Sheet-shaped boron-doped porous silicon electrode material and preparation method thereof

An electrode material, boron doping technology, applied in battery electrodes, silicon, circuits, etc., can solve the problems of electrical conductivity and low initial efficiency of silicon carbon negative electrode, and achieve the effect of reducing oxide layer, improving initial efficiency, and facilitating wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

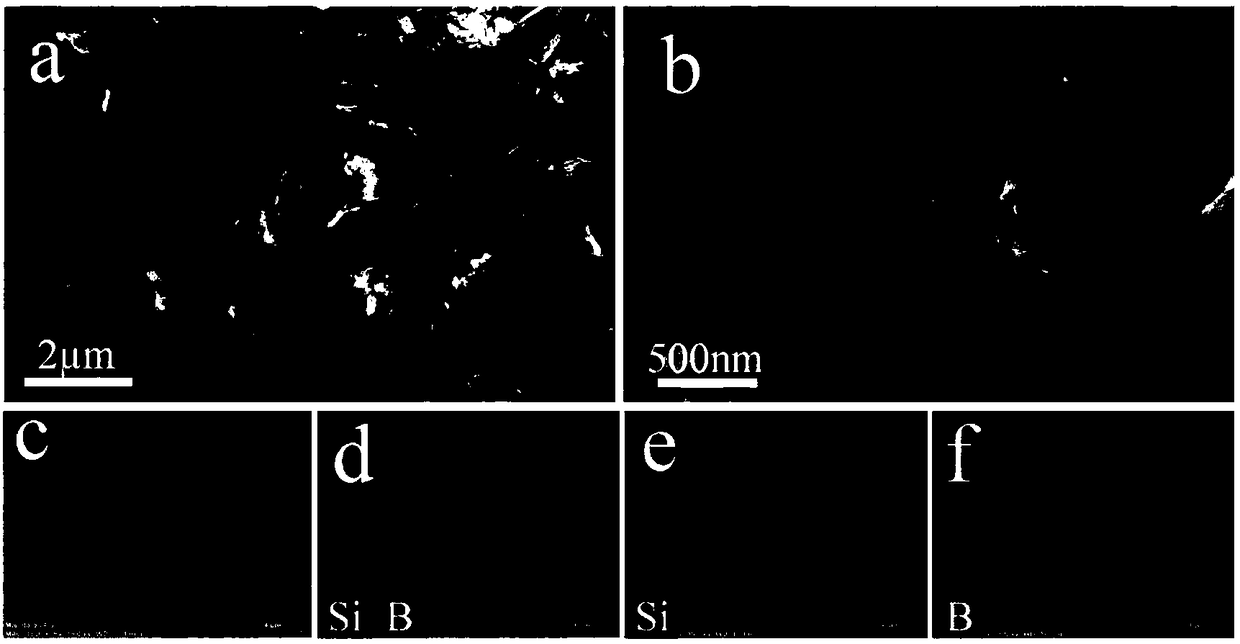

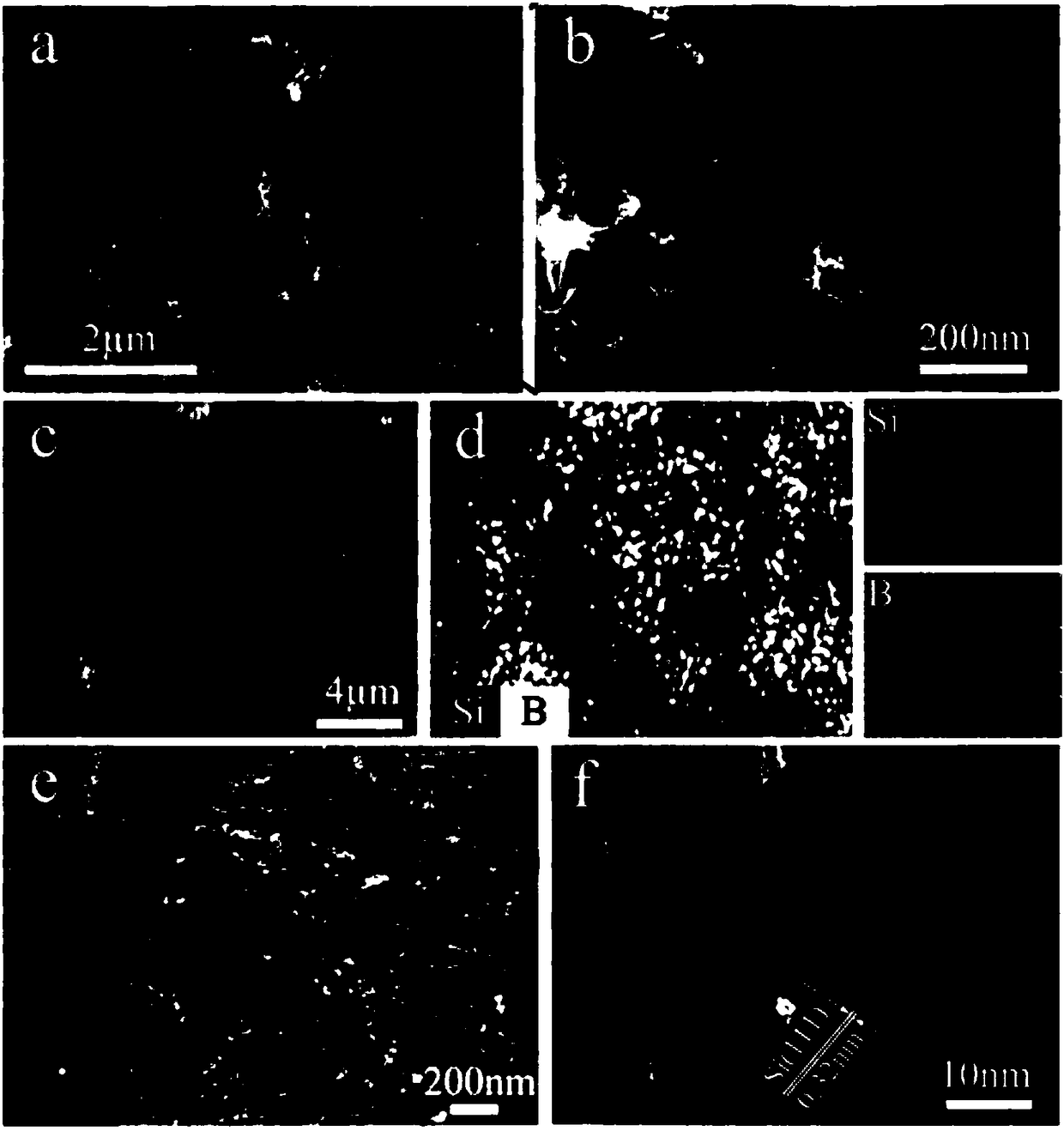

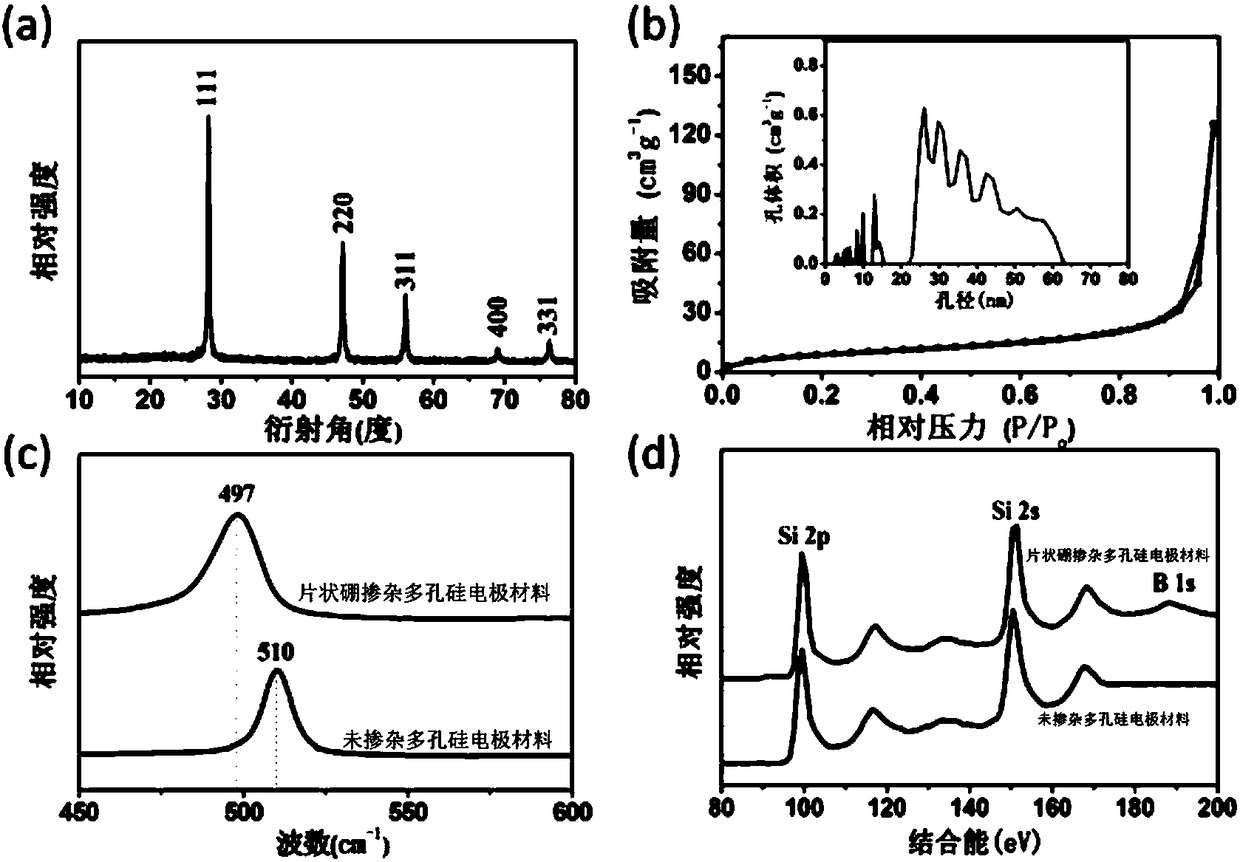

[0048] A flaky boron-doped porous silicon electrode material with a particle size of 0.2-5 μm, assembled from silicon nanoparticles with a particle size of 10-20 nm; the specific surface area of the flaky boron-doped porous silicon electrode material 38m 2 / g, the pore diameter is 20-70nm; the molar percentage of boron in the sheet-like boron-doped porous silicon electrode material is 5%.

[0049] The preparation method of the above-mentioned flaky boron-doped porous silicon electrode material is:

[0050] (1) Soak the boron-doped P-type silicon chips in 1M hydrochloric acid for 6 hours to remove metal impurities and their oxides in the boron-doped P-type silicon chips, then filter them with suction, wash them with water, and dry them in vacuum at 70°C treatment to obtain boron-doped silicon powder; wherein, the particle diameter of the boron-doped P-type silicon debris is 0.2-5 μm; the molar percentage of boron in the boron-doped P-type silicon debris (mol percent ) is 5%...

Embodiment 2

[0059] Prepare undoped porous silicon electrode material with undoped commercial silicon powder as raw material, the preparation method of described porous silicon electrode material is:

[0060] (1) Soak undoped commercial silicon powder with 1M hydrochloric acid for 6 hours, then filter, wash with water, and dry in vacuum at 70°C to obtain silicon powder; wherein, the particle size of the undoped commercial silicon powder is 0.2-5μm;

[0061] (2) Mix silicon powder and magnesium powder evenly at a molar ratio of 1:2.1 to obtain a mixture, which is heat-treated under an argon atmosphere to generate Mg 2 Si powder; the heat treatment temperature is 550°C, and the heat treatment time is 5h;

[0062] (3) Mg 2 Si powder was subjected to high-temperature oxidation at 600°C for 5 hours to obtain a reaction product. The reaction product was soaked in mineral acid for 6 hours, filtered with suction, washed with water, soaked and cleaned with 20% HF acid solution for 6 hours, and th...

Embodiment 3

[0065] A flaky boron-doped porous silicon electrode material with a particle size of 0.2-5 μm, assembled from silicon nanoparticles with a particle size of 10-20 nm; the specific surface area of the flaky boron-doped porous silicon electrode material 65m 2 / g, the pore diameter is 20-70nm; the molar percentage of boron in the sheet-like boron-doped porous silicon electrode material is 0.5%.

[0066] The preparation method of the above-mentioned flaky boron-doped porous silicon electrode material is:

[0067] (1) Soak the boron-doped P-type silicon chips in 0.1M hydrochloric acid for 24 hours to remove metal impurities and their oxides in the boron-doped P-type silicon chips, and then filter, wash with water, and vacuum at 70°C Drying treatment to obtain boron-doped silicon powder; wherein, the particle diameter of the boron-doped P-type silicon debris is 0.2-5 μm; the molar percentage of boron in the boron-doped P-type silicon debris (mol percentage) is 0.5%;

[0068] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com