Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1205 results about "Cerium nitrate hexahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cerium nitrate hexahydrate, with the formula Ce(NO3)3.6H2O (CAS number 10294-41-4) is the most common nitrate of cerium(III). It is a component in a burn treatment cream that also includes silver sulphadiazine.

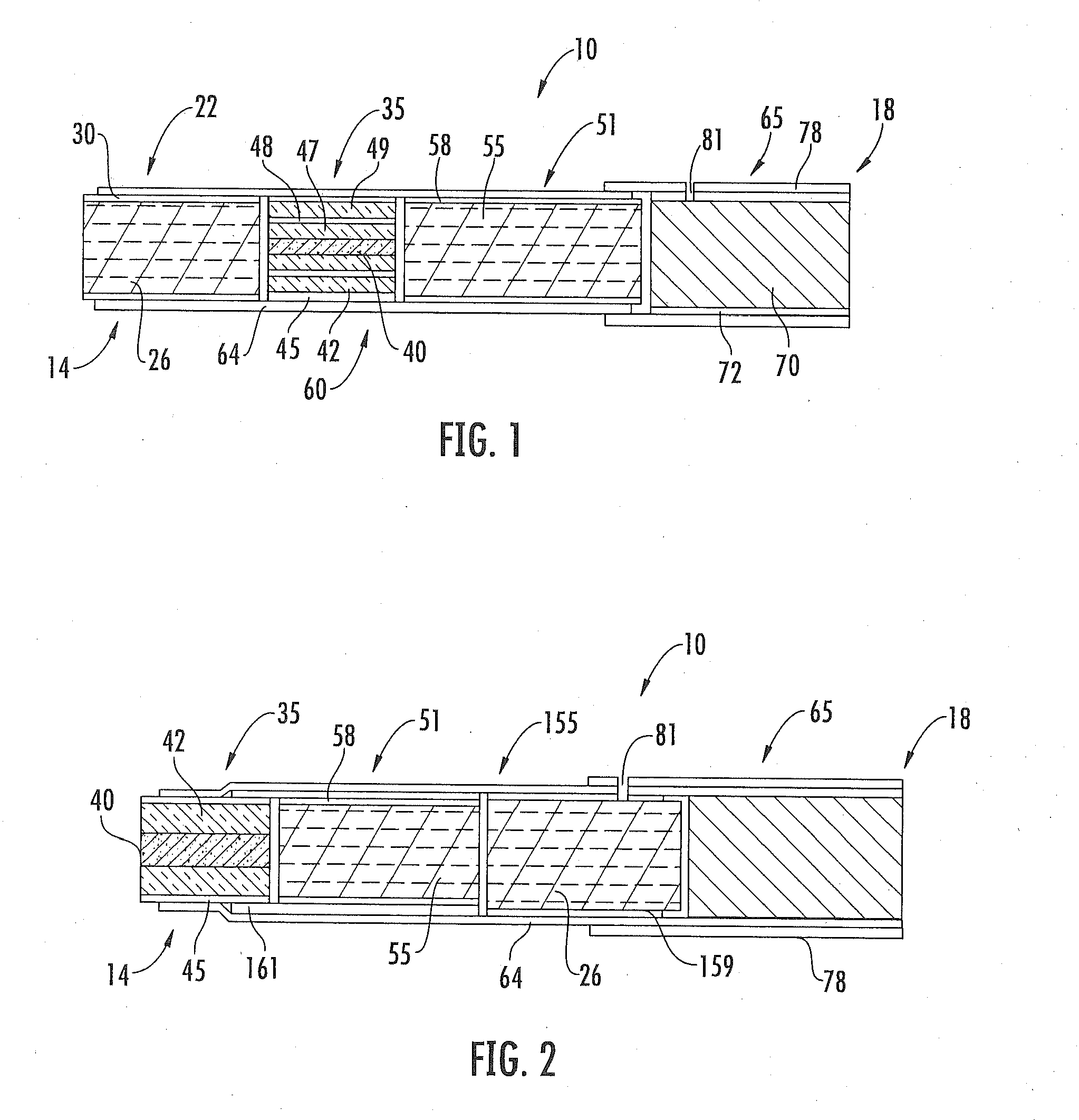

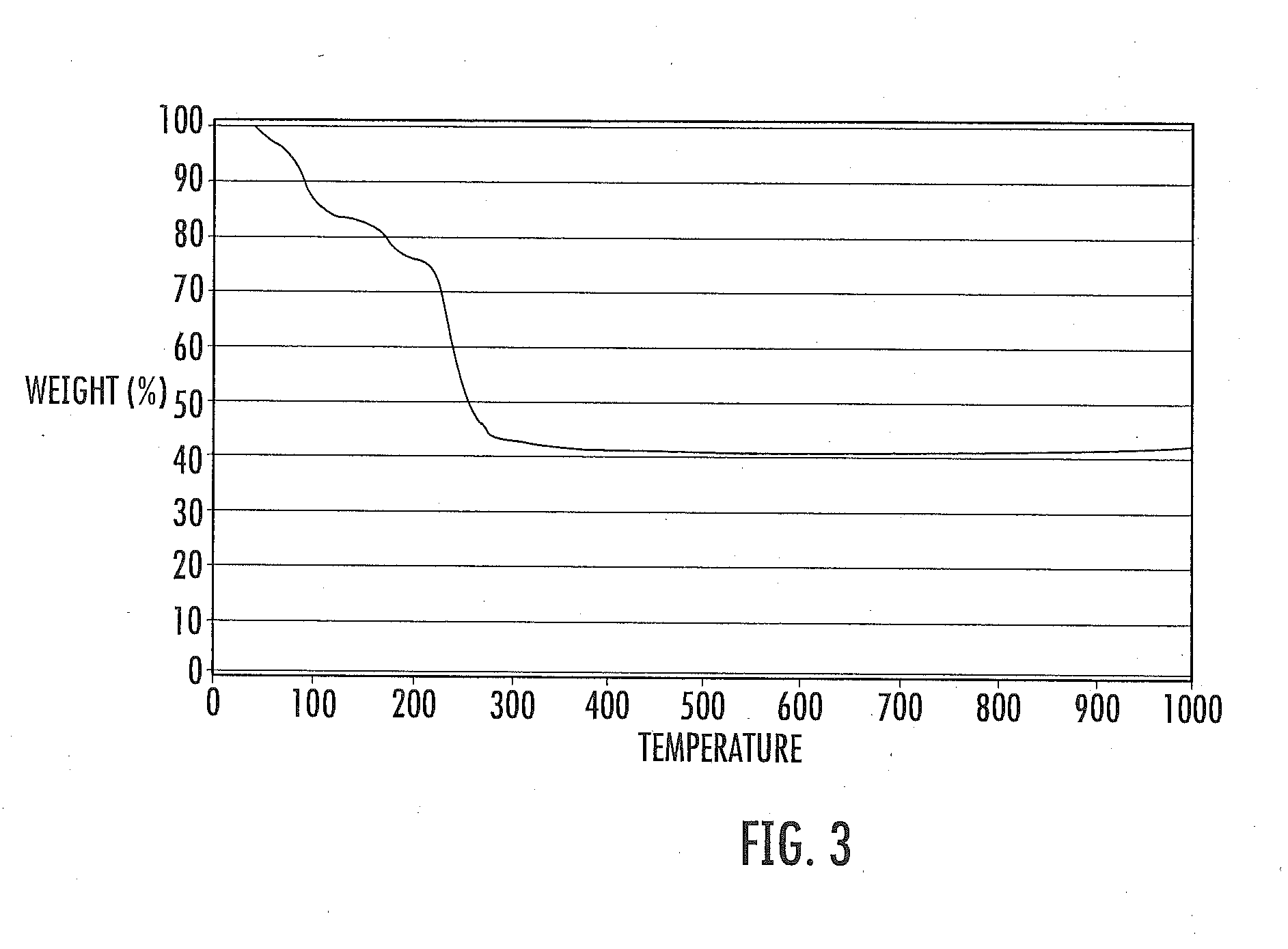

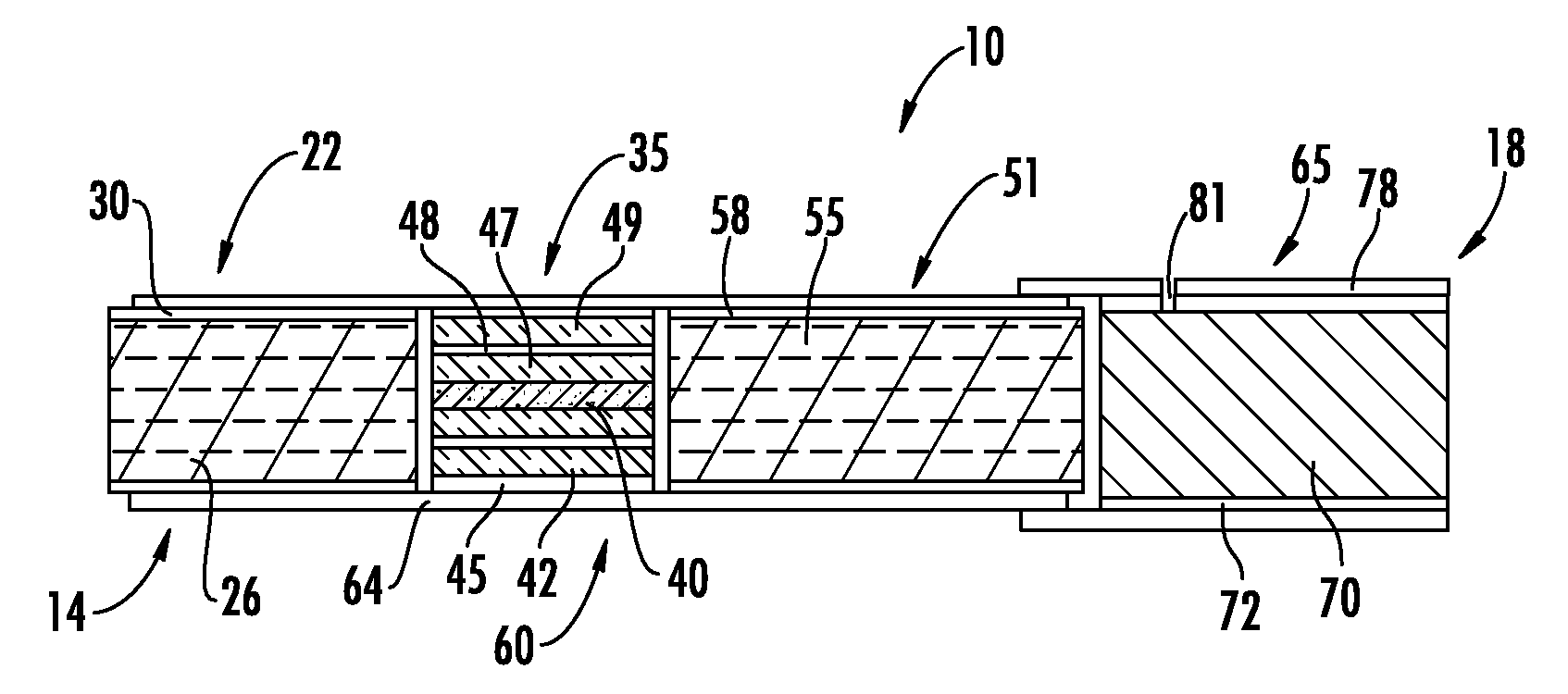

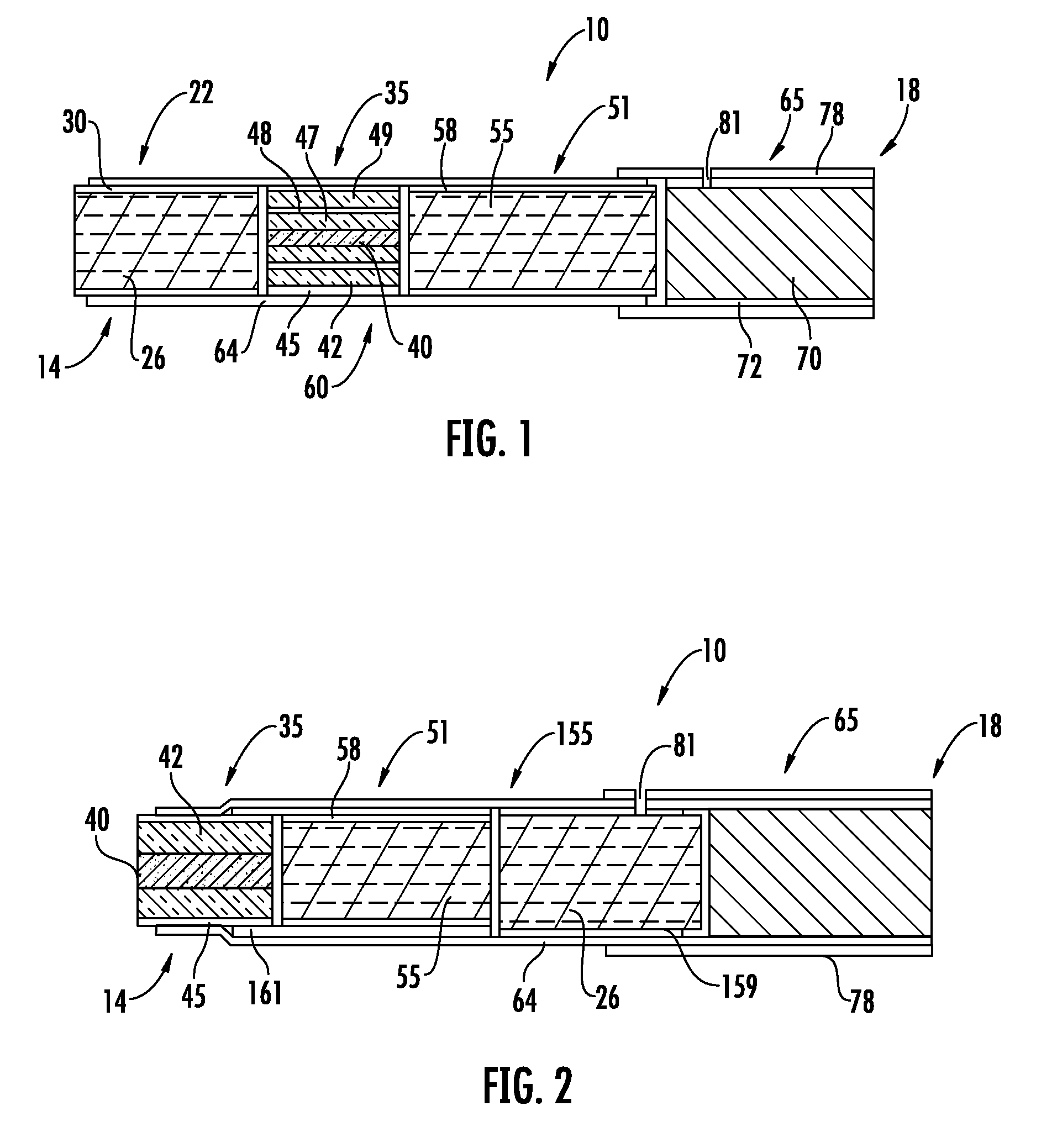

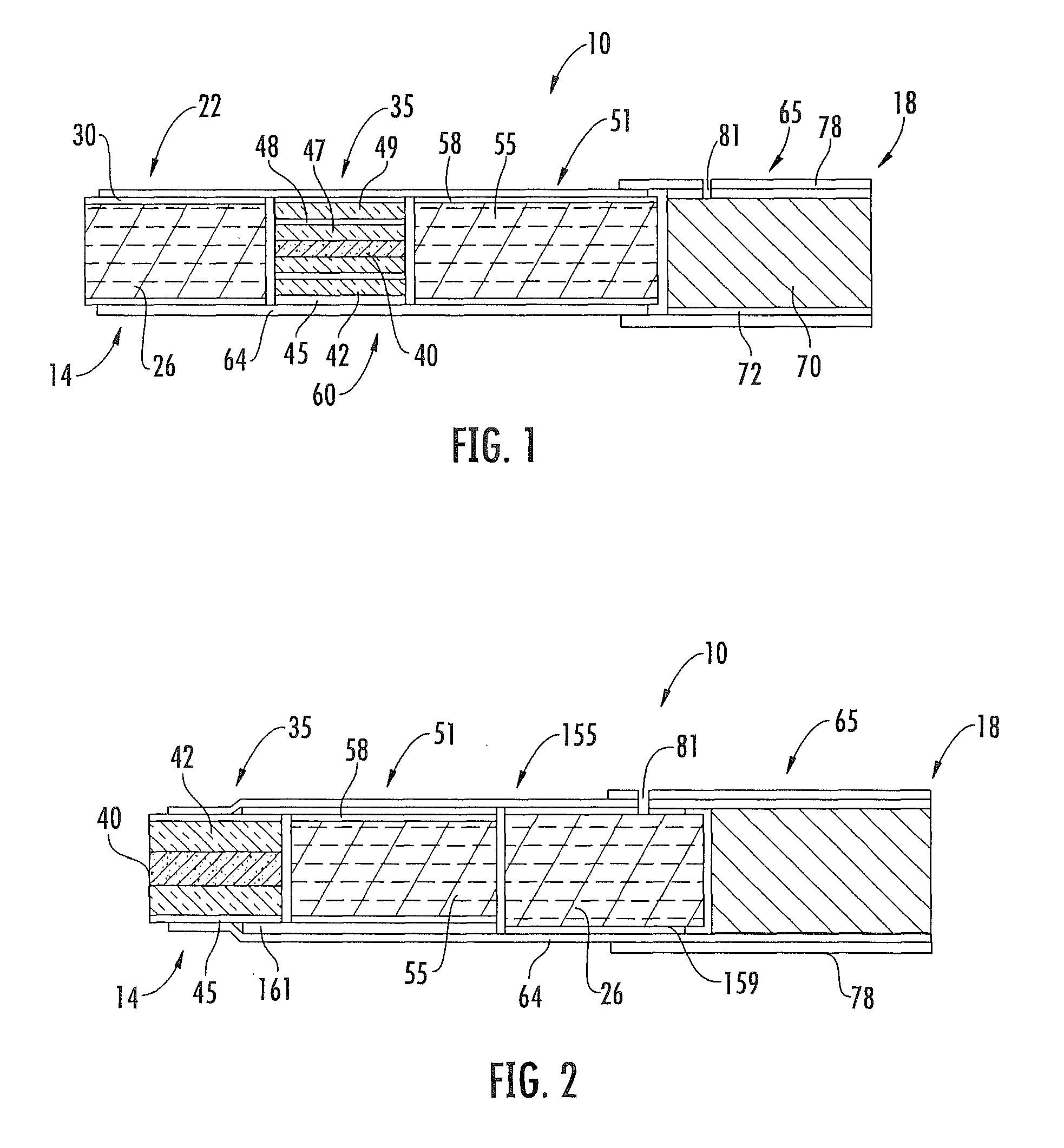

Method for Preparing Fuel Element For Smoking Article

ActiveUS20100065075A1Good water solubilityTobacco treatmentTobacco smoke filtersCerium nitrateCopper nitrate

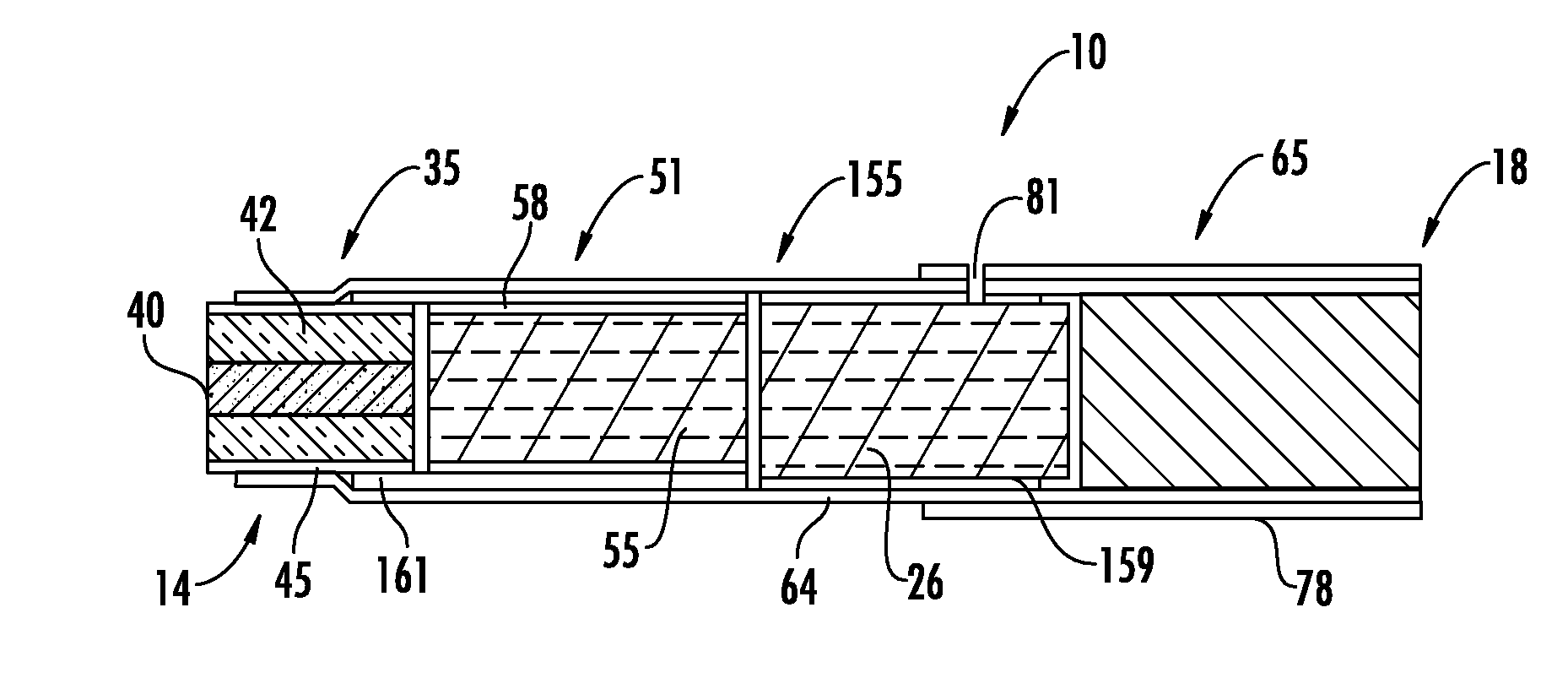

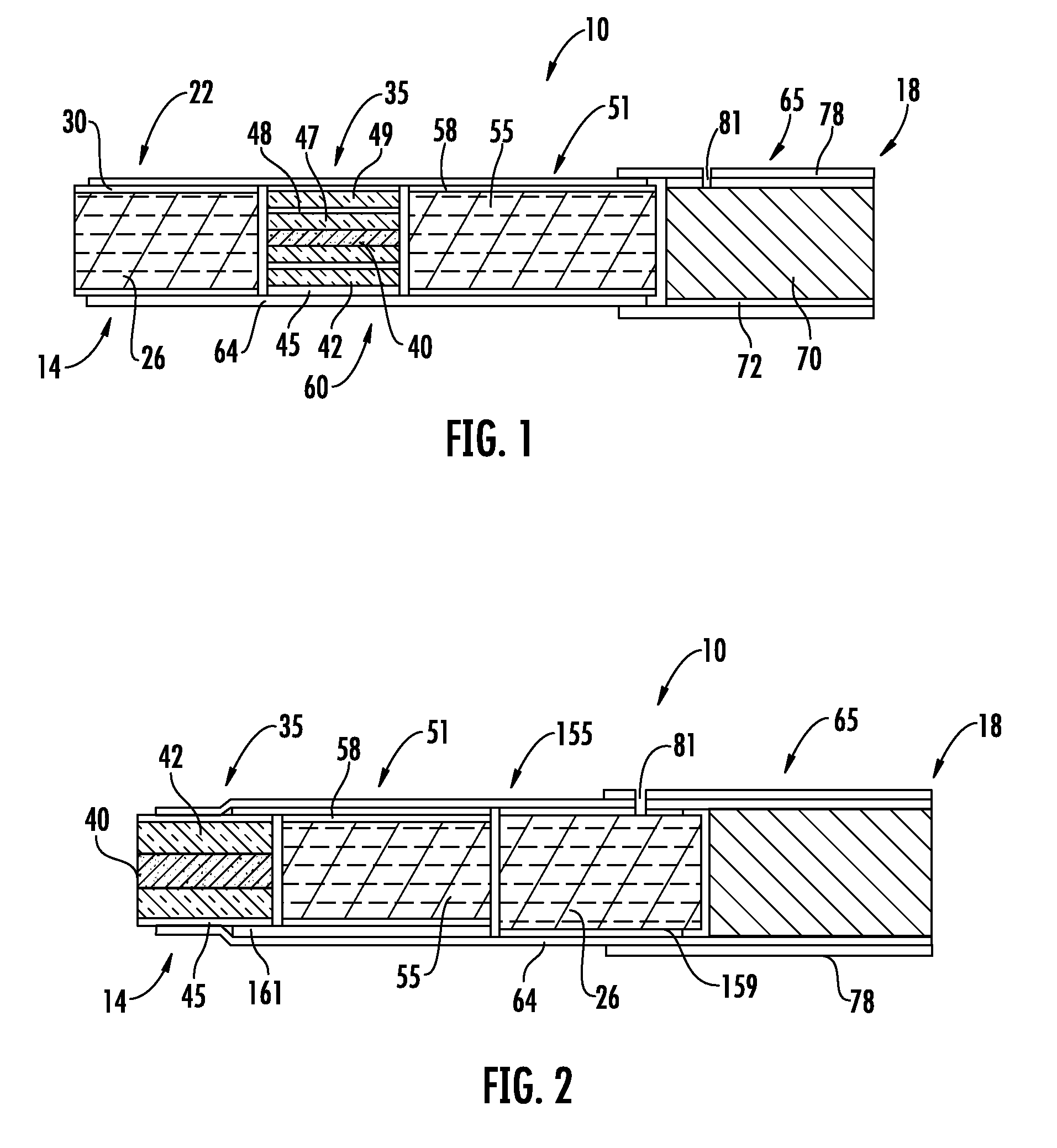

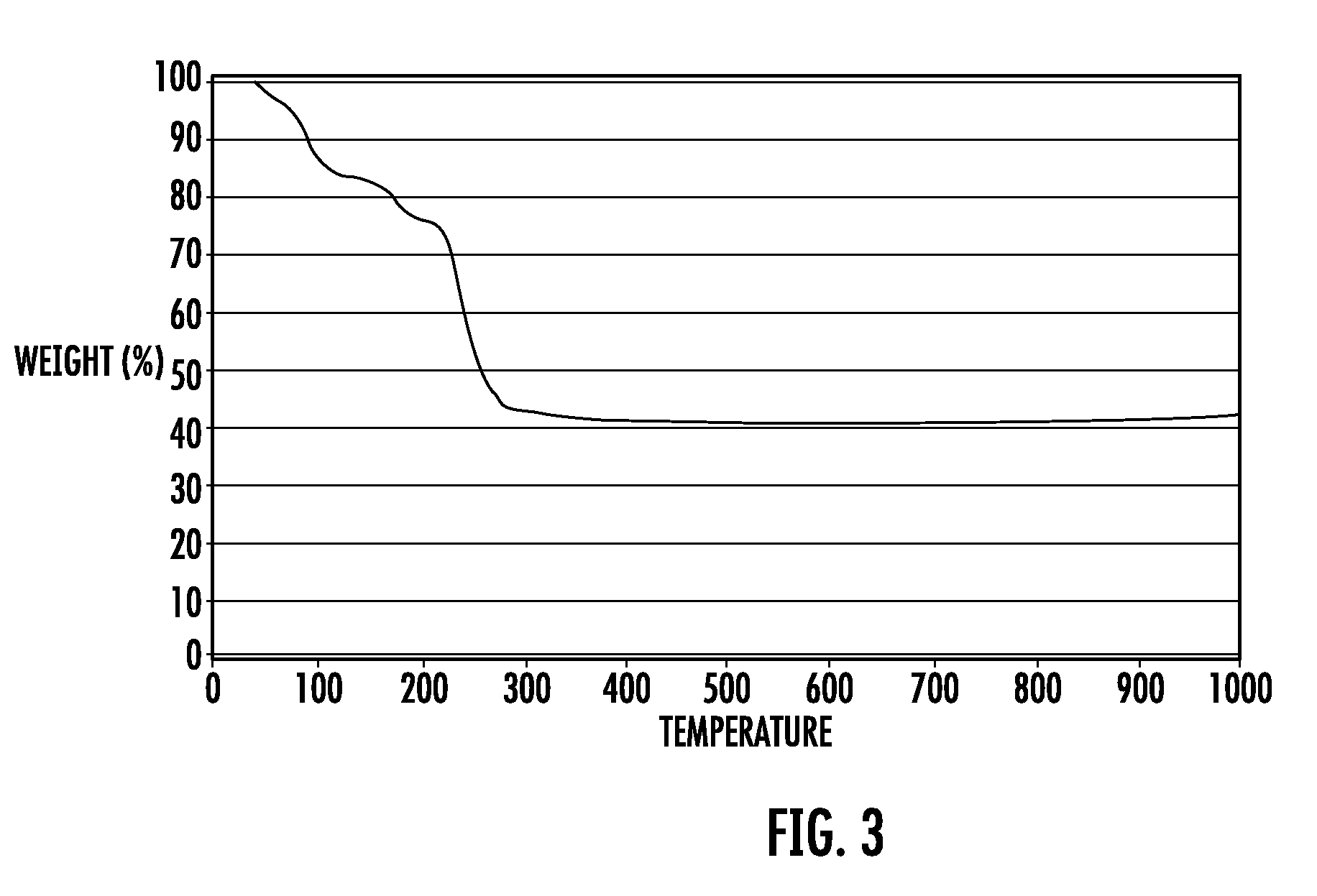

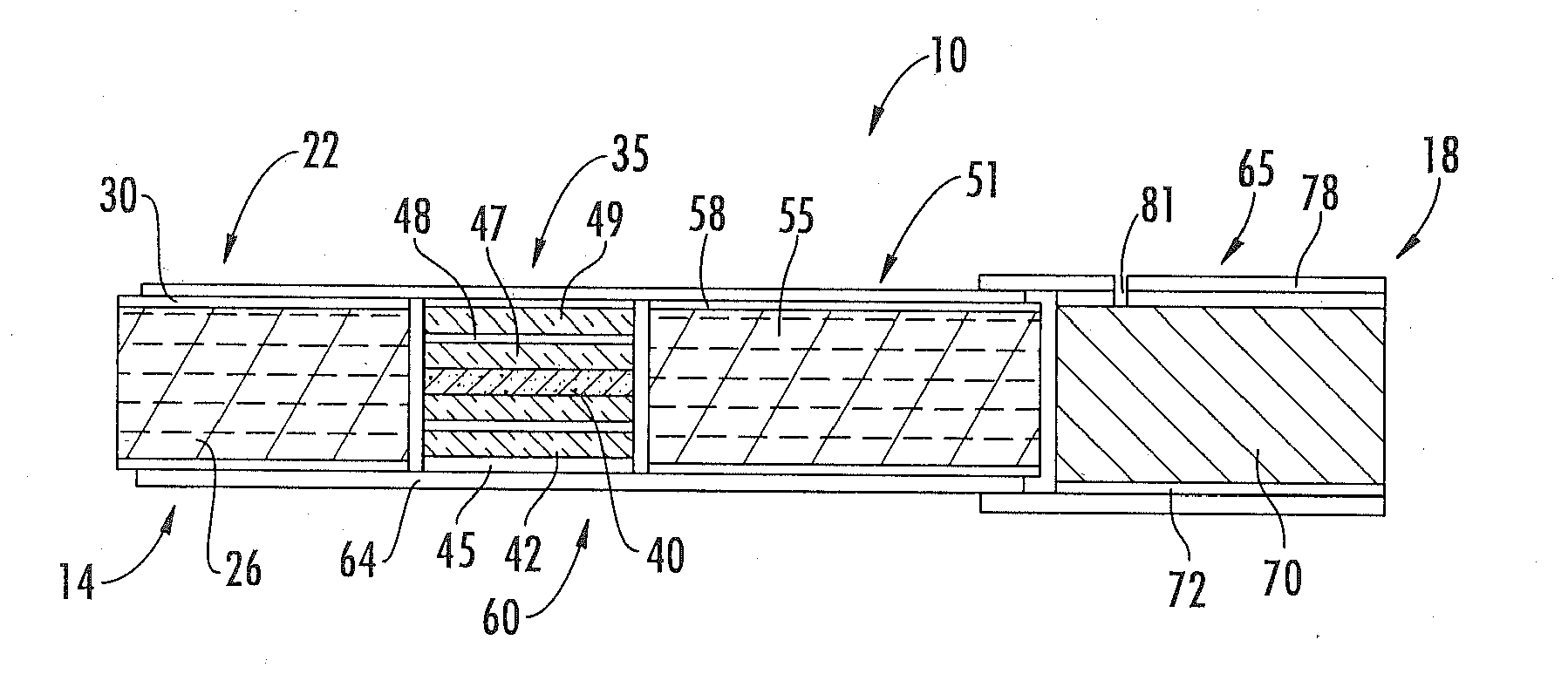

The invention provides a method for making a fuel element for a smoking article comprising forming a combustible carbonaceous material into a fuel element adapted for use in a smoking article; incorporating a metal-containing catalyst precursor into the fuel element or onto the surface thereof to form a treated fuel element, the incorporating step occurring before, during, or after said forming step; and optionally heating or irradiating the treated fuel element at a temperature and for a time sufficient to convert the catalyst precursor to a catalytic metal compound. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article including the steps of mixing a metal-containing catalyst precursor with a filler material or graphite or a combination thereof to form a pre-treated fuel element component; optionally calcining the pre-treated fuel element component in order to convert the catalyst precursor to a catalytic metal compound; after the optional calcining step, combining the pre-treated fuel element component with a carbonaceous material and a binder to produce a fuel element composition; and forming the fuel element composition into a fuel element adapted for use in a smoking article. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article comprising forming a combustible carbonaceous material into a fuel element adapted for use in a smoking article; incorporating a metal-containing catalyst precursor into the fuel element or onto the surface thereof to form a treated fuel element, the incorporating step occurring before, during, or after said forming step; and optionally heating or irradiating the treated fuel element at a temperature and for a time sufficient to convert the catalyst precursor to a catalytic metal compound. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

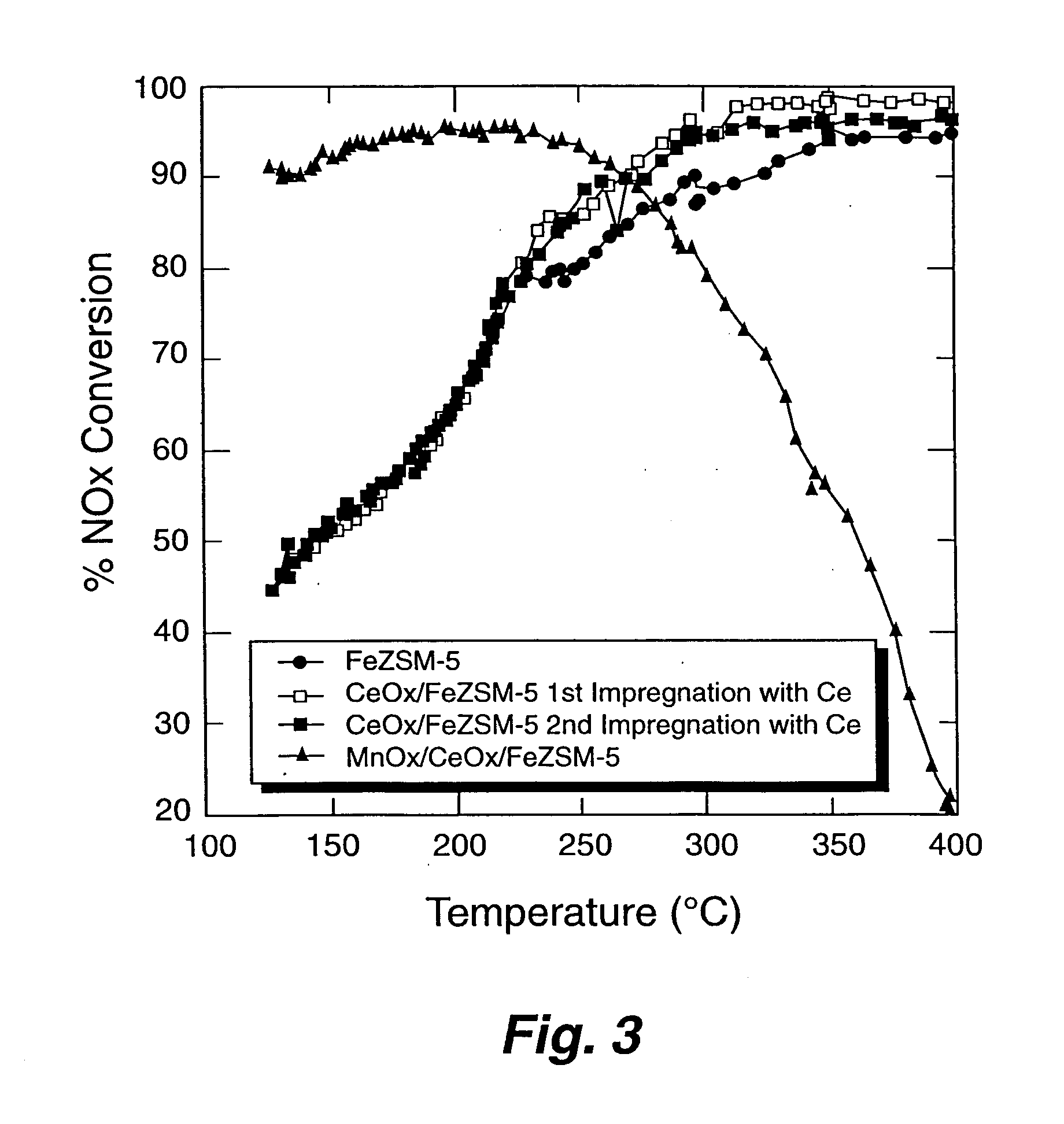

Catalyst and method for reduction of nitrogen oxides

InactiveUS20060029535A1Efficient workSelective catalytic reductionNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

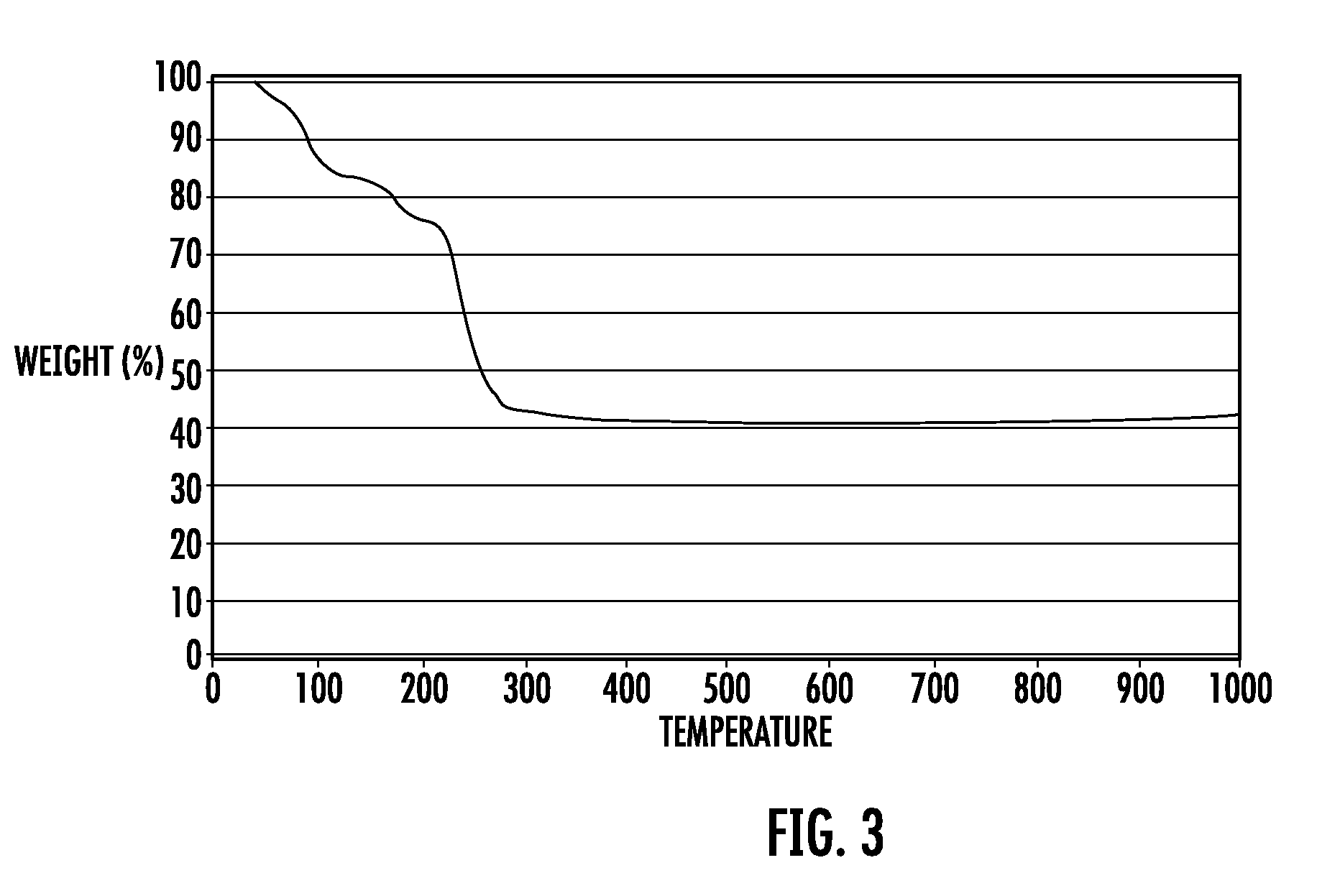

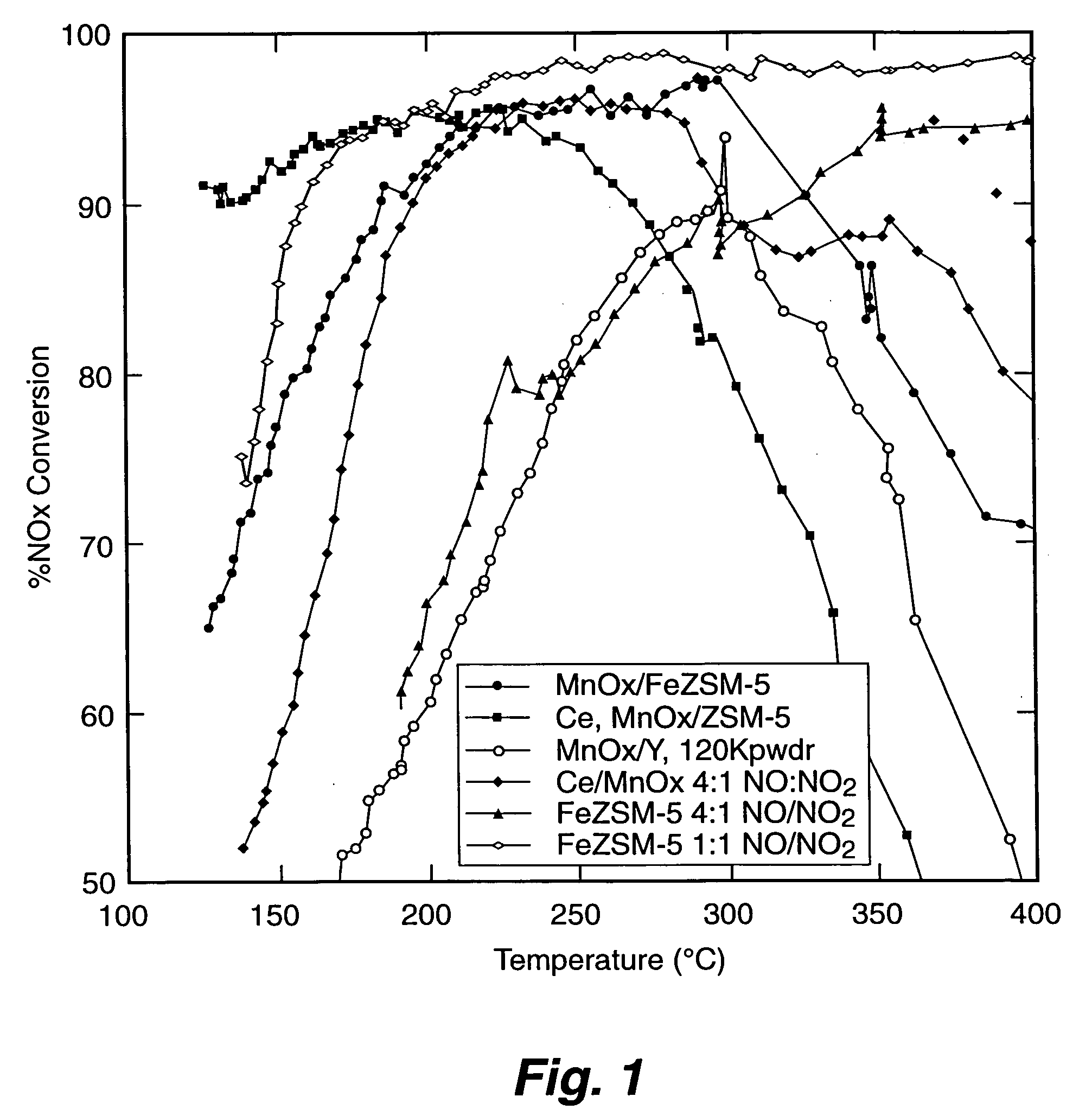

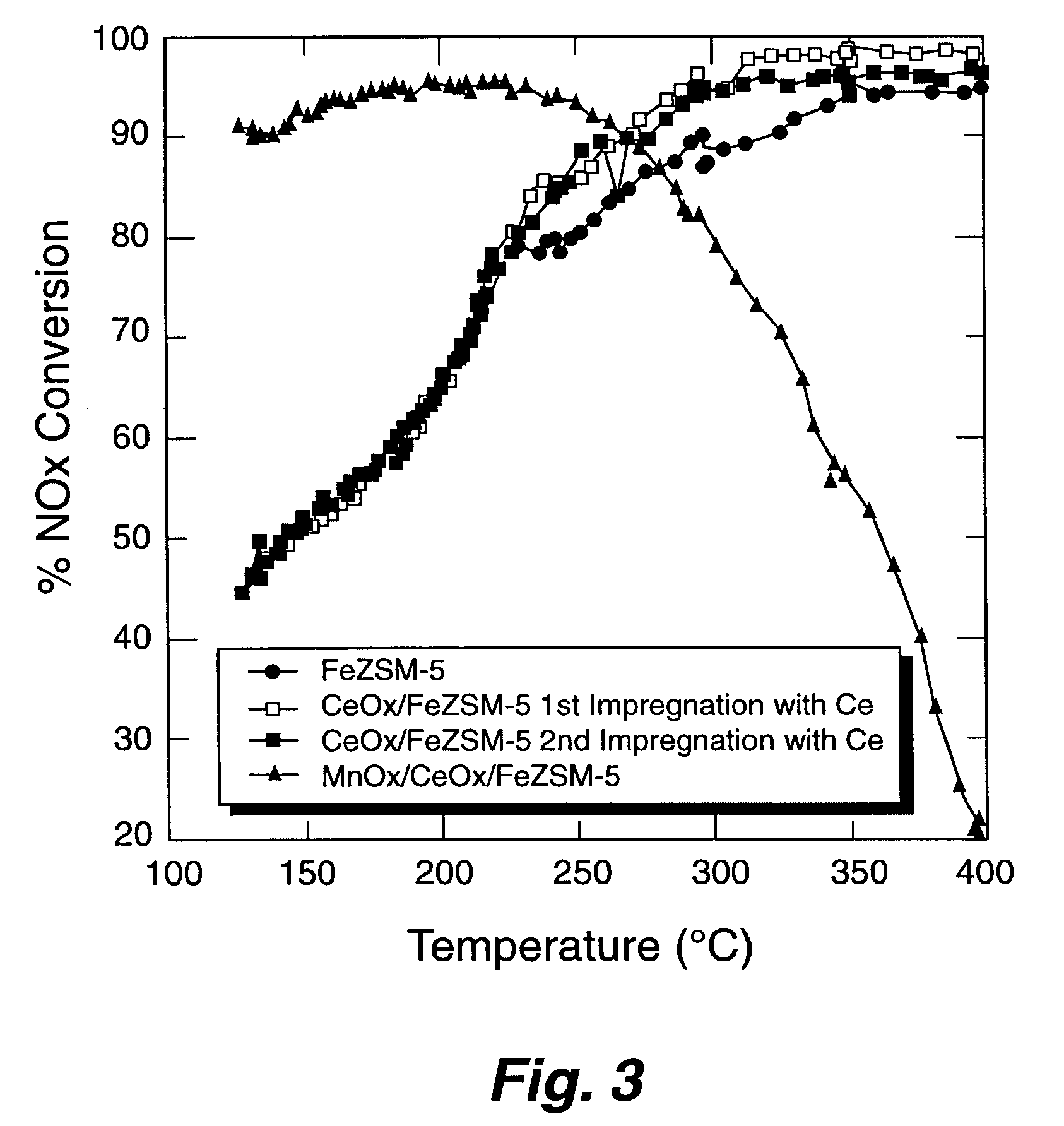

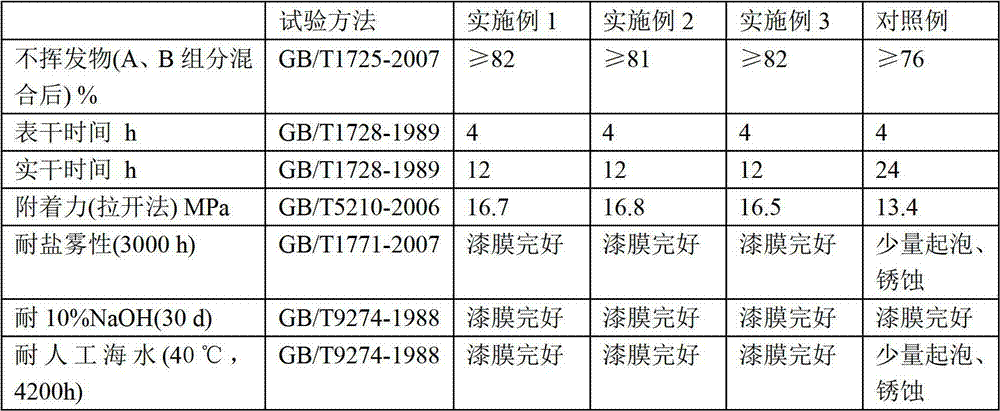

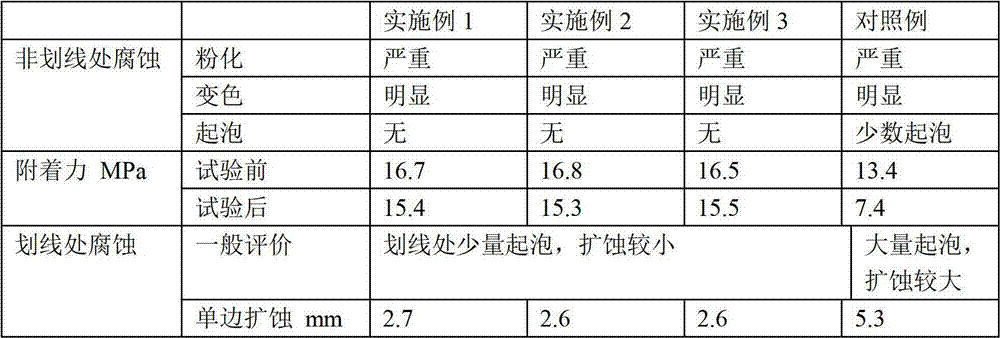

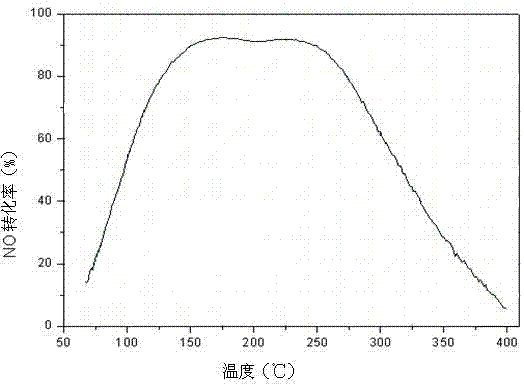

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

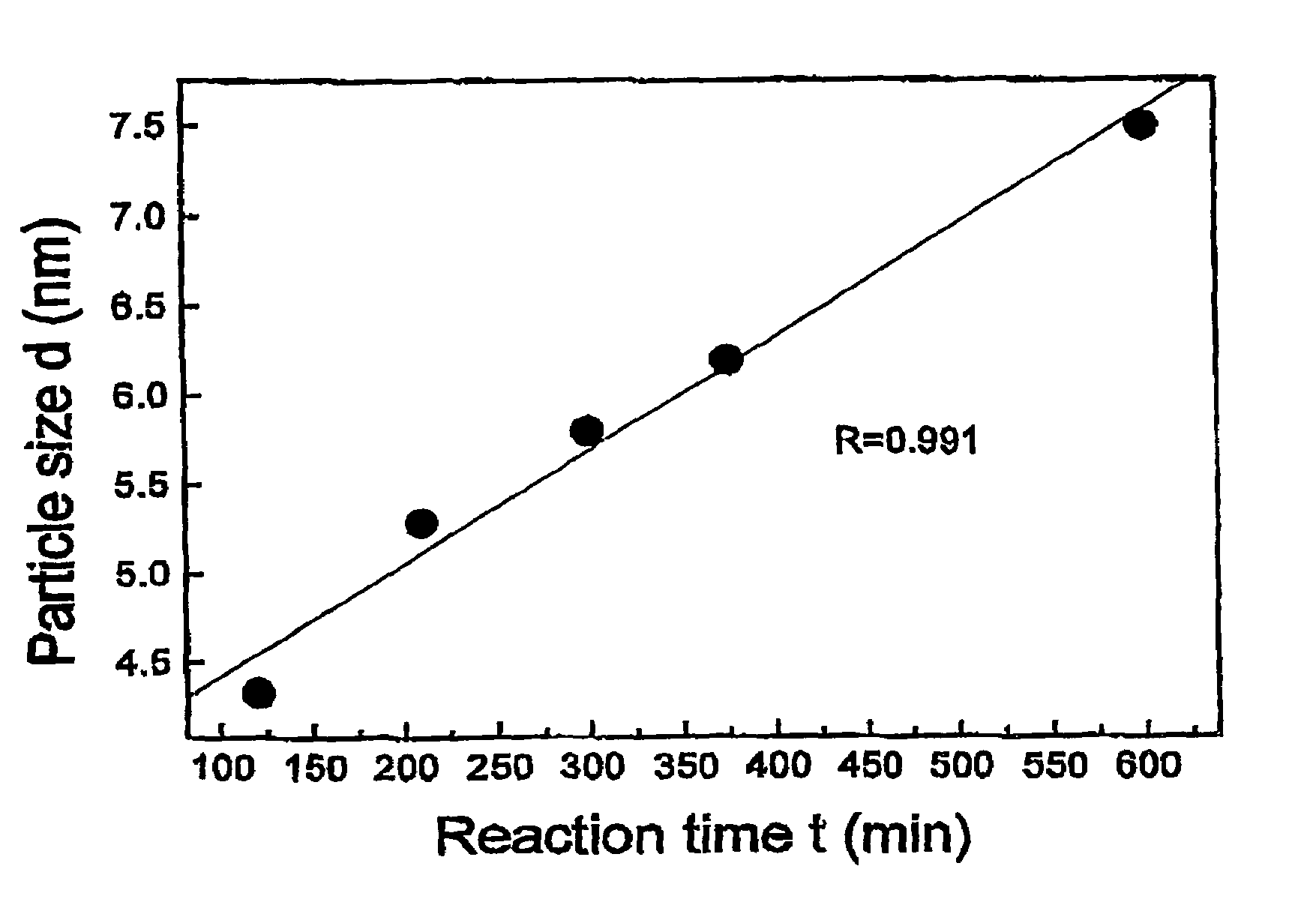

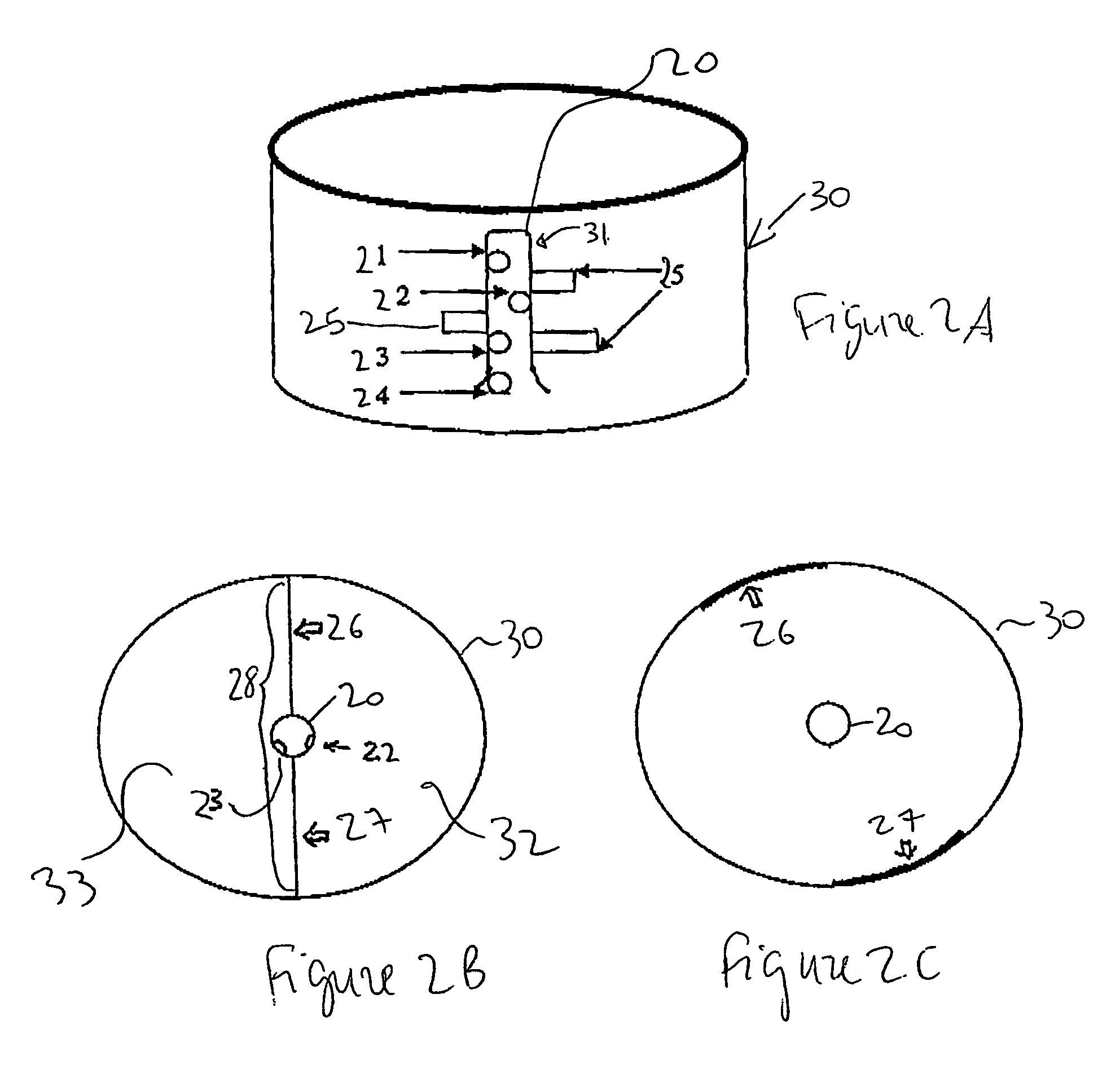

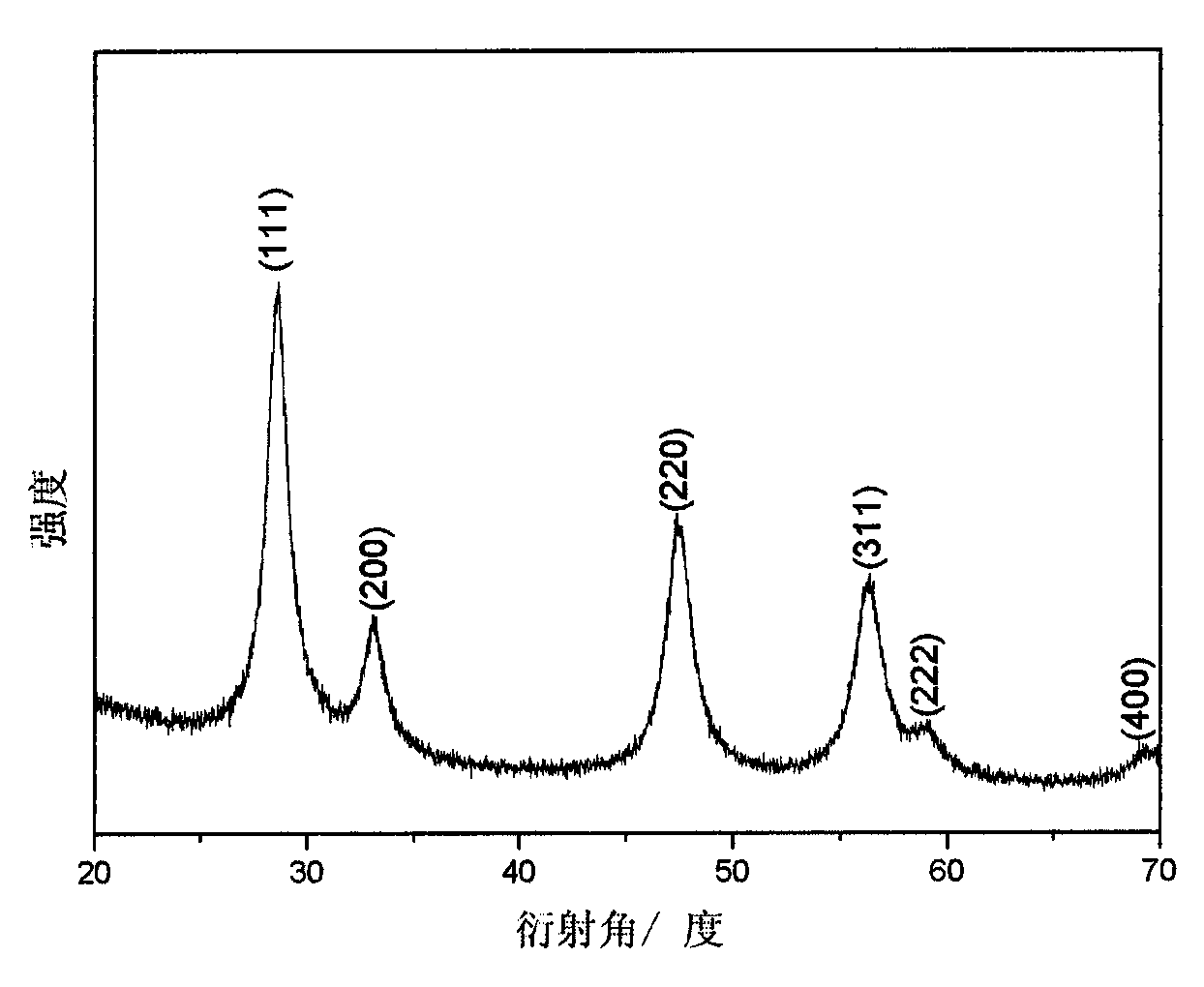

Apparatus and method for preparing cerium oxide nanoparticles

InactiveUS20050031517A1Quick responseReaction time is thus limitedMaterial nanotechnologyMixing methodsCerium nitrateNanoparticle

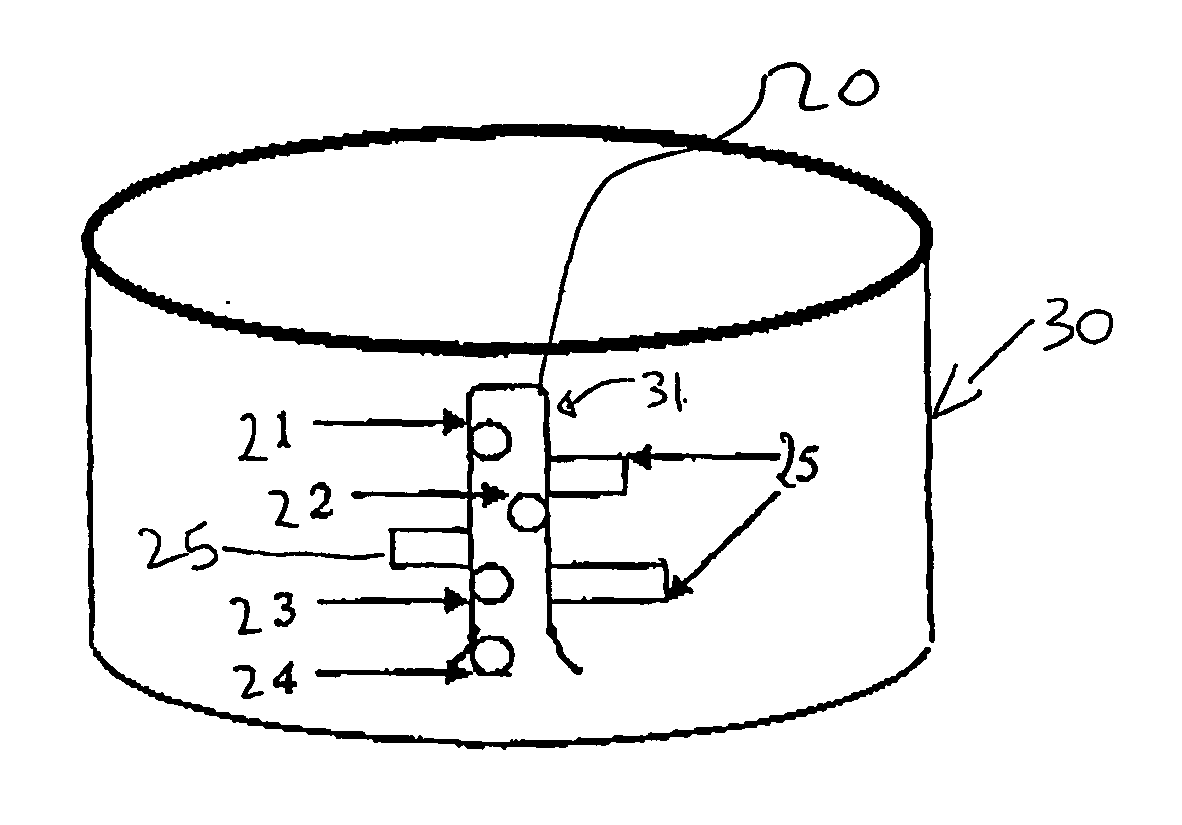

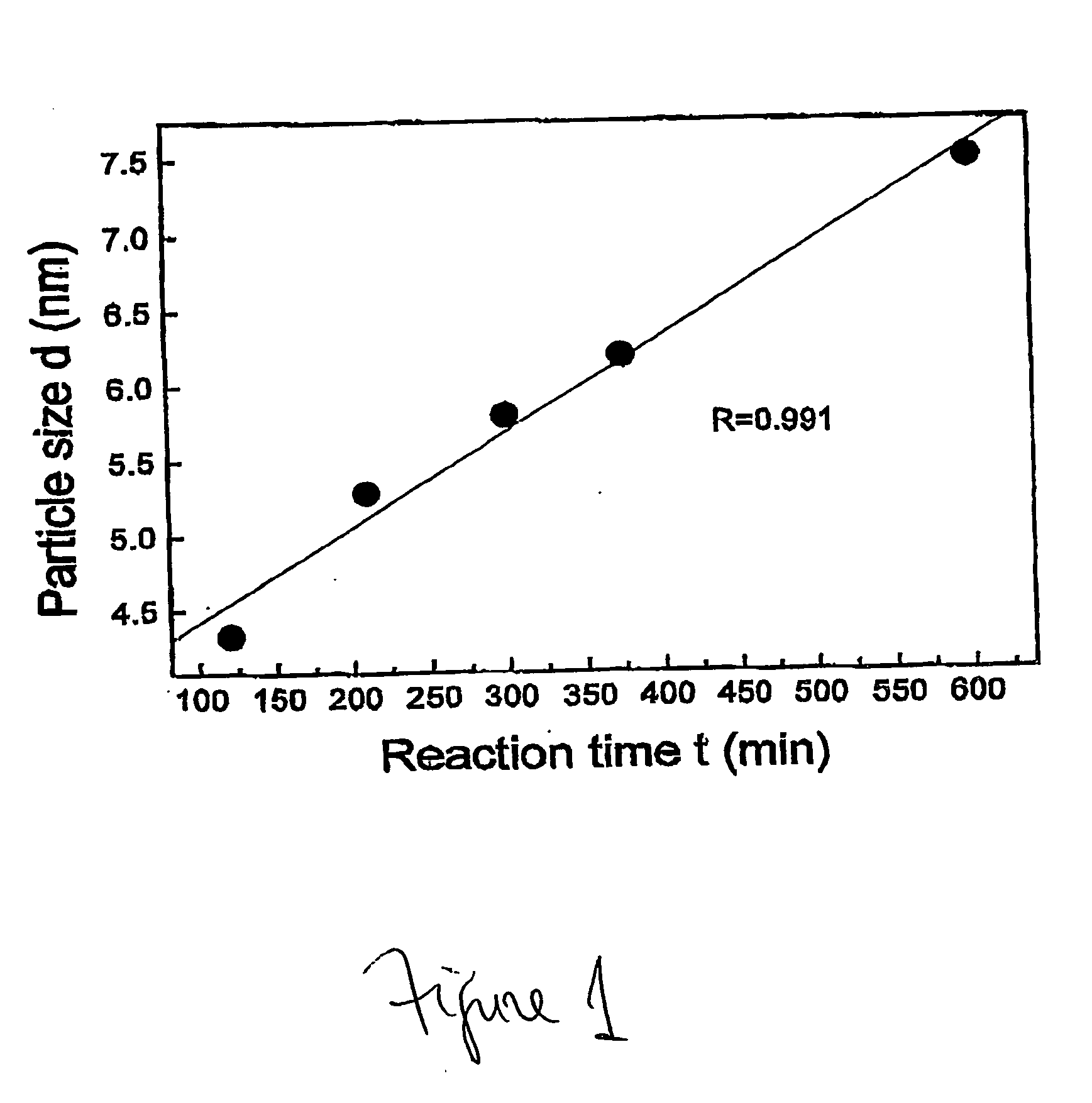

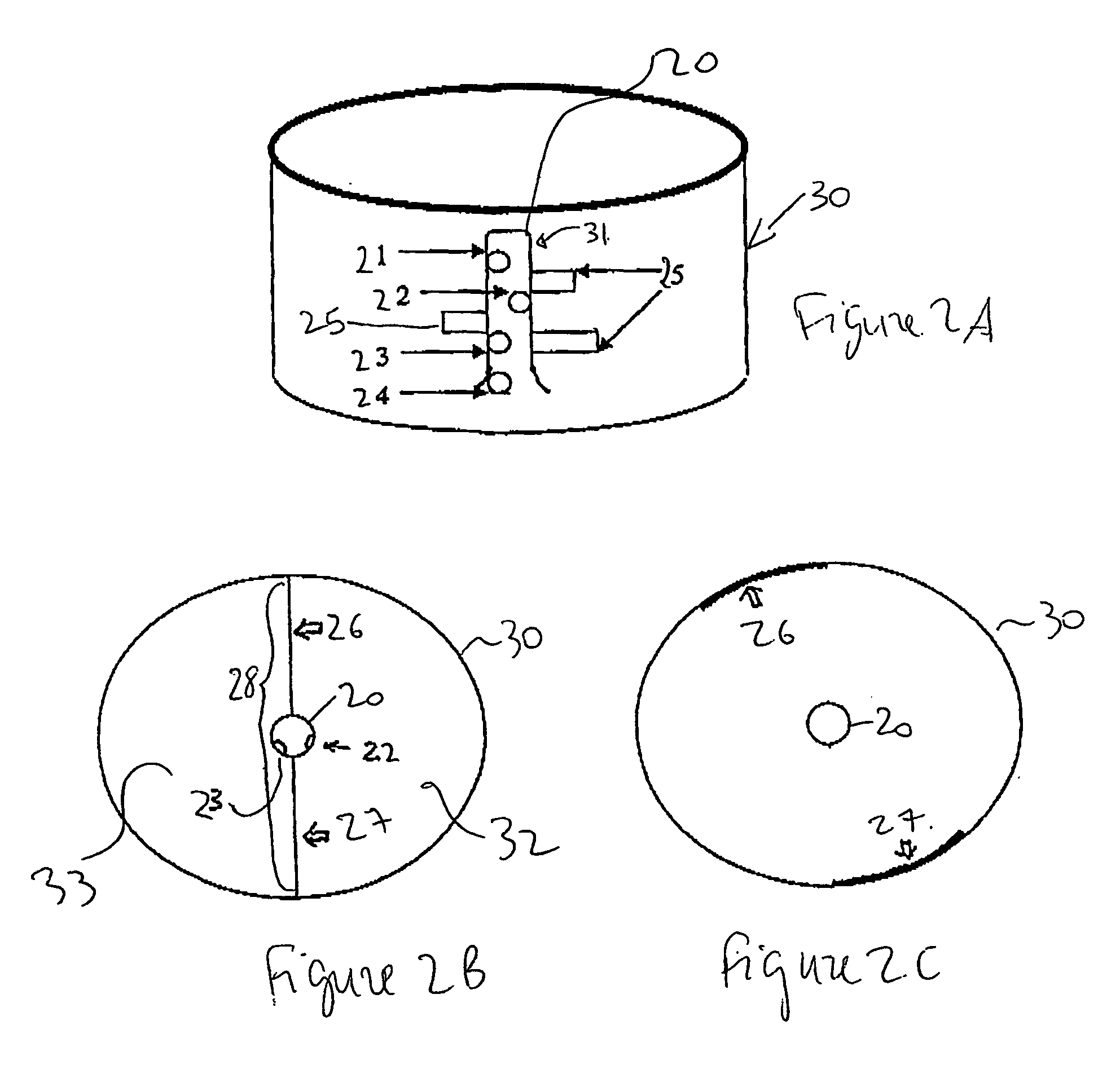

This invention provides a method for preparing cerium oxide nanoparticles with a narrow size distribution. The cerium oxide nanoparticles obtained by the method of the invention are nearly all crystalline. The method comprises providing a first aqueous solution comprising cerium nitrate and providing a second aqueous solution comprising hexamethylenetetramine. The first and second aqueous solutions are mixed to form a mixture, and the mixture is maintained at a temperature no higher than about 320° K to form nanoparticles. The nanoparticles that are formed are then separated from the mixture. A further aspect of the present invention is an apparatus for preparing cerium oxide nanoparticles. The apparatus comprises a mixing vessel having a first compartment for holding a first aqueous solution comprising cerium nitrate and a second compartment for holding a second aqueous solution comprising hexamethylenetetramine. The mixing vessel has a retractable partition separating the first and second compartments. When the retractable partition is retracted, rapid mixing of the first aqueous solution with the second aqueous solution takes place to form a mixture, and the mixture is maintained at a temperature no higher than about 320° K to form nanoparticles therein.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article including the steps of mixing a metal-containing catalyst precursor with a filler material or graphite or a combination thereof to form a pre-treated fuel element component; optionally calcining the pre-treated fuel element component in order to convert the catalyst precursor to a catalytic metal compound; after the optional calcining step, combining the pre-treated fuel element component with a carbonaceous material and a binder to produce a fuel element composition; and forming the fuel element composition into a fuel element adapted for use in a smoking article. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

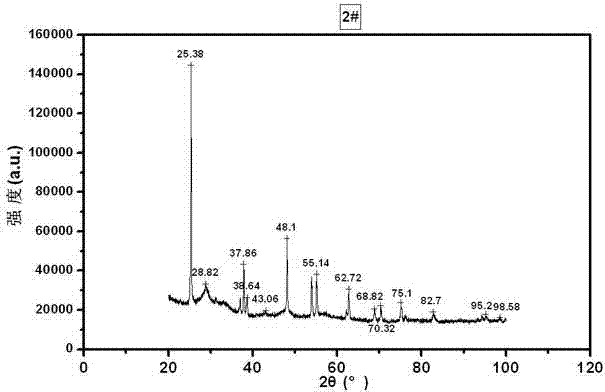

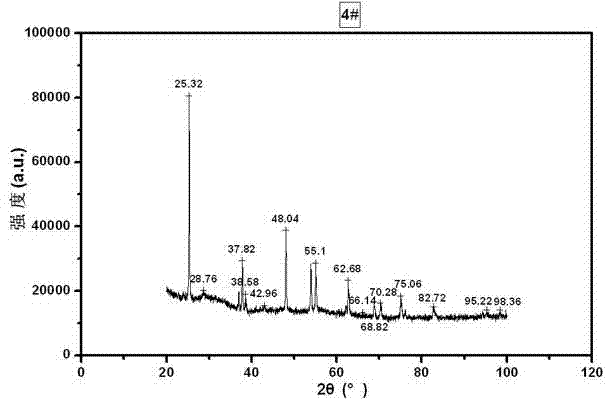

Preparation method of structured flue gas denitration catalyst, prepared catalyst and application of catalyst

ActiveCN102166514AReduce oxidation rateHigh mechanical strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTungstateNitric oxide

The invention relates to a preparation method of structured flue gas denitration catalyst, a prepared catalyst and application of the catalyst. The method comprises the following steps of: pre-mixing TiO2 powder and ammonium meta-tungstate-containing oxalic acid solution to prepare WO3-containing TiO2 powder; mixing the prepared TiO2 powder, an inorganic binder, a plasticizer, glass fibers and sesbania powder in a special mass ratio; adding oxalic acid solution of ammonium metavanadate and aqueous solution of cerous nitrate; mixing the materials; adding ammonia water to adjust the pH value tobetween 9 and 10; ageing the mixture for 5 to 10 days; coating the aged mud material onto a stainless steel net; after rolling the aged mud, forming, and drying and roasting the prepared plate type structural V2O5 / TiO2-based denitration catalyst. The plate type structural V2O5 / TiO2-based denitration catalyst has high mechanical strength and catalytic activity and low SO2 oxidation rate, so the catalyst can be widely applied to the removal of nitric oxide in coal / oil / gas boilers and nitric acid industry.

Owner:CHINA DATANG TECH & ENG

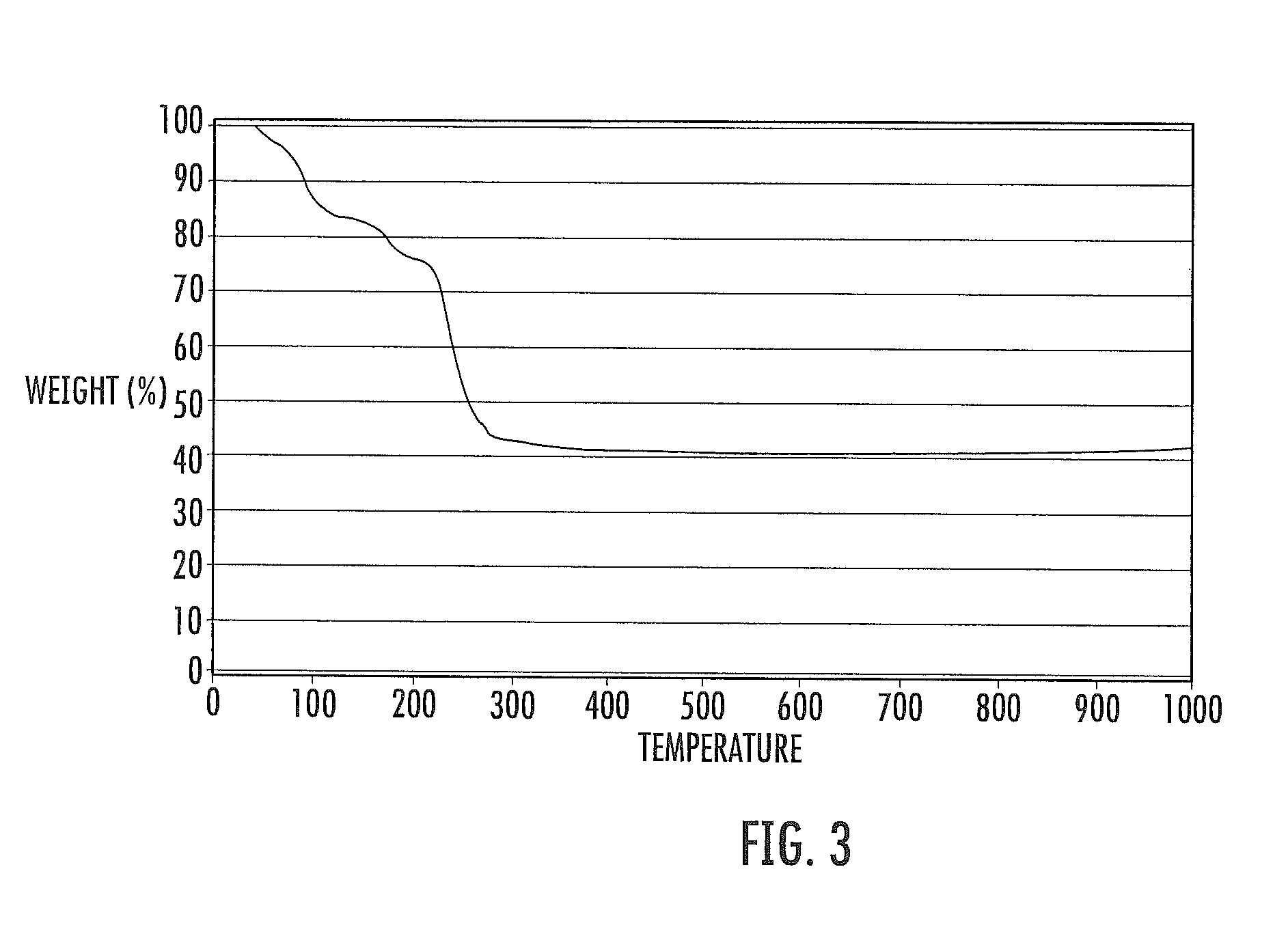

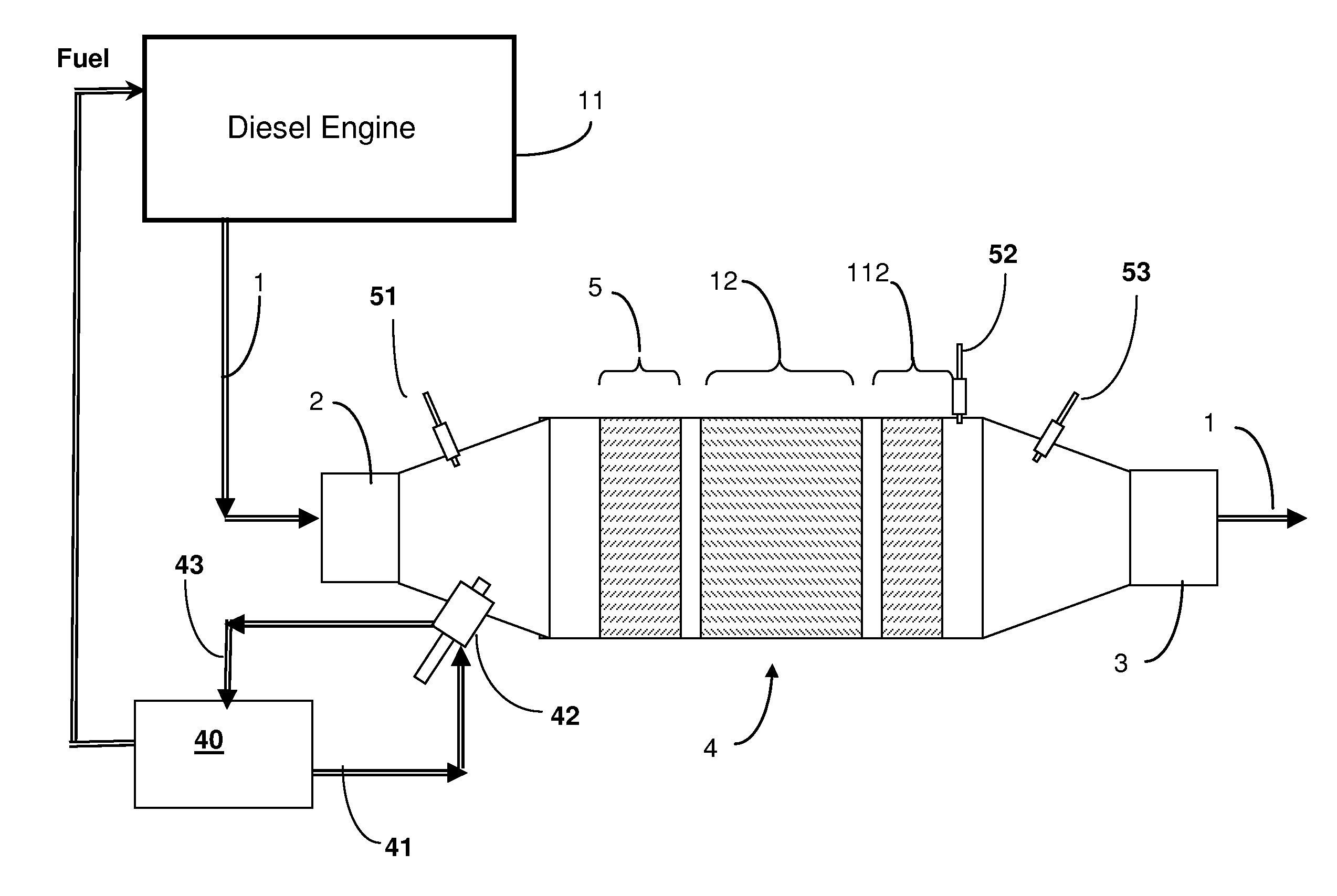

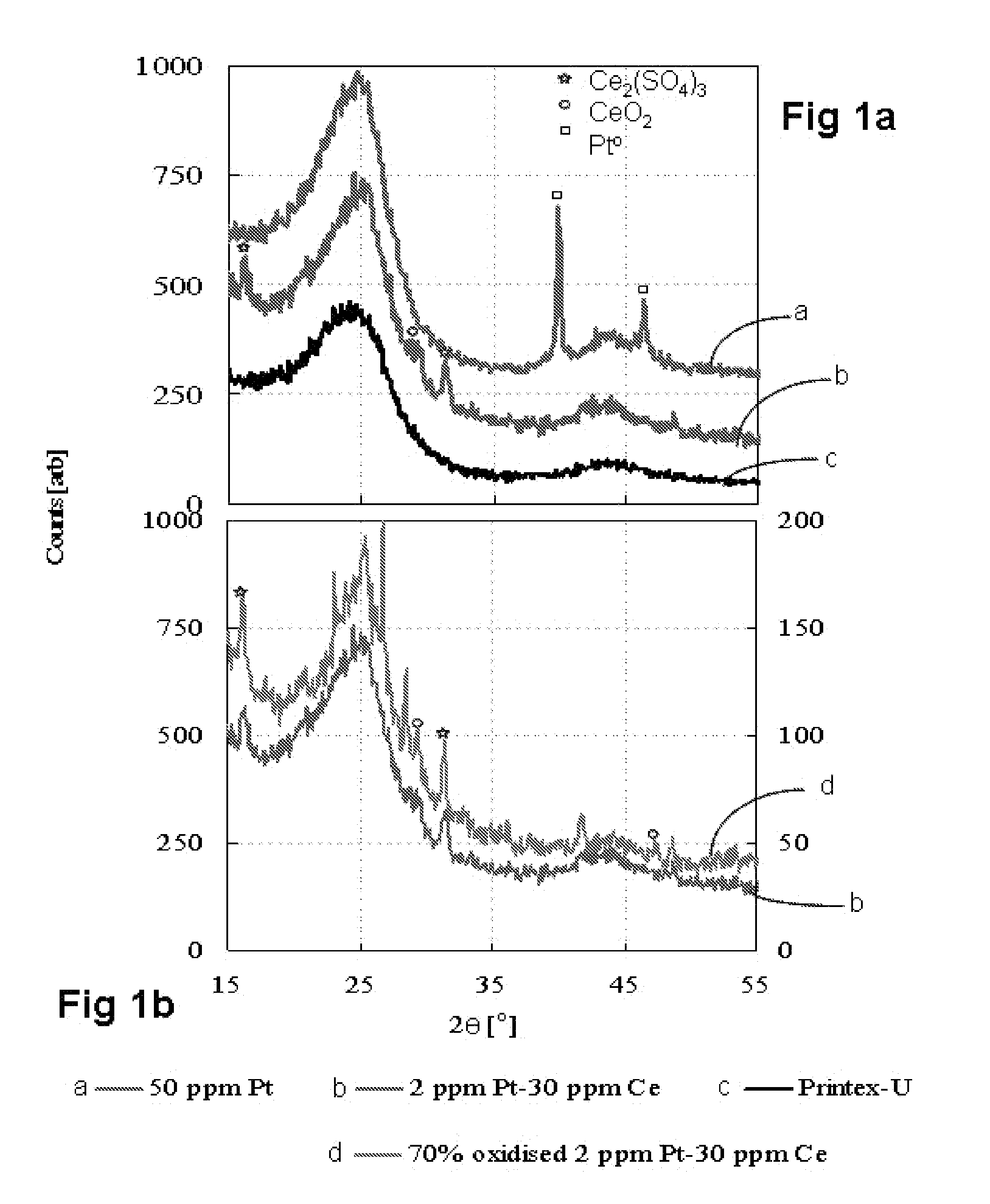

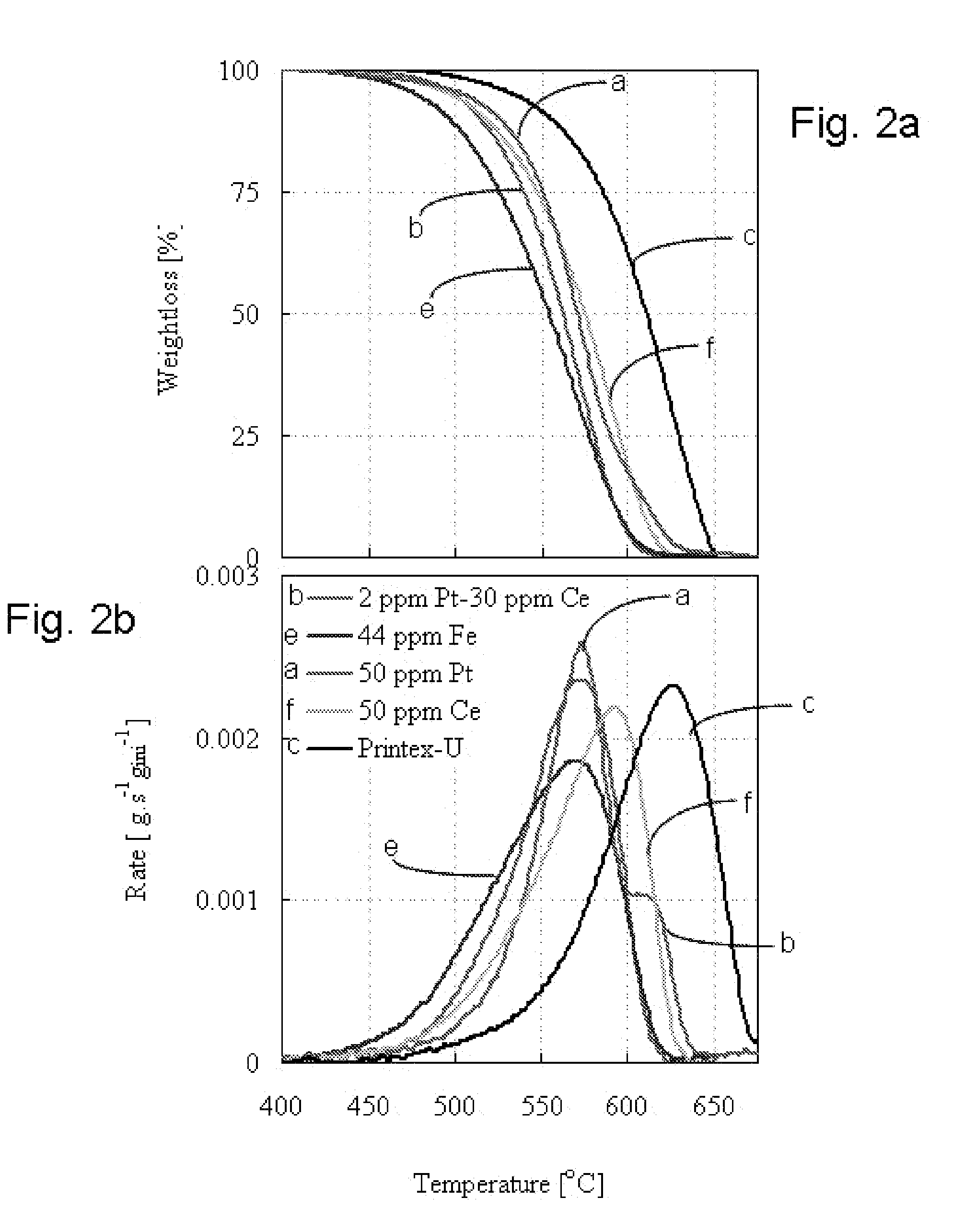

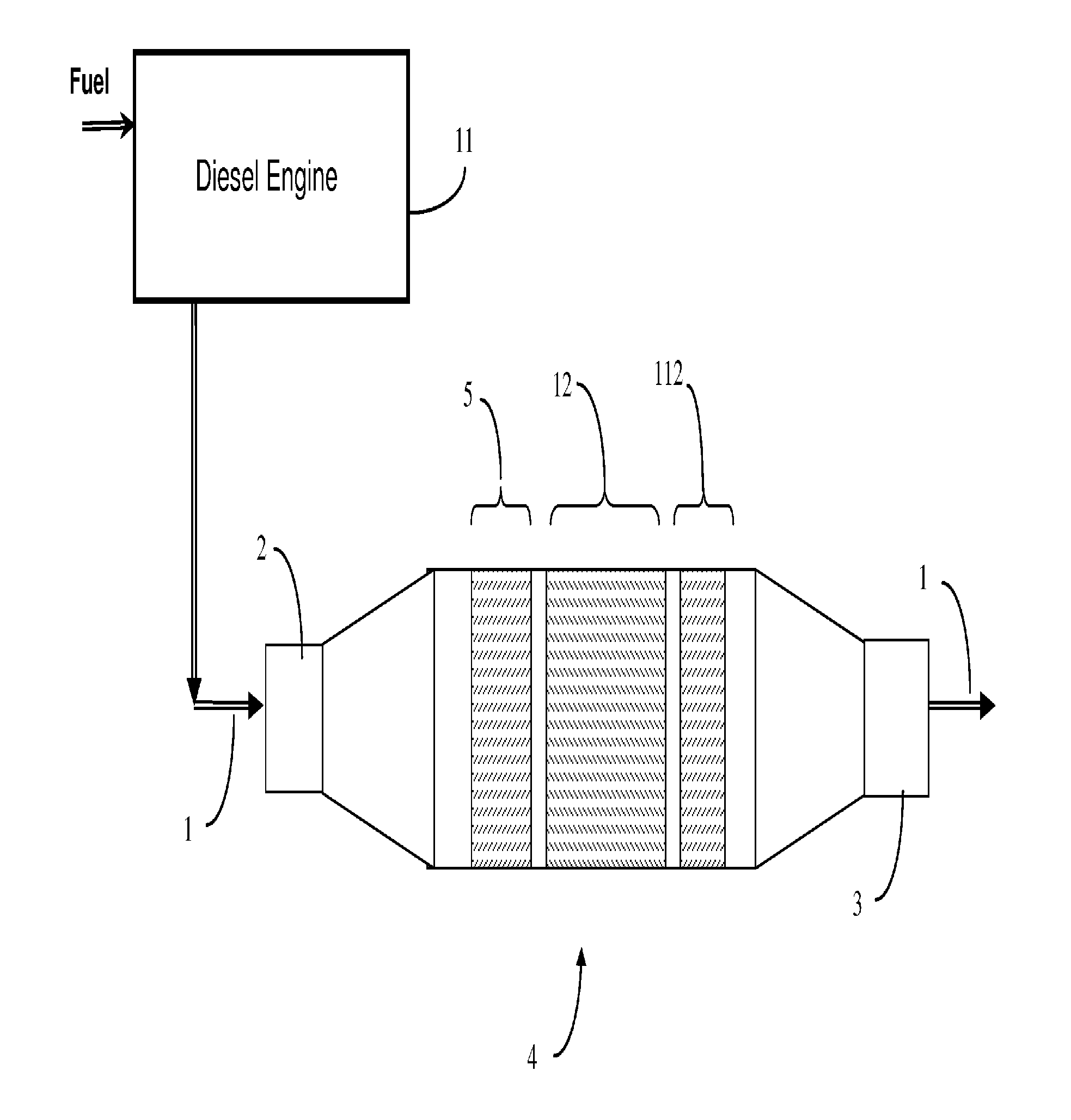

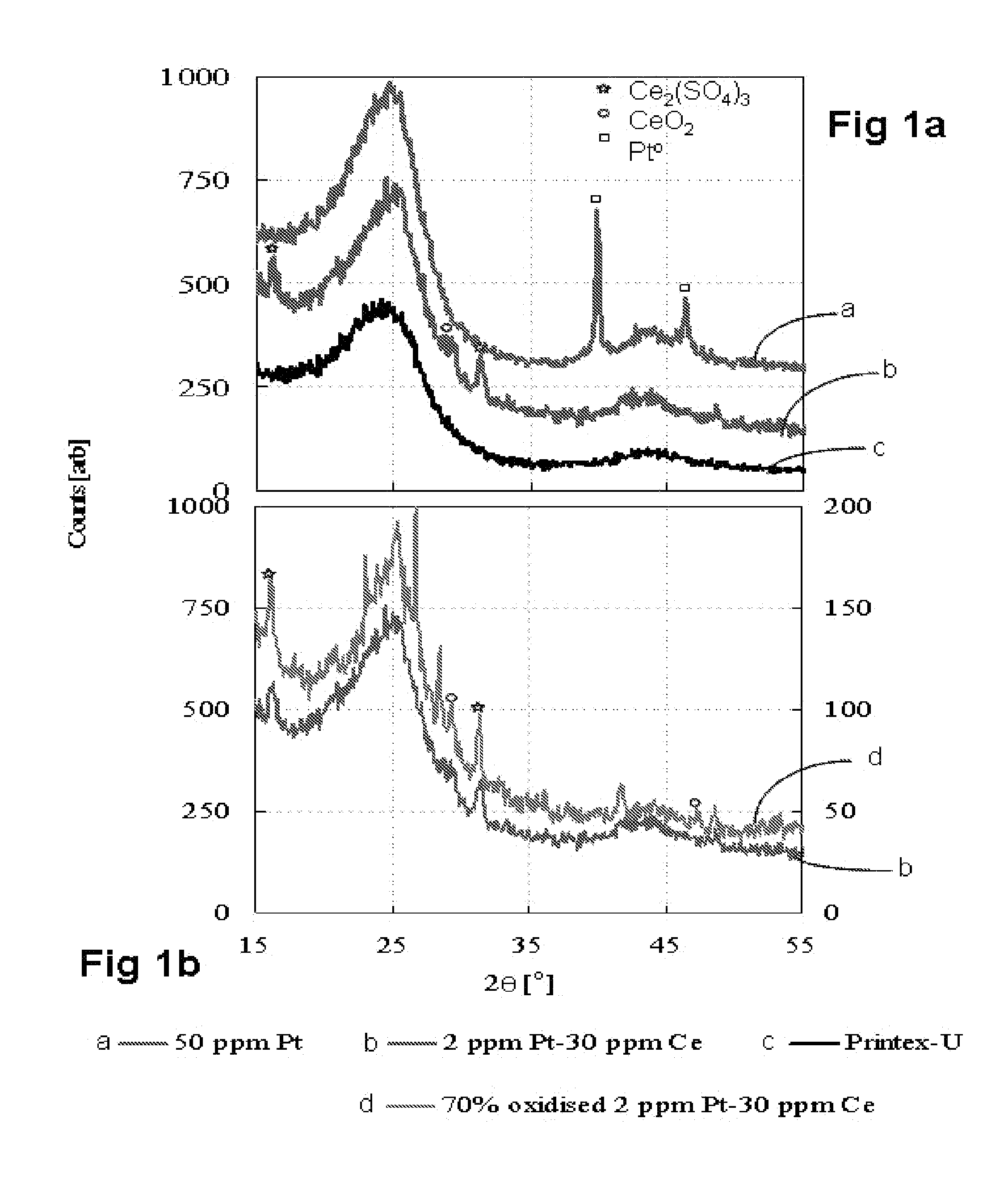

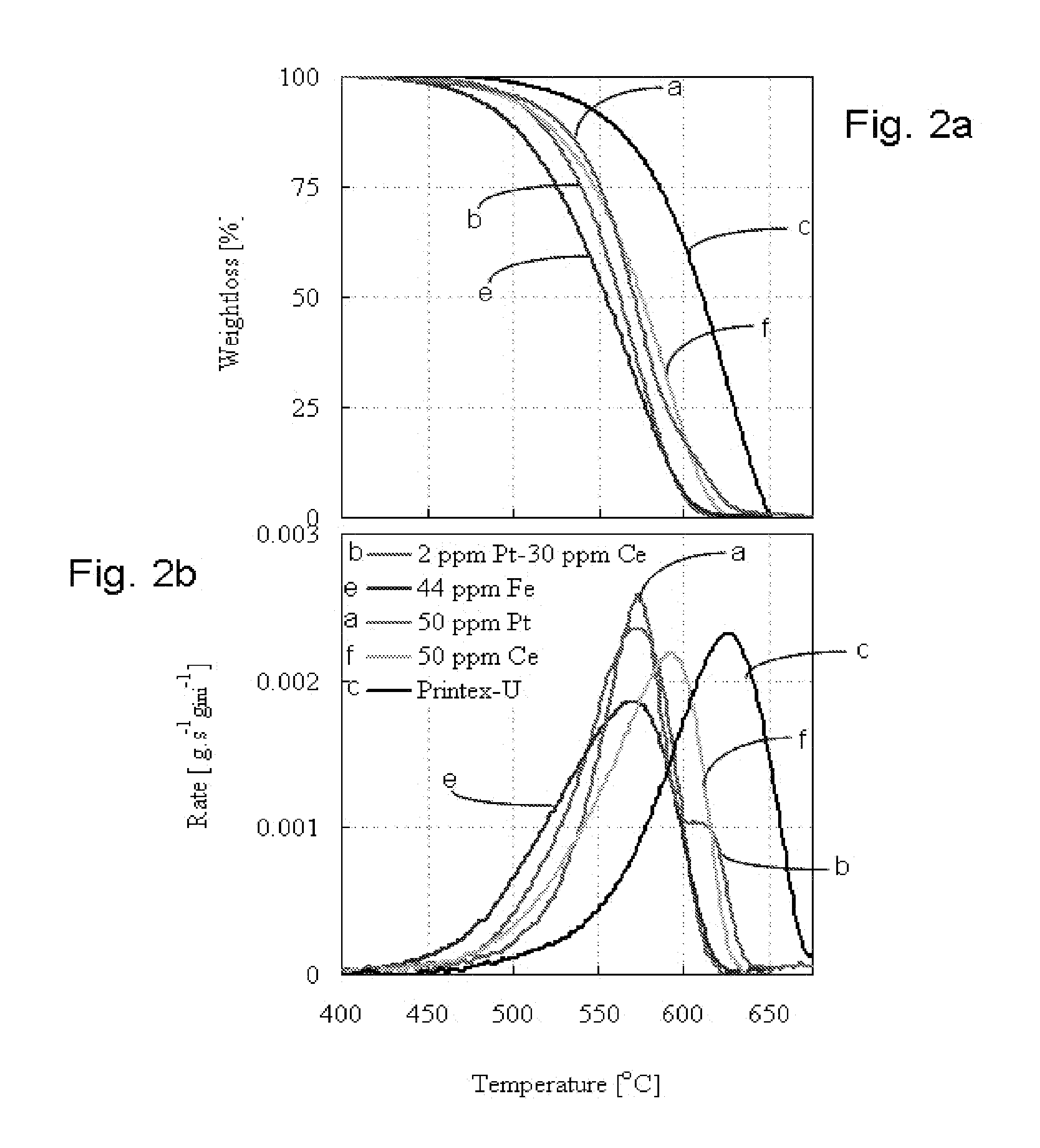

Diesel particulate control

InactiveUS20070283681A1Improve efficiencyImprove featuresCombination devicesNitrogen compoundsParticulatesCerium nitrate

A method and apparatus are provided for reducing emissions of particulates from diesel engines. Exhaust is passed through a diesel particular filter having at least two stages comprised of (a) a catalyst section having a platinum group metal catalyst on contact surfaces within the catalyst section and (b) a filter section comprised of passages effective to remove particulates from a moving stream of combustion gases generated by combusting the fuel in the engine and holding them therein to permit their oxidation. Carbon removal is enhanced by utilizing levels of platinum group metal composition, cerium compositions, fuels and / or optional chemical enhancers to generate NO2 in the catalyst section in amounts sufficient to form cerium nitrates in the filter section. The cerium oxide is associated with and maintains dispersion of the platinum in the filter section, and the cerium nitrates are available at the surface and within the soot particles to provide enhanced soot oxidation at a lower balance point.

Owner:CLEAN DIESEL TECHNOLOGIES

Apparatus and method for preparing cerium oxide nanoparticles

InactiveUS7141227B2Quick responseMaterial nanotechnologyTransportation and packagingCerium nitrateHexamethylenetetramine

This invention provides a method for preparing cerium oxide nanoparticles with a narrow size distribution. The cerium oxide nanoparticles obtained by the method of the invention are nearly all crystalline. The method comprises providing a first aqueous solution comprising cerium nitrate and providing a second aqueous solution comprising hexamethylenetetramine. The first and second aqueous solutions are mixed to form a mixture, and the mixture is maintained at a temperature no higher than about 320° K to form nanoparticles. The nanoparticles that are formed are then separated from the mixture. A further aspect of the present invention is an apparatus for preparing cerium oxide nanoparticles. The apparatus comprises a mixing vessel having a first compartment for holding a first aqueous solution comprising cerium nitrate and a second compartment for holding a second aqueous solution comprising hexamethylenetetramine. The mixing vessel has a retractable partition separating the first and second compartments.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and using method of rare-earth modified Ti-Zr chemical passivation solution

ActiveCN103103512AImprove compactnessImprove performanceMetallic material coating processesCerium nitratePotassium fluoride

The invention discloses a rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and a using method of the rare-earth modified Ti-Zr chemical passivation solution. The rare-earth modified Ti-Zr chemical passivation solution is characterized in that the passivation solution is a main salt for auxiliary film-formation, which takes rare-earth compounds as a Ti-Zr passivation treatment solution, and a passivation film is light yellow in appearance and has field judgement property on the quality of a formed film. A formula of the rare-earth modified Ti-Zr chemical passivation solution is as follows: each litre of solution contains 0.5g.L<-1>-10g.L<-1> of potassium fluotitanate (hexafluorotitanic acid), 0.5g.L<-1>-10g.L<-1> of potassium fluozirconate (fluozirconic acid), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (ceric sulfate and ammonium ceric nitrate), 2g.L<-1>-10g.L<-1> of potassium nitrate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (potassium fluoride), 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate or OP-10, 0.2mL-5mL.L<-1> of nitric acid and 1g.L<-1>-5g.L<-1> of boric acid. The using method of the rare-earth modified Ti-Zr chemical passivation solution comprises the following steps of: (1) clearing dirt, such as dirt attached to an aluminium alloy; (2) pretreating the surface of the aluminium alloy; (3) carrying out passivating treatment on the surface of the aluminium alloy by using the rare-earth modified Ti-Zr chemical passivation solution; and (4) washing the aluminium alloy by using water and drying the aluminium alloy. The rare-earth modified Ti-Zr chemical passivation solution disclosed by the invention has the advantages of light yellow appearance, high film formation speed, simple process, uniformity in film layer, strong corrosion resistance, low environment pollution and the like.

Owner:GUANGDONG XINGFA ALUMINUM

Method for preparing cerium oxide rhombus nano sheet-shaped material

ActiveCN101264922AProcess stabilityEasy to operateNanostructure manufactureRare earth metal compoundsCerium nitrateUltraviolet lights

The invention relates to a preparation method for cerium oxide rhombus nanometer sheet material, belonging to the technical field of preparation process for the inorganic nanometer material. The preparation method is characterized in that by using heating backflow method, three-valent cerium nitrate is organic or inorganic solvent in which surfactant and precipitant exist, then the solution goes through ultrasonic dispersion for 20 to 30 minutes, and enters heating backflow reaction process; the temperature for the heating backflow reaction is 90 to 140 DEG C, and the reaction time lasts 2 to 10 hours; subsequently, suction filtering or centrifugal separation is conducted, the resultant precipitate is washed to be neutral, then washed by alcohol, and dried under 60 DEG C; next, the precipitate is calcined under the temperature of 400 to 600 DEG C for 2 to 6 hours, finally, the CeO2 rhombus nanometer sheet microcrystal material is obtained. Furthermore, the acquired CeO2 material enjoys tremendous potential application prospects in the fields of shielding ultraviolet light and automobile exhaust catalysis.

Owner:SHANGHAI UNIV

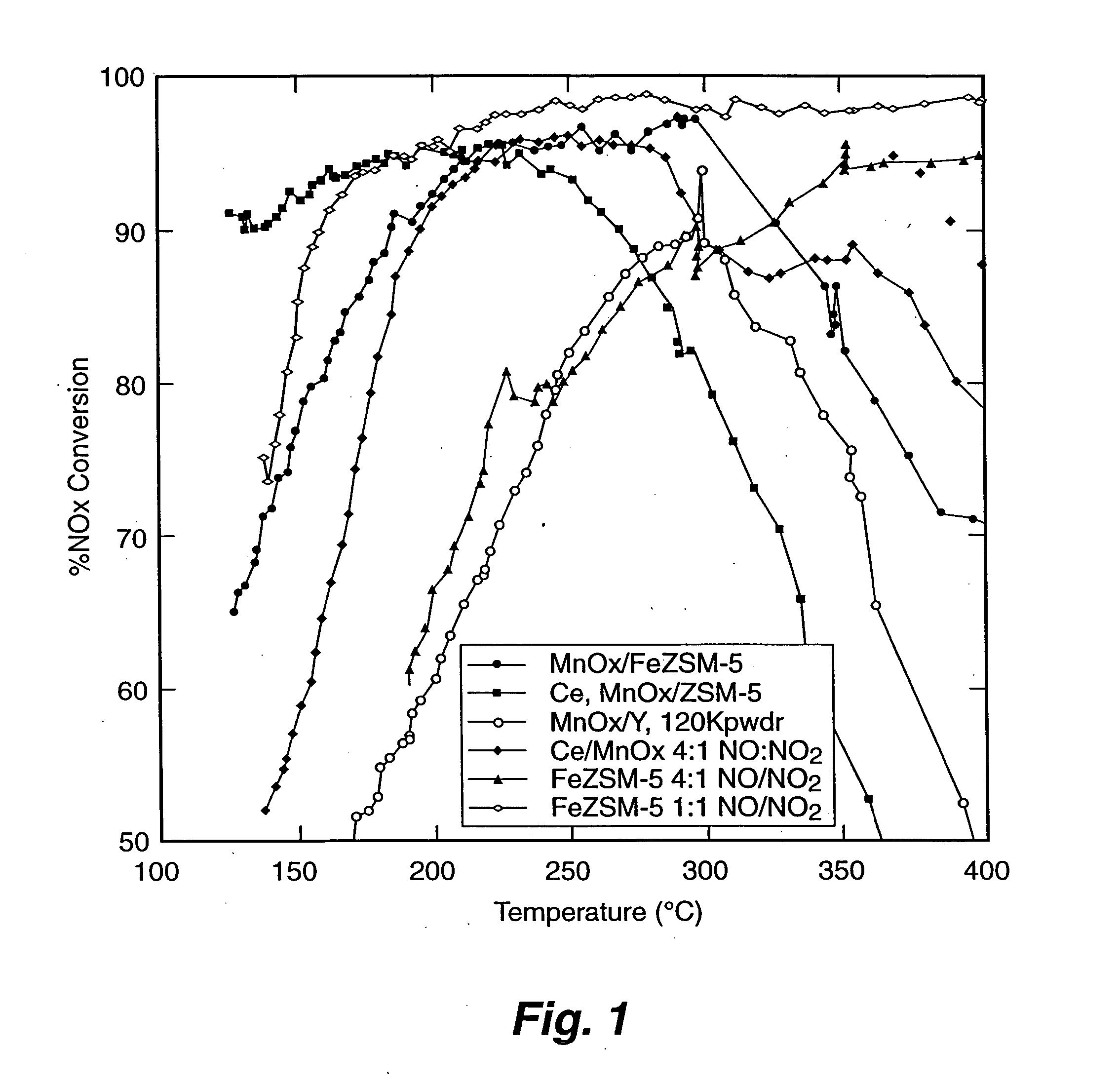

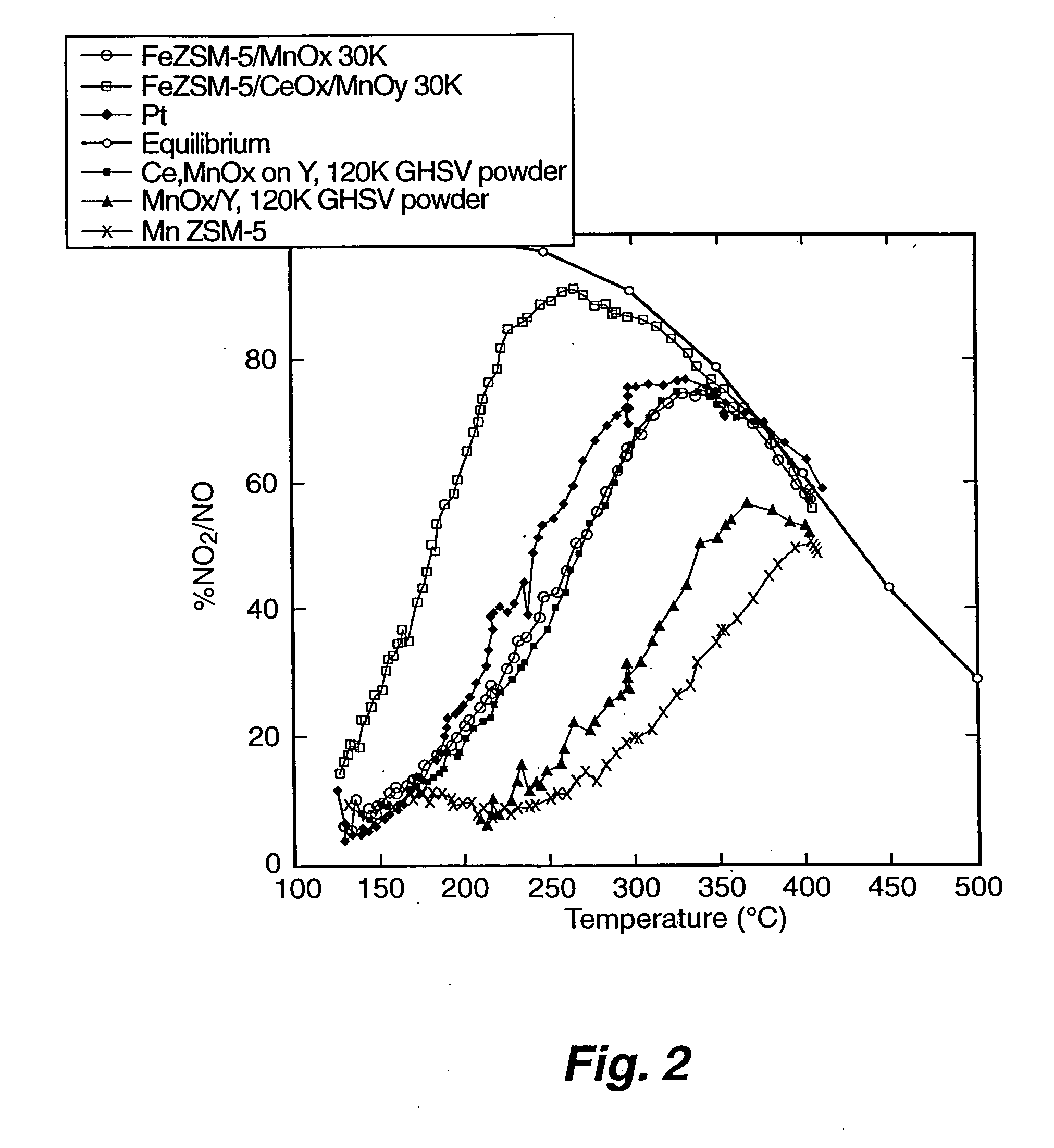

Seawater corrosion-resistant paint

InactiveCN102876192AStrong resistance to seawater corrosionChloropene polymer coatingsAnti-corrosive paintsEpoxyCerium nitrate

The invention provides seawater corrosion-resistant paint which comprises component A and component B. The component A comprises the following materials by weight: 20-30 parts of epoxy resin, 10-20 parts of petroleum resin, 5-10 parts of chloroprene rubber, 3-6 parts of polytetrafluoroethylene, 2-8 parts of polyvinyl acetate, 2-4 parts of a coupling agent, 1-2 parts of a defoaming agent, 5-8 parts of silica sol, 1-2 parts of cerium nitrate, 1-2 parts of montmorillonite, 1-2 parts of iron red, 4-6 parts of zinc phosphate, 2-3 parts of barium sulfate, 3-4 parts of aluminum tripolyphosphate, 1-2 parts of titanium oxide, 4-7 parts of zinc oxide, 25-35 parts of and solvent. The component B comprises the following materials by weight: 20-35 parts of a curing agent, and 15-20 parts of butanol. The inventive paint has excellent seawater corrosion resistance, salt fog resistance above 2,000 hr, 10% NaOH solution resistance above 30 days, and artificial seawater resistance above 4,200 hr.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

Micro-ball iron-based catalyst for Fischer-Tropsch synthesis and its preparation and use

ActiveCN1583259AEasy to prepareGood sphericityHydrocarbon from carbon oxidesCatalyst activation/preparationNitrateCerium nitrate

A microspherical Fe-base catalyst for slurry-bed Fischer-Tropsch synthesis contains Fe, Ce, Cu, K and SiO2. Its preparing process includes such steps as preparing the deposit slurry from the mixed solution of iron nitrate, cerium nitrate, copper acetate, and sodium carbonate, adding the mixed solution of K2C2O4 and silica sol, spray drying, and calcining.

Owner:SYNFUELS CHINA TECH CO LTD

Catalyst and method for reduction of nitrogen oxides

InactiveUS20060159607A1Reduce the temperatureNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

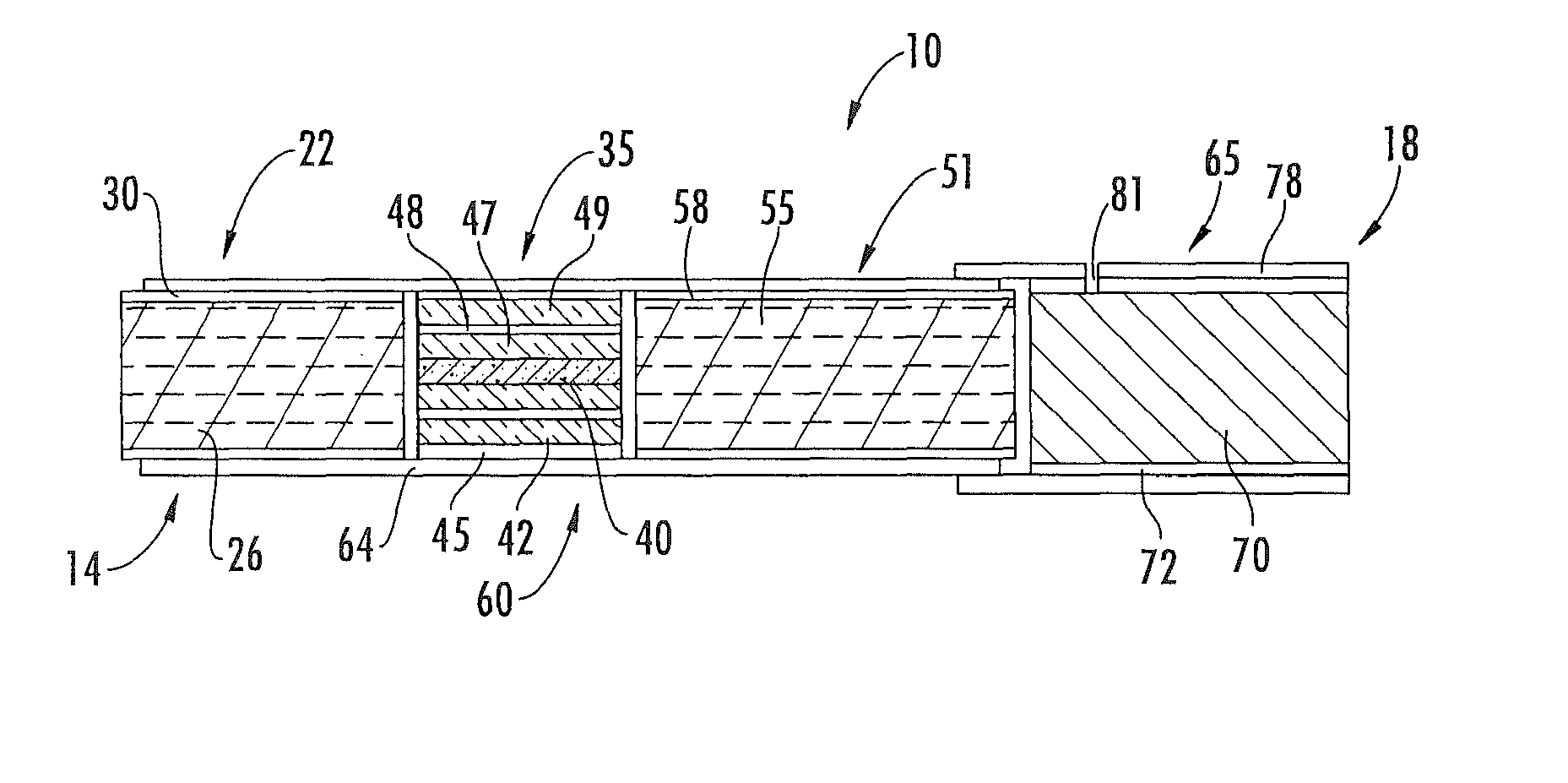

Diesel Particulate Control

InactiveUS20110239626A1Improve efficiencyImprove featuresInternal combustion piston enginesExhaust apparatusParticulatesCerium nitrate

A method and apparatus are provided for reducing emissions of particulates from diesel engines. Exhaust is passed through a diesel particular filter having at least two stages comprised of (a) a catalyst section having a platinum group metal catalyst on contact surfaces within the catalyst section and (b) a filter section comprised of passages effective to remove particulates from a moving stream of combustion gases generated by combusting the fuel in the engine and holding them therein to permit their oxidation. Carbon removal is enhanced by utilizing levels of platinum group metal composition, cerium compositions, fuels and / or optional chemical enhancers to generate NO2 in the catalyst section in amounts sufficient to form cerium nitrates in the filter section. The cerium oxide is associated with and maintains dispersion of the platinum in the filter section, and the cerium nitrates are available at the surface and within the soot particles to provide enhanced soot oxidation at a lower balance point.

Owner:CLEAN DIESEL TECHNOLOGIES

Cerium-doped nano titanium dioxide/activated carbon fiber composite photocatalyst for air purification and preparation method thereof

ActiveCN102658115AEnhance the quantum effectImprove photocatalytic activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonFiber

The invention discloses a cerium-doped nano titanium dioxide / activated carbon fiber composite photocatalyst for air purification and a preparation method thereof. The preparation method comprises the following steps: doping cerium nitrate into nano titanium dioxide to obtain the cerium-doped nano titanium dioxide suspension, putting proper amount of activated carbon fiber into the suspension, soaking for 20-60 minutes under ultrasonic conditions, taking out, airing, and keeping the temperature at 200-220 DEG C for 2-4 hours, thereby obtaining the cerium-doped nano titanium dioxide / activated carbon fiber composite photocatalyst for air purification. Compared with the prior art, the rare-earth cerium is doped into the nano titanium dioxide, thereby prolonging the service life of photovoltaic electron-hole pairs, enhancing the quantum effect of the nano titanium dioxide, and further enhancing the photocatalytic activity of the nano titanium dioxide; and the whole method is simple and easy to control; and the product prepared by the method has high degradation efficiency for volatile organic pollutants, especially formaldehyde gas, reaching more than 90%.

Owner:ZHEJIANG GLOBALVILLAGE TECH INNOVATION CO LTD

Preparation of rare earth ammonium bimolybdate

InactiveCN1644512AReduce microhardnessEasy to processMolybdeum compoundsRare earth metal compoundsCerium nitrateNitrate

Production of rare earth ammonium dimolybdate is carried out by adding ammonium tetramolybdate with ammonium tetramolybdate : soft water: ammonia water = 1kg: 4-5L: 1L, heating agitating, forming mother liquid, regulating the pH value of mother liquid between 7-8.5, adding the cerium nitrates, lanthanum nitrates or illinium nitrates into the mother liquid, heating evaporating for 2.0-6.0hrs with heating temperature 100deg.C-130deg.C until the solution transparent, discharging the materials, pumping filtering, drying with temperature 110-150deg.C for 6-8hrs, and obtaining the rare earth ammonium dimolybdate. It achieves low cost, higher material processing and using performance and no environmental pollution.

Owner:临沂市科创材料有限公司

Iron-based low-temperature SCR denitration catalyst and preparation method thereof

InactiveCN104722307AObvious cost advantageLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereCerium nitrate

The invention provides an iron-based low-temperature SCR denitration catalyst and a preparation method thereof. Iron and cerium compounds are taken as active components, or iron, manganese and cerium compounds are taken as active components, titanium oxide is taken as a carrier, the molar ratio of iron, manganese and cerium is 1:(0.5-4):(0.5-1.5), and the molar ratio of iron and titanium oxide is 0.15-0.25. The preparation method comprises the steps of dissolving iron nitrate, manganese nitrate and cerium nitrate in deionized water, adding the titanium oxide, stirring intensely so as to mix the above compounds thoroughly, then performing ultrasonic mixing, putting the mixture into an oven for drying, calcining in an air atmosphere, and then grinding the mixture into powder. The iron-based low-temperature SCR denitration catalyst provided by the invention has an obvious advantage in cost, and meanwhile, the iron-based low-temperature SCR denitration catalyst has higher denitration efficiency under a medium and low temperature.

Owner:STATE GRID CORP OF CHINA +2

Smokeless polishing treatment solution for high-gloss aluminum profile and method of use

The invention provides a smoke-free polishing treatment solution for a high-gloss aluminum sectional material and a use method thereof. The smoke-free polishing treatment solution is characterized by comprising 85% H3PO4, 98% H2SO4, 30% hydrogen peroxide or potassium permanganate or perchloric acid or sodium molybdate or ammonium persulfate or sodium vanadate, cerium nitrate or sodium silicate, imidazoline or benzotriazole or phytic acid or thiourea, sodium dodecyl benzene sulfonate or sodium benzene sulfonate or sodium toluene sulfonate or sodium xylene sulfonate, and nickel chloride or nickel sulfate or lead acetate. Compared with the prior art, the smoke-free polishing treatment solution provided by the invention has advantage of no generation of high-pollution NOx yellow smoke, and enables the surface of the aluminum sectional material to have excellent gloss and no pitting microscopic defects.

Owner:GUANGDONG XINGFA ALUMINUM

Low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and preparation method and application thereof

InactiveCN103433033AHigh activityImprove operating economyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAluminium nitrateCerium nitrate

The invention discloses a low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and a preparation method and an application thereof. The low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is composed of carriers and active components, wherein the carriers are TiO2 and Al2O3 and the active components are MnOx and CeO2. The molar ratio of Ce:Ti:Al:Mn in the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is 0.2-0.4:1:1:0.4-1.2. The preparation method is that: the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is prepared by taking titanium sulfate, aluminium nitrate, manganous nitrate and cerium nitrate as precursors and employing a coprecipitation method. The preparation cost is low, and the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 has better denitration effect in a flue gas at a temperature of 150-300 DEG C.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Mesoporous metal oxide catalyst for photo-catalytic CO2 reduction and preparation method

InactiveCN104549412ALarge specific surface areaLarge pore volumeHydrocarbon from carbon oxidesMolecular sieve catalystsCerium nitratePtru catalyst

The invention discloses a mesoporous metal oxide catalyst for photo-catalytic CO2 reduction and a preparation method. The mesoporous metal oxide catalyst for the photo-catalytic CO2 reduction consists of an active component and a doping agent, wherein the active component is mesoporous CeO2, and the doping agent is transition metal ions. In the preparation process, transition metal nitrate and cerium nitrate are dissolved into acetone, mesoporous silica materials are added into an obtained metal nitrate acetone solution and are uniformly mixed, the mixture is naturally dried to obtain first powder, the first powder is calcined in a muffle furnace to obtain second powder, the second powder is etched by using a sodium hydroxide aqueous solution to remove the mesoporous silica materials, and the second powder is washed by using pure water and then is dried to obtain the mesoporous metal oxide catalyst for the photo-catalytic CO2 reduction, which has higher specific surface area, larger aperture and a regular pore structure. The mesoporous metal oxide catalyst is high in activity and selectivity in terms of photo-catalytic CO2 conversion, and the preparation method is relatively simple, and easy to expand.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Low-temperature preparation method of ceria nano-crystalline microsphere of graduation structure

InactiveCN101584981ASimple processEasy to controlOther chemical processesRare earth metal compoundsCerium nitrateHigh absorption

The invention discloses a low-temperature preparation method of ceria nano-crystalline microsphere of graduation structure. The non-aqueous system low-temperature preparation method is used and cerium chloride, ammonium ceric nitrate, cerium nitrate or cerium sulfate is used as the precursor and benzyl alcohol is used as solvent and surfactant and the raw materials react for a certain time in oil-bath heating condition to obtain the ceria nano-crystalline microsphere powder of graduation structure. The prepared ceria has three-dimensional graduation spheroidal structure. The ceria nano-crystalline microsphere powder of graduation structure can quickly and effectively absorb the inorganic and organic pollutant in waste water at room temperature with very high absorption capacity. The low-temperature preparation method has features of simple technology, low cost, friendly environment, high yield, accordance with the practical production requirement.

Owner:XUANCHENG JINGRUI NEW MATERIAL CO LTD

Low-temperature and highly efficient denitration catalyst and corresponding method of preparation

InactiveUS20160279609A1Simple processLow costGas treatmentMolecular sieve catalystsDispersityCerium nitrate

The present invention relates to a field of control of nitrogen oxide pollution, and involves a high-efficient catalyst for denitration at low temperature and preparation method thereof, which comprises the steps: (1) preparing aqueous solution of cerium nitrate; (2) soaking mesoporous silica materials SBA-15 with aqueous solution from step (1), after stirring, filtrating, washing and drying; (3) calcining materials from step (2) to obtain evenly dispersed CeO2-SBA-15 materials; (4) preparing ethanol solution of manganese nitrate; (5) soaking CeO2-SBA-15 materials from step (3) with ethanol solution of manganese nitrate from step (4) and volatilizing ethanol, washing and drying; (6) calcining materials from step (5) to obtain evenly distributed MnxOy / CeO2-SBA-15 catalyst for denitration; The preparation method has simple process with lower cost, and the obtained MnxOy / CeO2-SBA-15 catalyst has uniform and ordered pores, large specific area, narrow pore size distribution, well dispersity of catalytic components, high catalytic activity, better effect of denitration at low temperature range and wider temperature range available for denitration.

Owner:TONGJI UNIV +1

Catalyst for methanation and preparation method thereof

InactiveCN102500379AHigh mechanical strengthImprove stabilityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateMethanation

The invention which belongs to the technical field of catalysis relates to a catalyst for methanation and a preparation method thereof. The preparation method comprises the following steps: 1, fully mixing alumina (or pseudoboehmite) with a pore forming agent and a binder, adding deionized water, granulating, drying, compression-molding, and roasting to prepare a catalyst carrier; and 2, dipping the catalyst carrier in a solution of nickel nitrate and lanthanum nitrate (or potassium nitrate, or potassium carbonate, or cerium nitrate, or cerous nitrate), drying, and roasting to prepare the catalyst. The catalyst prepared through the method of the invention, which has the advantages of high mechanical strength and good hydrothermal stability, is suitable for methanation reactions carried out under conditions that the CO content is high and the reaction temperature is high, and can effectively prevent carbon deposition.

Owner:CHINA PETROLEUM & CHEM CORP +1

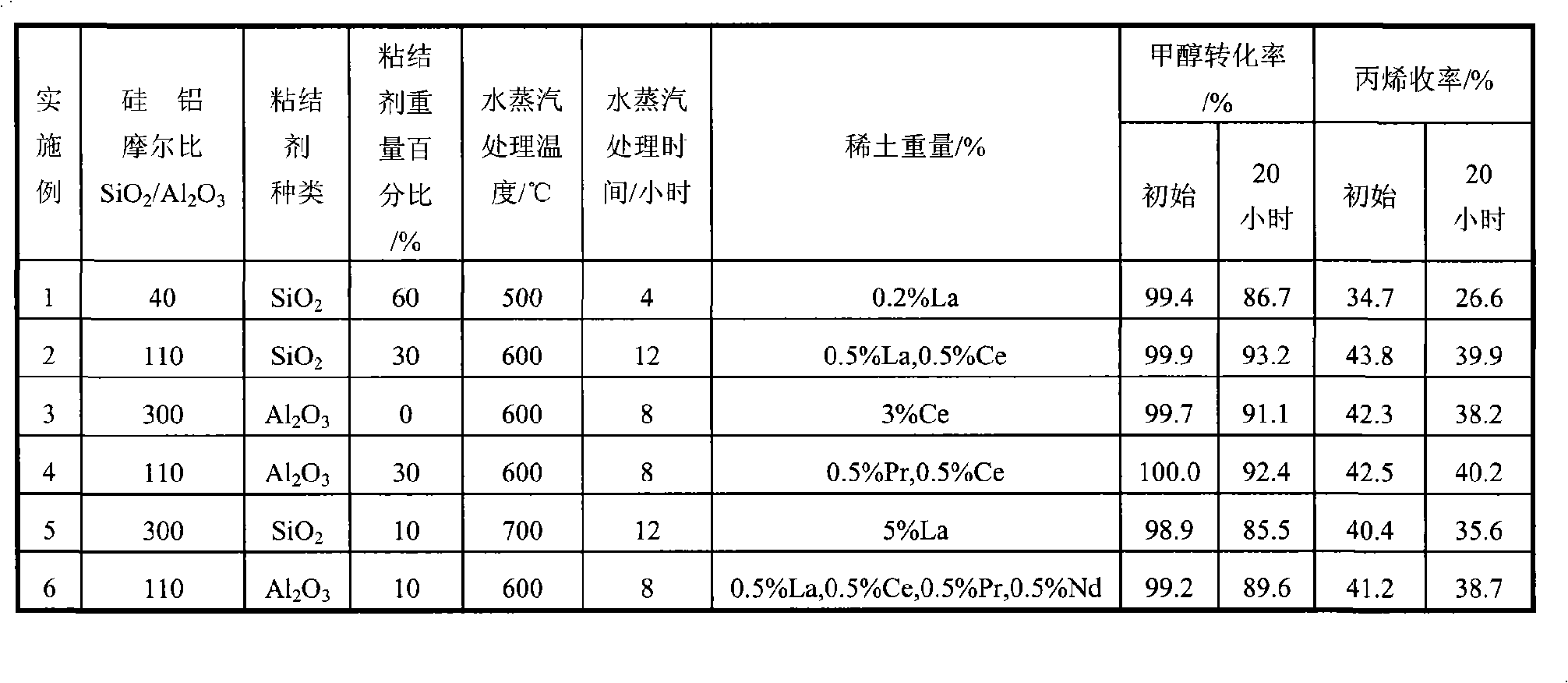

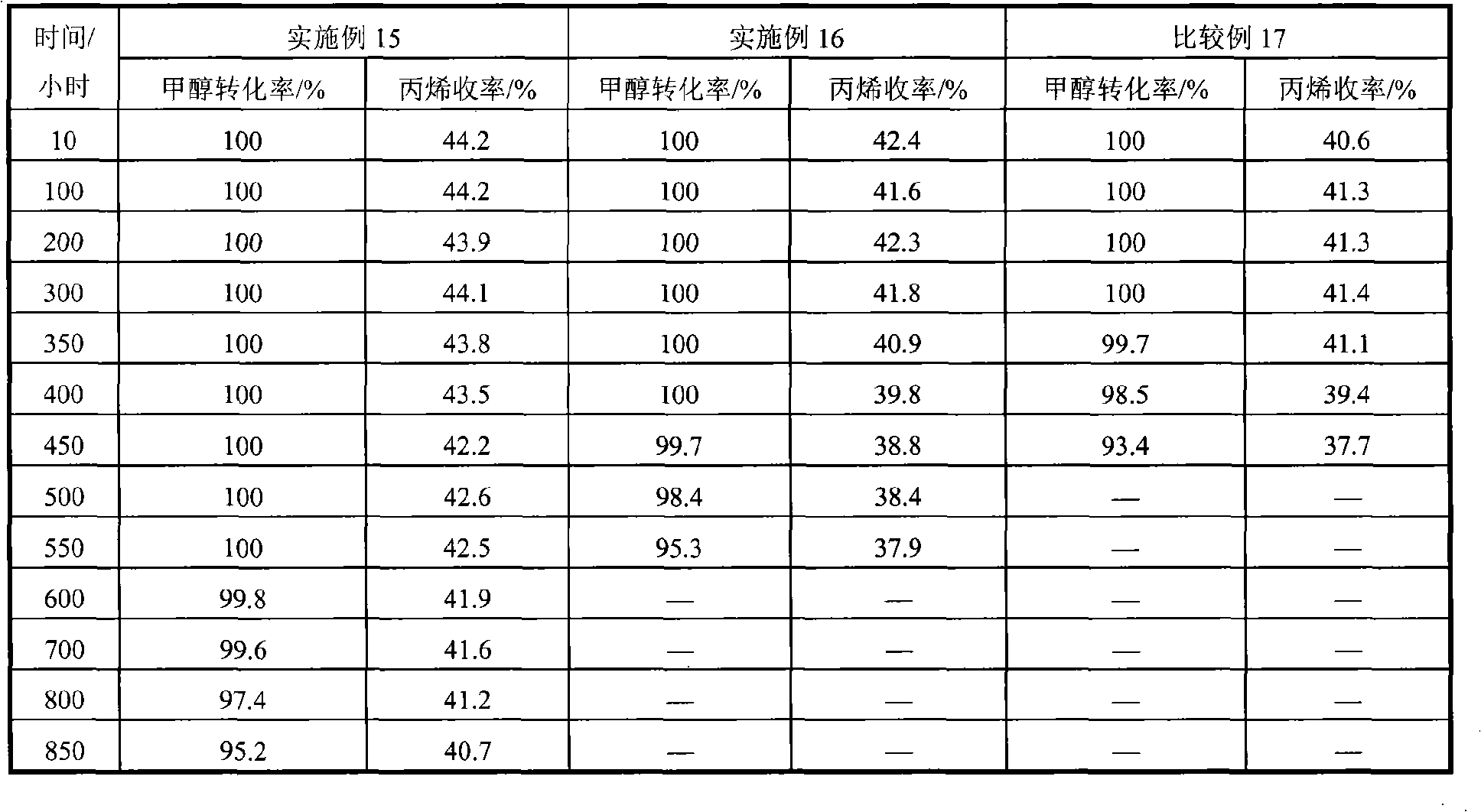

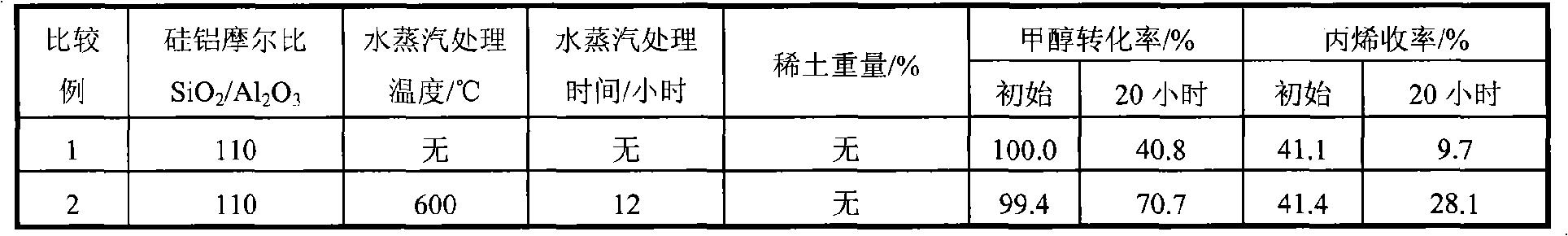

High stability molecular sieve catalyst for preparing propylene transformed from methanol and preparation thereof

ActiveCN101279281AStay acidicImprove anti-coking performanceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsCerium nitratePhosphoric acid

The present invention relates to a high stability molecular sieve catalyst for preparing propylene by being converted from methanol and a preparation method thereof which mainly solve the problems of poor molecular sieve stability and water thermal stability as well as easy coking and deactivation in the prior art. The present invention adopts the technical proposal of adopting the molecular sieve raw powder with a silicon-aluminum mol ratio SiO2Al2O3 of 20 to 1000 and a weight percentage of 25 to 99.9 percent as well as at least one caking agent from SiO2, clay and Al2O3 to extrude, tablet or spray ball to shape; then treating for 1 to 8 hours by 0.1 to 3 mol / l of at least one ammonium liquor from ammonium nitrate, ammonium chloride or ammonium sulphate or 0.1 to 8.5 mol / l of at least one acid liquor from muriatic acid, nitric acid, vitriol, phosphoric acid or acetic acid under a temperature of 20 to 90 DEG C; then using 0.1 to 5 percent of at least one liquor selected from lanthanum, cerium nitrate or chloride calculated by weight percentage to treat for 4 to 8 hours under a temperature of 20 to 90 DEG C; then using steam to treat for 2 to 15 hours under the temperature condition of 400 to 700 DEG C; using a liquor of 0.1 to 3mol / l selected from at least one of oxalic acid, citric acid, phosphoric acid and maleic acid under a temperature condition of 20 to 90 DEG C to dip for 2 to 5 hours to obtain the modified molecular sieve catalyst, thus better solving the problems. The present invention can be used in the industrial production of propylene by being converted from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

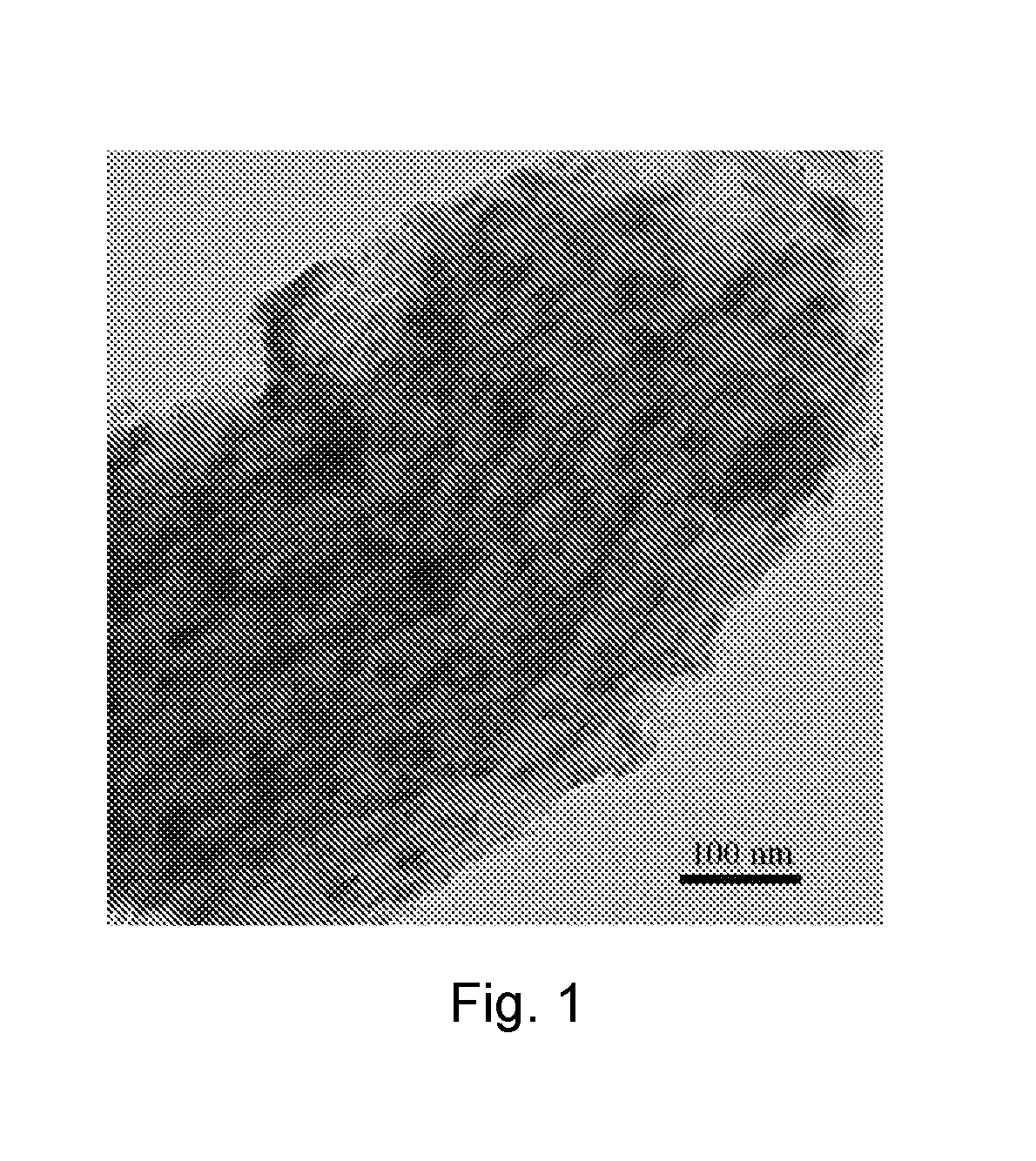

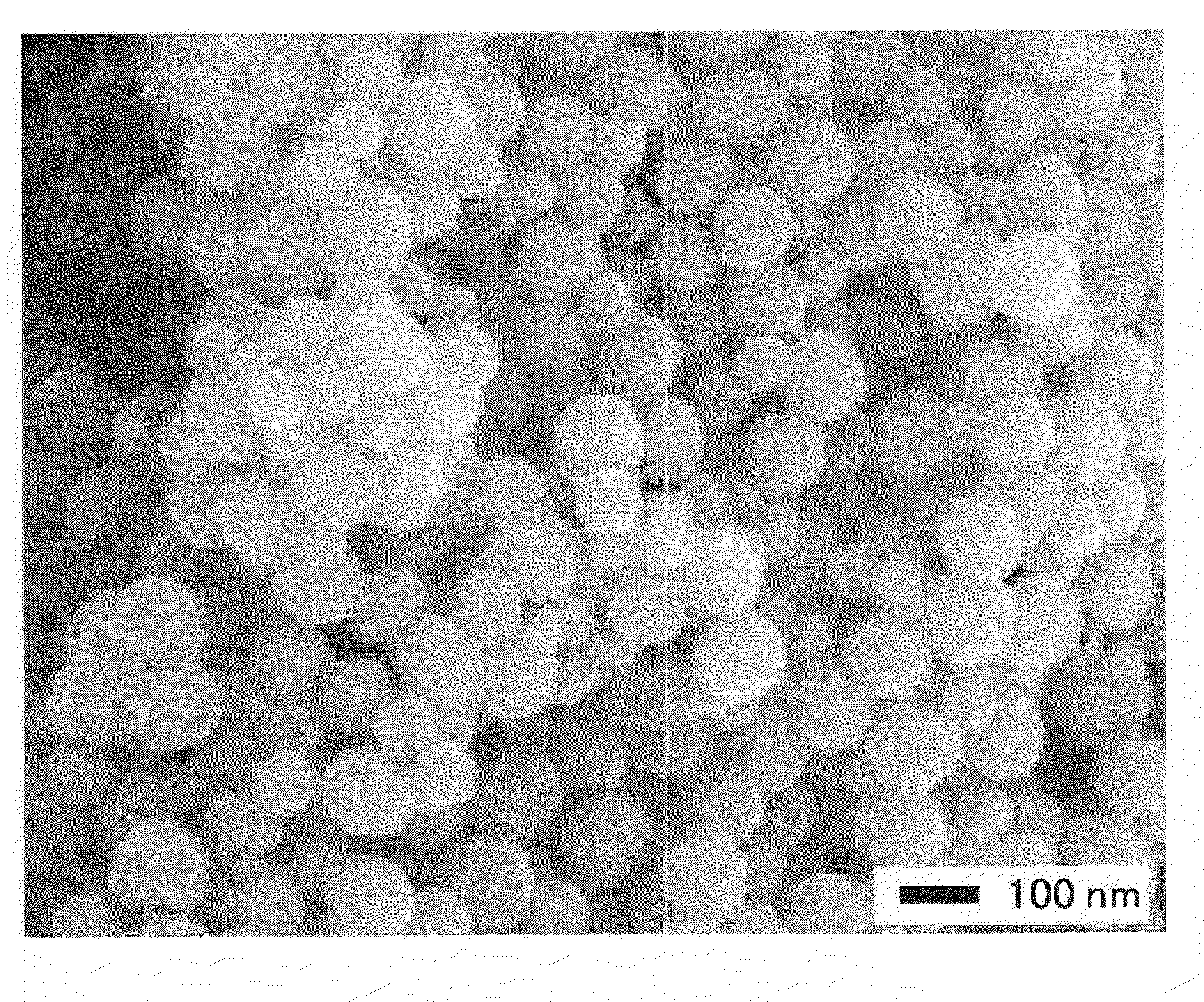

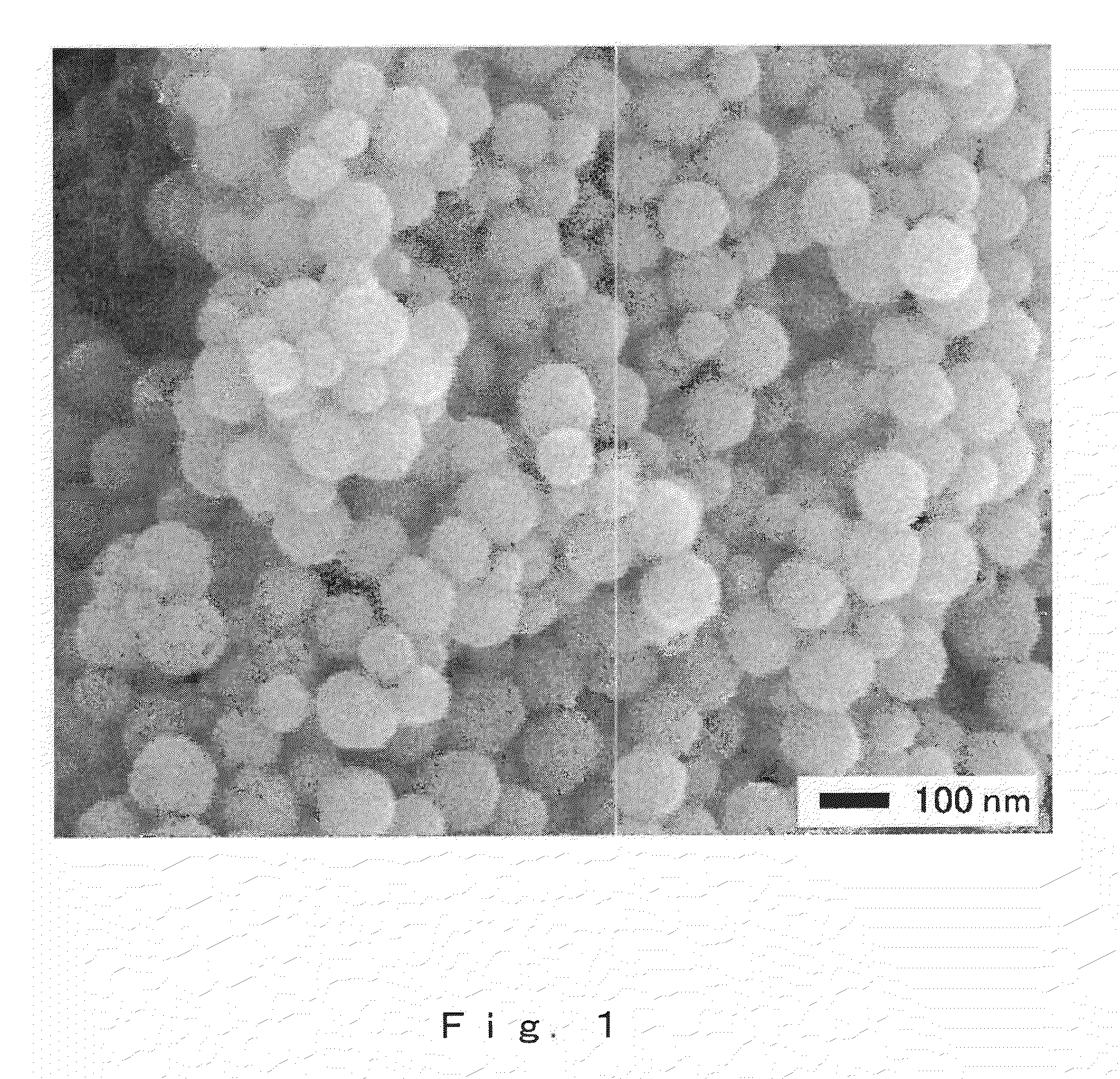

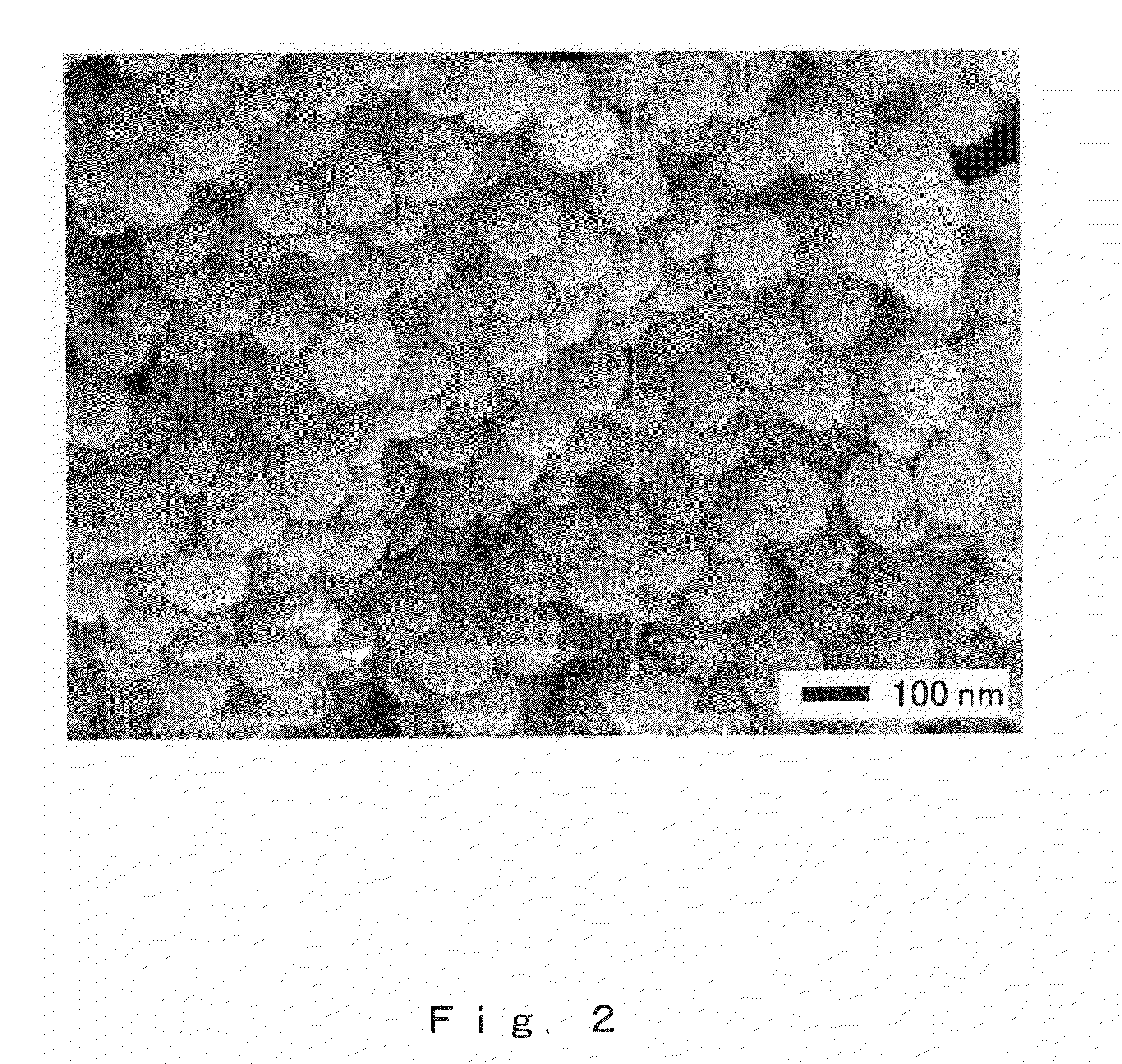

Core-shell-type cerium oxide microparticle, dispersion solution comprising the microparticle, and process for production of the microparticle or dispersion solution

An object of the present invention is to provide a core-shell-type cerium oxide microparticle, a dispersion solution comprising the microparticle, and a process for production of the microparticle or dispersion solution, and to achieve the object, the present invention provides a core-shell-type cerium oxide microparticle which has an average particle diameter of 30 to 200 nm and a coefficient of variation therein no greater than 0.25, and in which the secondary particle forming the core portion is spherical in shape and a polymer is attached to its surface, a dispersion solution of this cerium oxide microparticle and a dry powder from the cerium oxide microparticle dispersion solution, and a process of producing a core-shell-type cerium oxide microparticle or a dispersion solution thereof, which comprises the steps of: mixing a cerium salt and a polymer in an organic solvent to obtain a mixture; and heating this mixture under reflux at a prescribed temperature to precipitate core-shell-type cerium oxide microparticles, wherein the cerium salt is cerium nitrate and the particle diameter of the microparticles is adjusted using the molecular weight of the polymer.

Owner:NAT INST OF ADVANCED IND SCI & TECH

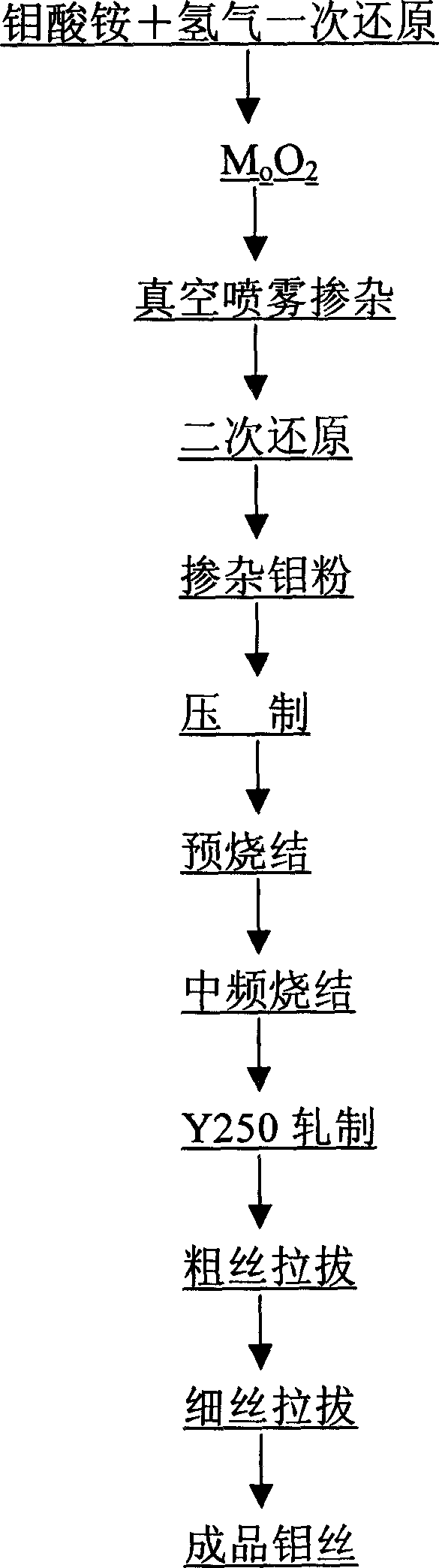

Mo-La-Ce rare earth molybdenum alloy wire and preparation method thereof

InactiveCN1876874ARaise the recrystallization temperatureHigh strengthTemperature control deviceHeat treatment process controlCerium nitrateHigh rate

The invention relates to a Mo-La-Ce rare-earth molybdenum alloy wire and its process for preparing. The invention is characterized in that the said molybdenum alloy wire contains 0.4 %-1.0% lanthanum oxide and cerium oxide(mass %) and the proportion by weight of lanthanum oxide and cerium oxide is 4:1. The process for preparing is different from the traditional powder metallurgy productive technology, which includes performing vacuum drying and liquid-solid doping for molybdenum dioxide, lanthanum nitrate and cerium nitrate solution, then performing secondary reduction to prepare binary rare-earth doping molybdenum powder, finally preparing rare-earth doping molybdenum wire with Mo-La-Ce of 0.5-0.8mm diameter by impression, agglomeration and pressure processing procedure. The raw materials of this invention is cheap and facile, and the prepared molybdenum wire is of high tensile strength, strong abrasive resistance and simple process and is inflexible, and has high rate of finished products, good compatibility and long durability.

Owner:JINDUICHENG MOLYBDENUM CO LTD

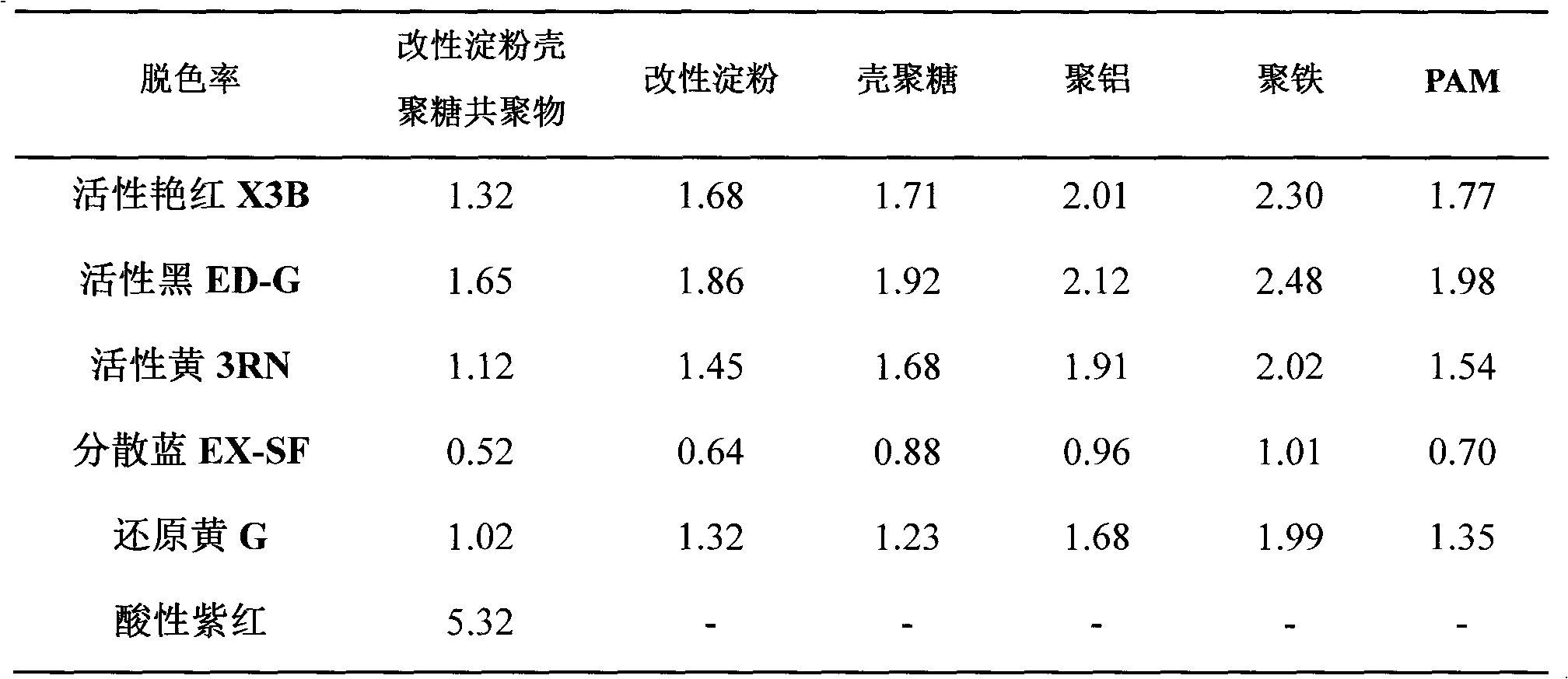

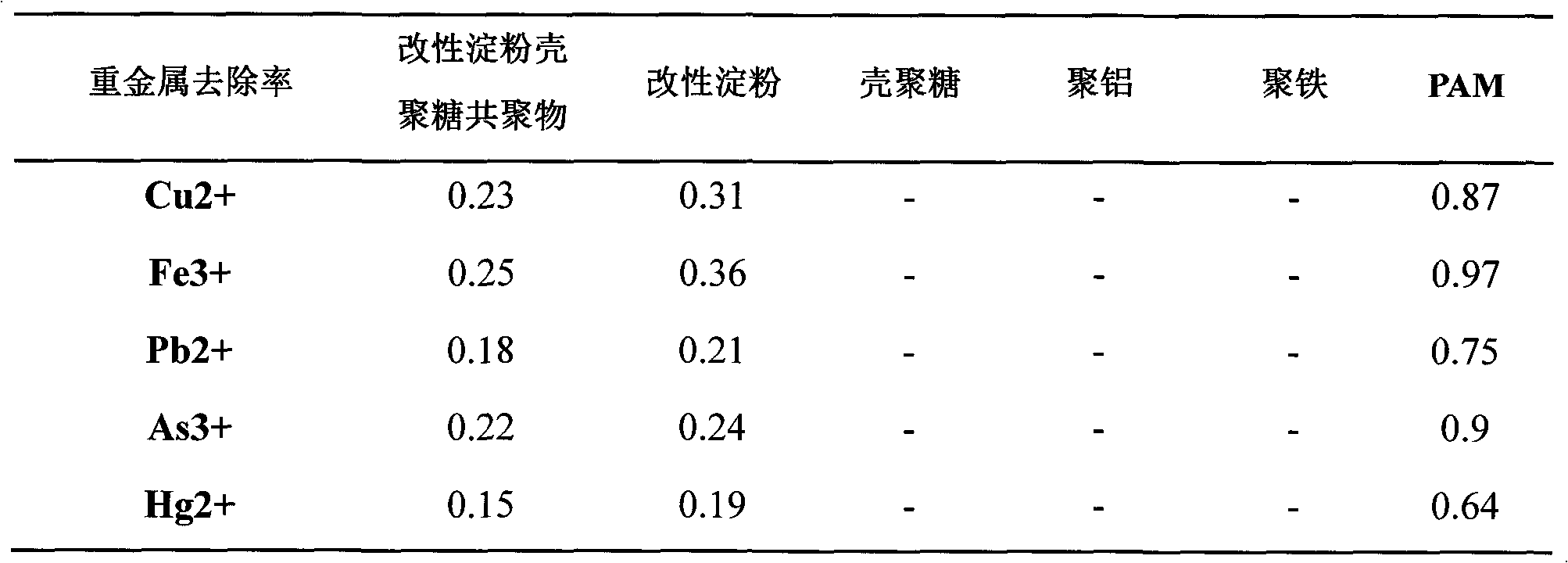

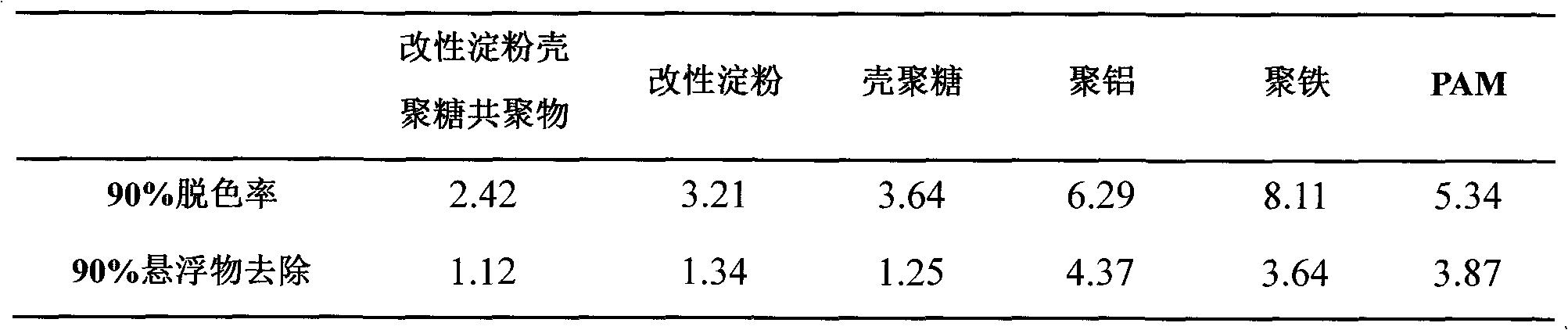

Modified starch-chitosan copolymer flocculating agent and preparation method thereof

InactiveCN102604116AImprove applicabilityImprove environmental friendlinessWater/sewage treatment by flocculation/precipitationCerium nitrateTurbidity

The invention relates to a modified starch-chitosan copolymer flocculating agent and a preparation method thereof. The flocculating agent and the method are characterized in that: modified starch and chitosan are adopted as raw materials; ammonium cerium nitrate is adopted as an initiator; and the modified starch / chitosan copolymer flocculating agent is synthesized under an alkaline condition. In the steps, the mass ratio of the modified starch to chitosan is (1-4):1, the reaction temperature is 45-90 DEG C, a reaction time is 12-16h, and the initiator accounts for 0.1-1% of a total mass of the system. With the method provided by the invention, the prepared modified starch / chitosan copolymer flocculating agent is highly efficient, cheap, and environment-friendly. With the modified starch / chitosan copolymer flocculating agent, heavy metal ions can be removed. Compared with common flocculating agents, aiming at different sewages, wastewater decolourization rate, wastewater turbidity removal rate, and heavy metal removal rate are higher than 99% with a small dosage.

Owner:WUHAN TEXTILE UNIV

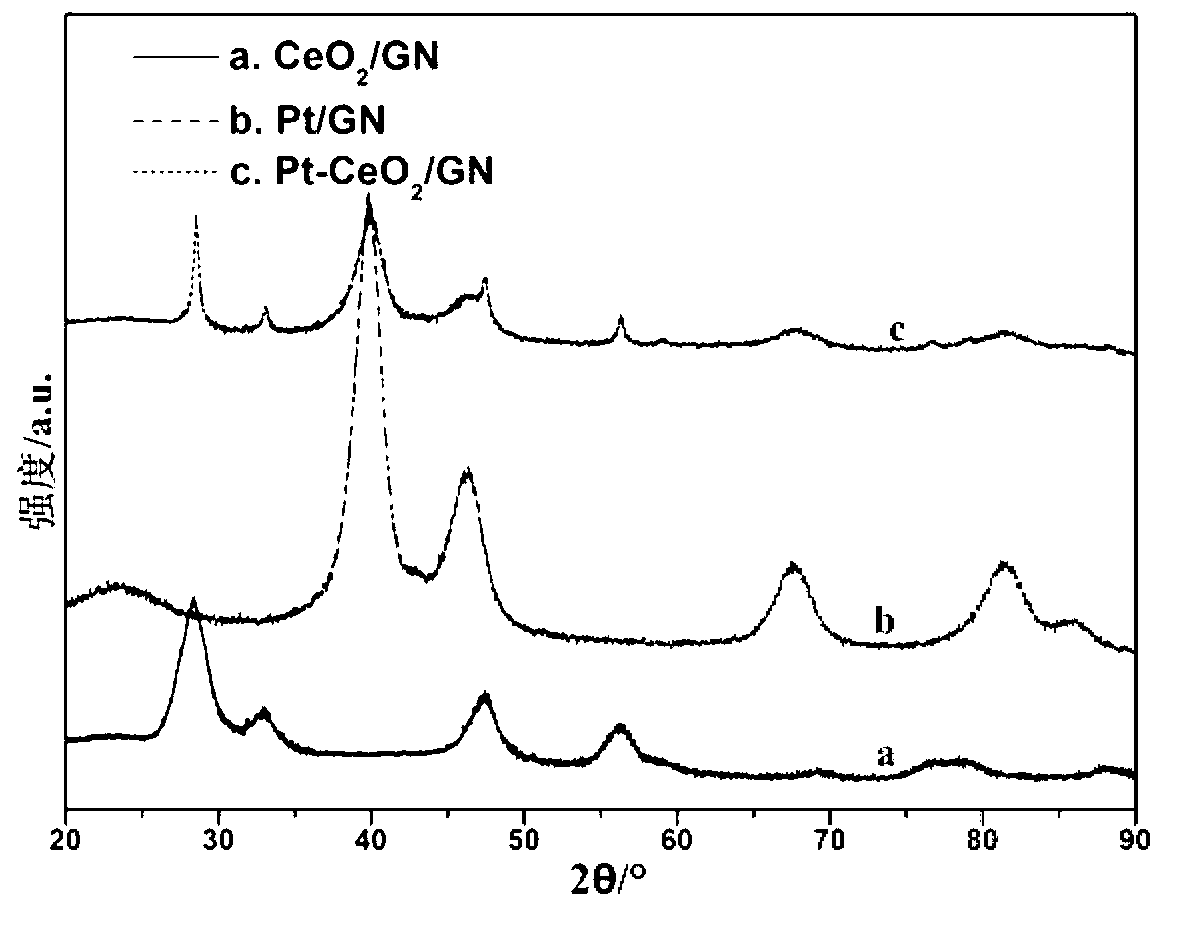

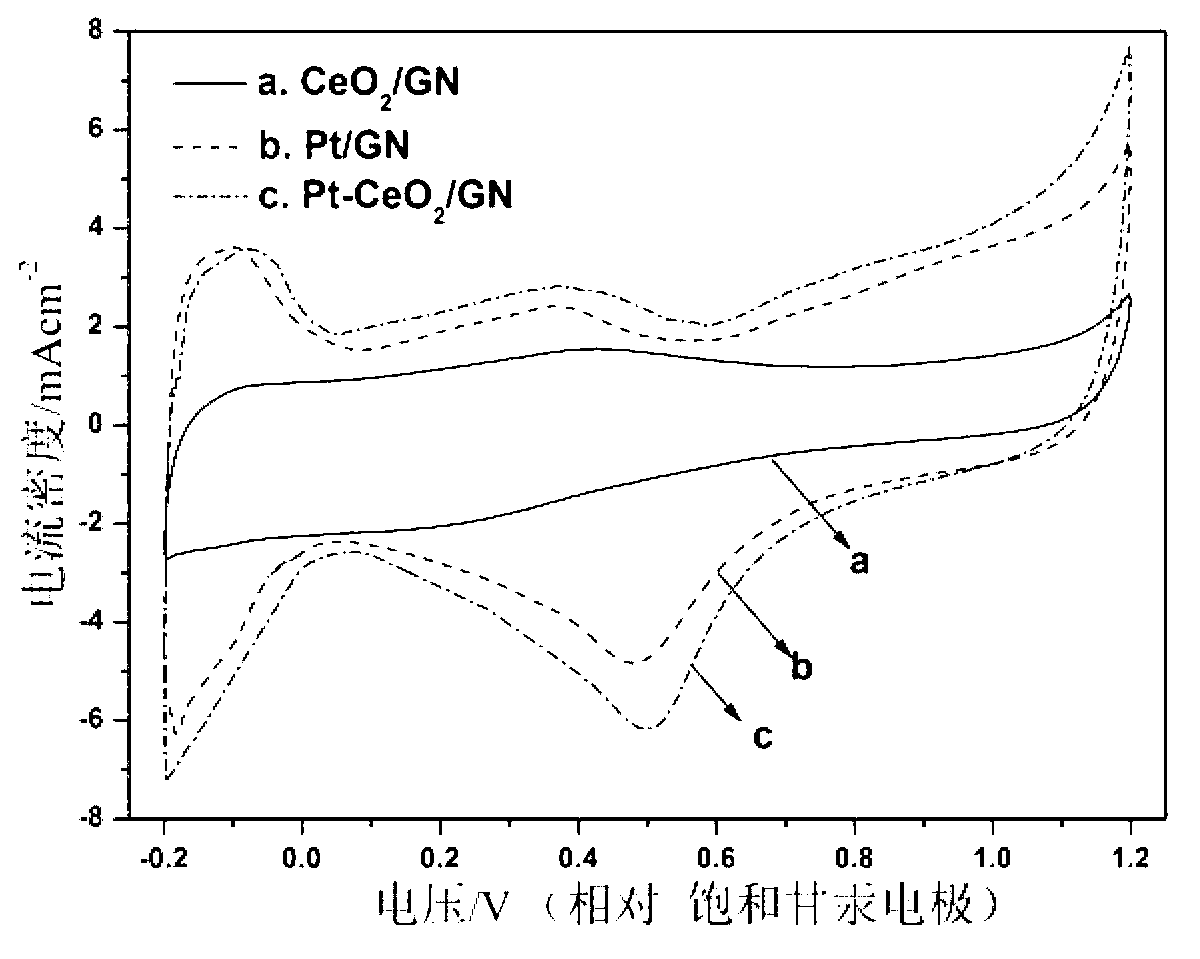

Fuel cell catalyst and preparation method thereof

ActiveCN103078123ALow priceImprove oxygen storage capacityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateCatalytic oxidation

The invention discloses a fuel cell catalyst and a preparation method thereof. The fuel cell catalyst Pt-CeO2 / GN takes graphene as a carrier, and Pt-CeO2 is taken as the catalyst of active components, wherein composite nano particles of Pt and CeO2 are uniformly distributed on the surface of the graphene, and the particle size of the Pt is 3-5 nm; the catalytic activity of the fuel cell catalyst is improved by 20-35 percent, compared with the catalytic activity of Pt / GN catalyst; and the electrochemical activity area of the fuel cell catalyst reaches 59.1-66.4 m<2> / g<-1>, and the density of current for catalyzing methanol oxide reaches 279.5-440.1 mA / g<-1>Pt. The preparation method comprises the following steps: graphite oxide and cerium nitrate are dispersed in water, ammonia is used to regulate the pH value, and CeO2 / GN is obtained via reaction; and prepared CeO2 / GN is dispersed in ethylene glycol solution in an ultraphonic manner, chloroplatinic acid solution is added, the pH value is regulated, and Pt-CeO2 / GN catalyst is obtained via reaction. The preparation method disclosed by the invention is simple, can prepare catalysts provided with higher catalytic activity and stability, and has a broad application prospect in the filed of fuel cells.

Owner:BEIJING UNIV OF CHEM TECH

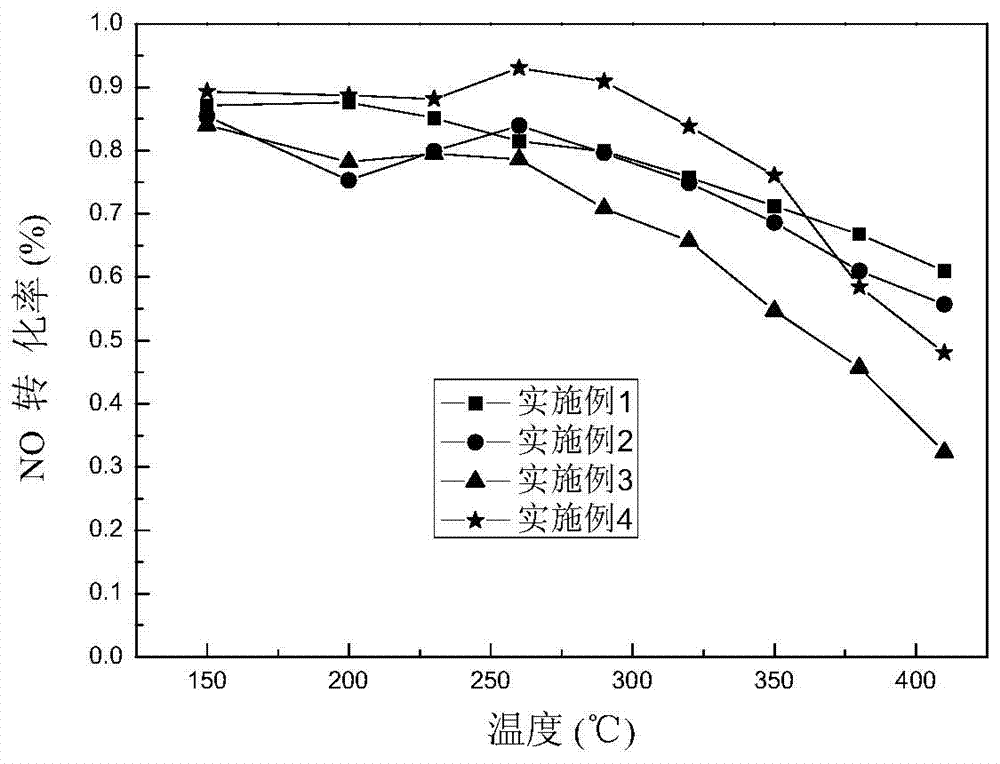

Method for preparing low-temperature denitration composite catalyst by adopting ultrasonic treatment and step-by-step impregnation method

InactiveCN103785409AEffective recoveryReduce contentDispersed particle separationCatalyst activation/preparationCerium nitrateTungstate

The invention provides a method for preparing a low-temperature denitration composite catalyst by adopting ultrasonic treatment and a step-by-step impregnation method. The method comprises the following steps: ultrasonically treating 0.1-5g of oxalic acid for a certain time, completely dissolving the oxalic acid in water, adding 0.01-1g of ammonium metavanadate to perform the ultrasonic treatment, then adding 0.01-1g of ammonium tungstate to perform the ultrasonic treatment, and stirring to obtain a solution A; adding 1-10g of titanium dioxide powder into a container which contains the water, adding 1-20g of 50wt% manganese nitrate solution, 1-10g of cerium nitrate and 1-10g of ferric nitrate, performing the ultrasonic treatment until the added materials are completely dissolved to obtain a solution B; adding the solution A into the solution B, stirring and reacting for 0.5-3 hours at 100-200 DEG C; drying; grinding; roasting for 1-5 hours at 400-800 DEG C; cooling to room temperature, and then grinding to obtain the low-temperature denitration composite catalyst. According to the method disclosed by the invention, the ultrasonic treatment is combined with the step-by-step impregnation method to prepare a high-efficiency low-temperature denitration composite catalyst. The denitration efficiency of the prepared catalyst at 150-370 DEG C is over 80%, and the denitration activity at 230 DEG C is up to 95%.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com