Spherical low-expansion high-capacity graphite anode material, preparation method and lithium ion battery

A graphite negative electrode and low-expansion technology, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of adverse effects on processing performance, low specific capacity, poor economy, etc., and achieve easy control of material quality and minimum spheroidization orientation The effect of increasing the degree of isotropy and isotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

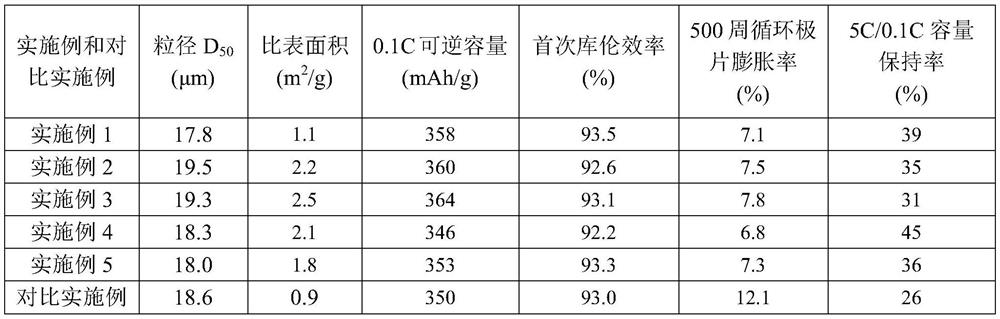

Embodiment 1

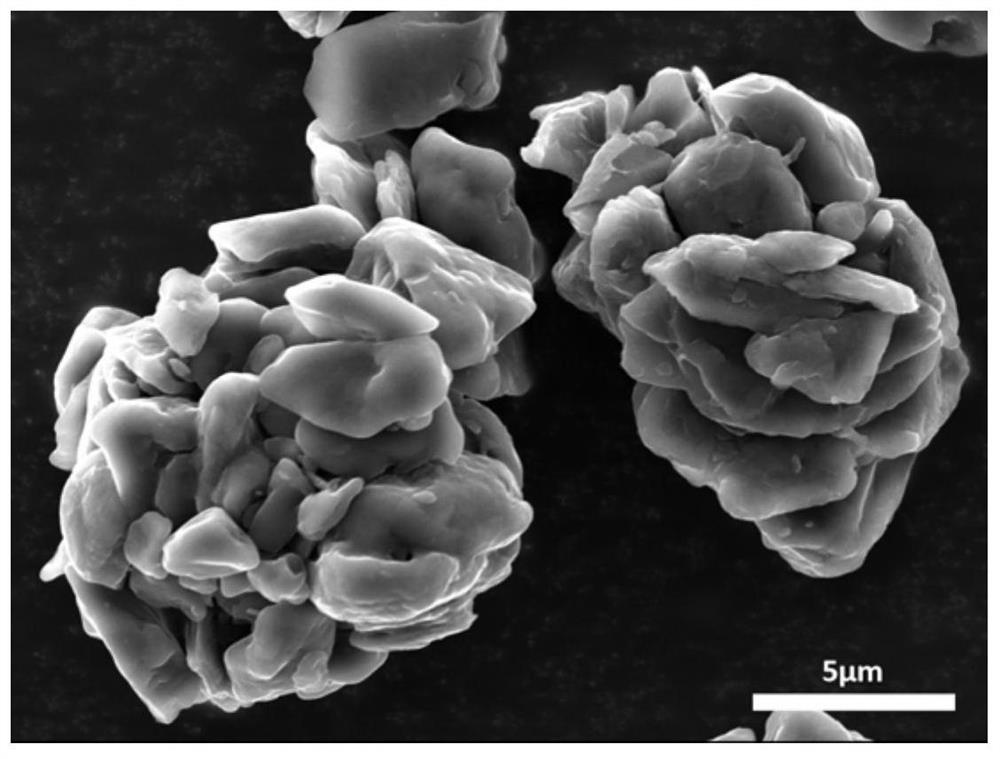

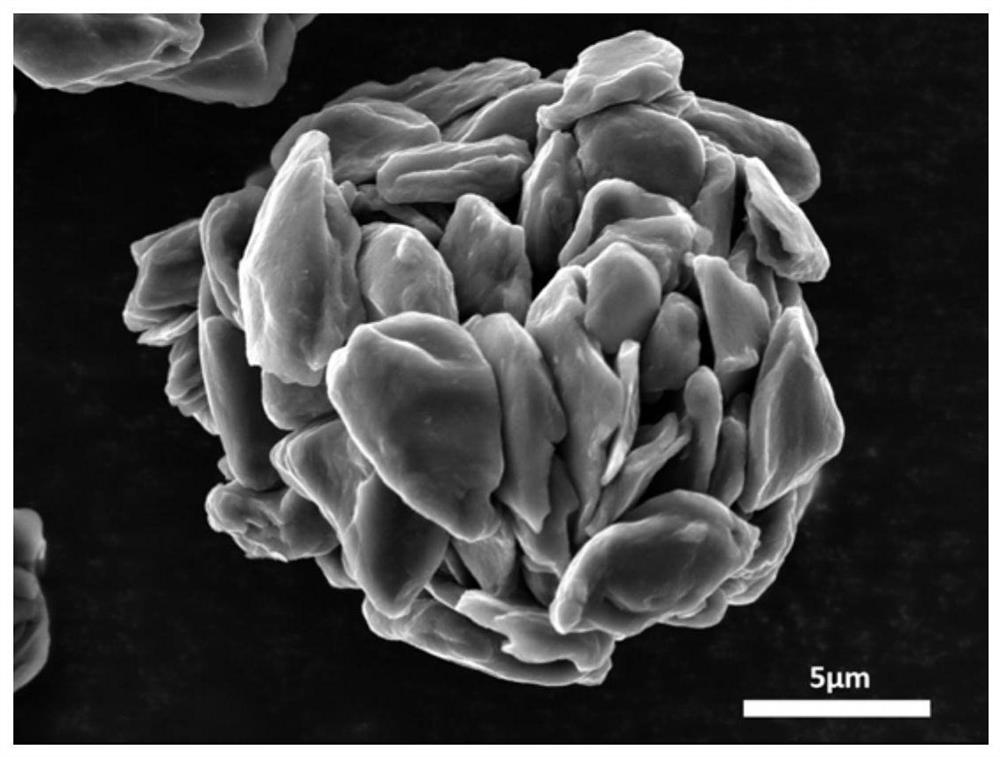

[0027] Petroleum coke with a volatile content of 5% is processed by a mechanical grinding-shaping integrated machine to obtain a primary particle A with an average particle size D50 of 7.5 μm, which contains 25% medium-temperature emulsified pitch and 4.5% cetyl trimethyl bromide The aqueous solution of ammonium (both mass fractions) and the primary particle A are put into the high-speed mixer at a mass ratio of 30:100, and stirred for 20min at a speed of 600rpm (linear velocity greater than 3m / s); then add 6% cracking oil slurry, 1.5% Tween-80, 0.5% AlCl3 (both mass fractions, relative to primary particle A) continue to stir with 800rpm rotating speed for 20min to obtain precursor B; under nitrogen protection, the temperature of precursor B is raised to Heat preservation at 600°C for 4 hours, then graphitize at 3000°C for 24 hours, discharge and sieve to obtain spherical graphite negative electrode material.

Embodiment 2

[0029] The needle coke with a volatile content of 5% is processed by a mechanical grinding-shaping integrated machine to obtain a primary particle A with an average particle diameter D50 of 7.5 μm, which will contain 35% sucrose and 4.5% Tween-20 (both mass fractions) The aqueous solution and the primary particle A are put into the high-speed mixer at a mass ratio of 35:100, and stirred for 20min at a speed of 600rpm (the linear velocity is greater than 3m / s); then add 8% washing oil (mass fraction, relative to the primary particle A ) continue to stir at 800rpm for 20min to obtain precursor B; under the protection of nitrogen, raise the temperature of precursor B to 600℃ at 5℃ / min for 4 hours, and then graphitize at 3000℃ for 24 hours, and the material is sieved A similar spherical graphite anode material was obtained.

Embodiment 3

[0031] The needle coke with a volatile content of 0.5% is processed by a rolling mill-shaping integrated machine to obtain a primary particle A with an average particle diameter D50 of 8.5 μm, which will contain 35% sucrose and 4.5% Tween-20 (both mass fractions ) and the primary particle A are put into a high-speed mixer at a mass ratio of 30:100, and stirred for 20min at a speed of 600rpm (the linear velocity is greater than 3m / s); then add 8% vegetable oil (mass fraction, relative to the primary particle A ) continue to stir at 800rpm for 20min to obtain precursor B; under the protection of nitrogen, raise the temperature of precursor B to 600℃ at 5℃ / min for 4 hours, and then graphitize at 3000℃ for 24 hours, and the material is sieved A similar spherical graphite anode material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com