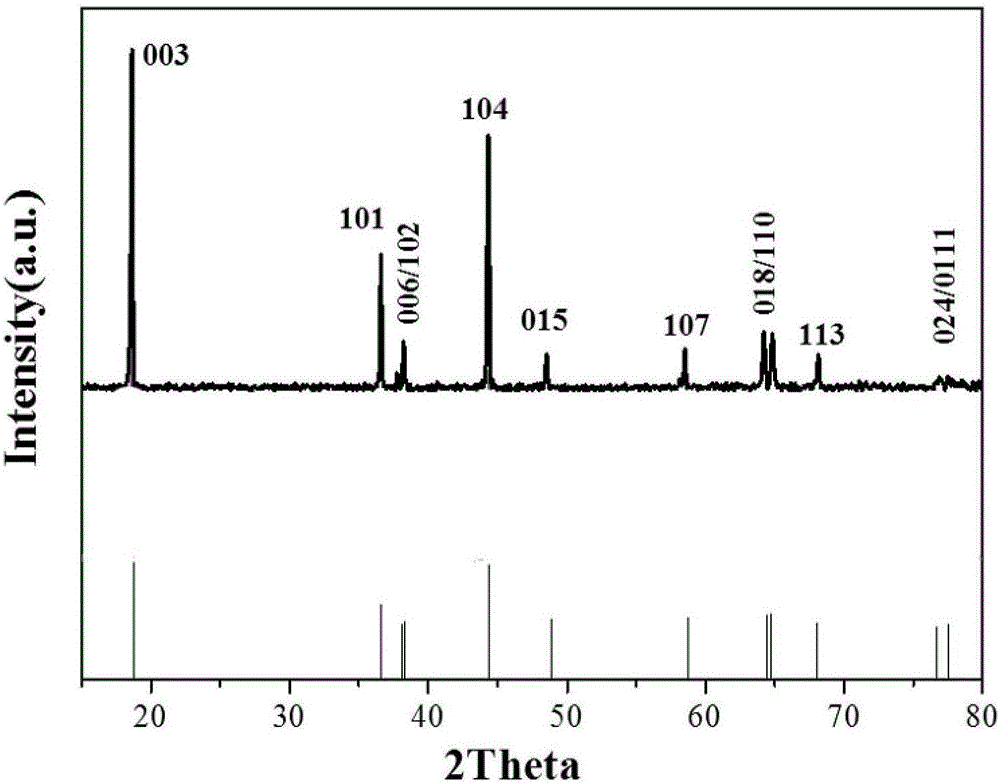

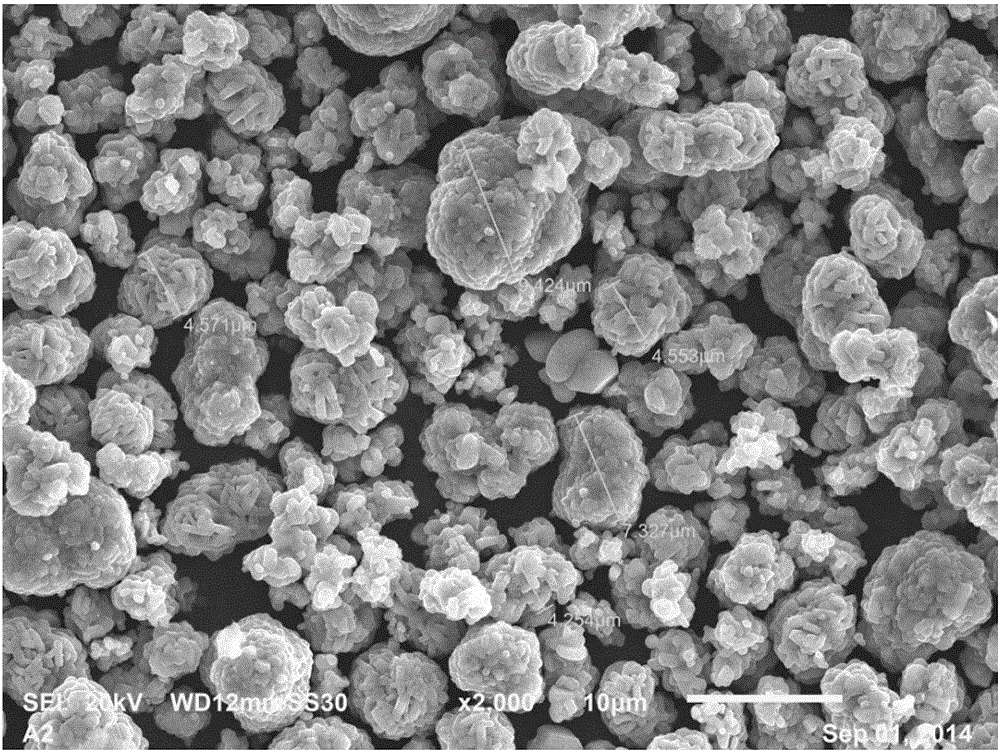

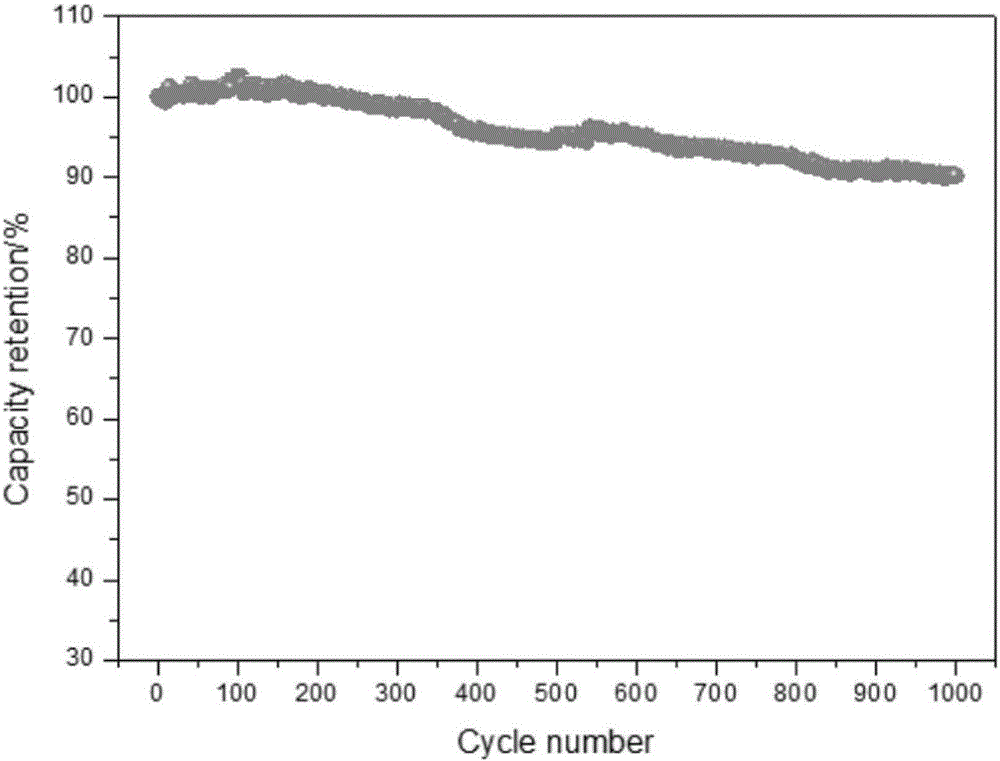

Preparation method for ternary positive electrode material of lithium battery

A cathode material, lithium battery technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of lack of lithium ion channels, affecting electrochemical performance, hindering lithium ion transmission, etc., to reduce residual alkali content, The effect of improving cycle performance and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a preparation method of a lithium battery ternary positive electrode material, comprising the following steps:

[0024] 1) Configure a certain concentration of iron nitrate (Fe(NO 3 ) 3 ) solution, the molar concentration range of the ferric nitrate solution is 0.01-0.1mol / L; slowly add a certain proportion of LiNi under stirring 1-x-y co x mn y o 2 (04 with LiNi 1-x-y co x mn y o 2 The mass ratio is 0.001 to 0.1; after stirring for 30 minutes, ultrasonically, and then drop a certain concentration of (NH 4 ) 2 HPO 4 solution, the (NH 4 ) 2 HPO 4 The molar concentration range of the solution is 0.01-1mol / L; continue stirring for 4-8h.

[0025] 2) The solution obtained in step 1) is filtered, washed with deionized water, and then dried at 80-120°C for 14-24h.

[0026] 3) keeping the powder obtained after drying in step 2) in an air atmosphere at 250-400° C. for 4-6 hours, and then naturally cooling to room temperature.

[0027] In ot...

Embodiment 1

[0029] 1) Prepare 1L ferric nitrate solution with a molar concentration of 0.02mol / L, slowly add 75.5g LiNi under stirring 1 / 3 co 1 / 3 mn 1 / 3 o 2 , after stirring for 30min, sonicate, and then dropwise add molar concentration of 0.02mol / L (NH 4 ) 2 HPO 4 Solution, continue to stir for 4h.

[0030] 2) After filtering and washing with deionized water, dry at 120° C. for 20 h.

[0031] 3) The dried powder is kept at 400° C. in an air atmosphere for 4 hours, and finally cooled to room temperature naturally.

Embodiment 2

[0033] 1) Prepare 1L ferric nitrate solution with a molar concentration of 0.01mol / L, slowly add 25.17gLiNi under stirring 0.5 co 0.3 mn 0.2 o 2 , stirred for 30min and then ultrasonically, then added dropwise NH with a molar concentration of 0.02mol / L according to the stoichiometric ratio 4 h 2 PO 4 Solution, continue to stir for 5h.

[0034] 2) After filtering and washing with deionized water, dry at 100°C for 16h.

[0035] 3) The dried powder is kept at 350° C. in an air atmosphere for 6 hours, and finally cooled to room temperature naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com