Low-temperature preparation method of Co ferrite Nano powder

A technology of cobalt ferrite and nano-powder, which is applied in the field of nano-material preparation, can solve the problems of reducing powder calcination activity, high cost, and difficult industrial application, and achieves good magnetic properties, uniform size, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

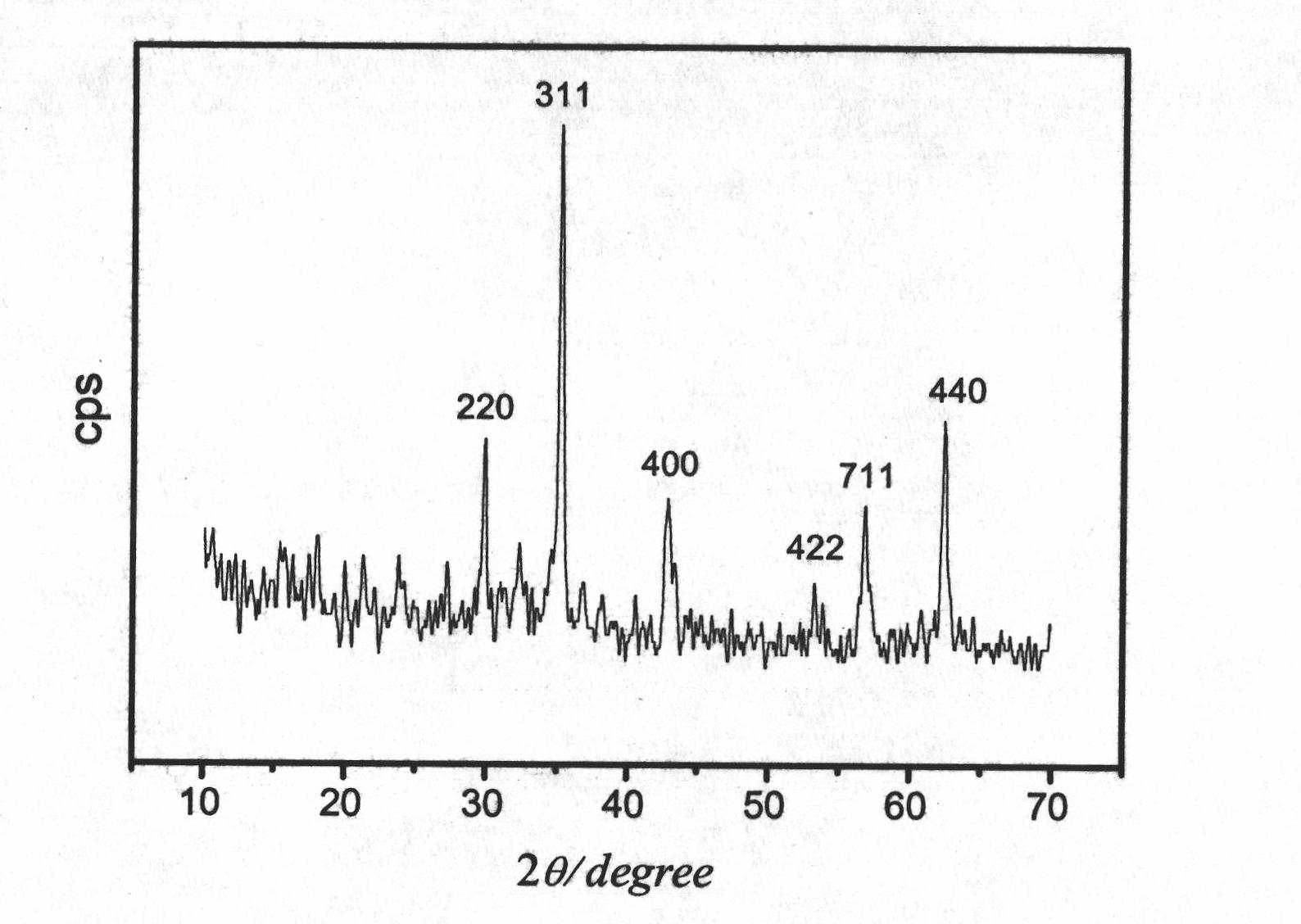

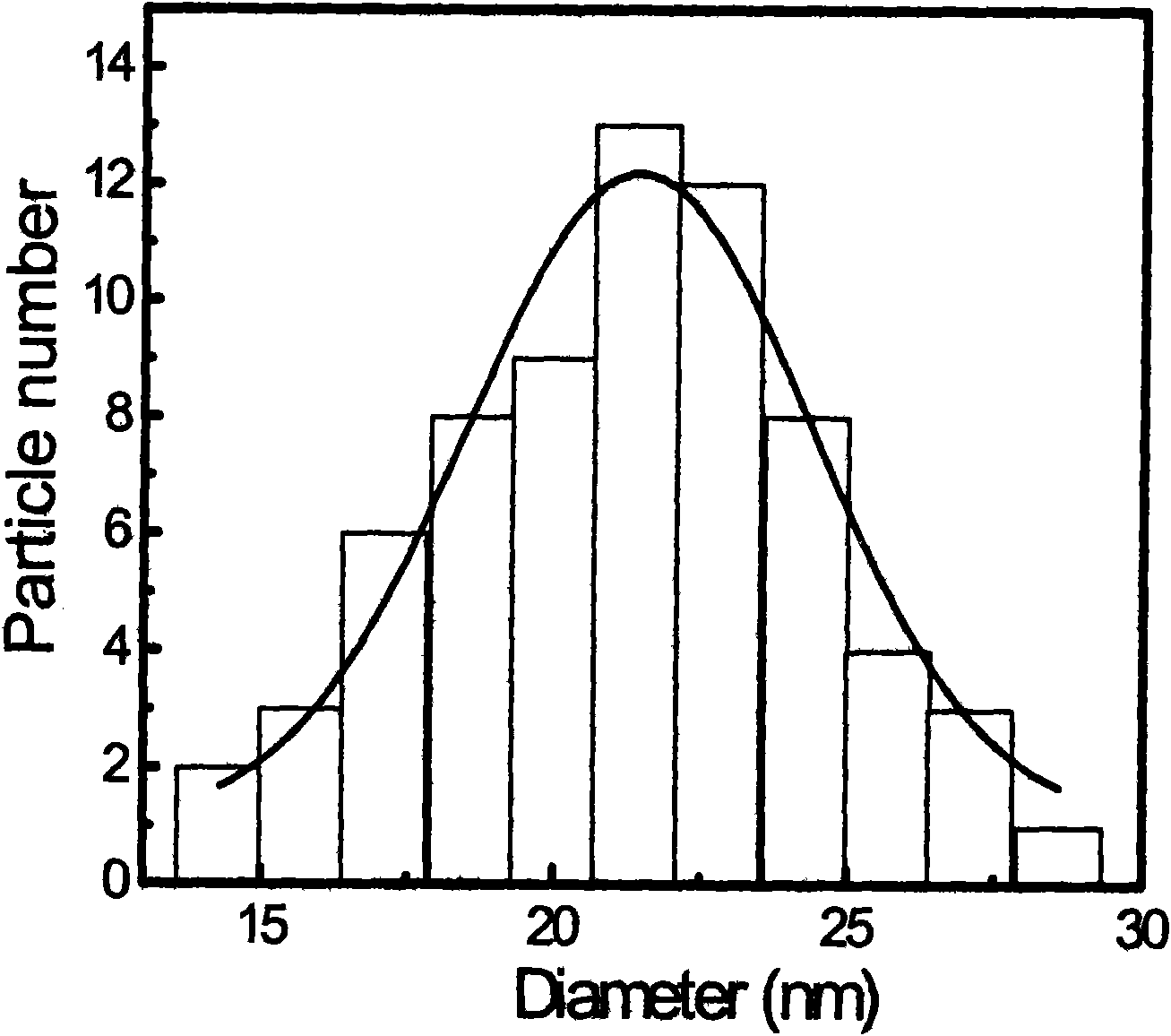

[0015] Take Co(CH 3 CO 2 ) 2 4H 2 O, Fe(NO 3 ) 3 9H 2 O and citric acid are raw materials, analytically pure ethylene glycol methyl ether and water are mixed as a solvent, and the volume ratio is 7:1, and 4.982 grams of Co(CH 3 CO 2 ) 2 4H 2 O, 16.165 g Fe(NO 3 ) 3 9H 2 O was dissolved in 100mL of the above mixed solvent to obtain a transparent solution, and then 15.130 g of citric acid was added to the solution, and analytically pure ammonia water was slowly added dropwise to the solution under stirring conditions, and the pH value was adjusted to about 6. Evaporate slowly to form a brown sol, then heat to 130°C until a brown-black xerogel is formed, transfer it to an oven at 250°C, the xerogel will undergo self-propagating combustion to form a dendritic fluffy product, and the particle size will be obtained after grinding evenly Tan iron cobalt oxide powder of about 20nm. The structure of the product is shown in the X-ray diffraction (XRD) pattern, such as figu...

Embodiment 2

[0017] Take Co(CH 3 CO 2 ) 2 4H 2 O, Fe(NO 3 ) 3 9H 2 O and malic acid are raw materials, analytical pure ethylene glycol methyl ether and water are mixed as a solvent, and the volume ratio is 8:1, and 6.227 grams of Co(CH 3 CO 2 ) 2 4H 2 O, 20.206 g Fe(NO 3 ) 3 9H 2 O was dissolved in 120mL of the above mixed solvent to obtain a transparent solution, and then 12.068 grams of malic acid was added to the transparent solution, and the pH value was adjusted to about 6 with analytical pure ammonia water under stirring, and refluxed in a water bath at 70°C for 12 hours to form a brown-black dry coagulation Gel, transfer it into an oven at 250°C, the dry gel will undergo self-propagating combustion to form a dendritic fluffy product, and after uniform grinding, a brown cobalt ferrite powder with a particle size of about 22nm is obtained.

Embodiment 3

[0019] Take Co(CH 3 CO 2 ) 2 4H 2 O, Fe(NO 3 ) 3 9H 2 O and lactic acid are raw materials, analytical pure ethylene glycol methyl ether and water are mixed as a solvent, and the volume ratio is 9:1, and 7.473 grams of Co(CH 3 CO 2 ) 2 4H 2 O, 24.247 g Fe(NO 3 ) 3 9H 2 O was dissolved in 150 mL of the above mixed solvent to obtain a transparent solution, and then 9.729 g of lactic acid was added to it, and the pH value was adjusted to about 6 with analytical pure ammonia water under stirring, and the solution was slowly evaporated in a water bath at 70°C to form a brown sol, and then heated Transfer it to an oven at 250°C until it forms a brown-black xerogel at 150°C. The xerogel will undergo self-propagating combustion to form a dendritic fluffy product. After grinding evenly, a brown cobalt iron oxide with a particle size of about 25nm will be obtained. body powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com