Method for preparing composite cathode material by modification of graphite

A negative electrode material and graphite technology, which is applied in the field of graphite modification to prepare composite negative electrode materials, can solve problems such as poor liquid absorption capacity, low gram capacity, and poor stability, and achieve improved structural stability, large specific surface area, and improved conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

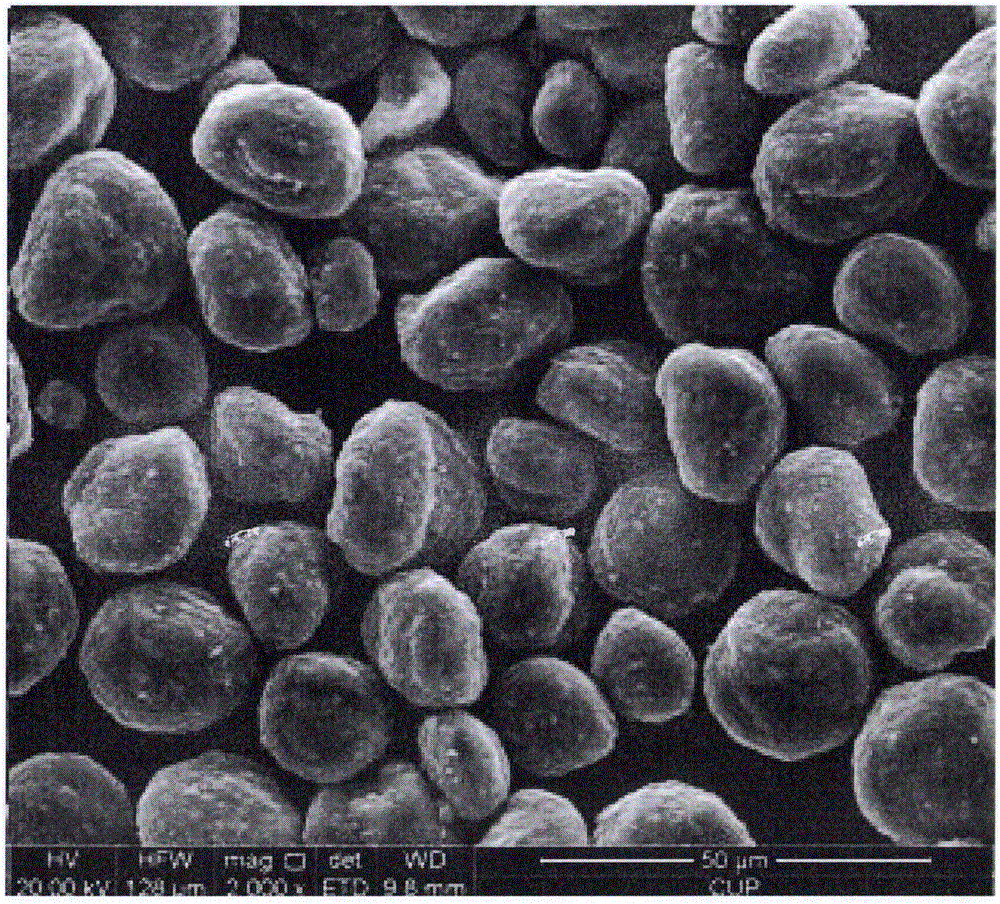

Image

Examples

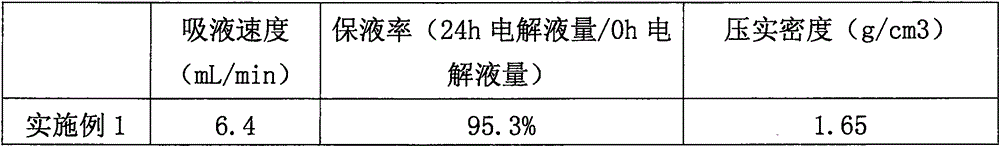

Embodiment 1

[0034] I. Preparation of solution A: 5g polymethylacrylate, 3g ammonium bicarbonate, 3g carbon nanotubes and 1.5g silicon dioxide were added to 100mL of N, N-dimethylformamide under stirring conditions to prepare a uniform and transparent solution A.

[0035] II. Preparation of solution B: Add 8g of pitch to 40mL of N,N-dimethylformamide, mix and stir evenly to obtain solution B.

[0036] III. Preparation of solution C: Add solution B in above II to 100 g of solution A in above I and mix evenly to obtain solution C.

[0037] IV. Preparation of composite negative electrode material: Add 80g of graphite to the three-dimensional mixer and add 100g of solution C in the above III for stirring. During stirring, the heating rate of the three-dimensional mixer is controlled at 8°C / min and heated to 120°C. The speed of the mixer was controlled at 120 rpm and stirred for 5 hours. After that, the three-dimensional mixer continued to heat up to 800°C and kept warm for 12 hours. Finally, ...

Embodiment 2

[0039] I. Preparation of solution A: 1.0 g of polyvinyl alcohol, 1.0 g of urea, 1.0 g of graphene and 1.0 g of silicon dioxide were added to 100 mL of acetone under stirring conditions to prepare a uniform and transparent solution A.

[0040] II. Preparation of solution B: Add 5g of asphalt into 30mL of acetone, mix and stir evenly to obtain solution B.

[0041] III. Preparation of solution C: Add solution B in above II to 100 g of solution A in above I and mix evenly to obtain solution C.

[0042] IV. Preparation of composite negative electrode material: Add 50g of graphite to the three-dimensional mixer and add 100g of solution C in the above III for stirring. During stirring, the heating rate of the three-dimensional mixer is controlled at 2°C / min and heated to 100°C. The speed of the mixer was controlled at 100 rpm and stirred for 10 hours. After that, the temperature of the three-dimensional mixer continued to rise to 600 °C and kept for 24 hours. Finally, the composite n...

Embodiment 3

[0044] I. Preparation of solution A: Add 10 g of polyacrylamide, 5 g of polyethylene glycol, 5 g of hollow carbon spheres and 2 g of silicon dioxide into 100 mL of chloroform under stirring to prepare a uniform and transparent solution A.

[0045]II. Preparation of solution B: Add 10 g of asphalt into 50 mL of chloroform, mix and stir evenly to obtain solution B.

[0046] III. Preparation of solution C: Add solution B in above II to 100 g of solution A in above I and mix evenly to obtain solution C.

[0047] IV. Preparation of composite negative electrode material: Add 100g of graphite to the three-dimensional mixer and add 100g of solution C in the above III for stirring. During stirring, the heating rate of the three-dimensional mixer is controlled at 10°C / min and heated to 160°C. The speed of the mixer was controlled at 150 rpm and stirred for 1.0 h. After that, the three-dimensional mixer continued to heat up to 1000 ° C and held for 6 h. Finally, the composite negative el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com