Solid-phase synthetic method of highly ordered mesoporous carbon material

A highly ordered, solid-phase synthesis technology, applied in the field of materials, can solve problems such as low efficiency, time-consuming, labor-intensive, and complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

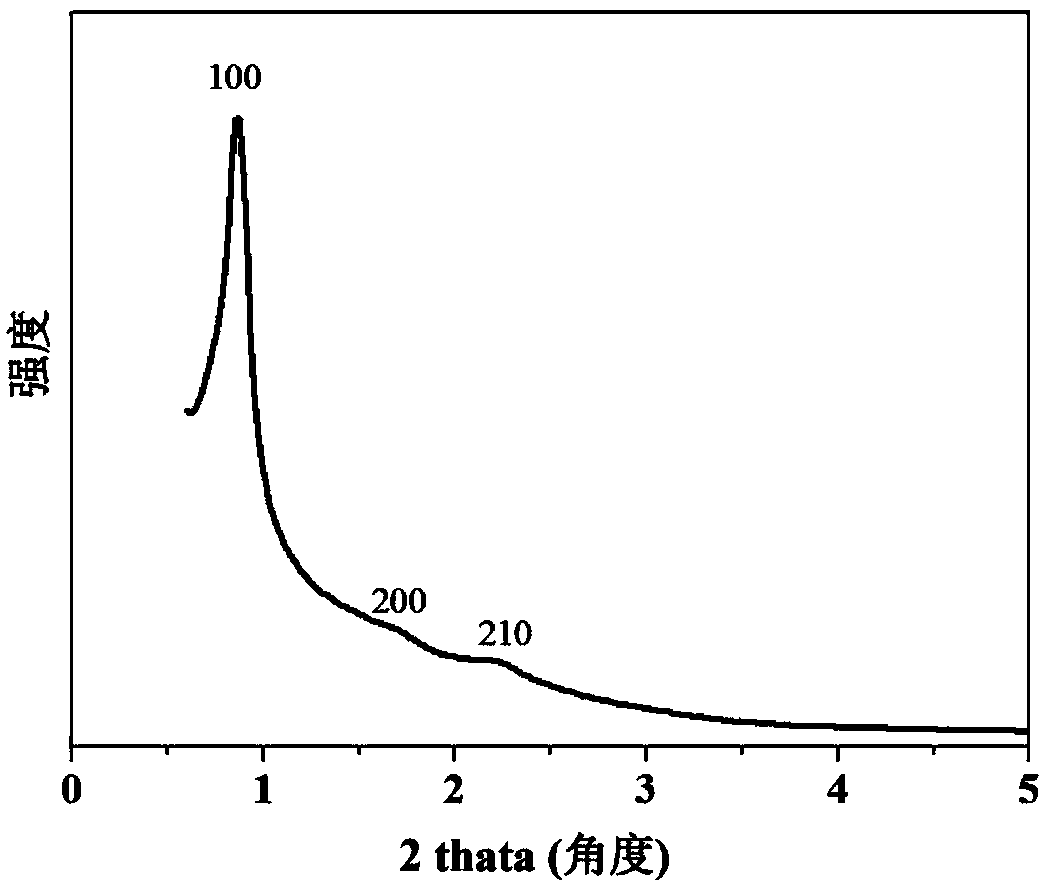

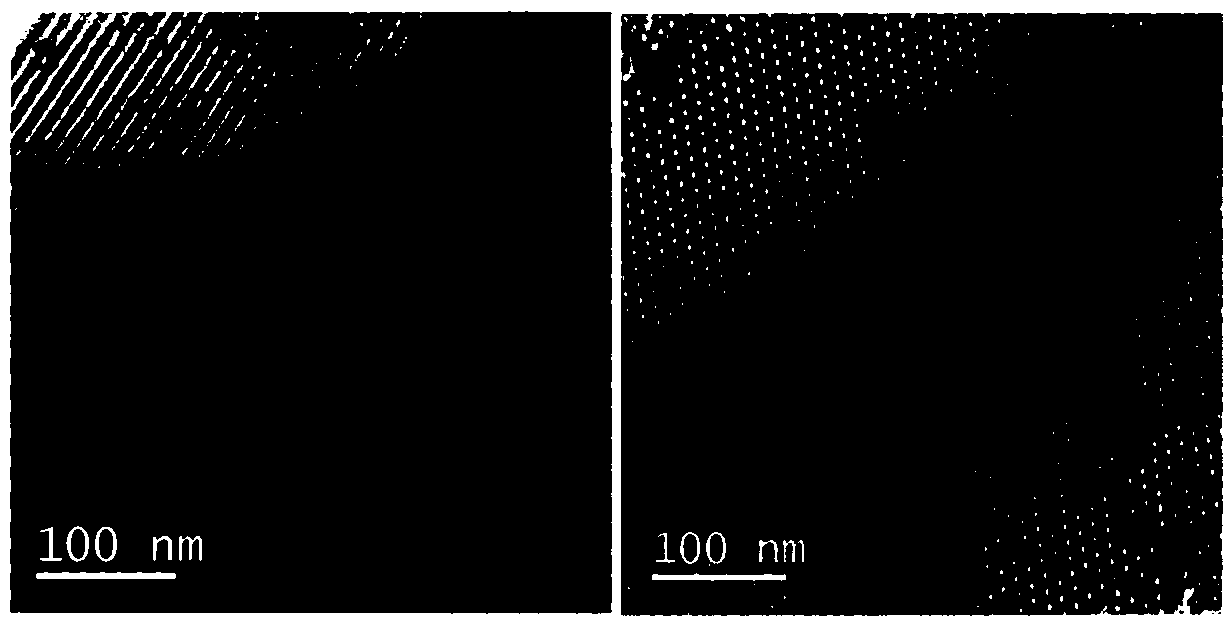

Embodiment 1

[0023] At room temperature, 0.62 g of triblock copolymer EO 106 PO 70 EO 106 Add to an agate mortar and grind to a fine powder. Then 0.62 g of resorcinol was added and ground for 5 minutes until powdered. Then 0.45 g of terephthalaldehyde was added in three batches, followed by careful grinding for 5 minutes and mixing as homogeneous as possible. The solid turned into a white to off-white pasty dough-like viscous solid during grinding, and the viscous solid from grinding was transferred to a corundum crucible. Put the newly prepared samples into ovens at 80°C and 100°C for heat treatment for 300 minutes respectively to obtain a hard bulk polymer composite material, remove it and grind it into powder, then place it in a tube furnace and protect it in an inert atmosphere calcination at 900°C for 360 minutes to obtain carbon mesoporous materials. This material has a pore diameter of 5.4nm and a pore volume of 0.55cm 3 / g, the specific surface area is 700m 2 / g, the pore sp...

Embodiment 2

[0025] At room temperature, add 0.81 g of cationic surfactant cetyltrimethylammonium bromide into an agate mortar and grind to fine powder; then add 0.42 g of resorcinol and grind for 5 minutes to powder. Then 0.49 g of terephthalaldehyde was added in three batches followed by careful grinding for 5 minutes and mixing as homogeneous as possible. During grinding, the solid turned into a white to off-white pasty dough-like sticky solid, which was transferred to a corundum crucible. Put the newly prepared samples into ovens at 80°C and 100°C for heat treatment for 300 minutes respectively to obtain a hard bulk polymer composite material, remove it and grind it into powder, then place it in a tube furnace and protect it in an inert atmosphere calcination at 900°C for 300 minutes to obtain carbon mesoporous materials. This material has a pore diameter of 5.4nm and a pore volume of 0.26cm 3 / g, the specific surface area is 420m 2 / g.

Embodiment 3

[0027] At room temperature, 1.5 grams of triblock copolymer Brij56 was added into an agate mortar and ground to a fine powder, then 1.50 grams of melamine was added and ground to make the mixture uniform. Then 0.54 g of resorcinol was added and ground for 5 minutes until powdered. Then 0.76 g of terephthalaldehyde was added in three batches, followed by careful grinding for 5 minutes, and the viscous solid obtained by grinding was transferred to a corundum crucible. The newly prepared samples were heat-treated in ovens at 80°C and 100°C for 300 minutes, respectively, to obtain bulk polymer composite materials. It was removed and ground into powder, then placed in a tube furnace, under the protection of an inert atmosphere, and fired at a high temperature of 600°C for 180 minutes, and finally a carbon mesoporous material was obtained. The material has a pore size of 3.3nm and a pore volume of 0.17cm 3 / g, the specific surface area is 310m 2 / g, the nitrogen content is 14.0wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com