Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Reduce the first irreversible capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

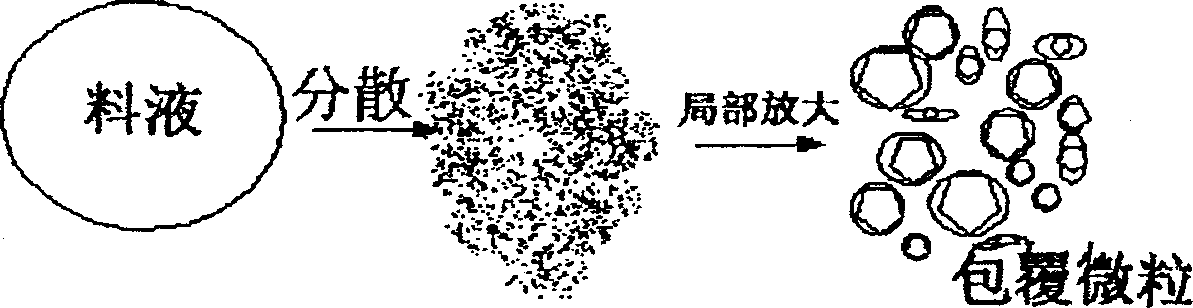

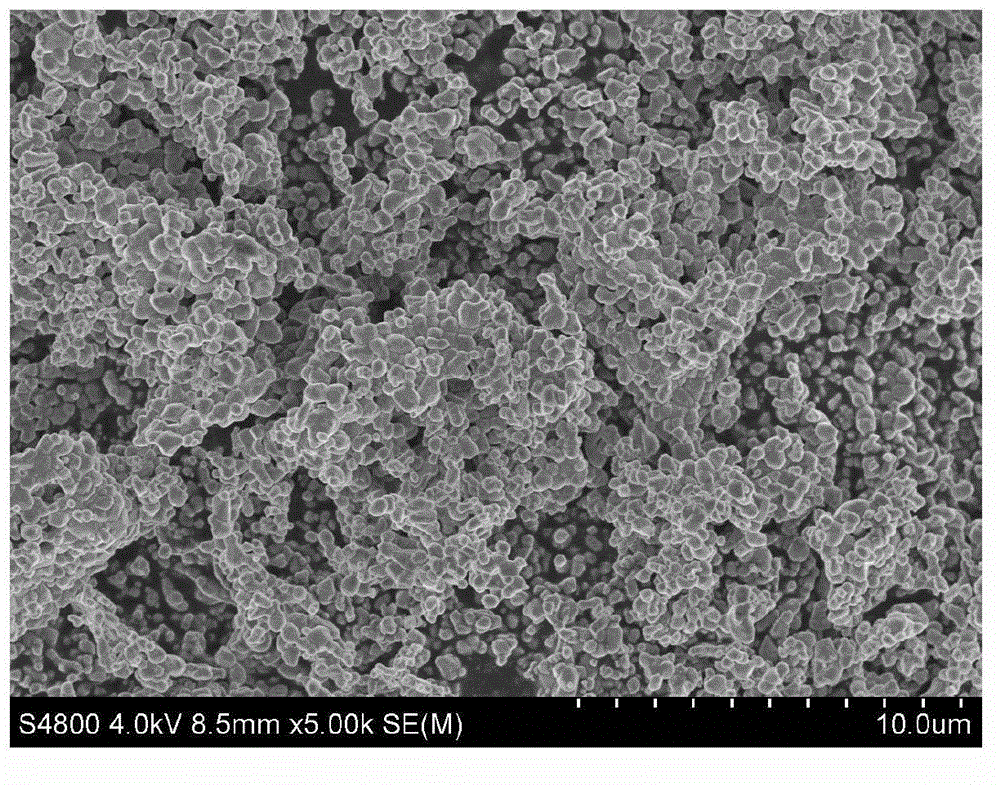

Process for preparing carbon coated graphite microparticles

InactiveCN1397598AReduce the first irreversible capacityLow charge and discharge voltagePigment treatment with macromolecular organic compoundsMicroparticleGraphite

A process for preparing carbon coated graphite microparticles used as negative electrode material of Li-ion battery features use of spray granulating method. It can elongate the service life of Li-ion battery.

Owner:TSINGHUA UNIV

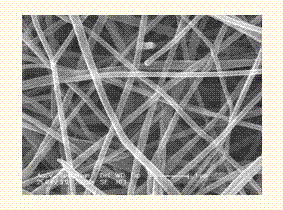

Preparation method for flexible graphene-modified knittable carbon nanofiber

InactiveCN103569997AImprove conductivity uniformityReduced electrode polarization effectMaterial nanotechnologyCell electrodesDimethyl formamideChemical industry

A preparation method for a flexible graphene-modified knittable carbon nanofiber belongs to the technical field of chemical industry. The preparation method comprises the following steps: at first, graphene oxide is taken to be placed in a container filled with DMF (Dimethyl Formamide) to obtain a graphene oxide saturated solution with the brown-yellow upper layer, then, polyacrylonitrile macromolecules are dissolved in the DMF to obtain a transparent macromolecular solution, the graphene oxide saturated solution and the macromolecular solution are mixed to obtain a precursor solution, a grapheme-modified polyacrylonitrile fiber is obtained through the electrostatic spinning technology or the melt spinning technology, the drying and stabilizing are performed, and at last, the carbon nanofiber is prepared from the dried polyacrylonitrile fiber in the inert gas environment or the vacuum condition. The carbon nanofiber prepared by the method can be applicable to lithium ion batteries or electrochemical capacitors, and besides, is also applicable to the fields of the war industry and the aerospace.

Owner:NORTHEAST NORMAL UNIVERSITY

Carbonaceous lithium ion battery negative electrode material with nuclear shell structure and producing method thereof

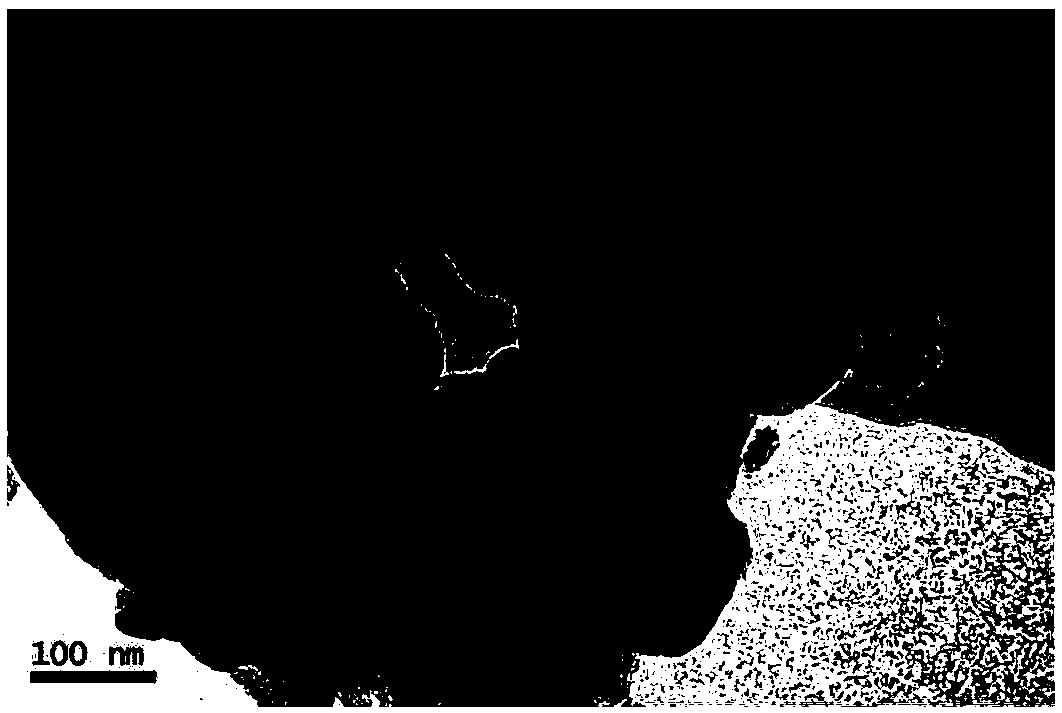

ActiveCN1848490AIncrease capacityReduce the first irreversible capacityCell electrodesCore shellNanometre

The present invention relates to a carbonaceous lithium ion cell negative electrode material with core-shell structure and its preparation method, belonging to the field of carbon material and chemical power supply technology. The described negative electrode material is formed from core portion and shell portion. The core portion is graphite obtained after the graphite intercalation compound is disintercalated, the shell portion is amorphous carbon obtained by pyrolysis of organics. Said invention also provides the concrete steps of its preparation method.

Owner:TSINGHUA UNIV

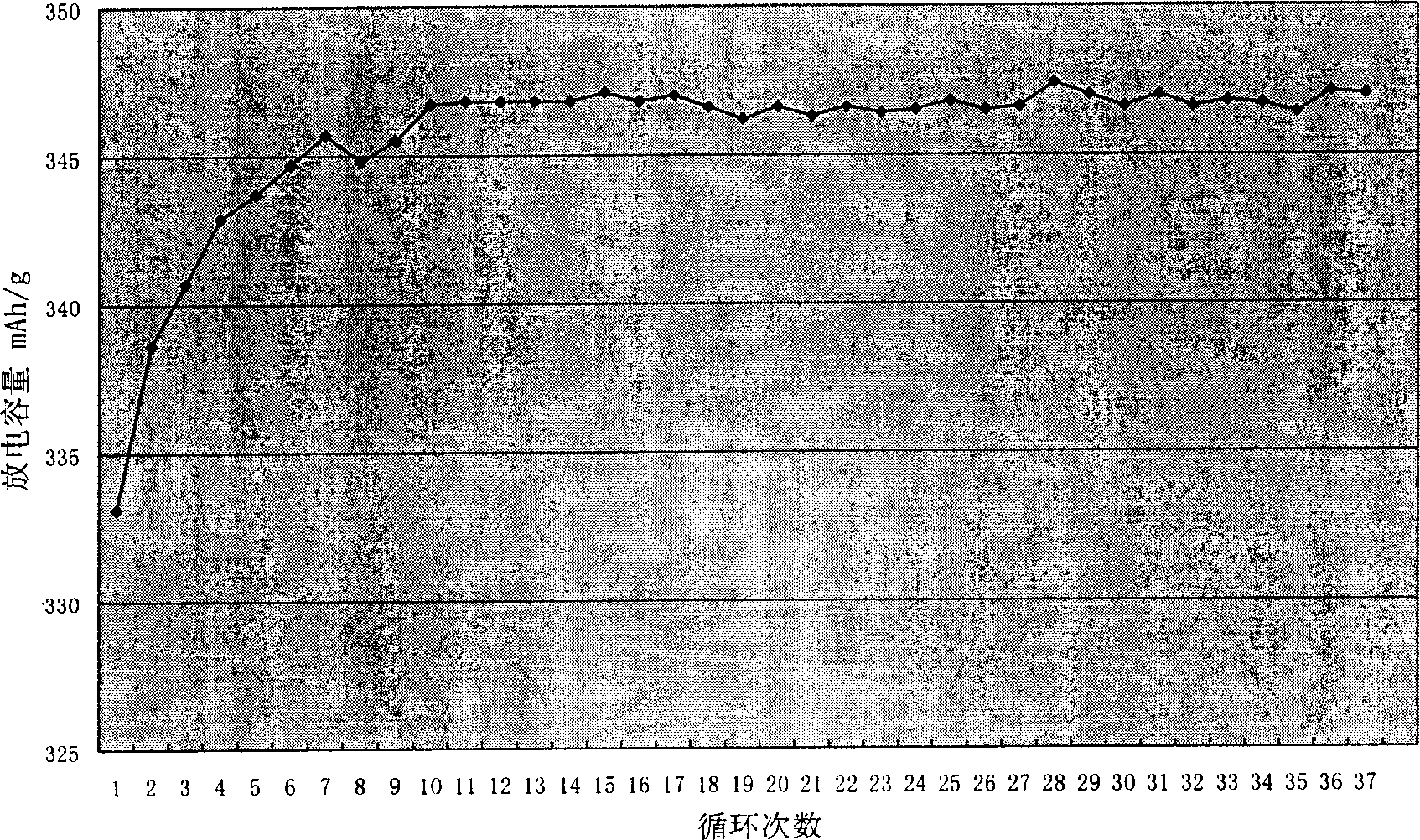

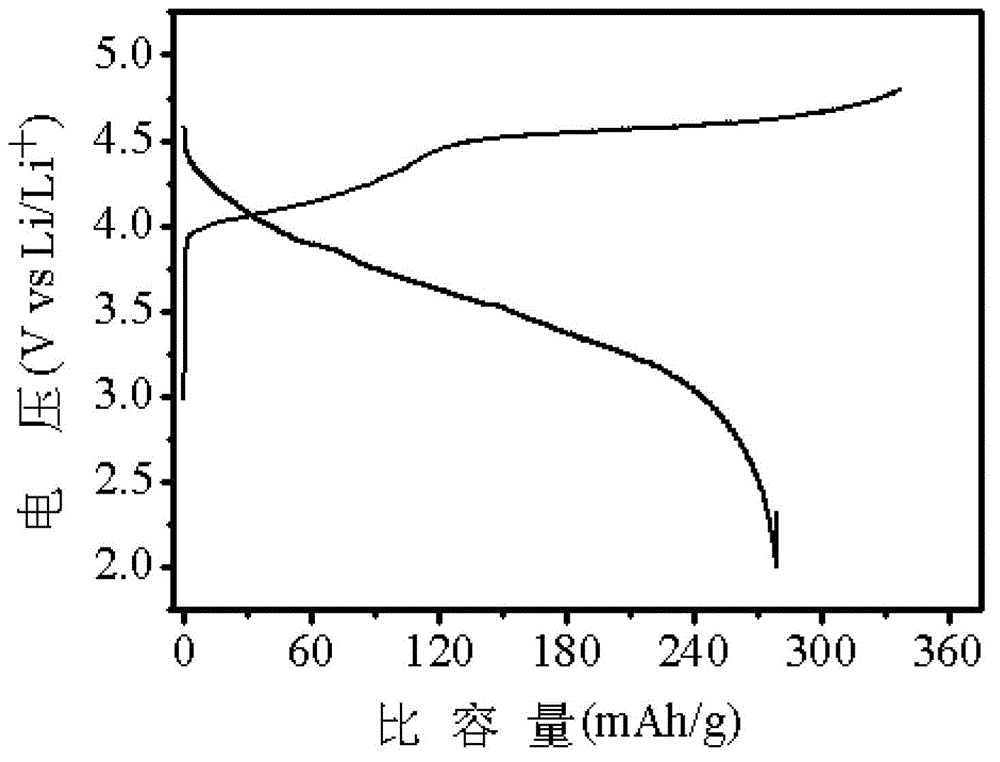

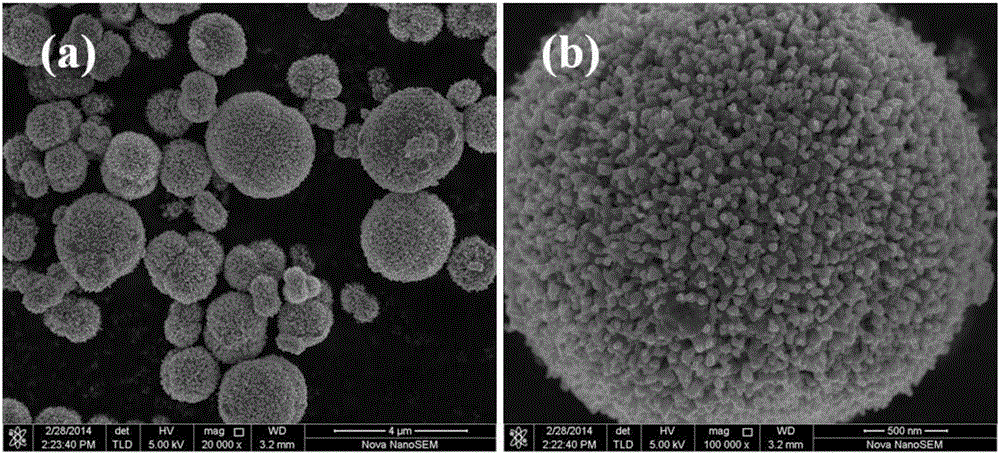

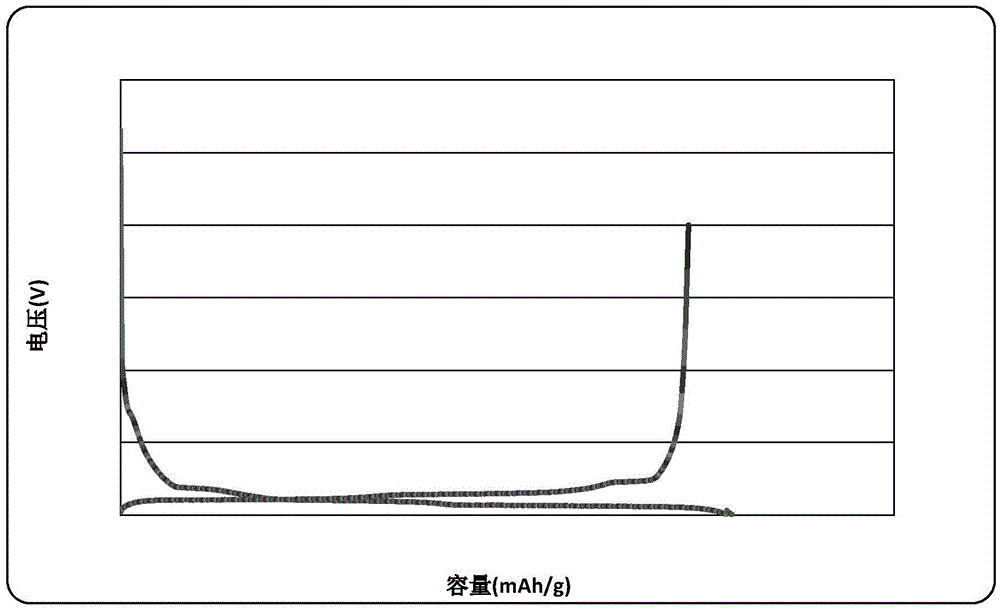

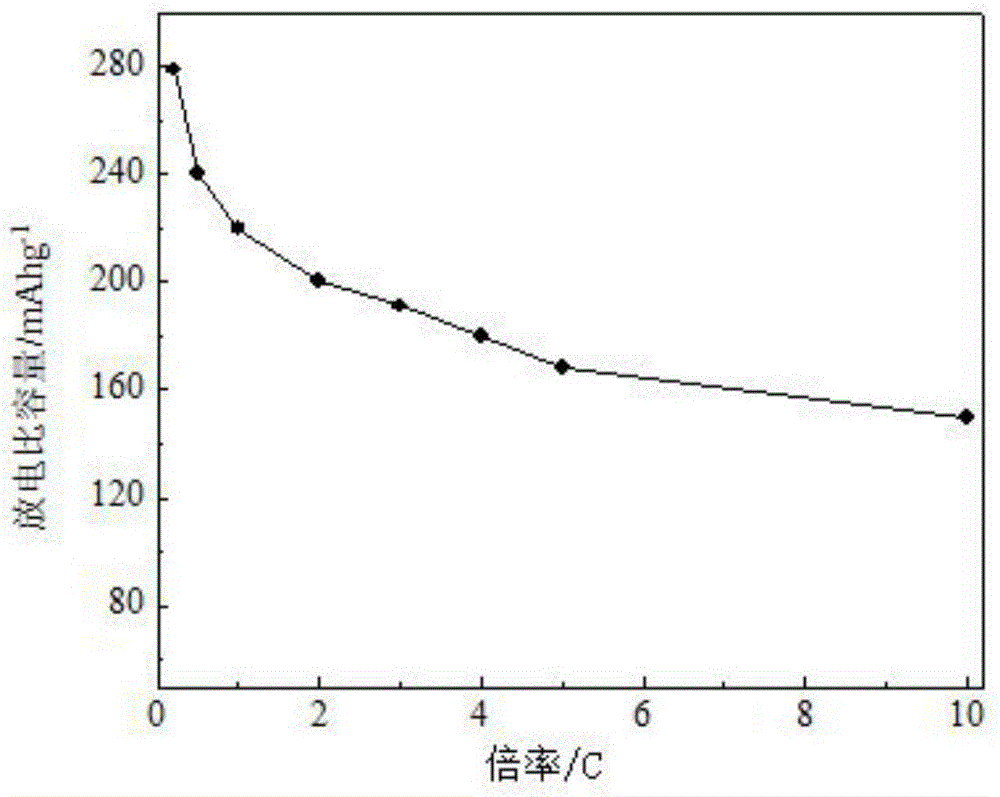

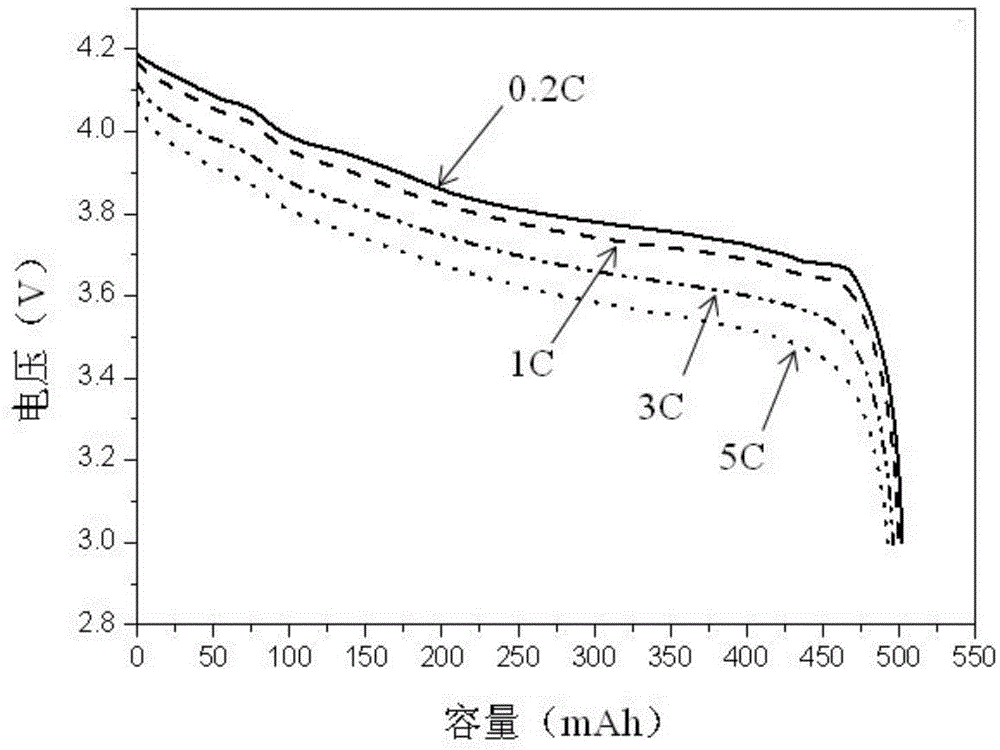

Lithium-rich manganese-based anode material and method for manufacturing same

ActiveCN102916169AImprove featuresUniform structureCell electrodesSecondary cellsPtru catalystActive agent

The invention discloses a lithium-rich manganese-based anode material and a method for manufacturing the same. The method includes steps of (a), providing mixed solution containing lithium compounds, nickel compounds and manganese compounds, optional titanium compounds, optional iron compounds, optional cobalt compounds or an optional combination of the titanium compounds, the ion compounds and the cobalt compounds; (b), adding complexing agents, catalysts and surfactants into the mixed solution to form pre-coagulated substances; and (c), calcining the pre-coagulated substances to obtain the lithium-rich manganese-based anode material Li[LixNiaMnbM1-a-b-x]O2 or a combination of lithium-rich manganese-based anode materials. The complexing agents, the catalysts and the surfactants are used for forming the pre-coagulated substances, the complexing agents contain resorcinol and formaldehyde, in the molecular formula of the lithium-rich manganese-based anode material, the M represents Ti, Fe, Co or a combination of the Ti, the Fe and the Co, the x is larger than 0 and is smaller than or equal to 0.4, the a is larger than 0 and is smaller than or equal to 0.5, the b is larger than or equal to 0.33 and smaller than or equal to 0.6, and a result of 1-a-b-x is larger than or equal to 0. The lithium-rich manganese-based anode material is of a multi-channel porous structure, is small in grain size, uniform in grain distribution, advanced in porosity and stable in electrochemical performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing lithium battery silicon carbon anode material

InactiveCN103022448AImprove volume effectAlleviate volume effectCell electrodesCarbon compositesCopper foil

The invention discloses a sodium alginate bonding agent used in a lithium battery silicon carbon anode, particularly discloses a method for preparing a silicon carbon anode material by the bonding agent. The method comprises the steps that: step one, micron-grade silica powder is added into a ball milling tank, and a solvent is added to perform ball milling; step two, natural graphite is added into the industrial silicon powder subjected to the ball milling in the step one to continuously perform the ball milling; step three, substances subjected to the ball milling in the step two are dried, and the dried substances are finely ground; step four, 70-80 parts by weight of the silicon carbon composite material, 5-20 parts by weight of sodium alginate and 5-20 parts by weight of acetylene black are weighed, defined amount of deionized water is added, and the materials are uniformly stirred, then coated on a copper foil and dried to obtain the silicon carbon anode material. The novel bonding agent adopted by the invention can effectively improve the cycling performance of the silicon carbon anode material and prolong the cycling service life of the anode material.

Owner:TIANJIN B&M SCI & TECH

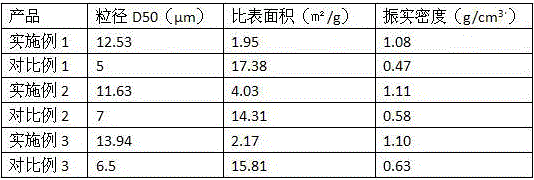

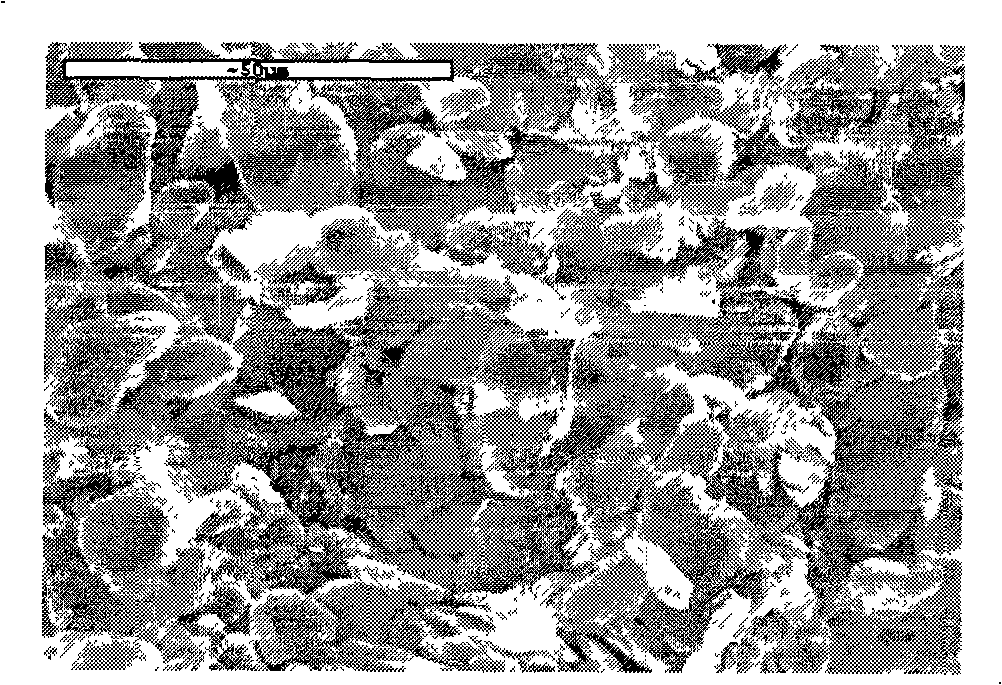

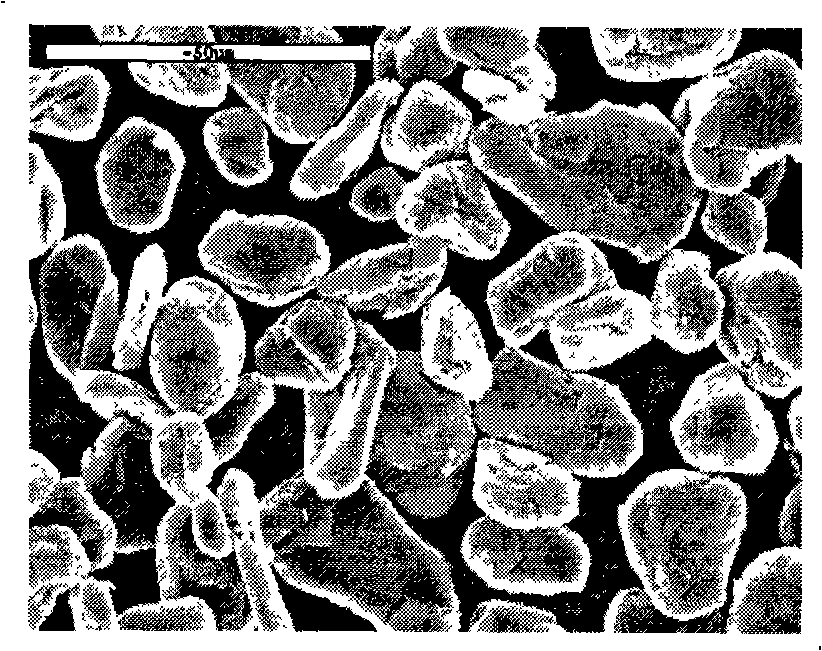

Preparation method for graphite anode material of lithium ion battery

InactiveCN105932281AReduce turnoverReduce lossesElectrode manufacturing processesSodium-ion batteryLithium-ion battery

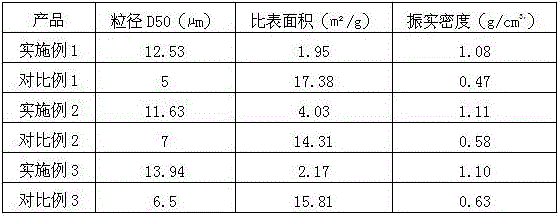

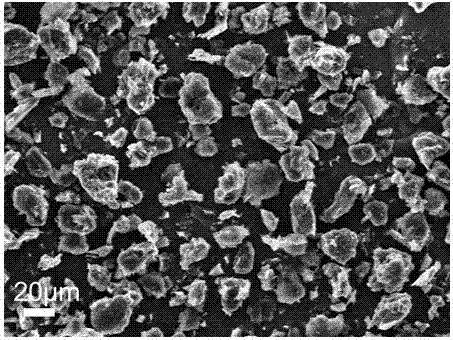

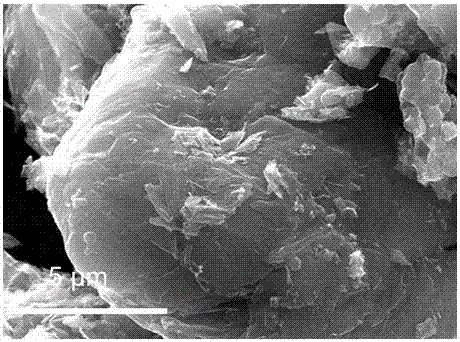

The invention discloses a preparation method for a graphite anode material of a lithium ion battery. Fine graphite powder with a small particle size and an organic carbon source are taken as raw materials; through adoption of processes such as mixing, high temperature processing, graphitizing and sieving and through mixing of the fine powder and the organic carbon source in a heating environment, coating, kneading and secondary granulating effects can be realized; and under the adhering effect of the organic carbon source, the fine powder with the small particle size forms secondary particles. The anisotropy problem of the materials is solved, and the tap density of the materials is improved. According to the method, the turnover and device residual loss of the materials are reduced, the yield is high, the processes are simple, the energy consumption is low, the environment is protected, the surface coating effects of the materials are even, and the consistency is high. The prepared anode material is characterized in anisotropy, low iron impurity content, low initial irreversible capacity, low volume expansion, high liquid absorbency, high cycle performance, high cost performance and high comprehensive performance.

Owner:田东

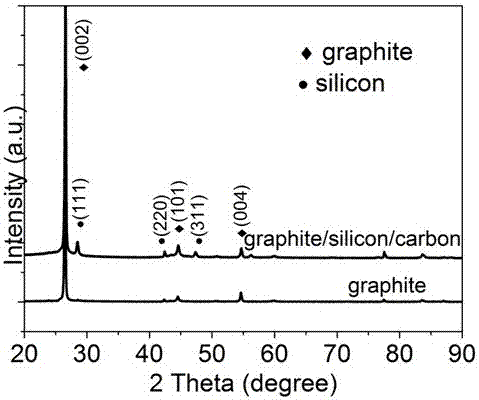

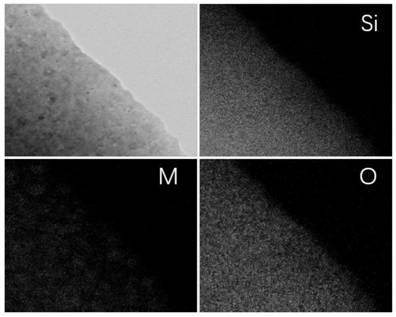

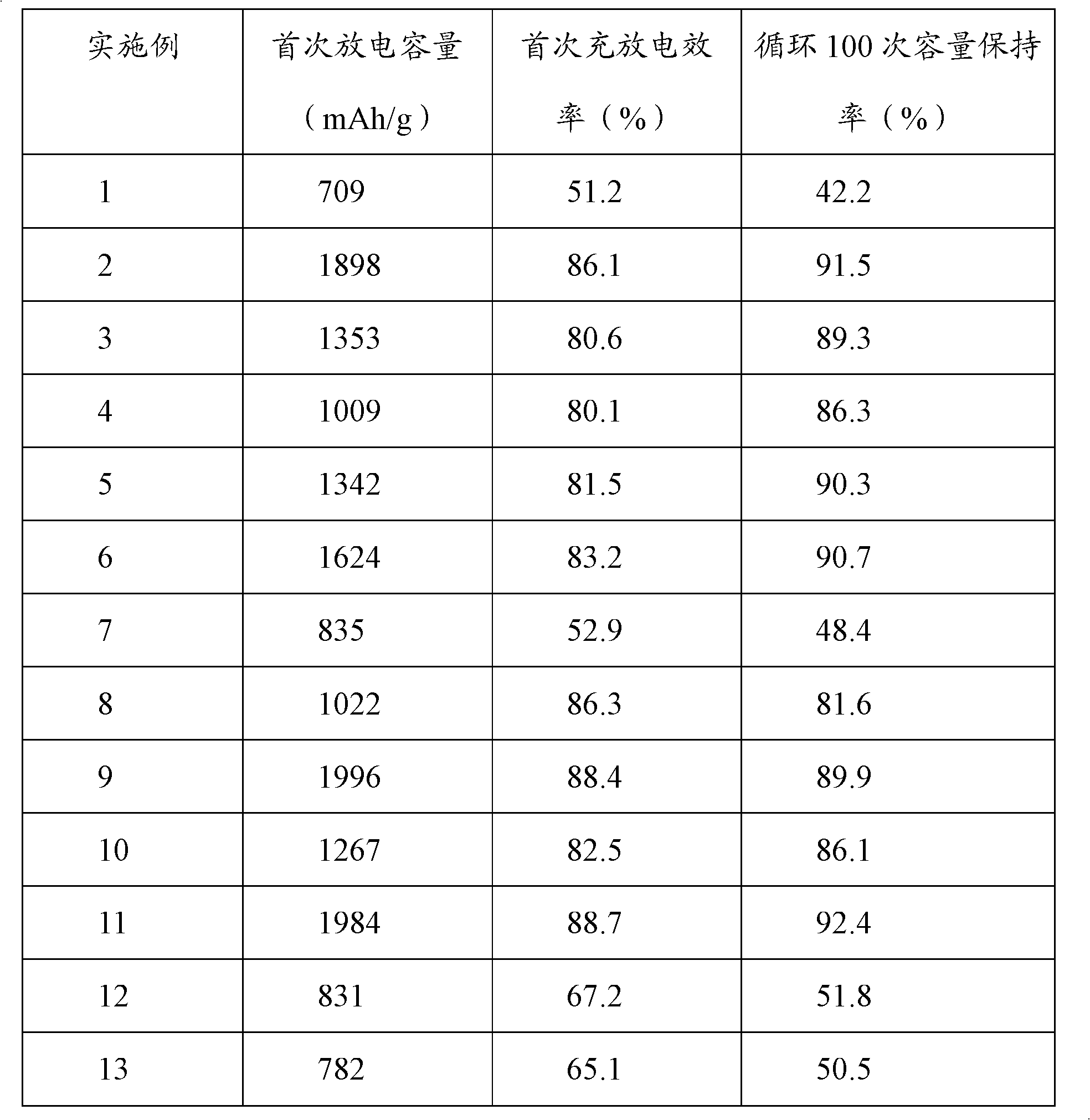

Graphite/silicon@carbon core-shell structure composite spherical cathode material and preparation method thereof

InactiveCN107093721ASimple preparation processReduce the first irreversible capacityCell electrodesSecondary cellsCarbon compositesComposite cathode

The invention discloses a graphite / silicon@carbon core-shell structure composite spherical cathode material and a preparation method thereof. By means of the material, the volume expansion effect of silicon in the lithium de-intercalation process can be inhibited, and a high-capacity lithium iron battery silicon / carbon composite cathode material is obtained. By means of the technical scheme, a spherical graphite / silicon framework precursor serves as the core of the composite cathode material, and an amorphous pyrolytic carbon or graphite-like carbon material wrapping layer serves as the shell; nanometer or micrometer silicon is embedded in flake graphite cracks to form a graphite framework, the volume expansion effect of silicon in the lithium de-intercalation process is inhibited through the mechanical characteristics of the graphite framework, then a spherical framework is formed by mixing and granulating 3-20 wt% of nanometer or micrometer silicon, 50-80 wt% of flake graphite and 10-40 wt% of amorphous pyrolytic carbon or graphite-like carbon, and an amorphous pyrolytic carbon or graphite-like carbon spherical composite conductive carbon net structure wrapping a graphite / silicon surface is formed.

Owner:四川聚能仁和新材料有限公司

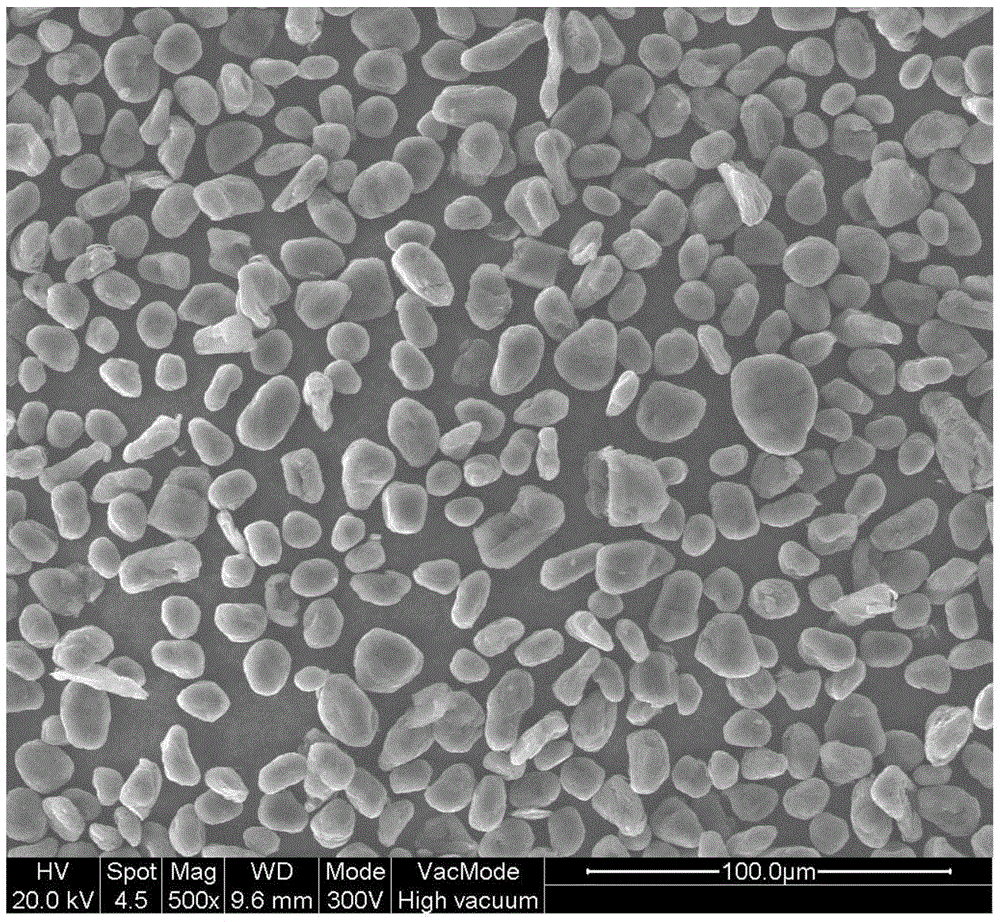

Modified silicon monoxide material for lithium ion battery negative electrode and preparation method thereof

ActiveCN111072038ASmall volume expansionReduce consumptionSilicaSecondary cellsSilicon monoxideSilicon oxide

The invention discloses a modified silicon monoxide material and a preparation method thereof. The modified silicon monoxide material is the modified silicon monoxide material used for a lithium battery negative electrode. The modified silicon monoxide material is prepared by the following steps: reacting raw materials silicon, silicon dioxide and metal silicate under high-temperature and vacuum conditions to prepare silicon monoxide, and reacting metal steam with silicon monoxide in the preparation process to form metal silicate in situ; wherein the metal silicate is uniformly dispersed around the silicon and the silicon monoxide to form silicon-containing particles, and the carbon material is coated on the surfaces of the silicon-containing particles. The silicate in the modified siliconmonoxide material is uniformly dispersed, the carbon material is uniformly coated, and the modified silicon monoxide material shows high specific capacity, high initial coulombic efficiency, excellent cycle performance and rate capability when used as the lithium ion battery negative electrode material. Moreover, the preparation method disclosed by the invention is low in raw material price and beneficial to industrial implementation, so that the modified silicon monoxide has a very wide application prospect.

Owner:JIANGXI IAMETAL NEW ENERGY TECH CO LTD

Silicon-based cathode composite material for lithium ion battery and preparation method thereof

ActiveCN102324501ARelief of mechanical stressEliminate volume effectCell electrodesSodium-ion batteryLithium-ion battery

The invention discloses a silicon-based cathode composite material for a lithium ion battery and a preparation method thereof. The cathode composite material is a Si / CuOx / C composite material (0<=x<=1) with a porous structure. Silicon with a porous structure is used as a base, and CuOx particles are inserted in the pores, and carbons with different forms are distributed on a surface and pore walls of the silicon-based material. The preparation method of the cathode composite material comprises steps that silicon material realizes pore-forming through an in situ catalytic reaction between silicon and halogenated hydrocarbon, and reaction condition parameters are regulated to control pore size, distribution and amount of porosity of the silicon material; a post-modification technology is employed to carry out modifications on the surface and the pore walls of the porous silicon, so as to obtain the Si / CuOx / C composite material with a porous structure. The porous silicon-based cathode composite material has low production costs, simple process and no pollution, and is suitable for industrialized production; besides the porous silicon-based cathode composite material has high charge and discharge capacity, small initial irreversible capacity and good cycle performance.

Owner:河北中芯凤华科技发展有限公司

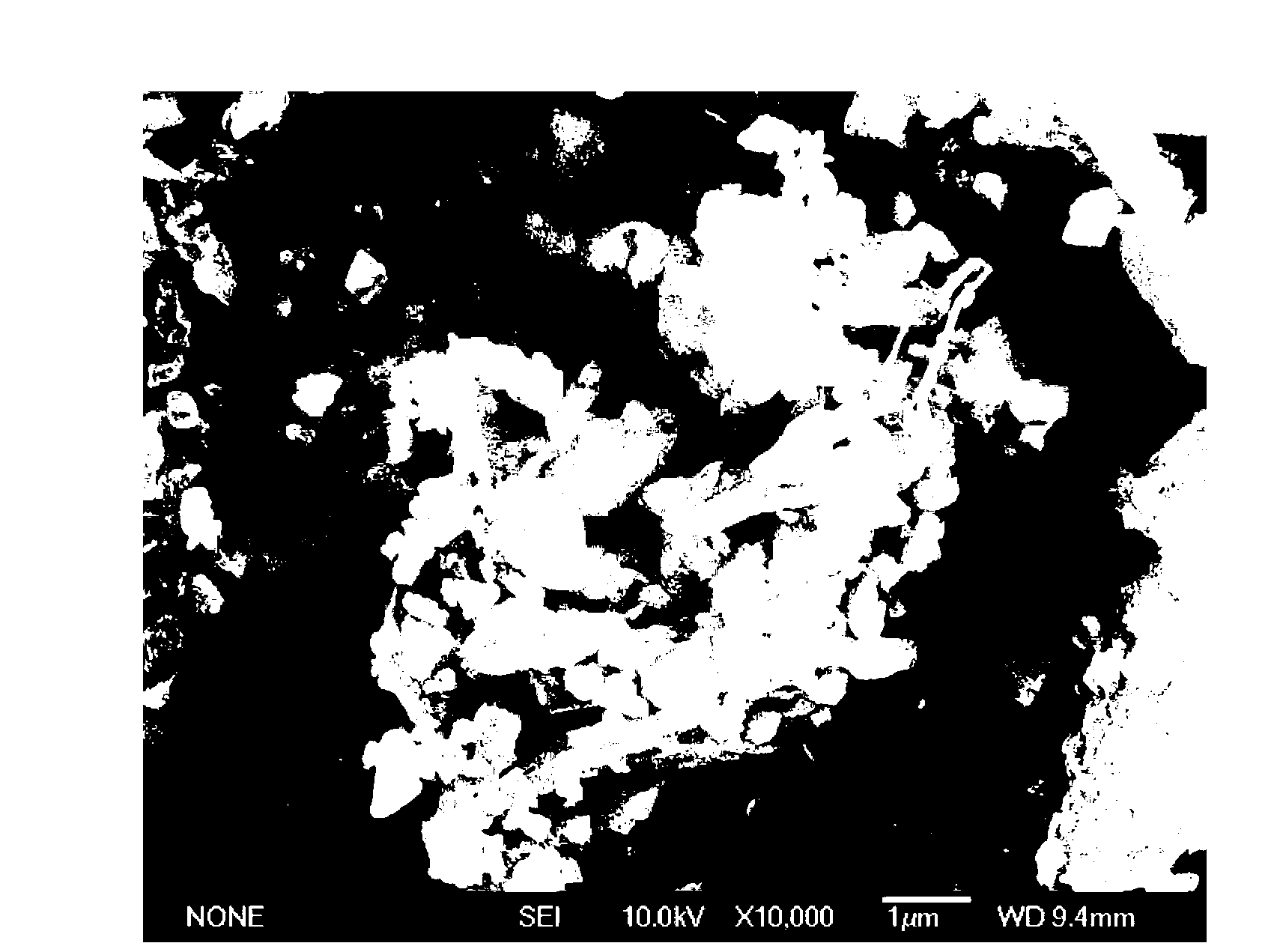

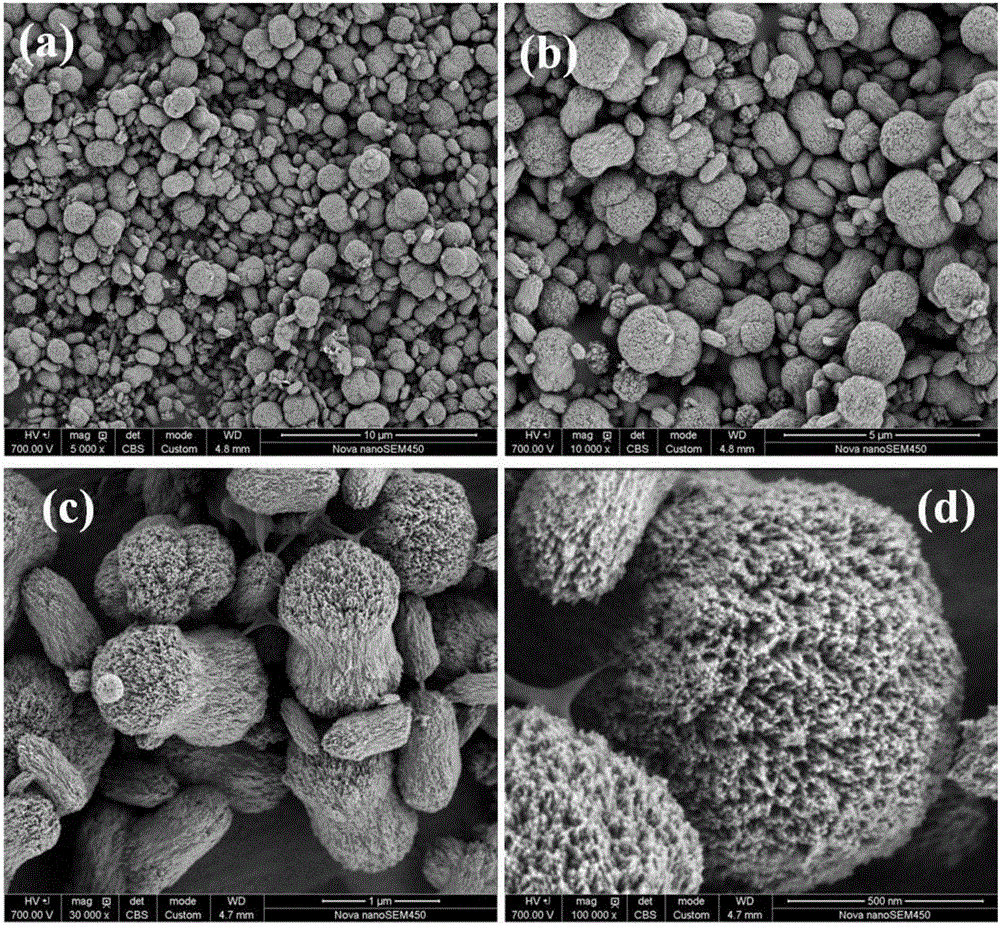

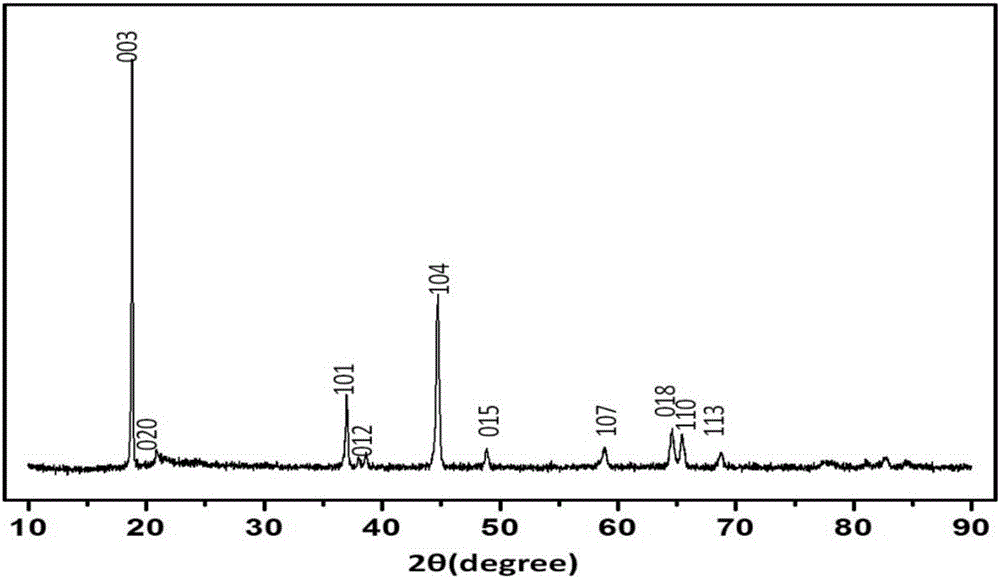

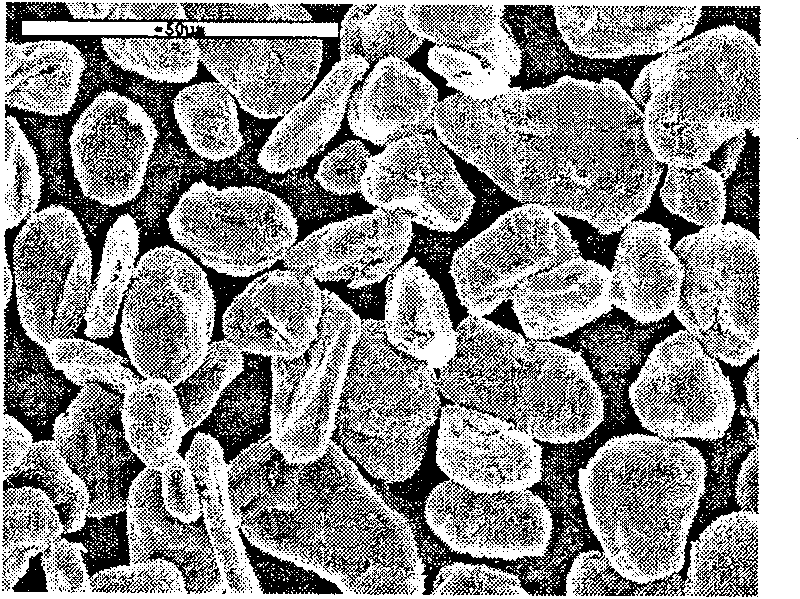

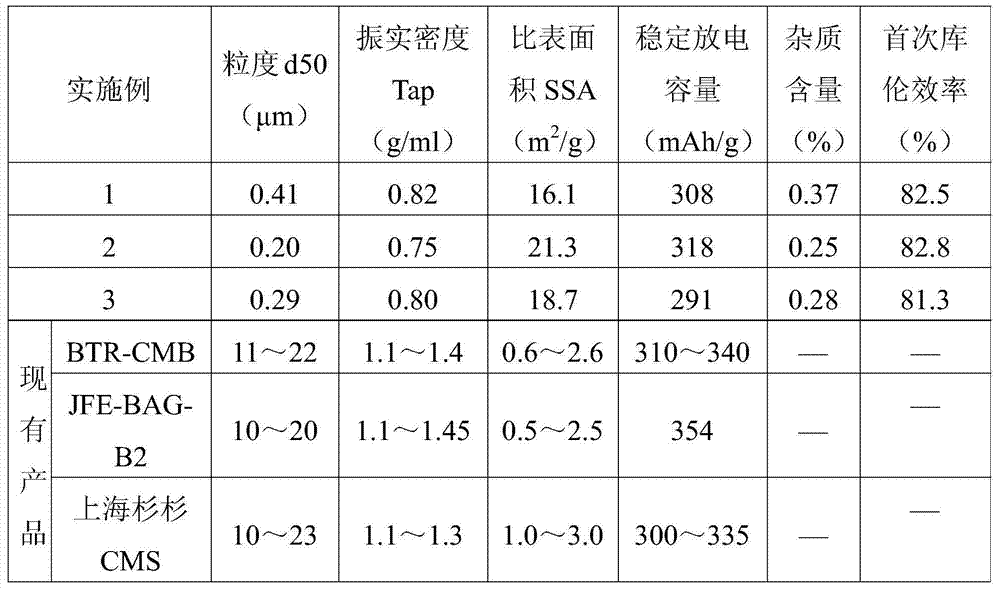

Lithium-rich manganese-based cathode material precursor, cathode material and preparation method thereof

ActiveCN106564967AAccelerates and intensifies the mass transfer processWell mixedMaterial nanotechnologyCell electrodesNickel saltManganese

The invention belongs to the field of electrode material preparation and relates to a lithium-rich manganese-based cathode material precursor, a cathode material and a preparation method thereof. The preparation method comprises the following steps: mixing metal salts (manganese salt, cobalt salt and nickel salt) and a surfactant and water, and dissolving to obtain a metal salt solution; putting a precipitant in water, stirring and dissolving to obtain a precipitant solution; carrying out liquid-liquid coprecipitation reaction on the metal salt solution and the precipitant solution in a hypergravity field reactor, filtering, cleaning, and carrying out vacuum drying so as to obtain a precursor; mixing the precursor and lithium salt and then calcining so as to obtain the lithium-rich manganese-based cathode material. By the coprecipitation method based on the hypergravity technology, the lithium-rich manganese-based cathode material precursor with primary particle being below 100 nm and secondary particle being 1-10 microns is rapidly prepared, and furthermore the prepared cathode material has advantages of uniform component distribution and particle size distribution, small granularity and high activity. Initial irreversible capacity can be reduced, and cycle performance of a lithium ion secondary battery can be enhanced.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

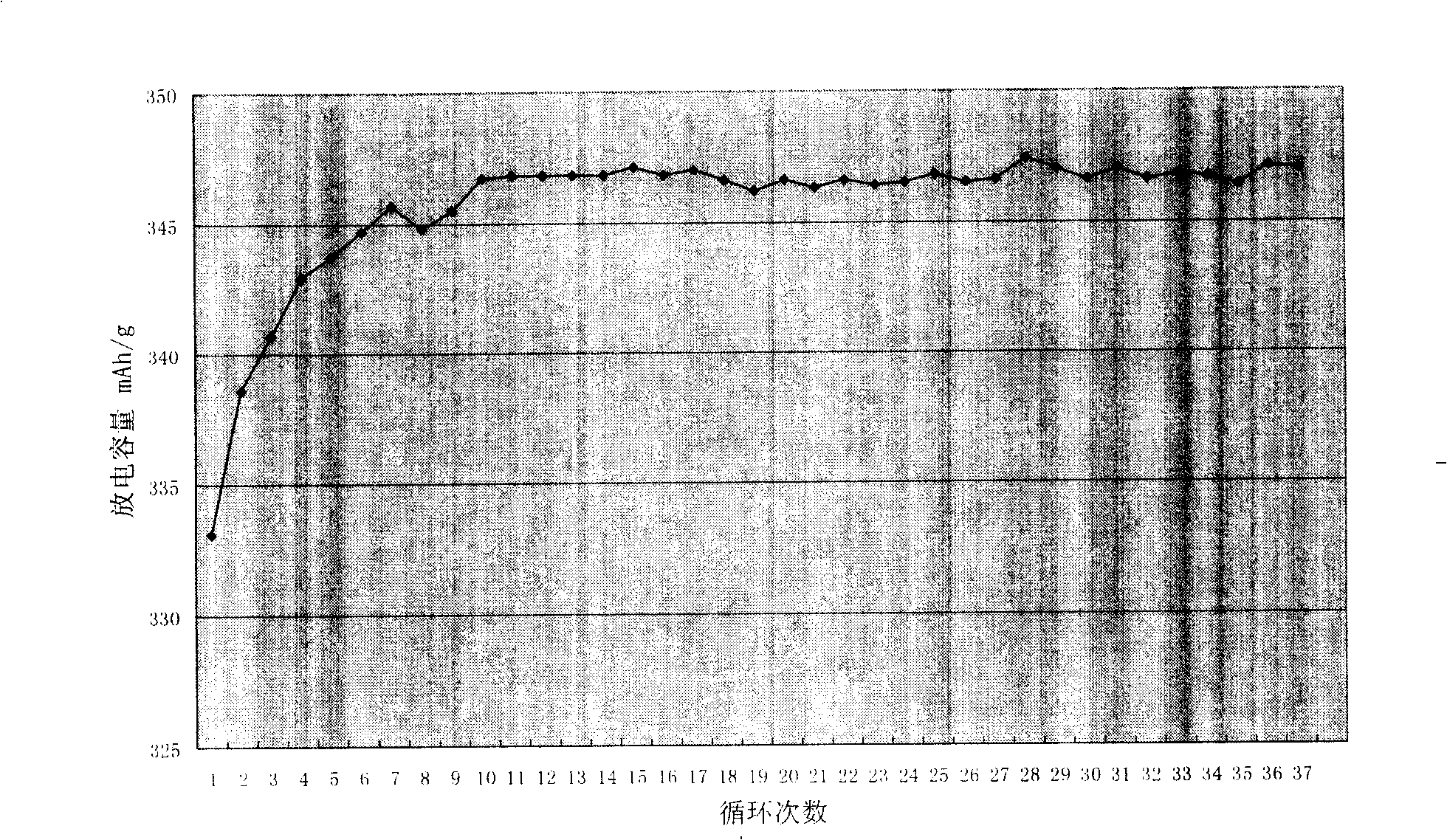

Preparation method for artificial graphite negative electrode material for lithium ion battery

InactiveCN105958070ALow tap densityHigh tap densityCell electrodesSecondary cellsEnvironmental resistanceLithium-ion battery

Disclosed is a preparation method for an artificial graphite negative electrode material for a lithium ion battery. Artificial graphite coke powder with small grain diameter and an organic carbon source are taken as the raw materials; the raw materials are subjected to procedures of mixing, high-temperature treatment, graphitization treatment, sieving and the like; the coke powder and the organic carbon source are mixed in a heating environment, and the effects of coating, mixing and holding, secondary pelleting and the like can be achieved; the small-particle coke powder can form secondary particles under the cohesive action of the organic carbon source; therefore, the problem of anisotropy of the material is solved, and the tap density of the material is improved; meanwhile, the artificial graphite negative electrode material is capable of lowering the material turnover and equipment residual loss, high in yield, simple in procedures, low in energy consumption, environment-friendly, uniform in the coating effect on the surface of the material, and high in consistency; and in addition, the prepared negative electrode material has the characteristics of isotropy, low iron impurity content, low initial irreversible capacity, small volume expansion, high absorbency, high circulation performance, high performance cost ratio, excellent comprehensive performance and the like.

Owner:田东

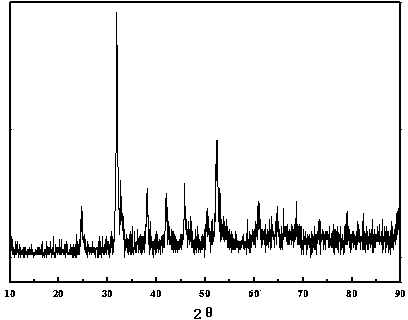

Graphitic cladding method by nano-scale mesophase asphalt

InactiveCN101286556AReduce the first irreversible capacityLow charge and discharge voltageElectrode manufacturing processesLiquid stateCarbonization

The invention relates to a preparation method for secondary battery cathode material, more particularly to a preparation method thereof which is formed by coating graphite by using nano-intermediate phase asphalt. The key point of the method is that nano-processing is carried out to the intermediate phase asphalt which is in semi-liquid state, the nano-intermediate phase asphalt in the semi-liquid state is sprayed on the substrate surface of the graphite by a nano-spray device, then even coating is realized, finally, the secondary battery cathode material is obtained by the traditional processes of drying, carbonization and graphitization. The adoption of the method can improve the coating evenness and the spherical completeness in a greater degree, thus further reducing the first-time irreversible capacity of the graphite, improving the cyclical stability and having the advantages that the charging and discharging voltage of the secondary battery is low, the charging and discharging platform is long and the cycle life is good.

Owner:晟茂(青岛)先进材料有限公司

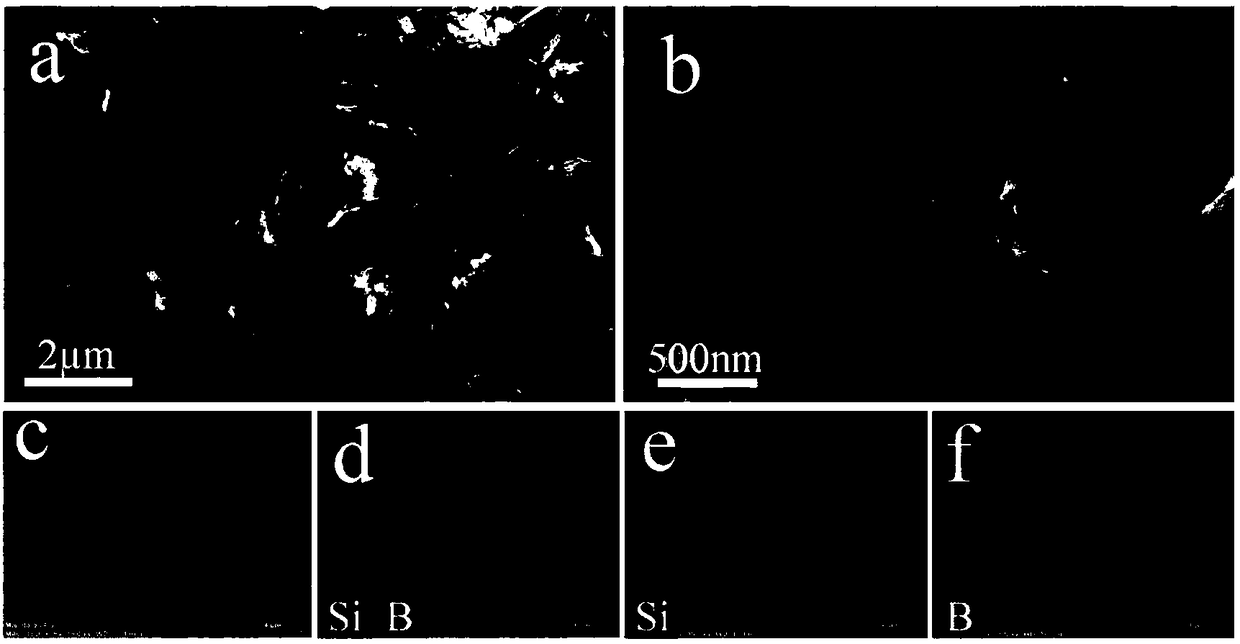

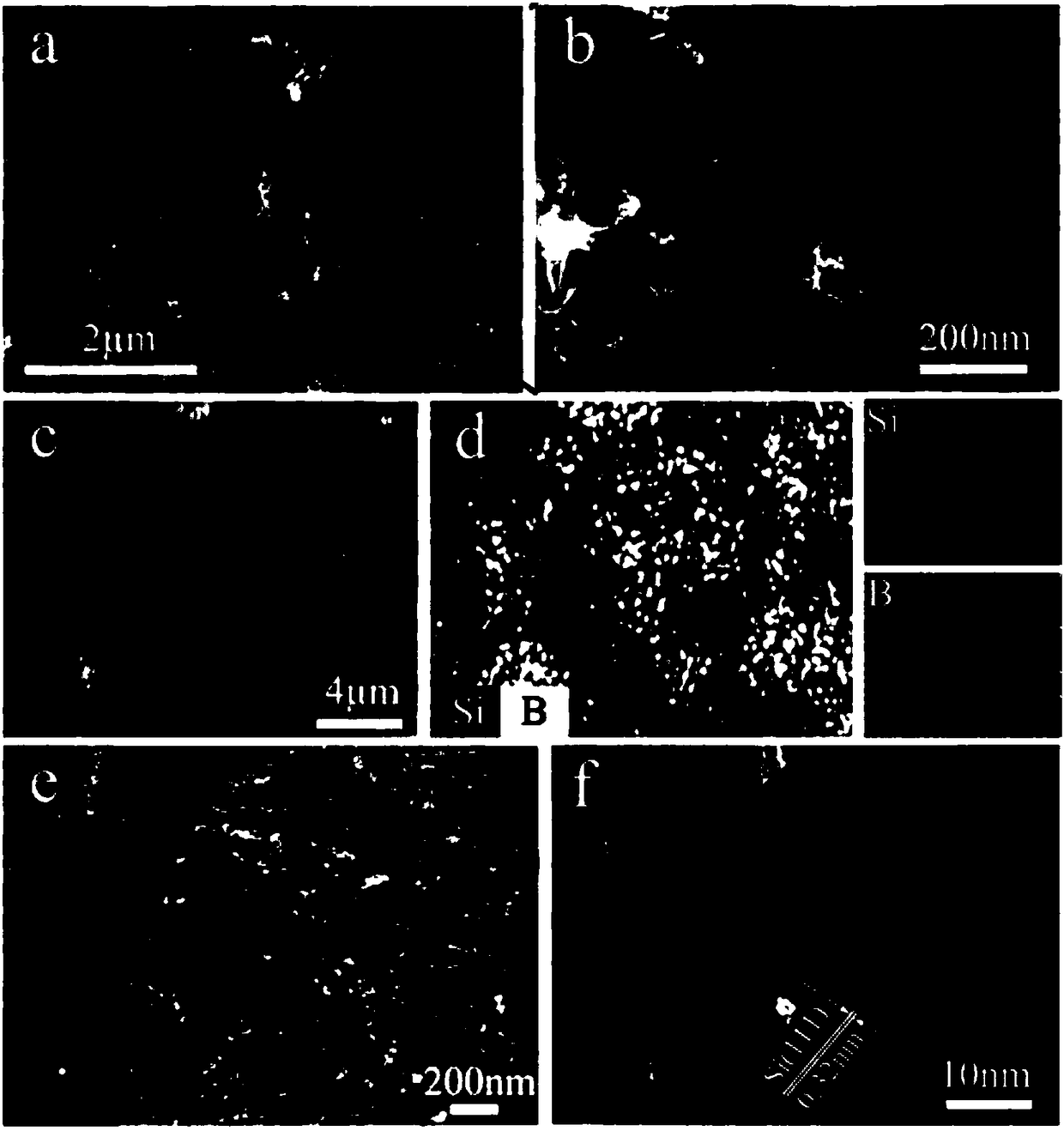

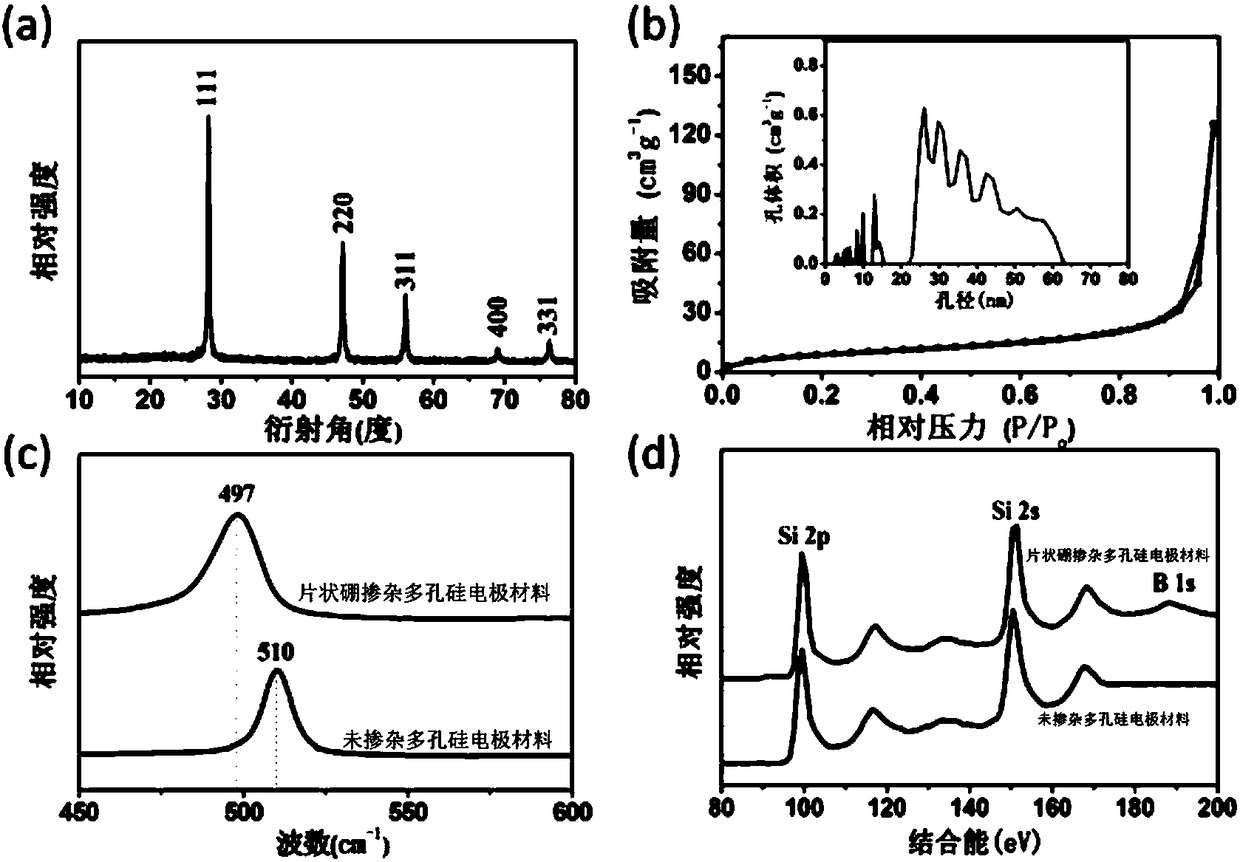

Sheet-shaped boron-doped porous silicon electrode material and preparation method thereof

ActiveCN108390053AImprove conductivityMeet the needs of conductionSiliconCell electrodesMixed materialsP type silicon

The invention discloses a preparation method of a sheet-shaped boron-doped porous silicon electrode material. The preparation method comprises the steps of (1) immersing boron-doped P-type silicon debris with an inorganic acid for 6-24 hours, and performing washing and drying to obtain boron-doped silicon powder; (2) uniformly mixing the boron-doped silicon powder and magnesium powder according toa mole ratio being 1:(1-2.5) to obtain a mixed material, and performing thermal processing on the mixed material under inert atmosphere to generate Mg2Si powder; (3) oxidizing the Mg2Si powder undera high temperature of 400-850 DEG C to obtain a reaction product, immersing the reaction product with the inorganic acid, cleaning and washing the reaction product with an HF solution, and obtaining the sheet-shaped boron-doped porous silicon electrode material after drying. The grain size of the prepared sheet-shaped boron-doped porous silicon electrode material is 0.2-5 micrometers, the specificarea is (10-100) m<2> / g, and the pore diameter is 20-70 nanometers. The sheet-shaped boron-doped porous silicon electrode material has favorable cycle stability and high specific capacity.

Owner:中国平煤神马控股集团有限公司 +2

High-capacity lithium-enriched positive electrode material and preparation method thereof

ActiveCN104134797AHigh crystallinityUniform and controllable particle sizeCell electrodesSecondary cellsLithiumCalcination

The invention belongs to the field of electrochemistry and particularly relates to a high-capacity lithium-enriched positive electrode material and a reparation method thereof. The molecular formula of the high-capacity lithium-enriched positive electrode material is Li[Li<x-beta>Na<beta>Mn<1-y-z-alpha>Co<y>Ni<z>Y<alpha>]O2, wherein x is more than or equal to 0 and less than or equal to 0.6, y is more than 0 and less than or equal to 0.4, z is more than 0 and less than or equal to 0.4, alpha is more than or equal to 0 and less than or equal to 0.1 and beta is more than or equal to 0 and less than or equal to 0.2; the result of (1-y-z-alpha) is more than 0 and the result of (x-beta) is more than 0. The lithium-enriched positive electrode material containing Na and Y has the characteristics of low first-time irreversible capacity, large electrochemical capacity, high cycling stability, excellent rate performance and the like. The preparation method has the advantages that a preparation process is simple, raw materials are cheap and easily available, the cost is low, the high-temperature calcination time is very short, the repeatability is good and the industrialization is easy to realize.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

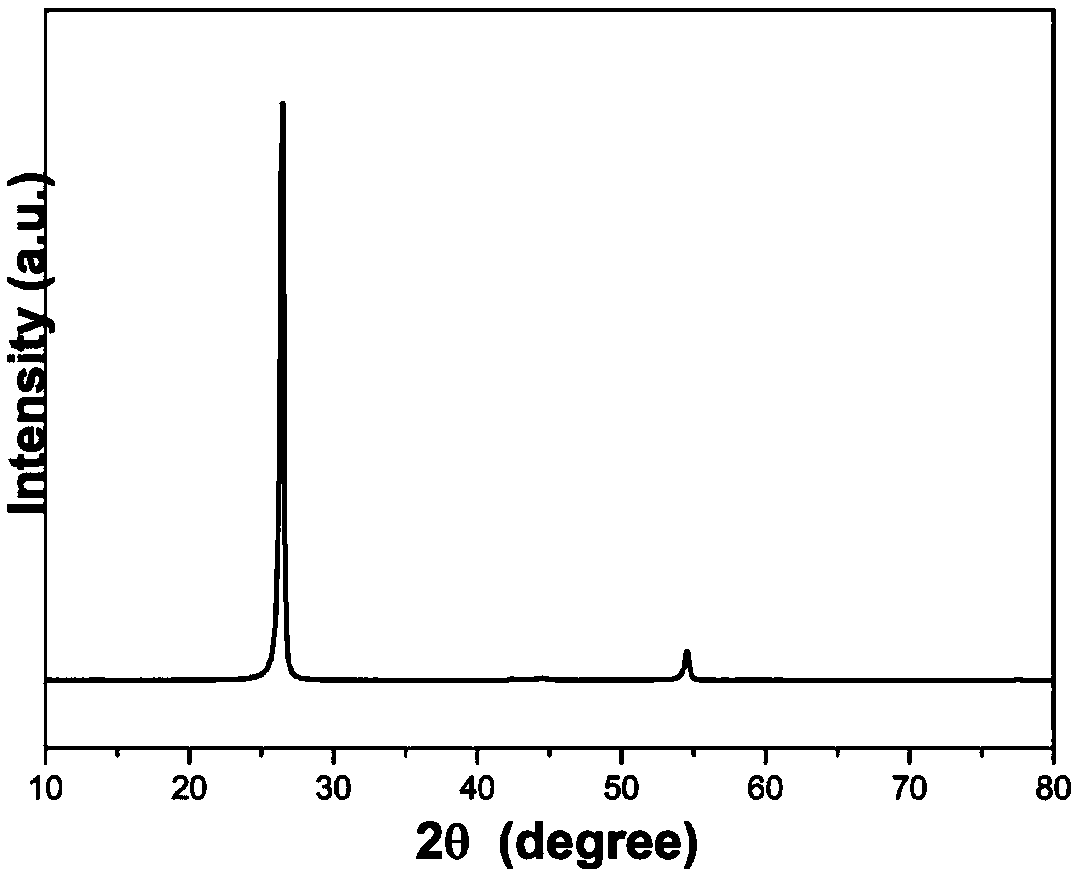

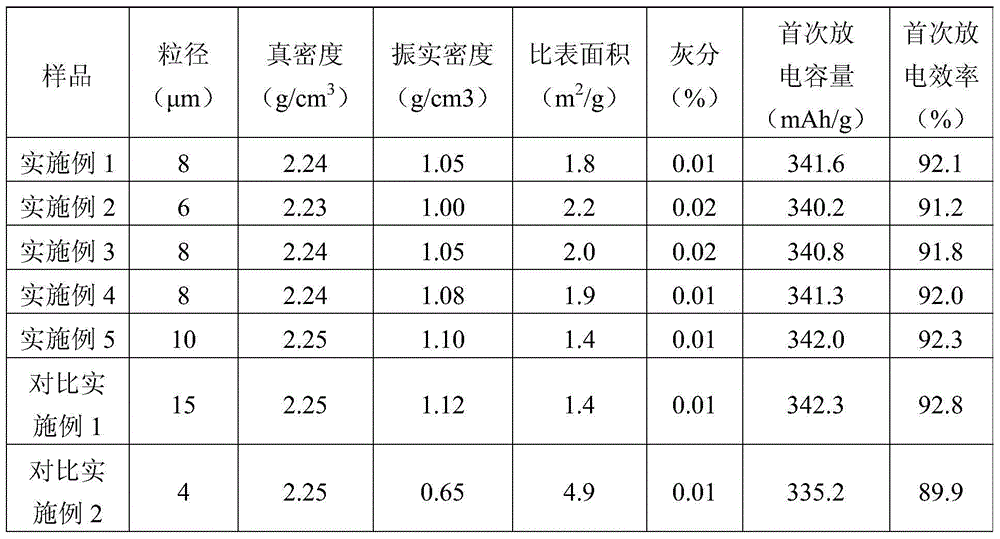

Graphite negative electrode material of lithium-ion battery and preparation method of graphite negative electrode material

InactiveCN106486652AImprove performanceImprove discharge capacityCell electrodesSecondary cellsMass ratioCarbonization

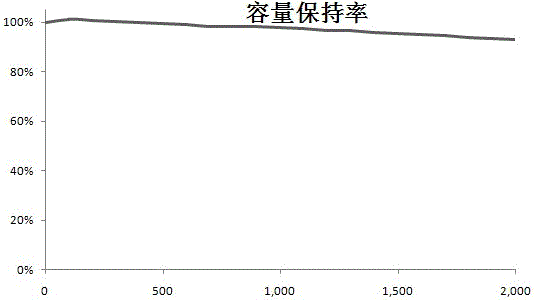

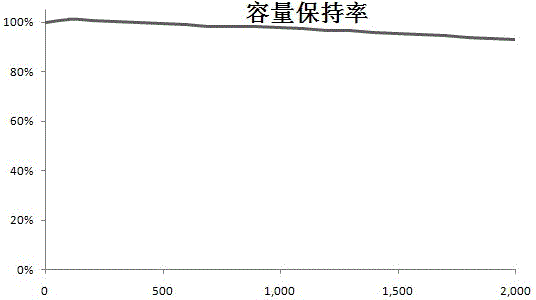

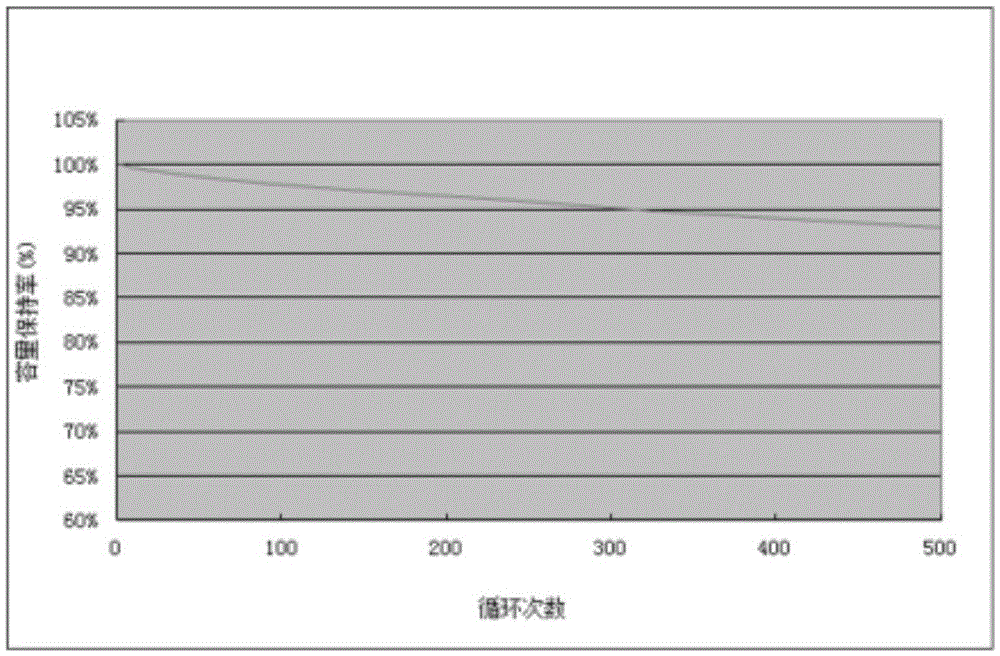

The invention discloses a preparation method of a graphite negative electrode material of a lithium-ion battery. The method comprises the following steps of firstly mixing natural graphite with asphalt and carrying out surface modification treatment of natural graphite; carrying out vacuum carbonization treatment on the mixture of which the surface is modified; and finally carrying out screening treatment on the materials obtained by vacuum carbonization treatment to obtain a finished product, wherein the mass ratio of the natural graphite to the asphalt is (85:15) to (98:2) and the carbonization treatment temperature is 1,000-1800 DEG C. The graphite negative electrode material of the lithium-ion battery has high tap density, small specific surface area, high discharge capacity, high initial charge-discharge efficiency and long cycle life; the initial discharge capacity is over 360mAh / g; the initial charge-discharge efficiency is over 93%; and the cycle performance is over 90% after 500 cycles. According to the preparation method of the graphite negative electrode material of the lithium-ion battery, the process is simple and feasible, the raw material source is wide and the cost is low.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Artificial graphite negative electrode material with gradient structure and preparation and application thereof

ActiveCN109585803AExcellent rate performanceImprove cycle performanceMaterial nanotechnologyCell electrodesPorosityHigh rate

The invention belongs to the technical field of a lithium ion battery negative electrode material, and particularly discloses an artificial graphite negative electrode material with a gradient structure. The artificial graphite negative electrode material is a carbon material with a core / shell structure, and the graphitization degree and the porosity of the carbon material are in gradient distribution in a radial direction; and from core to shell, the graphitization degree is gradually reduced, and the porosity is gradually reduced. The invention also provides the artificial graphite negativeelectrode material with the gradient structure. By pore-forming, catalyst carrying and two-segment electro-forging on anthracite, the negative electrode material with the graphitized and porosity dual-gradient structure can be prepared; and the material with the gradient structure is compatible with the advantages of high reversible capacity, high rate performance, long cycle lifetime and the like.

Owner:湖南宸宇富基新能源科技有限公司

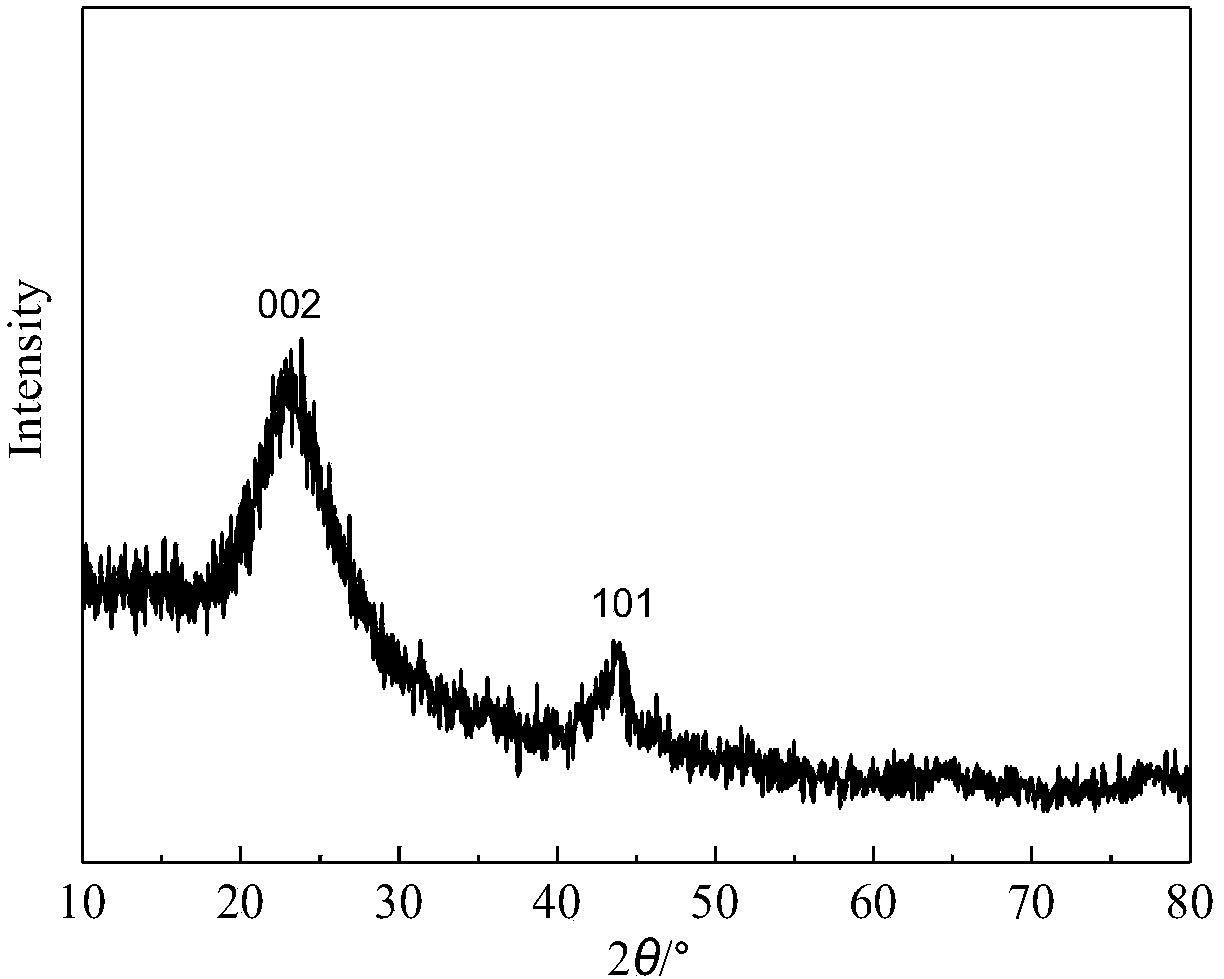

Method for preparing modified graphite negative electrode material of sodium ion battery

ActiveCN104377346AIncrease sodium storage capacityImprove structural stabilityCell electrodesCarbon layerCarbonization

The invention provides a method for preparing a modified graphite negative electrode material of a sodium ion battery and aims at solving the problem of lacking of a suitable negative electrode material of the sodium ion battery at present. The method comprises the steps of preparing paste graphite oxide by using a Hummer method, cladding the graphite oxide with asphalt, phenolic resin or glucose as carbon precursors, and carrying out carbonization heat treating on the graphite oxide clad with the carbon precursors under an inert gas atmosphere. The method has the advantages of being simple, wide in raw material sources, suitable for large-scale industrial production, and the like. According to the obtained modified graphite negative electrode material, the carbon layer spacing is not less than 0.35nm, and the thickness of the carbon clad layer is 0.01-1 micron.

Owner:LIAONING TECHNICAL UNIVERSITY

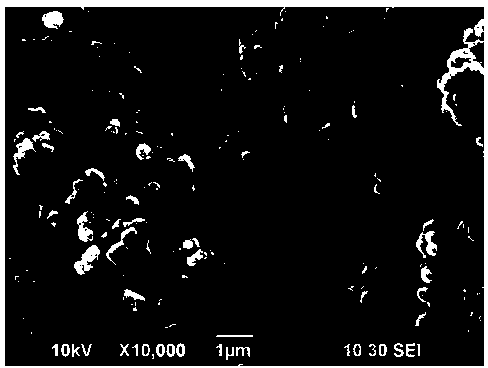

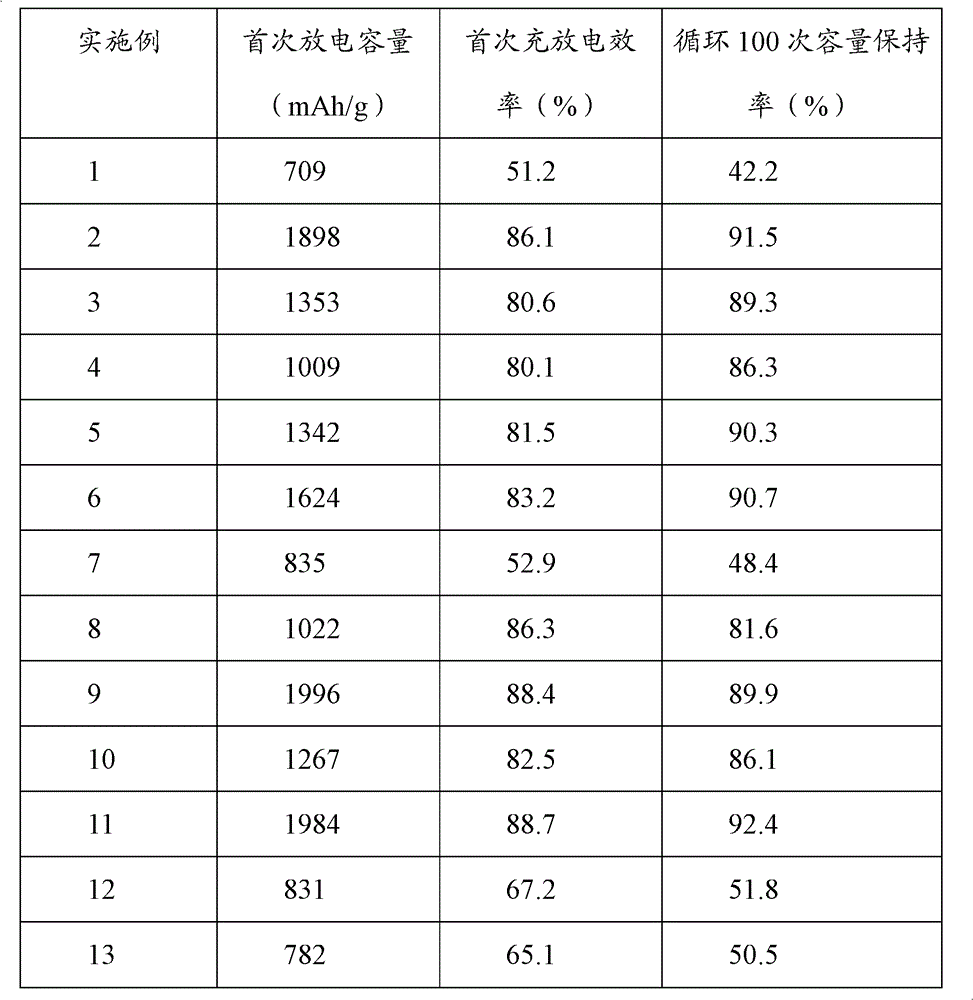

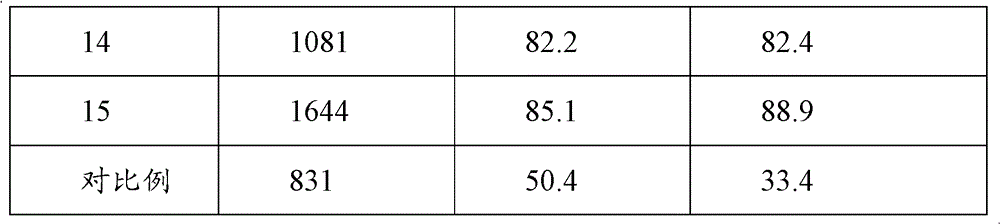

Conductive polymer-coated silicon composite carbon nanotube anode material and preparation method and application thereof

ActiveCN108963227ASmall specific surface areaEffective use of lithium storage capacityMaterial nanotechnologyCell electrodesOrganic solventConductive polymer

The invention relates to a preparation method of conductive polymer-coated silicon composite carbon nanotube negative electrode material, In-situ polymerization of polyaniline on submicron or nano-sized silicon surface without organic solvent and simultaneous doping of conductive polymer polyaniline can effectively inhibit the volume expansion of silicon and provide good conductivity for silicon,and then polymerization of polyaniline with [pi]- [pi] conjugate effect, adding pre-dispersed carbon nanotubes, so that polyaniline coated silicon particles are uniformly dispersed and firmly fixed inthe carbon nanotube dispersion system. Carbon nanotubes with high conductivity and elasticity provide stable expansion elastic space and conductivity for polyaniline-coated silicon particles, which can completely solve the volume expansion of silicon and the destruction of negative electrode caused by pulverization. Polyaniline-coated silicon nanocomposite carbon nanotubes were synthesized. Underthe synergistic effect of silicon, polyaniline and carbon nanotubes, the content of elemental silicon can reach 50% and the specific capacity can reach more than 1800 mAh / g.

Owner:淄博巨浪新能源科技有限公司

Hard carbon-metal oxide-soft carbon composite material and preparation method and application thereof

ActiveCN107240680AHigh specific capacitySmall specific surface areaCell electrodesSecondary cellsCarbon compositesSodium-ion battery

The invention discloses a hard carbon-metal oxide-soft carbon composite material and a preparation method and application thereof. The preparation method comprises the steps of firstly, performing a hydrothermal method on hydrocarbon in a reaction kettle to prepare a hard carbon precursor; secondly, pre-coating the hard carbon precursor and a titanium salt, placing asphalt in a muffle furnace for low-temperature pyrolysis reaction to obtain a soft carbon precursor; and finally, fully mixing the pre-coated hard carbon precursor and the soft carbon precursor, and performing high-temperature pyrolysis reaction under protection of an inert gas to obtain the product, wherein the product is the hard carbon-metal oxide-soft carbon composite material. The material can be used as a negative active material of a sodium ion battery. The preparation method is wide in raw material source and low in cost, and the prepared hard carbon-metal oxide-soft carbon composite material has the advantages of large reversible capacity, high initial charge-discharge coulombic efficiency, good cycle property and the like in the sodium ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Lithium ion battery negative material and preparation method thereof

ActiveCN104538630ASimple and fast operationEasy to operateCell electrodesSecondary cellsMetallic lithiumCharge discharge

The invention discloses a lithium ion battery negative material and a preparation method thereof. The preparation method comprises the following steps: firstly adding metallic lithium to a non-aqueous solvent to dissolve to form a lithium solution; then adding a complexing agent of which the weight is 1-1.2 times more than the molar weight of the metallic lithium to the lithium solution to obtain a sol solution; then adding a negative material, stirring to obtain suspension liquid; then evaporating the suspension liquid to dryness at the temperature of 30-80 DEG C to obtain a precursor, uniformly grinding, then placing into a vacuum drying box, drying at 120 DEG C for 8-12 hours, and cooling with a furnace; and finally loading the powder obtained by grinding and drying into a corundum boat, placing the corundum boat into a cavity of an inert atmosphere furnace, and sintering at the temperature of 400-800 DEG C for 2-6 hours. According to the preparation method disclosed by the invention, previous lithiation treatment is carried out on the negative material by adopting the lithium sol solution, lithium ions are provided for the formation of an SEI film in a first-time charge-discharge process, the loss of positive lithium ions is reduced and the first-time charge-discharge coulomb efficiency, capacity and circulating property of the negative material are greatly improved.

Owner:李震祺 +1

Method for preparing high capacity lithium ion cells cathode material

InactiveCN101086040AHigh specific capacitySynthesis speedElectrode manufacturing processesFinal product manufacturePotassiumAlloy

The invention discloses a submicron powder alloy particles and its utilization, and is is in order to provide a cathode material for lithium battery. It comprises following steps: arc heating and melting metals with inert gas such as argon to get alloy, then under condition of with the mixture gas of hydrogen and inert gas, evaporating alloy to submicron powder by controlling arc current, arc pressure and total pressure, inactivating and getting material that can be used as cathode materials for lithium battery. The invention is characterized in that the reversible stored kalium of prepared submicron powder is 2-3 times as much as that of general carbon material generally used in current days, and the circularity is good.

Owner:PEKING UNIV

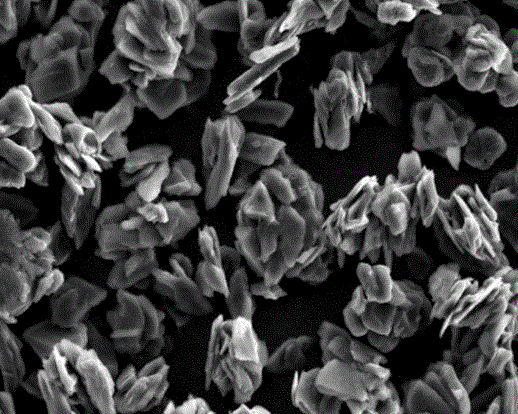

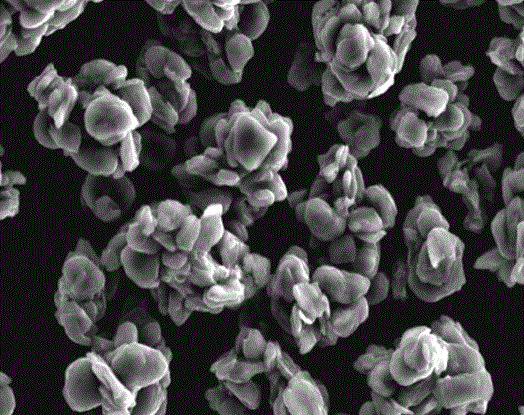

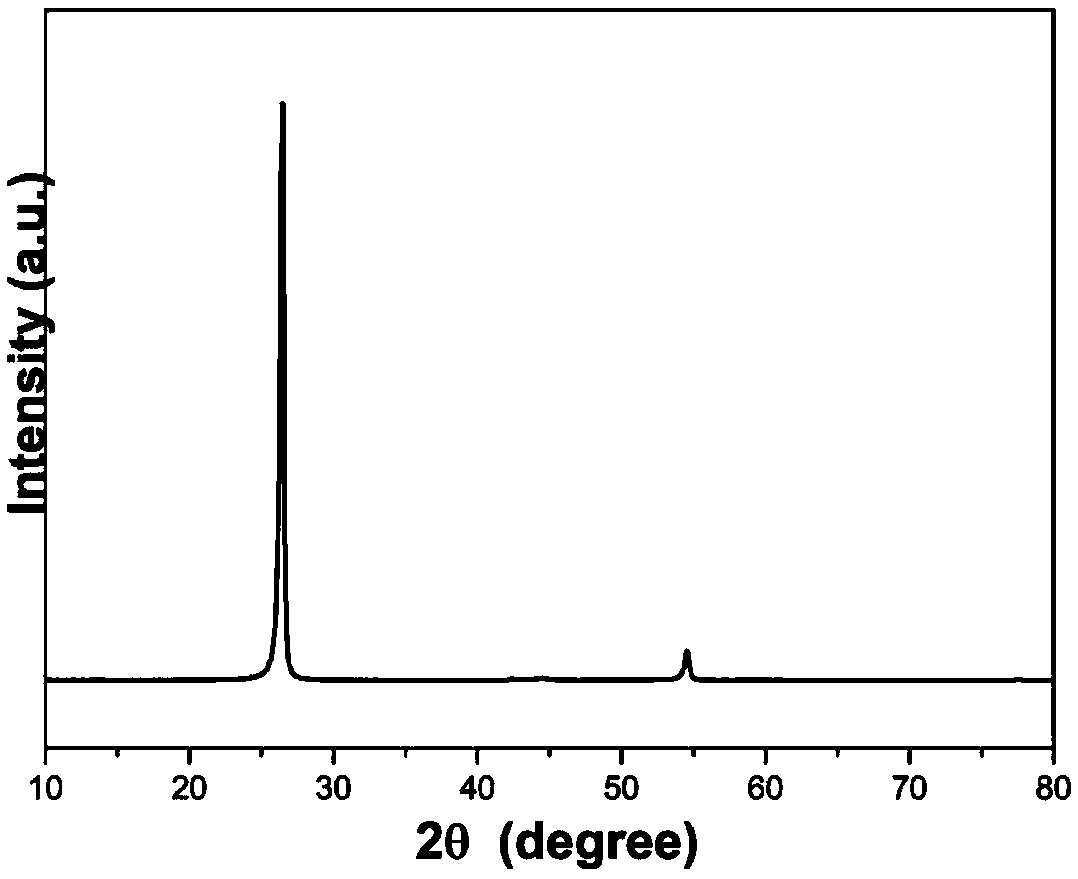

Lithium-rich anode material for lithium ion battery and preparation method thereof

InactiveCN106328908ADiffusion fastUniform particle size distributionCell electrodesSecondary cellsNickel saltAluminium-ion battery

The invention provides a lithium-rich anode material for a lithium ion battery and a preparation method thereof. The chemical formula of the anode material is Li[LixCo1-x-y-z-a NiyMnzCea]O2, wherein x is more than 0 and less than 1, y is more than or equal to 0 and less than 1, z is more than or equal to 0 and less than 1 and alpha is more than 0 and less than or equal to 0.3. The preparation process is as follows: firstly, mixing cobalt salt, nickel salt, manganese salt, ceric salt and water at ratio of 1-x-y-z-a:y:z:a, thereby obtaining a first solution; mixing oxalic acid matters, urea and water, thereby obtaining a second solution; under inert gas shielding, mixing the first solution with the second solution and performing coprecipitation reaction, thereby obtaining an oxalate precursor; milling and mixing lithium source with oxalate precursor, roasting the mixed powder, and then obtaining the lithium-rich anode material for the high-capacity lithium ion battery. The lithium-rich anode material provided by the invention is uniform in size distribution, excellent in high-magnification charge and discharge performance, low in initial irreversible volume and high in cycling stability.

Owner:JILIN INST OF CHEM TECH

Graphitic cladding method by nano-scale mesophase asphalt

InactiveCN101286556BReduce the first irreversible capacityLow charge and discharge voltageElectrode manufacturing processesLiquid stateCarbonization

The invention relates to a preparation method for secondary battery cathode material, more particularly to a preparation method thereof which is formed by coating graphite by using nano-intermediate phase asphalt. The key point of the method is that nano-processing is carried out to the intermediate phase asphalt which is in semi-liquid state, the nano-intermediate phase asphalt in the semi-liquidstate is sprayed on the substrate surface of the graphite by a nano-spray device, then even coating is realized, finally, the secondary battery cathode material is obtained by the traditional processes of drying, carbonization and graphitization. The adoption of the method can improve the coating evenness and the spherical completeness in a greater degree, thus further reducing the first-time irreversible capacity of the graphite, improving the cyclical stability and having the advantages that the charging and discharging voltage of the secondary battery is low, the charging and discharging platform is long and the cycle life is good.

Owner:晟茂(青岛)先进材料有限公司

Graphite negative-electrode material with graphitization degree and hole diameter double-gradient structure, preparation method of material and application of material

ActiveCN109301225AExcellent rate performanceImprove cycle performanceCell electrodesSecondary cellsPorous carbonPore diameter

The invention belongs to the technical field of lithium ion battery negative-electrode materials, and particularly discloses a graphite negative-electrode material with a graphitization degree and hole diameter double-gradient structure. The graphite negative-electrode material is a carbon material with a core / shell structure, the graphitization degree and the hole diameter of the carbon materialare distributed in a radial gradient manner, the graphitization degree from a core to a shell is gradually reduced, and the hole diameter from the core to the shell is gradually reduced. The inventionfurther provides a preparation method of the graphite negative-electrode material with the double-gradient structure of the graphitization degree and the hole diameter. The graphite negative-electrode material serves as a catalyst in porous carbon pore gaps, and subsequent secondary electrical forging treatment is implemented to prepare the negative-electrode material with the double-gradient structure of the graphitization degree and the hole diameter. The material with the gradient structure has the advantages of high reversible capacity and rate performance, long cycle life and the like.

Owner:湖南宸宇富基新能源科技有限公司

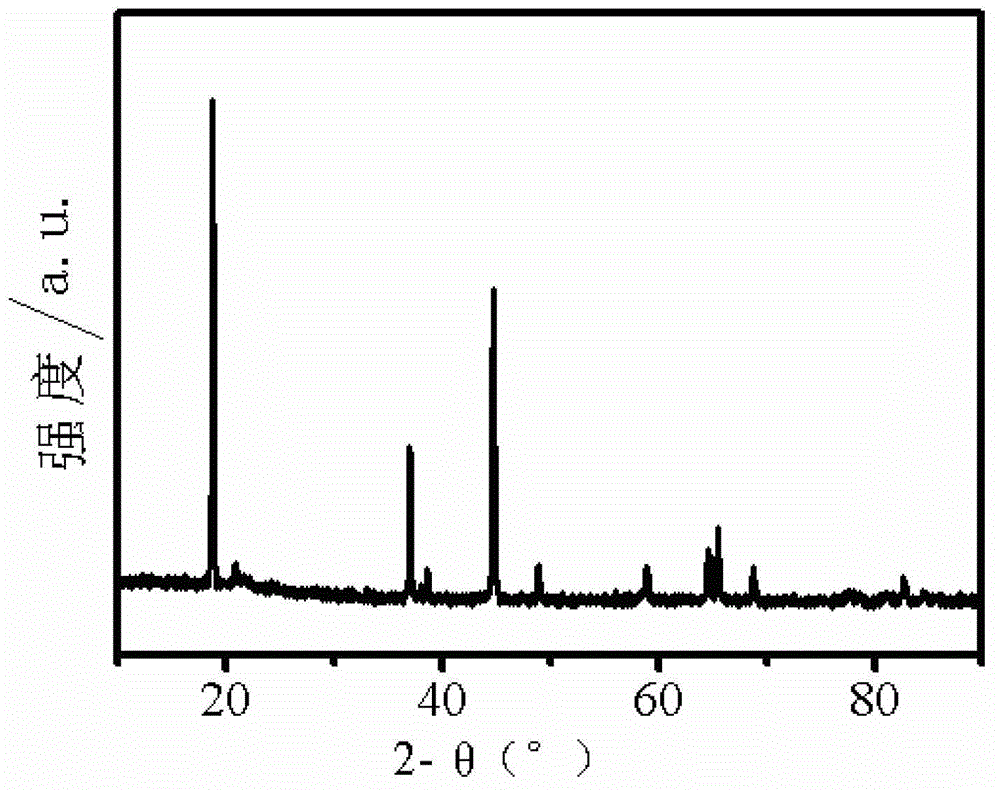

Carbonaceous lithium ion battery negative electrode material with nuclear shell structure and producing method thereof

ActiveCN100413127CIncrease capacityReduce the first irreversible capacityElectrode manufacturing processesElectrical batteryCore shell

The present invention relates to a carbonaceous lithium ion cell negative electrode material with core-shell structure and its preparation method, belonging to the field of carbon material and chemical power supply technology. The described negative electrode material is formed from core portion and shell portion. The core portion is graphite obtained after the graphite intercalation compound is disintercalated, the shell portion is amorphous carbon obtained by pyrolysis of organics. Said invention also provides the concrete steps of its preparation method.

Owner:TSINGHUA UNIV

Method for preparing lithium ion battery cathode material by utilizing biomass gasification furnace filter residue

ActiveCN104766952ALow ashSmall specific surface areaElectrode manufacturing processesNegative electrodesFiltrationEngineering

The invention discloses a method for preparing a lithium ion battery cathode material by utilizing biomass gasification furnace filter residue. The method comprises the following steps: (1) mixing the biomass gasification furnace filter residue with a surface active agent to obtain a mixture, grinding the mixture adequately, removing the surface active agent in a water washing manner, carrying out the suction filtration, and obtaining the filter residue for standby use; (2) placing hydrochloric acid into the filter residue obtained in the step (1), adequately removing impurities, and filtering and washing the filter residue to be neutral for standby use; (3) placing the filter residue obtained in the step (2) into a mixed solution of polyethyleneimine and ethnoal, carrying out the oscillation, washing the polyethyleneimine and the ethanol after the adequate oscillation, filtering the mixed solution, and obtaining the filter residue for standby use; (4) placing nitric acid with mass fraction of 55 to 70 percent into the filter residue obtained in the step (3), adequately stirring the nitric acid and the filter residue under the temperature of 35 to 45 DEG C, carrying out the modification, washing the nitric acid, and filtering and drying to obtain the lithium ion battery cathode material. The prepared lithium ion battery cathode material is high in capacity, high in primary efficiency, good in cycling performance, safe and pollution-free; the method is simple in process flow, low in cost and applicable to the mass production.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Lithium ion battery graphite anode material and preparation method thereof

The invention discloses a lithium ion battery graphite anode material and a preparation method thereof. The preparation method comprises the following steps: roasting green coke with a median particle diameter D50 of 3-7 micrometers and volatile ingredients of 10wt percent-20wt percent, carbonizing, graphitizing, and fractionating to obtain the lithium ion battery graphite anode material, wherein the after fractionating, the median particle diameter D50 of the lithium ion battery graphite anode material is controlled to be 6-10 micrometers, and the maximum particle size is not more than 30 micrometers. The preparation method provided by the invention is simple; the industrialized large-scale production is easily realized; the prepared lithium ion battery graphite anode material is small in particle diameter, excellent in rate performance, small in first-time reversible capacity and good in use stability, and has good cycle performance.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

Technology for processing cladded superfine graphite powder

InactiveCN103803535AImprove coating uniformity and spherical integrityReduce the first irreversible capacityElectrode manufacturing processesCarbon compoundsNanometreCharge and discharge

The invention relates to a processing technology for preparing cladded superfine graphite powder for composite graphite cathode materials of multiple types of secondary batteries in a high-temperature semiliquid spraying manner. The technology comprises the following steps: firstly, putting 60-90% of powdered graphite into a high-temperature reaction kettle protected by an inert gas at 300-500 DEG C; heating 10-40% of nanoscale mesophase pitch for a cladding layer to the semiliquid state and then spraying nanoscale droplets into the high-temperature reaction kettle at a high speed by a nano nozzle, mixing and cladding the powdered graphite for 2-3 hours to form cladded graphite; then drying the cladded graphite in hot air at 200 DEG C for 2-3 hours; carrying out carbonizing treatment at 700-1200 DEG C and graphitizing treatment at 1,000-3,000 DEG C, so as to obtain the balanced cladded superfine graphite powder. The prepared product is good in cladding uniformity and sphere integrity, low in irreversible capacity for the first time, high in circulating stability, low in charge and discharge voltage, and long in circulating service life, and can be widely applied to cathode materials of multiple typs of secondary batteries.

Owner:于洪洲

Silicon-based cathode composite material for lithium ion battery and preparation method thereof

ActiveCN102324501BRelief of mechanical stressEliminate volume effectCell electrodesSodium-ion batteryLithium-ion battery

The invention discloses a silicon-based cathode composite material for a lithium ion battery and a preparation method thereof. The cathode composite material is a Si / CuOx / C composite material (0<=x<=1) with a porous structure. Silicon with a porous structure is used as a base, and CuOx particles are inserted in the pores, and carbons with different forms are distributed on a surface and pore walls of the silicon-based material. The preparation method of the cathode composite material comprises steps that silicon material realizes pore-forming through an in situ catalytic reaction between silicon and halogenated hydrocarbon, and reaction condition parameters are regulated to control pore size, distribution and amount of porosity of the silicon material; a post-modification technology is employed to carry out modifications on the surface and the pore walls of the porous silicon, so as to obtain the Si / CuOx / C composite material with a porous structure. The porous silicon-based cathode composite material has low production costs, simple process and no pollution, and is suitable for industrialized production; besides the porous silicon-based cathode composite material has high charge and discharge capacity, small initial irreversible capacity and good cycle performance.

Owner:河北中芯凤华科技发展有限公司

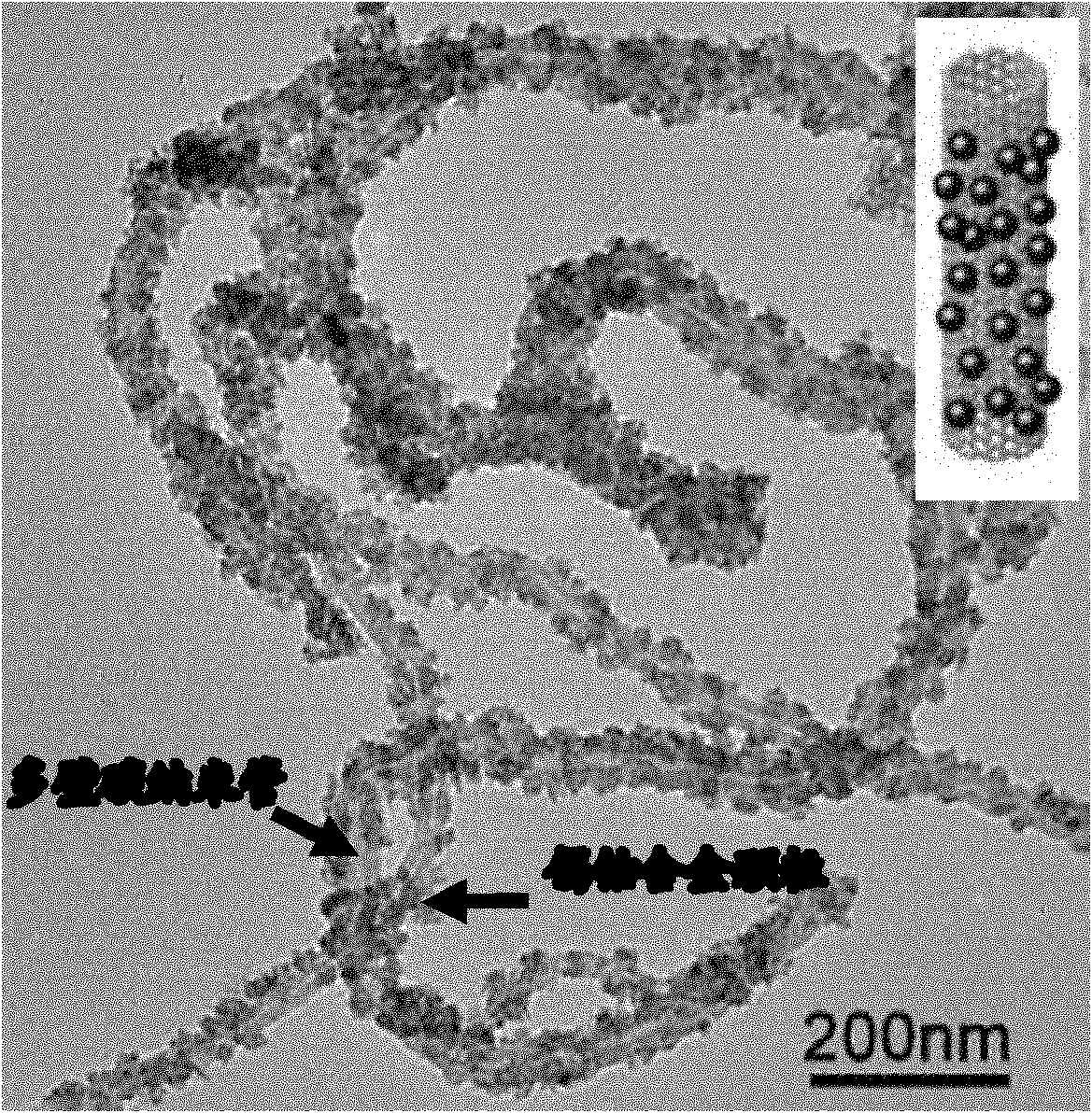

Preparation method of composite material containing multi-walled carbon nanotubes and tin-cobalt alloy nanoparticles

InactiveCN102064321AReduce clumpingGood electron transport propertiesMaterial nanotechnologyCell electrodesCarbon nanotubeLithium electrode

The invention discloses a preparation method a composite material containing multi-walled carbon nanotubes and tin-cobalt alloy nanoparticles. The preparation method comprises modifying the multi-walled carbon nanotubes with polyelectrolytes; preparing diethylene glycol solution containing sodium borohydride; preparing diethylene glycol solution containing stannic chloride and cobalt chloride; dispersing the modified multi-walled carbon nanotubes in the diethylene glycol solution containing sodium borohydride, and heating to a certain temperature under the protection of argon; adding the diethylene glycol solution containing stannic chloride and cobalt chloride into the above mixture solution while heating and stirring; reacting at 160 to 220 centigrade for 30 to 60 minutes; cooling to room temperature; adding ethanol; centrifuging to separate; and drying to obtain the final products. The method provided by the invention is simple, and the obtained composite material has a unique structure. The tin-cobalt alloy nanoparticles are uniformly adhered on the surface of the multi-walled carbon nanotubes, so that the composite material used as the negative electrode material of a lithium ion battery has lower reduction of irreversible capacity and higher cycle stability.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com