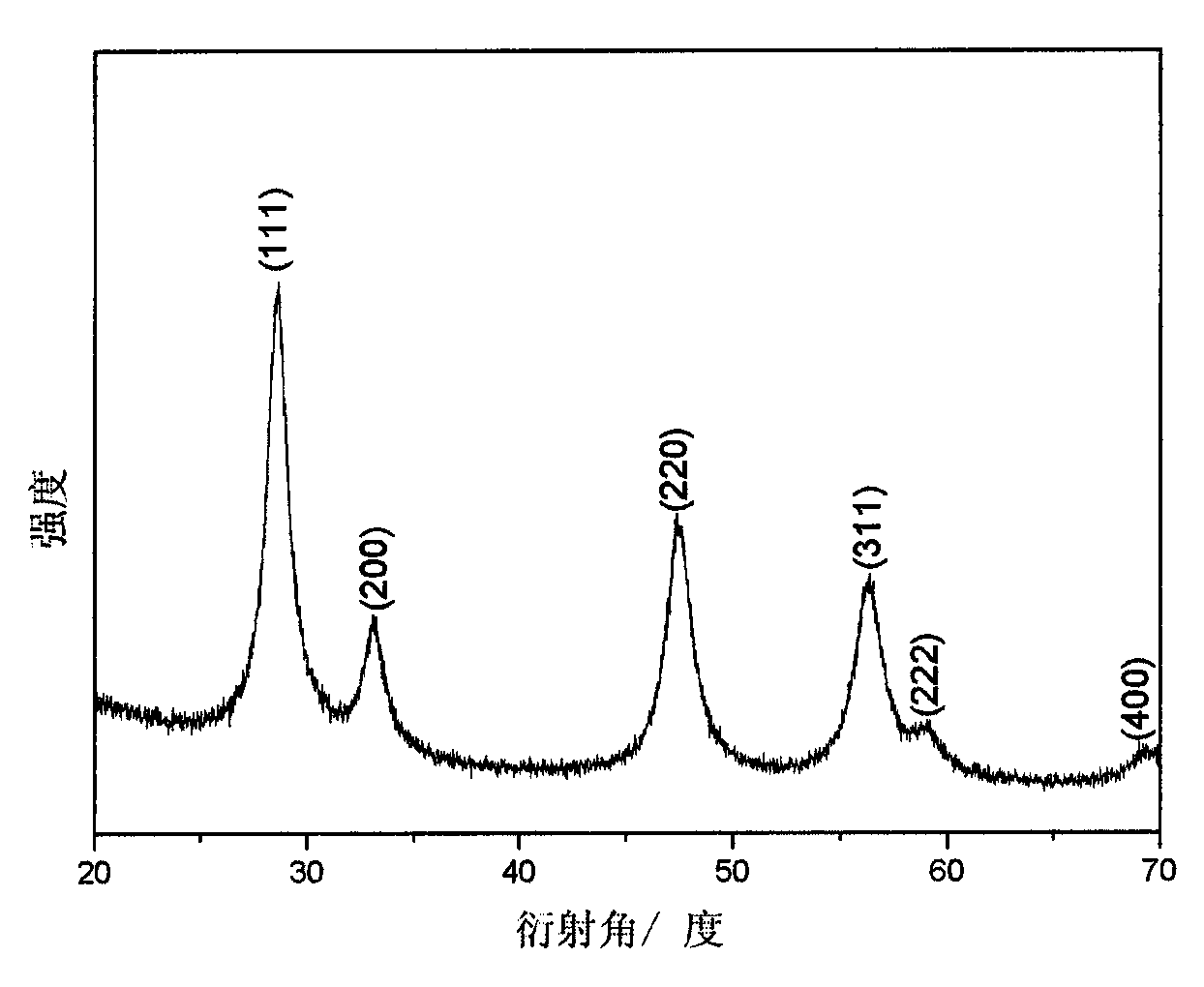

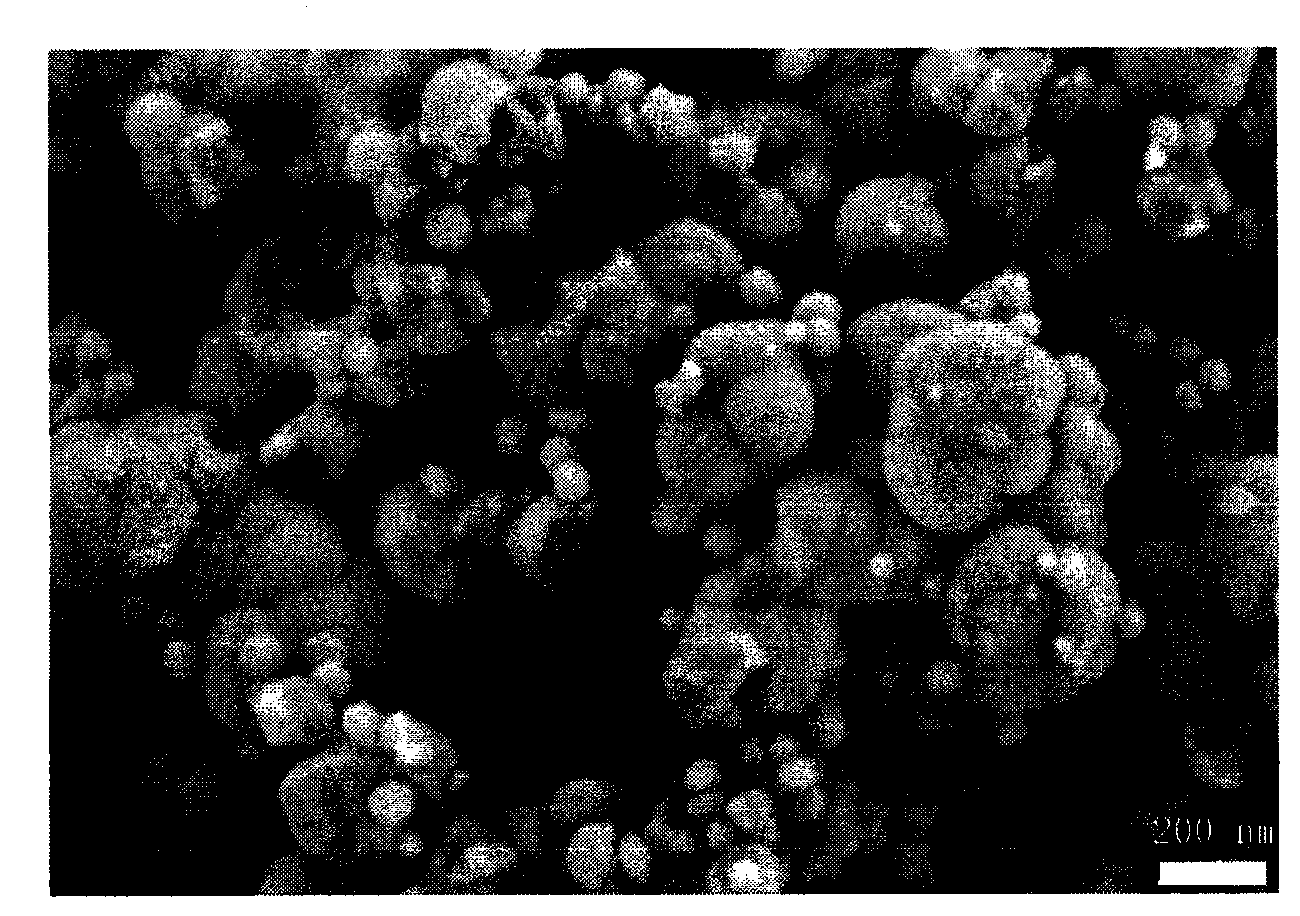

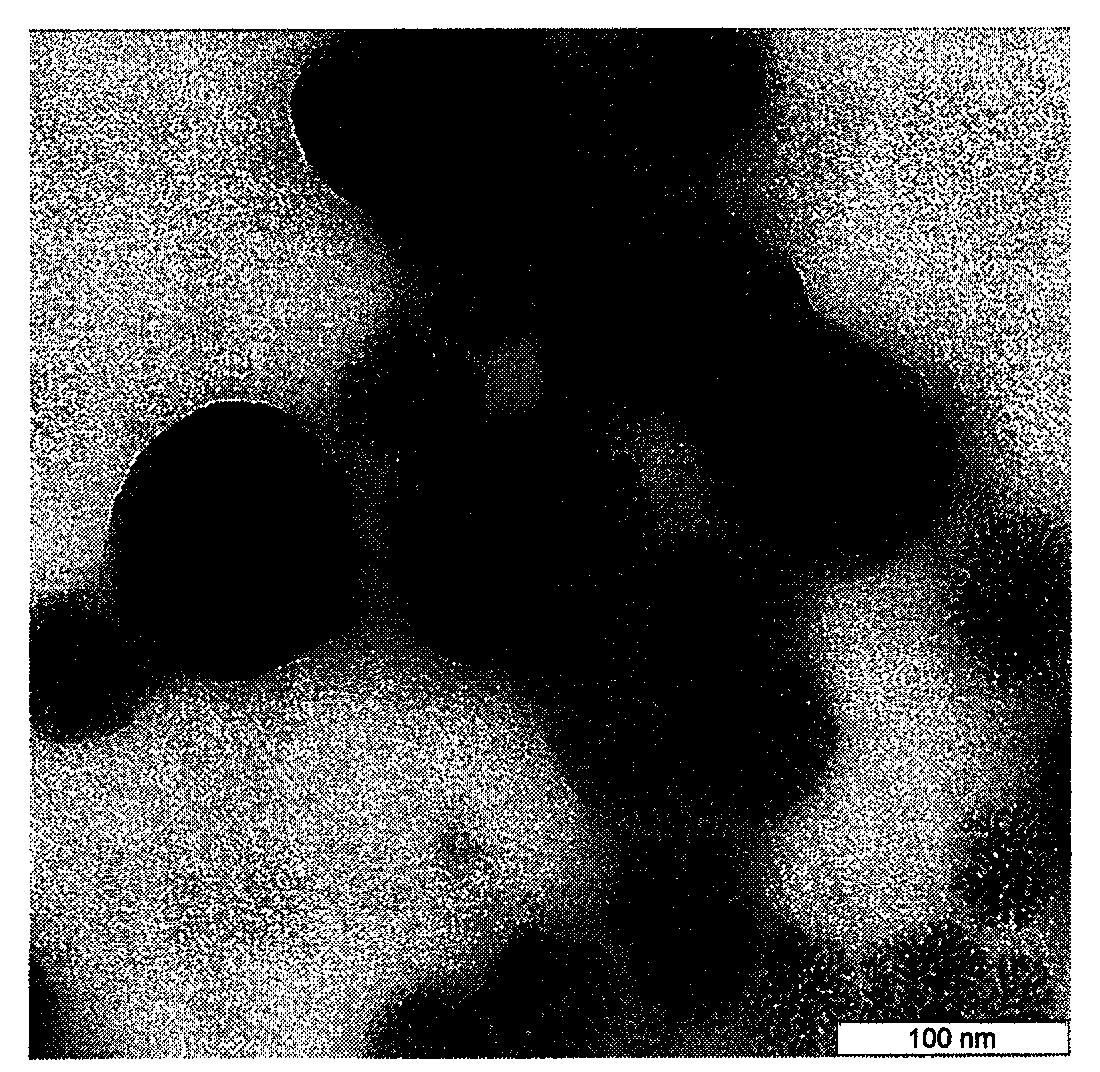

Low-temperature preparation method of ceria nano-crystalline microsphere of graduation structure

A technology of nanocrystalline microspheres and cerium oxide, which is applied in the direction of microsphere preparation, chemical instruments and methods, and microcapsule preparations, and can solve problems such as unfavorable industrial production and application, complicated surface of surfactants, and large investment in equipment. To achieve the effect of simple and easy control of the process, less energy consumption and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add cerium nitrate to 10 ml of benzyl alcohol, form a colorless and clear solution after magnetic stirring at room temperature, the concentration of cerium nitrate is 0.05 mol / liter, then put the colorless and clear solution in a flask, and heat it in an oil bath at 100°C Stirring and reacting for 36 hours, a khaki precipitate was formed, and the obtained precipitate was washed with ethanol, separated, and dried at 50°C to obtain a high-purity hierarchical structure ceria nanocrystalline microsphere powder.

Embodiment 2

[0026] Add cerium nitrate to 10 ml of benzyl alcohol, and form a colorless and clear solution after magnetic stirring at room temperature. The concentration of cerium nitrate is 0.05 mol / liter. After heating and stirring for 48 hours, a khaki precipitate was formed, and the obtained precipitate was washed with ethanol, separated, and dried at 50°C to obtain a high-purity hierarchical structure ceria nanocrystalline microsphere powder.

Embodiment 3

[0028] Add cerium nitrate to 10 ml of benzyl alcohol, and form a colorless and clear solution after magnetic stirring at room temperature. The concentration of cerium nitrate is 0.1 mol / liter. After heating and stirring for 60 hours, a khaki precipitate was formed, and the obtained precipitate was washed with ethanol, separated, and dried at 50°C to obtain a high-purity hierarchical structure ceria nanocrystalline microsphere powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com