Efficient selectable pyrolysis system and using method thereof

A pyrolysis and high-efficiency technology, applied in special forms of dry distillation, petroleum industry, biofuels, etc., can solve the problems of poor quality of finished charcoal, low production efficiency, low heating efficiency, etc., and achieve good quality, high heating efficiency, and pyrolysis good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1: This embodiment is only heated to the stage of pyrolysis and carbonization, mainly to obtain finished charcoal:

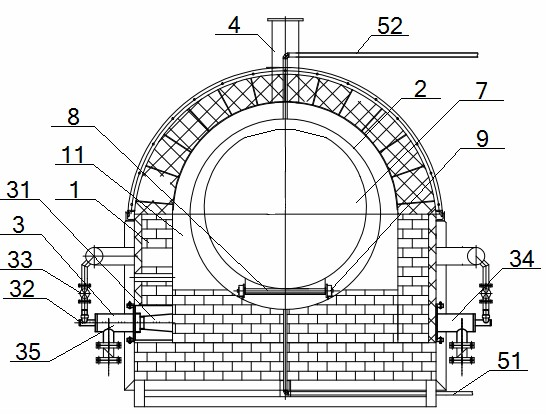

[0086] A high-efficiency optional pyrolysis system, including a furnace body 1, a dry distillation furnace 2, a gas nozzle 3 and a cooling device 5, a dry distillation furnace 2 is arranged in a furnace chamber 11 in the furnace body 1, and the dry distillation furnace 2 is horizontal Arrangement, including an upper side 21, a lower side 22, a top 23 and a bottom 24, the upper side 21 and the lower side 22 are located between the top 23 and the bottom 24, and the upper side 21 is close to the top The position of 23 communicates with one end of the exhaust pipe 4, and the other end of the exhaust pipe 4 is connected with the release valve 41 positioned at the outside of the body of heater 1 after the body of heater 1, and the position near the exhaust pipe 4 on the body of heater 1 is provided with The thermometer 6 communicating with the furnac...

Embodiment 2

[0094] Embodiment 2: This embodiment continues heating to the calcination stage, mainly to obtain biomass gas:

[0095] The basic content is the same as in Example 1, except that the method of use also includes a calcination stage between the pyrolysis carbonization stage and the cooling charcoal collection stage, and the calcination stage is an endothermic reaction;

[0096] The calcination stage refers to: when the pyrolysis and carbonization stage ends, continue to heat the retort 2, and enter the calcination stage when the temperature in the furnace chamber 11 is observed to rise to 500°C from the thermometer 6. In the calcination stage, the finished charcoal A reduction reaction occurs, and the reaction equation is C+CO 2 =2CO, C+H 2 O=H 2 + CO, and collect the gas produced in the calcination stage through the exhaust pipe 4. When the temperature in the furnace chamber 11 is observed from the thermometer 6 to rise to the set temperature, the calcination stage ends, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com