Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

443 results about "Graphite anode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cation-substituted spinel oxide and oxyfluoride cathodes for lithium ion batteries

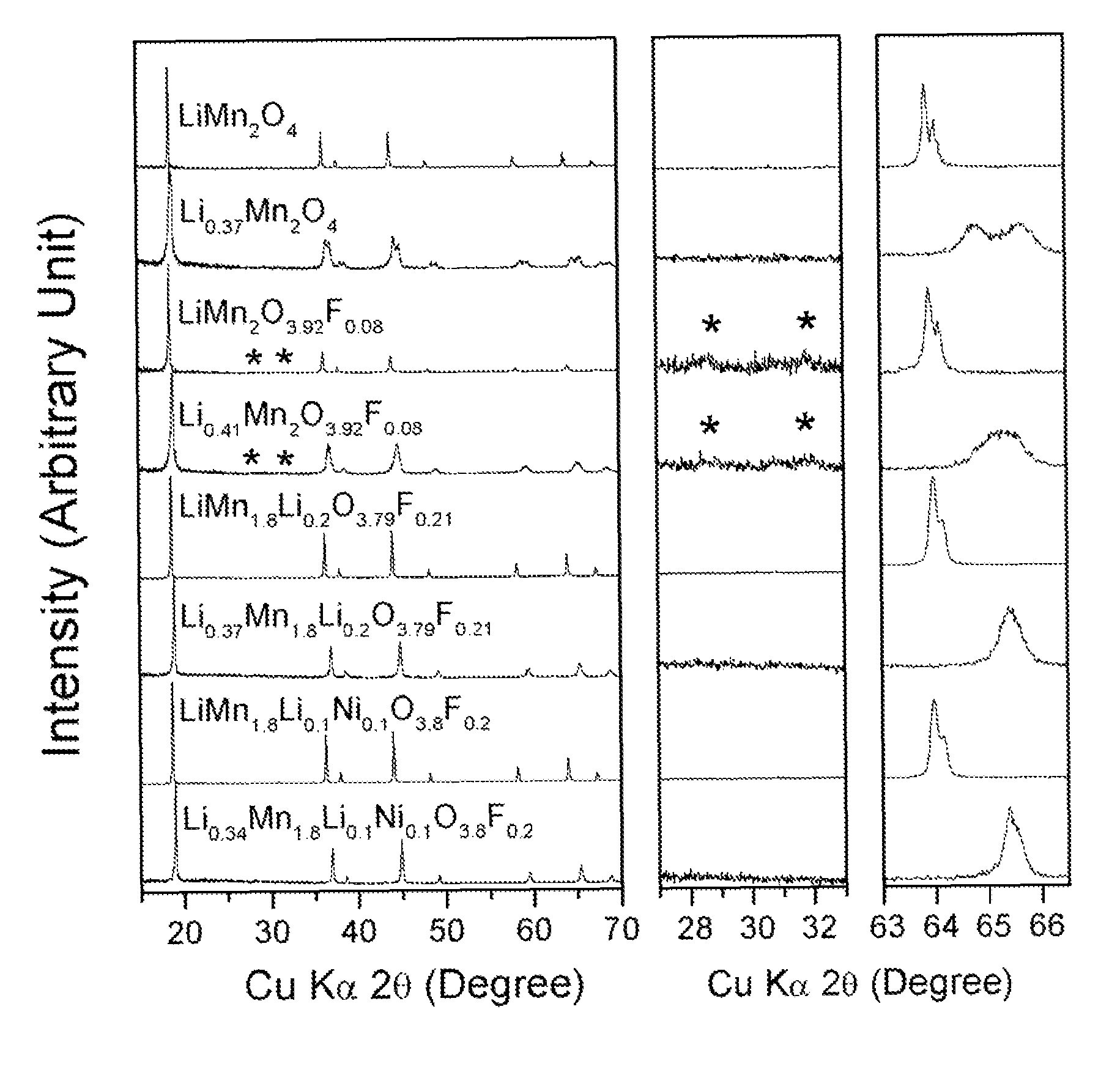

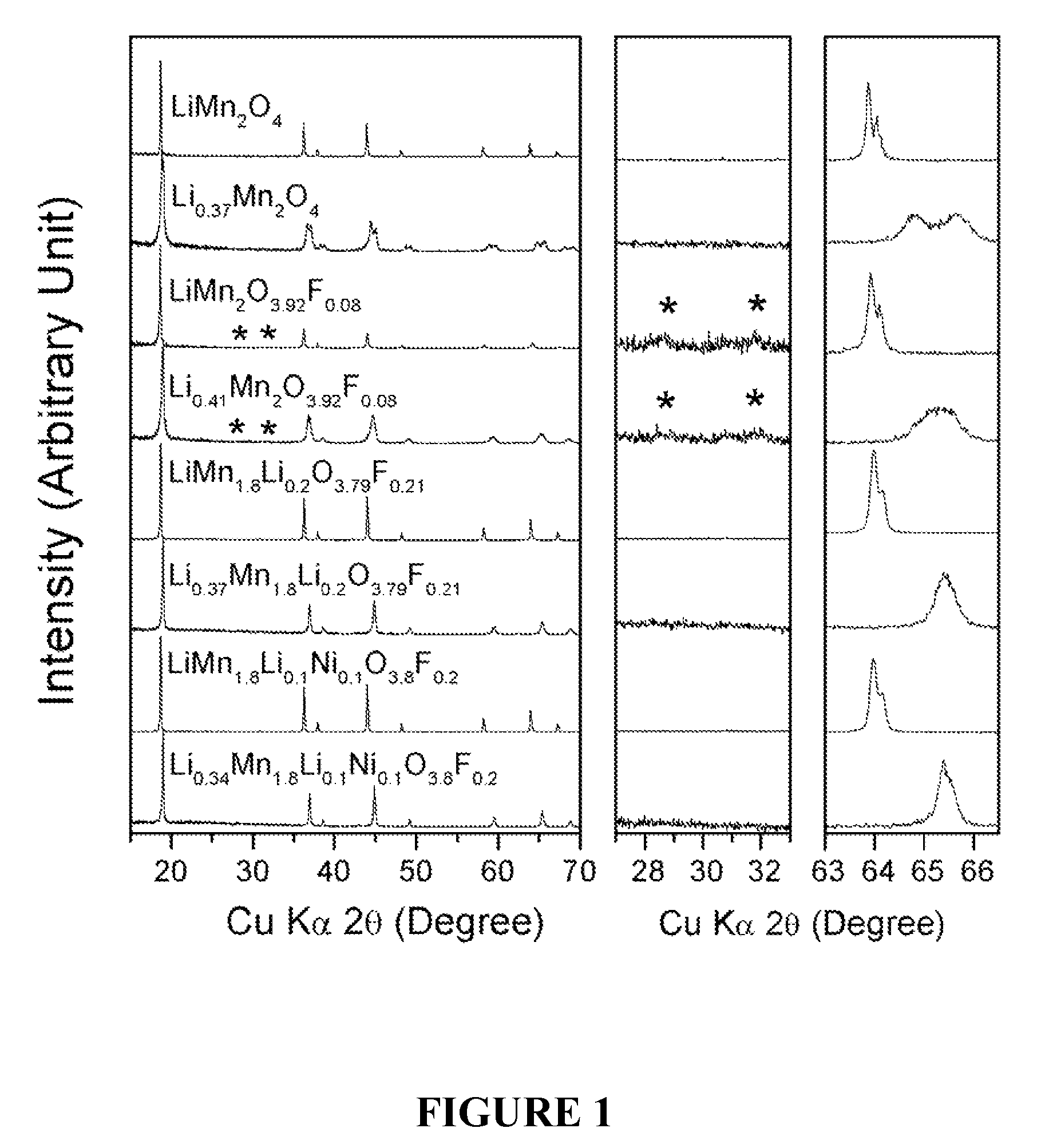

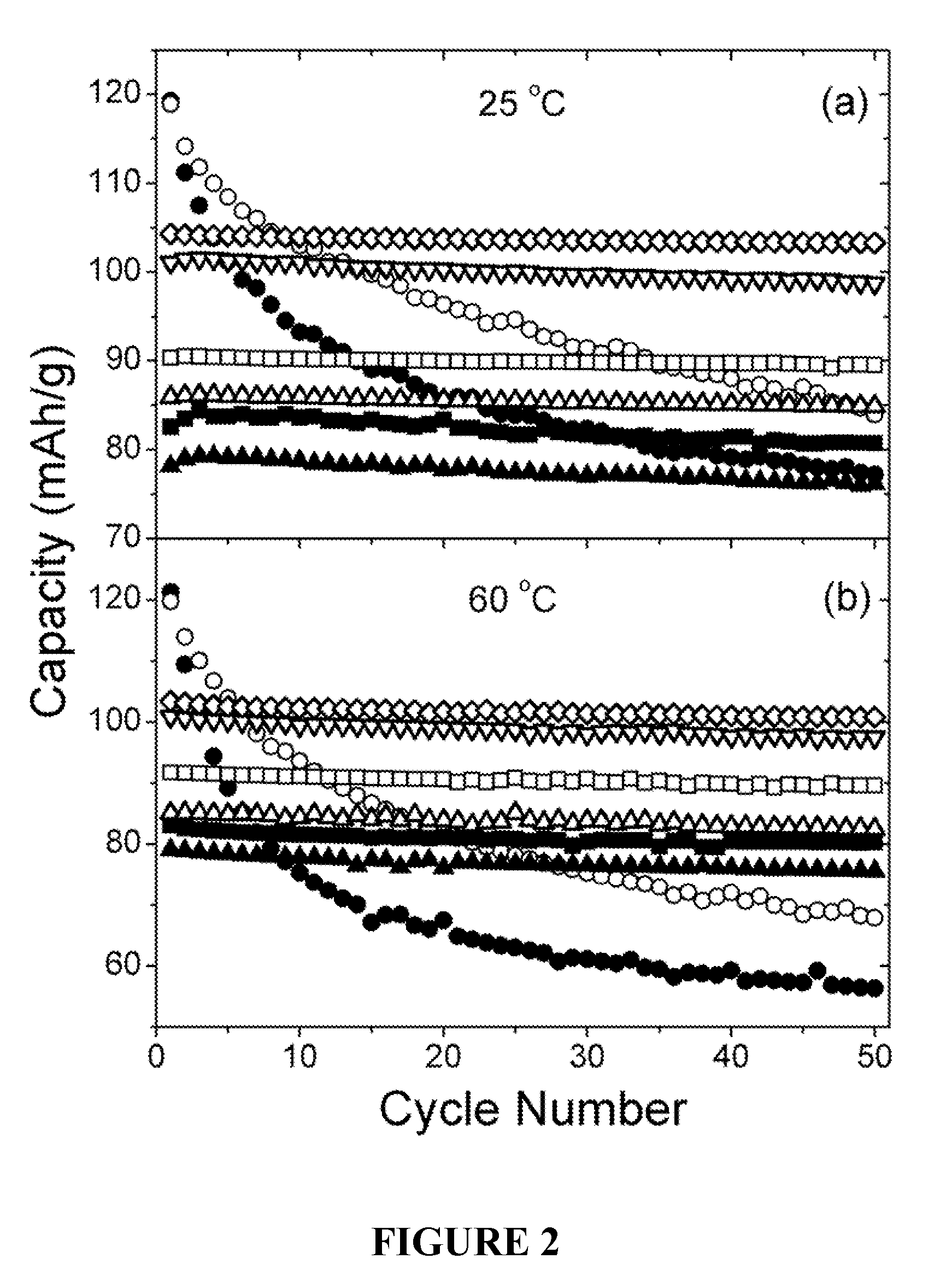

InactiveUS7718319B2Cyclability at elevated temperaturesImprove rendering capabilitiesElectrode carriers/collectorsConductive materialSpinelGraphite

The present invention includes compositions and methods of making cation-substituted and fluorine-substituted spinel cathode compositions by firing a LiMn2−y−zLiyMzO4 oxide with NH4HF2 at low temperatures of between about 300 and 700° C. for 2 to 8 hours and a η of more than 0 and less than about 0.50, mixed two-phase compositions consisting of a spinel cathode and a layered oxide cathode, and coupling them with unmodified or surface modified graphite anodes in lithium ion cells.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

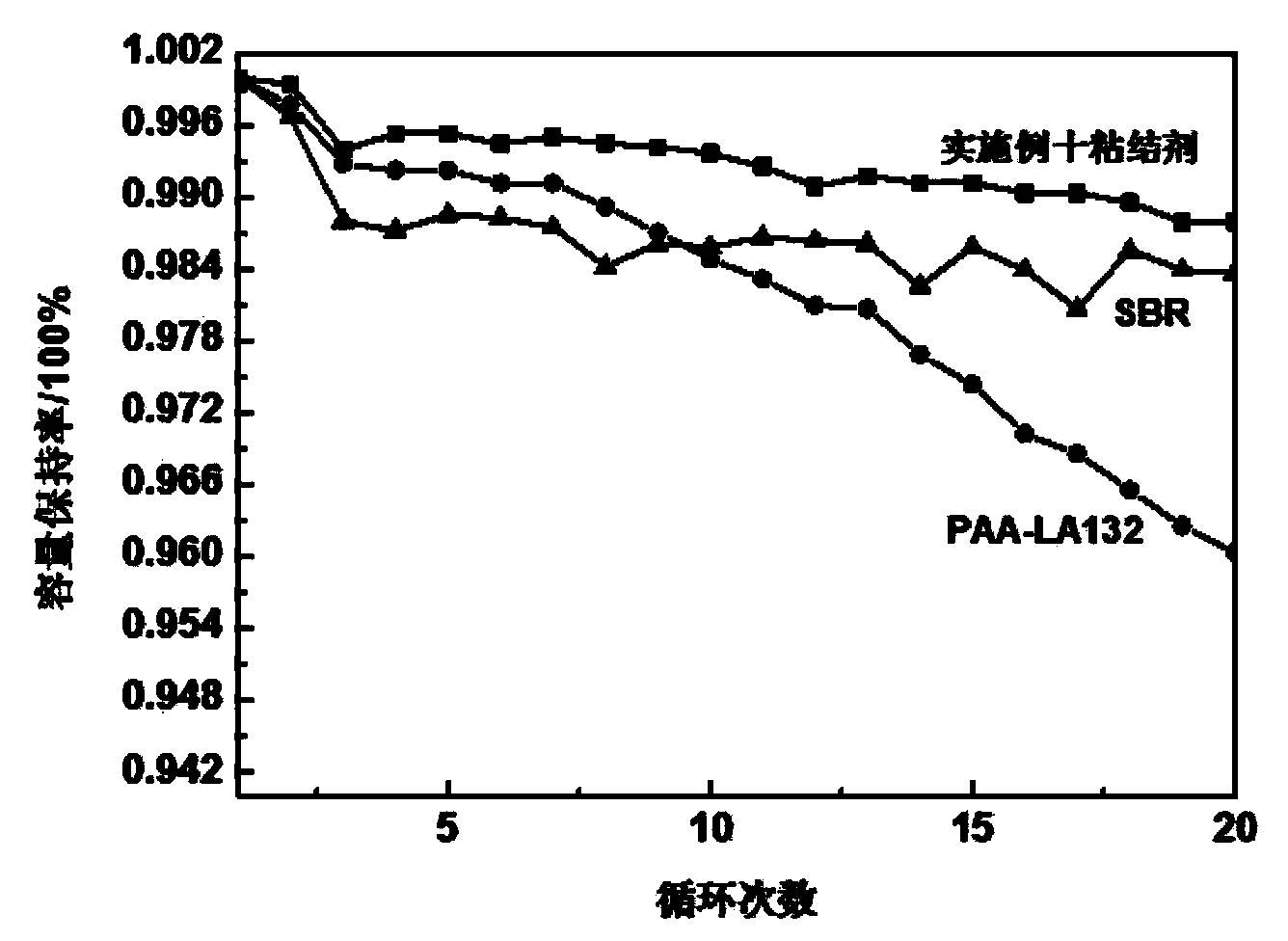

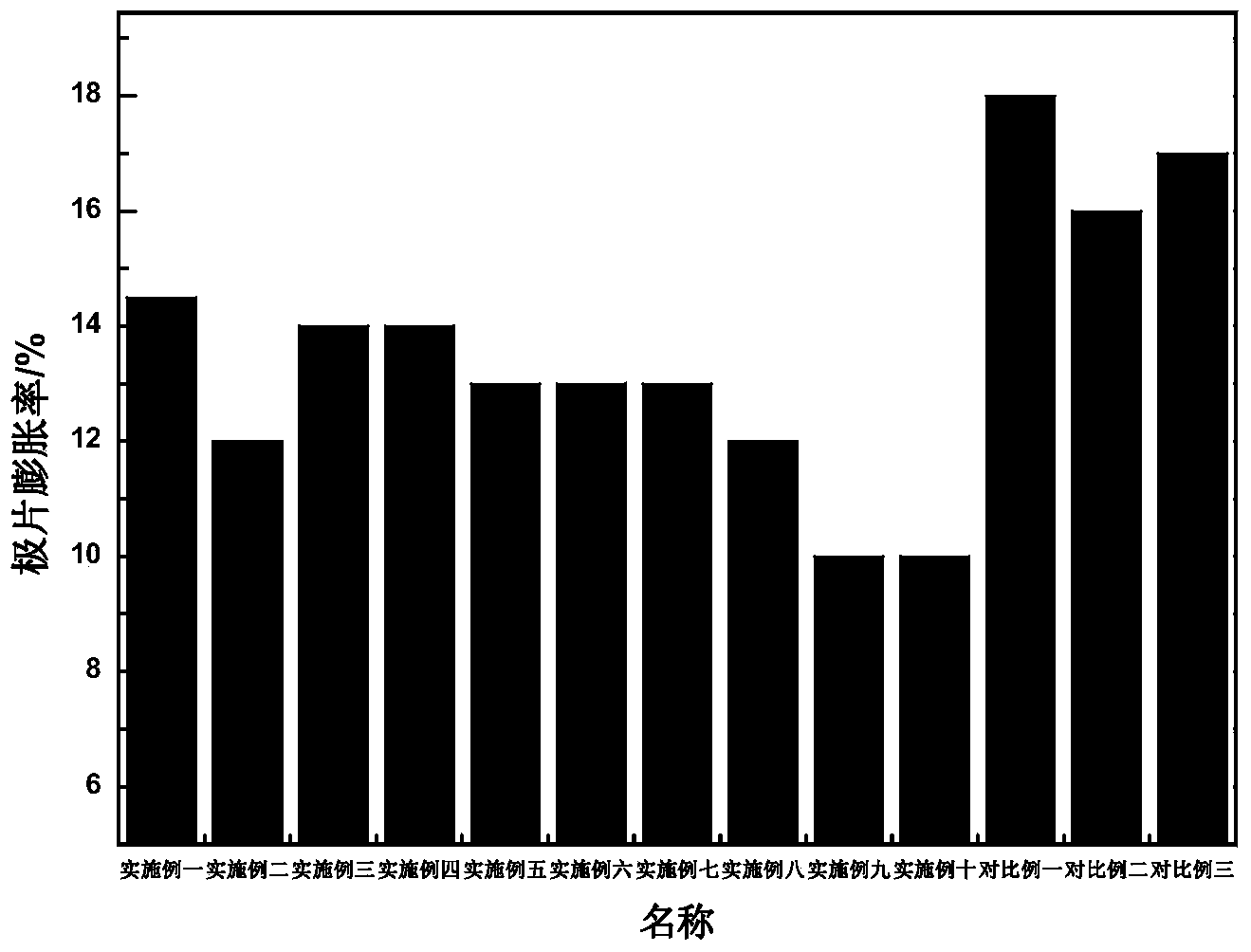

Polyacrylate water-based adhesive for electrode materials of lithium ion battery, preparation method of adhesive and electrode plates of lithium ion battery

ActiveCN104356979AAvoid pollutionAvoid harmAcid polymer adhesivesEster polymer adhesivesWater basedCross-link

The invention relates to a polyacrylate water-based adhesive for electrode materials of a lithium ion battery, a preparation method of the adhesive and electrode plates of the lithium ion battery. The adhesive is a cross-linked high-solid-content polyacrylate water-based adhesive; the polymer molecule chain segment of the adhesive comprises a hydrophilic segment and a lipophilic segment which are cross-linked through a cross-linking agent to form a spatial reticular structure. The electrode plates produced by the adhesive cannot fall off in charge and discharge processes, the adhesive has a relatively good adhesion effect on the positive and negative electrode materials of the lithium ion battery, and the expansion of electrode plates of graphite anode materials, especially silicon-based materials can be inhibited.

Owner:YANYI NEW ENERGY TECH CO LTD

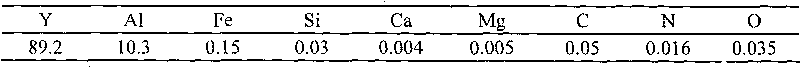

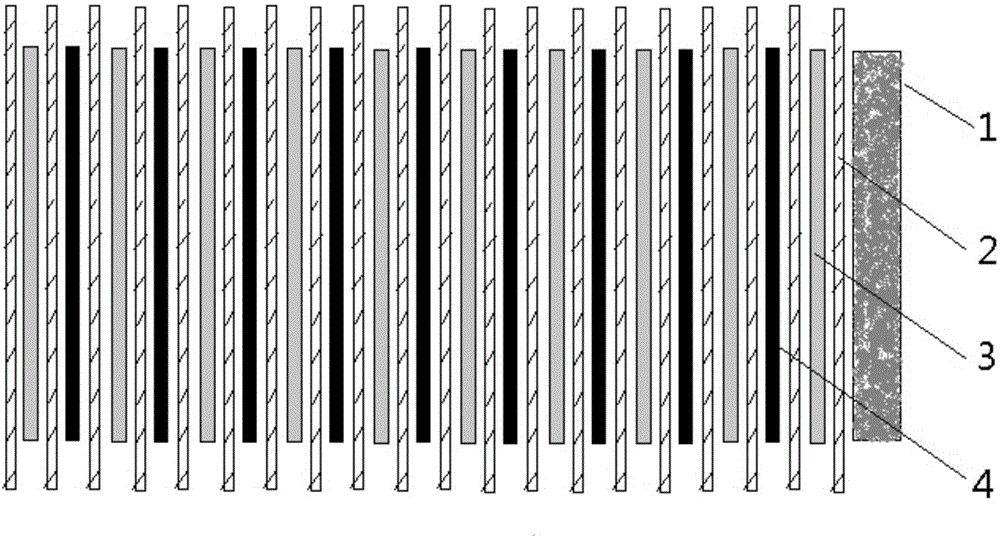

Rare earth aluminum alloy, and method and device for preparing same

The invention discloses a rare earth aluminum alloy, and a method and a device for preparing the same. The alloy contains at least one rare earth metal of lanthanum, cerium, praseodymium, neodymium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, lutetium, scandium and yttrium, the content of raw earth is 5 to 98 weight percent, and the balance is aluminum and inevitable impurities. The device for preparing the rare earth aluminum alloy is characterized in that: a) graphite serves as an electrolysis bath, a graphite plate is an anode, a tungsten bar is a cathode and a molybdenum crucible serves as a rare earth aluminum alloy receiver; b) the diameter of the tungsten bar is 30 to 55 mm; and c) the anode of the graphite consists of a plurality of graphite plates. The rare earth aluminum alloy, and the method and the device for preparing the same have the advantages that: the alloy has uniform components, little segregation and low impurity content; technology for preparing the rare earth aluminum alloy through fusion electrolysis can maximally replace a process for preparing single medium-heavy metal through metallothermic reduction, greatly reduce energy consumption and the emission of fluorine-containing tail gas and solid waste residue, improve current efficiency and metal yield and reduce the consumption of auxiliary materials and the energy consumption; and the rare earth aluminum alloys with different rare earth contents can be obtained by controlling different electrolytic temperatures and different cathode current densities.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Polymer electrolyte and preparation method and application thereof

InactiveCN102005611AHigh ion conductivityImprove toughnessSecondary cellsHigh energyTemperature resistance

The invention discloses polymer electrolyte and a preparation method and application thereof. The provided polymer electrolyte consists of a high polymer matrix, lithium salt, an organic small molecular plasticizer and / or inorganic superfine nanoparticles. The provided polymer electrolyte has high ionic conductivity, high toughness and high-temperature resistance, and when the polymer electrolyte is used as lithium ion secondary battery electrolyte, the structure of a commercial lithium ion secondary battery is simplified, the structure of the lithium ion secondary battery is enriched, and simultaneously the potential safety hazard in the traditional lithium ion secondary battery can be effectively avoided. Meanwhile, in the process of preparing a lithium battery from the provided polymer electrolyte, the conventional commercial micron-sized graphite anode can be replaced by a metal lithium foil, so the prepared novel lithium ion battery has higher energy density and power density.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for regenerating graphene by recovering waste lithium ion battery

ActiveCN103259062APromote oxidationImprove propertiesFinal product manufactureWaste accumulators reclaimingGraphite electrodeGraphite

The invention discloses a method for regenerating graphene by recovering a waste lithium ion battery. The method is characterized by comprising the following steps of: S1, recovery of an active substance of a battery electrode: carrying out pre-charge or pre-discharge treatment on the waste lithium ion battery which takes graphite as an anode material, and then separating a cathode coating and an anode coating from a current collector and an outer package to obtain a cathode and anode blending material; S2, separation of an intercalated graphite electrode material: drying and crushing the cathode and anode blending material, and separating the active substances of a positive electrode and a negative electrode by adopting a physical method to obtain intercalated graphite powder; and S3, preparation of graphene from the intercalated graphite powder: preparing the graphene by an oxidation-reduction method or an ultrasonic stripping method based on the intercalated graphite powder as a raw material. After the method is adopted, the industrial recovery of the lithium ion battery is realized, and a graphene material can be regenerated by a graphite anode with high added value, so that the method has better application prospect and feasibility, and can produce greater economic benefit and social benefit.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

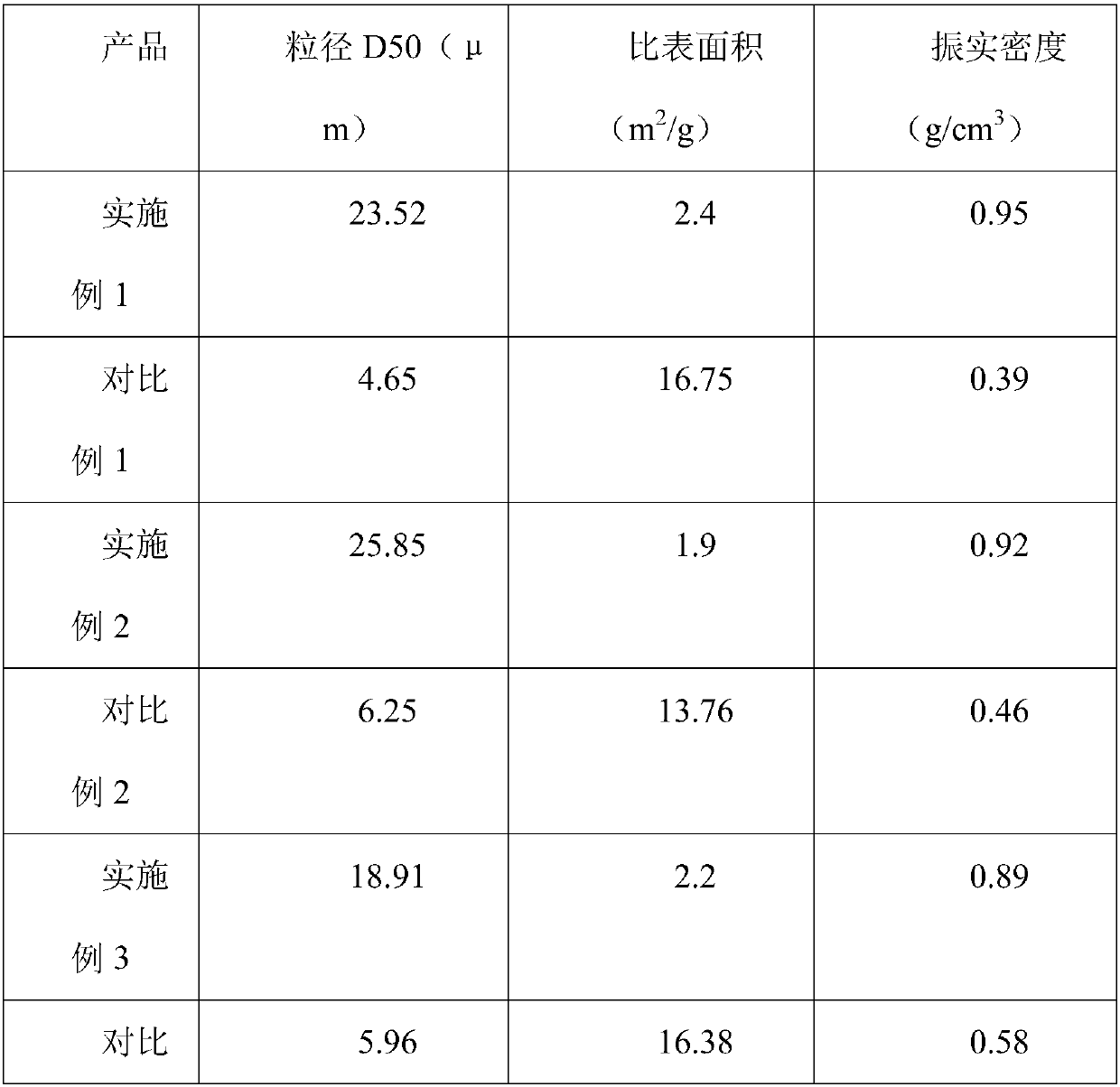

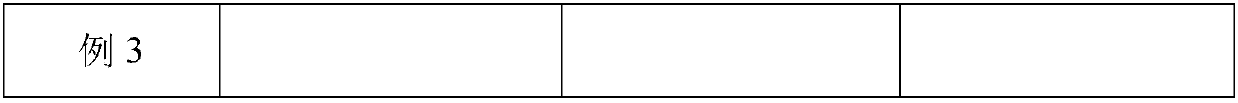

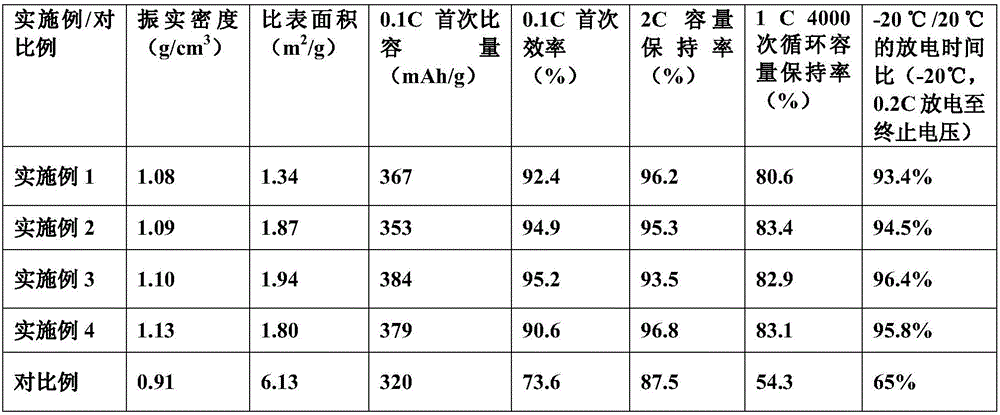

Preparation method of soft/hard carbon modified anode material for lithium ion batteries

InactiveCN107845810ALow tap densityHigh tap densityCell electrodesSecondary cellsCarbon compositesDischarge efficiency

The invention discloses a preparation method of a soft / hard carbon modified anode material for lithium ion batteries. The method comprises the following steps: (1) carrying out mixed granulation; (2)screening and crushing; (3) mixing; (4) treating at high temperature; (5) screening; (6) modifying; (7) carrying out secondary carbonization. The method is characterized in that a soft carbon precursor and a hard carbon precursor are both used as binding agents, kneading and granulating are carried out at a certain temperature and under other conditions, small graphite particles are polymerized soas to enable the internal structure to be further densified and increase the volume density, high-temperature graphitization is then performed, and asphalt and resin are converted to pyrolytic carbon, so that a soft / hard carbon graphite composite systems is formed; the surface of the modified soft / hard carbon composite anode material is evenly coated with a layer of Ti3SiC2, having good electrical conductivity and stable chemical properties, and a conductive network, so that the improvement of the discharge capacity, discharge efficiency and cycling stability of the graphite anode material isbetter promoted.

Owner:SHENZHEN SINUO INDAL DEV

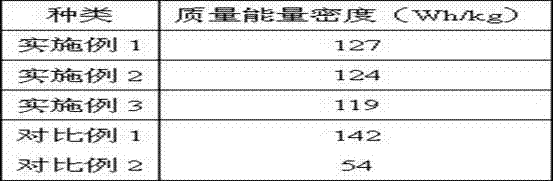

Recycling method for graphite anode material from waste lithium-ion battery

InactiveCN105552468AReduce recycling costsHigh recovery rateWaste accumulators reclaimingBattery recyclingOxalateElectricity

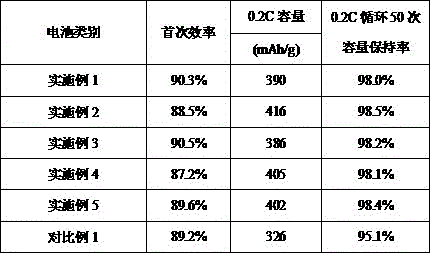

The invention discloses a recycling method for a graphite anode material from a waste lithium-ion battery, and belongs to the technical field of recovering of materials from the waste lithium-ion battery. According to the main points of the technical scheme, the method comprises the following steps: carrying out soaking pretreatment on the graphite material recovered from the waste lithium-ion battery; carrying out ball-mill mixing on pre-calcined and separated graphite powder and a ferrous oxalate or zinc oxalate or ferrous oxalate and zinc oxalate mixture evenly; and finally preparing the battery-grade graphite anode material through high-temperature treatment. The graphite anode material prepared by the method has excellent electrochemical activity and cyclic reversibility; the discharge capacity at 0.2C reaches over 400mAh / g; and the capacity retention rate after 50 cycles is greater than 98.0%. The recycling method can efficiently recover the graphite anode material from the waste lithium-ion battery, further improves the electrical property and achieves recycling of the graphite anode material.

Owner:河南环宇赛尔新能源科技有限公司

Method for regenerating waste and old graphite anode materials

ActiveCN102544629ANo generationHigh purityWaste accumulators reclaimingBattery recyclingImpurityMaterials science

The invention discloses a method for regenerating waste and old graphite anode materials. The method comprises the following step of: carrying out crushing, screening, impurity removal, coating, heat treatment and the like on the waste and old graphite cathode materials to obtain graphite anode material products. When the graphite cathode material is applied to an anode material of a lithium-ion battery, a first power generating capacity of the graphite anode material is higher than 320mAh / g, and 100-times circulation retention rate is 98.75 percent, and thus market requirements are met. The method for regenerating the waste and old graphite cathode materials, disclosed by the invention, has the characteristics of simple flow and high additional value and has remarkable economic benefits and social benefits.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

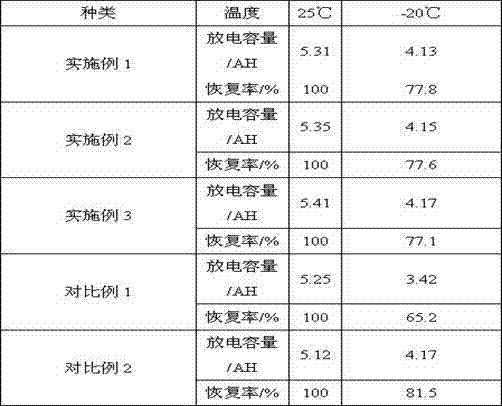

Ultralow temperature lithium iron phosphate power battery and preparation method thereof

InactiveCN106299291AEffective dispersionIncrease migration rateFinal product manufactureCell electrodesPower batteryLithium iron phosphate

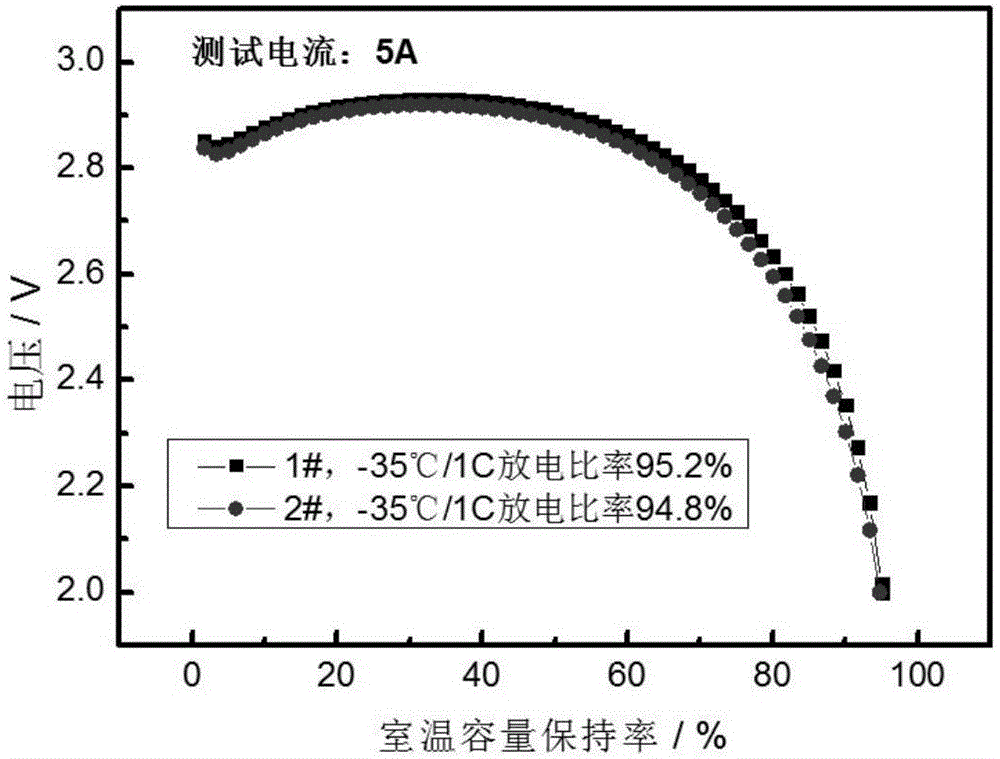

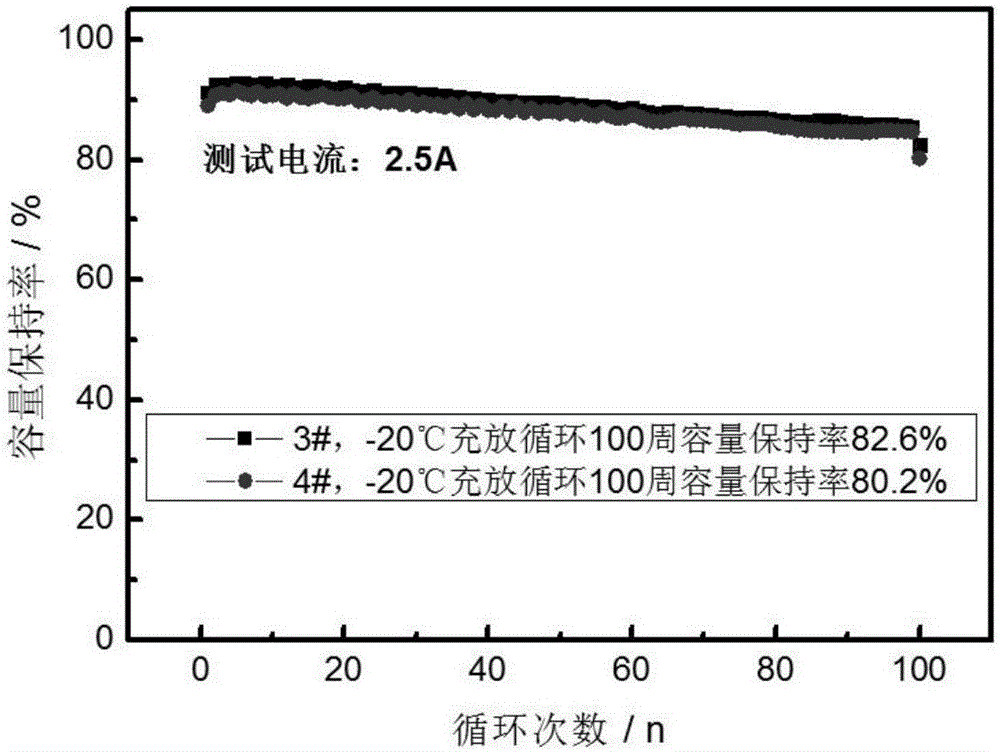

The invention provides an ultralow temperature lithium iron phosphate power battery. The ultralow temperature lithium iron phosphate power battery comprises a cathode plate, an anode plate, a diaphragm and a low-temperature electrolyte. The cathode plate comprises a cathode collector piece and nano lithium iron phosphate cathode slurry with which the cathode collector piece is coated. The nano lithium iron phosphate cathode slurry is prepared through the high-speed dispersion process that a glue solution and an active-matter-containing component are beaten separately, in other words, the glue solution and the active-matter-containing component are separately prepared. The glue solution is prepared according to a certain proportion; the active-matter-containing cathode powder raw material and a solvent are mixed according to a certain proportion and dispersed uniformly at high speed to form cathode premixed slurry; the prepared glue solution is added into the cathode premixed slurry step by step, by means of the stirring mode in which revolution and high-speed autorotation are combined, the glue solution and the cathode premixed slurry are fully mixed, stirred and dispersed uniformly, and then the cathode slurry is obtained. The anode plate comprises an anode collector piece and modified graphite anode slurry with which the anode collector piece is coated. The electrolyte is prepared from lithium salt, a solvent and an additive.

Owner:OPTIMUM BATTERY CO LTD

Lithium ion battery composite anode pole piece, preparation method and lithium ion battery

ActiveCN103700808AEasy to operateIncrease energy densityCell electrodesSecondary cellsLow voltagePole piece

The invention discloses a lithium ion battery composite anode pole piece which comprises an anode current collector; two sides of the anode current collector are coated with a first coating layer and a second coating layer respectively; the coating slurry of the first coating layer is graphite slurry, and the coating slurry of the second coating layer is lithium titanate slurry. According to the invention, two sides of the anode current collector are respectively coated with a first coating layer comprising graphite, a binder, and a conductive agent, and a second coating layer comprising lithium titanate, a binder, and a conductive agent; with the characteristics of high gram capacity, excellent processing property, and low voltage platform of the graphite anode material, the energy density of the battery is increased; with the characteristics of good rate capability, excellent cycle performance, and good low temperature performance of the lithium titanate anode material, the application scope of the battery is enlarged, and the electrochemical performance of the battery is improved. The invention also discloses a preparation method of the composite anode pole piece, and a lithium ion battery comprising the composite anode pole piece.

Owner:LUOYANG YUEXING NEW ENERGY TECH

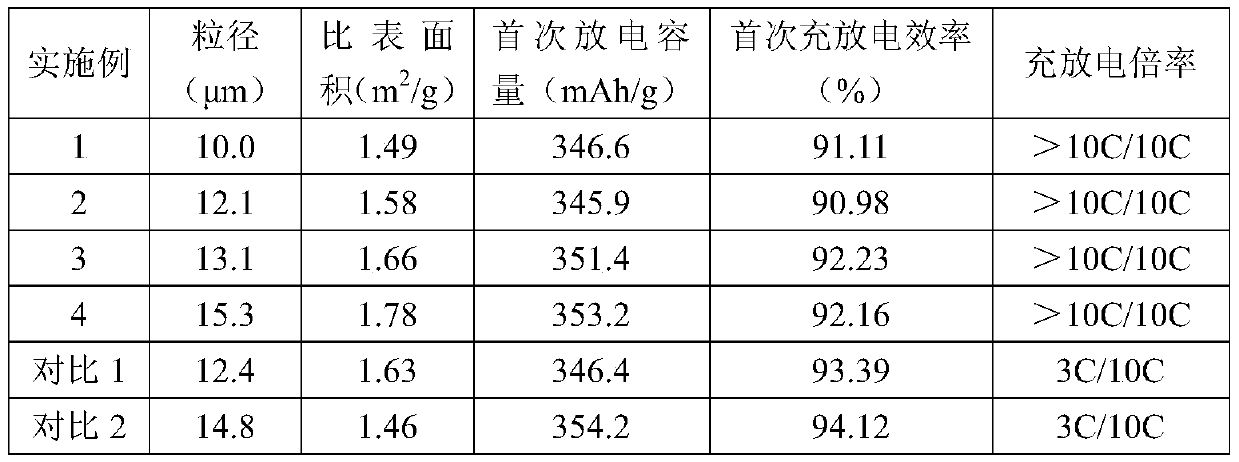

Graphite anode material for lithium ion batteries and preparation method thereof

InactiveCN106532053AHigh isotropyImproved fast charging capabilityGraphiteCell electrodesCarbonizationSodium-ion battery

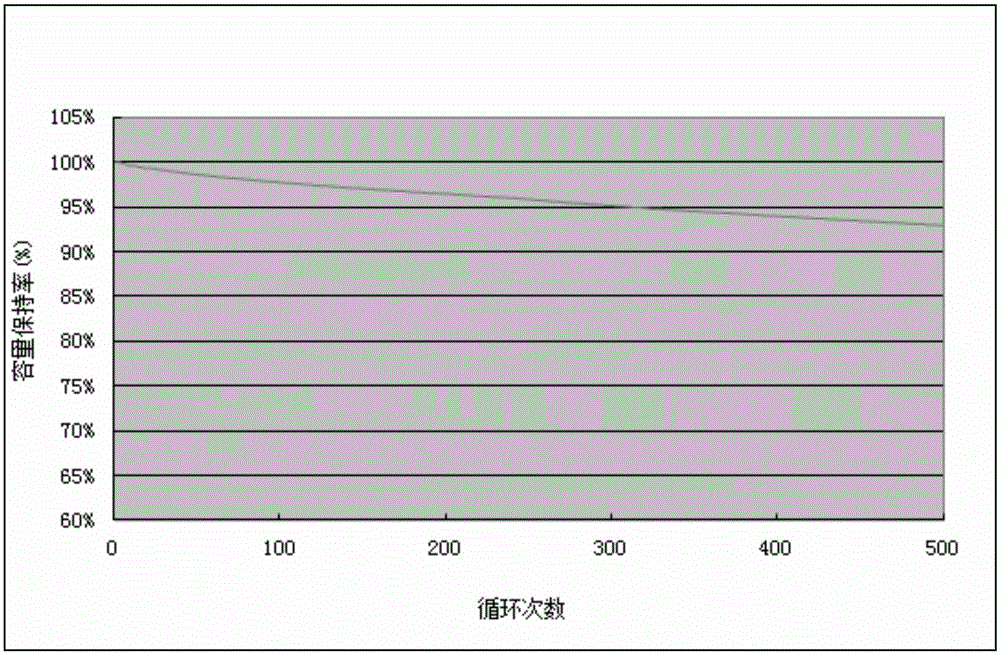

The invention discloses a graphite anode material for lithium ion batteries and a preparation method thereof. The method comprises the following steps: 1) carrying out smashing treatment on petroleum coke; 2) carrying out cladding modification treatment on petroleum coke powder obtained in the step 1) and asphalt 1; 3) carrying out graphitization treatment on a material obtained in the step 2); 4) carrying out sieving treatment on a material obtained in the step 3); 5) carrying out fusion treatment on a material obtained in the step 4) and asphalt 2; 6) carrying out vacuum carbonization treatment on a material obtained in the step 5); and 7) carrying out sieving treatment on a material obtained in the step 6), thus obtaining a finished product. The graphite anode material for the lithium ion batteries disclosed by the invention is excellent in quick charge performance, relatively high in discharge capacity and first-time charge and discharge efficiency, relatively good in cycle performance and relatively good in low-temperature performance, the quick charging rate of the graphite anode material reaches more than 3 C, the first-time discharge capacity of the graphite anode material is more than 350 mAh / g, the first-time charge and discharge efficiency of the graphite anode material is more than 92%, and the 500-week cycle capacity retention ratio of the graphite anode material is more than 90%.

Owner:SHANGHAI SHANSHAN TECH CO LTD

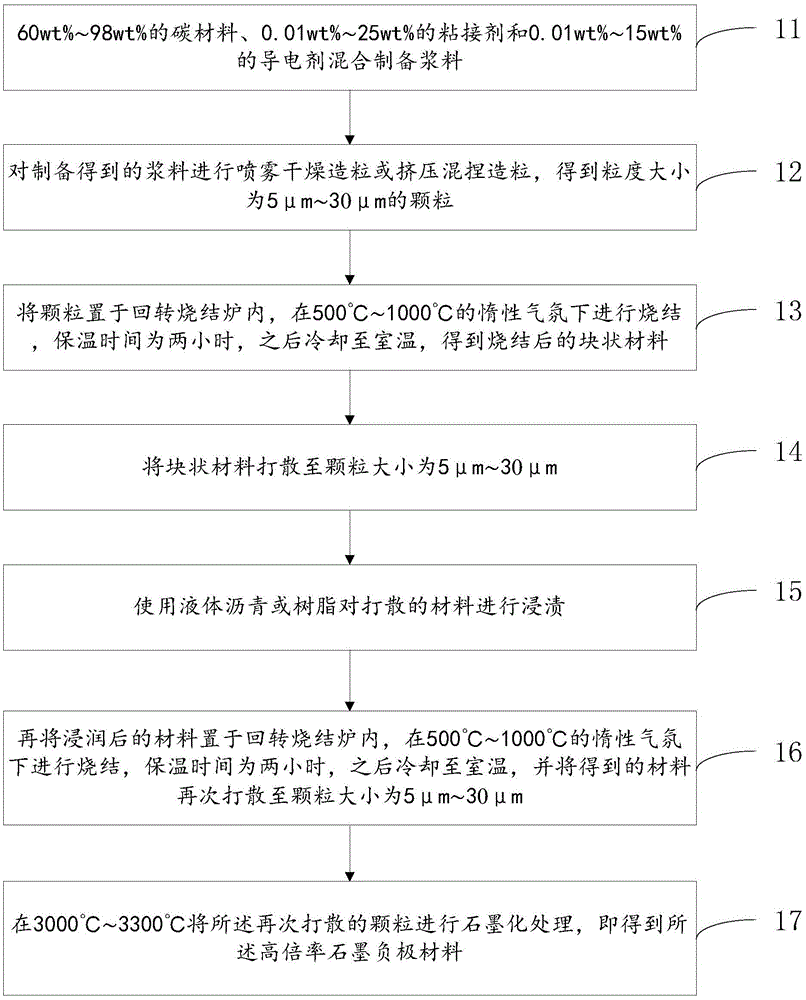

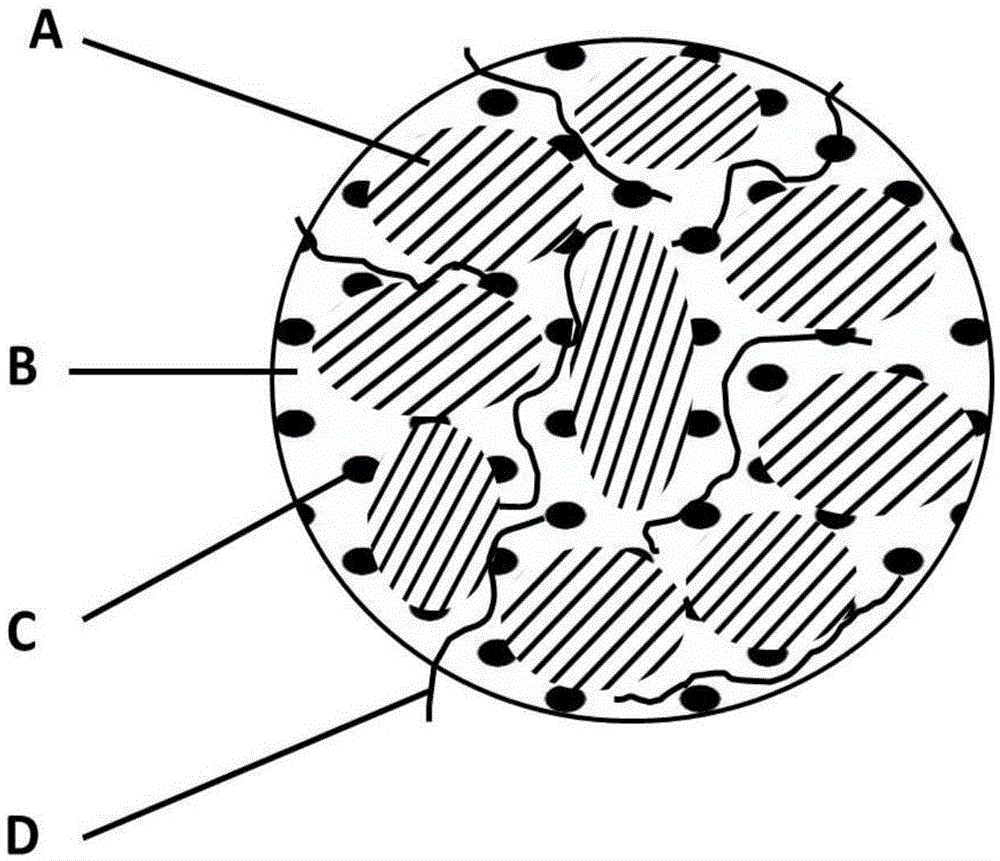

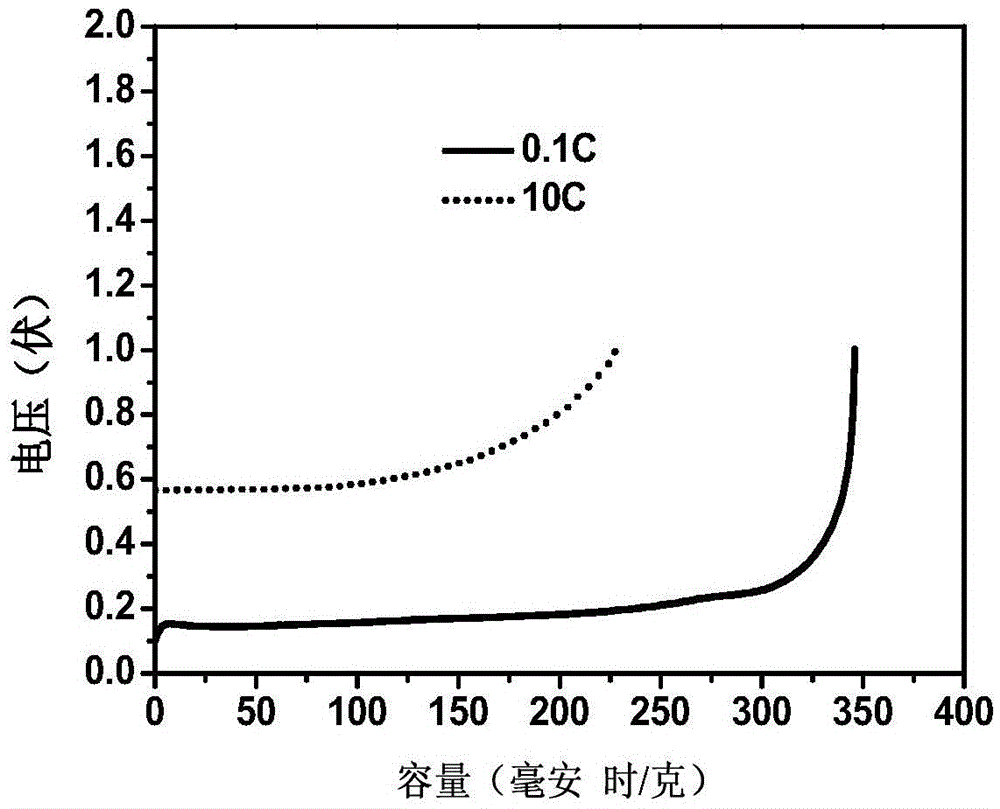

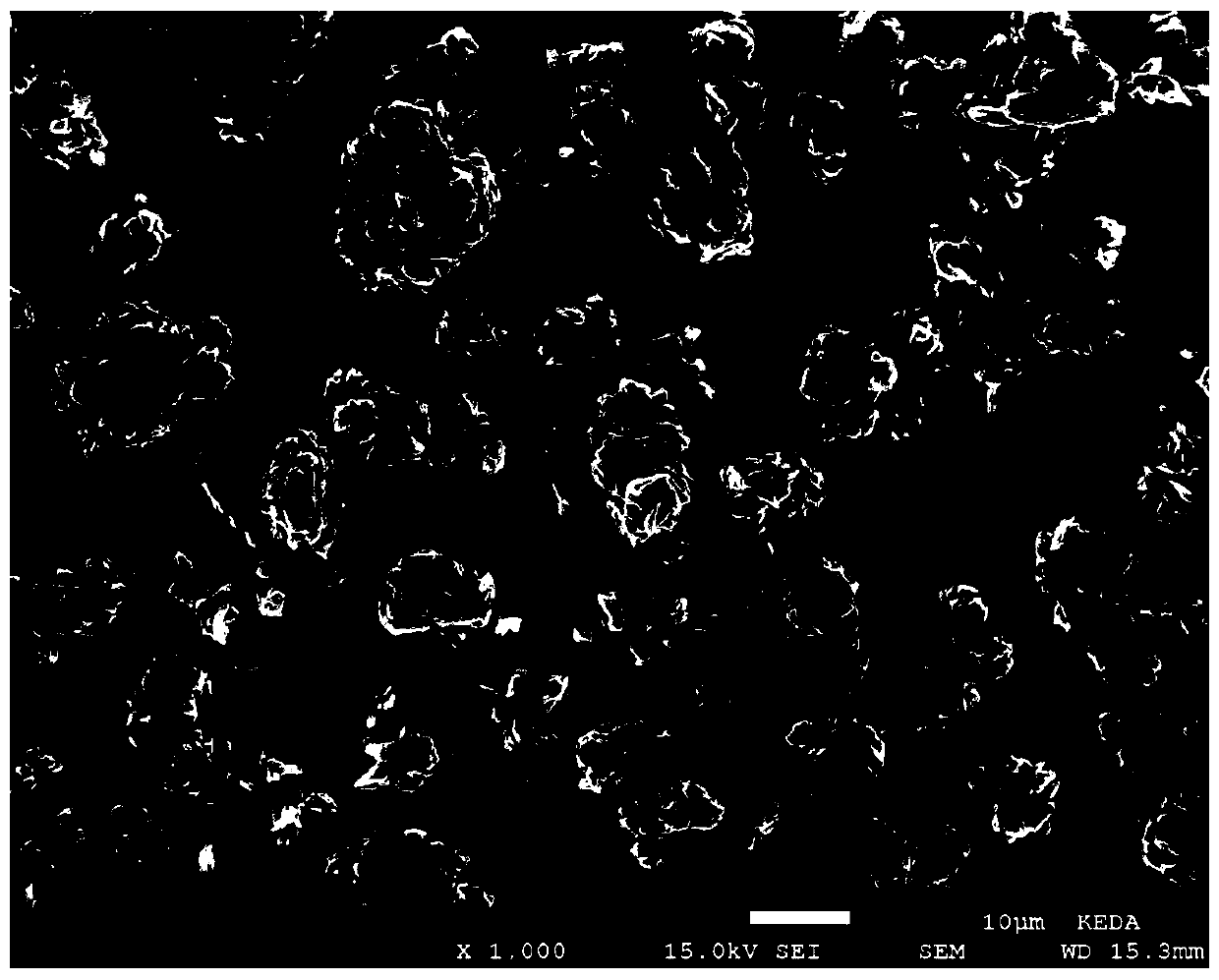

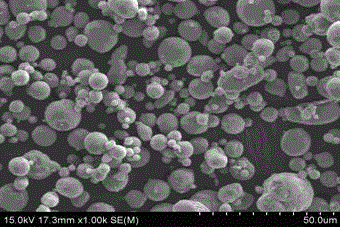

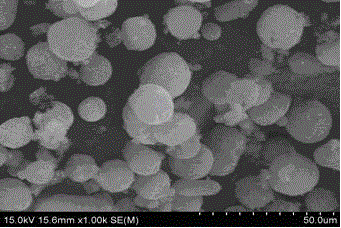

Preparation method of high-rate graphite anode material, anode material and lithium-ion battery

ActiveCN105633408AGuaranteed StrengthIncrease compaction densityNegative electrodesSecondary cellsHigh rateAdhesive

The invention discloses a preparation method of a high-rate graphite anode material, the anode material and a lithium-ion battery. The method comprises the following steps: mixing a carbon material, an adhesive and a conductive agent to prepare slurry; carrying out spray drying granulation or extruding kneading granulation on the slurry to obtain particles of which the particle sizes are 5-30 microns; putting the particles into a rotary sintering furnace, carrying out sintering in an inert atmosphere, carrying out heat preservation for 2 hours and cooling the particles to a room temperature to obtain a bulk material; scattering the bulk material into the particles of which the particle sizes are 5-30 microns; and impregnating the scattered material with liquid asphalt or resin, putting the impregnated material into the rotary sintering furnace, sintering the impregnated material in the inert atmosphere, scattering the obtained material into the particles of which the particle sizes are 5-30 microns again, and carrying out graphitization at 3,000-3300 DEG C to obtain the high-rate graphite anode material.

Owner:江西紫宸科技有限公司 +1

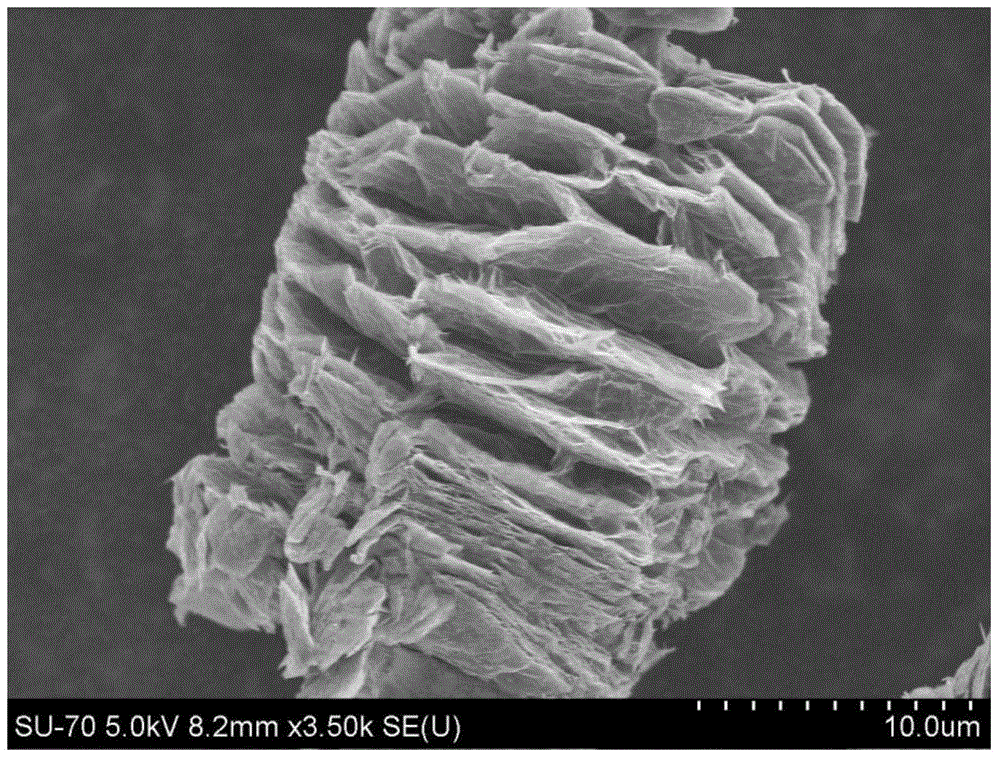

Method for preparing high-rate artificial graphite anode material

ActiveCN109830669AReduce processing costsReduce electrostatic attractionCell electrodesSecondary cells servicing/maintenanceHigh rateEconomic benefits

The invention belongs to the field of lithium ion batteries and relates to a method for preparing a high-rate artificial graphite anode material, comprising the following steps: (1) preferential selection of pulverized and shaped tailings; (2) mixing; (3) static coating and granulation; (4) breaking and spheroidization; (5) secondary mixing; (6) high-temperature graphitization; and (7) mixing andsieving. The anode material prepared by the method has excellent high rate charge / discharge performance, and has good cycle performance and low-temperature temperature. The method also fully processesand recycles the by-products produced in the processing of coke raw materials / asphalt raw materials in a high value-added manner, has broad market prospects, reduces the disposal cost of solid waste,and brings practical economic benefits.

Owner:KEDA (ANHUI) NEW MATERIAL CO LTD

Preparation method of graphene-dopedand carbon-coated modified graphite anode material

InactiveCN104934603AImprove conductivityHigh specific capacityCell electrodesSecondary cellsElectronic transmissionHigh rate

The invention discloses a preparation method of graphene-doped and carbon-coated modified graphite anode material. The doping and modification of the graphene to graphite could solve the problem that high-rate performance of the graphite is relative bad. Because the graphene is used as an electronic transmission buffer layer in a graphite composite material, the cycle performance of the graphite composite material is improved. In addition, the introduction of the graphene could effectively restrain the gather of graphite particles in a heat treatment process, and simultaneously, the Li-ion diffusion coefficient in the graphene-doped graphite composite material is increased. The graphene prepared according to the invention has higher specific surface area, and therefore, the high-rate performance of the graphite could be further improved.

Owner:田东

Preparation method for graphite carbon material

The invention provides a preparation method for a graphite carbon material, wherein, the graphite carbon material is prepared from the following required components in parts by weight:. 99-101 parts of calcined petroleum coke dry material and 20-25 parts of melting asphalt. The preparation method comprises the following steps: (1) mixing and kneading the dry material and an adhesive and then cooling and molding the mixture; (2) calcining for the first time; (3) soaking for the first time; (4) clacining for the second time; (5) soaking for the second time; (6) calcining for the third time; and (7) carrying out a graphitization process. The novel graphite carbon material prepared in accordance with the invention has the advantages of antioxidation, good heat and corrosion resistance, excellent conductivity and good thermal shock resistance, so that the lifetime is as over three times as that of a common graphite anode.

Owner:兴和县鑫源碳素有限公司 +1

Preparation method of micro-expansive graphite anode material

ActiveCN104157863ALow expansionImprove cycle stabilityElectrolytic capacitorsHybrid capacitor electrodesThermal insulationMass ratio

The invention relates to a preparation method of a micro-expansive graphite anode material which has a controllable expansion times being 2-10. The method includes following steps: mixing a battery-class powdery graphite material, an oxidizing agent and an intercalator according to a mass ratio of 1:0.05-1.0:0.5-10, performing an oxidizing and intercalating process for 30-60 min at 10-40 DEG C; performing a filtering process at room temperature to separate a solid subject, washing the solid subject until a pH value of a filtrate is 6-7; performing a drying process; feeding the solid subject to a horizontal tubular furnace; performing expansion in an inner atmosphere at 200-800 DEG C for 1-30 min; and performing thermal insulation to obtain the anode material.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

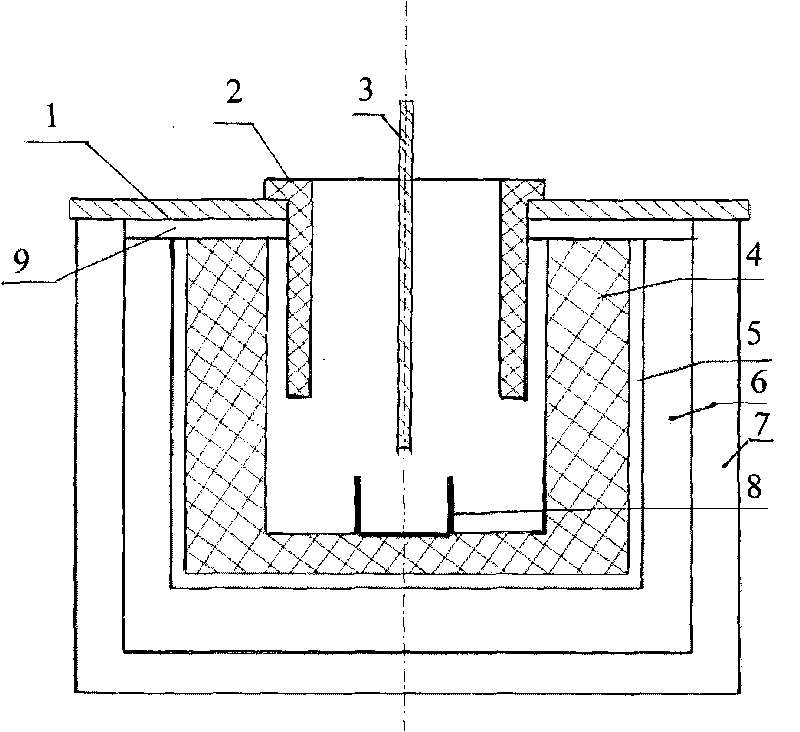

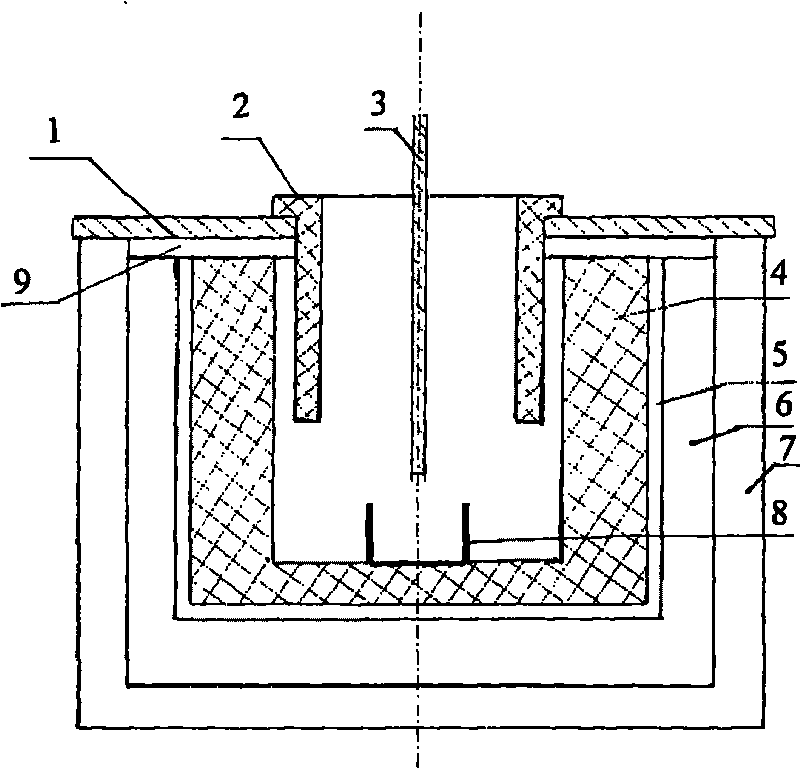

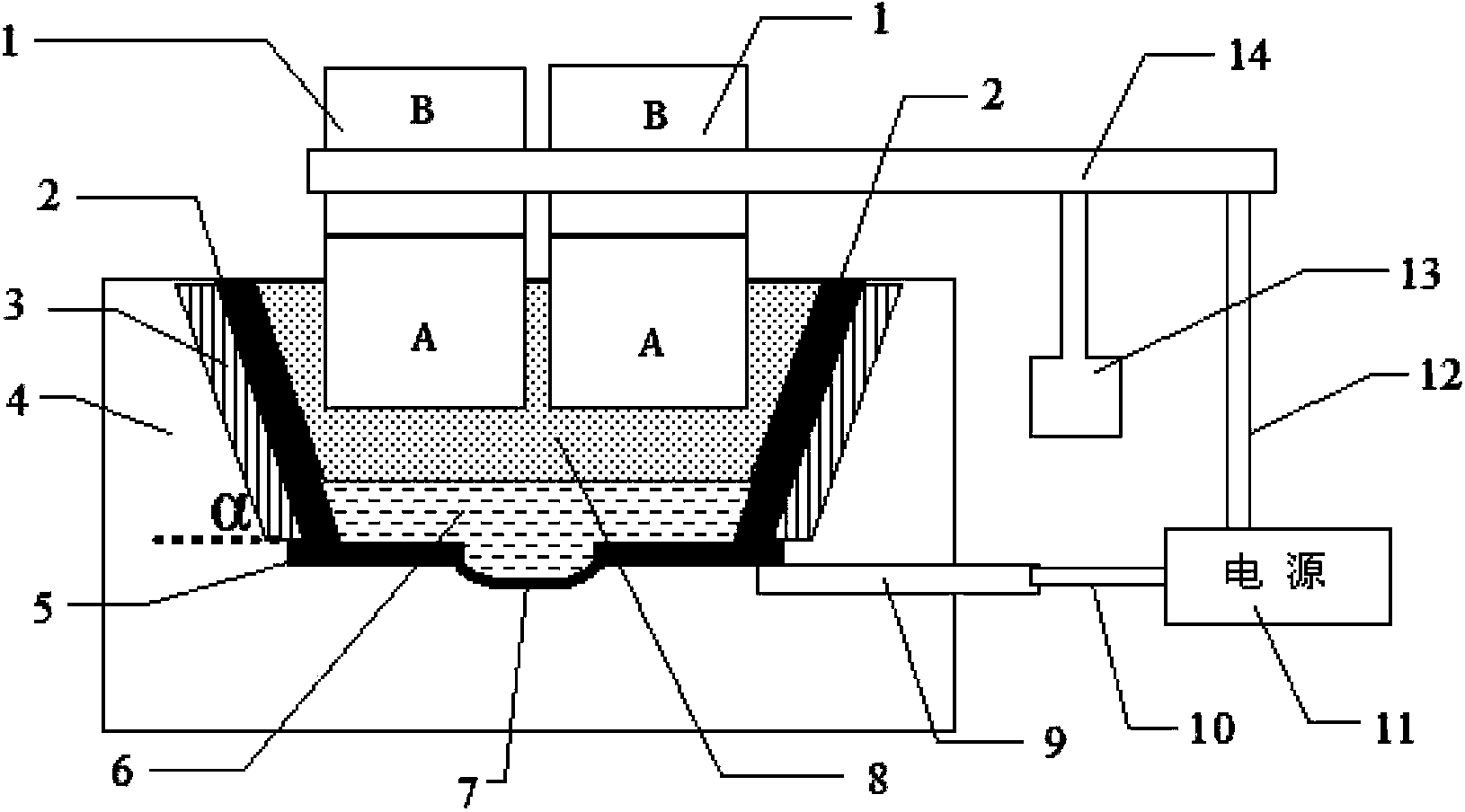

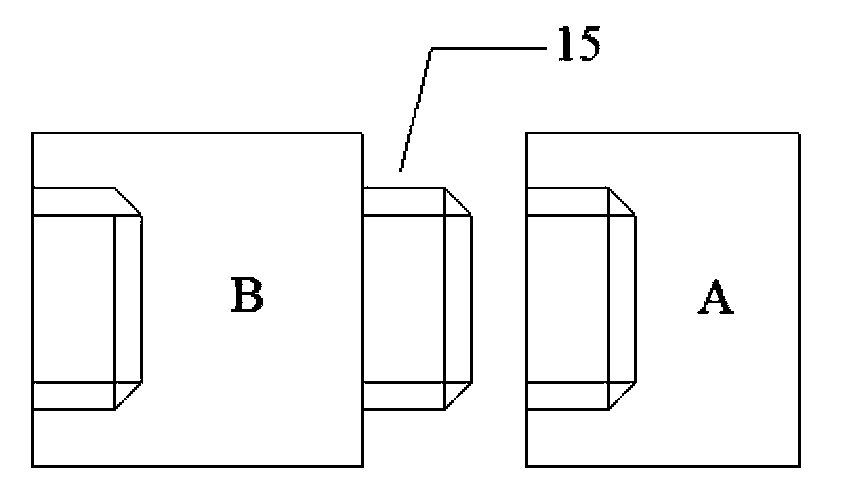

Electrolytic bath and method for electrolyzing light rare earth metals or alloys

The invention provides an electrolytic bath and a method for electrolyzing light rare earth metals or alloys. The wall of the electrolytic bath is composed of an incrustation protection layer 2 of an electrolyte solution 8 composed of rare earth fluoride-lithium fluoride, a starting cathode 5 is installed at the bottom part of the electrolytic bath, a plurality group of graphite anodes 1 are installed right above the starting cathode, each group of graphite anodes is composed of a graphite anode B to be electrolyzed at the upper side and a graphite anode A being electrolyzed at the lower side, and the graphite anode A is connected with the graphite anode B through threads 15. The contents of ferrum and carbon in the rare earth metals or alloys electrolyzed by the electrolytic bath are low; the generation of waste graphite anodes in the electrolytic process is quite small, even no waste graphite anode is generated. The electrolytic bath and the method for electrolyzing light rare earth metals or alloys provided by the invention are simple and feasible.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Porous silicon/graphite composite electrode material with low expansion rate and preparation method thereof

InactiveCN106784743AIncrease capacityNo significant volume changeCell electrodesSecondary cellsCarbon coatingExpansion rate

The invention discloses a porous silicon / graphite composite electrode material with low expansion rate and a preparation method thereof. The porous silicon / graphite composite electrode material is characterized in that porous silicon is prepared by a dealloying technology, so as to prepare nanometer silicon at low cost; by utilizing carbon coating, the conductivity and stability of the porous silicon are improved; the porous silicon is uniformly mixed with a graphite anode material according to a certain ratio, so as to prepare and design the porous silicon / graphite composite anode material. The porous silicon / graphite composite electrode material has the advantages that the space in the porous silicon can provide enough space for the expansion of silicon, so as to realize the low expansion rate of whole silicon and carbon anode, and ensure the low expansion rate of the electrode and the safety of a battery; the silicon is coated with carbon, and the carbon comprises graphite, amorphous cracking carbon and the like, so that the conductivity and stability of the porous silicon are improved; by adopting the low-cost dealloying method, the costs of silicon and whole composite anode are low.

Owner:山东泰纳新材料科技有限公司

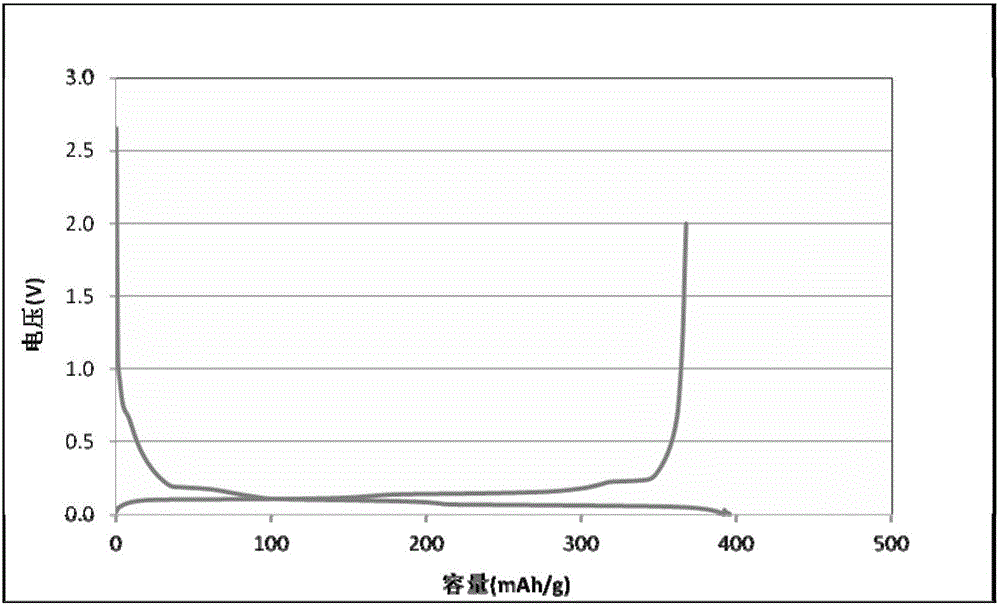

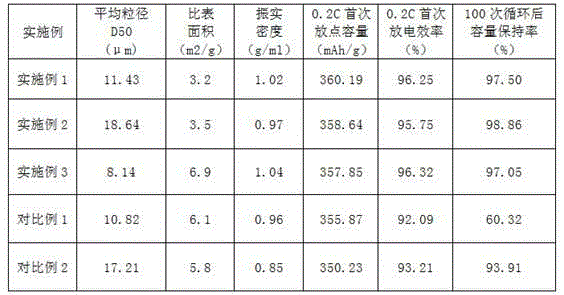

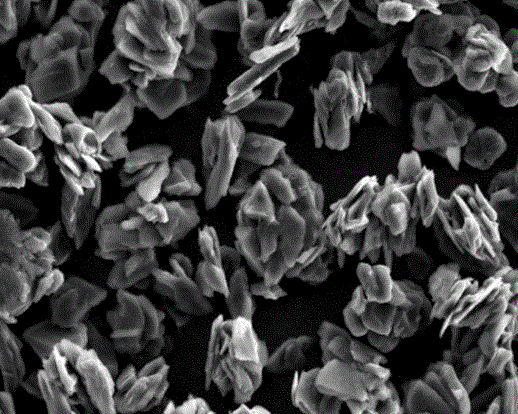

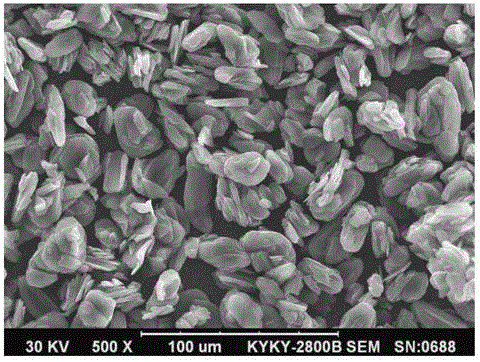

Preparation method of modified microcrystalline graphite anode material for lithium ion battery

ActiveCN105977489AImprovementIncrease capacityCell electrodesSecondary cellsPurification methodsCarbonization

The invention discloses a preparation method of a modified microcrystalline graphite anode material for a lithium ion battery. The preparation method comprises the following steps: 1) shaping crushing: adding natural microcrystalline graphite into a stirred ball mill and ball-milling for 1-4 h, filtering and drying to obtain ball-milled graphite powder; 2) cladding: mixing the graphite powder obtained in the step 1) and a catalyst and asphalt, vacuumizing, heating at 150-200 DEG C and stirring for 0.5-1h, wherein vacuum degree is 500-2,000 Pa, and stirring speed is 2,500-3,000 rpm; and 3) graphitization: graphitizing the clad graphite powder for 10-48 h, and carbonizing at the carbonization temperature of 2,800-3,200 DEG C to obtain the modified microcrystalline graphite anode material. By graphitization, natural microcrystalline graphite is purified. As no poisonous and harmful reagents in a chemical purification method are involved, the method is green and environmental friendly. By adding a catalyst during the cladding process, degree of graphitization can be boosted, and capacity can be greatly increased. By cladding under vacuum, surface cladding can be effectively achieved, tap density is promoted, specific surface area is reduced, and cycle performance is greatly improved.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

A kind of isotropic graphite negative electrode material and preparation method thereof

InactiveCN102280629ASolve the defect of irreversible capacityImprove the first charge and discharge efficiencyCell electrodesGraphiteSolvent

The invention relates to an isotropic graphite negative electrode material and a preparation method thereof. The negative electrode material is surface-coated artificial graphite prepared by coating and modifying isotropic graphite with a coating agent composed of pitch and / or coal tar The layered isotropic graphite negative electrode material, the weight ratio of the coating agent to the isotropic graphite is 0.03-0.15:1. The preparation method comprises the following steps: weighing 100 parts of isotropic graphite, 3 to 15 parts of coating agent, and 10 to 70 parts of solvent, stirring and mixing evenly at 25 to 350° C., then vacuumizing, removing the solvent, and discharging glue, carbonization, and finally high-temperature treatment under the condition of 2400-3000° C. in an inert protective atmosphere to obtain the negative electrode material. The isotropic graphite negative electrode material has high coulombic efficiency and good cycle performance for the first time. The preparation method is easy to implement industrially.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD

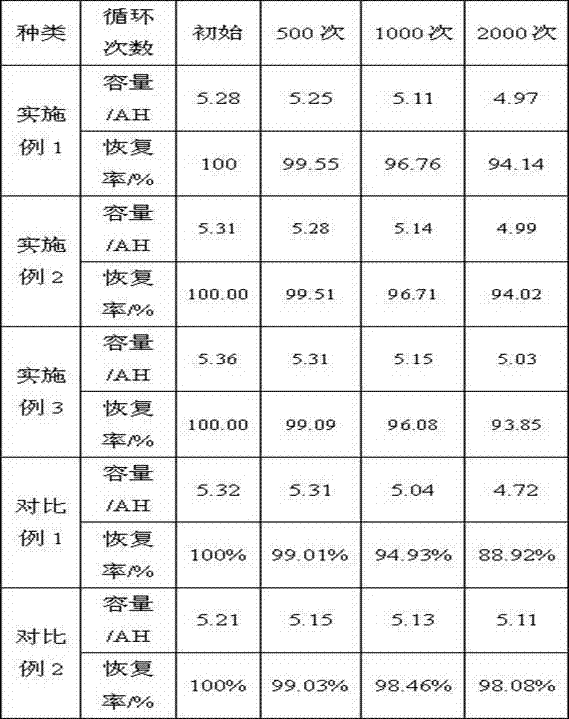

Production method of composite artificial graphite anode material

The invention provides a production method of a composite artificial graphite anode material. The production method includes the following steps: (A) employing two raw materials, comprising micro powders of petroleum coke and coal-based needle coke, according to certain ratio, and performing gas-flow mixing, shaping, fusion pressurization and such composite processes to attach the petroleum coke onto the surface of the coal-based needle coke; (B) performing low-temperature graphitization treatment in a resistance-type graphitization furnace (crucible free) with temperature controlled to be 2500-2800 DEG C; (C) after the materials are cooled to room temperature, performing acid pickling, and washing the materials in water and performing filtration until neutralization; (D) drying the materials at 120 DEG C and adding a little of asphalt to the materials to perform surface coating; and (E) performing low-temperature carbonization at 1200-1400 DEG C. The production method mainly employs the coal-based needle coke as the main raw materials, so that the anode material is low in raw material cost and graphitization temperature and is greatly reduced in production cost. By means of the petroleum coke and the asphalt to perform composite granulation and coating treatment, the material is ensured to have enough capacity and processing property, thereby increasing the cost-performance ratio of the material.

Owner:大连宏光锂业有限责任公司

Preparation method for graphite anode material of lithium ion battery

InactiveCN105932281AReduce turnoverReduce lossesElectrode manufacturing processesSodium-ion batteryLithium-ion battery

The invention discloses a preparation method for a graphite anode material of a lithium ion battery. Fine graphite powder with a small particle size and an organic carbon source are taken as raw materials; through adoption of processes such as mixing, high temperature processing, graphitizing and sieving and through mixing of the fine powder and the organic carbon source in a heating environment, coating, kneading and secondary granulating effects can be realized; and under the adhering effect of the organic carbon source, the fine powder with the small particle size forms secondary particles. The anisotropy problem of the materials is solved, and the tap density of the materials is improved. According to the method, the turnover and device residual loss of the materials are reduced, the yield is high, the processes are simple, the energy consumption is low, the environment is protected, the surface coating effects of the materials are even, and the consistency is high. The prepared anode material is characterized in anisotropy, low iron impurity content, low initial irreversible capacity, low volume expansion, high liquid absorbency, high cycle performance, high cost performance and high comprehensive performance.

Owner:田东

Lithium ion battery graphite anode material and preparation method thereof

ActiveCN105731427AAlleviate the volume expansion effectWide variety of sourcesCell electrodesAdhesiveCarbonization

The invention discloses a lithium ion battery graphite anode material and a preparation method thereof. The preparation method includes the steps of: 1) heating and kneading a mixture of natural graphite and an adhesive; 2) performing hot isostatic pressing moulding at 500-1000 DEG C under 50-100 MPa; 3) performing carbonization; 4) performing graphitization; and 5) crushing and classifying a product. The lithium ion battery graphite anode material has high tap density, large discharge capacity and good cycle performance, is reduced in internal pores of graphite particles, reduces expansion and is improved in cycle performance.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

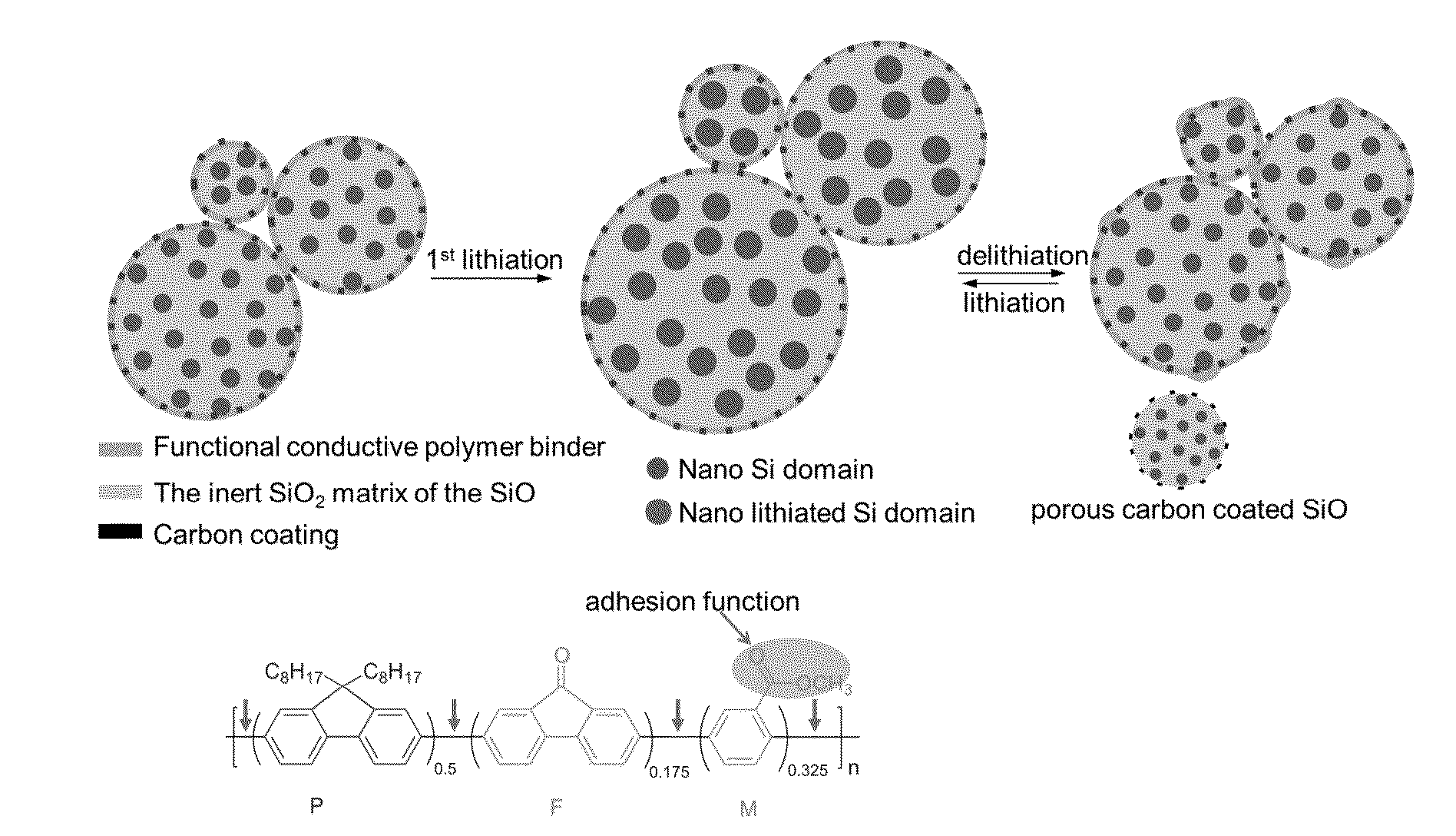

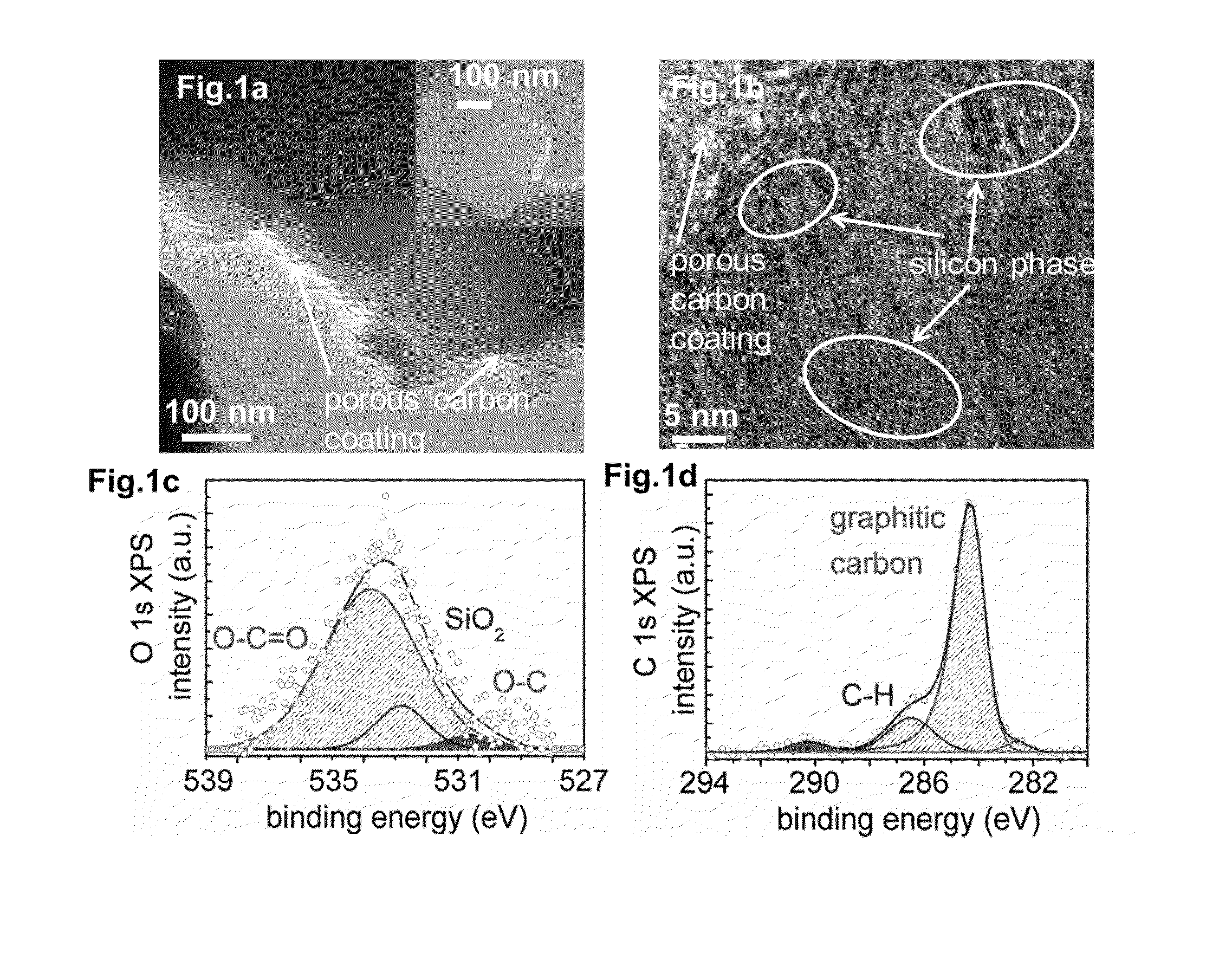

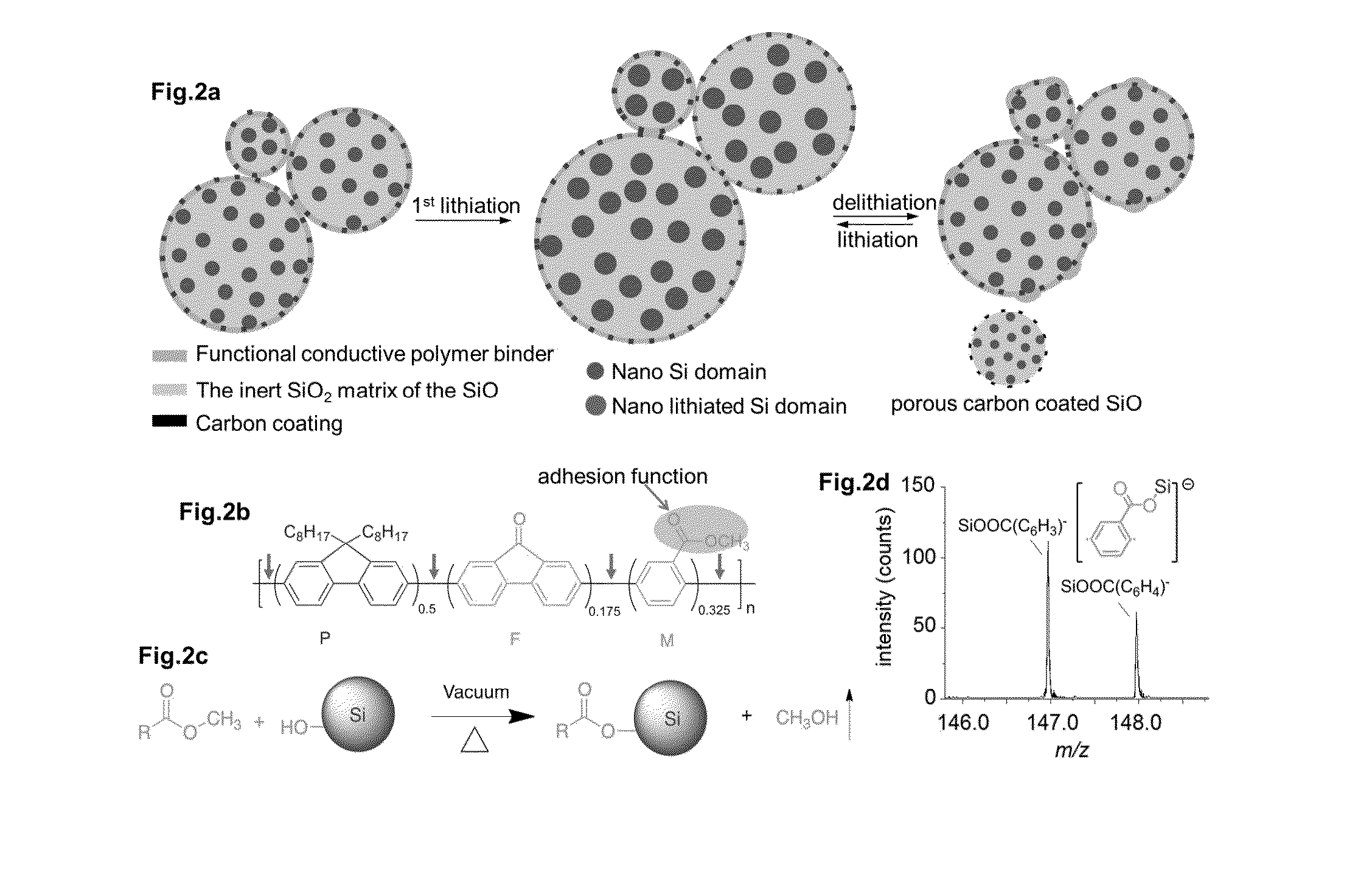

Porous Silicon Oxide (SiO) Anode Enabled by a Conductive Polymer Binder and Performance Enhancement by Stabilized Lithium Metal Power (SLMP)

ActiveUS20160164073A1Electrode carriers/collectorsConductive materialSilicon monoxidePerformance enhancement

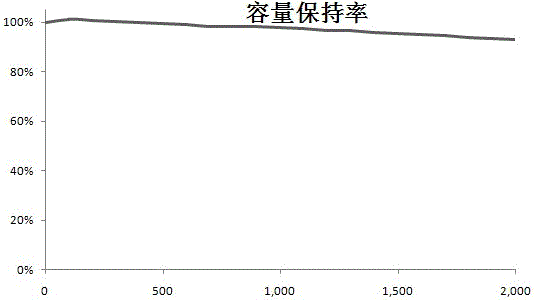

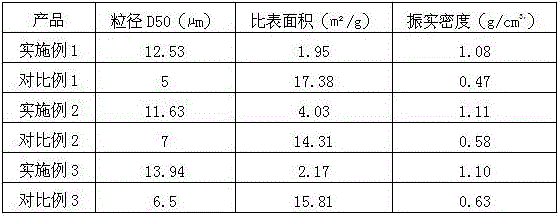

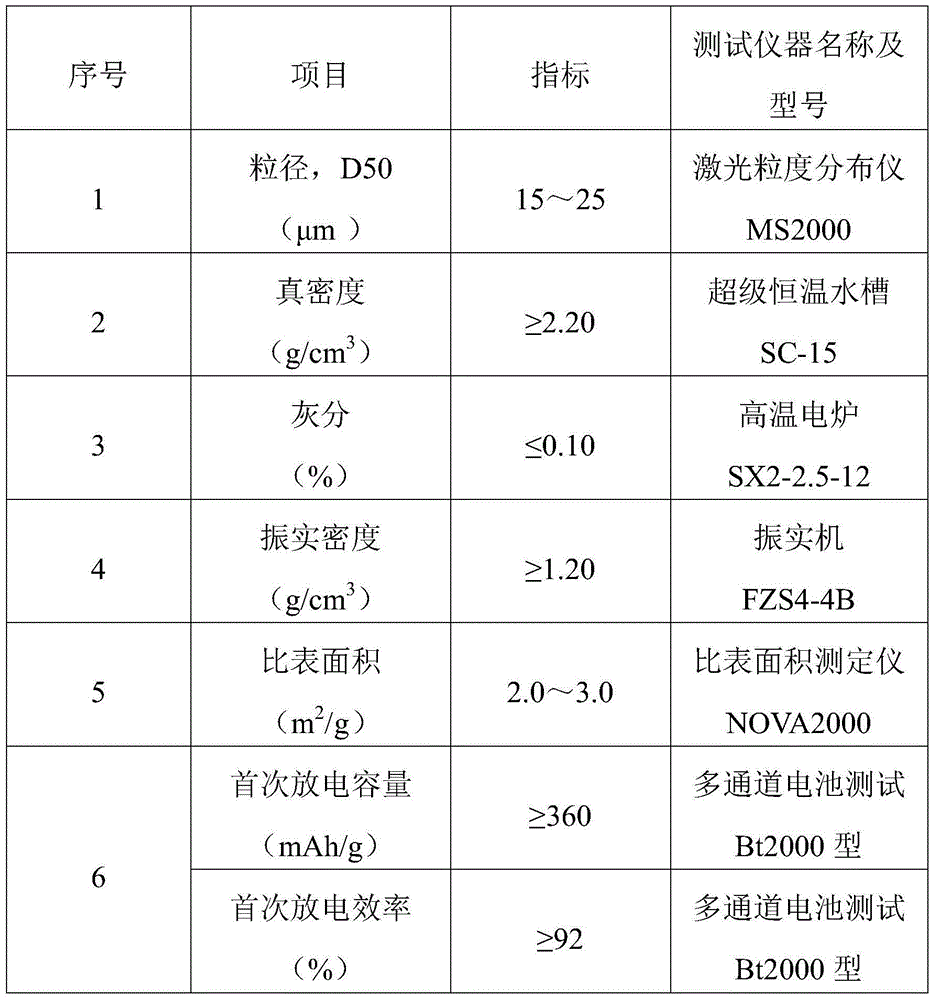

The invention demonstrates that only 2% functional conductive polymer binder without any conductive additives was successfully used with a micron-size silicon monoxide (SiO) anode material, demonstrating stable and high gravimetric capacity (>1000 mAh / g) for ˜500 cycles and more than 90% capacity retention. Prelithiation of this anode using stabilized lithium metal powder (SLMP®) improves the first cycle Coulombic efficiency of a SiO / NMC full cell from ˜48% to ˜90%. This combination enables good capacity retention of more than 80% after 100 cycles at C / 3 in a lithium-ion full cell. We also demonstrate the important connection between porosity and the loading of silicon electrodes. By employing a highly porous silicon electrode, a high areal capacity (3.3 mAh / cm2) is obtained. This method works well to achieve high loading of other high-capacity alloy anodes, the state-of-art graphite anode, as well as a high loading of positive electrodes for LIBs.

Owner:RGT UNIV OF CALIFORNIA

Method for producing semi-graphite prebaked anode

A method of producing prebaking semi-graphite anodes comprises: cracking-screening-blending-pugging-molding-baking. It is characterized in, after the middle forging, the prebaking anode thickener contains( by weight), 20úÑ-50úÑ petrolatum coke, 0úÑ-50úÑ semi-graphite petrolatum coke or graphite petrolatum coke, 0úÑ-40úÑ man-made graphite, 14úÑ-20úÑ coal pitch, 0úÑ-20úÑ stub, ash below 1%; puggingis at 140degree C-180degree C, molding is at 130degree C-150degree C, baking is at 1050degree C-1250degree C. The prebaking semi-graphite anode has a low resistance and a low oxidization activity, excellent performance of resisting heat and shock.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

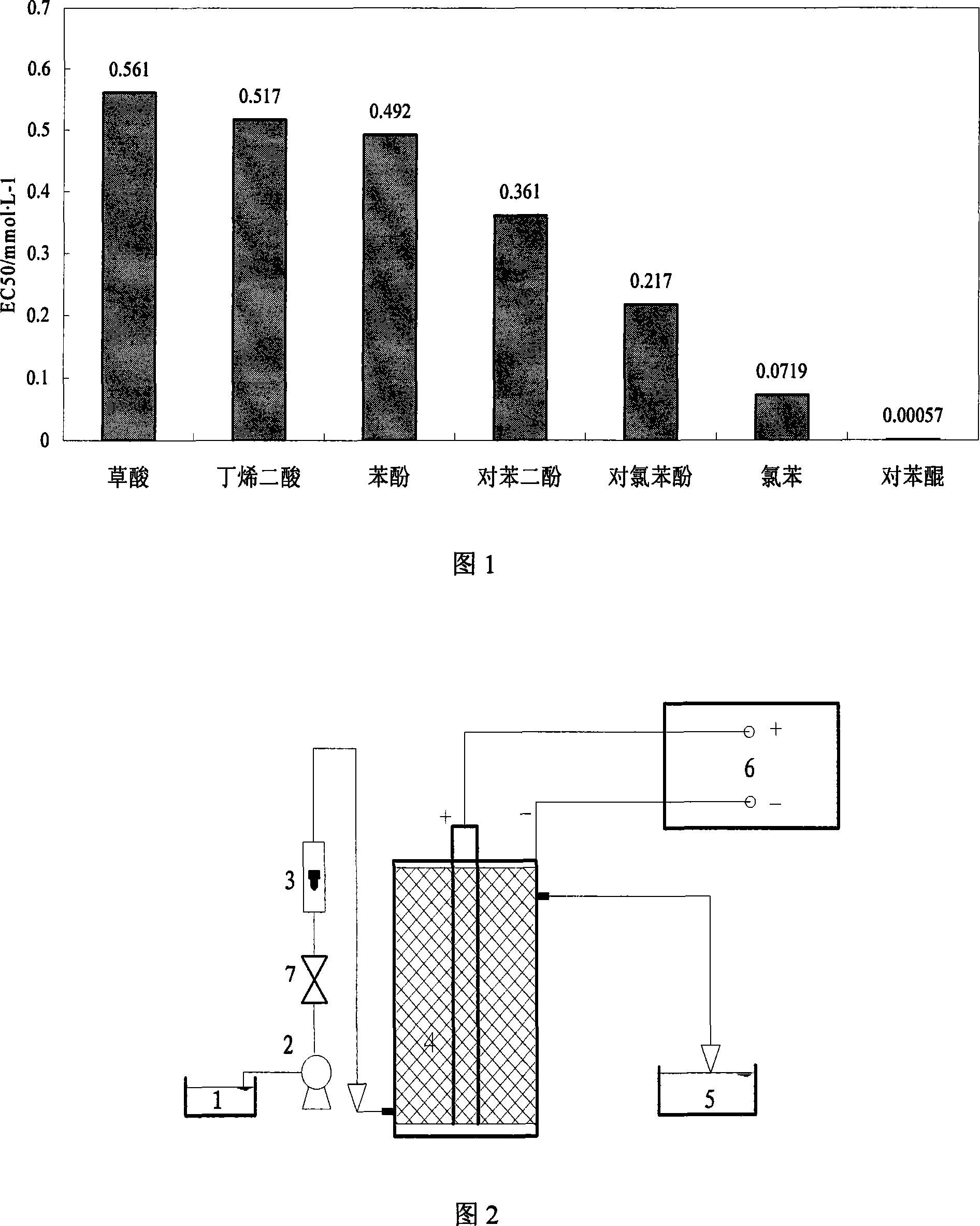

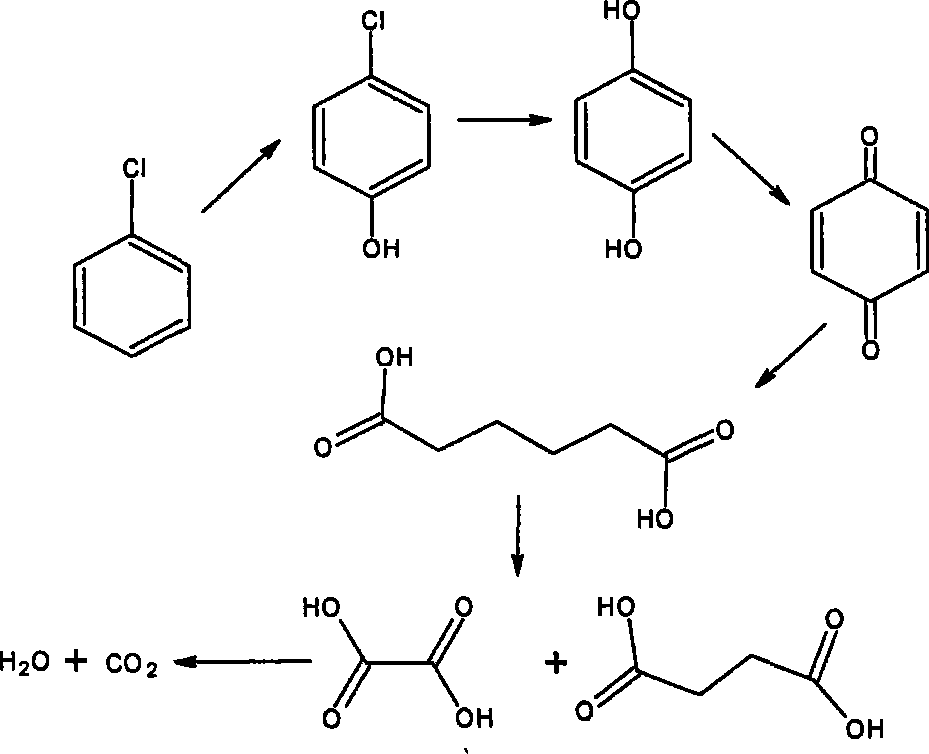

Three-dimensional electrode reactor and method for processing chlorobenzene waste water by using the same

InactiveCN101186361AReduce energy consumptionAchieve removalWater contaminantsWater/sewage treatmentChlorobenzenePower flow

The invention discloses a three-dimension electrode reactor, comprising a close vessel; the bottom inside the vessel is provided with a cylindrical graphite anode, the side wall of the vessel is a stainless steel cathode, conductive particles and catalyst are filled and a DC stabilized voltage supply is connected between the cylindrical graphite and the side wall. A method for treating chlorobenzene wastewater using the three-dimension electrode is that: the chlorobenzene wastewater is led into the three-dimension electrode reactor and the current is set between 1 to 5A, the staying time of the wastewater in the three-dimension electrode reactor is 30 to 120min and the tail wastewater after the reaction can be directly discharged or further biochemically treated. The concentration of chlorobenzene and the toxicity of the wastewater can be reduced at the same time through the device and the method of the invention.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

Graphite anode material for lithium-ion battery and preparation method of graphite anode material

InactiveCN105489893ARich sourcesLow priceCell electrodesSecondary cellsPtru catalystElectrical battery

The invention provides a graphite anode material for a lithium-ion battery and a preparation method of the graphite anode material. According to the method, with coke as a raw material, primary particles with certain shapes and particle size distribution are obtained by crushing, shaping and sieving; the coke obtained by crushing, shaping and sieving is evenly mixed with an adhesive, graphitization catalyst and an assistant under protecting and heating conditions of an inert gas; secondary granulation is carried out through mechanical action; secondary particles are formed by bonding two or more primary particles; catalytic graphitization high-temperature treatment is carried out on the secondary particles under the protection of the inert gas; and the final product is obtained by grading or sieving. The graphite material provided by the invention is used as an anode for the lithium-ion battery, and has the advantages of high compaction density, high specific capacity, long cycle lifetime, excellent heavy-current charge-discharge property, good high and low temperature performance, low expansion rate and the like.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

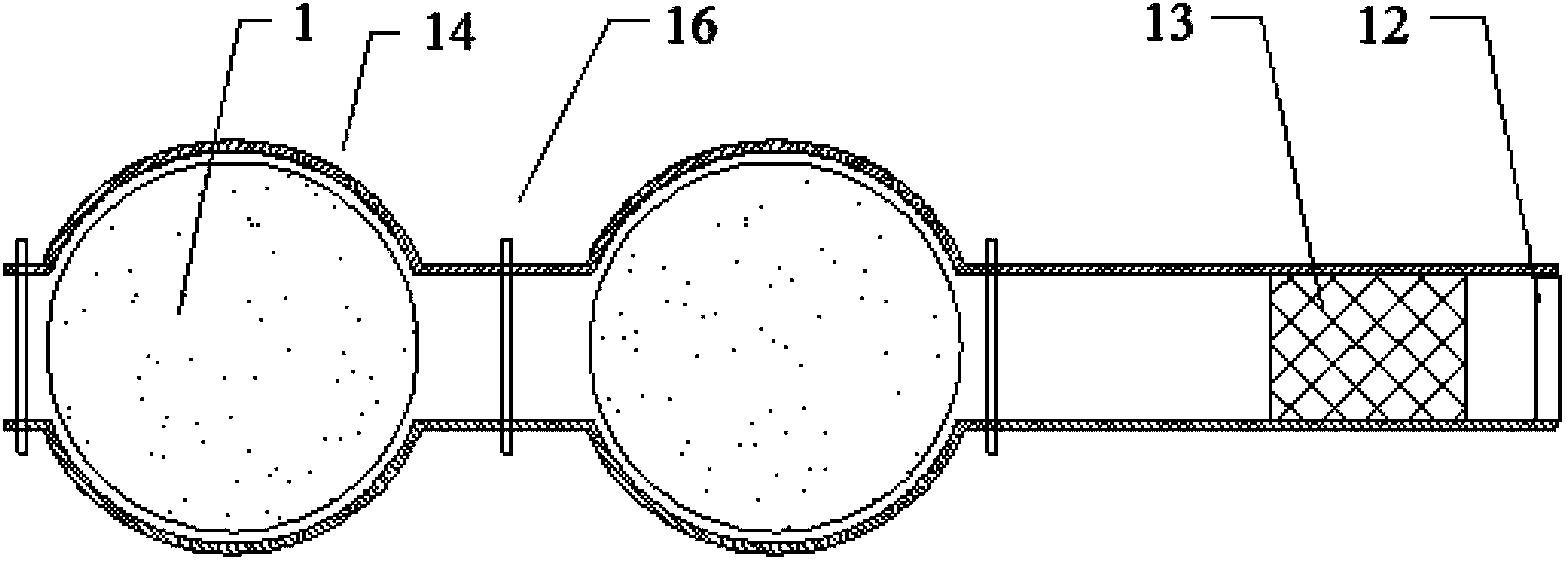

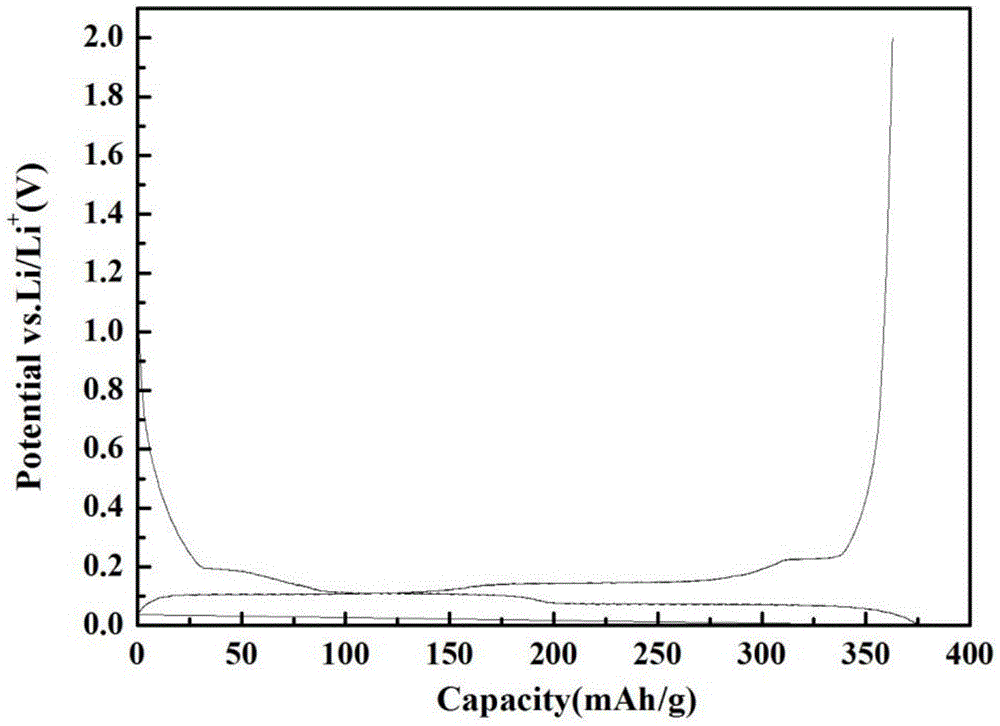

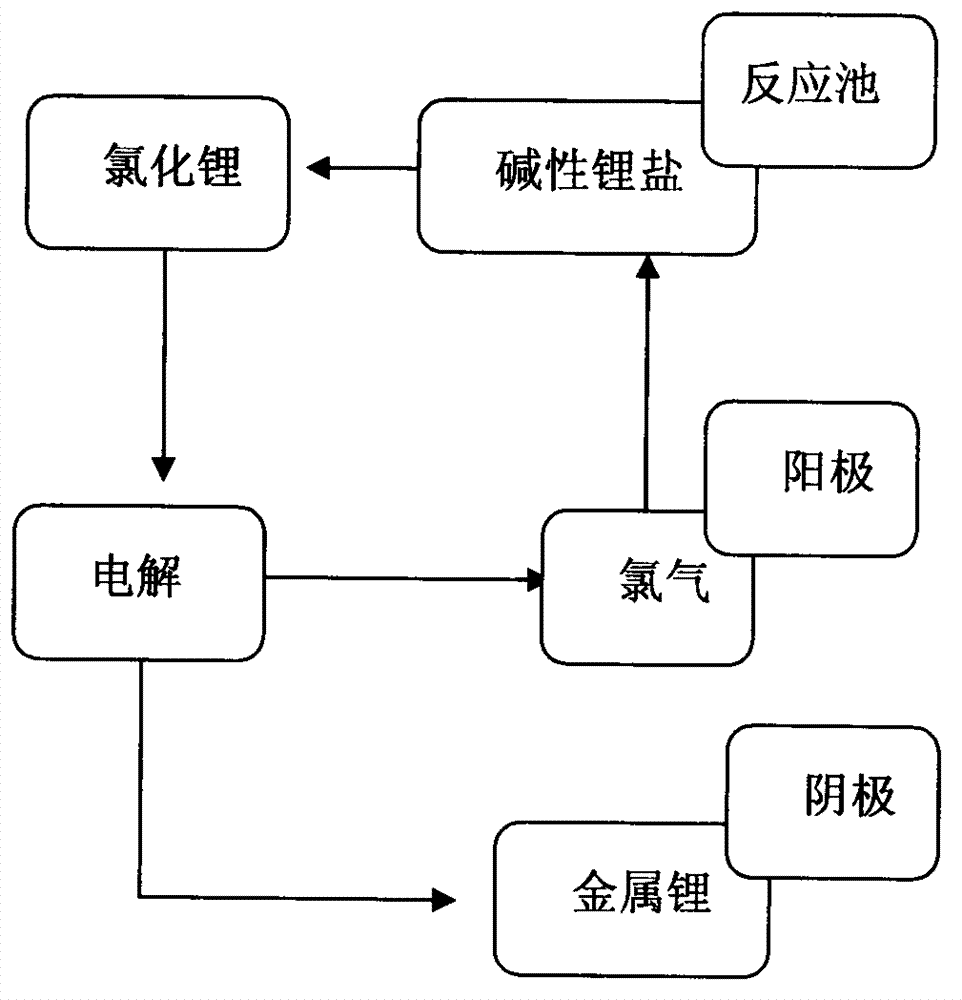

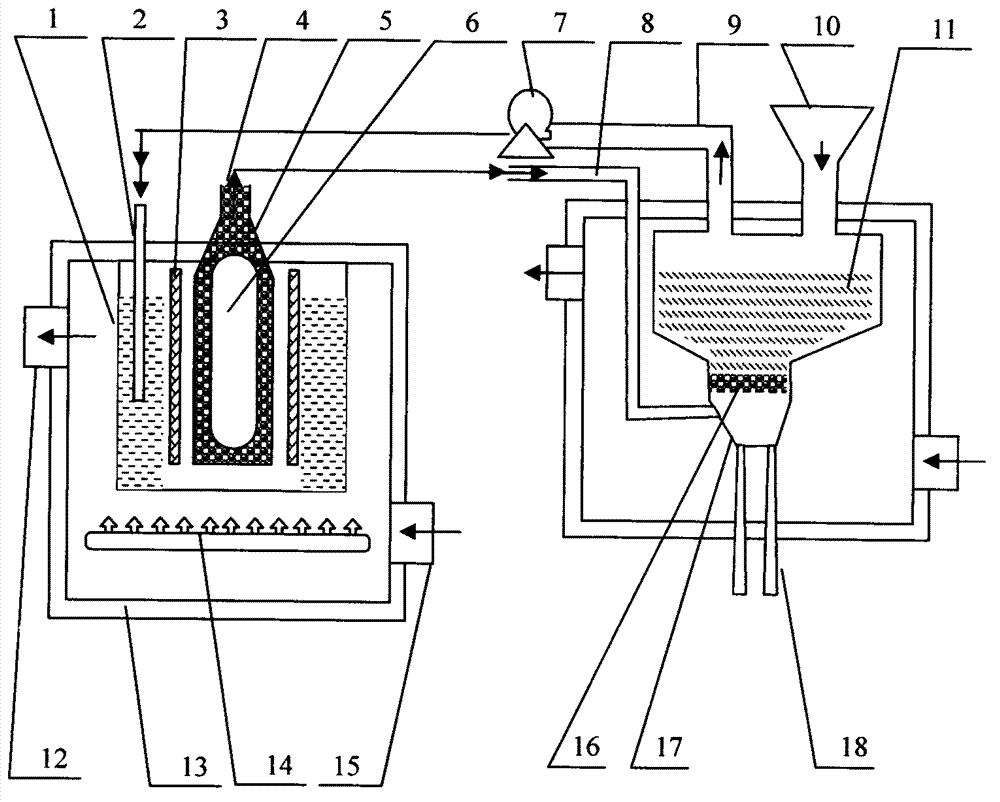

Method of preparing metallic lithium by one-step fusion electrolysis of lithium salt

The invention discloses a method of preparing metallic lithium by one-step fusion electrolysis of lithium salt. The method comprises the following steps that: chlorine gas generated by a graphite anode (6) in an electrolytic bath is pumped to a high-temperature fusion chamber (11) of a decomposition groove on a reaction tank (13) by a chlorine gas feedback pipe (8), passes through a porous-titanium sieve plate (16) from bottom to top, and reacts with the fused alkaline lithium salt to generate lithium chloride for further electrolysis, and due to rapid reaction, the metallic lithium is generated continuously from bottom to top. The method disclosed by the invention has the advantages that the chlorine gas becomes a carrier for carrying lithium ions actually, circulates between a decomposition chamber and the high-temperature fusion chamber (11) in the electrolytic bath in a back-and-forth manner without being exhausted outwards, so that not only are the production efficiency and the quality of the metallic lithium improved, but also auxiliary equipment required for exhausting the chlorine gas outwards and the influence are avoided; in addition, due to the reduced processes about concentrated crystallization, centrifugal separation, high-temperature drying, lithium ingot fusion and vacuum distillation and the like, the procedure is obviously saved, the cost for the equipment and production is reduced and large business opportunity is brought for application of downstream processes and products.

Owner:新疆骏强科技发展有限公司

Preparation method of nitrogen and phosphorus co-doped carbon-coated graphite anode material

ActiveCN105720255AEasy to operateLess production equipmentCell electrodesSecondary cellsCarbonizationCarbon coated

The invention discloses a preparation method of a nitrogen and phosphorus co-doped carbon-coated graphite anode material, which comprises the following steps of: (1) coating, i.e. weighing graphite and ionic liquid, adding the graphite and the ionic liquid into a high-speed stirrer, carrying out dispersion for 1 to 4h at a rotating speed of 500 to 5,000r / min, and after completing processing, obtaining graphite coated with the phosphorus-containing ionic liquid; and (2) carbonization, i.e. placing the graphite coated with the phosphorus-containing ionic liquid in an atmosphere protection furnace to carry out sintering, heating to a temperature of 400 to 1,000 DEG C at a heating rate of 2 to 25 DEG C per min and carrying out heat preservation for 4 to 18 hours to obtain the nitrogen and phosphorus co-doped carbon-coated graphite anode material. By the structure, the electrical conductivity and the activity of a surface coating layer are greatly strengthened, not only the electronic conductivity of the nitrogen and phosphorus co-doped carbon-coated graphite anode material is effectively improved, but also diffusivity of lithium ions is greatly improved, and the obtained material has excellent rate capability and low-temperature discharge performance.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD +1

Lithium-ion batteries

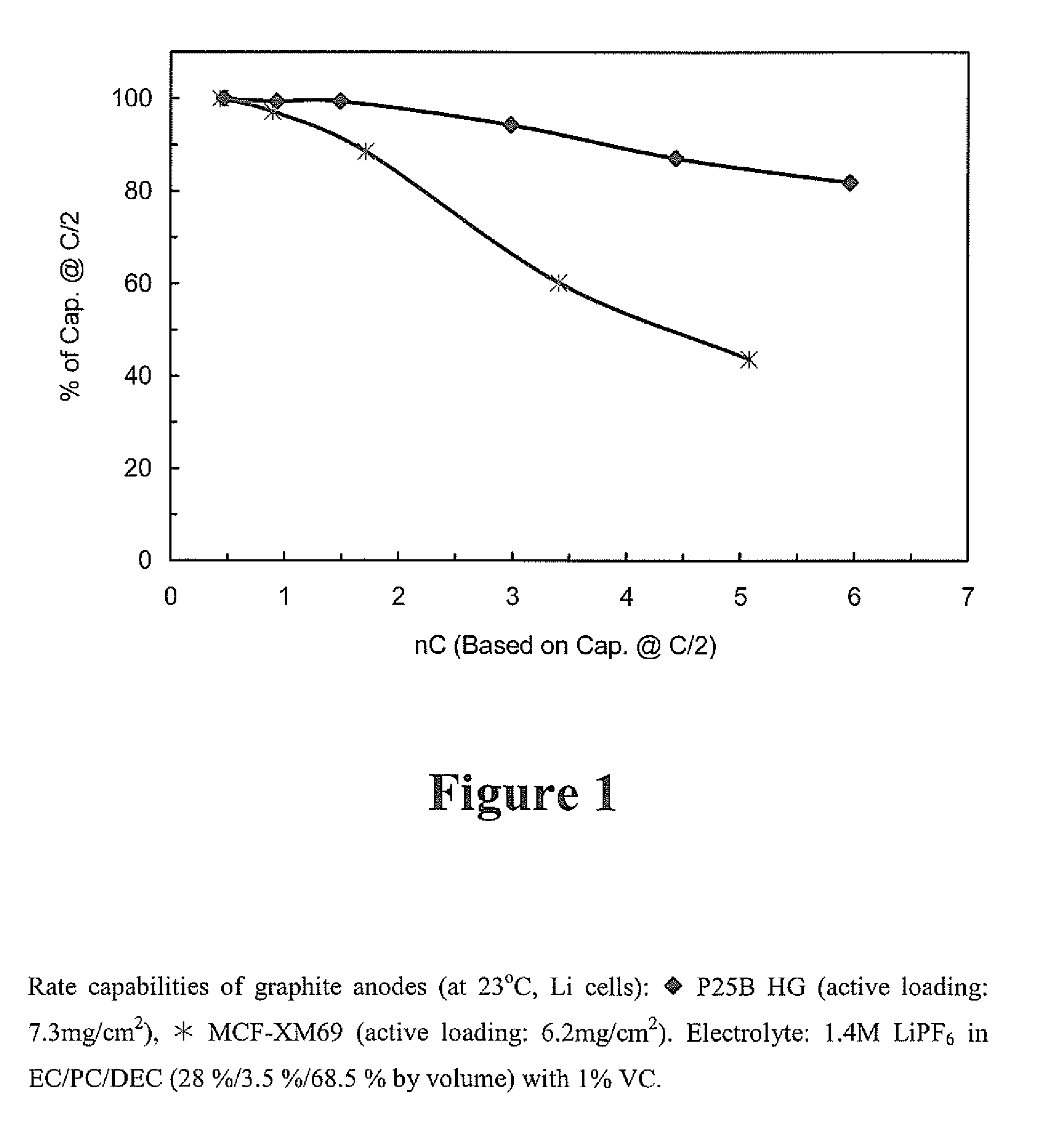

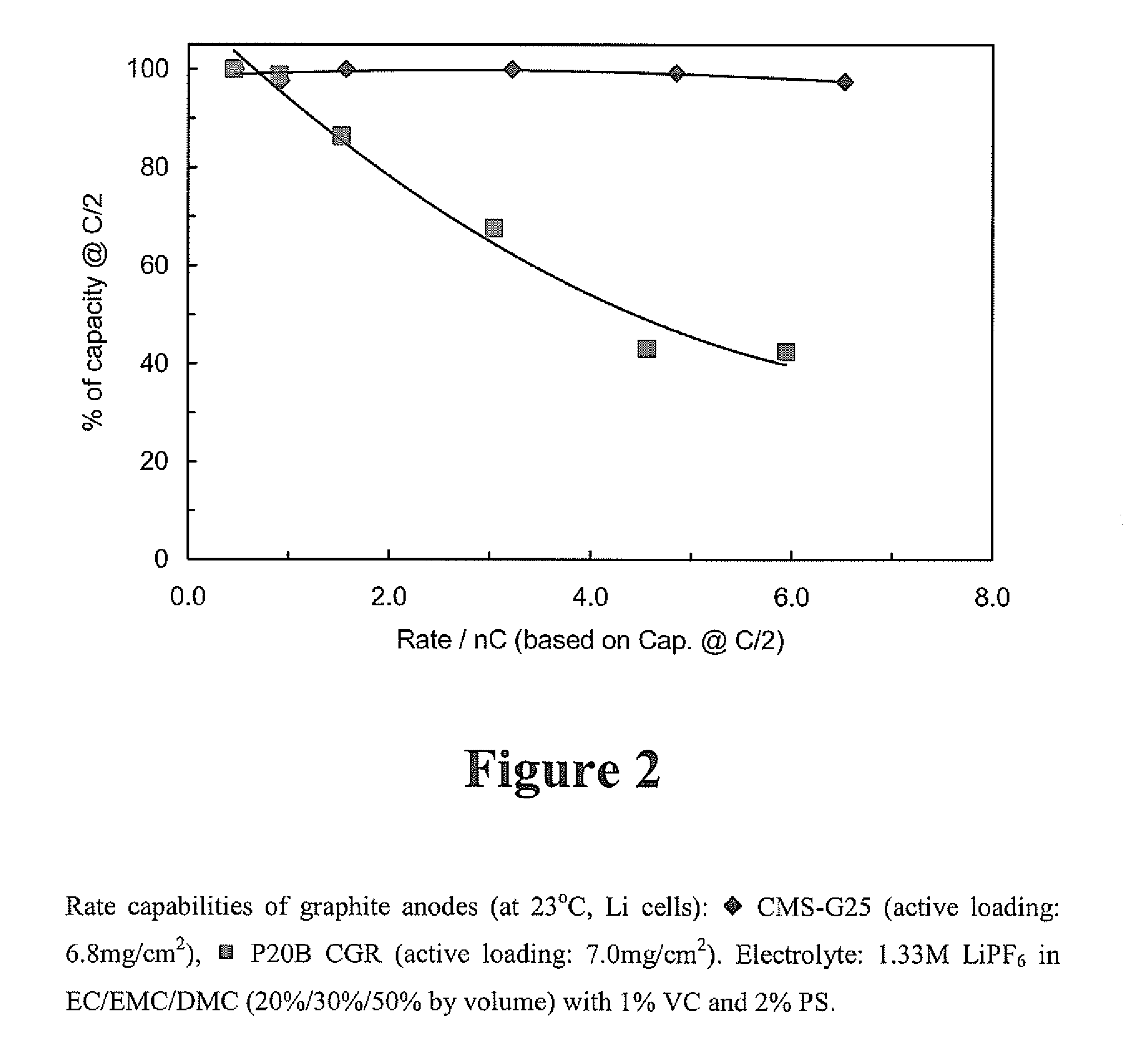

InactiveUS20090233178A1Improve rate performanceEasy dischargeCell electrodesOrganic electrolyte cellsPhosphateLithium metal

The present invention is based on the discovery that certain types of synthetic graphite exhibit superior rate capabilities when used in batteries or cells employing lithium metal phosphate cathodes. Additionally, it has been found that the use of dimethyl carbonate and / or ethyl methyl carbonate in the electrolyte when used in such graphite / lithium methyl phosphate batteries or cells facilitates the discharge reactions on both the cathode and the anode and in particular especially improves the rate capability of the graphite anode.

Owner:VALENCE TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com