Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Reduce residual alkali content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high-nickel ternary cathode material

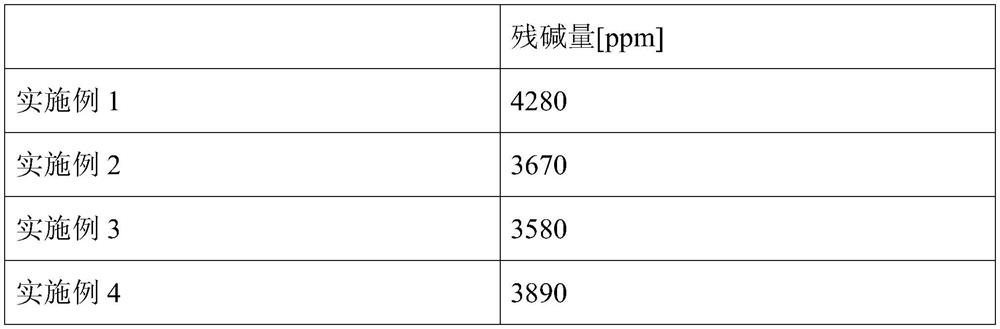

InactiveCN109461907AReduce mixingReduce residual alkali contentCell electrodesSecondary cellsPower batteryPhysical chemistry

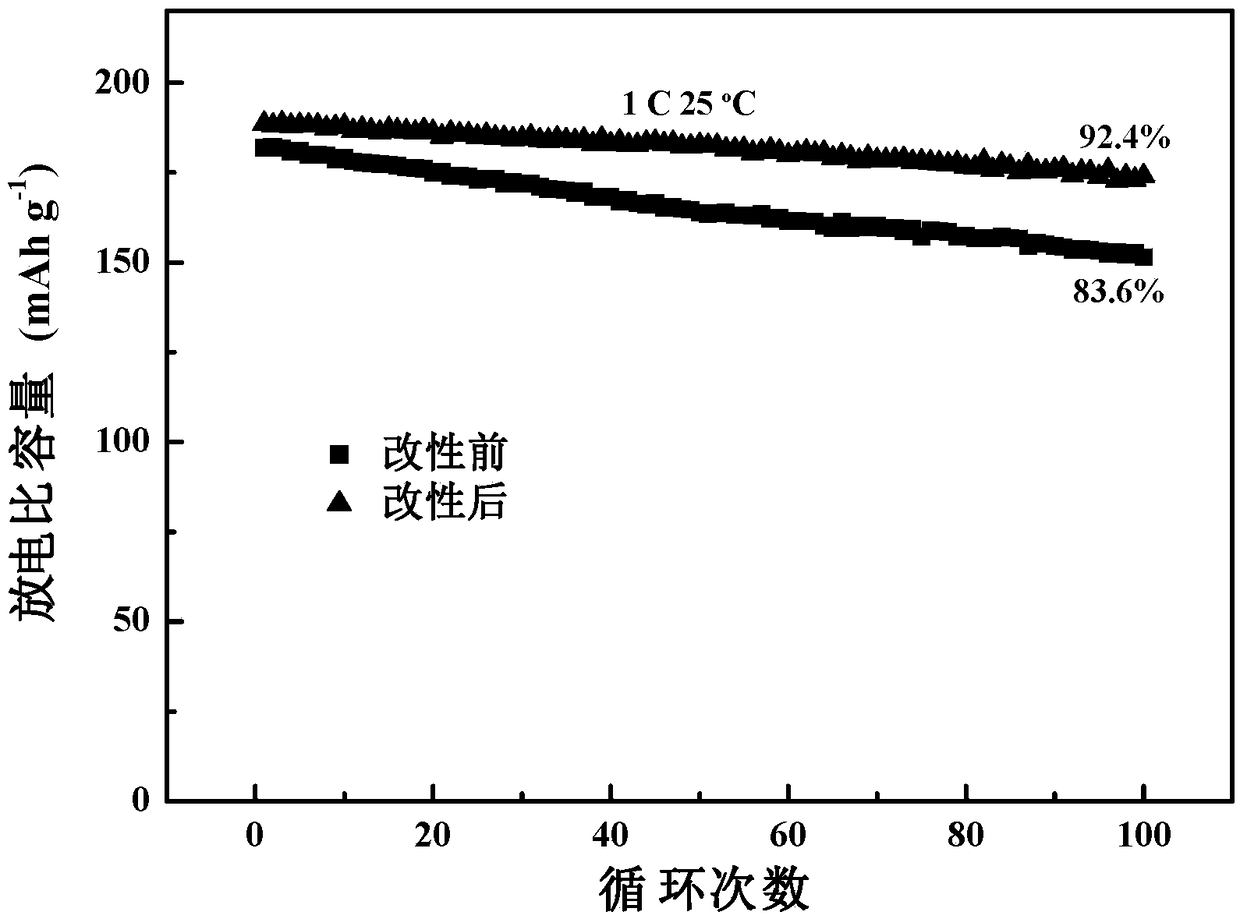

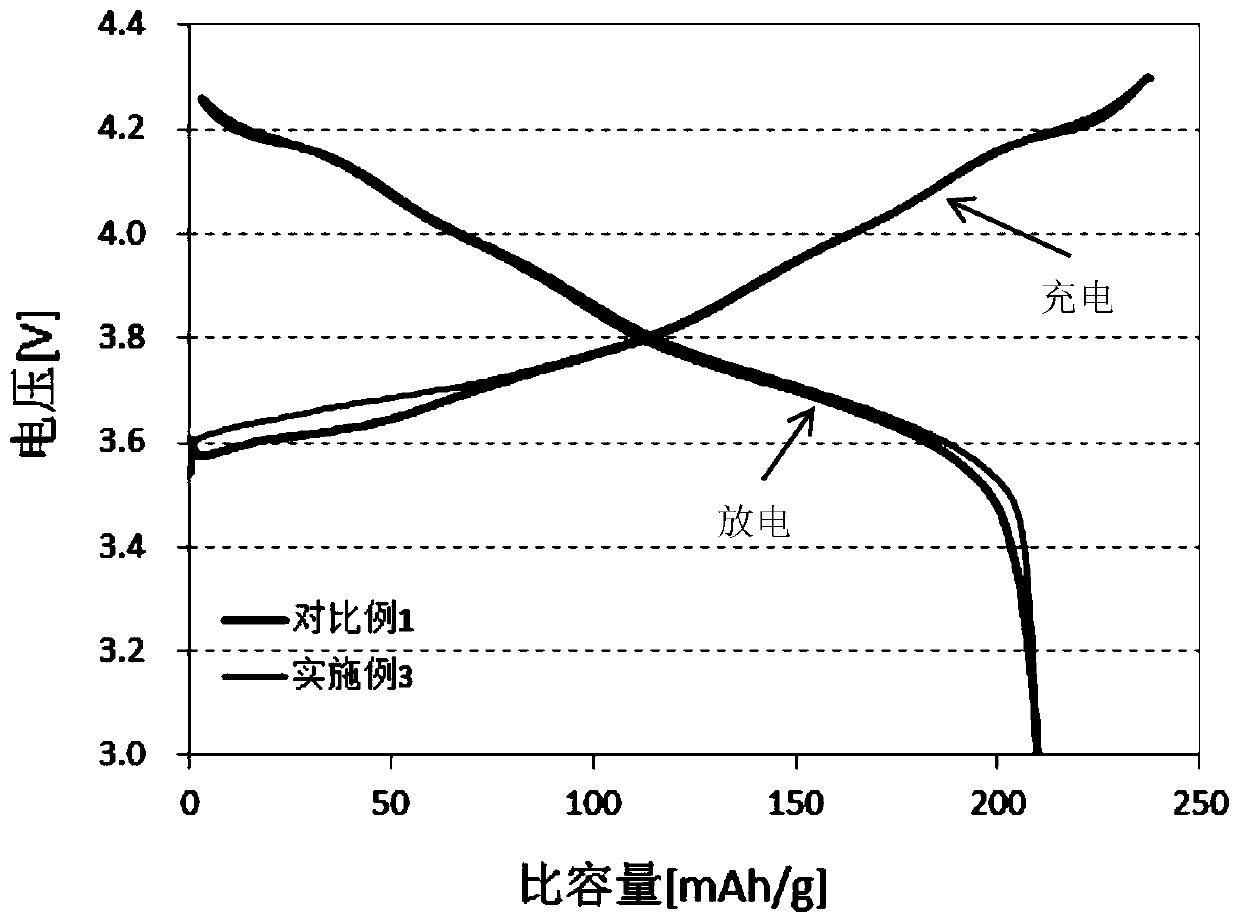

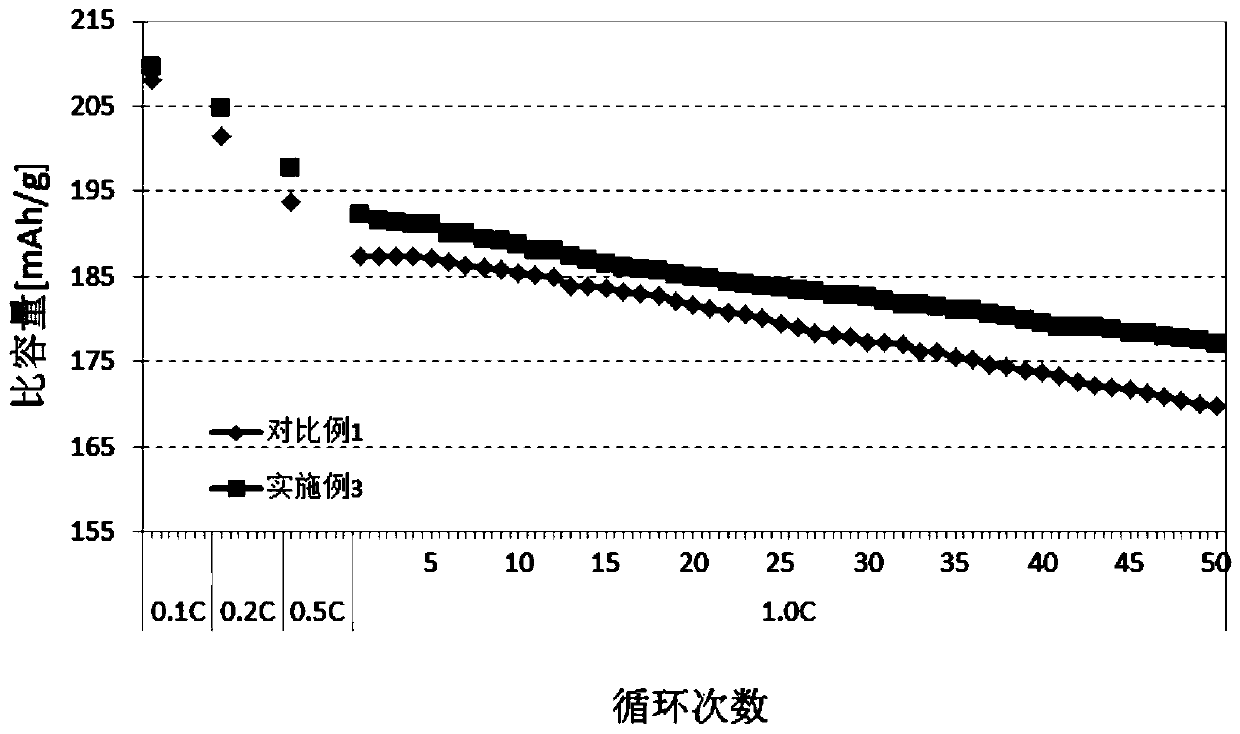

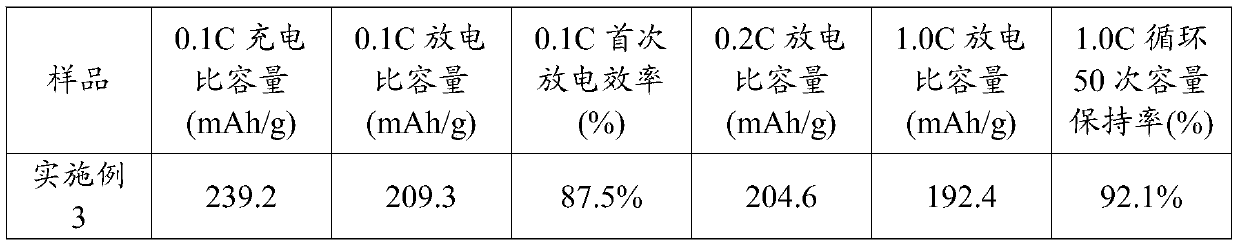

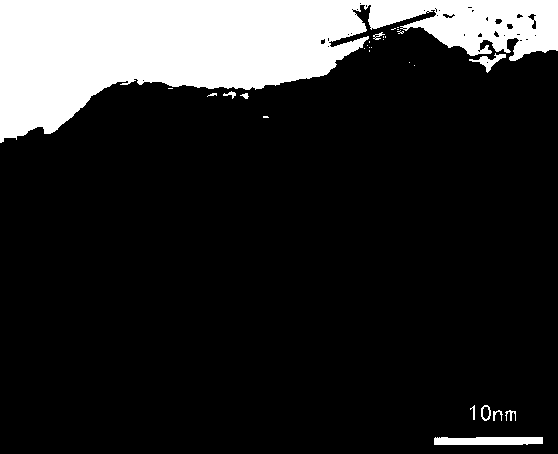

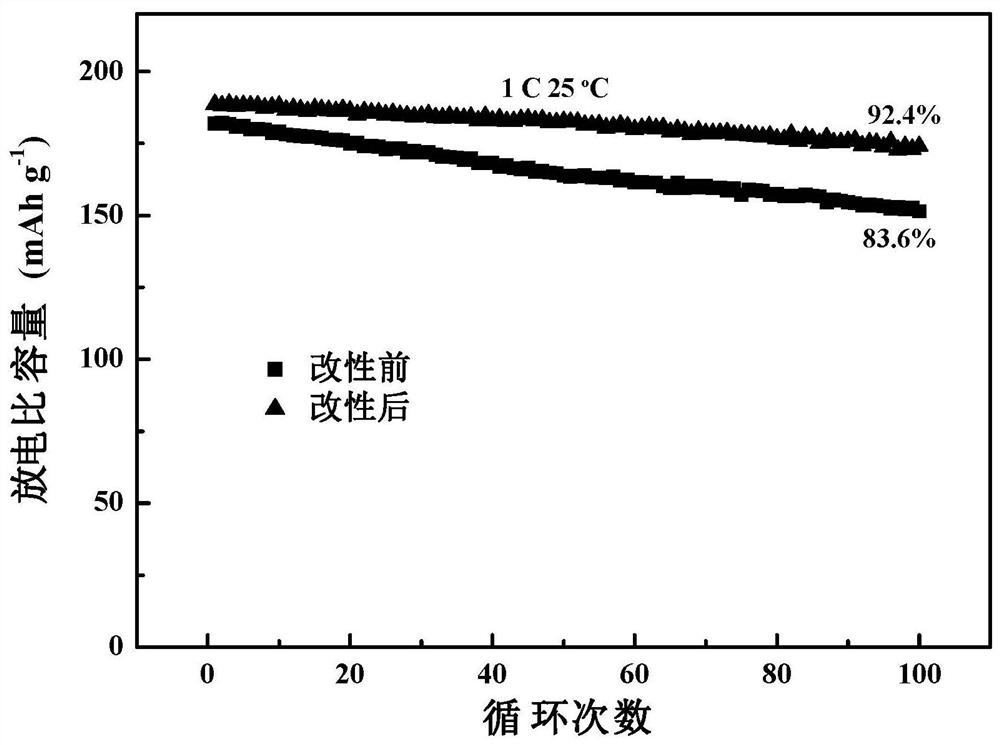

The invention discloses a preparation method of a high-nickel ternary cathode material. The method comprises the steps of 1) pre-oxidizing a high-nickel ternary cathode material precursor with an oxidizing agent to obtain an oxidized high-nickel ternary precursor; 2) uniformly mixing the pre-oxidized high-nickel ternary precursor with a lithium source and a modified assistant, and performing calcining to obtain an oxidized and modified high-nickel ternary cathode material; 3) carrying out coating modification of a lithium-containing compound on the oxidized and modified high-nickel ternary cathode material to obtain a coated and modified high-nickel ternary cathode material for a power battery. According to the method disclosed by the invention, the material precursor is pre-oxidized withthe oxidizing agent, so that Ni<2+> can be fully oxidized into Ni<3+>, the cation mixing degree of the material is reduced, and the capacity of the material is expanded; and through the coating modification of the lithium-containing compound, the content of residual alkali on the surface of the material can be reduced, the generation of side reactions can be effectively inhibited, the embedding and separation of lithium ions are improved, and finally the cycling performance and the rate performance of the material are improved.

Owner:郑州中科新兴产业技术研究院 +1

Ternary cathode material for lithium ion battery and preparation method thereof

InactiveCN106532035AImprove cycle performanceEasy to useCell electrodesElectrical batteryPhysical chemistry

The invention belongs to the field of electrochemical technique, and particularly relates to a ternary cathode material for a lithium ion battery and a preparation method of the ternary cathode material. The cathode material uses high-nickel nickel-cobalt lithium manganate or nickel-cobalt lithium aluminate as a basal body, and low-nickel lithium manganate is coated outside the basal body. A low-nickel ternary material is coated on the surface of a high-nickel ternary material, so that the pH and the content of residual alkali on the surface of the cathode material are reduced, the cathode material has processing performance of the low-nickel ternary material and specific capacity of the high-nickel ternary material, and the cycle performance of the cathode material can also be improved through the reduction of the surface basicity of the cathode material; and the high-nickel ternary material can be easily used in domestic enterprises, so that the invested cost of battery enterprises for using the high-nickel ternary material is greatly reduced.

Owner:WUXI JEWEL POWER & MATERIALS

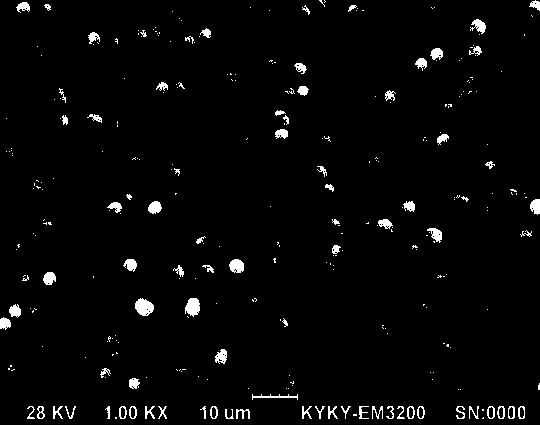

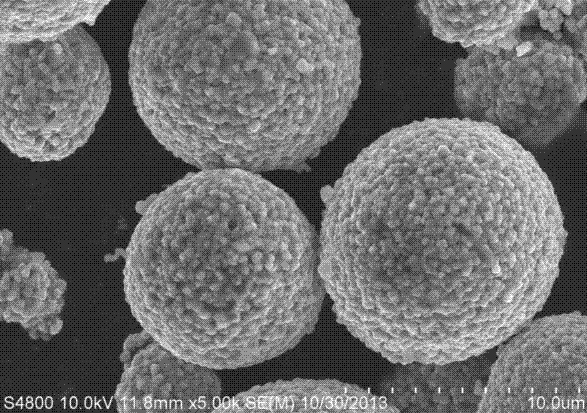

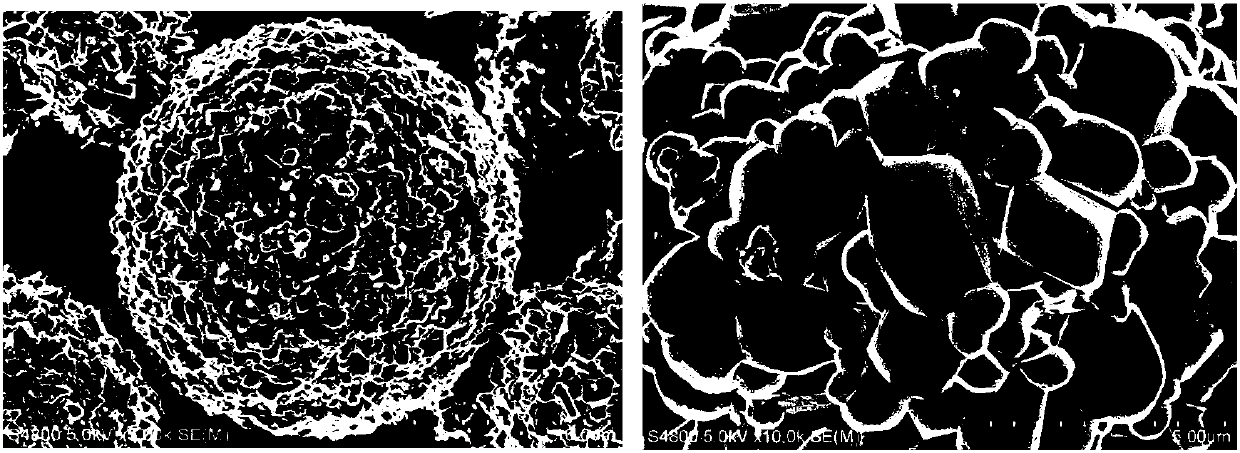

Preparation method of small-particle size ternary positive material precursor

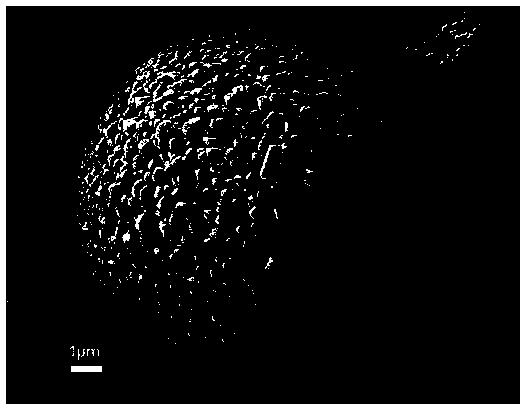

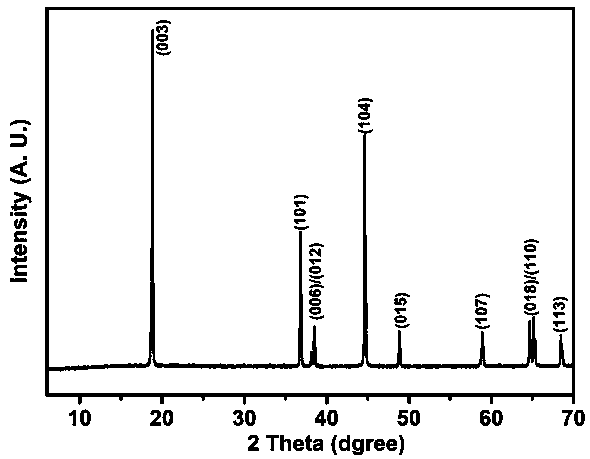

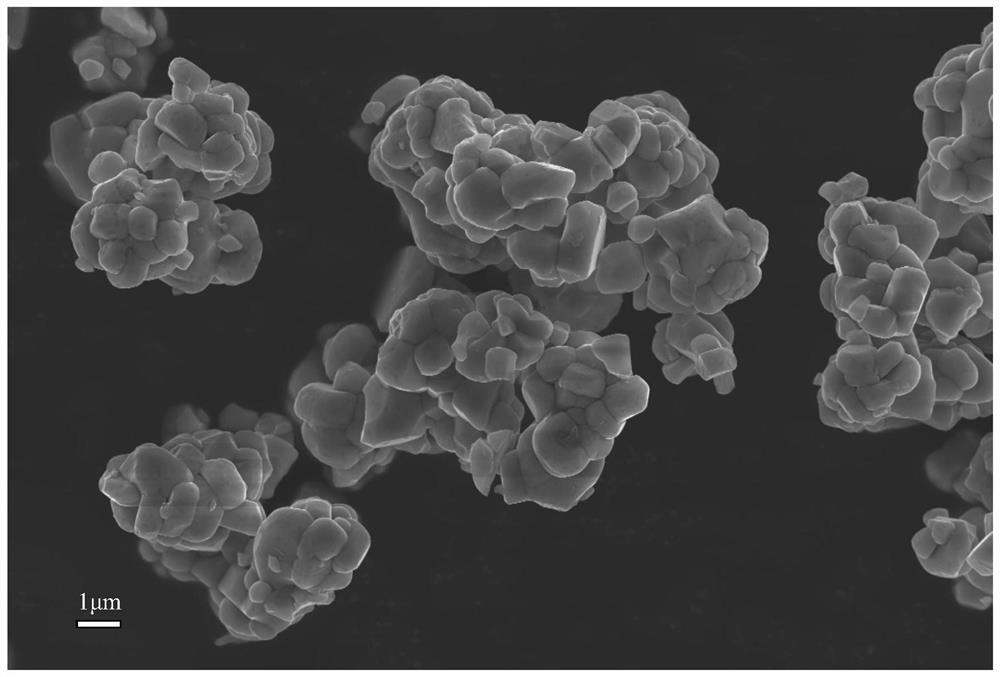

ActiveCN107915263AImprove cycle performanceReduce residual alkali contentSecondary cellsPositive electrodesCrystal structureCobalt

The invention discloses a preparation method of a small-particle size ternary positive material precursor. The preparation method comprises the following steps of (1) selecting a nickel, cobalt and manganese solution as the raw material, preparing into a metal mixing salt solution, adding a special reaction base solution into a reaction kettle in advance, mixing the metal salt solution, a complexing agent and a precipitant according to a stoichiometric number ratio, and adding into the reaction kettle in a cocurrent flow way; (2) filling particles with D50 particle size into the reaction kettle for the first time, and controlling the D50 particle size to 1 to 2mu m; after the reaction kettle is full, directly overflowing the material into a prepared aging kettle via an overflow pipe, and immediately stopping material feeding when the particle size of the particle in the reaction kettle grows to 3.5 to 4mu m after 10 to 20h; (3) washing, screening, and packaging, so as to obtain the small-particle size ternary precursor with particle size of 3 to 4mu m. The preparation method of the small-particle size ternary positive material precursor has the characteristics that the integrity ofthe crystal structure is good, the degree of sphericity is better, the cyclicity is better, the technology operation is simple, the continuous production is realized, and the green and energy-savingeffects are realized.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD

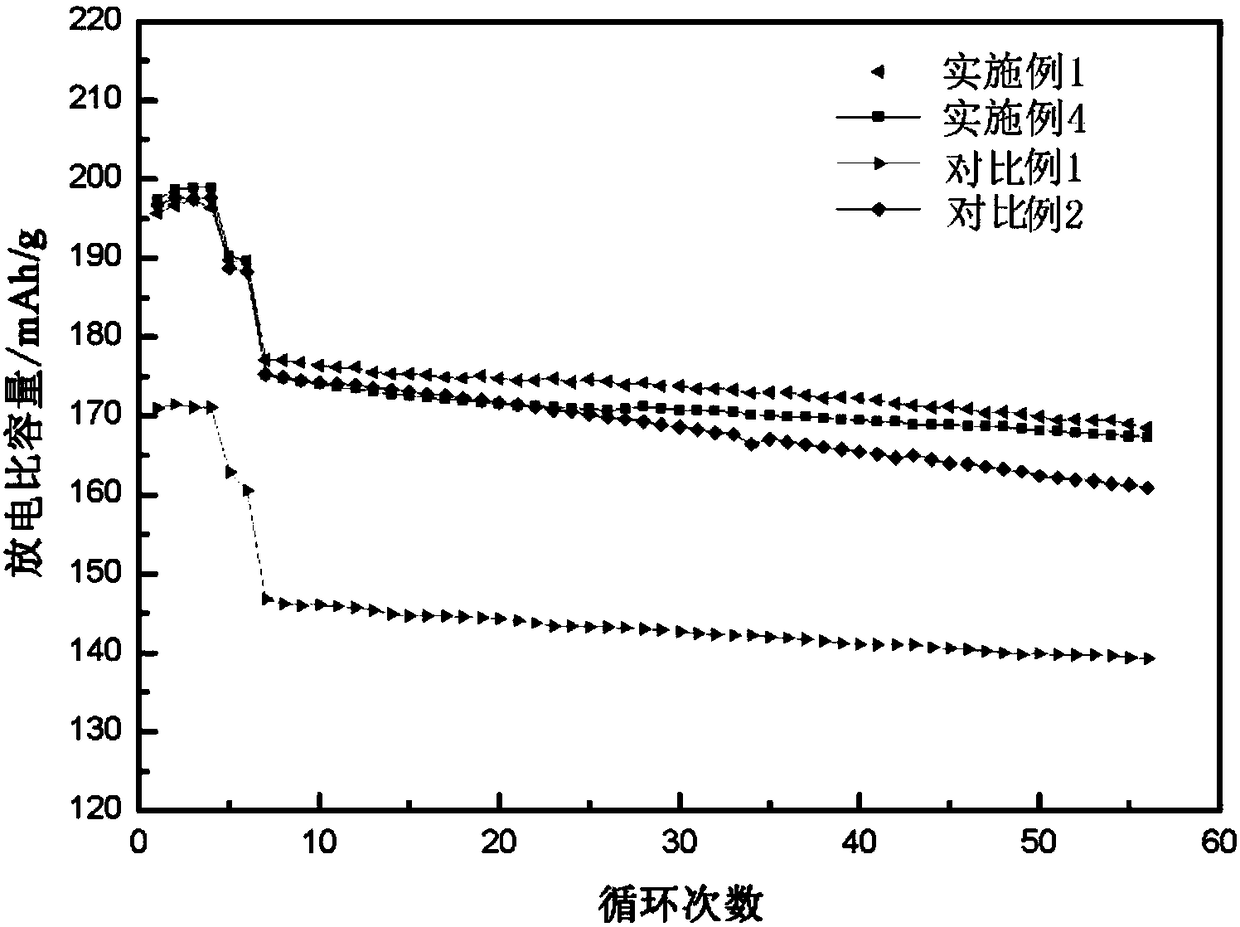

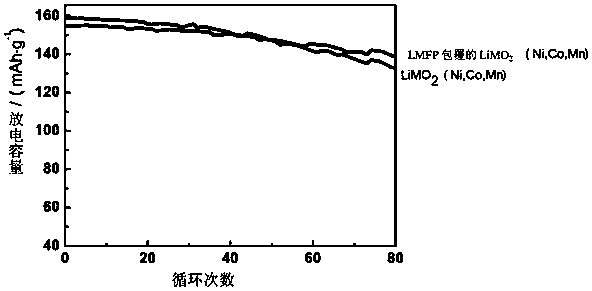

Method for processing ternary material by being clad with lithium ferric manganese phosphate

InactiveCN105406069AGood coating consistencyImprove consistencyCell electrodesSecondary cellsManganeseSlurry

The invention relates to a method for processing a ternary material by being clad with lithium ferric manganese phosphate. The invention belongs to the technical field of a cathode material of lithium ion batteries. The method for processing the ternary material by being clad with the lithium the ferric manganese phosphate comprises the steps of 1, preparation of LFMP precursor slurry: respectively weighing iron, manganese, lithium and phosphorus sources in proportion required by 0.1-100g LFMP, weighing 0-50g ascorbic acid, and adding a dispersion solvent, wherein the solid content is 10%-80%; 2, mixture of materials: weighing 100g ternary material with the constitute of Li(z)Ni(1-x-y)Co(x)Mn(y)O(2), or the mixture of two or more constitutes with the above proportion, adding the slurry, mixing the slurry and the mixture, and carrying out vacuum drying; 3, preparation of the ternary material / lithium ferric manganese phosphate composite cathode material: putting the materials into an argon protective atmosphere sintering surface, keeping warm at the temperature of 250-400 DEG C for 2-6h, then heating to 500-700 DEG C and keeping for 6-16h, cooling along with the furnace, and sieving. The method provided by the invention has the advantages of being simple in technology, convenient to operate, accordant in material performance, small in influence on cell capacity density, and being capable of improving safety performance of the ternary material.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Method for reducing content of residual alkaline in nickel cobalt manganese acid lithium

ActiveCN103700839AReduce residual alkali contentMaintain electrochemical activityCell electrodesLithiumCobalt

The invention discloses a method for reducing the content of residual alkaline in nickel cobalt manganese acid lithium. According to the method, LiH2PO4 serving as an alkaline treatment agent is used for removing alkaline components such as LiOH, Li2CO3 and LiHCO3 retained in a nickel cobalt manganese acid lithium positive electrode material, so that the structure of the positive electrode material cannot be damaged; furthermore, the circulating performance and the compaction density of the positive electrode material can be improved, and the performance of the battery can be improved; meanwhile, the method is simple and feasible and is suitable for industrial production.

Owner:北京盟固利新材料科技有限公司

Method for preparing graphene modified high-nickel series positive electrode material through spray drying process and positive electrode material prepared by same

InactiveCN108539152AImprove electronic conductivityImproved magnification performanceCell electrodesSecondary cellsEmulsionLithium hydroxide

The invention discloses a method for preparing a graphene modified high-nickel series positive electrode material through a spray drying process and the positive electrode material prepared by the same. The method includes following steps: 1), well mixing high-nickel precursor with lithium carbonate or lithium hydroxide according to a certain molar ratio, calcining in an oxygen atmosphere roller way kiln, and smashing to obtain a high-nickel primary smashed material; 2), adding a dispersant, a binder and graphene into a solvent, and stirring and dispersing well to form graphene electroconductive paste with certain solid content, wherein the graphene electroconductive paste is a uniform emulsion in dispersion state; 3), stirring and mixing an oxygen-containing compound source with the high-nickel primary smashed material, adding the graphene electroconductive paste, stirring to obtain graphene mixed paste; 4), utilizing a spray dryer for drying, calcining in the oxygen roller way kiln,smashing, and screening to obtain a final graphene modified high-nickel product. The graphene modified high-nickel positive electrode material produced by adopting the method has the advantages of lowresidual alkali and excellent rate performance and circulating performance and is suitable for industrial production.

Owner:宁夏汉尧石墨烯储能材料科技有限公司

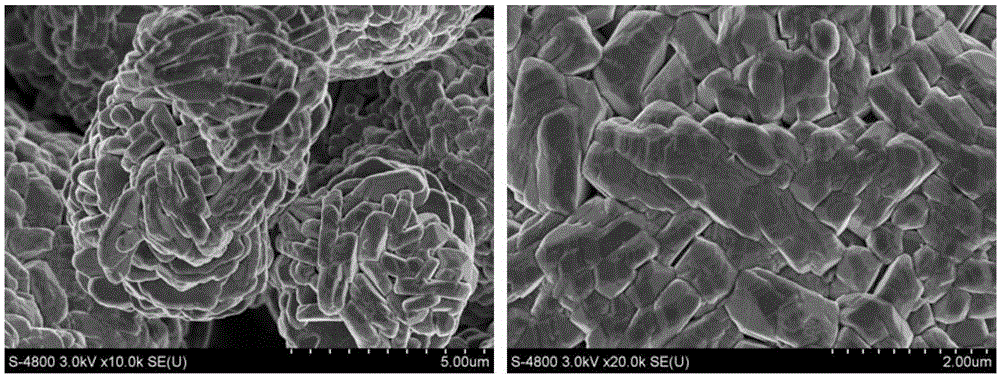

Lithium ion battery positive electrode material and preparation method thereof

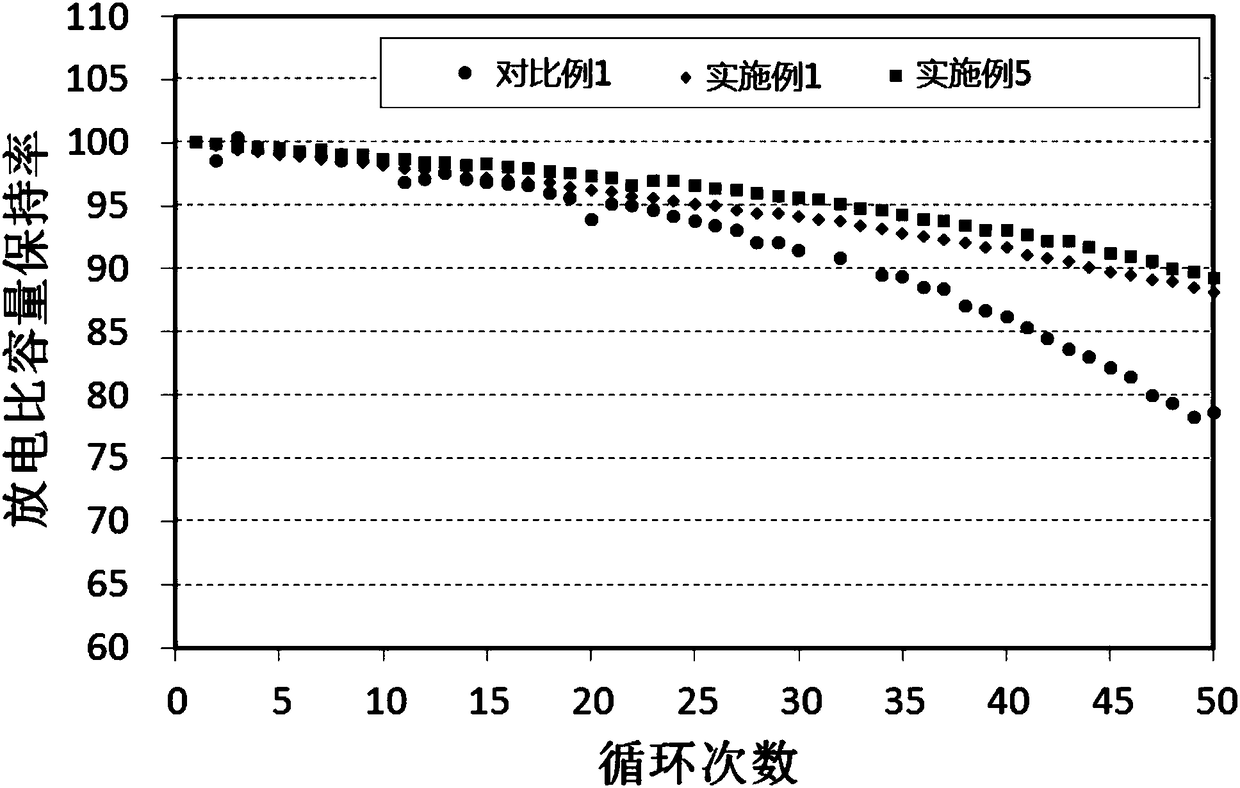

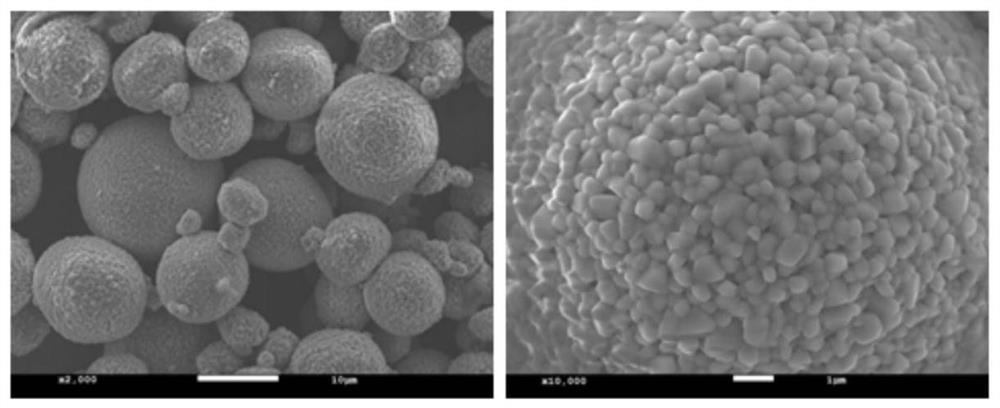

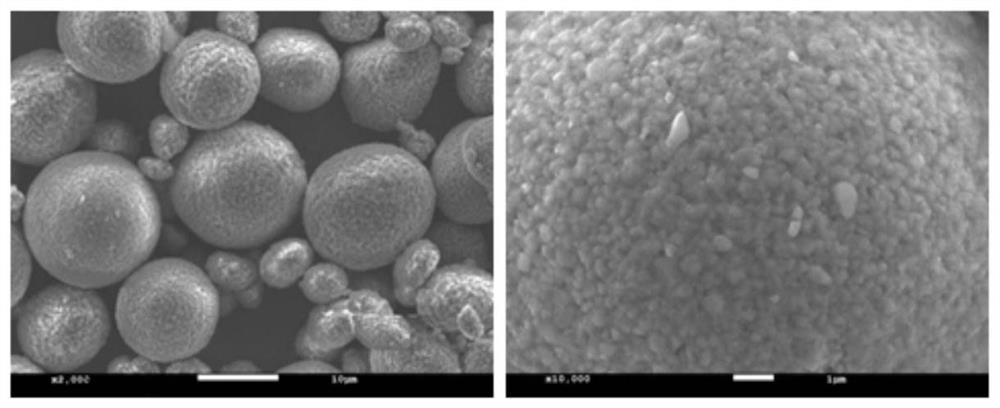

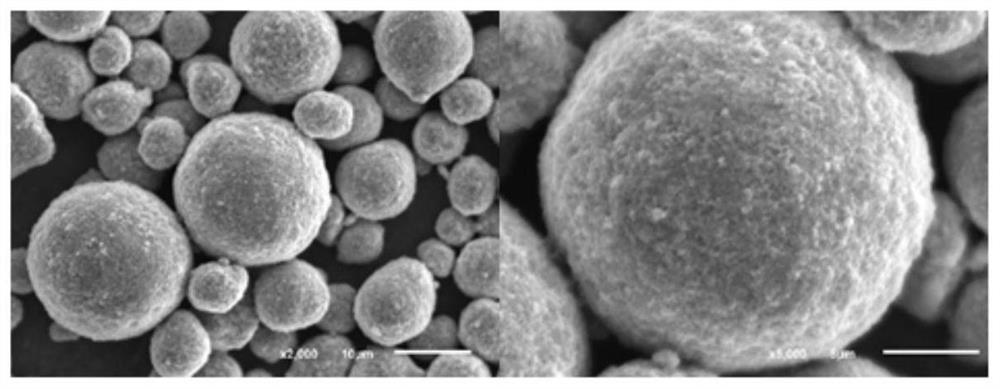

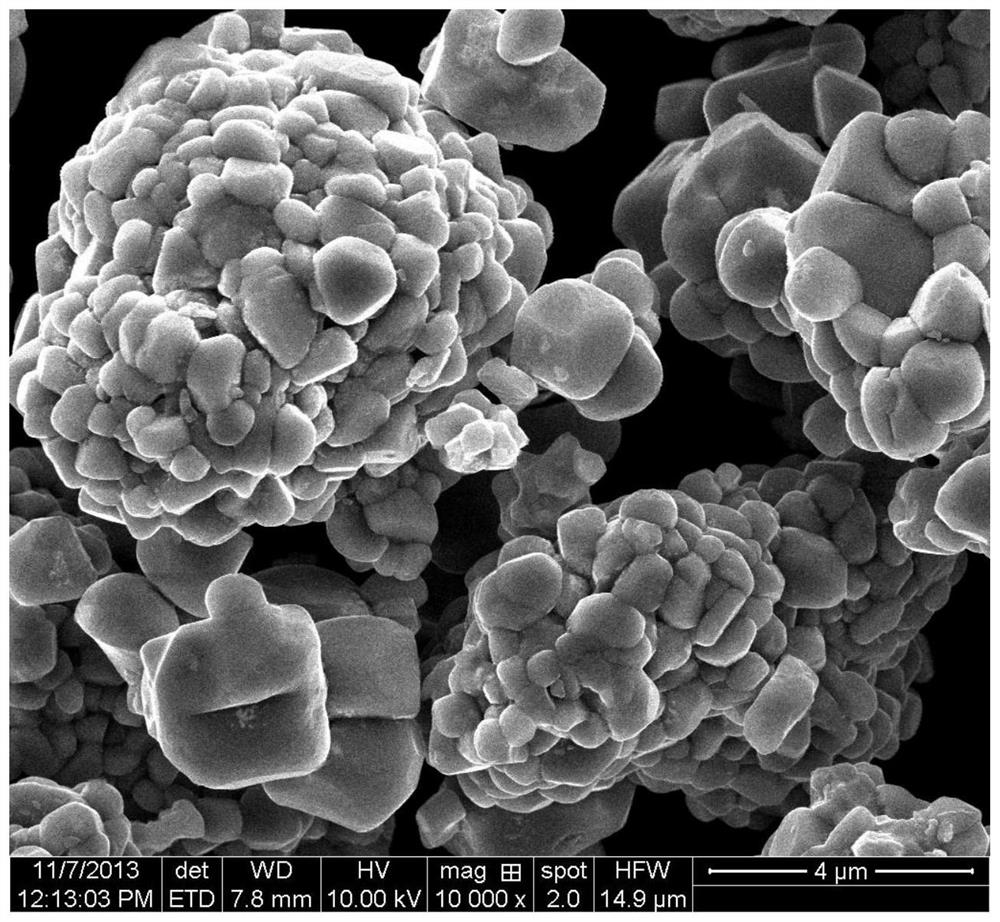

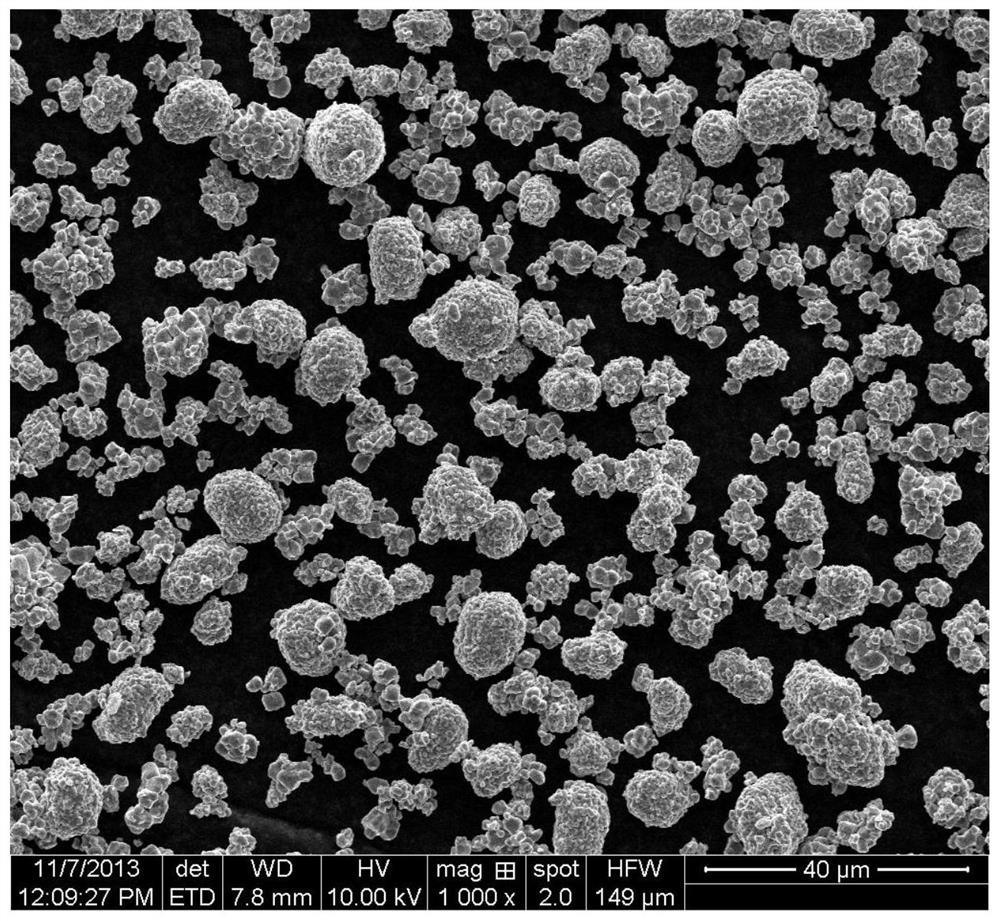

ActiveCN107681128AReduce residual alkali contentPromote circulationCell electrodesSecondary cellsSpherical shapedSingle crystal

The present invention provides a lithium ion battery positive electrode material. The chemical formula of the material is Li<1+n>Ni<0.8+x>Co<0.2-x-y>Al<y>M<z>O<2>, wherein x+y+z<0.2, 0<=x<0.2, 0.01<=y<=0.05, 0.01<=z<=0.05, and -0.1<=n<=0.1; and the M is one kind or several kinds of cobalt, aluminum, magnesium, titanium, zirconium and boron. The lithium ion battery positive electrode material is mixed by single-crystal-shaped nickel cobalt lithium aluminate particles and spherical-shaped nickel cobalt lithium aluminate particles, the median diameter of the spherical-shaped nickel cobalt lithiumaluminate particles is 8-15 [mu]m, and the median diameter of the single-crystal-shaped nickel cobalt lithium aluminate particles is 0.5-6 [mu]m. The present invention also provides a preparation method of the lithium ion battery positive electrode material.

Owner:PULEAD TECH IND

Preparation method of coated ternary nickel-cobalt-manganese lithium oxide positive electrode material

InactiveCN109638232AHigh ion conductivityImprove high temperature cycle performanceCell electrodesSecondary cellsLithium oxideElectrical conductor

The invention discloses a preparation method of a coated ternary nickel-cobalt-manganese lithium oxide positive electrode material. The preparation method comprises the following steps of (1) preparing a ternary nickel-cobalt-manganese lithium precursor; (2) preparing an oxide-coated ternary nickel-cobalt-manganese lithium precursor; and (3) preparing an ion conductor oxide-coated ternary nickel-cobalt-manganese lithium positive electrode material. By the preparation method of the positive electrode material, a lithium ion is easy to de-intercalate from a surface layer of the material, and thehigh-temperature circulation performance of the material is improved; a coating layer does not react with an electrolyte, interface side reaction caused by contact of the main body material and the electrolyte is reduced, and the safety of the material is improved; the processing performance of a pole plate during the uniform coating process is improved, and the high-temperature circulation performance of the material after being assembled into a battery is improved; and the prepared positive electrode material does not need to be subjected to a roasting process for two times, the energy consumption is reduced, and the cost is reduced.

Owner:宁夏汉尧富锂科技有限责任公司

Preparation method of graphene modified high-nickel-series anode material

InactiveCN108539131AImproved magnification performanceImprove electronic conductivityCell electrodesLithium hydroxideAdhesive

The invention discloses a preparation method of a graphene modified high-nickel-series anode material. The preparation method of the graphene modified high-nickel-series anode material comprises the following steps: 1) uniformly mixing a high-nickel precursor with lithium carbonate or lithium hydroxide according to a certain molar ratio, and calcining and pulverizing the mixture in a roller kiln at an oxygen atmosphere to obtain a high-nickel primary pulverized material; 2) adding a dispersing agent, an adhesive and graphene in a solvent, and uniformly stirring and dispersing to form grapheneconductive slurry with a certain solid content, wherein the graphene conductive slurry is uniform emulsion in a dispersing state, and sedimentation and layering do not exist; 3) stirring the grapheneconductive slurry and the high-nickel primary pulverized material for a certain time according to a certain ratio, standing, filtering and drying; and 4) calcining and pulverizing the dried material in the roller kiln at a mixed gas atmosphere to obtain the final graphene modified high-nickel product. The graphene modified high-nickel anode material produced by the method has the characteristics of uniform wrapping, excellent rate capability and high-temperature cycle performance and stable process, and is suitable for industrial production.

Owner:宁夏汉尧石墨烯储能材料科技有限公司

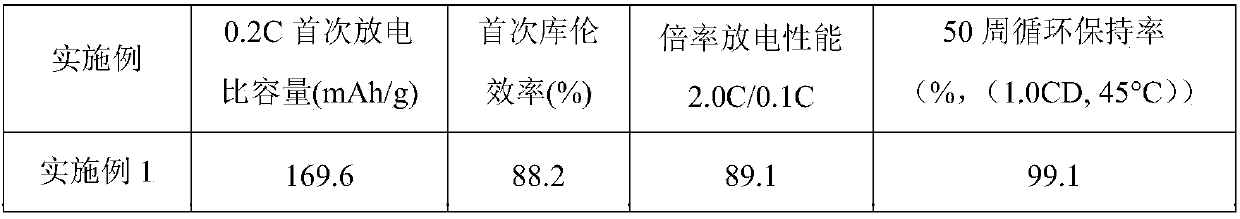

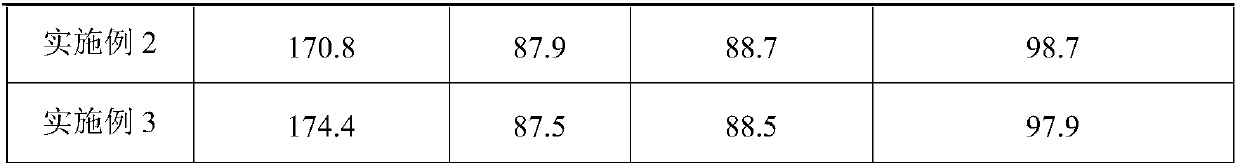

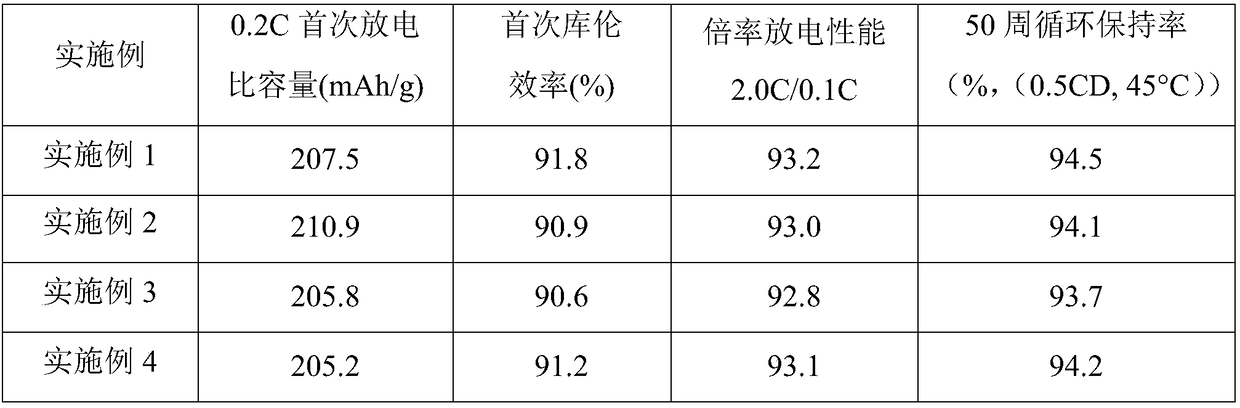

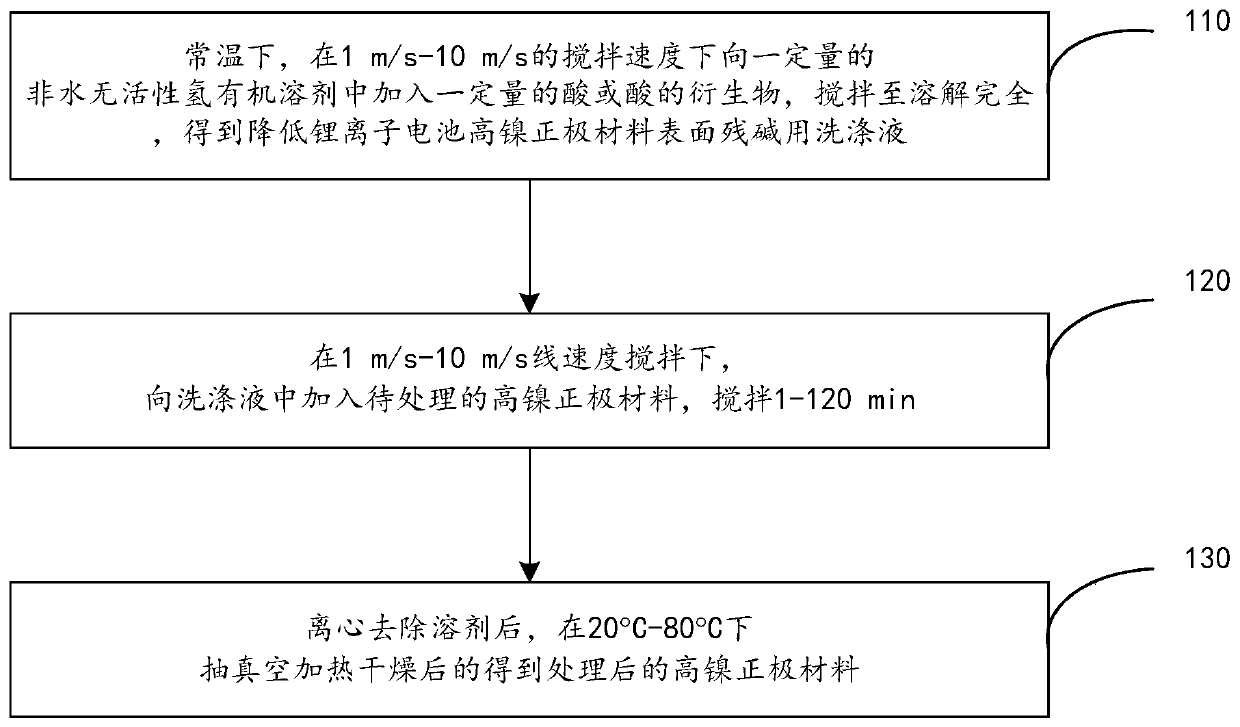

Method for reducing content of residual alkali on surface of high-nickel cathode material of lithium-ion battery

PendingCN111370684ALess side effectsImprove processing performance and cycle lifeCell electrodesSecondary cellsElectrical batteryOrganosolv

The embodiment of the invention relates to a method for reducing the content of residual alkali on the surface of a high-nickel positive electrode material of a lithium ion battery. The method comprises the following steps: adding a certain amount of acid or a derivative of the acid into a certain amount of non-aqueous inactive hydrogen organic solvent at a stirring speed of 1m / s to 10m / s at normal temperature, and stirring until the acid or the derivative of the acid is completely dissolved, so as to obtain a washing solution for reducing residual alkali on the surface of the high-nickel positive electrode material of the lithium ion battery; wherein the mass ratio of the to-be-treated high-nickel positive electrode material to the non-aqueous non-active hydrogen organic solvent is 1:0.5-1:4; wherein the molar concentration of the acid or the derivative of the acid in the washing liquid is 0.5-1.5 times of the molar weight of the residual alkali on the surface of the to-be-treated high-nickel positive electrode material; adding a to-be-treated high-nickel positive electrode material into the washing liquid while stirring at a linear speed of 1m / s to 10m / s, and stirring for 1 to 120 minutes; and centrifuging to remove the solvent, vacuumizing, heating and drying at 20-80 DEG C to obtain the treated high-nickel positive electrode material.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

Preparation method of modified positive electrode material, and lithium ion battery

ActiveCN107919460AReduce residual alkali contentReduce gas productionCell electrodesSecondary cellsDecompositionBoiling point

The invention provides a preparation method of a modified positive electrode material, and a lithium ion battery. The preparation method of the modified positive electrode material comprises the stepsof performing mixing on a layered positive electrode active material, acid with the boiling point of not higher than 600 DEG C and / or acidic salt of the acid with the boiling point of not higher than600 DEG C, and heating to a temperature higher than the boiling point temperature or the sublimation temperature of the acid, or heating to a temperature higher than the decomposition temperature, the boiling point temperature or the sublimation temperature of the acidic salt and performing heat treatment to change the acid and / or the acidic salt into a vapor state to be reacted with residual alkali on the surface of the layered positive electrode active material so as to lower the content of the residual alkali to obtain the modified positive electrode material. After the modified positive electrode material obtained by the method is applied to the lithium ion battery, gas production of the lithium ion battery can be lowered, and the service life of the lithium ion battery is prolonged.

Owner:CONTEMPORARY AMPEREX TECH CO

Nickel and manganese blended lithium ion battery positive material and preparation method thereof

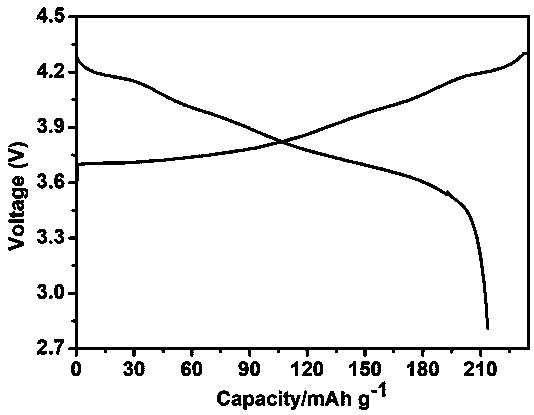

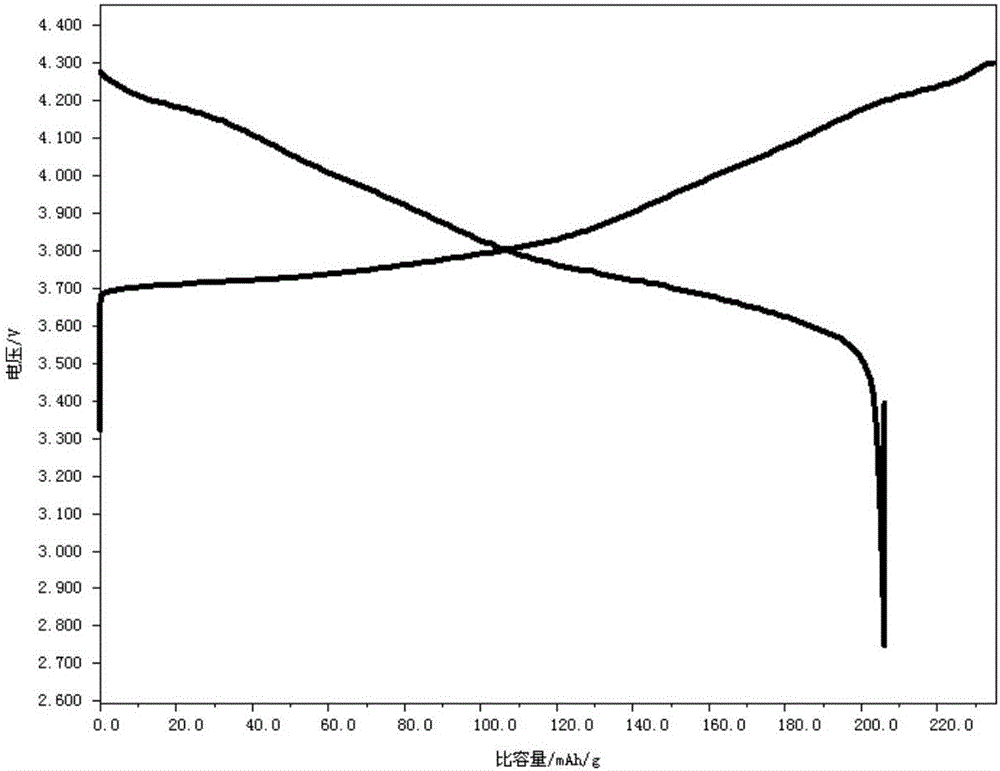

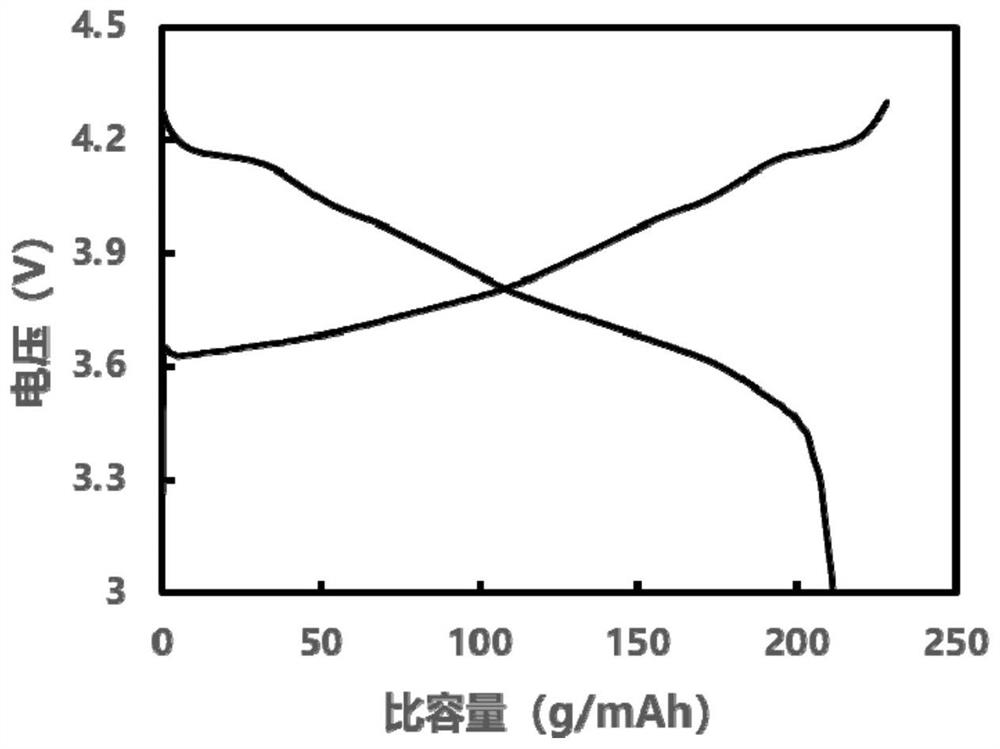

ActiveCN104993121AWide variety of sourcesEasy to prepareCell electrodesSecondary cellsPower batteryManganate

The invention provides a nickel and manganese blended lithium ion battery positive material and a preparation method thereof. The method comprises the following steps: carrying out two-stage roasting on a high-nickel material precursor and a lithium source as raw materials to prepare a high-nickel positive material, and blending the prepared high-nickel positive material with a lithium manganate positive material to prepare the nickel and manganese blended lithium ion battery positive material for a power battery. The prepared positive material has the advantages of high safety and good cycle performances, and the preparation method of the positive material has the advantages of simplicity, easy implementation, wide sources of the raw materials, and low cost.

Owner:北京盟固利新材料科技有限公司

A high-nickel positive electrode material and a preparation method thereof

InactiveCN109148875AEasy to handleReduce residual alkali contentCell electrodesSecondary cellsSolventMaterials science

The invention discloses a high-nickel positive electrode material and a preparation method thereof. The method comprises weighing the positive electrode material, adding a solvent and stirring; solid-liquid separation is carried out to obtain the washed cathode material. Then the washed cathode material is dried and sintered twice to obtain the cathode material with low residual alkali content. Ahigh-nickel cathode material is prepared by washing or pickling the high-nickel cathode material with water or acid at a set time and temperature, strictly controlling conditions such as time and solid-liquid ratio, and the like, so that the high-nickel cathode material has low residual alkali content and good discharge performance. The preparation method has simple and controllable conditions, has low requirements for production equipment, and is a practical method capable of popularization and application.

Owner:北京盟固利新材料科技有限公司

Lithium-ion battery composite positive electrode material and preparation method thereof

ActiveCN111769267AEffective isolation from direct contactAvoid redox reactionsTungsten oxides/hydroxidesCell electrodesComposite electrodeLithium-ion battery

The invention relates to a lithium-ion battery composite positive electrode material and a preparation method thereof. The composite electrode material comprises a base material, and a first coating layer and a second coating layer which sequentially coat the surface of the base material. The lithium-ion battery composite positive electrode material and the preparation method thereof provided by the invention are simple in process, easy for industrial production, low in residual alkali and excellent in cycle and safety performance.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Method for reducing residual alkali content of high-nickel material and prepared low-residual-alkali high-nickel material

ActiveCN112499696AReduce residual alkali contentStable structureCell electrodesNickel compoundsLithiumMaterials science

The invention provides a method for reducing the residual alkali content of a high-nickel material, which comprises the following steps of: mixing a high-nickel ternary positive electrode material precursor, a lithium salt and an additive, and carrying out gradient sintering to obtain a low-residual-alkali high-nickel ternary monofired product, wherein the additive is a weak acid salt. According to the method, a gradient sintering mode is adopted, a low-temperature platform is arranged, a weak acid salt additive is molten in the low-temperature platform, and residual alkali such as LiOH and Li2CO3 on the surface of the high-nickel ternary material is consumed through the molten weak acid salt additive.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

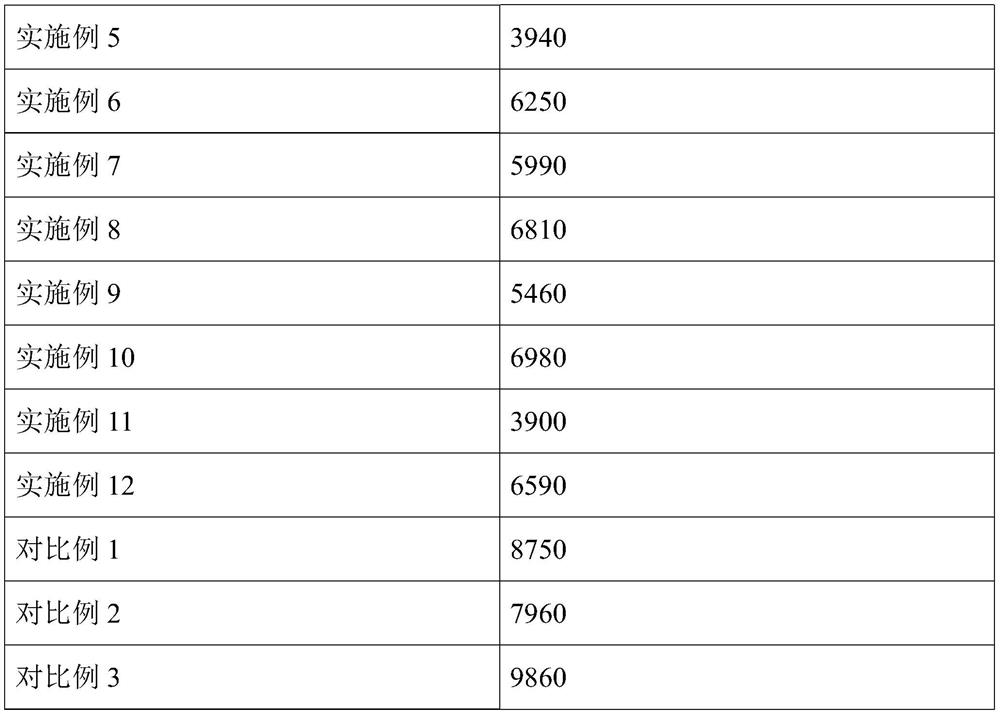

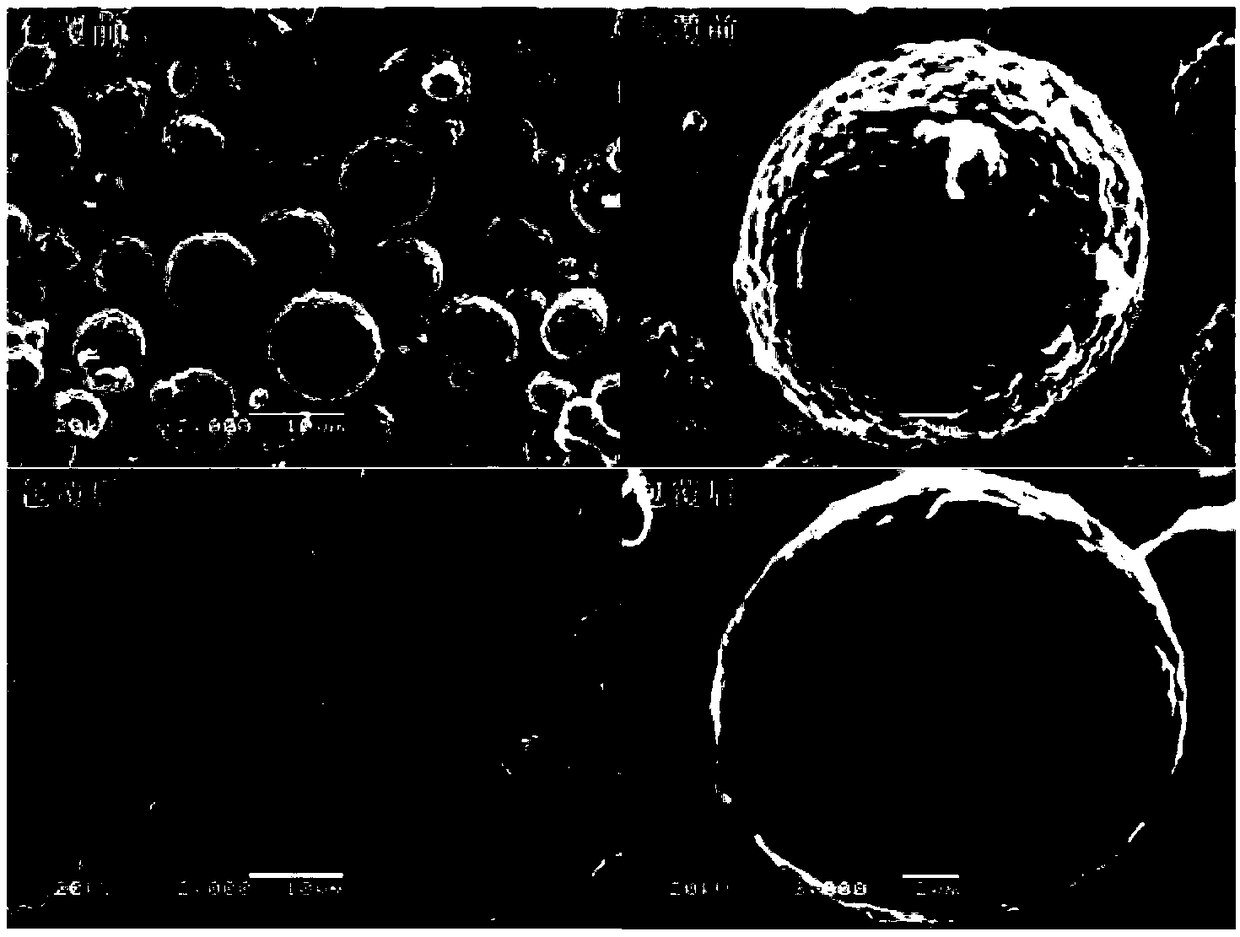

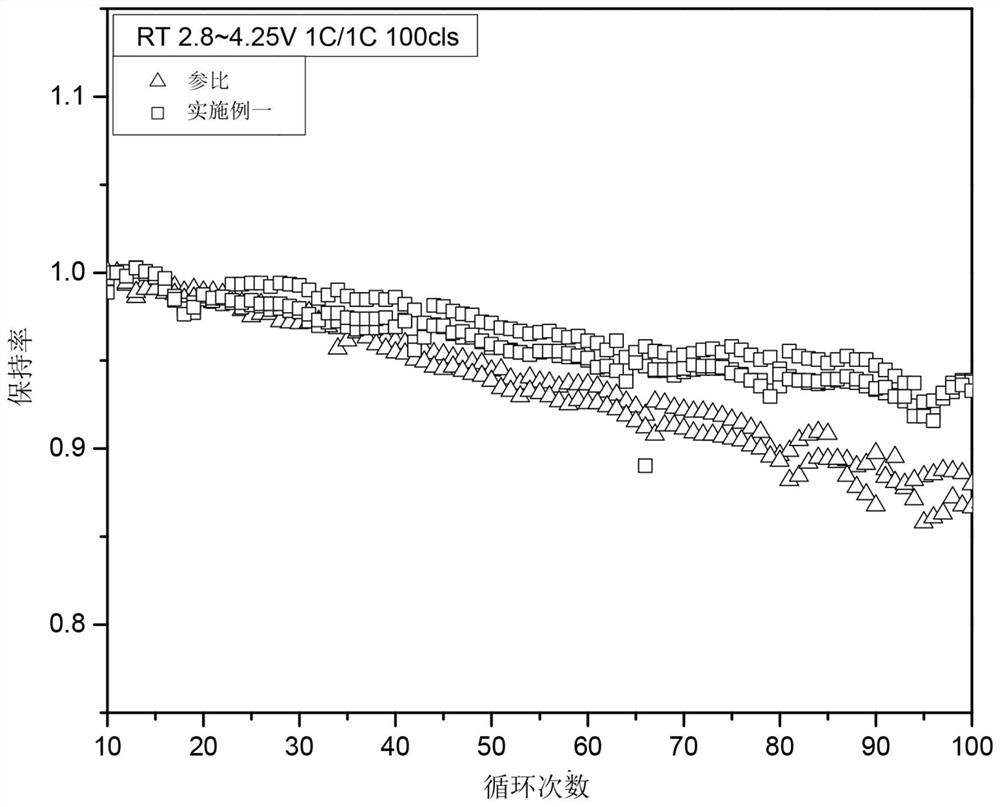

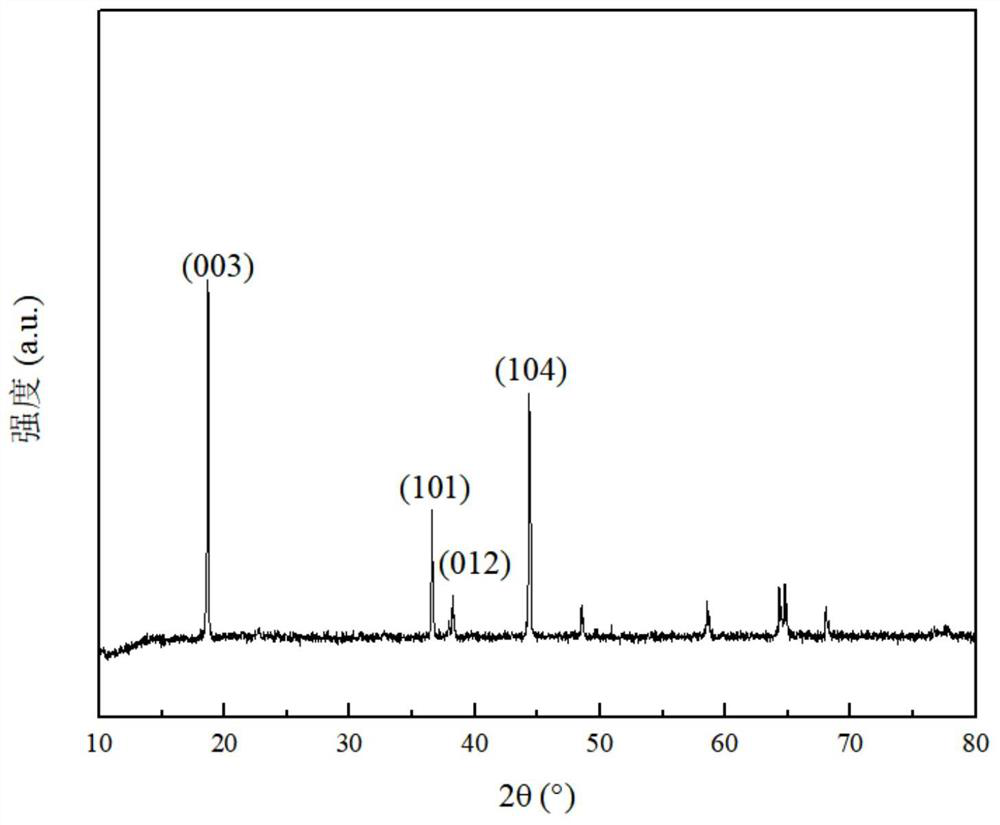

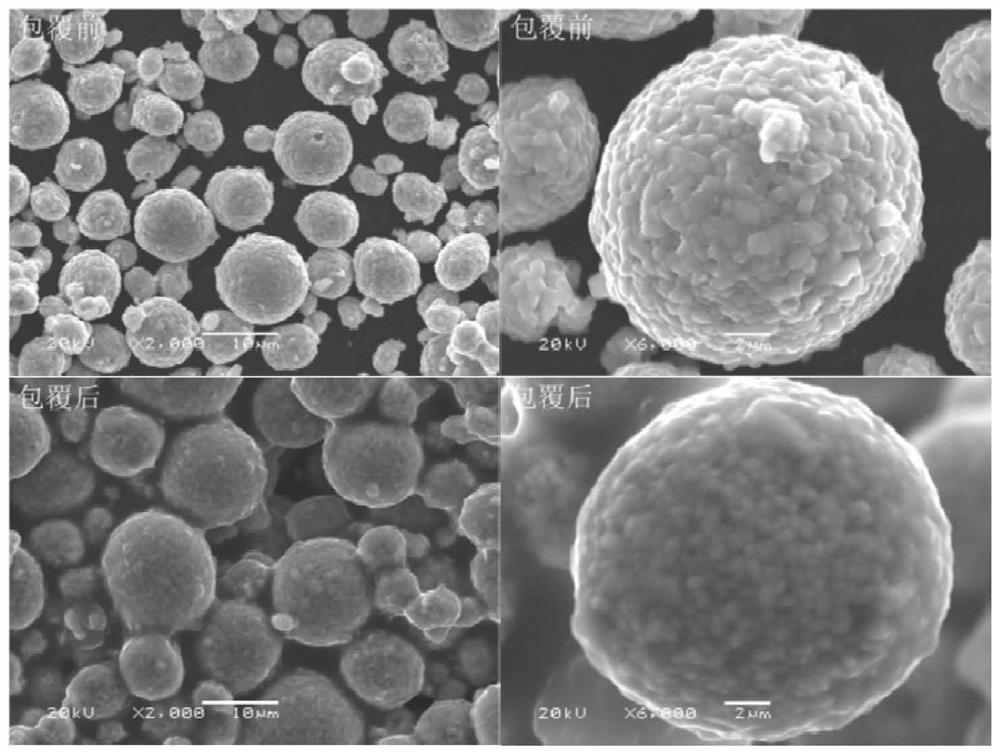

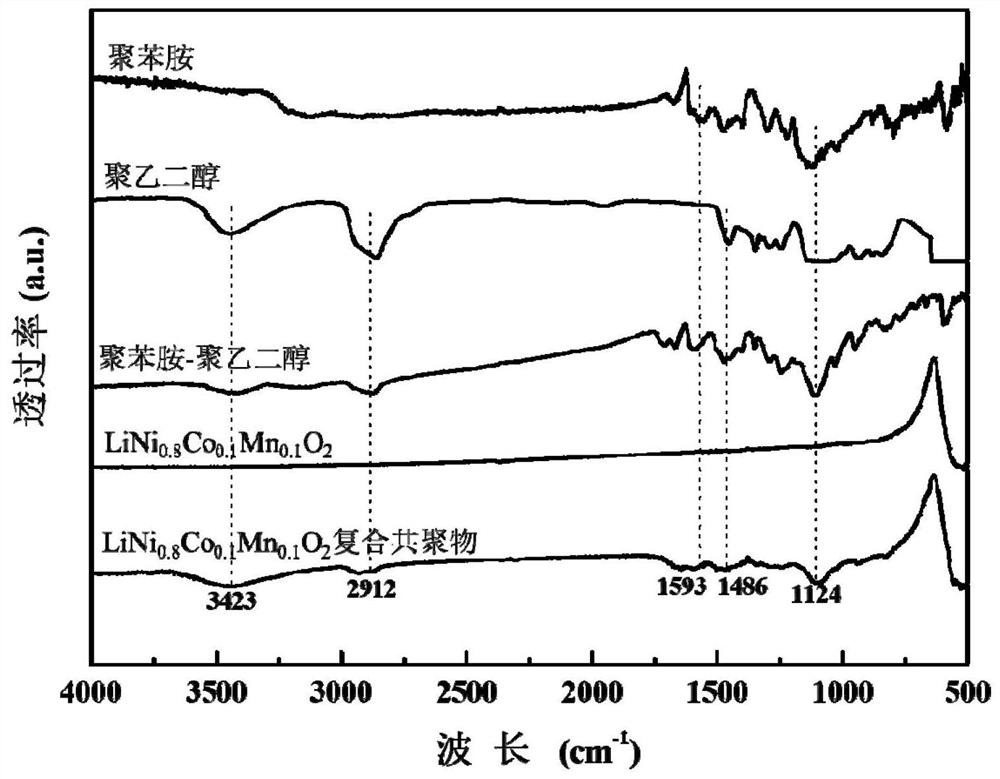

Polyaniline/polyethylene glycol-co-coated composite ternary positive electrode material and preparation and application thereof

ActiveCN108711613AImprove electrochemical performanceImprove the first irreversible capacityMaterial nanotechnologyCell electrodesPolyethylene glycolPolyaniline

The invention belongs to the technical field of positive electrode materials for lithium-ion batteries and particularly relates to a polyaniline / polyethylene glycol-co-coated composite ternary positive electrode material. The composite ternary positive electrode material comprises a ternary positive electrode material, polyaniline and polyethylene glycol, wherein the polyaniline and the polyethylene glycol coat the surface of the ternary positive electrode material. The invention further provides a preparation method and application of the composite ternary positive electrode material. According to the composite ternary positive electrode material, the electrical property of the obtained composite ternary positive electrode material is cooperatively improved through the surface action between the ternary positive electrode material and the polyaniline and the polyethylene glycol, and the coating effect and the chemical stability are improved. Furthermore, a wet coating method is innovatively adopted, so that the process is simple; the coating effect can be further improved through component cooperation; the performance of the material is improved; and the polyaniline / polyethylene glycol-co-coated composite ternary positive electrode material has the advantages of being simple in operation and high in consistency.

Owner:CENT SOUTH UNIV

Lithium ion battery cathode material and preparation method thereof and lithium ion battery

PendingCN109698346AReduce residual alkali contentGood rate stabilityCell electrodesSecondary cellsConductive polymerLithium-ion battery

The purpose of the invention is to present a lithium ion battery cathode material and a preparation method thereof and a lithium ion battery. The cathode material includes a cathode active material, lithium phosphate arranged on at least part of the outer surface of the cathode active material, and a coating layer coating the exposed outer surfaces of the cathode active material and the lithium phosphate and including a conductive polymer. Thus, the residual alkali content on the surface of the cathode active material is low, and the rate performance stability and cyclic capacity retention rate of the cathode material can be improved. The lithium phosphate and the conductive polymer enable the cathode material to have ion-electron conductivity (double conduction), and further improve the rate performance stability and cyclic capacity retention rate of the cathode material. The coating layer can reduce or prevent the side reaction between the cathode active material and the electrolyteand improve the service life of the cathode material.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Preparation method of low residual alkali Li(NiCoAl)O2 cathode material

InactiveCN108206280AEasy to prepareEase of large-scale industrial productionCell electrodesPhosphateAluminium hydroxide

The invention discloses a preparation method of a low residual alkali Li(NiCoAl)O2 cathode material. The preparation method comprises following steps: 1, a nickel cobalt aluminium hydroxide precursoris mixed with a lithium source, and an obtained mixture is subjected to pre-sintering; 2, a product obtained in step 1 is smashed, and is subjected to sencondary sintering so as to obtain a matrix material; 3, the matrix material is smashed, an alkali treatment agent is added, and a third time of sintering is carried out after mixed so as to obtain the low residual alkali Li(NiCoAl)O2 cathode material. The pre-sintering is carried out at 300 to 700 DEG C, preferably at 400 to 650 DEG C, and more preferably at 400 to 600 DEG C, such as 500 DEG C; the secondary sintering is carried out at 600 to900 DEG C, preferably at 700 to 800 DEG C, and more preferably at 750 DEG C; and the third time of sintering is carried out at 600 to 900 DEG C, preferably at 700 to 800 DEG C, and more preferably at750 DEG C; the alkali treatment agent is one or a mixture of a plurality of ingredients selected from nanometer aluminium phosphate, nanometer alumina, nanometer aluminium hydroxide, nanometer cobaltous phosphate, nanometer cobalt oxide, and nanometer cobaltous hydroxide.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

A preparing method of a nickel cobalt lithium aluminate cathode material

InactiveCN104752712ADifficult to solveSolve for uniformityCell electrodesSecondary cellsPhysical chemistryLithium aluminate

A preparing method of a nickel cobalt lithium aluminate cathode material is disclosed. Aluminum and lithium elements are introduced in one step in a wet material mixing process and evenly cover a nickel cobalt compound intermediate, thus avoiding the process difficulty that nickel, cobalt and lithium elements are difficult in uniform deposition in a precursor preparing process. The method is easy in industrial production. A production process of the method is free of pollution and low in energy consumption.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Metal element-doped lithium iron phosphate-coated lithium nickel-cobalt manganate and preparation method thereof

InactiveCN109755487ASolve the problem of serious water absorptionImprove electrochemical performanceMaterial nanotechnologyCell electrodesSolventLithium-ion battery

The invention relates to the field of a lithium ion battery electrode material, and discloses metal element-doped lithium iron phosphate-coated lithium nickel-cobalt manganate and a preparation methodthereof. The preparation method comprises the steps of performing thermal treatment on the lithium nickel-cobalt manganate and a mixture of an M element-doped lithium iron phosphate precursor mixed liquid comprising a lithium source, a doped metal M source, an iron source and a phosphorus source; performing solid-liquid separation on a product obtained after thermal treatment, and drying to obtain a solid phase, wherein a solvent in the M element-doped lithium iron phosphate precursor mixed liquid comprising the lithium source, the doped metal M source, the iron source and the phosphorus source is used as an organic solvent. The organic solvent is used as a reaction liquid, the problem of serious water absorption of a lithium nickel-cobalt manganate ternary material, particularly a high-nickel ternary material is effectively solved, so that the metal element-doped lithium iron phosphate-coated lithium nickel-cobalt manganate having favorable electrochemical performance is prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lithium battery anode material and preparation method and application thereof

InactiveCN109860588AReduce residual alkali contentHigh yieldCell electrodesSecondary cellsOperabilityAqueous solution

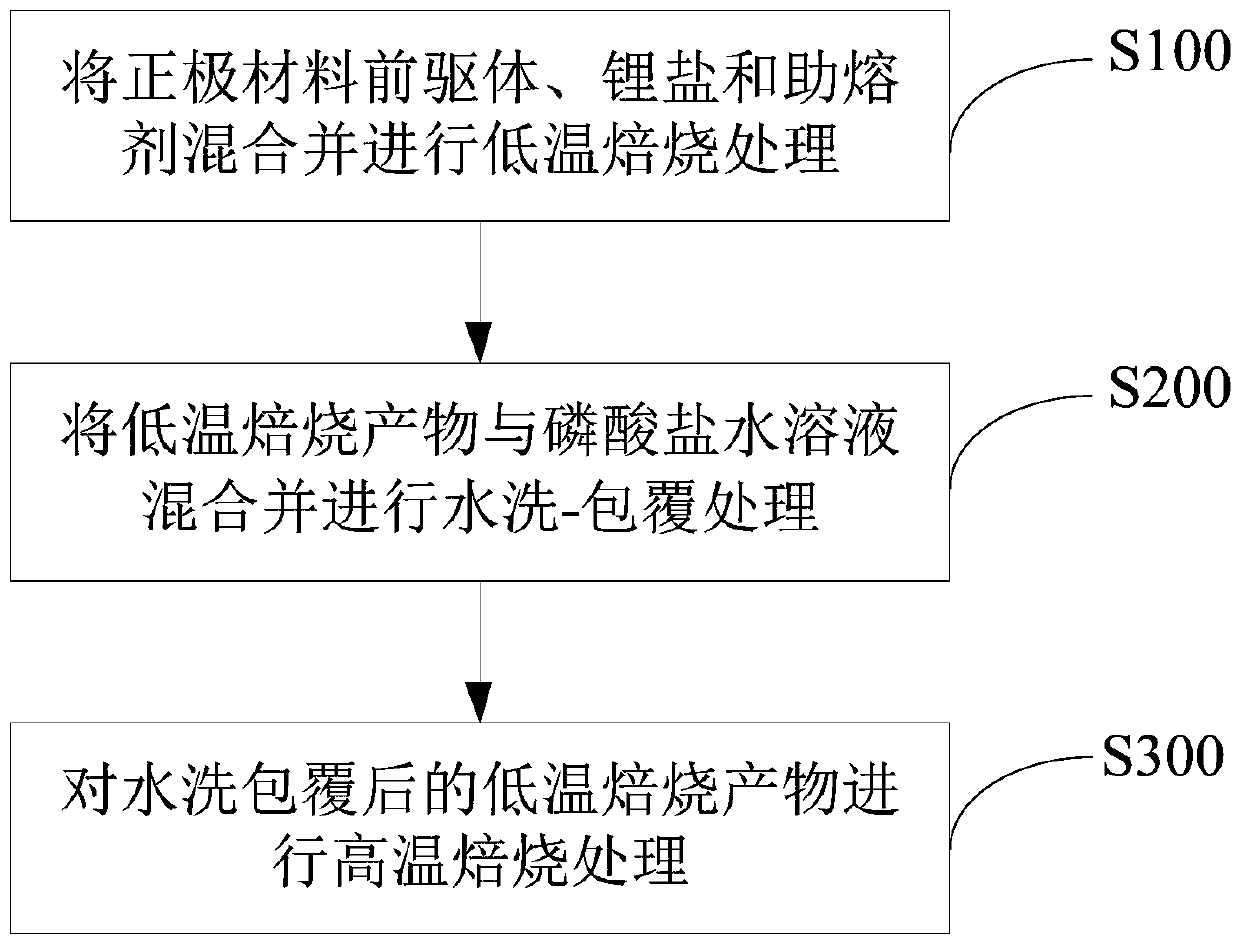

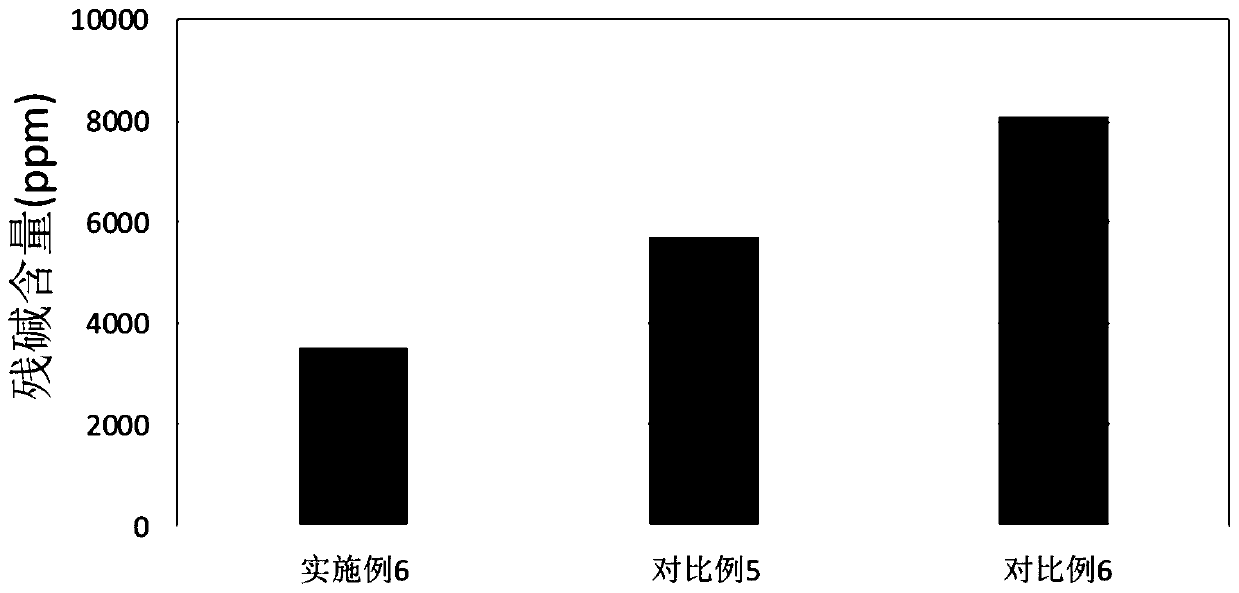

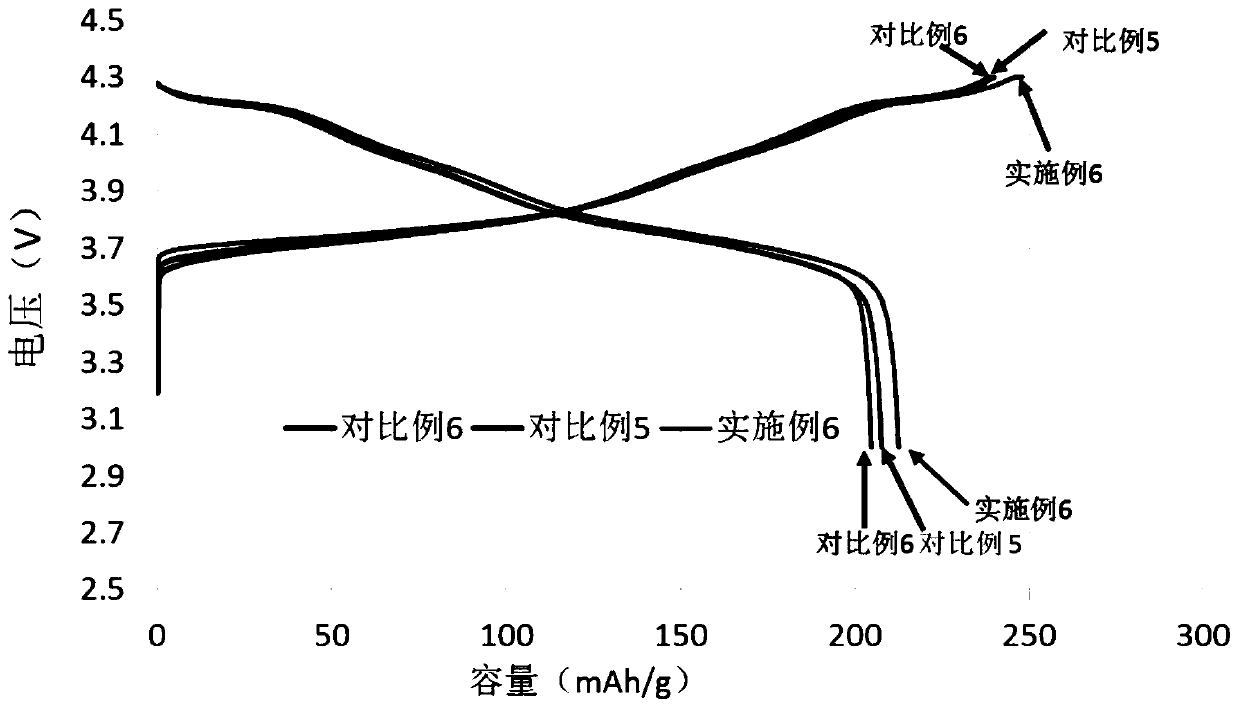

The invention discloses a lithium battery positive electrode material and a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing a positive electrode material precursor, lithium salt and a fluxing agent, and carrying out low-temperature roasting treatment to obtain a low-temperature roasted product; (2) mixing the low-temperature roasted product with phosphate aqueous solution, and performing water washing-coating treatment to obtain a low-temperature roasting product after water washing-coating; (3) carrying out high-temperature roastingtreatment of the low-temperature roasted product after water washing-coating to obtain the positive electrode material. The method is strong in operability, high in preparation efficiency and low incost, and the prepared positive electrode material is high in yield, relatively uniform in coating, low in material residual alkali content, good in cycling stability and long in cycling service life.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

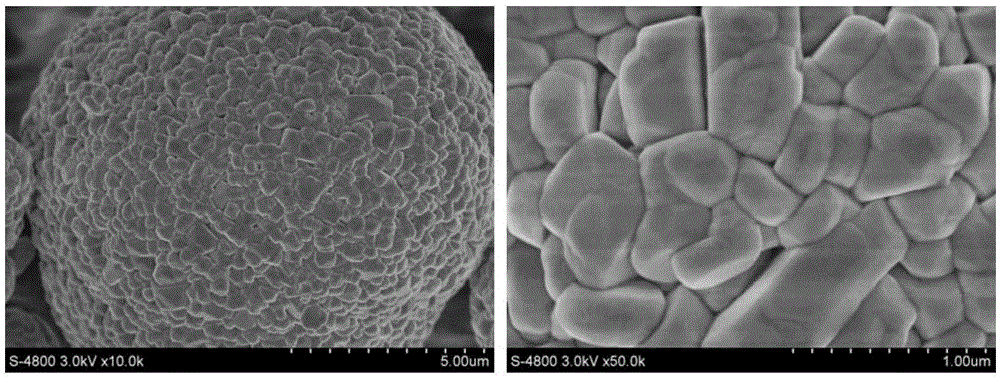

High-tap-density high-nickel positive electrode material and preparation method thereof

InactiveCN111384393AHigh tap densityReduce volumeSecondary cellsPositive electrodesLithium electrodeMetallurgy

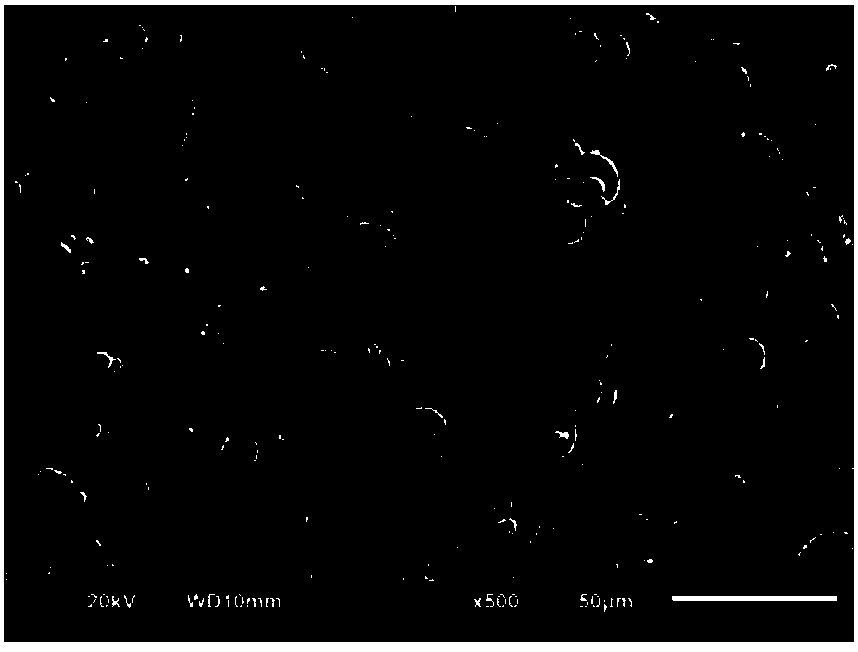

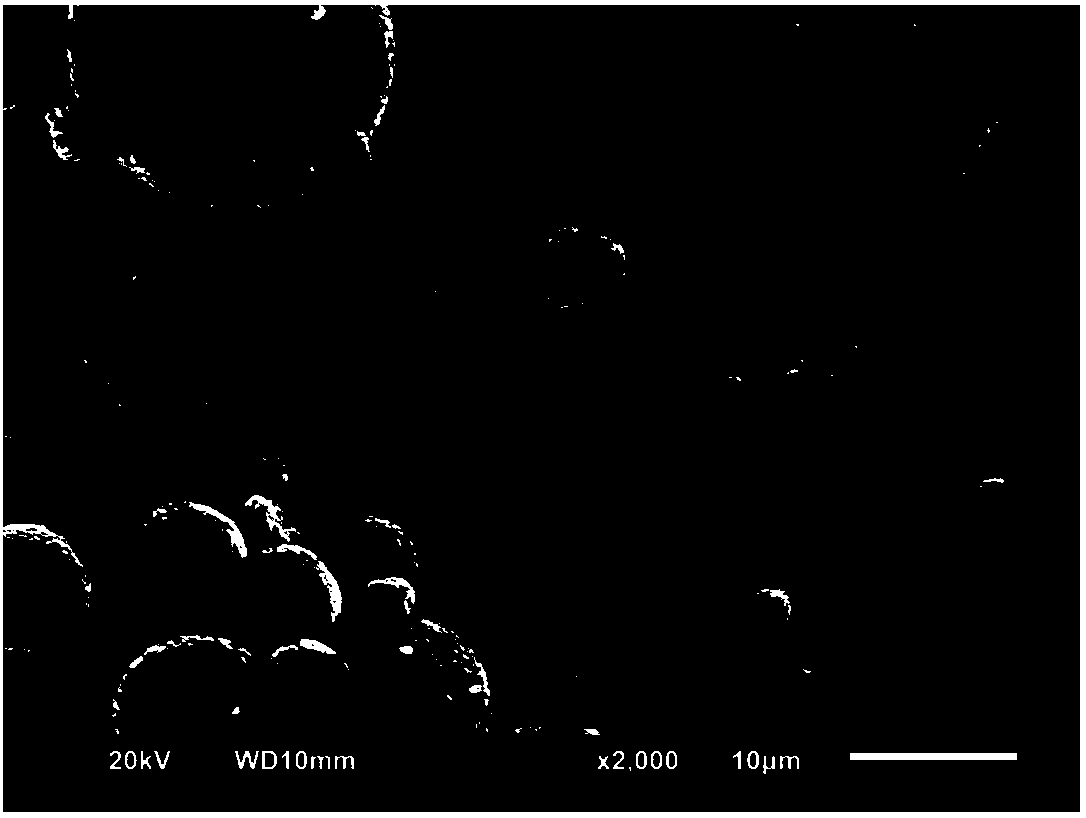

The invention discloses a high-tap-density high-nickel positive electrode material and a preparation method thereof. The high-nickel positive electrode material is formed by grading two or more high-nickel base materials with different median particle sizes D50. The preparation method of the high-tap-density high-nickel positive electrode material comprises the steps of 1, preparing high-nickel base materials with different particle sizes; and 2, mixing the high-nickel base materials with different particle sizes. According to the invention, the high-tap-density high-nickel positive electrodematerial is prepared by adopting a grading method of particles with large and small particle sizes, the prepared high-nickel positive electrode material has relatively high tap density and relativelylow residual alkali content, a lithium ion battery prepared from the positive electrode material has excellent electrochemical performance, and the preparation method is simple, efficient, low in cost, environmentally friendly and suitable for large-scale industrial production.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

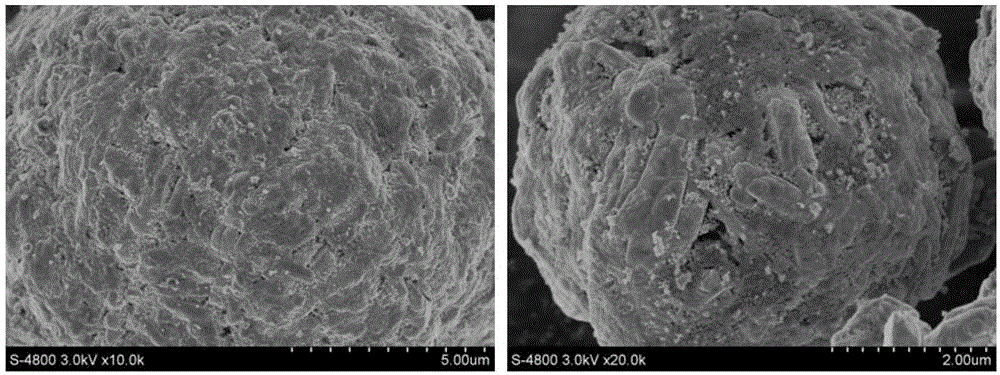

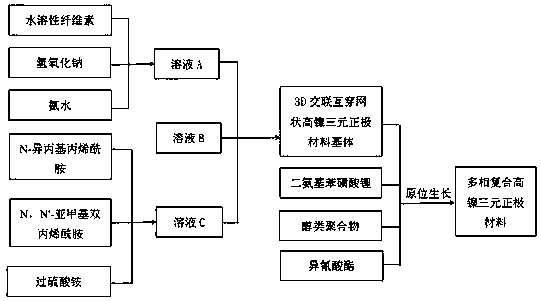

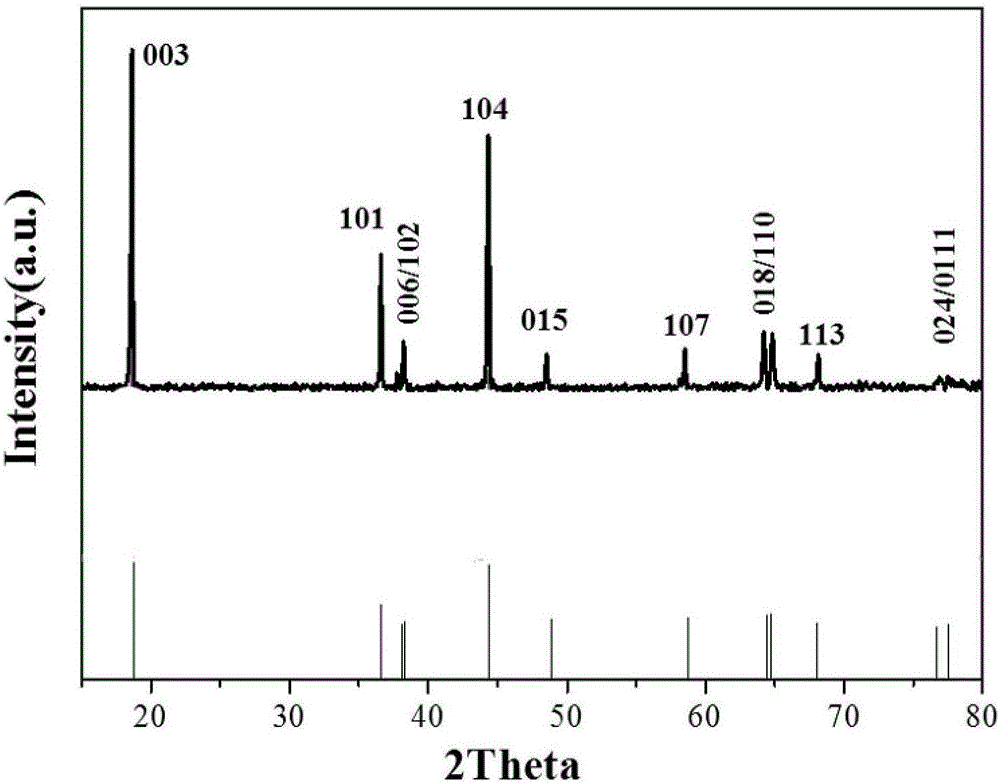

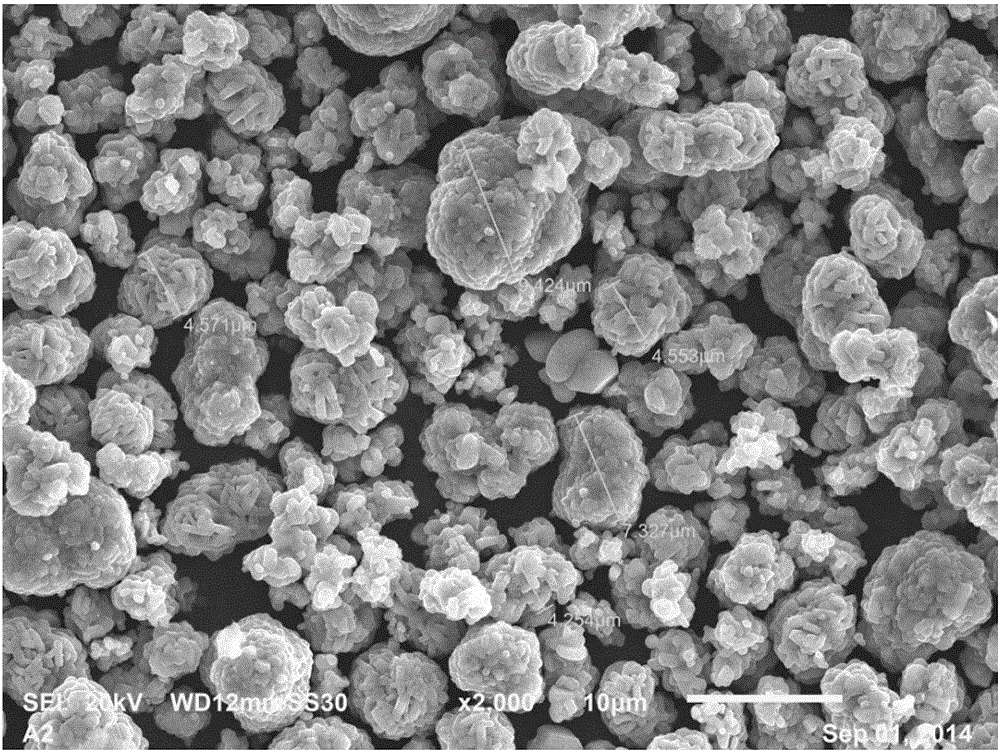

Multiphase composite high-nickel ternary positive electrode material and preparation method thereof

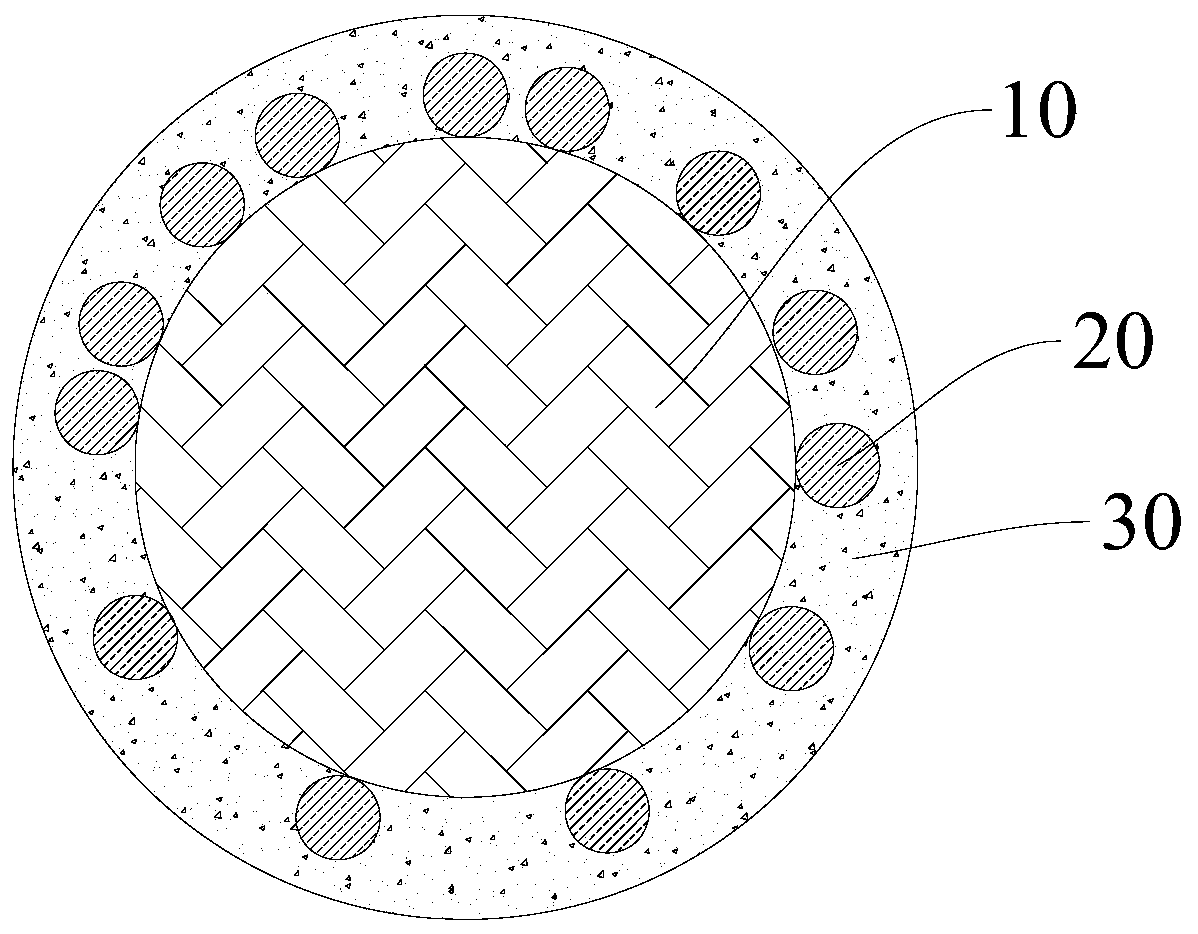

ActiveCN110350164AWith shuffling phenomenonReduce breakageCell electrodesSecondary cellsCross-linkElectrical conductor

The invention belongs to the field of batteries, and particularly relates to a multiphase composite high-nickel ternary positive electrode material and a preparation method thereof. The material is formed by bonding a 3D cross-linked interpenetrating netty high-nickel ternary positive electrode material matrix and a single-ion conductor polymer, and has a 3D cross-linked interpenetrating netty core-shell structure. The required preparation method comprises the following steps: 1) carrying out gradient temperature reaction on a solution A, a solution B and a solution C in a reaction kettle, andthen carrying out high-temperature treatment to obtain the 3D cross-linked interpenetrating netty high-nickel ternary positive electrode material matrix; and 2) carrying out in-situ growth on lithiumaminobenzenesulfonate, an alcohol polymer, isocyanate and the 3D cross-linked interpenetrating netty high-nickel ternary positive electrode material matrix in the reaction kettle, and carrying out annealing treatment to obtain the multi-phase composite high-nickel ternary positive electrode material. The multi-phase composite high-nickel ternary positive electrode material prepared by the preparation method is good in cycling performance, easy for size mixing of a lithium ion battery, excellent in rate performance and low-temperature performance, and stable in structure; and the process is simple and easy to operate, and is environment-friendly.

Owner:HUNAN ZHENGYUAN ENERGY STORAGE MATERIALS & DEVICE INST

Preparation method for ternary positive electrode material of lithium battery

InactiveCN106654196AReduce gas productionImprove securityCell electrodesSecondary cellsAir atmosphereFree cooling

The invention provides a preparation method for a ternary positive electrode material of a lithium battery. The preparation method comprises the following steps of 1) configuring a ferric nitrate solution at certain concentration, stirring and slowly adding LiNi<1-x-y>Co<x>Mn<y>O<2> (x is greater than 0 and less than 1, y is greater than 0 and less than 1) at certain proportion, stirring for a certain time and then performing ultrasonic processing, and dropwise adding a (NH<4>)<2>HPO<4> solution at certain concentration based on a stoichiometric ratio, and continuing to stir for 4-8h; 2) filtering the solution obtained in the step 1), washing by deionized water and then drying at a temperature of 80-120 DEG C for 14-24h; and 3) performing heat preservation on the powder dried in the step 2) at a temperature of 250-400 DEG C in air atmosphere for 4-6h, and then naturally cooling to room temperature. The invention provides the preparation method for the ternary positive electrode material of the lithium battery by adopting amorphous iron phosphate (FePO<4>) through coating treatment, so that the structural stability is improved, and the safety and cycling performance are improved; and the method has the advantages of simple process, convenience in operation, and high product consistency.

Owner:OPTIMUM BATTERY CO LTD

Method for reducing content of residual alkali on surface of positive electrode material and application thereof

PendingCN111453779AReduce residual alkali contentSmall increase in specific surface areaCell electrodesSecondary cellsElectrical batteryManganese

The invention discloses a method for reducing the content of residual alkali on the surface of a positive electrode material and application thereof. The method for reducing the content of residual alkali on the surface of the positive electrode material comprises the following steps: mixing a nickel-cobalt-manganese ternary positive base material having alkali residues on the surface with a coating agent, and carrying out roasting treatment so as to allow residual alkali on the surface of the positive base material to react with the coating agent to form a coating layer on the surface of thepositive base material, thereby obtaining the positive electrode material with low content of alkali residues on the surface. The method not only can effectively solve the problem of harm of conventional residual alkali removing methods to the performance and the environment of positive electrode materials, but also can improve the electrochemical performance and the safety performance of a lithium ion battery and prolong the service life of the lithium ion battery.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

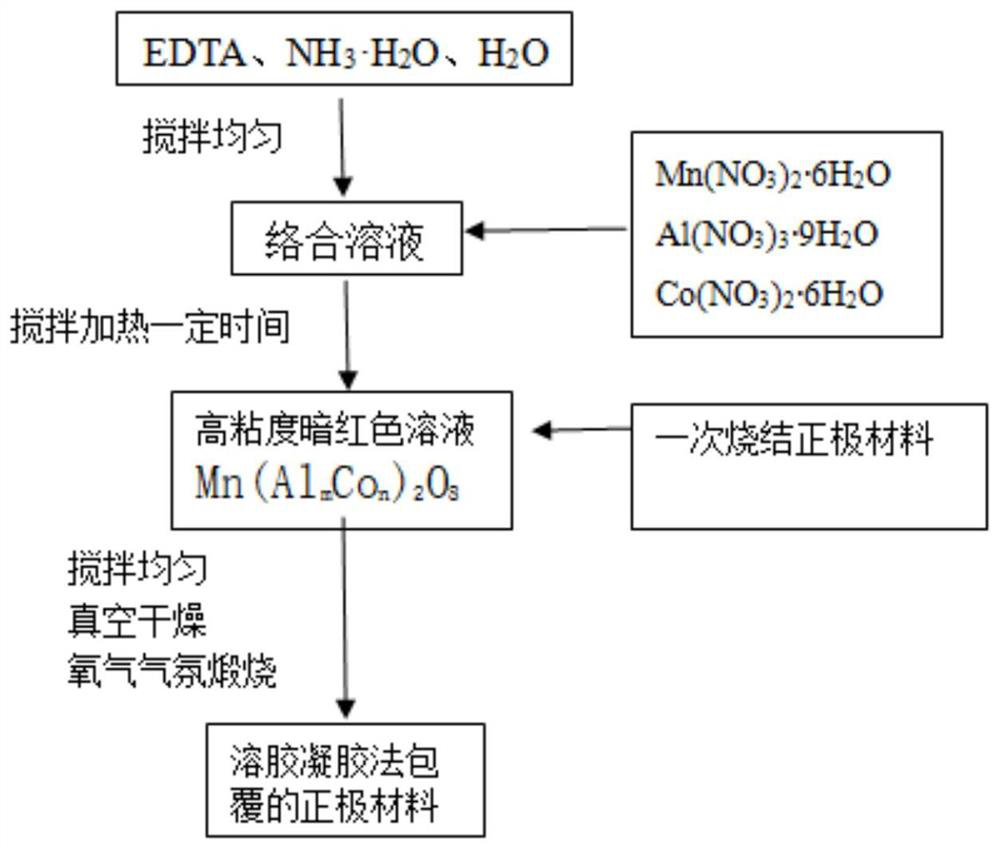

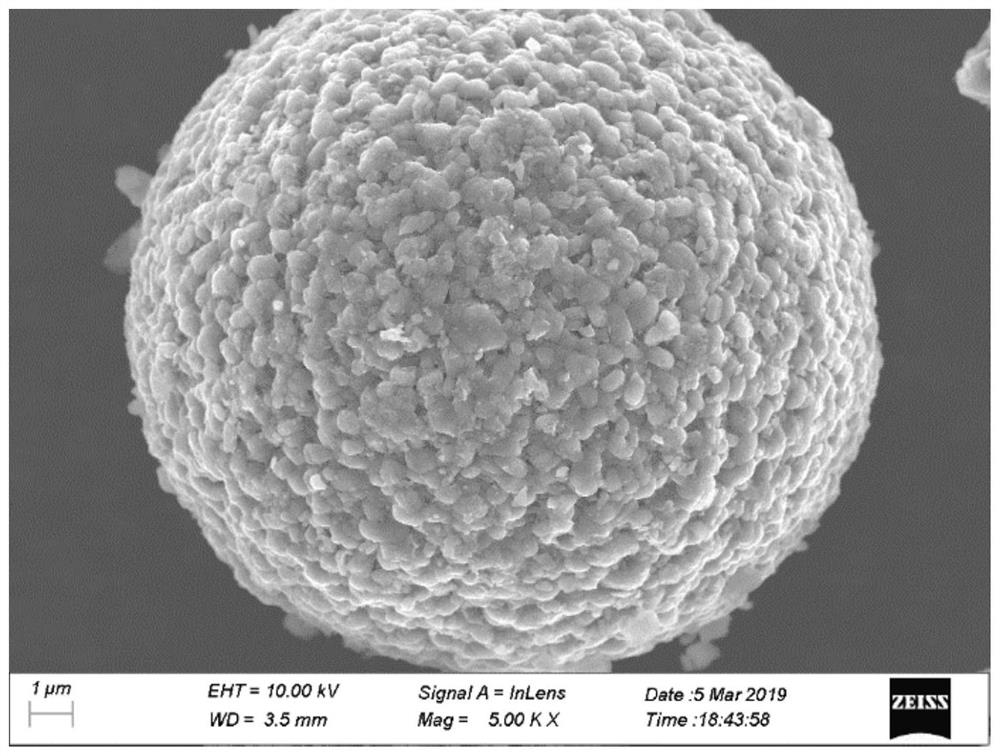

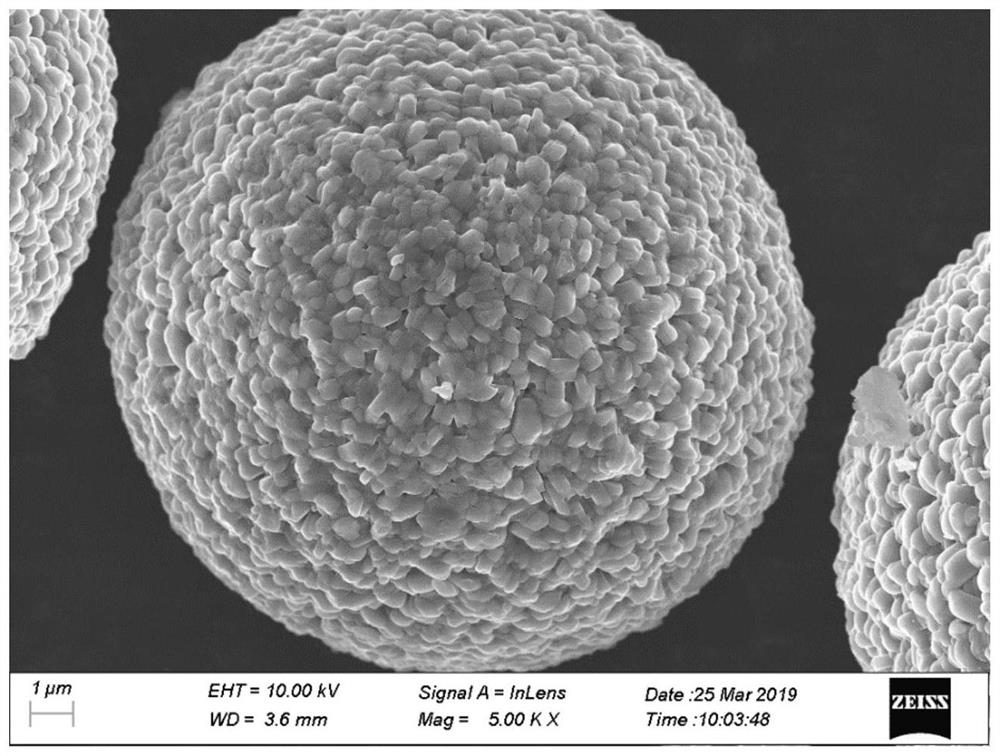

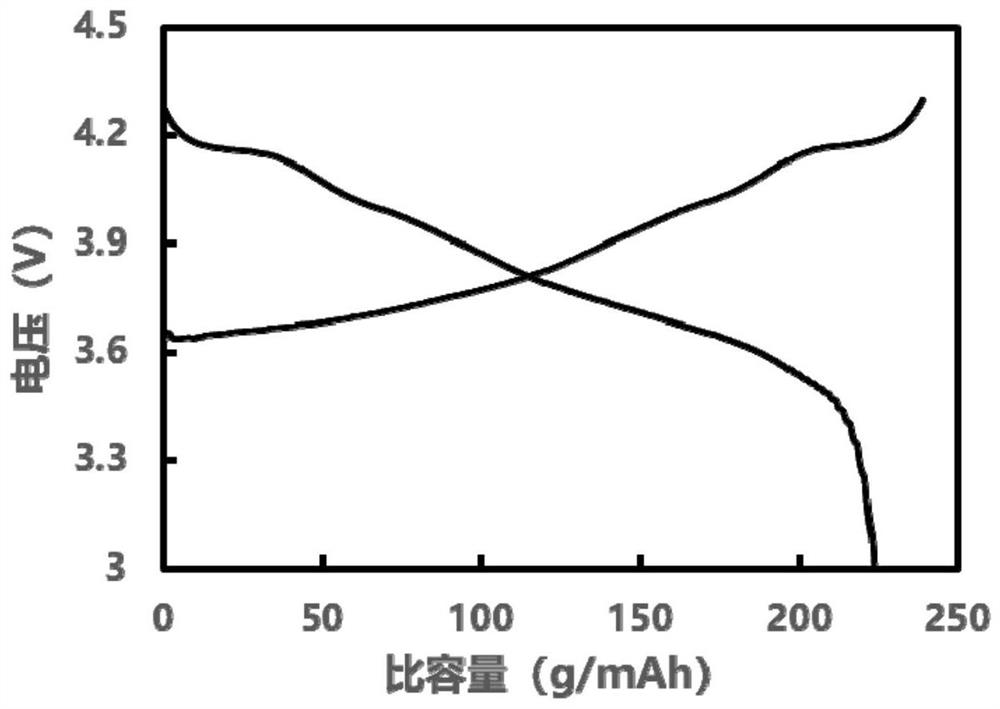

Coated positive electrode material and preparation method and application thereof

ActiveCN111916701AReduce residual alkali contentElectronically conductiveCell electrodesSecondary cellsElectrolytic agentPhysical chemistry

The invention relates to a coated positive electrode material and a preparation method and application thereof. The preparation method comprises the steps: adding a coated metal source into a complexing solution, performing mixing and heating to obtain gel, adding a positive electrode material into the gel, and performing mixing and calcining to obtain the coated positive electrode material, wherein the coated metal source comprises a cobalt source, a manganese source and an aluminum source. According to the preparation method, the sol-gel method is adopted, residual alkali on the surface of the positive electrode material can be effectively reduced, a coating layer of the obtained coated positive electrode material has electronic conductivity, the contact area of the positive electrode material and electrolyte can be effectively reduced, side reactions are reduced, and the electrochemical performance of the positive electrode material is improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Ultrahigh nickel single-crystal positive electrode material and preparation method thereof

PendingCN113839015AImprove cycle stabilityPromote crystallization co-growthSecondary cellsPositive electrodesManganeseSingle crystal

The invention belongs to the technical field of lithium ion battery positive electrode material preparation, and particularly relates to an ultrahigh nickel single crystal positive electrode material and a preparation method thereof. According to the invention, an ultrahigh nickel positive electrode material precursor (nickel-cobalt-manganese-aluminum hydroxide) is used as a matrix raw material, the precursor is fully crushed by using the acting force of high rotating speed and high pressure, and a lithium source and strontium carbonate are added during the period, so that the lithium source and the precursor are promoted to be mutually dissolved and then crystallized and co-grown at a relatively low temperature, the lithium-nickel mixing is reduced, and finally, calcining is performed to obtain the single-crystal-like material. The monocrystal-like material provided by the invention is uniform in size and high in particle strength, and the cycling stability of the material is enhanced. The technical problems that due to the fact that the nickel content in the ultrahigh nickel material is high, nickel in generated mono-like crystals is severely separated out due to high-temperature calcination, the later battery capacity fades, the residual alkali content is high and the like in the preparation process of the ultrahigh nickel mono-like materials are solved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

A kind of positive electrode material of lithium ion battery and preparation method thereof

ActiveCN107681128BReduce residual alkali contentPromote circulationCell electrodesSecondary cellsTitanium zirconiumPhysical chemistry

The present invention provides a lithium ion battery positive electrode material. The chemical formula of the material is Li<1+n>Ni<0.8+x>Co<0.2-x-y>Al<y>M<z>O<2>, wherein x+y+z<0.2, 0<=x<0.2, 0.01<=y<=0.05, 0.01<=z<=0.05, and -0.1<=n<=0.1; and the M is one kind or several kinds of cobalt, aluminum, magnesium, titanium, zirconium and boron. The lithium ion battery positive electrode material is mixed by single-crystal-shaped nickel cobalt lithium aluminate particles and spherical-shaped nickel cobalt lithium aluminate particles, the median diameter of the spherical-shaped nickel cobalt lithiumaluminate particles is 8-15 [mu]m, and the median diameter of the single-crystal-shaped nickel cobalt lithium aluminate particles is 0.5-6 [mu]m. The present invention also provides a preparation method of the lithium ion battery positive electrode material.

Owner:PULEAD TECH IND

Ternary positive electrode material and preparation method and application thereof

ActiveCN113896253AEvenly distributedImprove doping uniformitySecondary cellsPositive electrodesDopantLithium

The invention discloses a ternary positive electrode material and a preparation method and application thereof. The preparation method comprises the following steps: mixing a ternary precursor, a lithium source and a metal dopant, and taking an organic solvent as a dispersion medium, and performing mixing, wet grinding and drying to obtain a mixture; ultrasonically infiltrating the mixture by using a fluorine-containing organic solvent, and performing granulating and tabletting to obtain mixed particles; and carrying out high-temperature sintering, crushing and grading on the mixed particles by adopting three-section programmed heating to prepare the ternary positive electrode material. By changing the mixing mode of the metal dopant and the precursor, ultrasonically infiltrating the fluorine-containing organic solvent and matching with the three-section programmed heating,the obtained ternary positive electrode material is uniformly doped with metal elements, the doping effect is good, the content of residual alkali on the surface of the material is effectively reduced, and the ternary positive electrode material has excellent electrochemical performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

A polyaniline/polyethylene glycol co-wrapped composite ternary cathode material and its preparation and application

ActiveCN108711613BUniform coating modificationImprove the first irreversible capacityMaterial nanotechnologyCell electrodesElectrical batteryPolyethylene glycol

The invention belongs to the technical field of positive electrode materials for lithium-ion batteries and particularly relates to a polyaniline / polyethylene glycol-co-coated composite ternary positive electrode material. The composite ternary positive electrode material comprises a ternary positive electrode material, polyaniline and polyethylene glycol, wherein the polyaniline and the polyethylene glycol coat the surface of the ternary positive electrode material. The invention further provides a preparation method and application of the composite ternary positive electrode material. According to the composite ternary positive electrode material, the electrical property of the obtained composite ternary positive electrode material is cooperatively improved through the surface action between the ternary positive electrode material and the polyaniline and the polyethylene glycol, and the coating effect and the chemical stability are improved. Furthermore, a wet coating method is innovatively adopted, so that the process is simple; the coating effect can be further improved through component cooperation; the performance of the material is improved; and the polyaniline / polyethylene glycol-co-coated composite ternary positive electrode material has the advantages of being simple in operation and high in consistency.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com