Method for preparing three-dimensional carbon nanomaterial by activating shaddock peel with strong base

A carbon nanomaterial and grapefruit peel technology is applied in the field of preparation of negative electrode materials for sodium ion batteries, which can solve the problems of increasing the contact area between the electrode material and the electrolyte, the proportion of interface atoms is high, and the van der Waals force is large and easy to bond. The effect of shortening the preparation cycle, good development prospects, and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

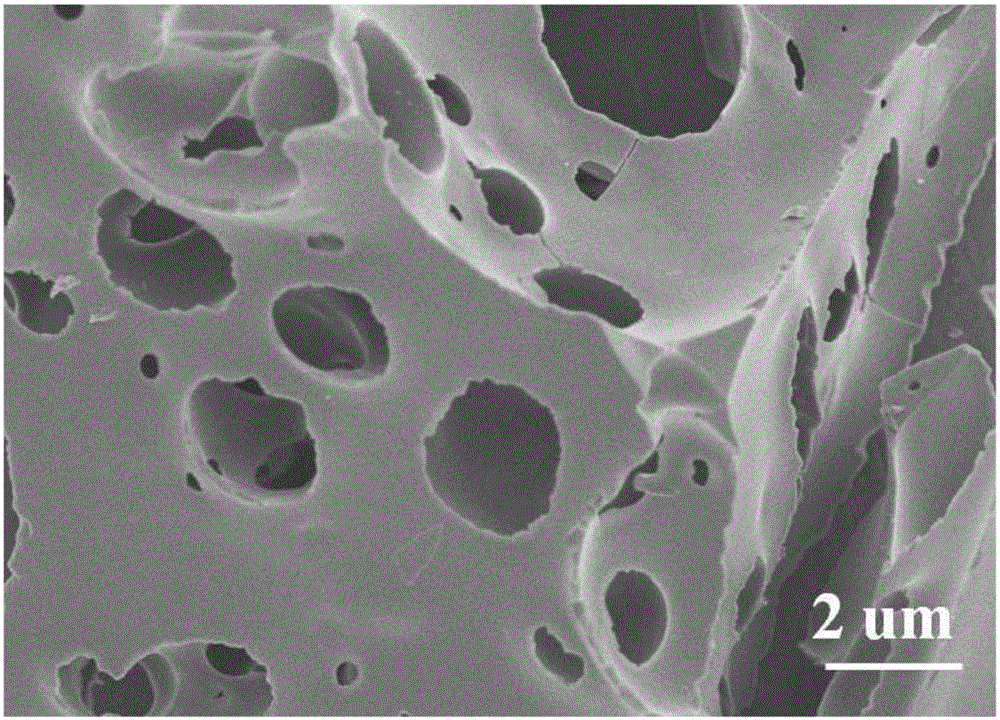

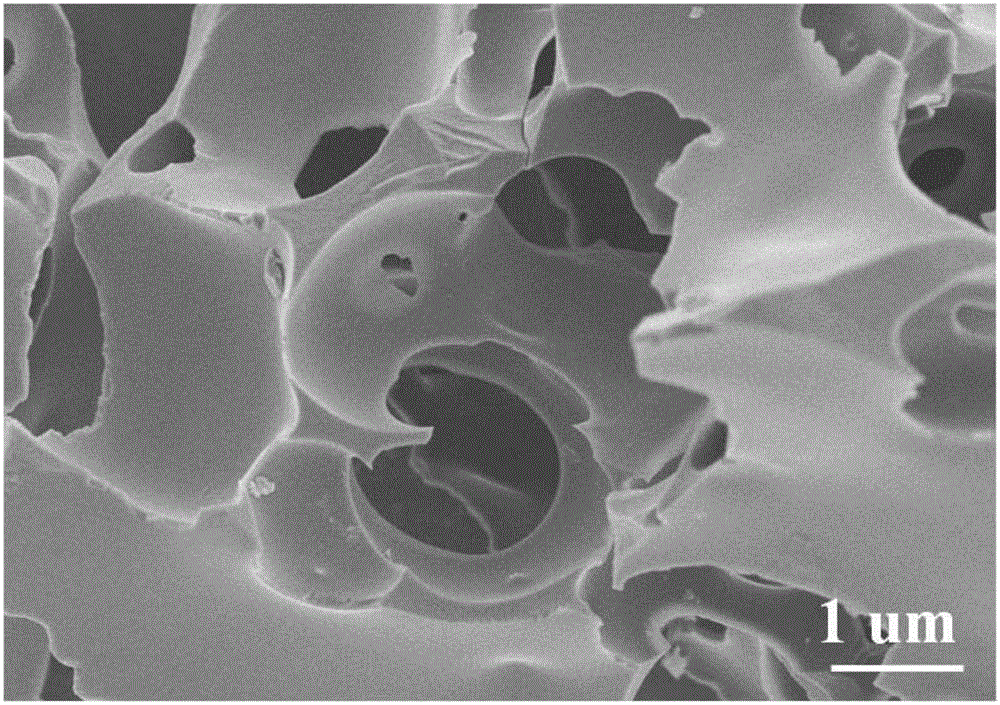

Image

Examples

Embodiment 1

[0039] (1) Wash the pomelo peel of the biomass prefabricated body to remove surface impurities, and shred it to obtain a uniform block A with a diameter of 5 mm;

[0040] (2) Freeze-dry the uniform block A at 0°C for 36 hours to obtain block B;

[0041] (3) Add 40 mL of 1 mol / L sulfuric acid solution to 1 g block B, and magnetically stir for 1.5 h to form a mixed liquid C;

[0042] (4) Transfer the mixed solution C to a homogeneous hydrothermal reaction kettle, seal it and put it into a homogeneous reactor, heat up to 180°C at a heating rate of 15°C / min for hydrothermal reaction for 24 hours, then cool naturally to room temperature to obtain water Thermal product D, wherein the lining of the reactor is polytetrafluoroethylene, and the filling ratio of the reactor is 40%;

[0043] (5) After the precursor D is washed and filtered, the precursor D: strong base is mixed evenly at a mass ratio of 1:3 and moved into a tube-type atmosphere furnace for carbonization. Under an argon atm...

Embodiment 2

[0046] (1) The pomelo peel of the biomass prefabricated body is cleaned and removed to remove surface impurities, and shredded to obtain a uniform block A with a diameter of 3 mm;

[0047] (2) Freeze-dry the uniform block A at -20°C for 12 hours to obtain block B;

[0048] (3) Add 50mL of 2mol / L sulfuric acid solution to 2g block B, and magnetically stir for 0.5h to form mixed solution C;

[0049] (4) Transfer the mixed liquid C to a homogeneous hydrothermal reaction kettle, seal it and put it into a homogeneous reactor, heat up to 150°C at a heating rate of 15°C / min for hydrothermal reaction for 12 hours, then cool naturally to room temperature to obtain water Thermal product D, wherein the lining of the reactor is polytetrafluoroethylene, and the filling ratio of the reactor is 50%;

[0050] (5) After washing and filtering the precursor D, mix the precursor D:strong base according to the mass ratio of 1:0.5 and move it into the tube atmosphere furnace for carbonization. Und...

Embodiment 3

[0053] (1) Wash the pomelo peel of the biomass prefabricated body to remove surface impurities, and shred it to obtain a uniform block A with a diameter of 3 mm;

[0054] (2) Freeze-drying uniform block A at 0°C for 24 hours to obtain block B;

[0055] (3) Add 60mL of 3mol / L sulfuric acid solution to 3g block B, and magnetically stir for 1h to form mixed solution C;

[0056] (4) Transfer the mixed solution C to a homogeneous hydrothermal reaction kettle, seal it and put it into a homogeneous reactor, heat up to 160°C at a heating rate of 15°C / min for hydrothermal reaction for 24 hours, then cool naturally to room temperature to obtain water Thermal product D, wherein the lining of the reactor is polytetrafluoroethylene, and the filling ratio of the reactor is 60%;

[0057] (5) After the precursor D was washed and filtered, the precursor D: strong base was mixed evenly in a mass ratio of 1:1 and moved into a tubular atmosphere furnace for carbonization. Under an argon atmosphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com