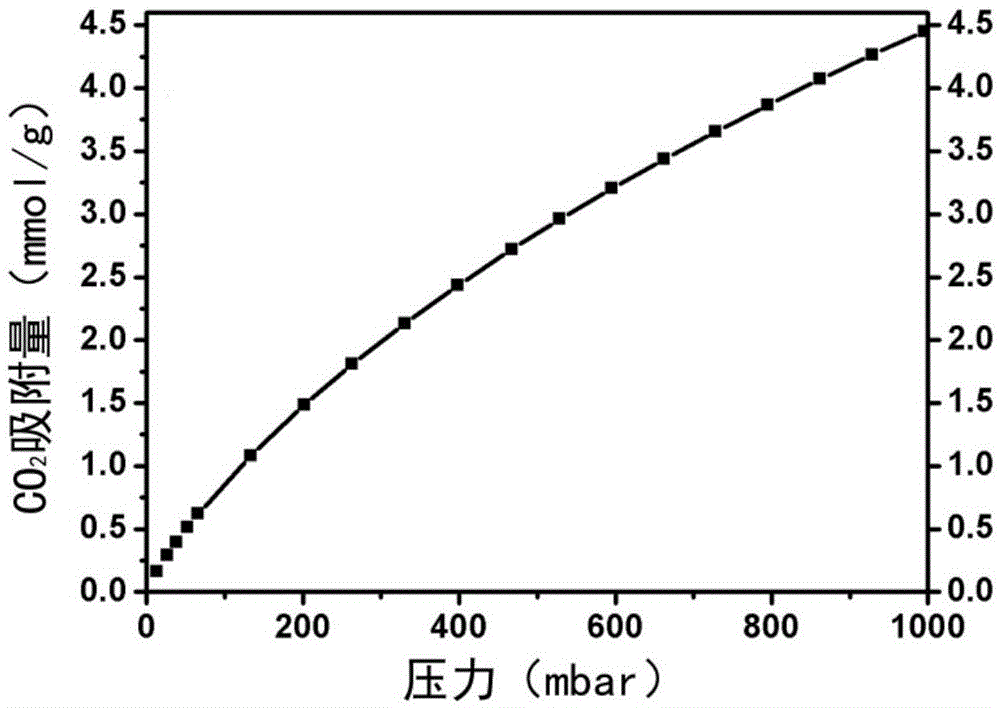

[0051] After testing, its specific surface area reaches 2780m 2 g -1 , with a total pore volume of 1.1 c...

Embodiment 2

[0060] Wash and dry the jujube stones, weigh 10 g of crushed jujube stones, put them into a porcelain crucible, and carbonize them at 600°C for 2 hours in a mixed gas of nitrogen, ammonia and water vapor to obtain a nitrogen-doped carbon material.

[0061] The mixed gas is made of nitrogen with 300mLmin -1 The flow rate was prepared by 75 °C, 1M ammonium nitrate solution. Control the volume ratio of the ammonia gas, water vapor and inert gas to 1:1-3:100-200 as much as possible, especially the volume ratio of 1:2:150 is better.

[0062] Take 1g of nitrogen-doped carbon material and 3g of KOH and add water to mix evenly, then dry at 130°C, put the resulting mixture in a tube furnace and calcinate at 700°C for 2 hours in a nitrogen atmosphere, and wash the obtained nitrogen-doped porous carbon material with distilled water until neutral , dried at 100°C for later use.

[0063] After testing, its specific surface area reaches 2400m 2 g -1 , with a total pore volume of 0.93 cm...

Embodiment 3

[0067] Wash and dry the jujube stones, weigh 10 g of crushed jujube stones, put them into a porcelain crucible, and carbonize them at 600°C for 2 hours in a mixed gas of nitrogen, ammonia and water vapor to obtain nitrogen-doped carbon materials.

[0068] The mixed gas is made of nitrogen with 300mLmin -1 The flow rate was prepared by 75 °C, 1 M ammonium nitrate solution. Control the volume ratio of the ammonia gas, water vapor and inert gas to 1:1-3:100-200 as much as possible, especially the volume ratio of 1:2:150 is better.

[0069] Take 1g of nitrogen-doped carbon material and 3g of KOH and add water to mix it evenly, then dry it at 130°C, put the resulting mixture in a tube furnace and calcinate at 900°C for 2 hours in a nitrogen atmosphere, and wash the obtained nitrogen-doped porous carbon material with distilled water until neutral , dried at 100°C for later use.

[0070] Specific properties of the product: as tested, its specific surface area reaches 2170m 2 g -1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| carbon dioxide adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com