Preparation method of graphene-dopedand carbon-coated modified graphite anode material

A graphite anode and graphene technology, which is applied to battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor graphite high-rate charge and discharge performance, poor compatibility with electrolyte organic solvents, etc. The effect of increasing the diffusion coefficient of lithium ions and suppressing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

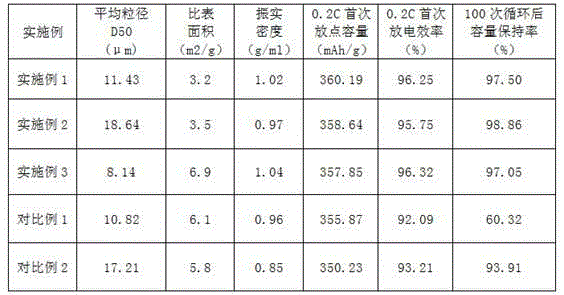

Embodiment 1

[0019] A preparation method of graphene-doped and coated graphite composite negative electrode material, comprising the following steps:

[0020] (1) Prepare a 5mg / mL graphene oxide aqueous solution, pour 40mL of a 5mg / mL graphene oxide aqueous solution into a 50mL stainless steel reactor with polytetrafluoroethylene as the liner, seal the stainless steel reactor and place it in a blast drying oven , reacted at 180°C for 20 hours, then naturally cooled the stainless steel reactor to room temperature, absorbed the water in the solution with filter paper to dryness, and placed the obtained powder in a vacuum drying oven to fully dry to obtain a graphene material. The specific surface of graphene material is at 2000m 2 / g;

[0021] (2) Under stirring conditions, press graphene: natural graphite (D50: 10.82μm, specific surface area: 6.1m 2 / g, tap density: 0.96g / cm 3 ) with a mass ratio of 0.05:1, mix the graphite evenly in the graphene solution, and add the carbon precursor-po...

Embodiment 2

[0025] A preparation method of graphene-doped and coated graphite composite negative electrode material, comprising the following steps:

[0026] (1) Prepare 2 mg / mL graphene oxide aqueous solution, pour 40 mL 2 mg / mL graphene oxide aqueous solution into a 50 mL stainless steel reaction kettle with polytetrafluoroethylene as the liner, seal it and place it in a blast drying oven React at 120°C for 12 hours, then naturally cool the reaction vessel to room temperature, absorb the water in the solution with filter paper to dryness, and place the obtained powder in a vacuum drying oven to fully dry to obtain a graphene material. The specific surface of graphene material is at 2300 m 2 / g;

[0027] (2) Under stirring conditions, according to graphene: artificial graphite (D50: 17.21μm, specific surface area: 5.8m 2 / g, tap density: 0.85g / cm 3 ) with a mass ratio of 0.1:1, mix the graphite evenly in the graphene solution, and add the carbon precursor-phenolic resin at a ratio of...

Embodiment 3

[0031] A preparation method of graphene-doped and coated graphite composite negative electrode material, comprising the following steps:

[0032] (1) Prepare 8 mg / mL graphene oxide aqueous solution, pour 40 mL 8 mg / mL graphene oxide aqueous solution into a 50 mL stainless steel reaction kettle with polytetrafluoroethylene as the liner, seal and place in a blast drying oven React at 150°C for 16 hours, then naturally cool the reaction vessel to room temperature, absorb the water in the solution with filter paper to dryness, and place the obtained powder in a vacuum drying oven to fully dry to obtain a graphene material. The specific surface of graphene material is at 1850 m 2 / g;

[0033] (2) Under stirring conditions, according to graphene: natural graphite (D50: 8.14μm, specific surface area: 6.9m 2 / g, tap density: 1.04g / cm 3) with a mass ratio of 0.08:1, mix the graphite evenly in the graphene solution, and add the carbon precursor-polyvinyl alcohol at a ratio of 7% by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com