Method for indirect synthesis of quartz glass, special equipment used therein and quartz glass

A technology for synthesizing quartz and quartz glass, applied in glass manufacturing equipment, glass molding, glass production, etc., can solve the problems of high manufacturing cost, high chlorine content, low deposition efficiency and deposition rate, etc., and achieve low manufacturing cost, chlorine Low content, energy and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Embodiment: Indirect method prepares quartz glass

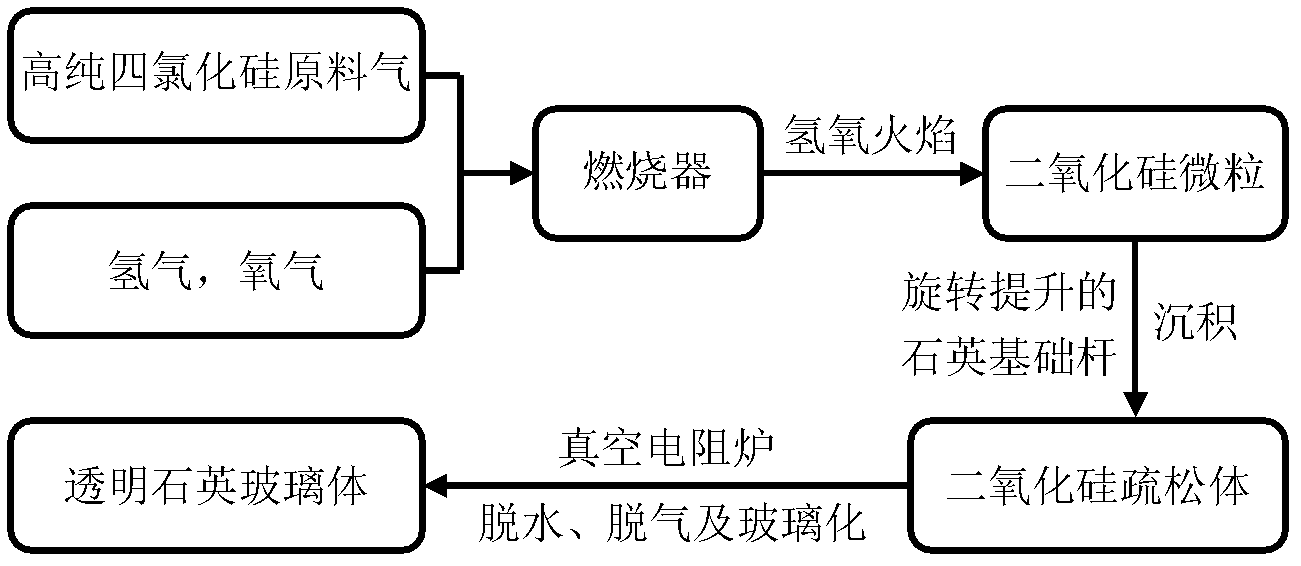

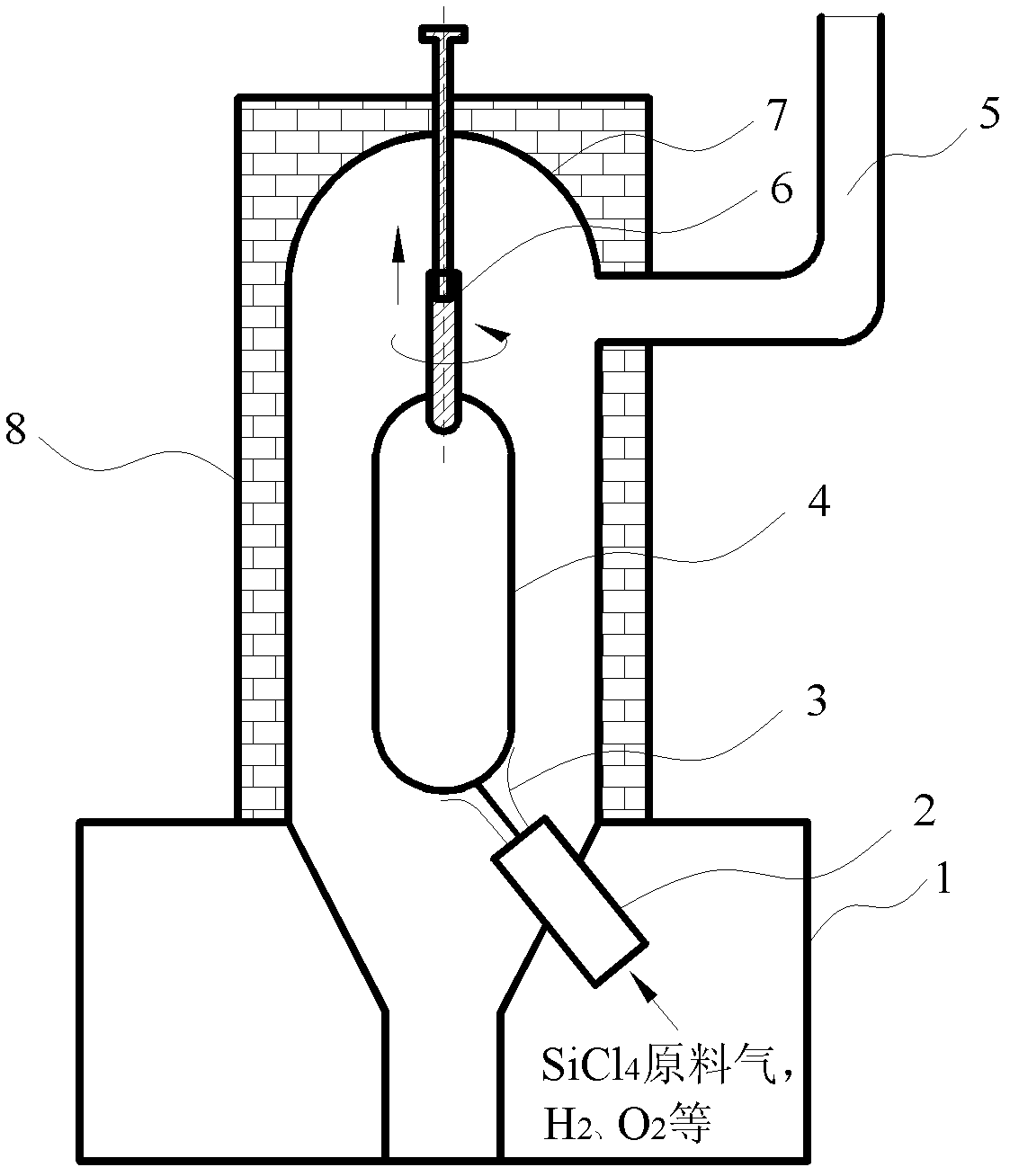

[0056] The invention uses a gas-phase deposition synthesis furnace to synthesize a silicon dioxide loose body and vitrifies it in a vacuum resistance furnace to prepare quartz glass.

[0057] 1) The acquisition of silicon tetrachloride raw material gas: first use the binder gas (at least one of high-purity nitrogen, high-purity helium and high-purity argon, the binder gas in the present embodiment is high-purity nitrogen, the purity reach more than 99.999%), the high-purity silicon tetrachloride raw material liquid (purity reaches more than 99.9999%) in the silicon tetrachloride raw material tank is introduced into the silicon tetrachloride bubble bottle, because the boiling point of the silicon tetrachloride raw material liquid is 57.6 ℃, adjust the temperature of the bubbling bottle to 48 ℃ (40-50 ℃ is acceptable), the carrier gas flows through the purification dryer (concentrated sulfuric acid dehydration and drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com