Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

241results about How to "Facilitate de-intercalation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of carbon-coated sodium-micron-scale lithium titanate composite anode material

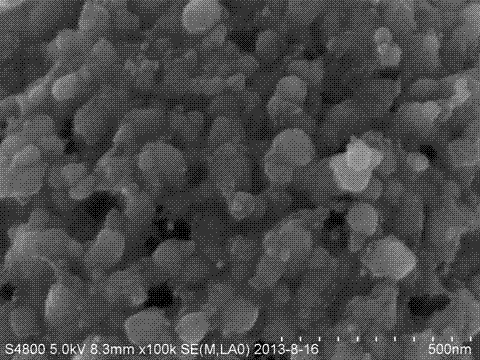

ActiveCN105591079AGuaranteed stabilityLoose particle structureMaterial nanotechnologyCell electrodesMicron scaleOrganotitanium compound

The invention relates to a preparation method of a carbon-coated sodium-micron-scale lithium titanate composite anode material. The method comprises steps as follows: lithium salt is dissolved in an aqueous solution of absolute ethyl alcohol, and the solution is marked a solution a; an organic titanium compound and a carbon source are dissolved in absolute ethyl alcohol, and the solution is marked a solution b; a chelating agent M is dissolved in absolute ethyl alcohol, ultrasonic dispersion is performed, and the solution is marked a solution c; the solution c is slowly dropwise added to the solution b while stirring, and white sol is obtained; then the solution a is slowly dropwise added to the white sol; after the sol is aged, heating, stirring, drying, grinding, sieving and calcination are performed, and the carbon-coated lithium titanate composite anode material is obtained. Lithium titanate has narrower particle size distribution and more uniform particle distribution, and sodium-micron-scale particles are uniformly inlaid to form particles with high tap density; the particle structure is loose and porous, the specific surface area of a formed electrode is larger, getting off of lithium ions in the lithium titanate material is facilitated, and the stability of the crystal structure of the lithium ions in the charge and discharge process is guaranteed.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

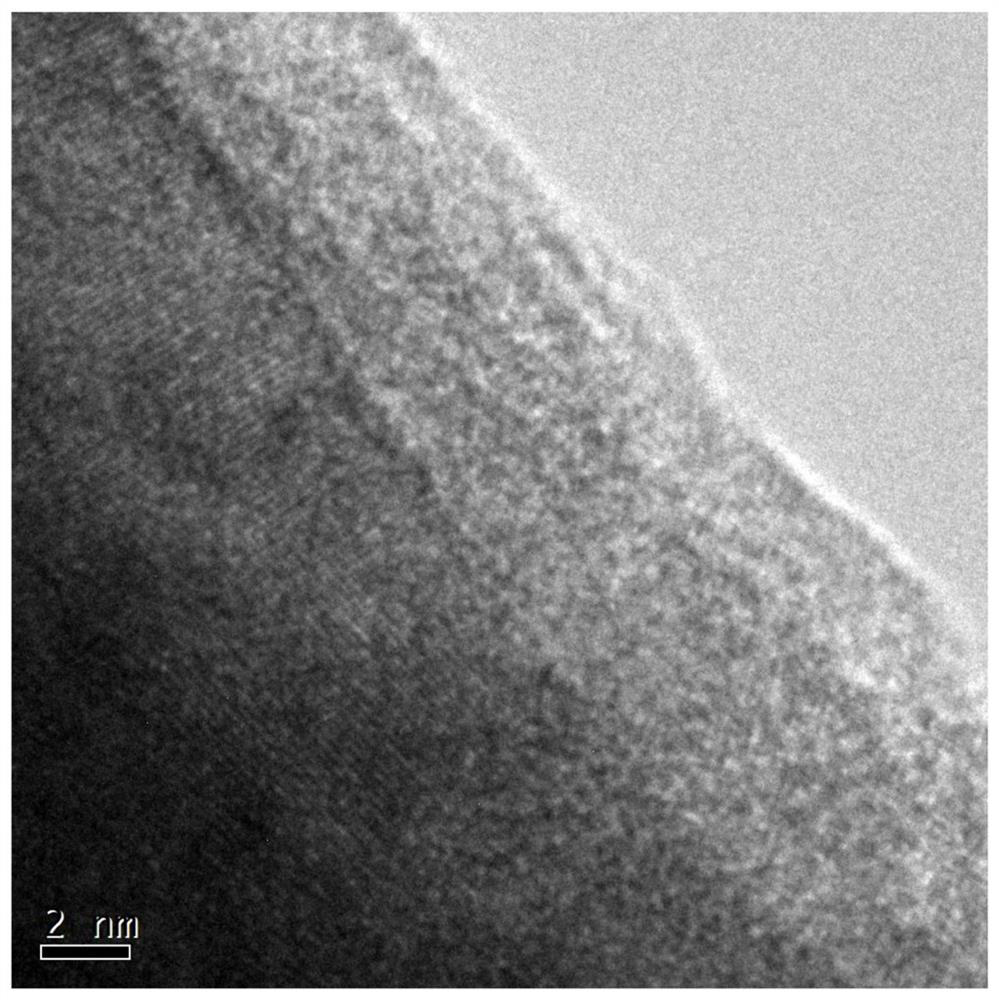

High-nickel ternary cathode material coated with fast ion conductor and preparation method thereof

InactiveCN110690435AClose contactSolving lithium-ion transport problemsCell electrodesSecondary cellsElectrical conductorInternal resistance

The invention provides a high-nickel ternary cathode material coated with a fast ion conductor and a preparation method thereof. The high-nickel ternary cathode material is spherical or spheroidic secondary particles composed of primary particles, the diameter of the high-nickel ternary cathode material is 1-30 [mu]m, and the chemical formula of the high-nickel ternary cathode material is LiNi0.8Co0.1Mn0.1O2. The preparation method comprises the following steps of: weighing raw materials for synthesizing the fast ion conductor in proportion, and uniformly dispersing the raw materials in a solvent to obtain a mixed solution; adding the high-nickel ternary precursor into the mixed solution, and then performing stirring, drying and grinding to obtain high-nickel ternary precursor powder coated with the fast ion conductor; and uniformly mixing the obtained precursor powder with a lithium salt, and performing sintering to obtain the high-nickel ternary cathode material coated with the fastion conductor. The fast ion conductor material is used as a coating substance of the ternary cathode material and can provide a fast transmission channel for lithium ion transmission, so that the purpose of reducing the internal resistance of the battery is achieved; and after coating, the cycling stability of the battery is improved under the condition that the specific discharge capacity of thebattery is not reduced.

Owner:CENT SOUTH UNIV +1

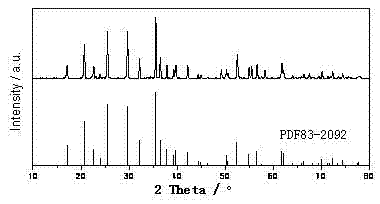

A kind of preparation method of spinel lithium titanate

InactiveCN102299313AStable structureHigh discharge specific capacityCell electrodesBall millCalcination

The present invention relates to the preparation method of lithium ion battery electrode material, especially relates to a kind of preparation method of spinel type lithium titanate; In the present invention firstly disperses surfactant, lithium source, titanium source in absolute ethanol and ball mills to obtain the precursor and then drying, calcining, grinding, tableting, calcining, regrinding and other treatments on the precursor, and finally obtain the spinel-type lithium titanate; the present invention uses a surfactant as a dispersant to make The raw materials are mixed more uniformly and dispersed better, and lithium titanate materials with small and uniform particle size and good electrochemical performance can be synthesized at lower calcination temperature and shorter calcination time; High, synthetic materials have good dispersion performance, small particle size, simple process, high production efficiency, environmental friendliness, and easy large-scale production.

Owner:MCNAIR TECH

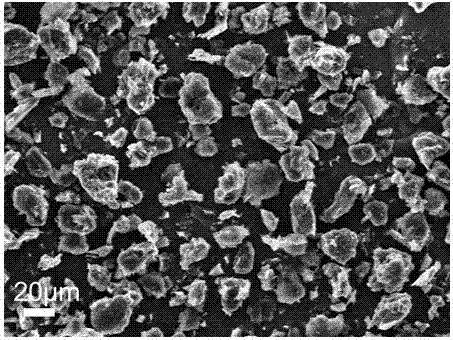

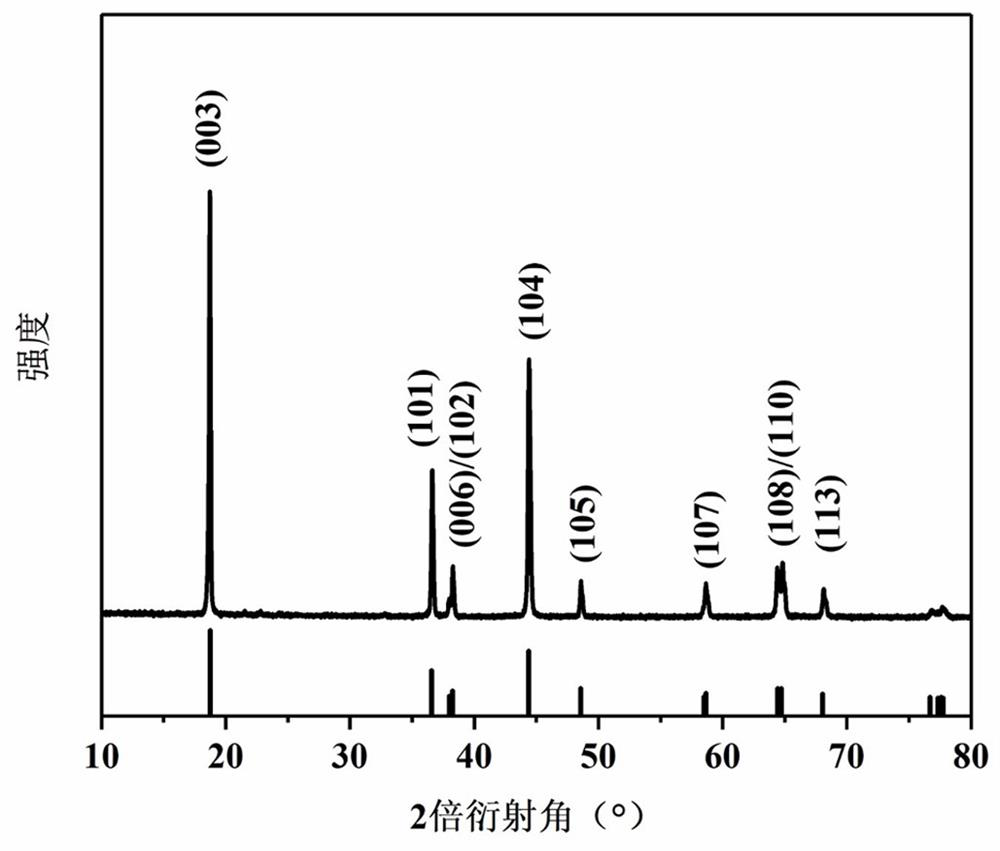

Plate-like particle for cathode active material of a lithium secondary battery, and a lithium secondary battery

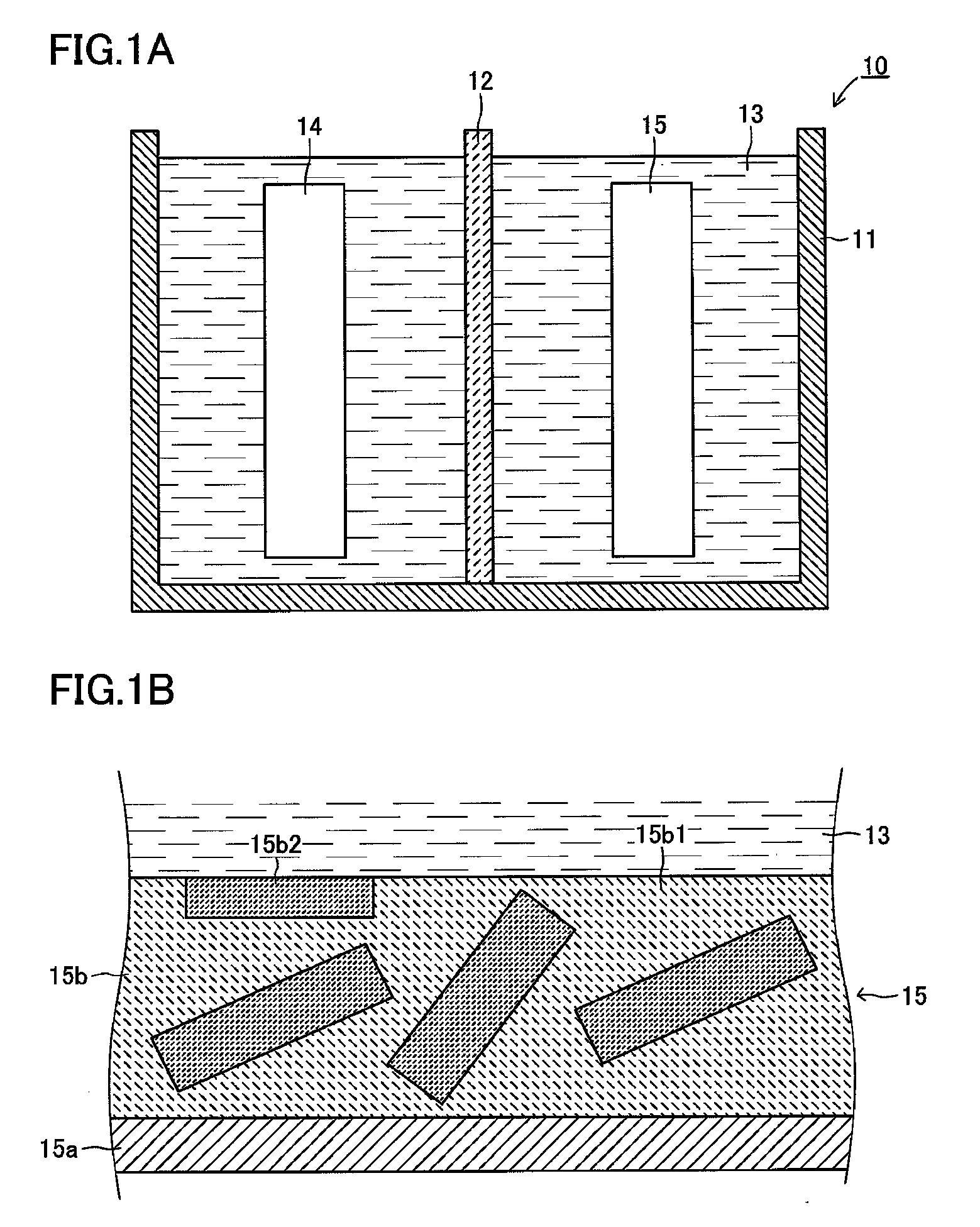

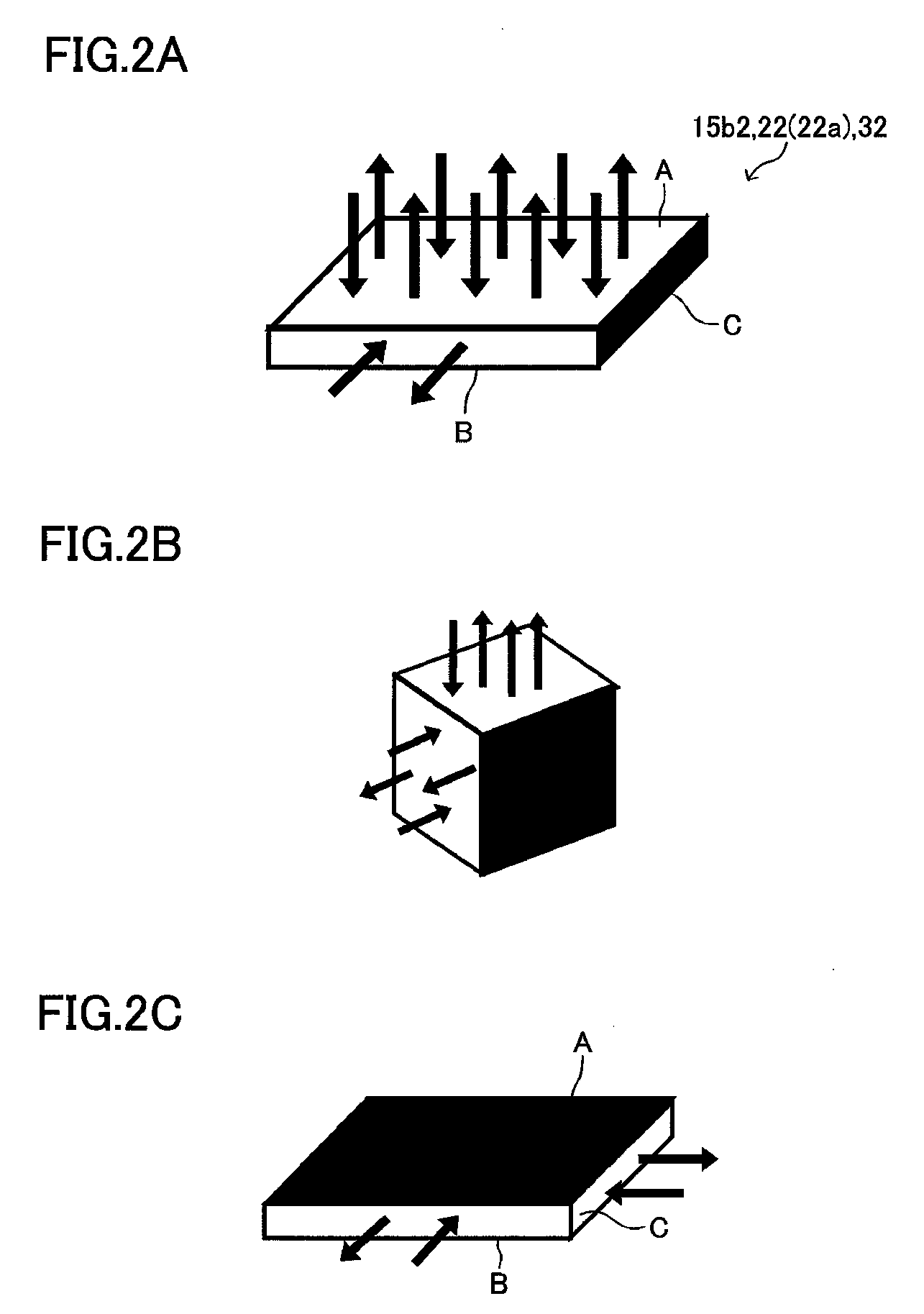

InactiveUS20100159333A1Increase battery capacityDeintercalation of lithium ions is facilitatedPositive electrodesNon-aqueous electrolyte accumulator electrodesPorosityLithium

By exposing the crystal plane (a plane other than the (003) plane: e.g., the (101) plane and (104) plane) through which lithium ions are favorably intercalated and deintercalated, more to an electrolyte, characteristics such as cell capacity is improved. The present invention relates a plate-like particle for a lithium secondary battery cathode active material. The particle has a layered rock salt structure. The (003) plane is oriented in a direction intersecting a particle plate surface. The porosity is 10% or less. The ratio of an observed surface area (β) determined from a measured value of a BET specific surface area to a virtual surface area (α) of the particle which is defined by the planar shape and thickness of the particle on the assumption that the plate surface is smooth, β / α is 3 or more and 10 or less

Owner:NGK INSULATORS LTD

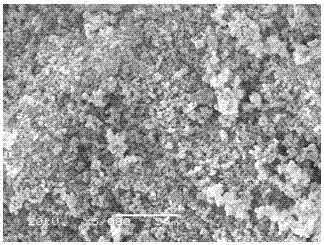

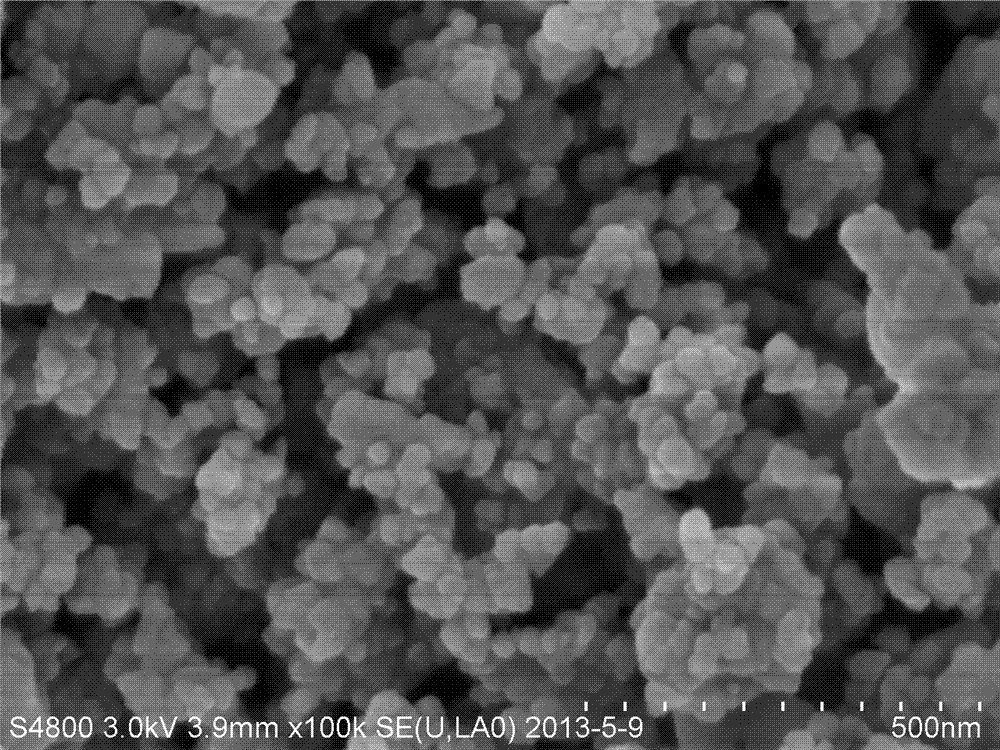

Preparation method of lithium-rich anode material

ActiveCN103094550AImprove electrochemical performanceWell mixedCell electrodesSecondary cellsSlurryCobalt

The invention discloses a preparation method of a lithium-rich anode material having a chemical formula of xLi2O.yMOb (wherein M is at least one of Mn, Ni, Co and Al, x / y is greater than 0.51 and lower than 0.95, and b is not lower than 1 and not greater than 2). The method comprises the following steps: 1, weighing raw materials comprising a lithium sauce and at least one of a manganese source, a cobalt source, a nickel source and an aluminum source according to the molar ratio in xLi2O.yMOb; 2, adding a liquid into the raw materials, and grinding to form a slurry, wherein the median particle size D50 of particles of the slurry is less than 0.05mum; 3, drying the slurry in a spray manner; and 4, roasting the material obtained after drying. The method has the advantages of simple process and easy industrialized production; the primary particles of the obtained powder are small, and the secondary particles are spherical in shape; and the lithium-rich anode material prepared through adopting the method has a large discharge specific capacity, and the specific energy of the lithium ion battery prepared through using the lithium-rich anode material is high.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Nano-composite material with molybdenum trioxide@molybdenum disulfide core-shell heterostructure, and preparation method and application thereof

ActiveCN108550805AAlleviate volume changesImprove cycle performanceNon-aqueous electrolyte accumulator electrodesSolventChemistry

The invention provides a nano-composite material with a molybdenum trioxide@molybdenum disulfide core-shell heterostructure, and a preparation method and an application thereof. The preparation methodcomprises the following steps: adding sodium molybdate and hydrochloric acid into redistilled water, used as a reaction solvent, in a closed high-temperature and high-pressure reactor, heating the reaction system to produce a high-temperature and high-pressure environment in order to prepare a nano-ribbon molybdenum trioxide precursor, adding the nano-ribbon molybdenum trioxide to redistilled water used as the reaction solvent, adding thiourea and hydrochloric acid, and heating the reaction system to generate high-temperature and high-pressure environment in order to prepare the three-dimensional porous sheet molybdenum oxide-molybdenum disulfide core-shell heterostructure nano-composite material. Compared with nano-composite materials in the prior art, the nano-composite material in theinvention has the advantages of high purity, good and controllable dispersibility, low production cost, good reproducibility, large specific surface area, facilitation of the infiltration of an electrode material with an electrolyte, and great potential application values in the energy storage field.

Owner:ANHUI NORMAL UNIV

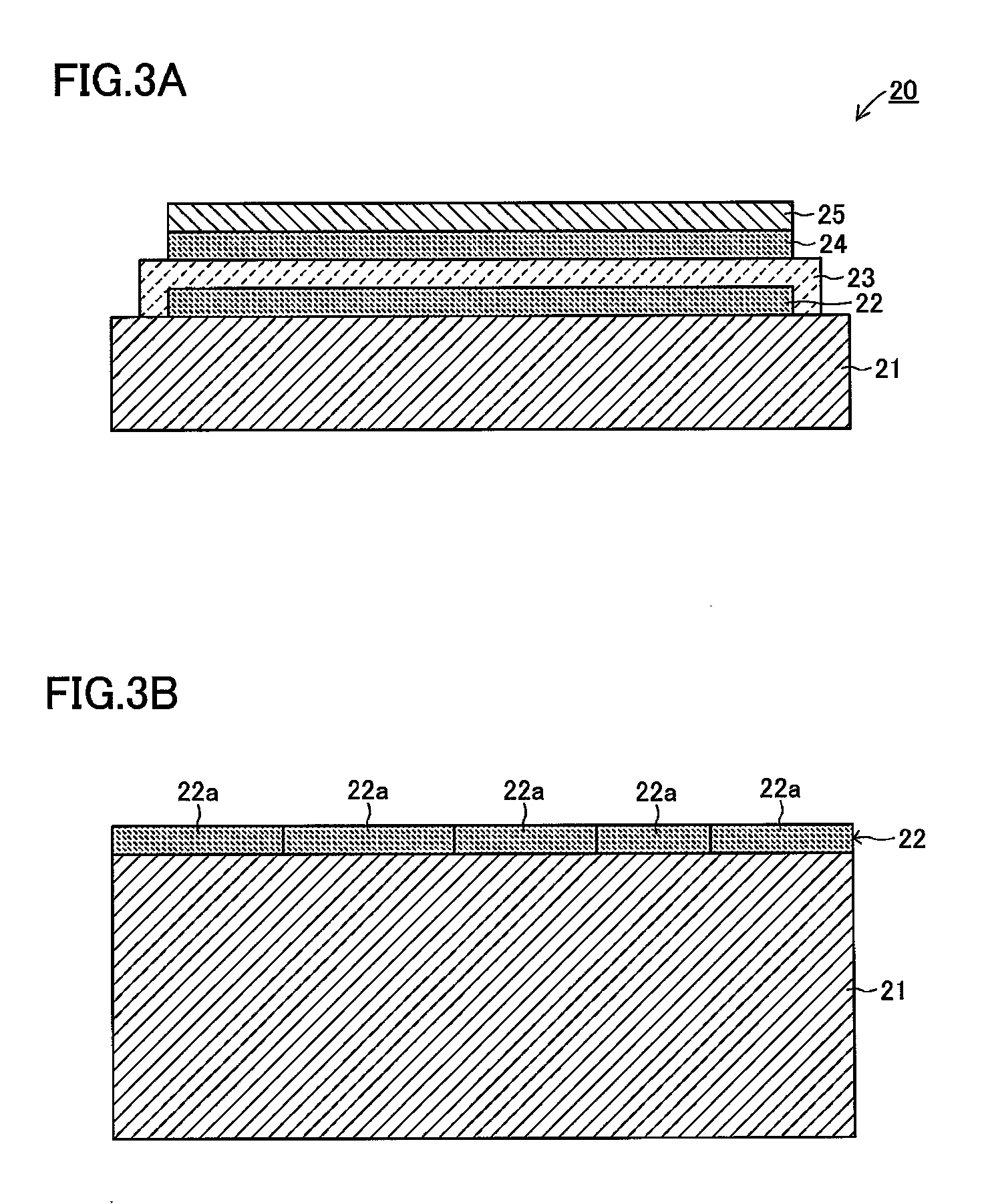

Plate-like particle for cathode active material of a lithium secondary battery, a cathode active material film of a lithium secondary battery, and a lithium secondary battery

InactiveUS20100159325A1Improve rate characteristicsReduce capacitySecondary cellsCobalt compoundsLithiumManganese

An object of the present invention is to provide a multi-component system (cobalt-nickel-manganese three-component system) cathode active material for a lithium secondary battery which has improved characteristic as compared with conventional lithium secondary batteries and a layered rock salt structure. A plate-like particle or a film for a lithium secondary battery cathode active material is represented by the following general formula:Lip(Cox,Niy,Mnz)O2 General formula(wherein 0.97≦p≦1.07, 0.1<x≦0.4, 0.3<y≦0.5, 0.1<z≦0.5, x+y+z=1)The particle or the film contains cobalt and lithium and has a layered rock salt structure. The (003) plane is oriented so as to intersect the plate surface of the particle or film.

Owner:NGK INSULATORS LTD

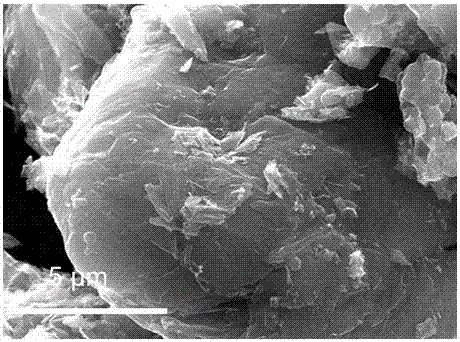

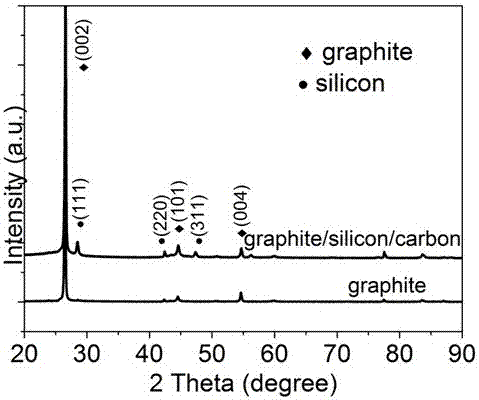

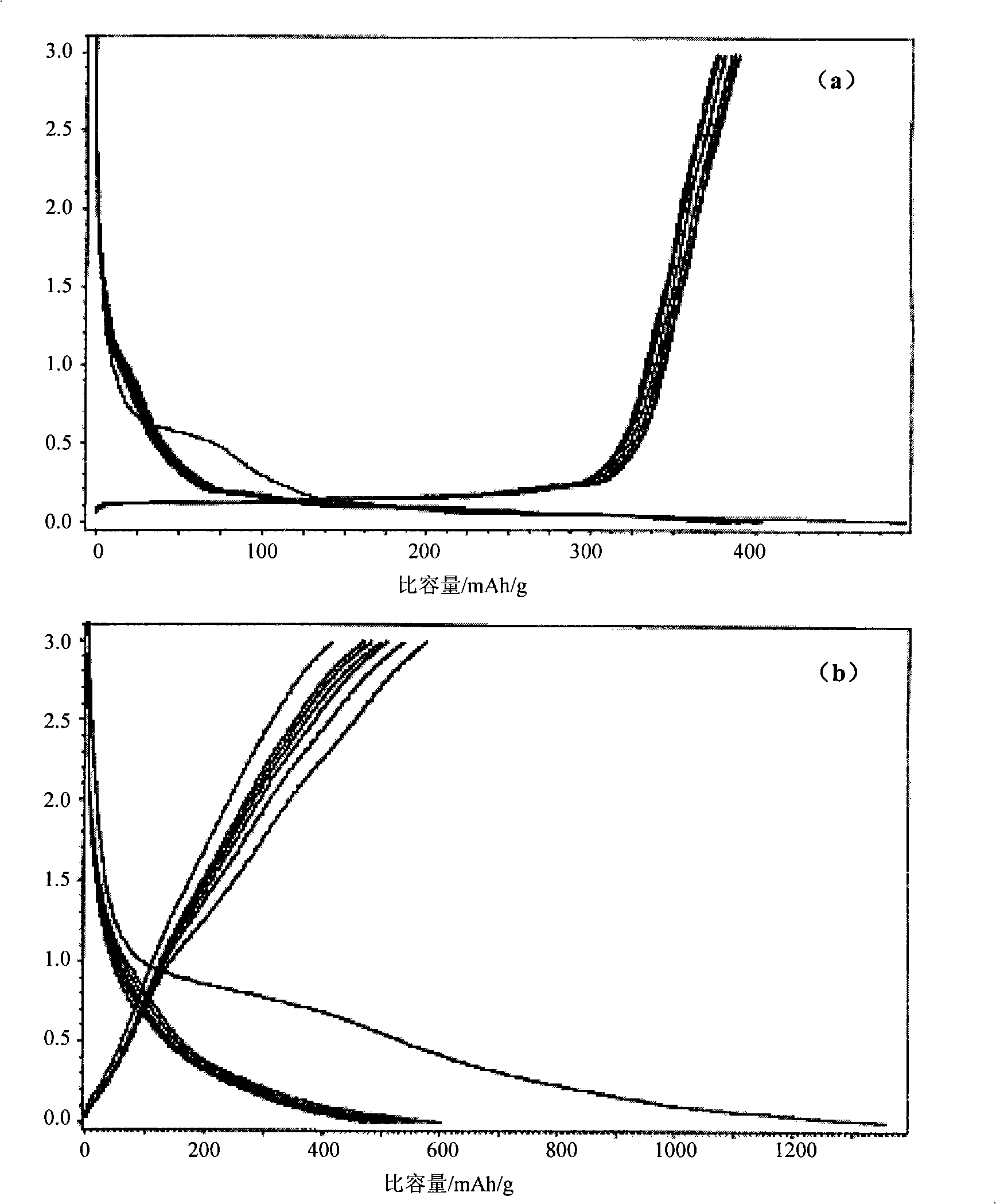

Graphite/silicon@carbon core-shell structure composite spherical cathode material and preparation method thereof

InactiveCN107093721ASimple preparation processReduce the first irreversible capacityCell electrodesSecondary cellsCarbon compositesComposite cathode

The invention discloses a graphite / silicon@carbon core-shell structure composite spherical cathode material and a preparation method thereof. By means of the material, the volume expansion effect of silicon in the lithium de-intercalation process can be inhibited, and a high-capacity lithium iron battery silicon / carbon composite cathode material is obtained. By means of the technical scheme, a spherical graphite / silicon framework precursor serves as the core of the composite cathode material, and an amorphous pyrolytic carbon or graphite-like carbon material wrapping layer serves as the shell; nanometer or micrometer silicon is embedded in flake graphite cracks to form a graphite framework, the volume expansion effect of silicon in the lithium de-intercalation process is inhibited through the mechanical characteristics of the graphite framework, then a spherical framework is formed by mixing and granulating 3-20 wt% of nanometer or micrometer silicon, 50-80 wt% of flake graphite and 10-40 wt% of amorphous pyrolytic carbon or graphite-like carbon, and an amorphous pyrolytic carbon or graphite-like carbon spherical composite conductive carbon net structure wrapping a graphite / silicon surface is formed.

Owner:四川聚能仁和新材料有限公司

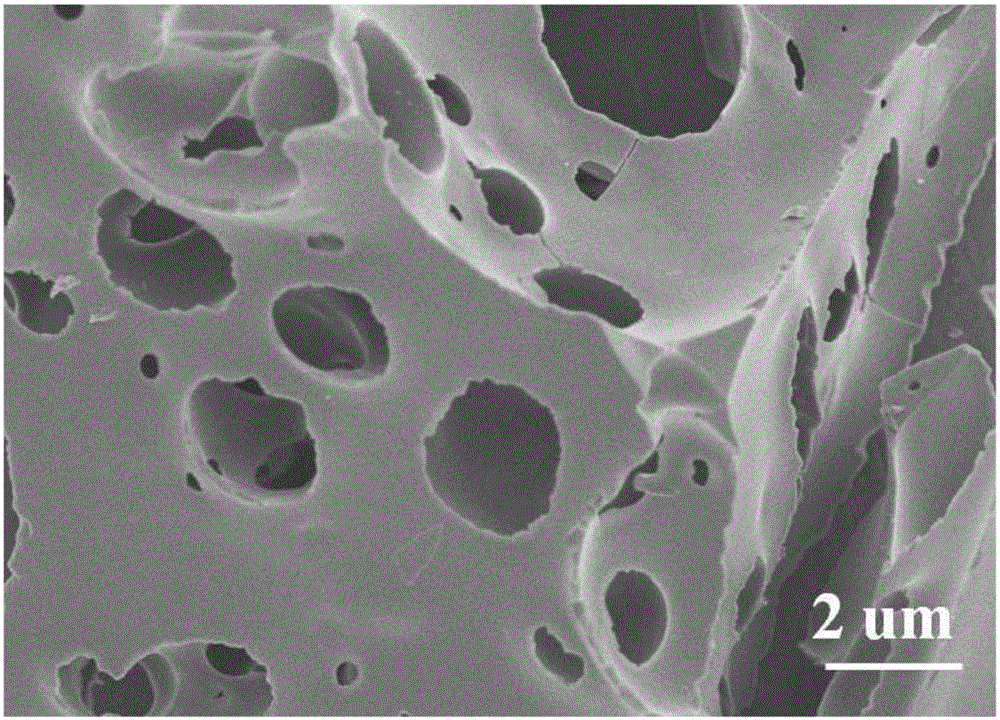

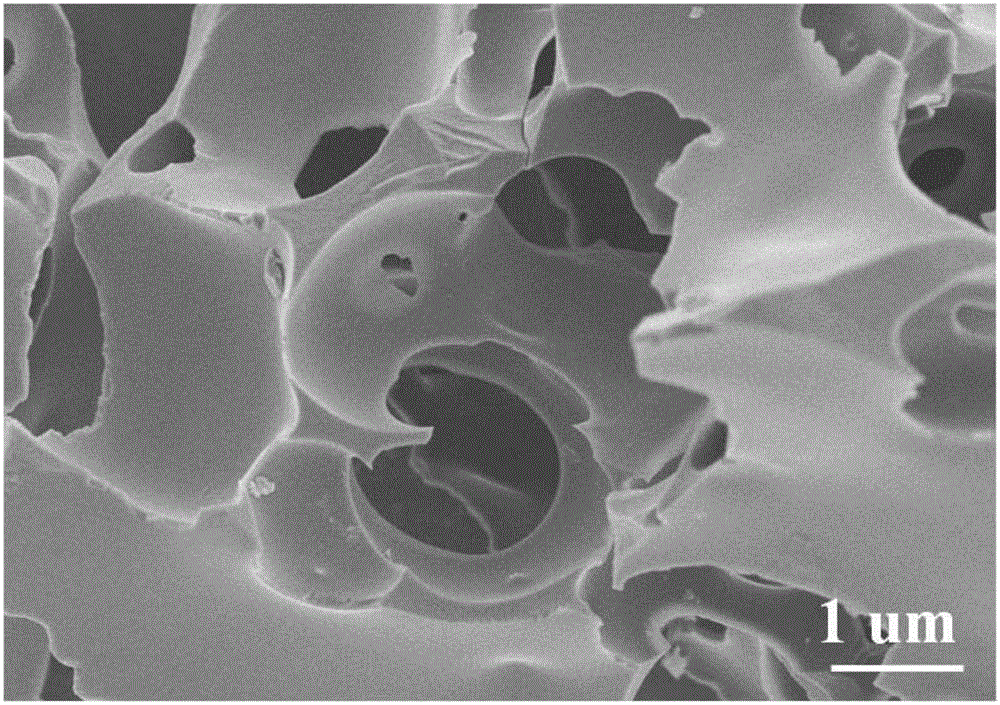

Method for preparing three-dimensional carbon nanomaterial by activating shaddock peel with strong base

InactiveCN106219510AReduce pollutionLarge specific surface areaCell electrodesSecondary cellsFiltrationFreeze-drying

The invention discloses a method for preparing a three-dimensional carbon nanomaterial by activating shaddock peel with a strong base. The method comprises the steps that the shaddock peel is washed to be clean and then subjected to freeze drying, a sulfuric acid solution is added for a hydrothermal reaction, and a biomass precursor is obtained; the biomass precursor is subjected to washing, suction filtration and drying and then mixed with the strong base to be subjected to carbonization in a tubular atmosphere furnace, and a carbonization product is obtained; the carbonization product is subjected to washing and suction filtration and then dried, and the three-dimensional carbon nanomaterial, namely, a carbon negative electrode material used for sodium-ion batteries is obtained. The strong base activated shaddock peel negative electrode material prepared through the method has a three-dimensional porous connected nantostructure, the specific surface area is large, more attachment sites are provided for sodium ions, micropores can be beneficial for entering of electrolyte to increase the contact area with the electrode material, a condition is provided for rapid transmission of the sodium ions, and the capacity of the material is increased.

Owner:SHAANXI UNIV OF SCI & TECH

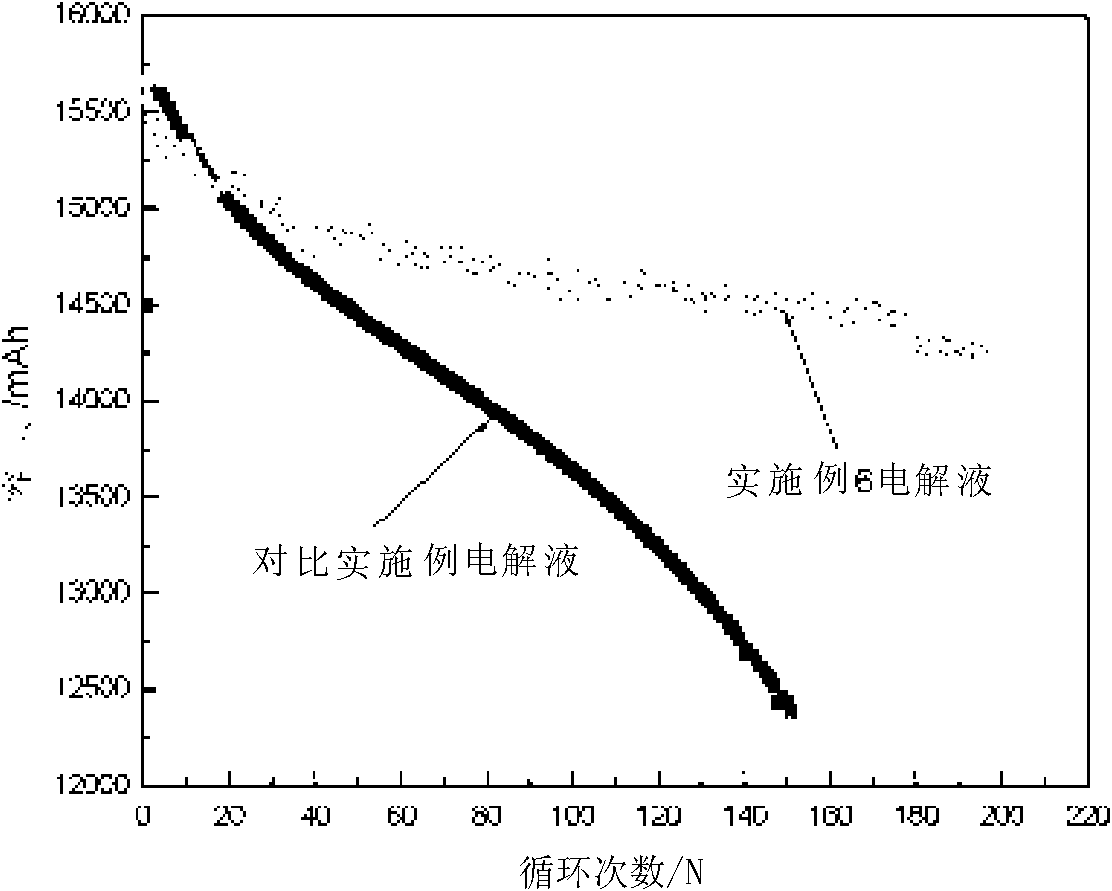

Electrolyte for lithium-ion power battery and preparation method thereof

ActiveCN101635379AImprovement of poor capacity retention at high temperatureAvoid flatulenceFinal product manufactureSecondary cellsGas explosionDecomposition

The invention discloses an electrolyte for a lithium-ion power battery, which comprises lithium salts, organic solvents and additives, wherein the lithium salts comprise at least one of LiODFB, LiPF6, LiClO4, LiBF4, LiAsF6, LiCF3SO3, LiN(SO2CF3)2 and LiBOB; the invention also discloses a preparation of the electrolyte, which comprises the following steps: mixing the organic solvents after impurities and water are removed; (2) adding the lithium salts in the mixed organic solvents, evenly stirring till the solution is clear and has no sediments, and allowing the solution to stand for at least half an hour to obtain mixed solution; (3) adding the additives into the mixed solution, evenly stirring, and then allowing the mixed solution to stand to obtain the required electrolyte. The invention improves the cycle performance of the battery at the high temperature, prevents gas explosion caused by electrolyte decomposition, can remarkably promote the long-life function of the volume conservation rate of the lithium-ion power battery at the high temperature, and has simple preparation method and easy industrialization production simultaneously.

Owner:WANXIANG 123 CO LTD

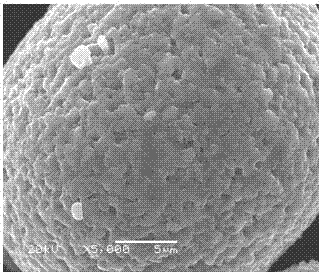

Dual-cladding 622-type Ni-Co-Mn ternary positive electrode material and preparation method thereof

InactiveCN107863514AImprove intrinsic electronic conductivityLarge cell parametersCell electrodesSecondary cellsManganeseHeat treated

The invention discloses a dual-cladding 622-type Ni-Co-Mn ternary positive electrode material. The molecular formula of the dual-cladding 622-type Ni-Co-Mn ternary positive electrode material is xMO.yMF.LiNi<0.6>Co<0.2>Mn<0.2>O2, wherein M is Na, Mg or Al, x is more than or equal to 0 but less than or equal to 0.09, and y is more than or equal to 0 but less than or equal to 0.09. The dual-cladding622-type Ni-Co-Mn ternary positive electrode material is implemented according to the following steps of 1) primary coating, in which lithium carbonate, Ni<0.6>Co<0.2>Mn<0.2>(OH)2 and an oxide are sequentially added into a ball-milling tank, and dry ball-milling is performed for 6-18 hours; 2) pre-sintering, in which powder in the step 1) is subjected to thermal processing for 6 hours under a temperature of 700-800 DEG C and then is naturally cooled; 3) washing, in which the powder in the step 2) is cleaned with deionized water and then is cleaned with ethyl alcohol; 4) secondary coating, inwhich the powder in the step 3) is taken out and mixed with a fluoride, and the product is placed in water bath for drying under 90-100 DEG C after ultrasonic treatment for 30 minutes; and 5) secondary sintering, in which the powder in the step 4) is subjected to heat preservation under a temperature of 800-900 DEG C and is naturally cooled to obtain the dual-cladding 622-type Ni-Co-Mn ternary positive electrode material. The method is safe and efficient, and the obtained dual-cladding 622-type Ni-Co-Mn ternary positive electrode material is fine and uniform distribution in particle, has a favorable microstructure and has relatively good electrochemical performance.

Owner:淮安新能源材料技术研究院

Hollow nano cubic NiCo2O4 dual-metal oxide material and preparation method thereof

The invention discloses a hollow nano cubic NiCo2O4 dual-metal oxide material and a preparation method thereof, and belongs to a metallurgical powder material and preparation thereof. The material disclosed by the invention is in the structure of a hollow nano cross cube of which the diameter is 500nm, the highest reversible capacity is 1160mAh / g, the capacity is greater than or equal to 1060mAh / g after circulating 100 times, the specific capacity is kept at 84%, and the performance is stable. According to the preparation method, a polyvinyl pyrrolidone (PVP) solution dissolved into high-purity water and ethanol is taken as a solvent, NiC12.6H2O and CoC12.6H2O are taken as metal sources, and S2O3<2+> and a home-made Cu2O nano cubic template from selective erosion are utilized at proper temperature, thereby finally generating the NiCo2O4 dual-metal oxide with the hollow nano cubic structure. The hollow nano cubic NiCo2O4 dual-metal oxide material is simple in preparation technology, and low in cost, and has industrial prospect.

Owner:YUNNAN UNIV

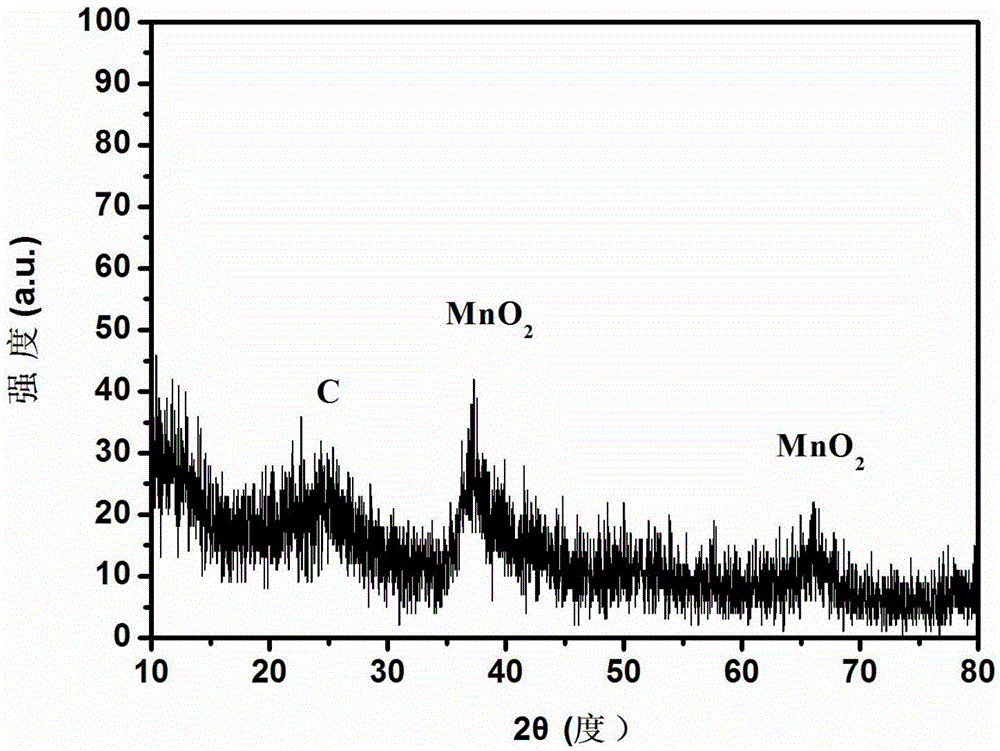

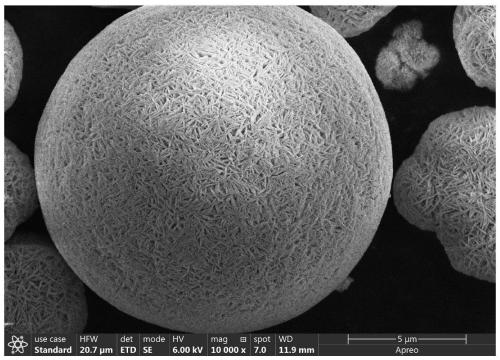

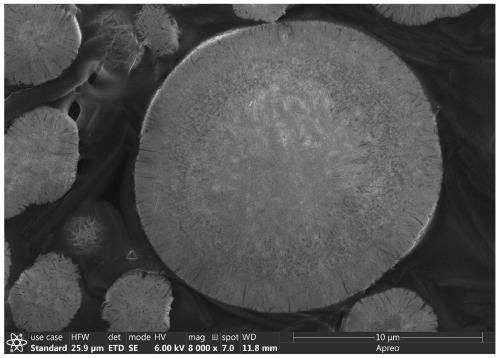

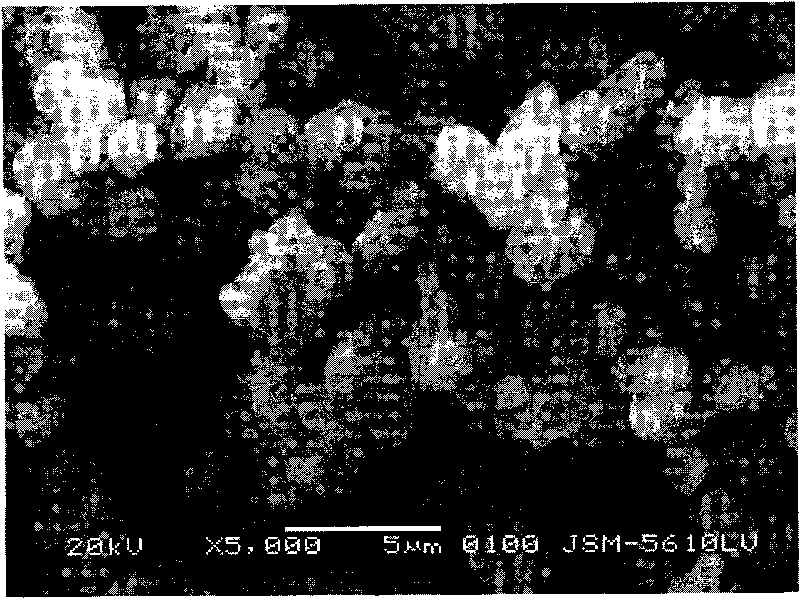

Flexible negative electrode with MnO2 attached onto carbon fiber of lithium ion battery and preparation method of flexible negative electrode

InactiveCN105552342ALithium extraction and extraction potential is lowImprove cycle performanceCell electrodesSecondary cellsFiberCarbon fibers

The invention relates to a flexible negative electrode with MnO2 attached onto carbon fibers of a lithium ion battery and a preparation method of the flexible negative electrode. A metal oxide in the prior art is wrapped inside the carbon nanofibers, and thus, the contact of the metal oxide serving as an active substance with an electrode and the de-intercalation process of the metal oxide with lithium ions are not promoted; and further, the metal oxide is Fe2O3, Fe3O4, Co3O4 and the like, and such metal oxide has a defect of relatively high de-intercalation lithium potential. The preparation method is characterized by comprising the following steps of firstly, preparing a flexible carbon nanofiber net, which comprises electrostatic spinning, pre-oxidation of a polymer nanofiber net and high-temperature calcination; secondly, preparing a flexible composite fiber thin film with an MnO2 nanowire attached onto the surfaces of the carbon nanofibers, placing the flexible carbon nanofiber net in a KMnO4 solution, and completing high-temperature reaction under process conditions of a reaction temperature of 150-200 DEG C and reaction time of 30-60 minutes; and finally, cutting the flexible carbon nanofiber net into the flexible negative electrode with MnO2 attached onto the carbon fibers of the lithium ion battery.

Owner:CHANGCHUN UNIV OF SCI & TECH

A preparation method of biomass hard carbon material for negative electrode of sodium ion battery

ActiveCN109004199ALarge carbon interlayer spacingLarge specific surface areaCell electrodesSecondary cellsCarbon layerDesorption

The invention discloses a preparation method of a biomass hard carbon material for a negative electrode of a sodium ion battery, which adopts cheap and easily available biomass as a carbon source to prepare a hard carbon material for the negative electrode of the sodium ion battery by a simple and convenient method, and can effectively reduce the cost of the sodium ion battery. At the same time, the hard carbon material has large carbon layer spacing and can accommodate sodium ion intercalation and desorption, and the prepared sodium ion battery has excellent electrochemical performance and good industrial prospect, and is very suitable for a large-scale energy storage system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

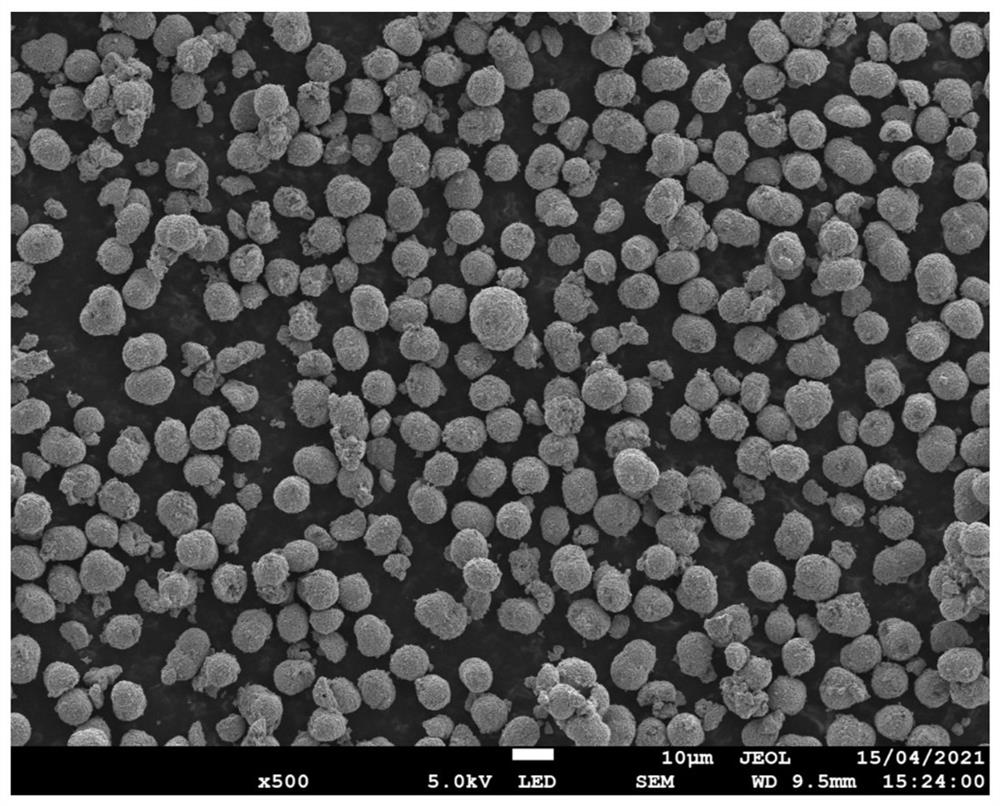

Al/La co-doped high-nickel ternary precursor with core-shell structure and preparation method thereof, and positive electrode material

ActiveCN111422926AImprove cycle performanceSmall sizeCell electrodesSecondary cellsManganeseLithium-ion battery

The invention relates to the field of lithium ion battery materials, and provides an Al / La co-doped high-nickel ternary precursor with a core-shell structure and a preparation method thereof, and a positive electrode material prepared from the precursor. The preparation method mainly comprises the following three steps: step 1, synthesizing an Al-doped high-nickel ternary precursor with rod-like primary particles under the condition of a low pH value; 2, increasing the pH value on the basis of the step 1, growing a La-doped high-nickel ternary precursor shell with needle-shaped primary particles by taking the Al-doped high-nickel ternary precursor as an inner core so as to synthesize an Al / La co-doped high-nickel ternary precursor with a core-shell structure; and 3, mixing the Al / La co-doped high-nickel ternary precursor with the core-shell structure and a lithium salt, and carrying out high-temperature calcination in an oxygen atmosphere to obtain the Al / La co-doped ternary positive electrode material with the core-shell structure. Due to the unique co-doped core-shell structure, the stability of an internal structure is effectively enhanced, the generation of mixed phases such ascation mixing and rock salt structures is inhibited, the breakage of grain boundaries is reduced, the average oxidation state of manganese ions is improved, the Jahn-Teller effect is effectively inhibited, the rapid attenuation of the capacity in a cycle process is reduced, the cycle stability of the material is remarkably improved, and the cycle life of the material is remarkably prolonged. Theproduct synthesized by adopting a coprecipitation method is uniform in component, good in sphericity, good in reproducibility, easy in condition control, low in preparation cost, high in economic value and wide in application prospect.

Owner:ZHUJI PAWA NEW ENERGY

Method for preparing graphitic carbon nanometer tube combination electrode material for lithium ion battery

InactiveCN101355150AGood natureLarge specific surface areaElectrode manufacturing processesSodium-ion batteryLithium-ion battery

The invention discloses a method for preparing a carbon nanotube composite electrode material by modifying graphite electrodes through a carbon nanotube and a single layer of graphite. The method comprises the following steps: (1) a precursor of a catalyst is prepared by an immersion method, and then is reduced to obtain a catalyst; (2) ethanol is cracked on the cracked catalyst and the cabon nanotube is grown in-situ; and (3) the product is mixed with acetylene black and a bonding agent to obtain a graphite carbon nanotube composite electrode material. The method allows the carbon nanotube to be grown on the surface of the graphite in situ, rather than takes the carbon nanotube as an addictive to be mixed in the graphite. The modifying method ensures that the carbon nanotube and the graphite are combined more closely and evenly microcosmically.

Owner:NORTHWEST UNIV(CN)

Preparation method of carbon-cladding graphite oxide/Sn composite cathode material of lithium ion battery

ActiveCN104766962AAbundant resourcesLow priceCell electrodesSecondary cellsDischarge efficiencyNew energy

The invention belongs to the technical field of new energy, and particularly relates to a preparation method of a carbon-cladding graphite oxide / Sn composite cathode material of a lithium ion battery. The method comprising the following steps of preparing graphite oxide by adopting natural crystalline flake graphite as a raw material and adopting a Hummers method, placing a tin-containing organic compound into the prepared graphite oxide to obtain a graphite oxide / Sn composite, carrying out the organic cladding by adopting a liquid-phase cladding method, carrying out the high-temperature calcining, and obtaining the carbon-cladding graphite oxide / Sn composite sodium ion battery cathode material. The prepared electrode material is large in reversible capacity, small in size variation, good in cycling property and high in primary charging-discharging efficiency.

Owner:LIAONING TECHNICAL UNIVERSITY

Cathode active substance of lithium secondary battery and preparation method thereof

InactiveCN101728525AHigh specific capacitySimple preparation processElectrode manufacturing processesLithium-ion batteryVanadium oxide

The invention discloses a cathode active substance of a lithium secondary battery, wherein the cathode active substance contains a lithium vanadium oxide and carbon, and the lithium vanadium oxide comprises LiVO2 and Li2V2O4. The cathode active substance of a lithium vanadium oxide mixed crystal can improve the specific capacity of the battery, has simple procedures for a preparation process and low production cost, and is suitable for industrial production.

Owner:BYD CO LTD

Plate-like particle for cathode active material of a lithium secondary battery, a cathode active material film of a lithium secondary battery, and a lithium secondary battery

InactiveUS20100159326A1Increase exposureReduce exposureElectrode thermal treatmentSecondary cellsLithiumCobalt

An object of the present invention is to provide a lithium secondary battery which has improved capacity, durability, and rate characteristic as compared with conventional lithium secondary batteries. A plate-like particle or a film for a lithium secondary battery cathode active material is represented by the following general formula:General formula: Lip(Nix,Coy,Alz)O2 (wherein 0.9≦p≦1.3, 0.6<x≦0.9, 0.1<y≦0.3, 0≦z≦0.2, x+y+z=1)The particle or the film contains cobalt and lithium and has a layered rock salt structure. The (003) plane is oriented so as to intersect the plate surface of the particle or film.

Owner:NGK INSULATORS LTD

Preparation method of modified high-nickel ternary positive electrode material

InactiveCN113479944AInhibition of structural collapseImprove cycle performanceSecondary cellsPositive electrodesElectrical conductorMagnesium doping

The invention discloses a preparation method of a modified high-nickel ternary positive electrode material, which comprises the steps of uniformly mixing a nickel-cobalt-manganese hydroxide precursor with a lithium source and a magnesium source, and carrying out two-stage sintering to obtain a magnesium-doped ternary high-nickel positive electrode material; and dispersing the magnesium-doped ternary high-nickel positive electrode material in an organic solvent, then adding a vanadium source and a lithium source, uniformly stirring, heating, evaporating to dryness, drying, and sintering at high temperature to obtain the lithium vanadate-coated magnesium-doped high-nickel ternary positive electrode material. According to the modified high-nickel ternary positive electrode material disclosed by the invention, the cycle performance and the rate capability of the material can be synergistically improved due to the high-nickel ternary positive electrode material is subjected to double modification treatment of magnesium ion doping and fast ion conductor coating.

Owner:CENT SOUTH UNIV +1

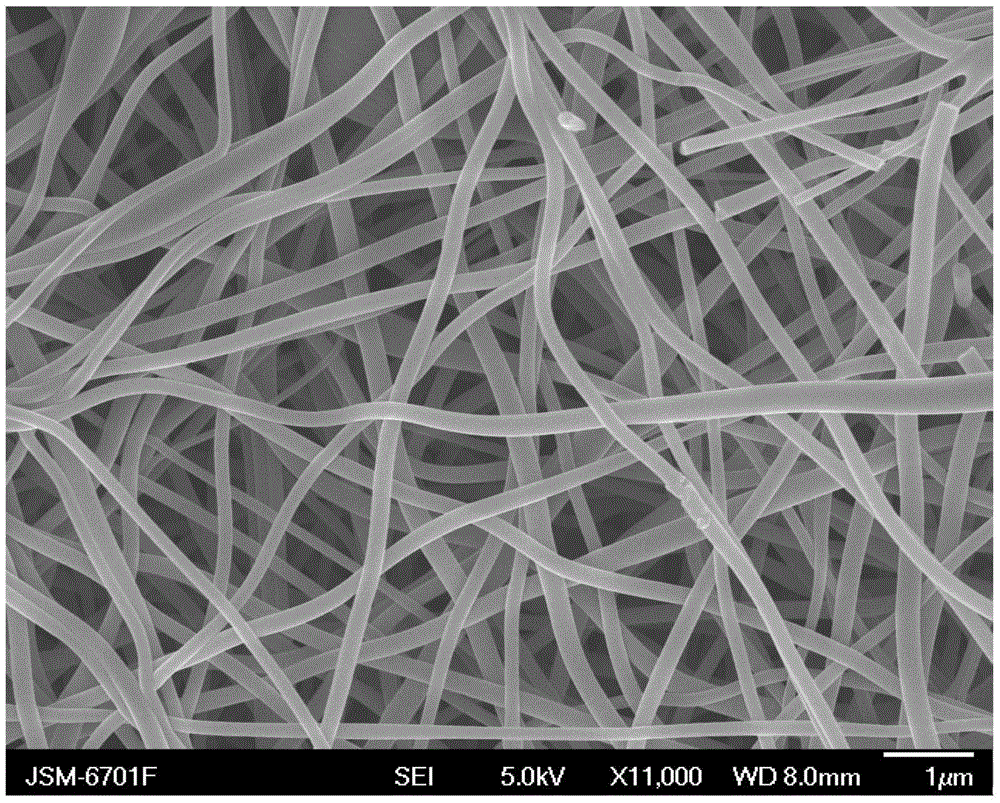

Electrospinning preparation method for cobaltosic oxide carbon nanometer fibers for sodium-n battery

InactiveCN106784745AShorten the diffusion pathEasy to embedMaterial nanotechnologyCell electrodesAir atmosphereFiber

The invention discloses an electrospinning preparation method for cobaltosic oxide carbon nanometer fibers for a sodium-ion battery. An electrospinning precursor liquid is prepared from Co2+ salts, polyvinylpyrrolidone and an organic solvent, a Co2+ salt / PVP composite fiber membrane by adopting an electrospinning method, then preparing Co3O4 carbon nanometer fibers through an air atmosphere calcination technology, and prepared Co3O4 crystals have a regular hexagonal nano-sheet structure and are uniformly inlaid in the carbon nanometer fibers to enable a material to have larger specific surface area. According to the electrospinning preparation method, with unique carbon nanometer fiber porous structure and ultrathin nano-sheet crosslinking structure, permeation of electrolyte and electron / ion transfer are effectively promoted, the diffusion path of sodium ions in the material is shortened, embedding and disembedding of the sodium ions are facilitated, the capacitance is higher, the cycling stability is better, and the dynamics performance of the material is greatly improved. The electrospinning preparation method is simple in technology and low in cost.

Owner:XIJING UNIV

Method for cladding vanadium phosphate on lithium ion battery anode material lithium cobalt nickel manganate

ActiveCN107230771AIncrease capacityImprove protectionElectrode thermal treatmentImpregnation manufacturingPhosphateManganate

The invention discloses a method for cladding vanadium phosphate on lithium ion battery anode material lithium cobalt nickel manganate. The method comprises the following steps: (1) mixing vanadate, phosphate and reducing agent in the deionized water according to the vanadium element, the phosphorus element and the reducing element, regulating pH by using ammonia water, stirring to obtain a uniform solution, reacting for 20-48h at 160-240 DEG C; filtering, washing, drying to obtain the vanadium phosphate; (2) adding the lithium cobalt nickel manganate ternary anode material and the vanadium phosphate in a high-speed mixer, wherein the vanadium phosphate mass in the obtained mixture is 1%-10% of the total mass of the mixture; stirring under a condition of 500-2000rmp to obtain a uniform product; and (3) sintering at 200-400 DEG C in an non-oxidation atmosphere, and keeping temperature for 1-5h, cooling to obtain the vanadium phosphate clad lithium ion battery anode material lithium cobalt nickel manganate. By using method disclosed by the invention, the capacity and the cyclic performance of the lithium ion battery are effectively improved.

Owner:湖南恒创睿能新能源科技有限公司

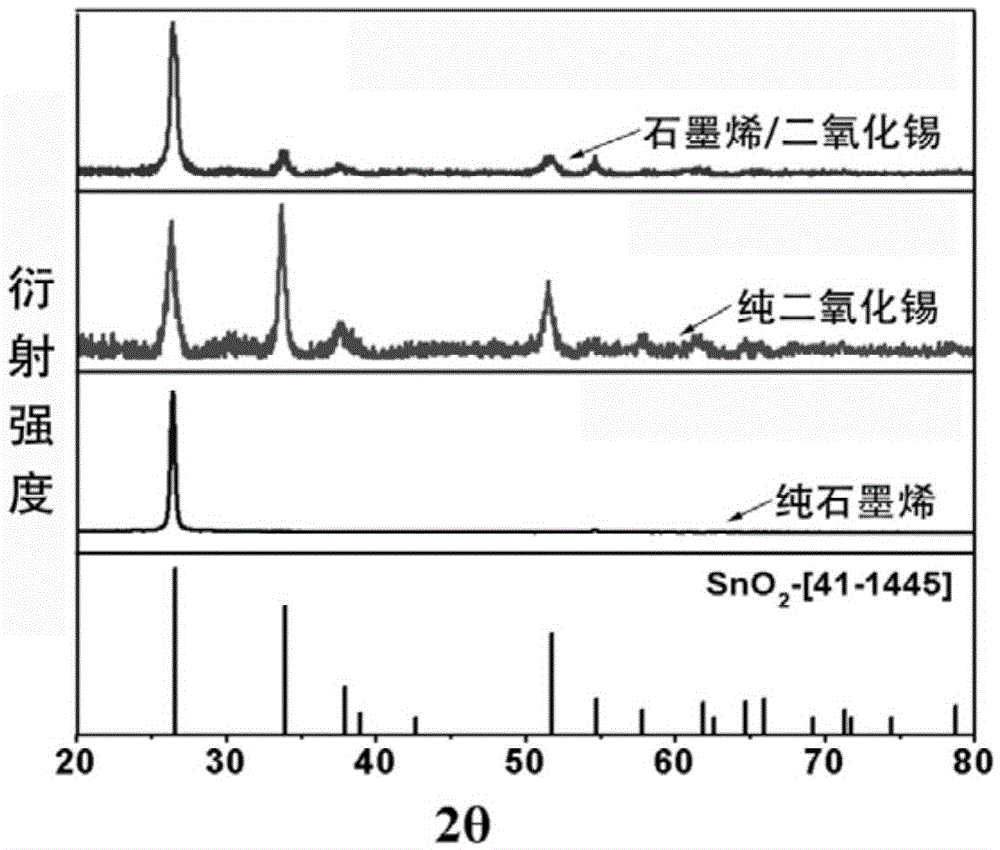

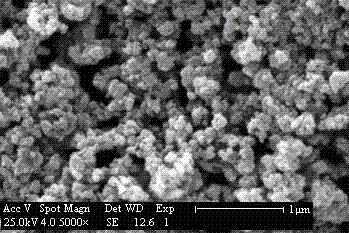

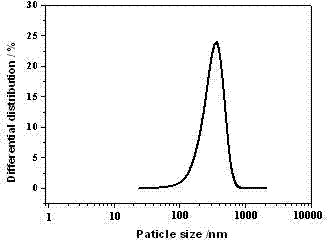

Preparation method of graphene/stannic oxide composite nanofiber membrane and application

InactiveCN105470484AEvenly distributedHigh porosityMaterial nanotechnologyCell electrodesFiberPorous graphene

The invention discloses a preparation method of a graphene / stannic oxide composite nanofiber membrane and an application, and relates to anode materials for lithium-ion batteries. The preparation method comprises the following steps: adding graphene to deionized water and carrying out ultrasonic treatment; adding NaOH and stannic chloride under a stirring condition, and mixing the deionized water evenly to obtain a mixed solution; transferring the mixed solution to a reaction kettle for reaction, and filtering, cleaning and drying the mixed solution to obtain graphene / stannic oxide composite nano-particles; ultrasonically dispersing the graphene / stannic oxide composite nano-particles into a mixed solvent of methanol and water, and adding PVAc to obtain a spinning precursor solution; carrying out high-pressure electrospinning on the spinning precursor solution to obtain a PVAc / graphene / stannic oxide composite nanofiber membrane; and carrying out drying and thermal treatment to obtain the porous graphene / stannic oxide composite nanofiber membrane, wherein the diameters of fibers in the composite nanofiber membrane are 800-1200nm and the lengths are greater than 0.5mm. A conductive agent and a binder do not need to add, and the graphene / stannic oxide composite nanofiber membrane can be directly applied to preparation of the lithium-ion battery as an electrode material.

Owner:XIAMEN UNIV

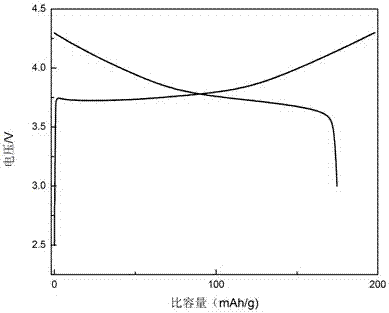

Positive active material for aqueous zinc ion secondary battery and aqueous zinc ion secondary battery

ActiveCN108878877AIncrease working voltageFacilitate de-intercalationCell electrodesSecondary cellsZincVanadium phosphate

The invention provides a positive active material for an aqueous zinc ion secondary battery. The positive active material comprises lithium vanadium phosphate. The lithium vanadium phosphate LiVOPO4 is used as the positive active material of the aqueous zinc ion battery. The positive active material is beneficial for de-intercalation of divalent zinc ions, and the built aqueous zinc ion secondarybattery has a relatively high working voltage.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Low-temperature type lithium iron phosphate anode material and preparation method thereof

The invention provides a low-temperature type lithium iron phosphate anode material and a preparation method of the low-temperature type lithium iron phosphate anode material. The method comprises the following steps of: proportioning lithium carbonate, metallic oxide, iron phosphate and glucose according to the molar ratio as follows: Li: R: Fe: P: C= (1.1-x): x: 1: 1: 0.8, wherein x=0.01-0.03, C is C in the glucose, and R is a doped metal ion; directly mixing, adding absolute ethyl alcohol of which the gross weight is 2-3 times as heavy as the gross weight of the mixture; ball-milling by means of wetting phase, and evenly mixing; drying, smashing and pelleting the ball-milled sizing agent; calcinating for 2-5h under the temperature of 300-500 DEG C in an inert atmosphere furnace under the status of open setting; cooling to be room temperature; calcinating the power for 8-12h under the temperature of 500-800 DEG C in the inert atmosphere furnace under the compacting status that the surface pressure is 10kg / cm<3>; and secondarily sintering and synthesizing so as to obtain the lithium iron phosphate anode material. The synthesized material is classified and screened by means of fluid energy milling to obtain the nanometer-level lithium iron phosphate anode material, wherein the material is good in electrical conductivity, and the low-temperature performance of a manufactured battery can be effectively improved.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

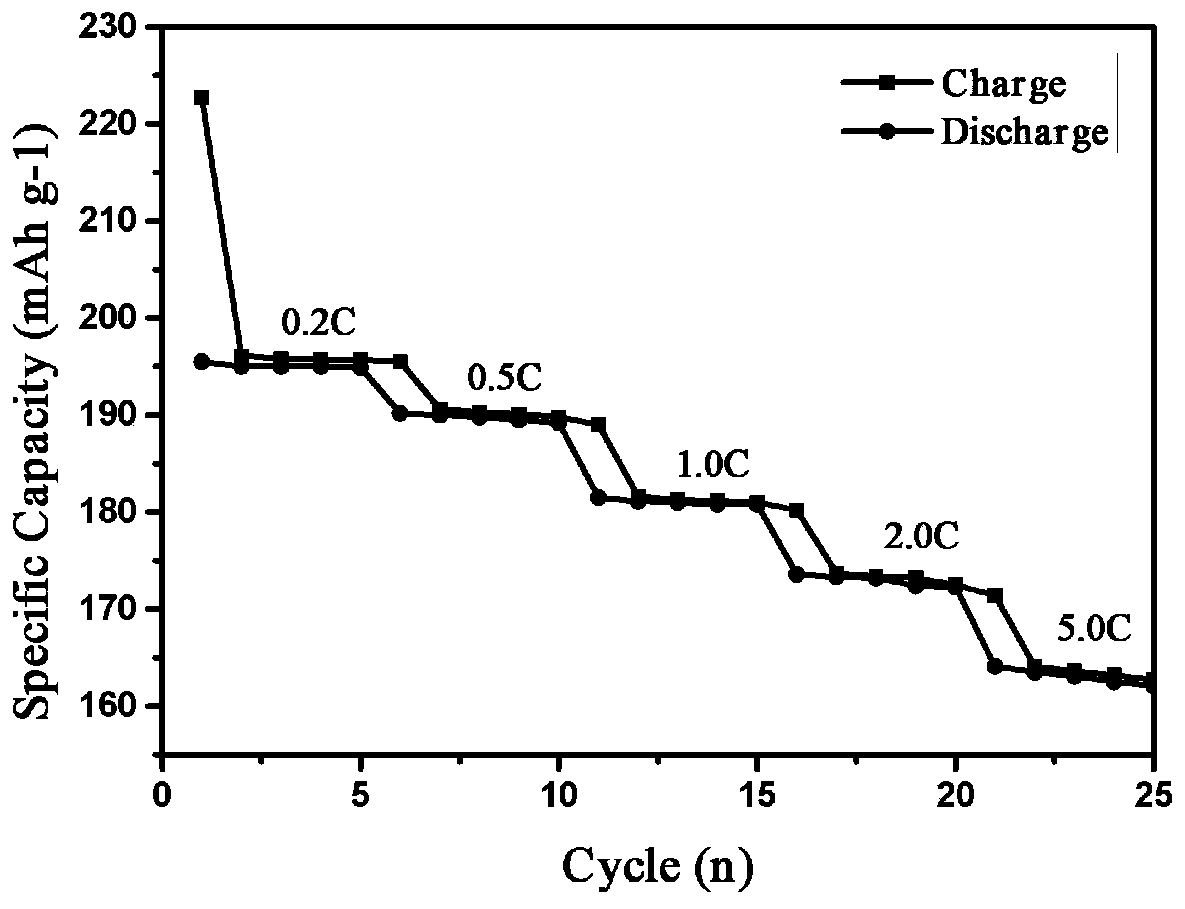

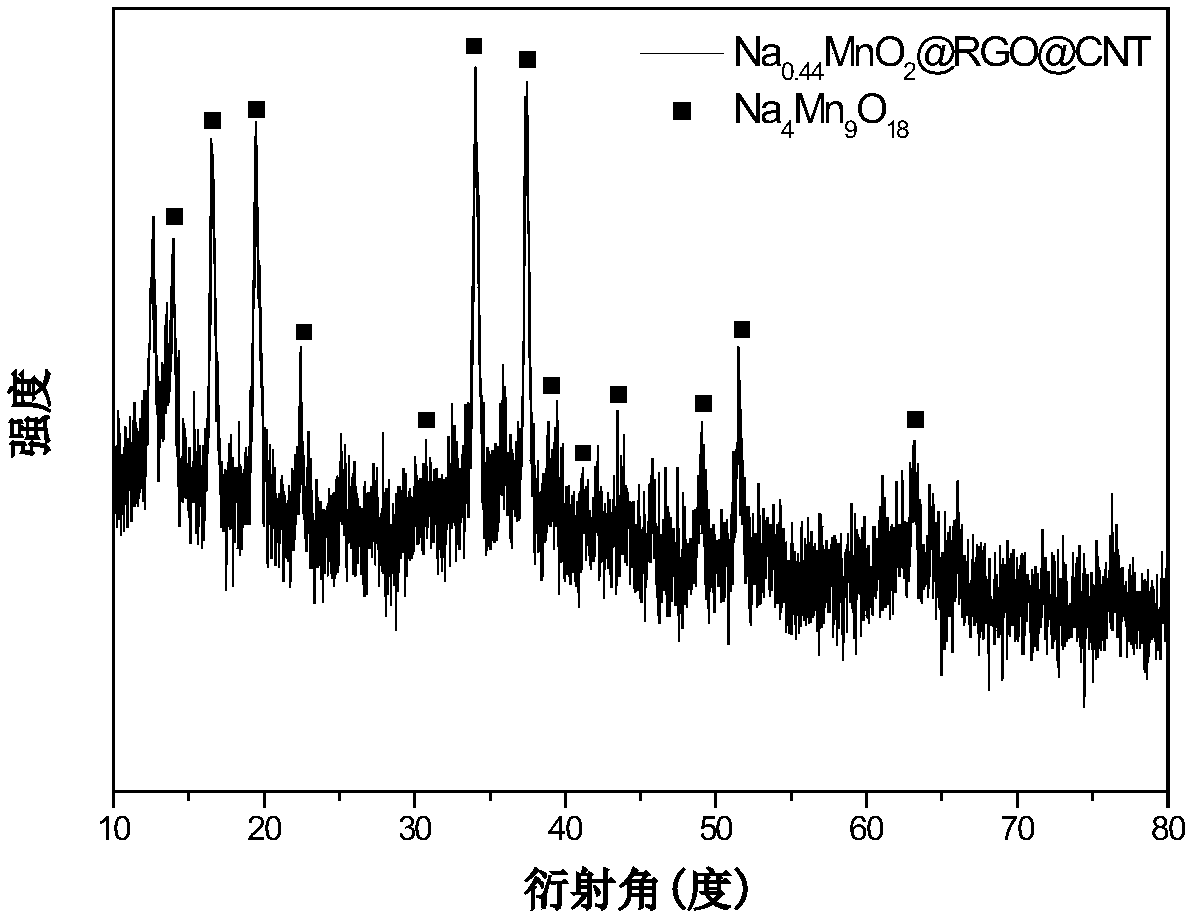

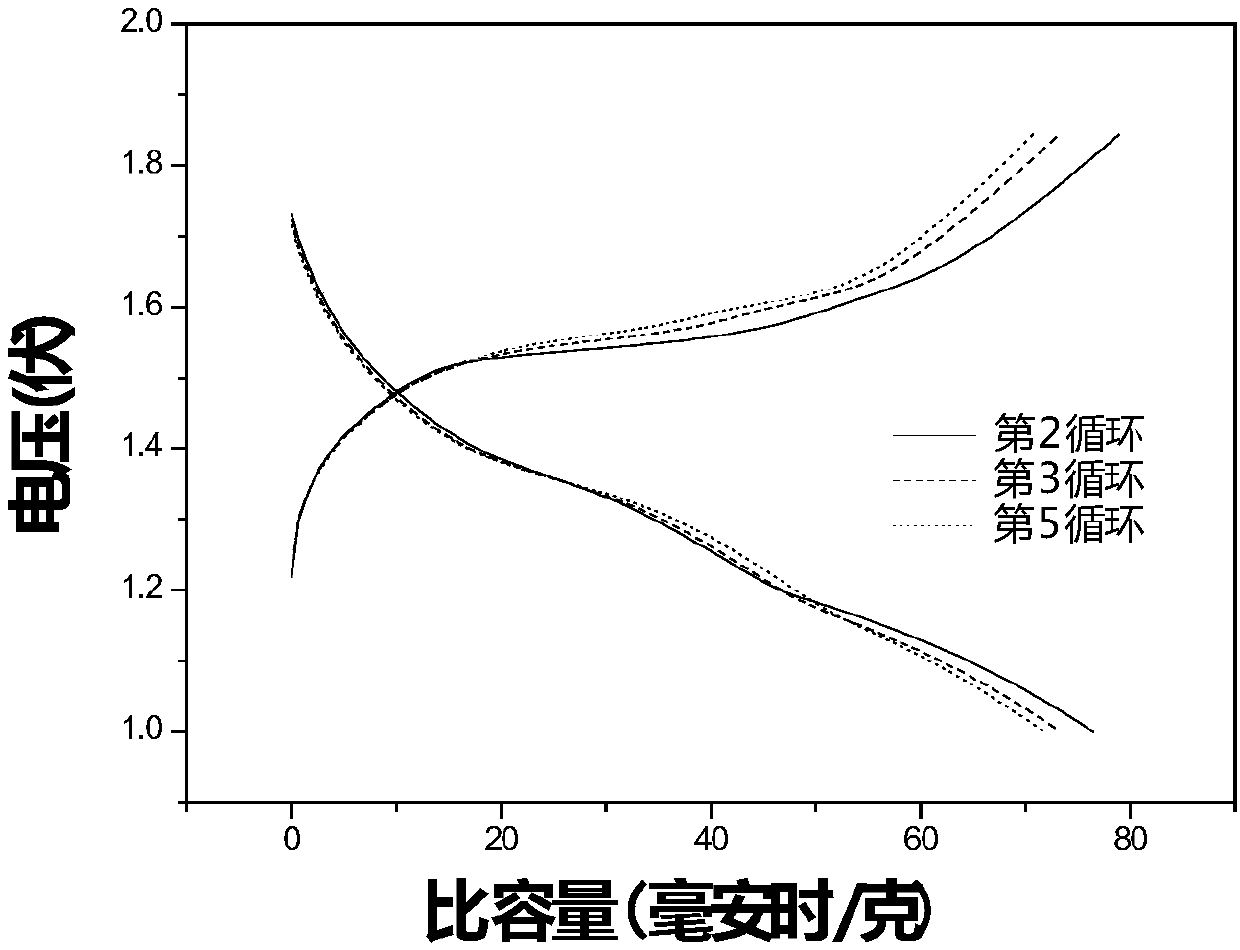

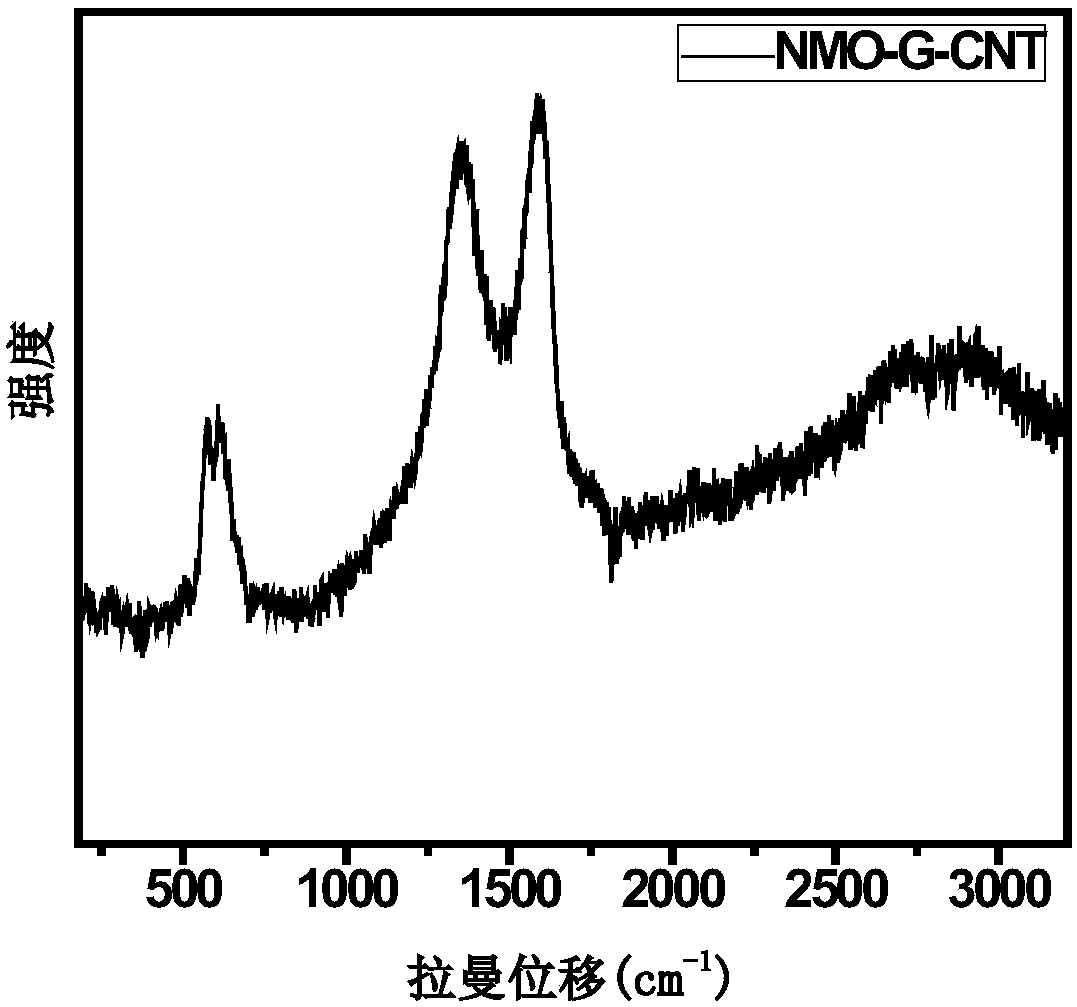

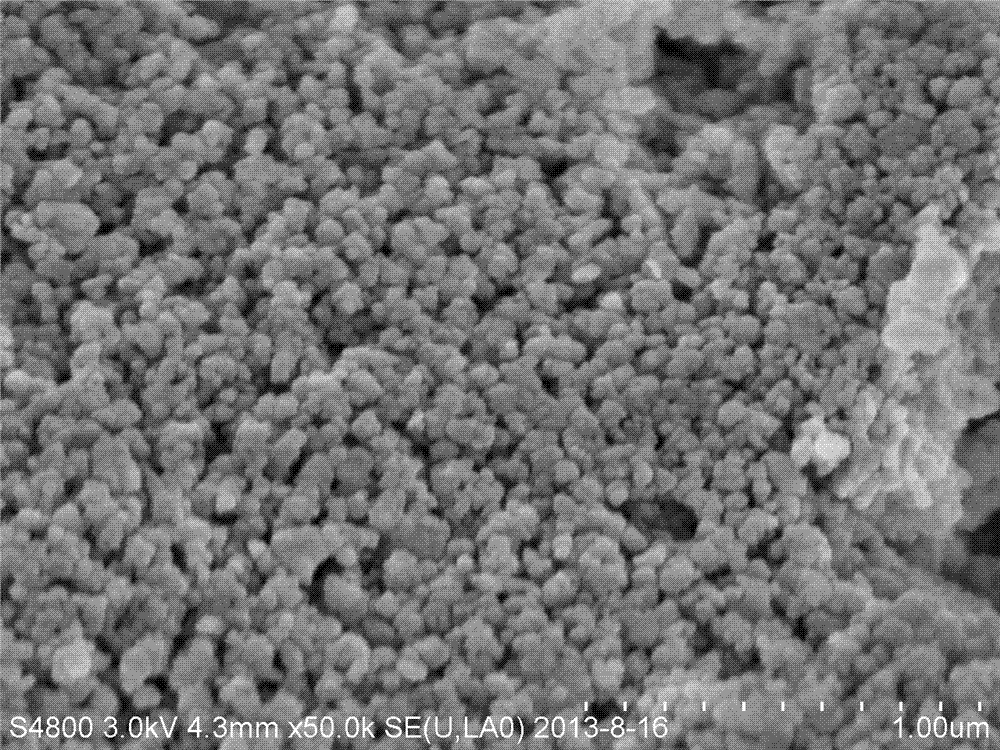

Preparation method of aqueous sodium ion battery cathode composite material

ActiveCN107732180AImprove electrical conductivityIncrease rateSecondary cellsPositive electrodesIonCarbon nanotube

The invention provides a preparation method of an aqueous sodium ion battery cathode composite material. The method comprises the following steps: S1. manganese sulfate is added into a mixed solutionof sodium hydroxide and permanganate and centrifugation is carried out, deposition after centrifugation is taken out, and a Na0.44MnO2 precursor is obtained; S2. the Na0.44MnO2 precursor obtained in the S1 is dissolved in a sodium hydroxide solution and a hydrothermal reaction is carried out, after the reaction ends, centrifugation is carried out, and drying is carried out in order to obtain Na0.44MnO2; S3. Na0.44MnO2 obtained in the S2, graphene and carbon nanotubes are added into water, after ultrasonic treatment, filtering and drying, calcination is carried out, and the aqueous sodium ion battery cathode composite material is obtained. The preparation method has the advantages of simple operation, low cost and green and environmental protection, and Na0.44MnO2 has a tunnel structure andis good for embedding and de-intercalation of sodion; reduced graphene oxide and carbon nanotubes are doped in Na0.44MnO2, conductivity of Na0.44MnO2 is enhanced, and multiplying power of the batteryis improved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

LiMnxFe1-xPO4 positive electrode active material and preparation method thereof

ActiveCN104752718AAvoid the defect of uneven mixingStable structurePositive electrodesPhosphorus compoundsHigh cellElectrical battery

The invention provides a preparation method of a LiMnxFe1-xPO4 positive electrode active material. The method comprises the following steps that a soluble trivalent manganese salt solution, a soluble ferric iron salt solution and a soluble phosphate radical-containing substance solution are blended to form a mixed solution, the mixed solution undergoes a reaction to produce a MnxFe1-xPO4.2H2O precursor, and LiMnxFe1-xPO4 is prepared from the MnxFe1-xPO4.2H2O precursor. The invention also provides the LiMnxFe1-xPO4 positive electrode active material obtained by the preparation method. The LiMnxFe1-xPO4 positive electrode active material has the advantages of uniform particle size distribution, perfect morphology, no agglomeration, small particle size and material electroconductivity improvement. A cell prepared from the LiMnxFe1-xPO4 positive electrode active material has excellent rate discharge performance, especially has high-rate discharge performance, has a high cell charging-discharging capacity, stable cell charging-discharging performances and good cycle performances, lays the foundation in excellent positive electrode active material development and is conducive to material application and cell development.

Owner:BYD CO LTD

Preparation method of LiMn1-x-yNixCoyO2 ternary positive electrode material

ActiveCN106784790AGuaranteed uniformityImprove structural stabilityCell electrodesSecondary cellsLithiumOxalate

The invention discloses a preparation method of a LiMn1-x-yNixCoyO2 ternary positive electrode material, and belongs to the technical field of energy materials. The preparation method comprises the following steps: (1) adding a lithium source, a nickel source, a cobalt source, a manganese source and a compound containing oxalates into a complexing agent solution, mixing until solving completely to obtain a mixed solution; (2) standing the mixed solution, and performing freezing crystallization to obtain flocculent precipitation; and (3) filtering the flocculent precipitation, washing, drying to obtain a precursor, calcining the precursor, and cooling with a furnace so as to obtain the ternary positive electrode material. The method can be used for improving the charge-discharge specific capacity, the rate capability and the cycle performance of the ternary positive electrode material obviously.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Silicon-based composite material and preparation method thereof

InactiveCN111653759ARelieve swellingPower optimizationNegative electrodesSecondary cells servicing/maintenanceCarbon coatingCarbon layer

The invention provides a silicon-based composite material and a preparation method thereof. The silicon-based composite material provided by the invention comprises a silicon-based matrix, a fast ionconductor layer coating the surface of the silicon-based matrix, and a carbon layer coating the surface of the fast ion conductor layer. A fast ion conductor of the fast ion conductor layer is LiAlSixOy, x is greater than or equal to 1, and y is greater than or equal to 1. According to the invention, the specific fast ion conductor layer LiAlSixOy and the carbon coating sequentially coat the surface of the silicon-based matrix, so that problems of relatively high charge transmission impedance and relatively low power output of the silicon-based negative electrode material are effectively improved, and the rate capability is improved; and meanwhile, the specific double coating layers are matched, so that the expansion of the silicon-based material is effectively relieved, and the cycle performance is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

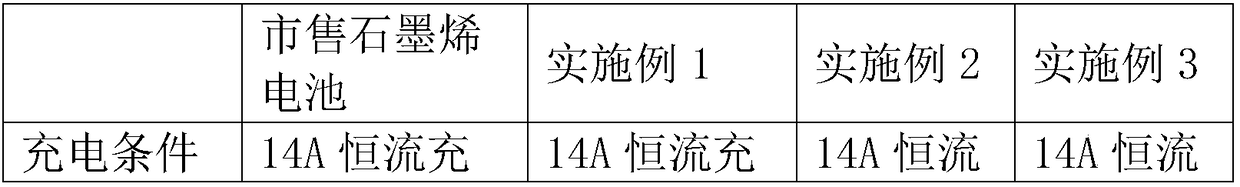

Large-capacity graphene battery capable of rapidly charging

InactiveCN108199039AImprove corrosion resistanceExtended service lifeCell electrodesSecondary cellsCorrosionEngineering

The invention provides a large-capacity graphene battery capable of rapidly charging, and relates to the technical field of batteries. The large-capacity graphene battery capable of rapidly charging,fabricated by the invention, comprises a positive pole plate, a negative pole plate, a separator, an electrolyte and a battery shell, the phenomena of small storage capacity and slow charging speed ofan existing graphene battery are solved, meanwhile, the corrosion resistance of the battery is improved, the service lifetime is prolonged, the large-capacity graphene battery is relatively good in stability, and no harm to a human body and an environment is generated; and compared with a traditional market graphene battery, it is verified that the charging time is obviously shortened by 34.94% under the same charging condition, and the charge-discharge efficiency of the battery can reach 87.73%.

Owner:长沙善道新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com