Preparation method of graphene/stannic oxide composite nanofiber membrane and application

A technology of composite nanofiber and tin dioxide, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of reducing surface area, reduce stacking, increase porosity, and improve electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

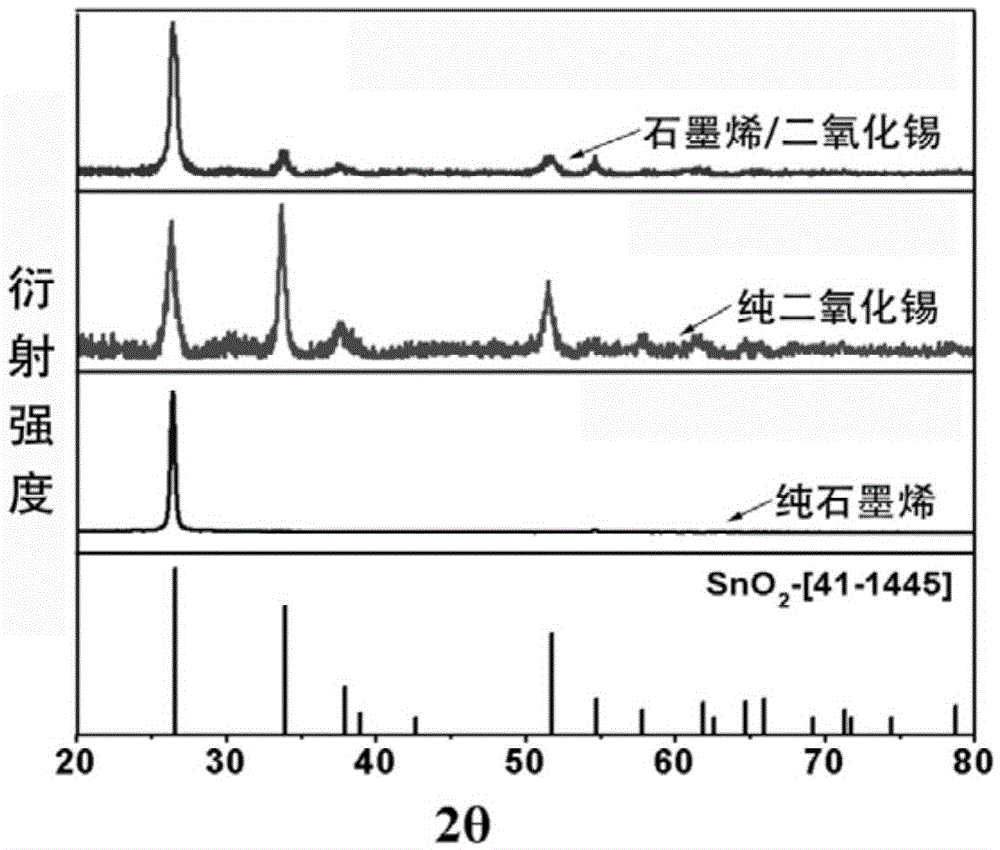

Embodiment 1

[0032] Graphene (0.05 g) was added to 30 ml of deionized water and sonicated for 0.5 h to disperse the graphene uniformly. NaOH (0.25g) was added under stirring conditions, then tin chloride (0.39g, 1.5mmol) was slowly added to the above solution under stirring conditions, and then the mixture was transferred to a 50ml polytetrafluoroethylene-stainless steel hydrothermal reaction kettle , and continuously reacted at 160°C for 15h. After the reaction was completed, the mixture solution was filtered and washed with ethanol and a large amount of distilled water to completely remove the soluble substances therein. Finally, the product graphene / tin dioxide nanoparticles were vacuum-dried at 60°C.

[0033] At room temperature, the obtained graphene / tin dioxide nanoparticles (0.04 g) were ultrasonically dispersed in a mixed solvent of methanol (8 ml) and water (2 ml). After it was mixed uniformly, PVAc (2 g) was added and stirred for 4 h to form a homogeneous solution. Then, the s...

Embodiment 2

[0038] Graphene (0.05 g) was added to 30 ml of deionized water and sonicated for 0.5 h to disperse the graphene uniformly. NaOH (0.25g) was added under stirring condition, and then the mixture was transferred to a 50ml polytetrafluoroethylene-stainless steel hydrothermal reaction kettle, and reacted continuously at 160°C for 15h. After the reaction was completed, the mixture solution was filtered and washed with ethanol and a large amount of distilled water to completely remove the soluble substances therein. Finally, the product pure graphene nanoparticles were vacuum-dried at 60°C.

[0039] At room temperature, pure graphene nanoparticles (0.04 g) were ultrasonically dispersed in a mixed solvent of methanol (8 ml) and water (2 ml). After it was mixed uniformly, PVAc (2 g) was added and stirred for 4 h to form a homogeneous solution. Then, the solution was sucked into a 10ml plastic syringe equipped with a 22# stainless steel needle, and the receiving device used a metal ro...

Embodiment 3

[0044] After 30 ml of deionized water was sonicated for 0.5 h, NaOH (0.25 g) was added with stirring, then tin chloride (0.39 g, 1.5 mmol) was slowly added to the above solution with stirring, and the mixture was transferred to 50 ml In a polytetrafluoroethylene-stainless steel hydrothermal reactor, and continuously reacted at 160°C for 15h. After the reaction was completed, the mixture solution was filtered and washed with ethanol and a large amount of distilled water to completely remove the soluble substances therein. Finally, the product pure tin dioxide nanoparticles were vacuum dried at 60°C.

[0045] Pure tin dioxide nanoparticles (0.04 g) were ultrasonically dispersed in a mixed solvent of methanol (8 ml) and water (2 ml) at room temperature. After it was mixed uniformly, PVAc (2 g) was added and stirred for 4 h to form a homogeneous solution. Then, the solution was sucked into a 10ml plastic syringe equipped with a 22# stainless steel needle, and the receiving devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com