Preparation method of nitrogen and phosphorus co-doped carbon-coated graphite anode material

A graphite negative electrode and co-doping technology, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of affecting the low-temperature charging ability of the battery, the decline of lithium insertion ability of graphite, and low activity, and is suitable for large-scale Production, easy promotion and application, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of nitrogen-phosphorus co-doped carbon-coated graphite negative electrode material, comprising the following steps:

[0020] (1) Coating: Weigh graphite and ionic liquid, add them to a high-speed mixer, and disperse for 1 hour at a speed of 5000r / min. After the treatment is completed, graphite coated with phosphorus-containing ionic liquid is obtained;

[0021] (2) Carbonization: put the graphite coated with phosphorus-containing ionic liquid into an atmosphere protection furnace for sintering, raise the temperature to 600°C at a rate of 2°C / min and keep it for 18 hours to obtain nitrogen-phosphorus co-doped carbon coating Graphite anode material.

[0022] The graphite is natural graphite, the purity is above 99.999, and the particle size d50=10-20um.

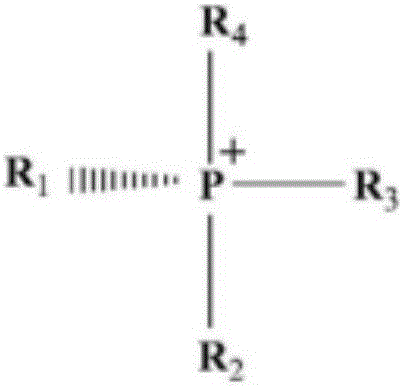

[0023] The cation of the phosphorus-containing ionic liquid is a quaternary phosphonium salt cation, and the structure is as follows:

[0024]

[0025] where: R 1 , R 2 , R 3 , R 4 Each is i...

Embodiment 2

[0031] A preparation method of nitrogen-phosphorus co-doped carbon-coated graphite negative electrode material, comprising the following steps:

[0032] (1) Coating: Weigh graphite and ionic liquid, add them to a high-speed mixer, and disperse for 4 hours at a rotating speed of 500r / min. After the treatment is completed, graphite coated with phosphorus-containing ionic liquid is obtained;

[0033] (2) Carbonization: sintering graphite coated with phosphorus-containing ionic liquid in an atmosphere protection furnace, raising the temperature to 1000°C at a rate of 25°C / min and holding it for 4 hours to obtain nitrogen-phosphorus co-doped carbon coating Graphite anode material.

[0034] The graphite is natural graphite, the purity is above 99.999, and the particle size d50=10-20um.

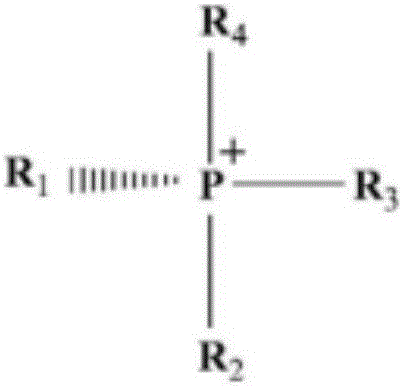

[0035] As a preferred option, the cation of the phosphorus-containing ionic liquid is a quaternary phosphonium salt cation, and the structure is as follows:

[0036]

[0037] where: R 1 , R 2...

Embodiment 3

[0043] A preparation method of nitrogen-phosphorus co-doped carbon-coated graphite negative electrode material, comprising the following steps:

[0044] (1) Coating: Weigh graphite and ionic liquid, add them to a high-speed mixer, and disperse for 2 hours at a rotating speed of 3000r / min. After the treatment is completed, graphite coated with phosphorus-containing ionic liquid is obtained;

[0045] (2) Carbonization: sintering graphite coated with phosphorus-containing ionic liquid in an atmosphere protection furnace, raising the temperature to 8000 °C at a rate of 10 °C / min and holding it for 8 hours to obtain nitrogen-phosphorus co-doped carbon coating Graphite anode material.

[0046] The graphite is natural graphite, the purity is above 99.999, and the particle size d50=10-20um.

[0047] The cation of the phosphorus-containing ionic liquid is a quaternary phosphonium salt cation, and the structure is as follows:

[0048]

[0049] where: R 1 , R 2 , R 3 , R 4 Each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com