High density ultrafine composite ferric lithium phosphate anode material and preparation method

A lithium iron phosphate and cathode material technology, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problems of uneven particle size distribution of reaction products, difficult to reach nano-scale, and high price of lithium cobalt oxide. Excellent cycle performance, uniform distribution of conductive agent, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Ammonium dihydrogen phosphate of 0.5mol / L, 0.5mol / L ferrous acetate, 0.5mol / L lithium carbonate, 3.07 grams of magnesium acetate, and 4.91 grams of polypropylene were mixed, placed in a closed reactor and stirred at high speed for 1 hour, and then Add oxalic acid dropwise therein, the concentration of oxalic acid is 0.03mol / L. Adjust the stirring rate to 120r / min, adjust the flow rate of ammonia water, and control the pH value of the solution to 9.0. Then remove the solvent from the obtained gel-type precipitate at less than 100°C, wash away the unreacted reaction with deionized water, and then separate the nano-precursor; in an atmosphere of inert gas protection, place it In a microwave oven at 700°C for 5-300 minutes of heat preservation reaction for microwave synthesis, and finally nano-scale lithium iron phosphate powder can be obtained.

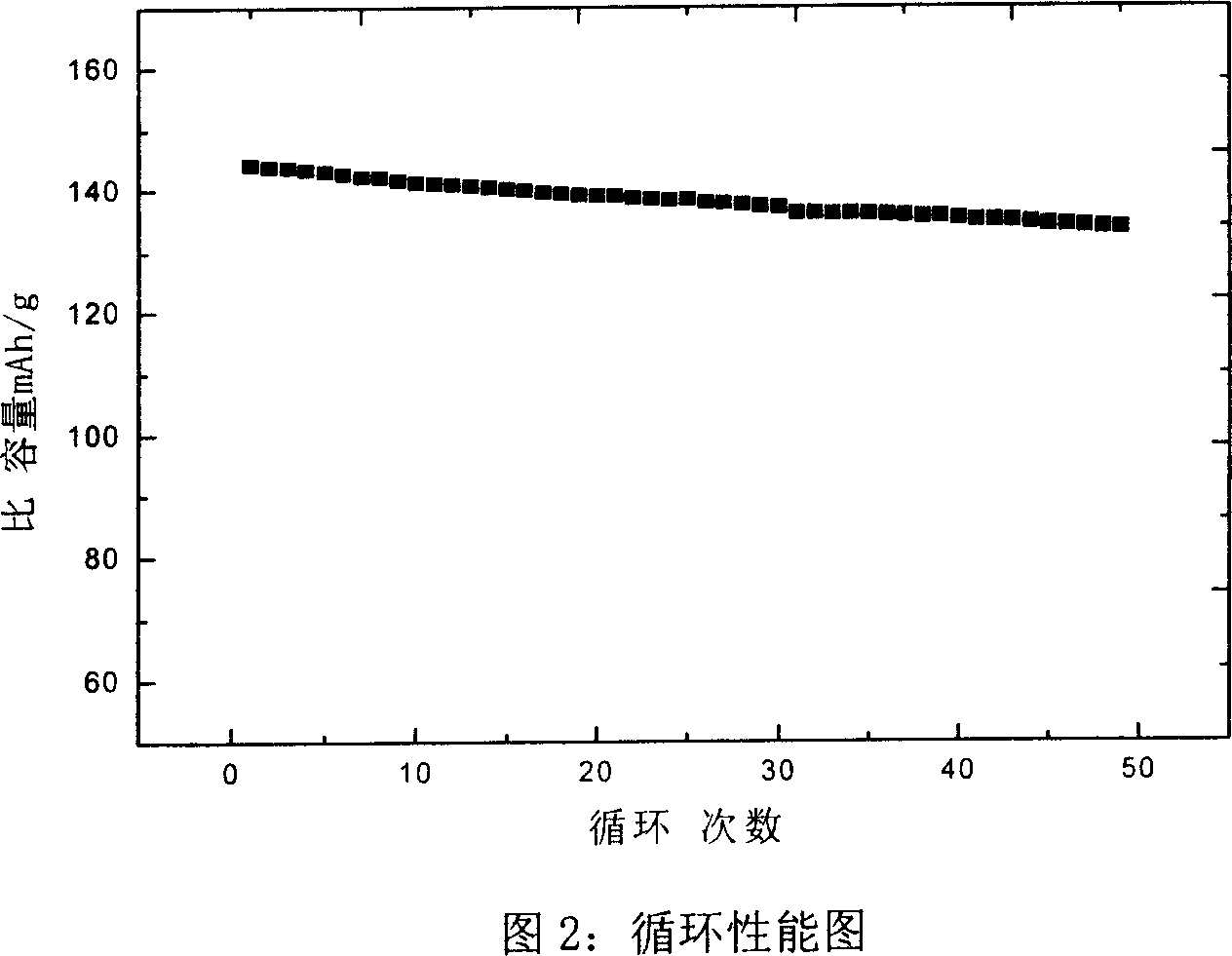

[0041] The electrochemical performance of the obtained material is determined by the following method: 92% positive electrode ac...

Embodiment 2

[0043] The ammonium dihydrogen phosphate of 0.5mol / L, the 0.5mol / L ferrous sulfate that is 1.2 times the theoretical amount, the 0.5mol / L lithium carbonate that is 1.2 times the theoretical amount, 5.06 grams of magnesium acetate and 6.09 grams of sucrose are mixed, placed in Carry out high-speed stirring in the closed reactor for half an hour, then drop tartaric acid wherein, the concentration of tartaric acid is 0.03mol / L. Adjust the stirring rate to 120r / min, adjust the flow rate of dripping ammonia water, and control the pH value of the solution to 8.5. Then remove the solvent from the obtained gel-type precipitate at less than 100°C, wash away the unreacted reaction with deionized water, and then separate the nano-precursor; in an atmosphere of inert gas protection, place it In a microwave oven at 650° C. for 5-300 minutes of heat preservation and reaction for microwave synthesis, nano-scale lithium iron phosphate powder can be finally obtained.

Embodiment 3

[0045] Mix 0.5mol / L phosphoric acid, 0.5mol / L ferrous oxide, 0.5mol / L lithium hydroxide, 5.06 grams of magnesium acetate and 7.58 grams of polyacrylamide, place them in a closed reactor for high-speed stirring for 2 hours, and then pour them into Tartaric acid was added dropwise, and the concentration of tartaric acid was 0.03mol / L. Adjust the stirring rate to 120r / min, adjust the flow rate of ammonia water, and control the pH value of the solution to 9.0. Then remove the solvent from the obtained gel-type precipitate at less than 100°C, wash away the unreacted reaction with deionized water, and then separate the nano-precursor; in an atmosphere of inert gas protection, place it In a microwave oven at 750° C. for 5-300 minutes of heat preservation and reaction for microwave synthesis, nano-scale lithium iron phosphate powder can be finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com