Graphite anode material for lithium ion batteries and preparation method thereof

A lithium-ion battery, graphite negative electrode technology, applied in the direction of battery electrodes, graphite, chemical instruments and methods, etc., can solve the problems of poor fast charging performance of artificial graphite, poor fast charging performance, large cycle expansion, etc., to improve fast charging performance , low cost, high efficiency for the first time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

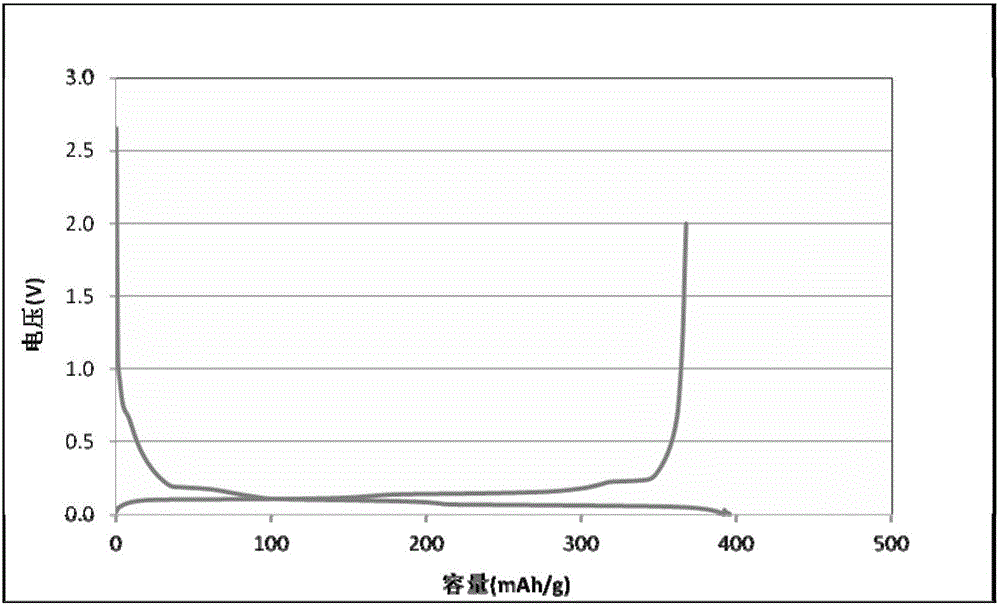

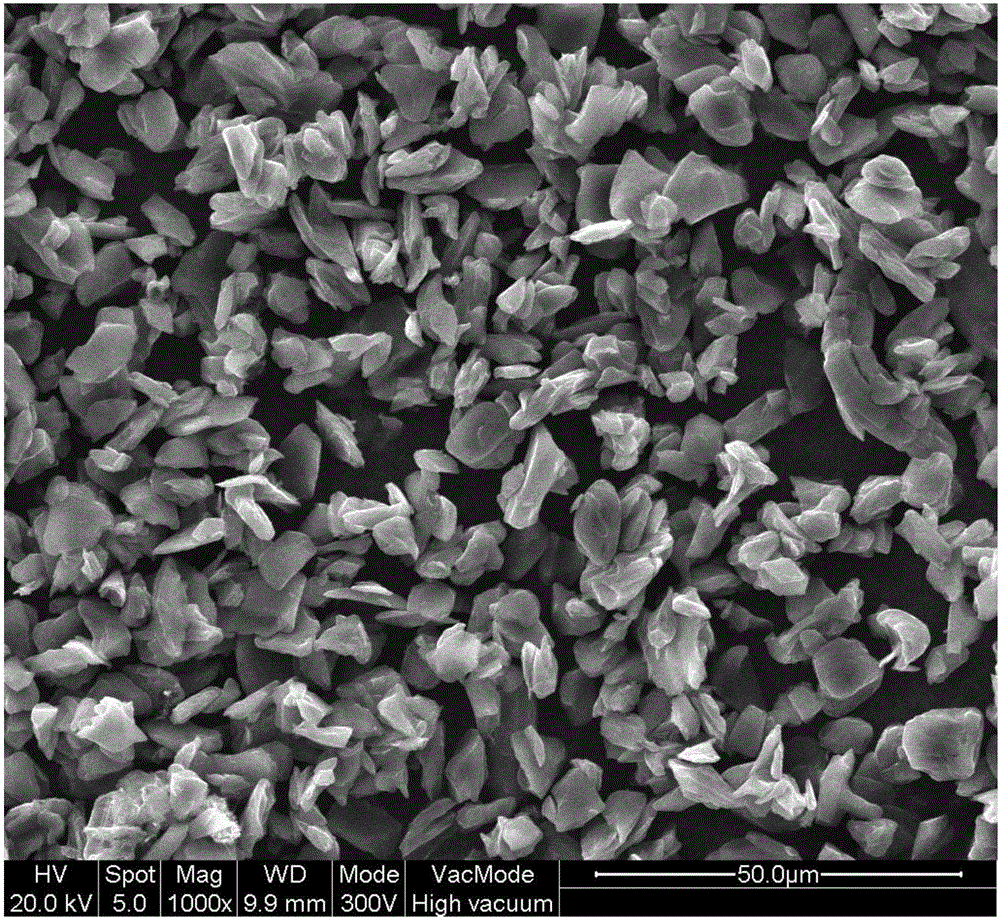

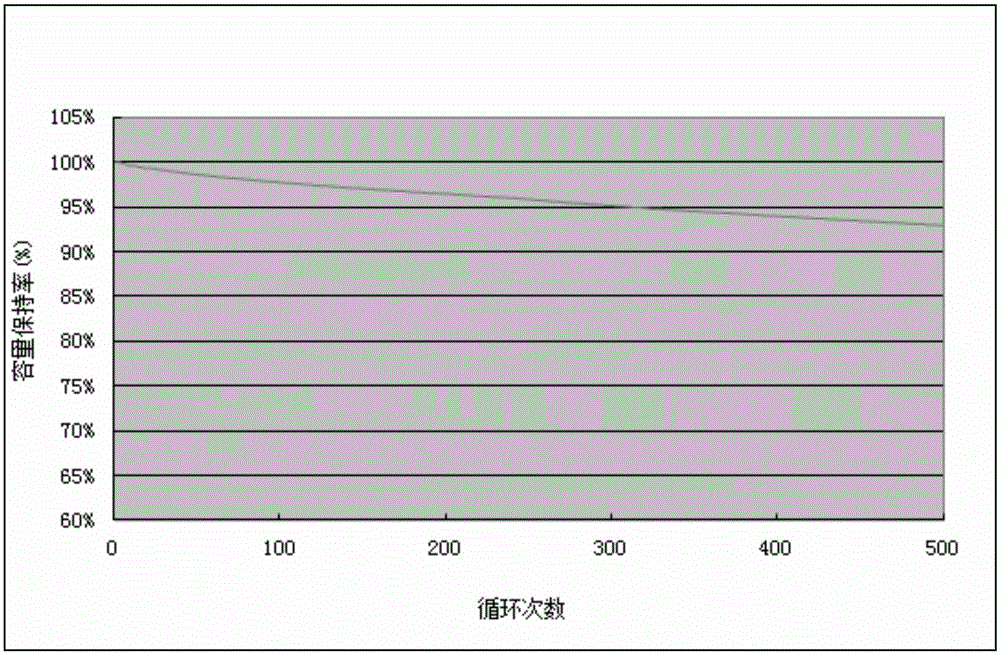

[0037] First, the petroleum coke is pulverized, and the true density of petroleum coke is 1.5g / cm 3 , the volatile content is 5%, and the specific surface area is 3.8m 2 / g, the ash content was 1.0%, and the particle diameter D50 after pulverization was 10.2 μm. Then, the pulverized petroleum coke and petroleum asphalt are coated and modified according to the mass ratio of 94:6. The coating modification temperature is: from 30°C to 500°C, the heating rate is 3°C / min, and the temperature is constant at 500°C 2h. Then, the coated and modified material is subjected to graphitization treatment, and the graphitization treatment temperature is 2800°C. Then, the graphitized material was screened with 300 meshes, and then fused with petroleum pitch at a mass ratio of 95:5. The fused frequency was 30 Hz, and the fused time was 10 minutes. Then carry out vacuum carbonization treatment, the temperature of vacuum carbonization treatment is: start from 30°C to 1300°C, the heating rate i...

Embodiment 2

[0039] First, the petroleum coke is pulverized, and the true density of petroleum coke is 1.5g / cm 3 , the volatile content is 5%, and the specific surface area is 3.8m 2 / g, the ash content was 1.0%, and the particle diameter D50 after pulverization was 10.2 μm. Then, the pulverized petroleum coke and petroleum asphalt are coated and modified according to the mass ratio of 94:6. The coating modification temperature is: from 30°C to 500°C, the heating rate is 3°C / min, and the temperature is constant at 500°C 2h. Then, the coated and modified material is subjected to graphitization treatment, and the graphitization treatment temperature is 3000°C. Then, the graphitized material was screened with 300 meshes, and then fused with petroleum pitch at a mass ratio of 95:5. The fused frequency was 25 Hz, and the fused time was 15 minutes. Then carry out vacuum carbonization treatment, the temperature of vacuum carbonization treatment is: start from 30°C to 1300°C, the heating rate is...

Embodiment 3

[0041] First, the petroleum coke is pulverized, and the true density of petroleum coke is 1.5g / cm 3 , the volatile content is 5%, and the specific surface area is 3.8m 2 / g, the ash content is 1.0%, and the particle diameter D50 after pulverization is 8.0 μm. Then, the pulverized petroleum coke and petroleum asphalt are coated and modified according to the mass ratio of 92:8. The coating modification temperature is: from 30°C to 500°C, the heating rate is 3°C / min, and the temperature is constant at 500°C 2h. Then, the coated and modified material is subjected to graphitization treatment, and the graphitization treatment temperature is 2800°C. Then, the graphitized material was screened with 300 meshes, and then fused with petroleum pitch at a mass ratio of 94:6. The fused frequency was 35 Hz, and the fused time was 10 minutes. Then carry out vacuum carbonization treatment, the temperature of vacuum carbonization treatment is: start from 30°C to 1300°C, the heating rate is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com