Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Uniform carbonization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

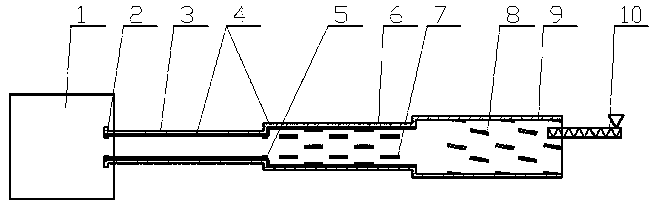

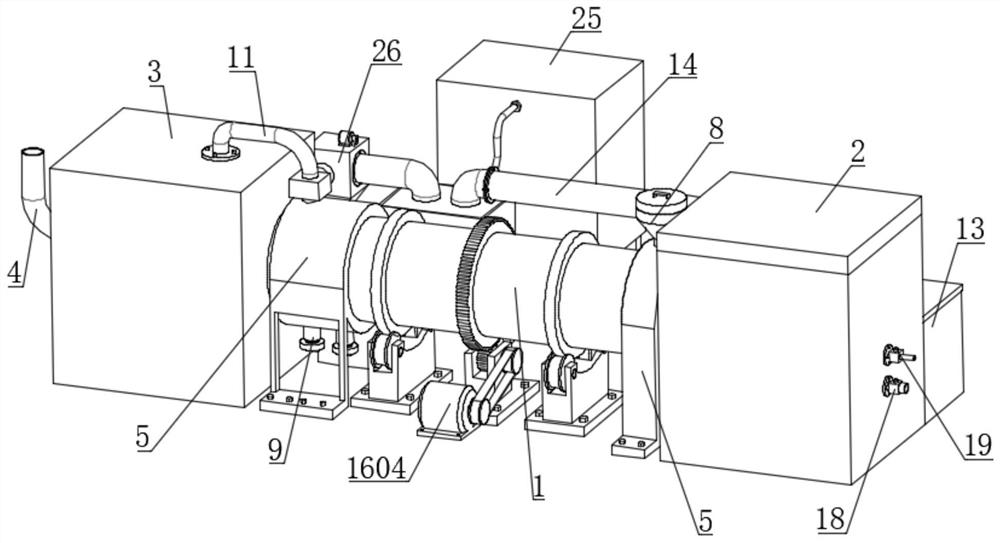

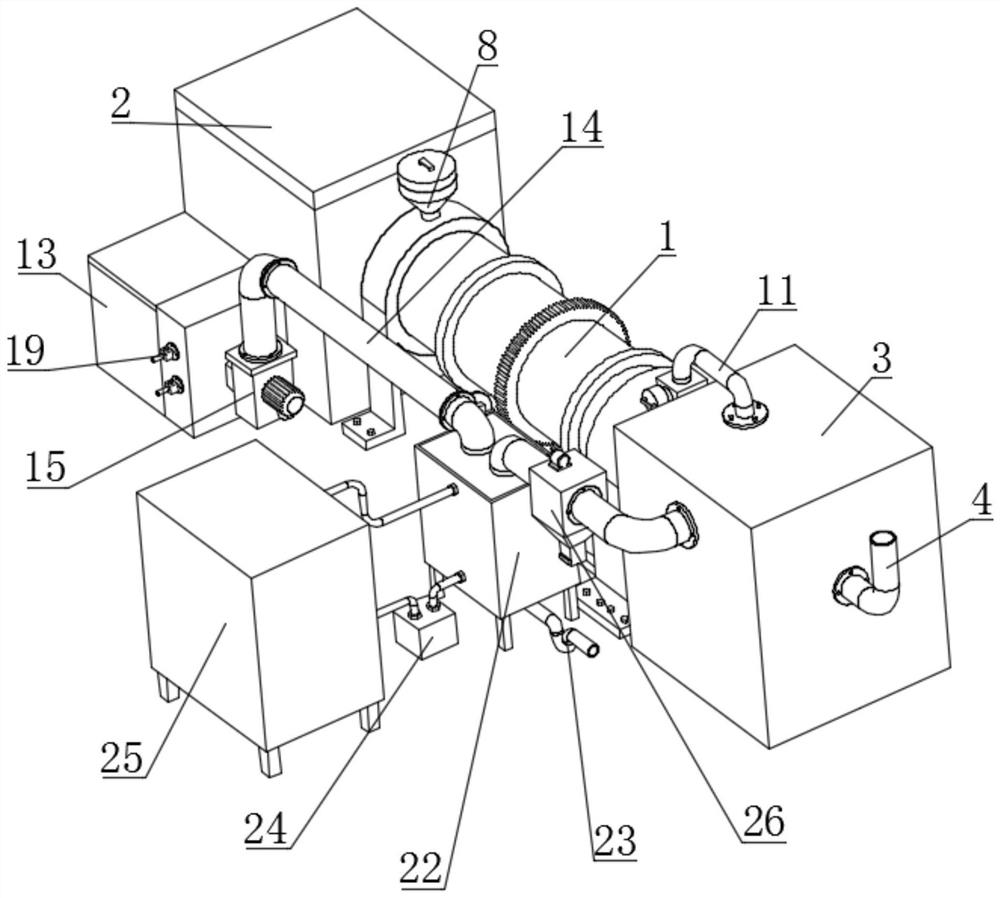

Efficient selectable pyrolysis system and using method thereof

ActiveCN102634358AGood value for moneyImprove adjustabilityBiofuelsSpecial form destructive distillationNitrogenProcess engineering

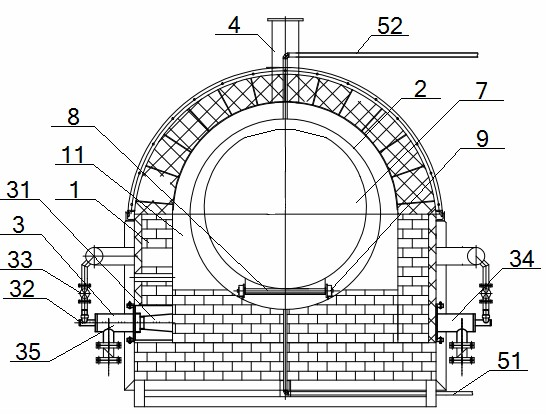

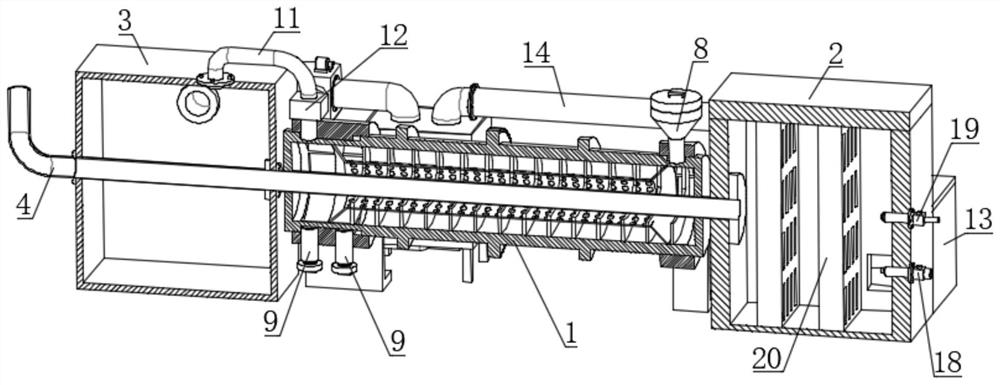

The invention discloses an efficient selectable pyrolysis system and a using method thereof, wherein the efficient selectable pyrolysis system comprises a furnace body, a dry distillation kettle, gas nozzles and a cooling device, wherein a furnace chamber in the furnace body is internally provided with the horizontally-arranged dry distillation kettle, wherein the dry distillation kettle comprises an upper side part, a lower side part, a kettle top and a kettle bottom; the part on the upper side part close to the kettle top is communicated with an exhaust pipe; the other end of the exhaust pipe is connected with a diffusion valve; the part on the furnace part close to the exhaust pipe is provided with a temperature meter communicated with the furnace chamber; the lower part of the lower side part is communicated with gas outlets of four staggered gas nozzles; the gas outlets of the gas nozzles are connected with a control valve; the cooling device comprises a nitrogen intake pipe and a nitrogen exhaust pipe, wherein the nitrogen intake pipe is communicated with the kettle top; the nitrogen exhaust pipe is communicated with the upper side part; and when the efficient selectable pyrolysis system is used, if carbon production is emphasized the heating is finished to pyrolysis carbonization stage, and if biomass gas production is emphasized, the heating is finished to the forging stage. The design not only has good adjustability, high cost performance and high heating efficiency, but also the finished product carbon has good quality and high production efficiency.

Owner:武汉天颖环境工程股份有限公司

Preparation method of black pottery artware

The purpose of the invention is to provide a preparation method of a black pottery artware. First, blank material yellow clay is selected, and processes of crushing, deposition, mud extruding, and fermentation are carried out on the yellow clay to obtain black pottery mud. Then, moulding processing is carried out on the black pottery raw material, and after the processes of shade drying, shape modification, polishing, painting, engraving, polishing once again and shade drying are carried out on an unburned earthenware body, surface treatment is carried out on the unburned earthenware body. Finally, the unburned earthenware body is put into a kiln special for black pottery sintering to carry out sintering, and the sintering process comprises preheating, heating, cooling, smoke drawing, kiln closing, and kiln moistening. In sintering, both the surface and the interior of the unburned earthenware body of the black pottery artware sintered in the invention can be carbonized uniformly, and present a black color. Fine channels favor the penetration of soot, so that the black pottery artware is pitch black and bright from inside to outside, has a natural, smooth, and non-fading color, and has no peculiar smell of asphalt or impurities. In addition, the preparation method of the invention has short sintering time, and saves both energy and labor.

Owner:苏兆起

Carbon powder preparation method

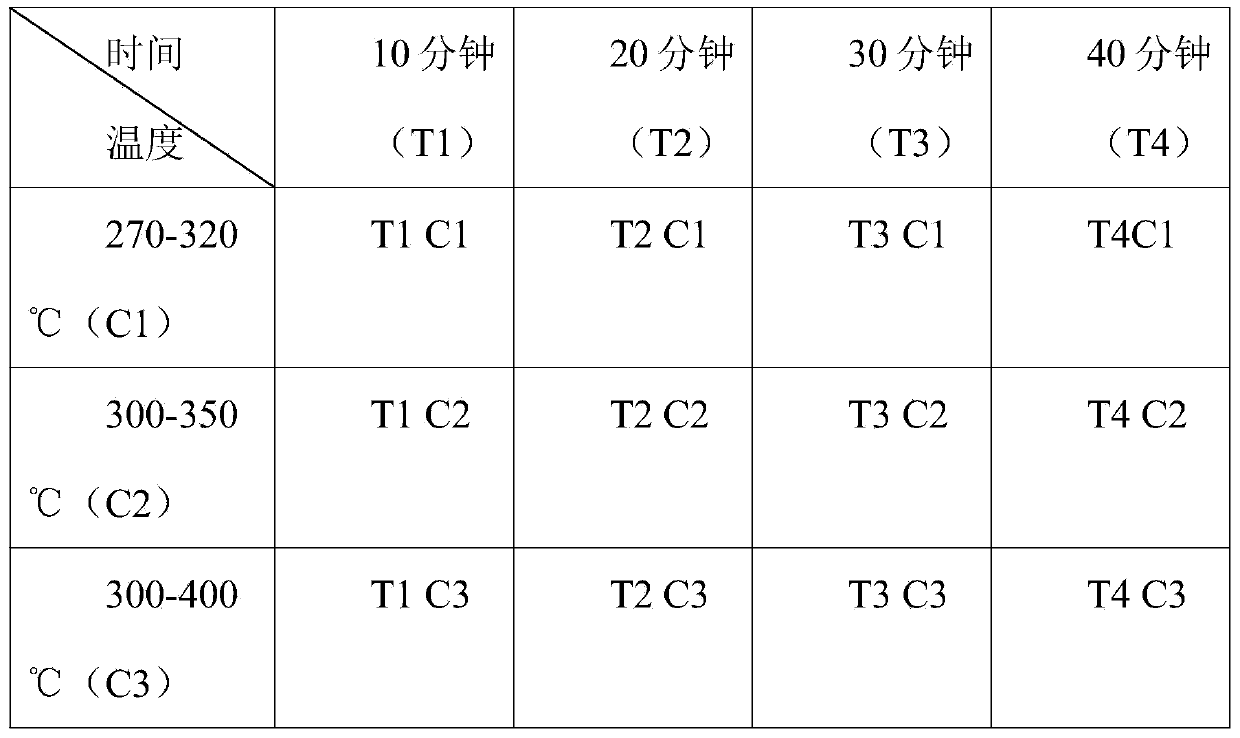

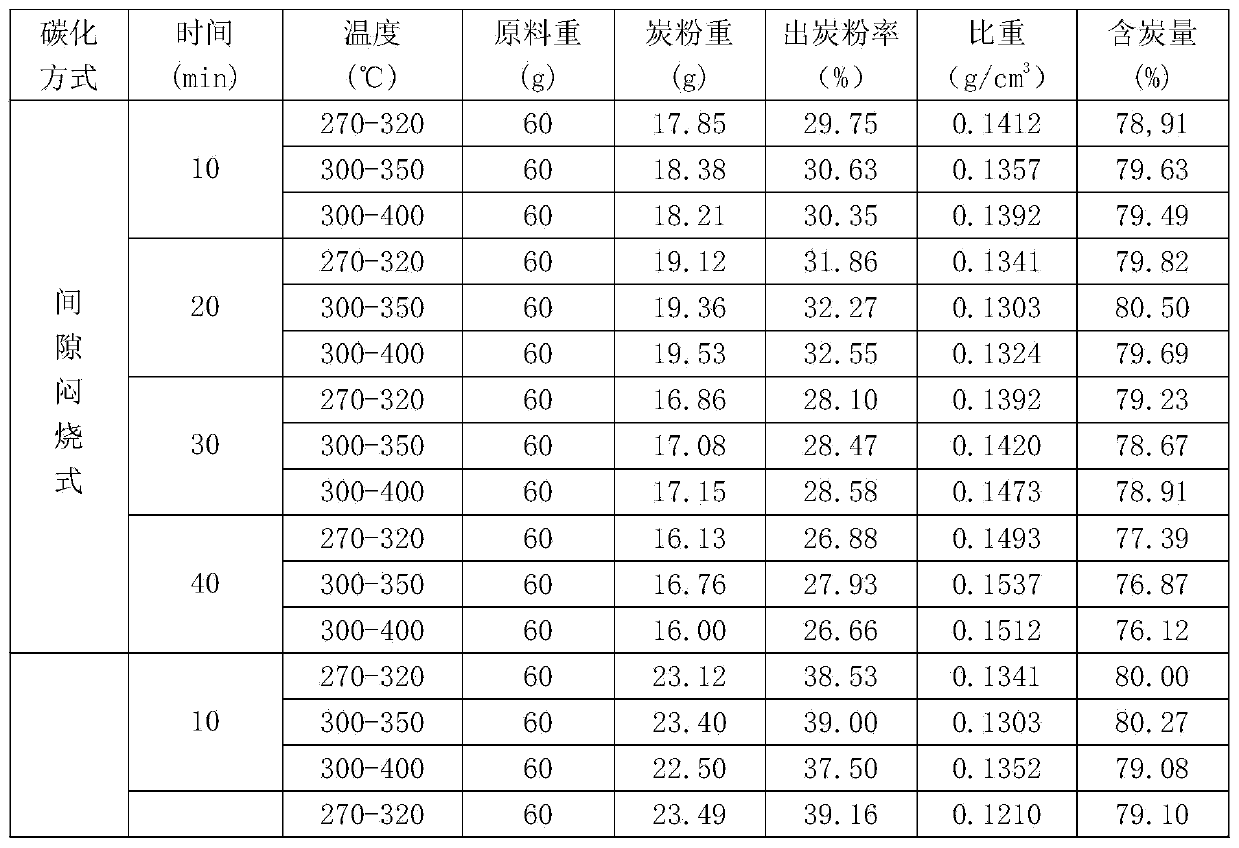

ActiveCN104194811AUniform carbonizationIncrease the rate of charcoal powderBiofuelsSpecial form destructive distillationHigh carbonCarbonization

The invention discloses a carbon powder preparation method which specifically comprises the following steps: drying raw materials, crushing, carbonizing, crushing and packaging, wherein the step of carbonizing adopts a sectional carbonizing mode which comprises three carbonization sections, the temperature of the first section is 200-250 DEG C, the temperature of the second section is 250-300 DEG C, the temperature of the third section is 300-400 DEG C, and the carbonization time is 10-30 minutes. According to the method, the carbonization temperature and the carbonization time of each period are set according to different raw materials, the carbonization uniformity is improved, and the purposes of high carbon powder rate and high quality are achieved at appropriate temperature and time for different raw materials.

Owner:吉林省金福一农业科技有限公司

Method for large-scale on-site production of biochar from crop straws

InactiveCN103265962AReduce investmentReduce manufacturing costBiofuelsSpecial form destructive distillationEngineeringLow oxygen

The invention discloses a method for large-scale on-site production of biochar from crop straws. The method comprises the following steps of building a soil pyrolysis tank in an open space, stacking air-dried crop straws on the soil pyrolysis tank according to a certain dimension, burning the crop straws under the condition of enough oxygen in a short time, and fast covering the burning area by soil so that the fire is extinguished completely, wherein by heat produced by combustion of a small part of biomass, under the conditions of low oxygen content and thermal resistance caused by soil covering, the rest of the biomass can be fast pyrolyzed into high-quality biochar. The biochar obtained by the method has the advantages of high yield, good charing uniformity, high charing level and low smoke production amount.

Owner:ZHEJIANG UNIV

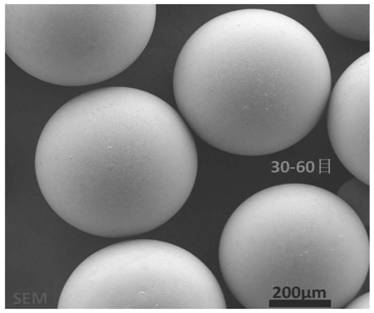

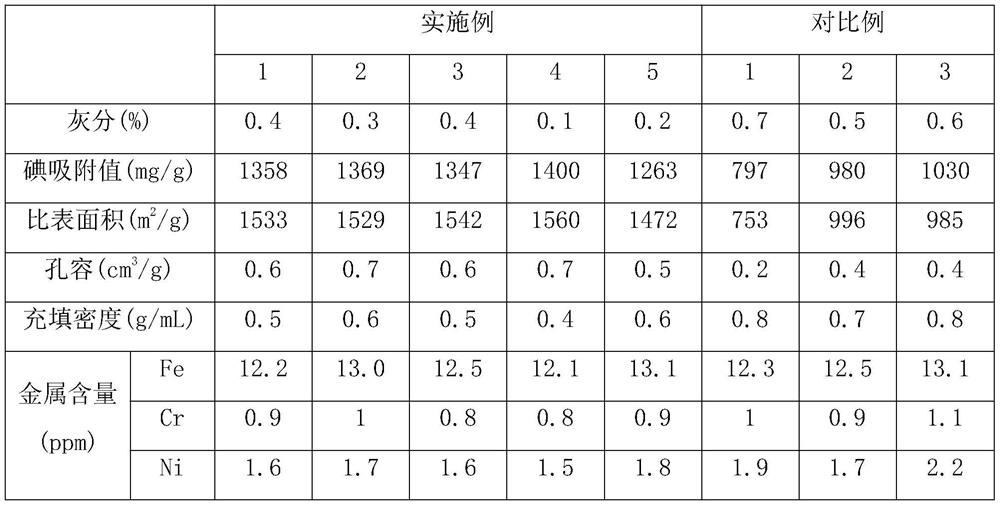

Preparation process of phenolic resin-based spherical activated carbon

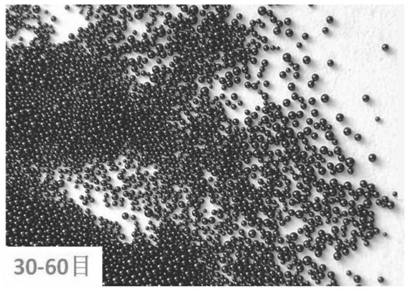

PendingCN111777066AReduced flow rate instabilityImprove performanceCarbon compoundsActivated carbonResin microsphere

The invention relates to the technical field of activated carbon preparation, and particularly discloses a preparation process of phenolic resin-based spherical activated carbon, which comprises the following steps: S1, adding phenol, formaldehyde, a catalyst, a curing agent and a solvent into a reaction kettle, and emulsifying to obtain phenolic resin microspheres; S2, placing the phenolic resinmicrospheres in a rotary furnace, introducing inert gas for protection, increasing the temperature to 150-250 DEG C at the speed of 1-10 DEG C / min, conducting heat preservation for 0-2 h, and completing curing; continuously heating to 600-900 DEG C at the speed of 3-10 DEG C / min under the protection of inert gas, and keeping the temperature for 0-1 hour to finish carbonization; s3, stopping introducing the inert gas, introducing water vapor with the temperature of 200-330 DEG C for activating treatment, and cooling to obtain activated carbon microspheres with mixed particle sizes; and S4, sieving the activated carbon microspheres with the mixed particle size by adopting sieves with different mesh numbers to obtain the phenolic resin-based spherical activated carbon with uniform particle size distribution. The activated carbon microspheres prepared by the preparation method disclosed by the invention are uniform in particle size, low in impurity content and high in adsorbability.

Owner:上海欧亚合成材料股份有限公司

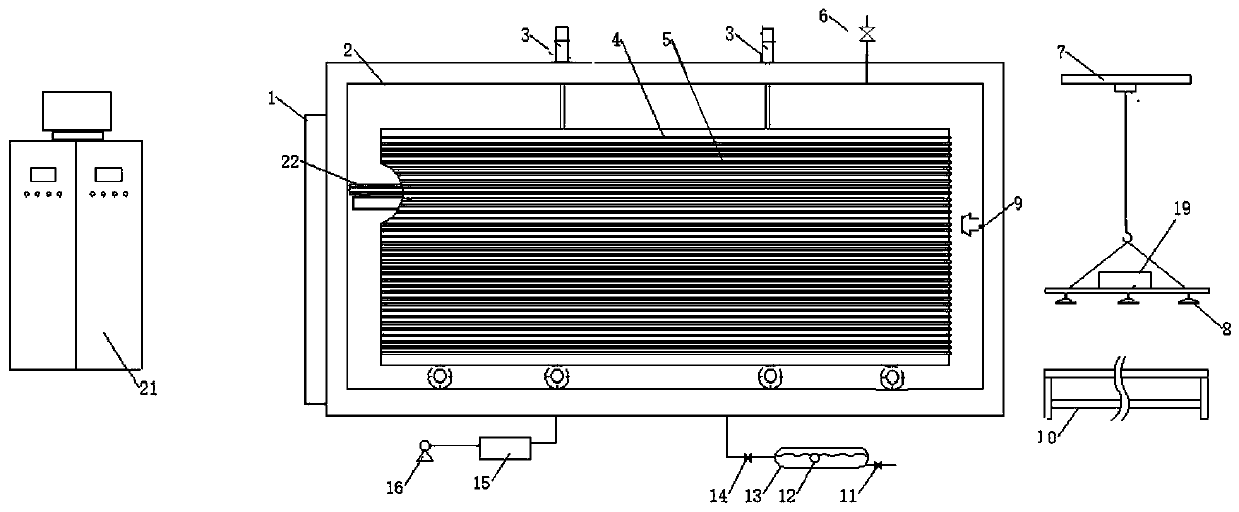

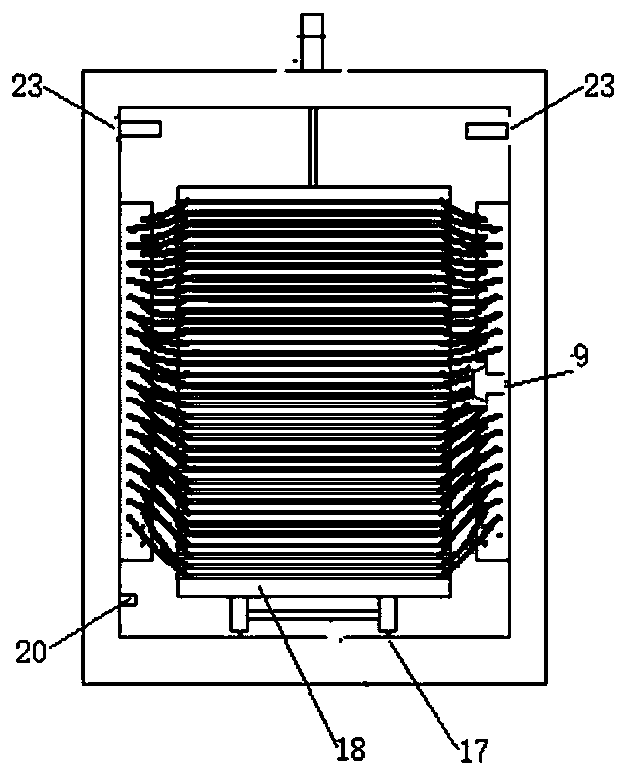

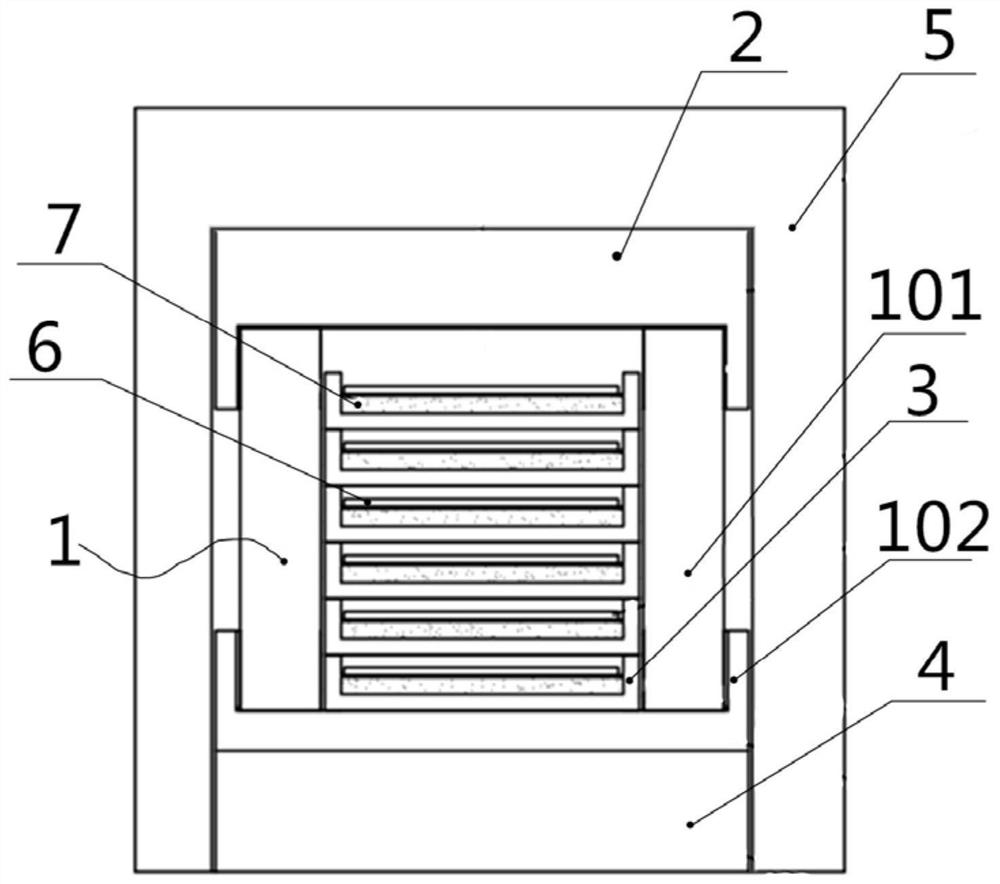

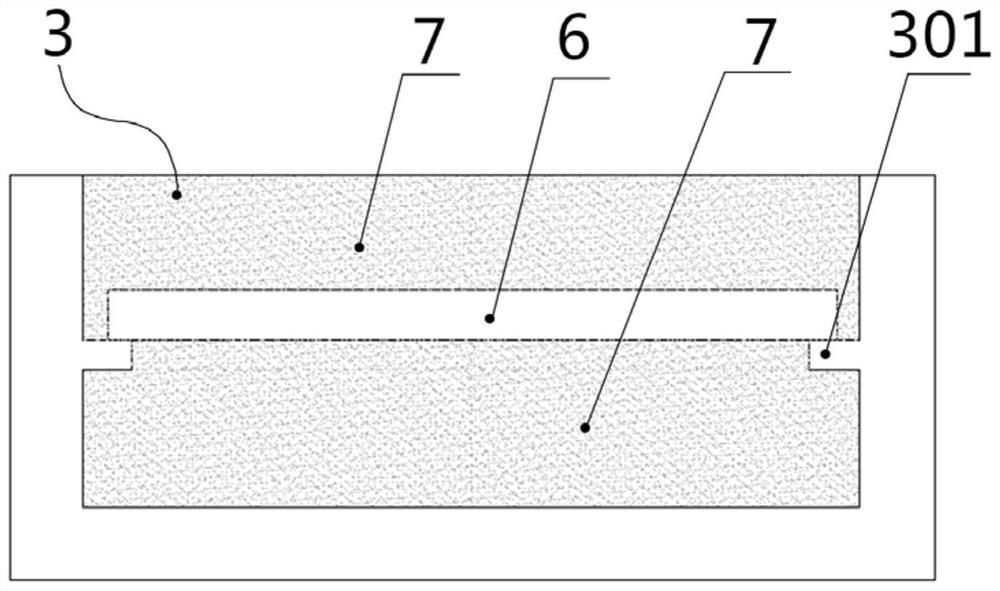

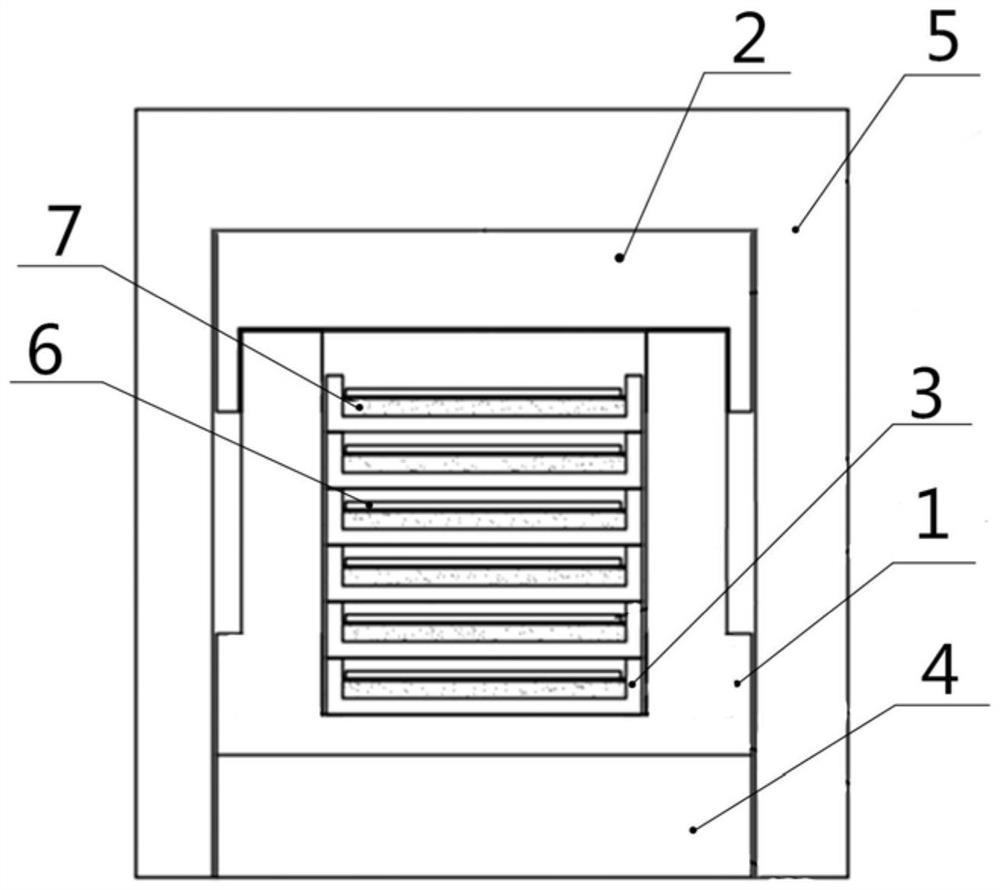

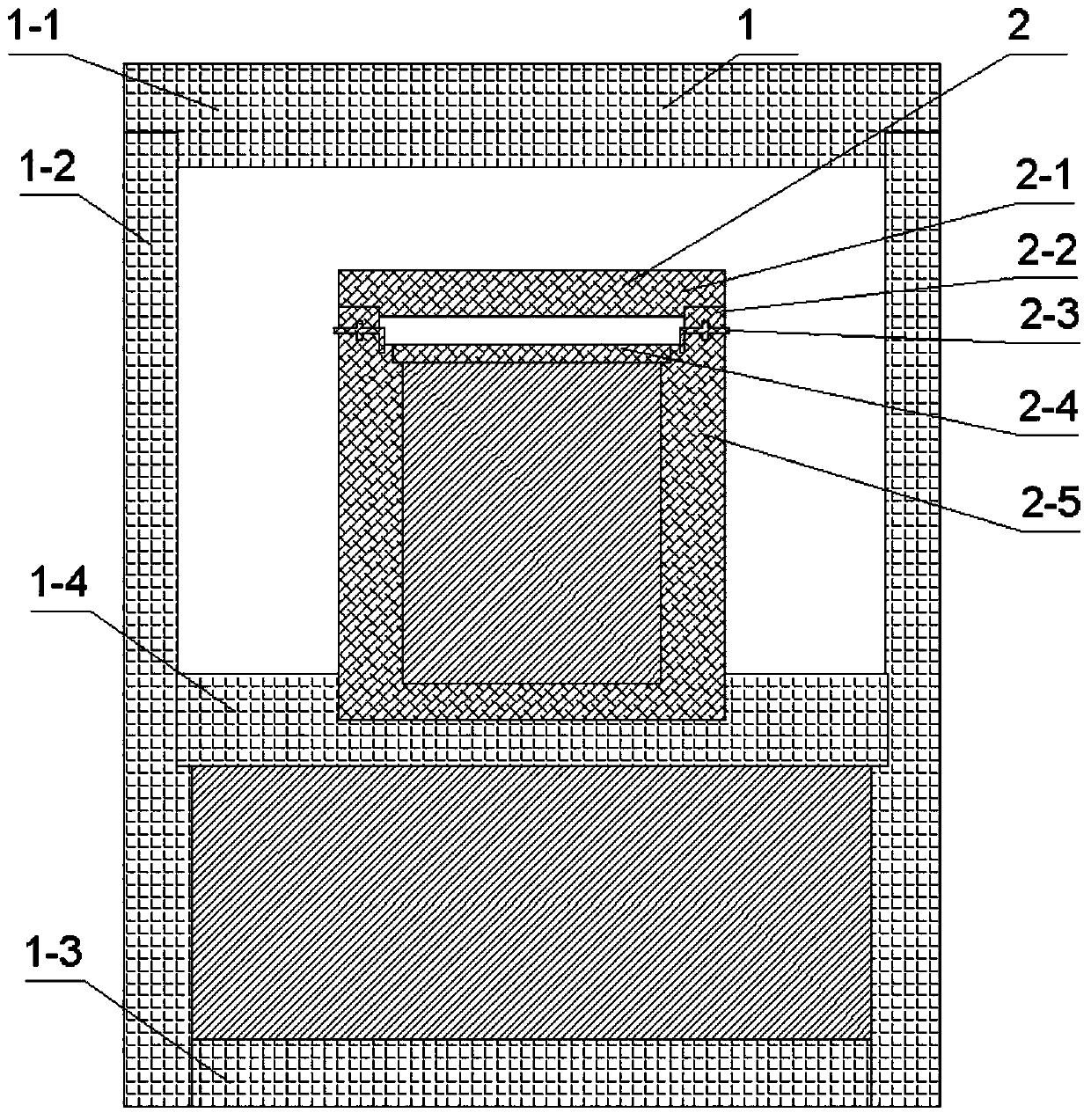

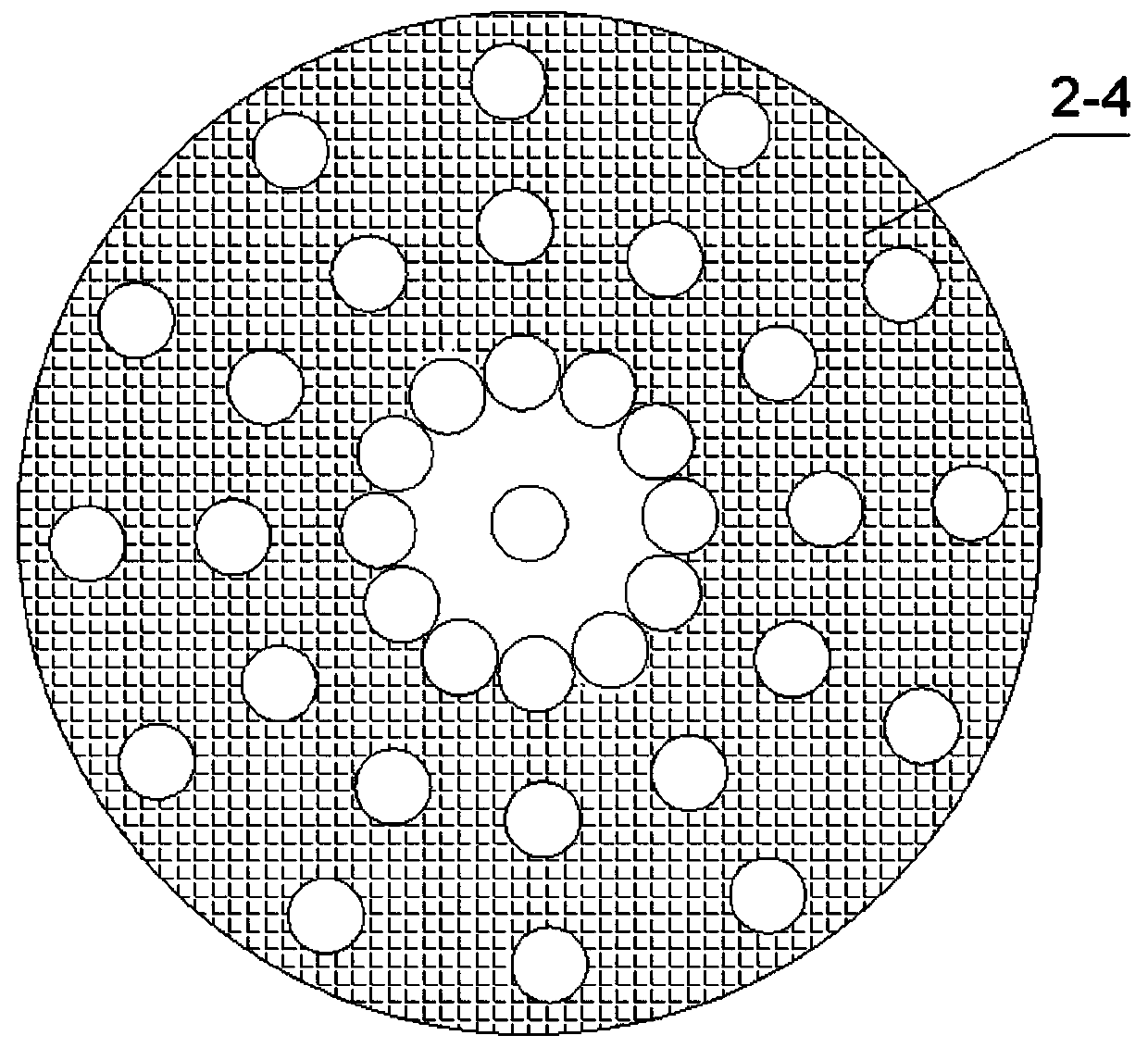

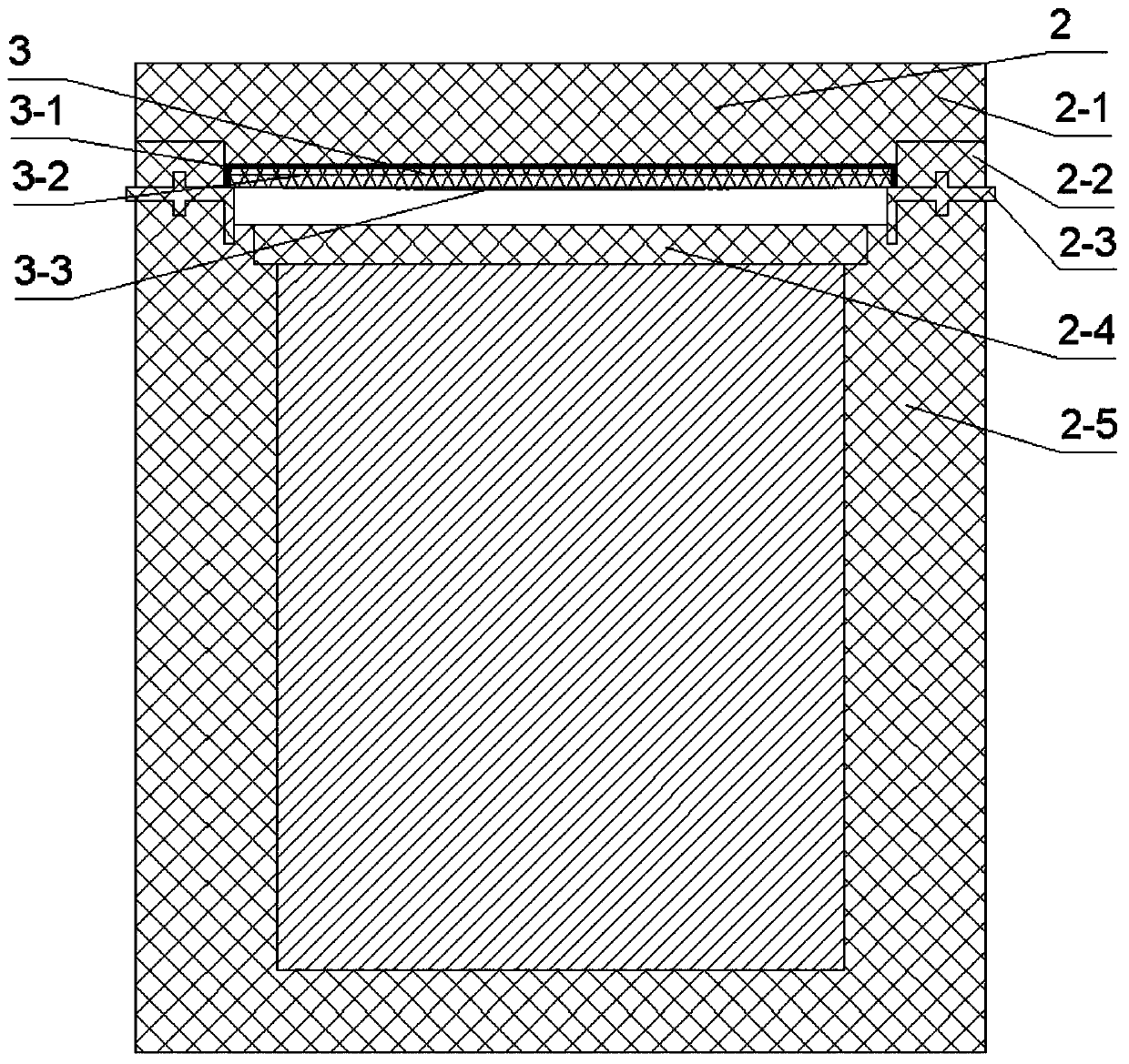

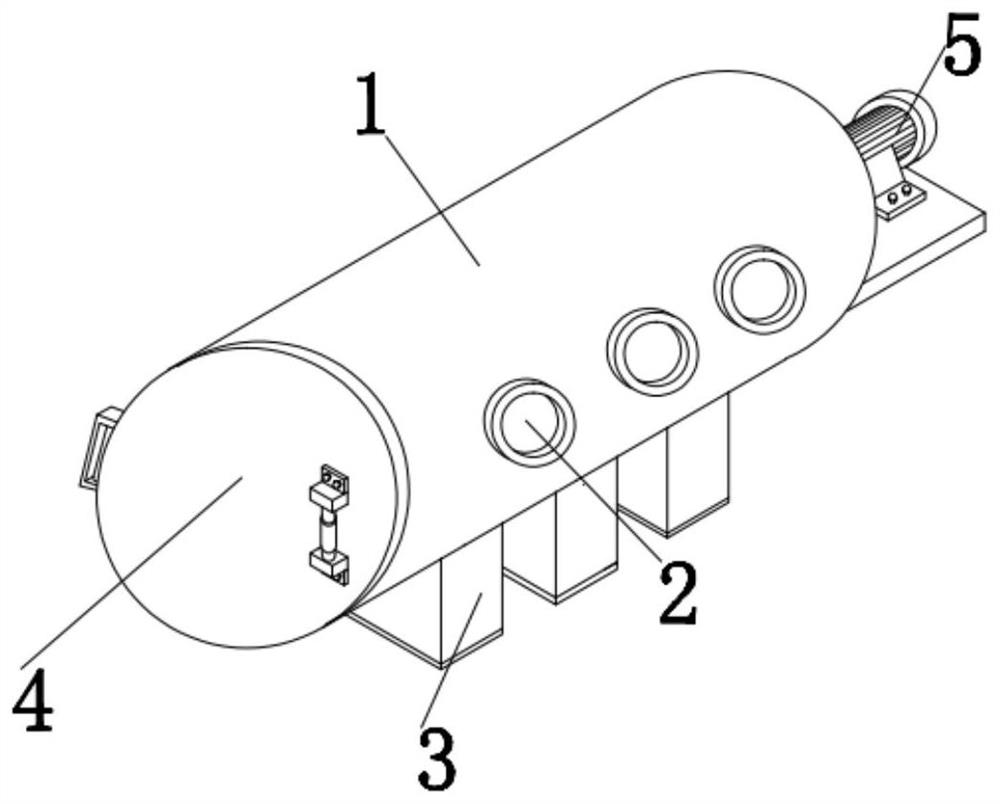

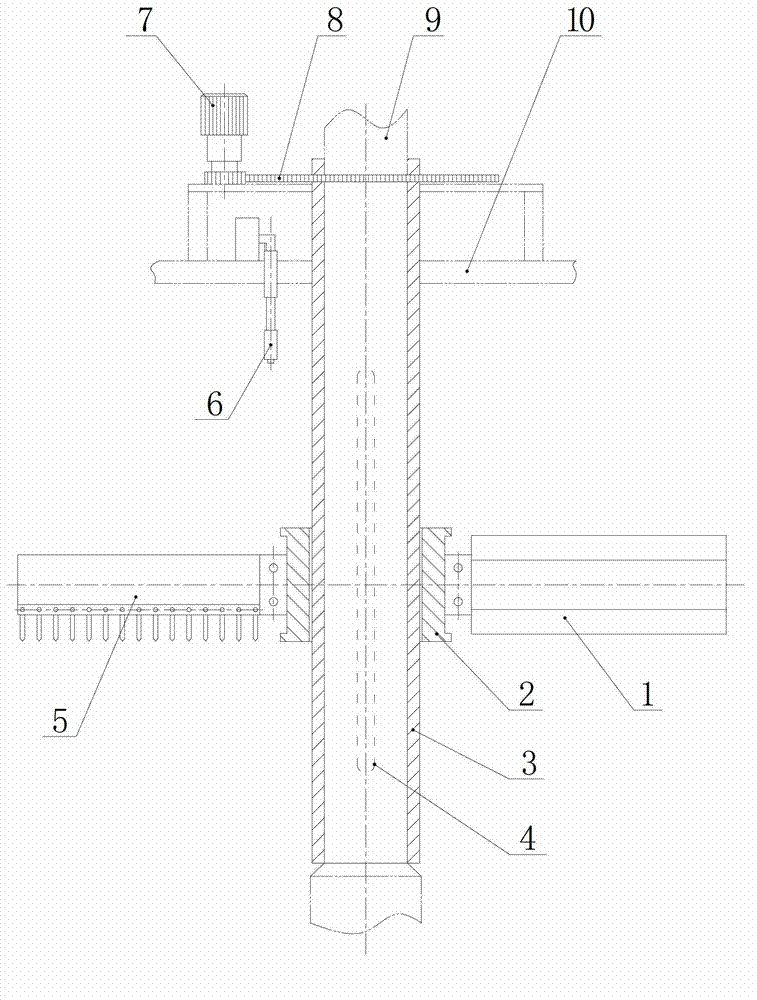

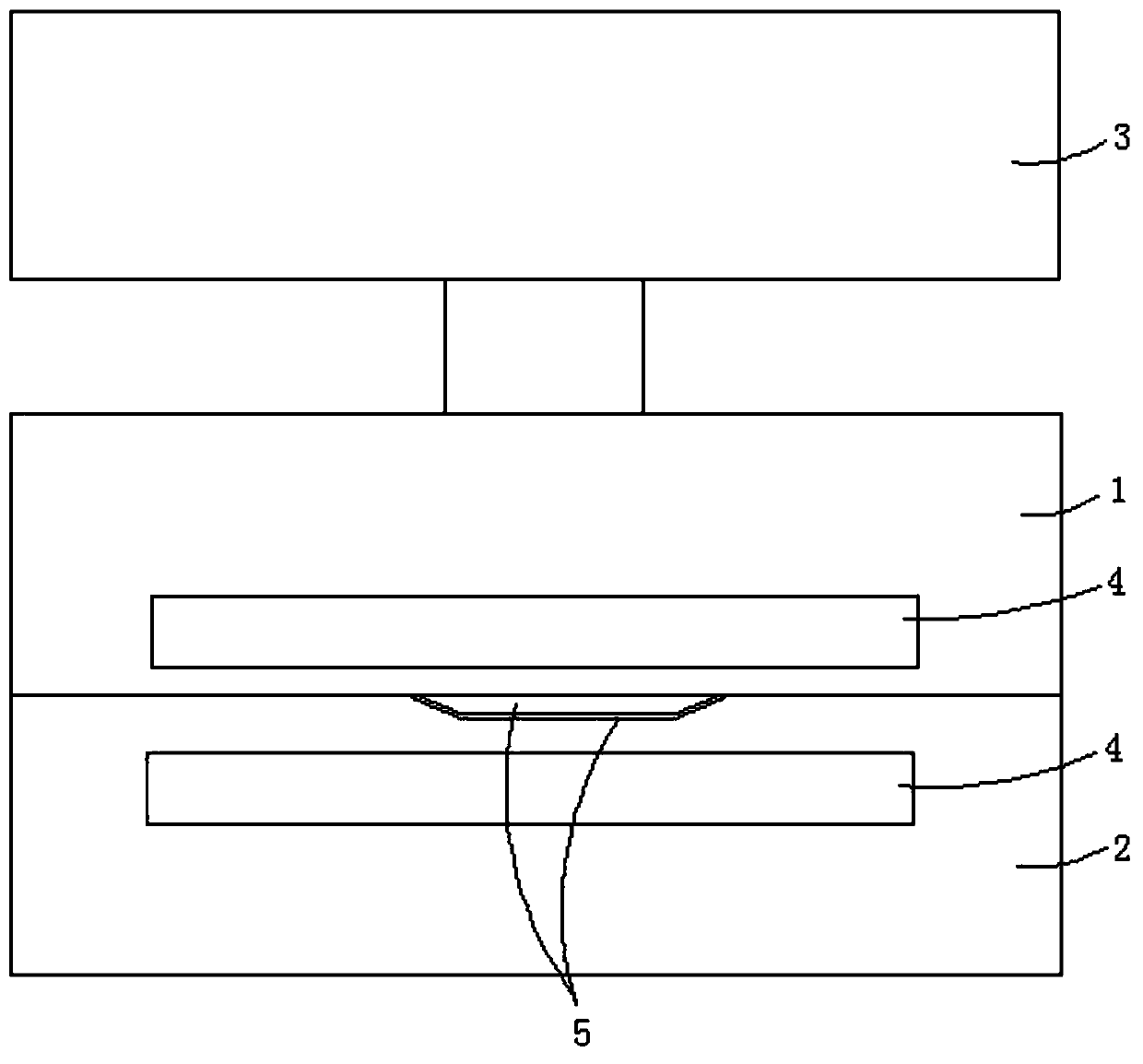

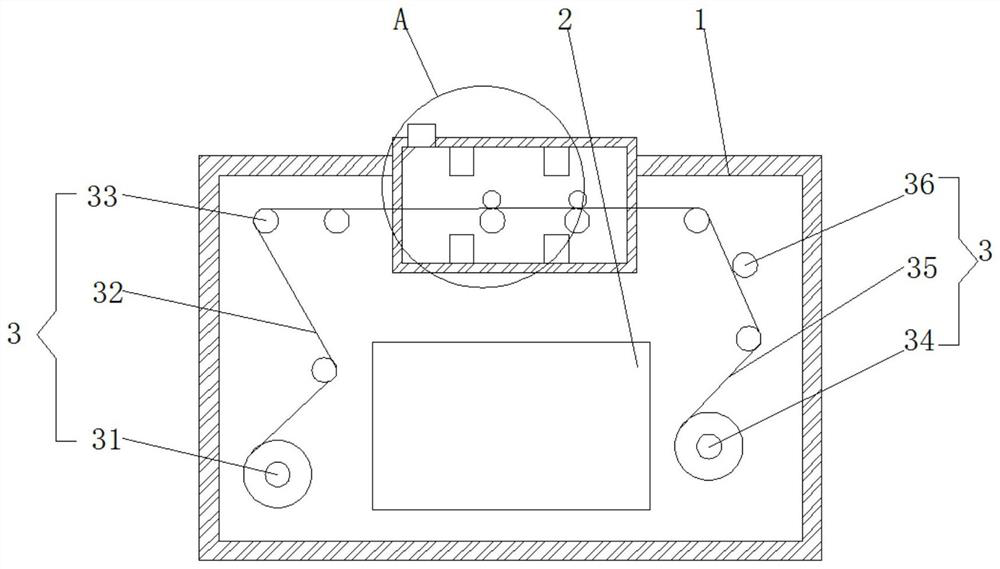

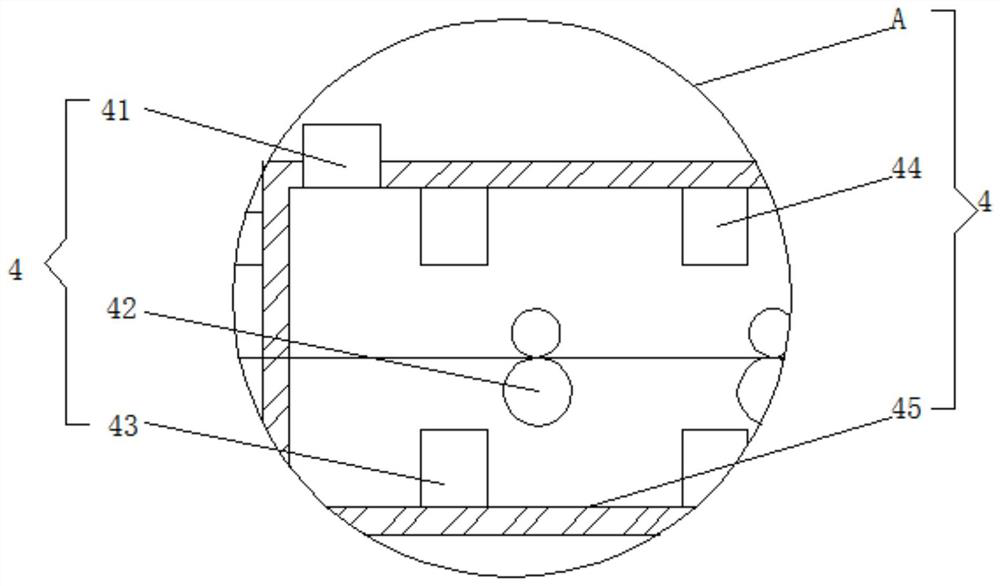

Equipment and method for drying-carbonizing combined treatment of wood material heated by electric heating plate in negative pressure environment

PendingCN111015854AReduce procurement costsReduce multiple reloadsPressure wood treatmentDrying solid materials without heatInsulation layerCarbonization

The invention relates to equipment and a method for drying-carbonizing combined treatment of a wood material heated by an electric heating plate in a negative pressure environment. The treatment equipment comprises a vacuum tank body, a vacuum acquisition device, an in-tank electric heating device, an electric control cabinet and a control device, wherein the vacuum tank body is also provided witha high-pressure fine water atomization humidifying device, the electric heating device in the vacuum tank body consists of a plurality of electric heating plates, and during use, the electric heatingplates and a to-be-processed wood material are alternately placed in parallel to form a stack, the uppermost electric heating plate and the lowermost electric heating plate of the stack are respectively provided with a heat insulation layer, and a hydraulic pressurizing device is arranged on the top of the stack. The wood material treatment method performs wood material processing treatment by using the wood material treatment equipment. According to the wood material treatment equipment and the wood material treatment method, one-time loading of a wood material can be achieved, wood materialdrying and wood material carbonization treatment or wood material drying-carbonization combined treatment can be carried out in the same equipment, and wood material drying and wood material carbonization treatment can be achieved efficiently, rapidly and efficiently in a high-quality mode.

Owner:中山市东成家具有限公司 +1

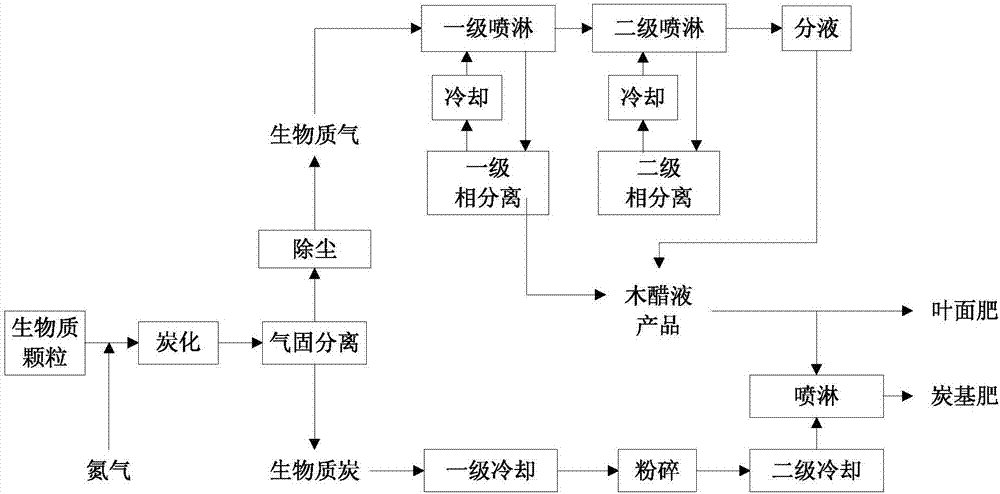

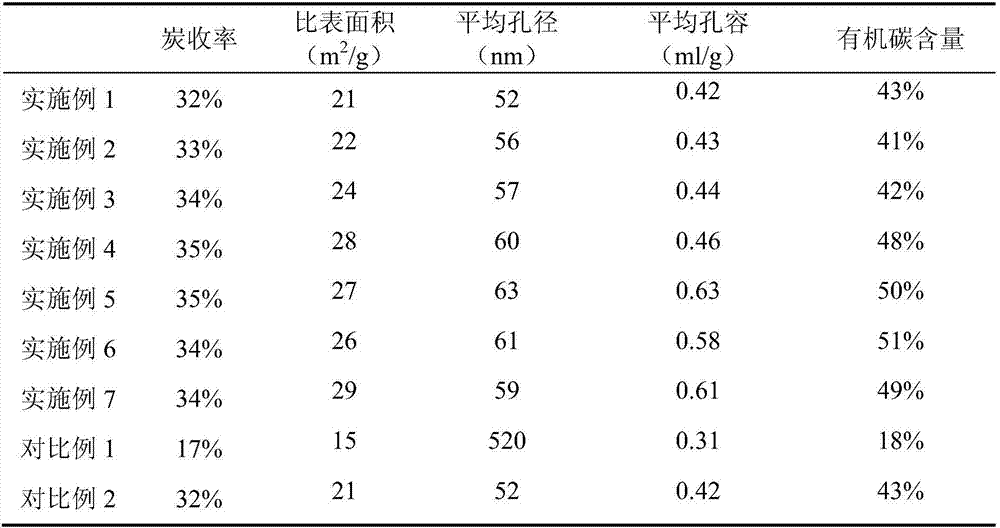

Process of preparing high-quality biomass charcoal for carbon-based fertilizer and co-producing wood vinegar

ActiveCN107541227AKeep active ingredientsActive ingredient accumulationProductsReagentsFlue gasPollution

The invention relates to the technical field of biomass utilization, and particularly provides a process of preparing high-quality biomass charcoal for carbon-based fertilizer and co-producing wood vinegar. Multi-pore high-quality biomass charcoal and wood vinegar are obtained by adopting a low and medium-temperature cracking mode. Under an anoxic condition, a biomass raw material is carbonized, so that organic carbon in biomass is retained to the maximum extent; the wood vinegar is operated through phase separation of spraying liquid, so that energy waste and flue gas pollution which are caused by combustion are avoided; the low-concentration wood vinegar is further cyclically used as a spraying agent at the same level for recycling, so that effective components in the wood vinegar can beaccumulated. As the obtained wood vinegar is sprayed to the biomass charcoal, the sterilization and parasite expelling effects of the biomass charcoal can be enhanced, and the biomass charcoal is also entitled with nutritional components.

Owner:BEIJING SANJU GREEN ENERGY TECH CO LTD

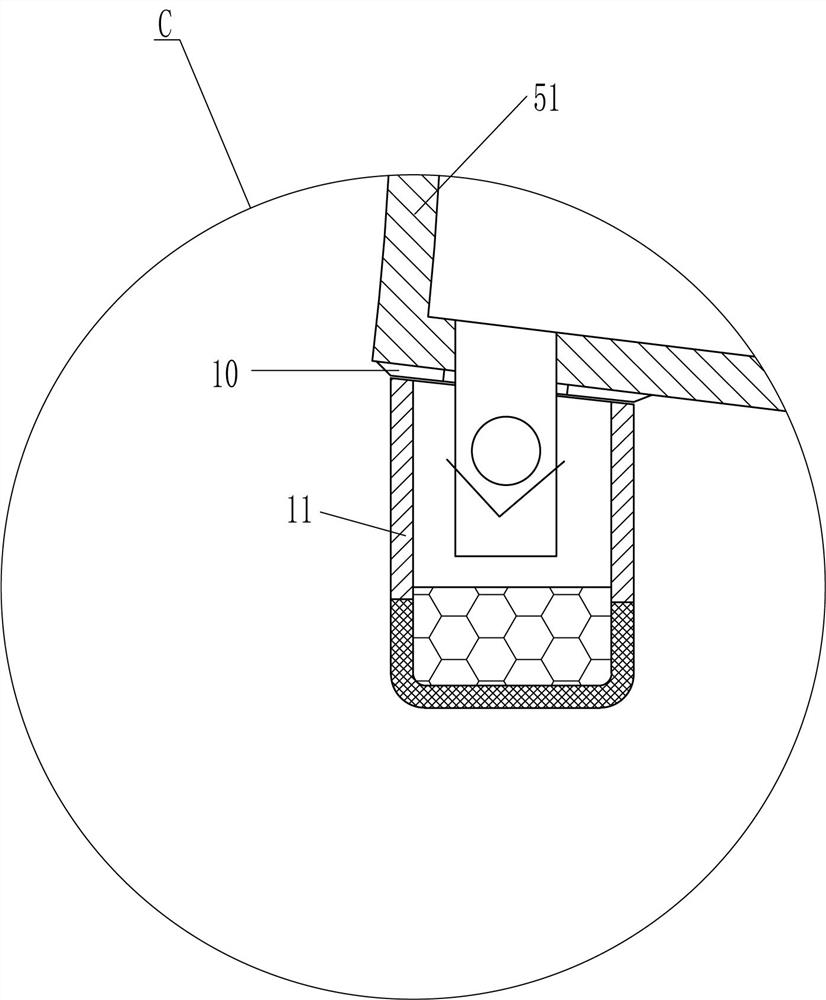

Device and method capable of carbonizing plurality of tantalum sheets simultaneously

ActiveCN112159952AGuaranteed growth qualityImprove carbonization efficiencyPolycrystalline material growthBiofuelsSemiconductor materialsInsulation layer

The invention relates to a device capable of carbonizing tantalum sheets, and belongs to the technical field of semiconductor material preparation. The device and the method aim to overcome the defectthat an existing tantalum sheet carbonization device cannot distinguish the tantalum sheet carbonization conditions before and after carbonization. The device capable of carbonizing the plurality oftantalum sheets simultaneously comprises a crucible body, a crucible upper cover, tantalum sheet brackets, an insulating layer cushion block and an insulating layer shell; and the tantalum sheet brackets are arranged in the crucible body in a stack mode, numbers are engraved on the outer walls of the tantalum sheet brackets, bosses are machined on the inner walls of the tantalum sheet brackets, the crucible upper cover covers the crucible body, and the insulating layer cushion block and the insulating layer shell are arranged outside the crucible body in a sleeving mode. The method capable ofcarbonizing the plurality of tantalum sheets simultaneously comprises the steps that carbon powder and the tantalum sheets are placed into the tantalum sheet brackets according to the sequence of thecarbon powder, the tantalum sheets and the carbon powder, the crucible upper cover is covered, the insulating layer is placed, heating is conducted, and the tantalum sheets are carbonized for a certain period of time at a certain carbonization temperature. The tantalum sheets are distinguished through the marks on the tantalum sheet brackets, and whether tantalum sheet carbonization reaches the standard or not is observed by comparing the weights of the tantalum sheets before and after carbonization.

Owner:哈尔滨科友半导体产业装备与技术研究院有限公司

Device and method for accurately expanding AlN seed crystal

ActiveCN111321472ASolve the problem of difficult diameter expansionAccelerate the rate of growth expansionAfter-treatment apparatusPolycrystalline material growthCarbide siliconCrucible

The invention relates to a device and method for accurately expanding AlN seed crystals, and belongs to the field of crystal growth. The operation is simple, the efficiency is high, and the AlN crystal with the corresponding size can be manufactured as required. The device for accurately expanding the AlN seed crystal comprises a graphite heater, a crucible and a growth combination, the crucible is positioned in the graphite heater; the growth combination is positioned in the crucible; the silicon carbide seed crystal gasket is detachably connected with the crucible gasket and the crucible body; AIN seed crystals with corresponding sizes can be obtained by replacing silicon carbide seed crystal gaskets with different sizes; the device and the method are simple to operate, the problem of difficulty in expanding in the growth process of the aluminum nitride crystal is fundamentally solved, and compared with the prior art, the device and the method for accurately expanding of the AlN seedcrystal accelerate the growth and expanding speed of the aluminum nitride crystal, save the growth and expanding cost and time of the aluminum nitride crystal and accelerate the development process of the growth industry of the aluminum nitride crystal.

Owner:哈尔滨科友半导体产业装备与技术研究院有限公司

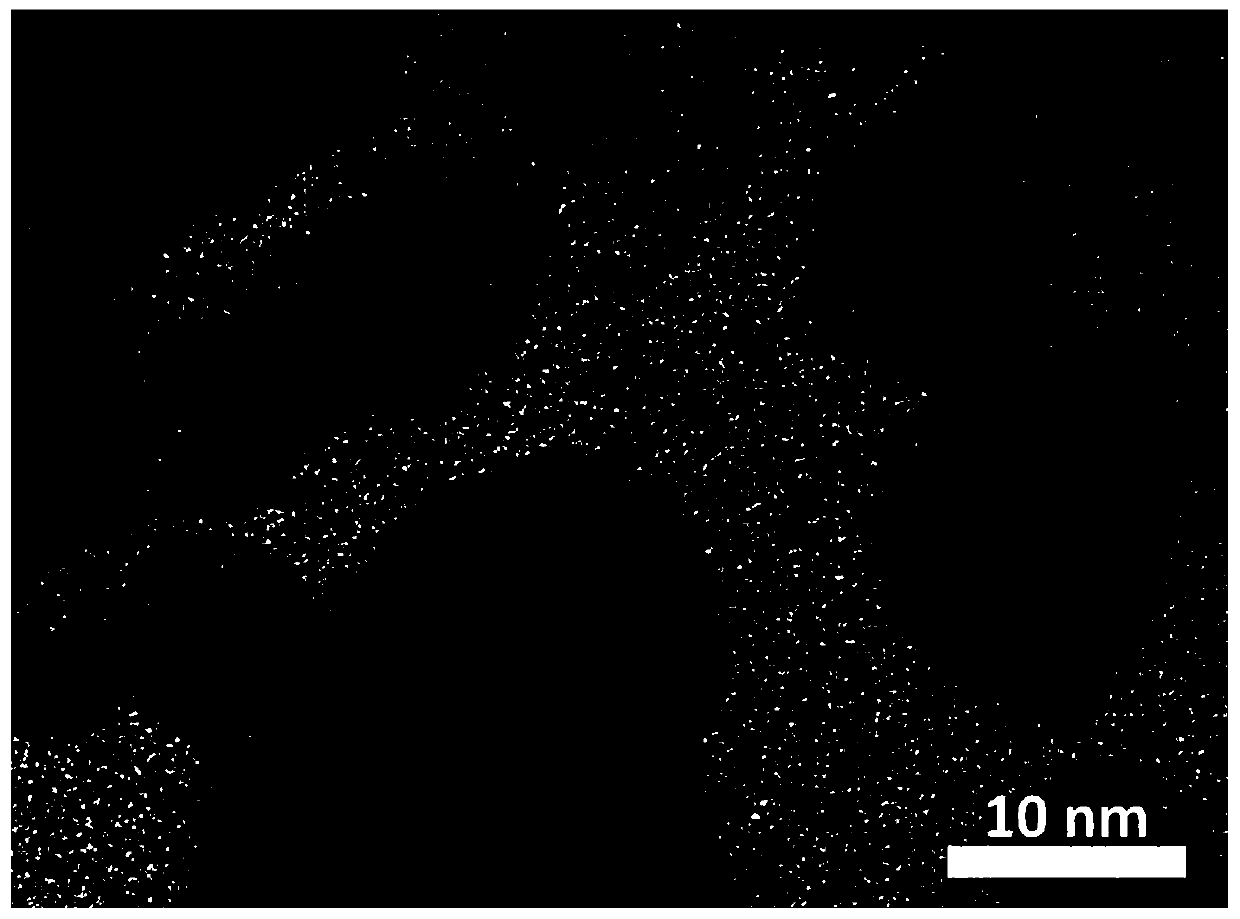

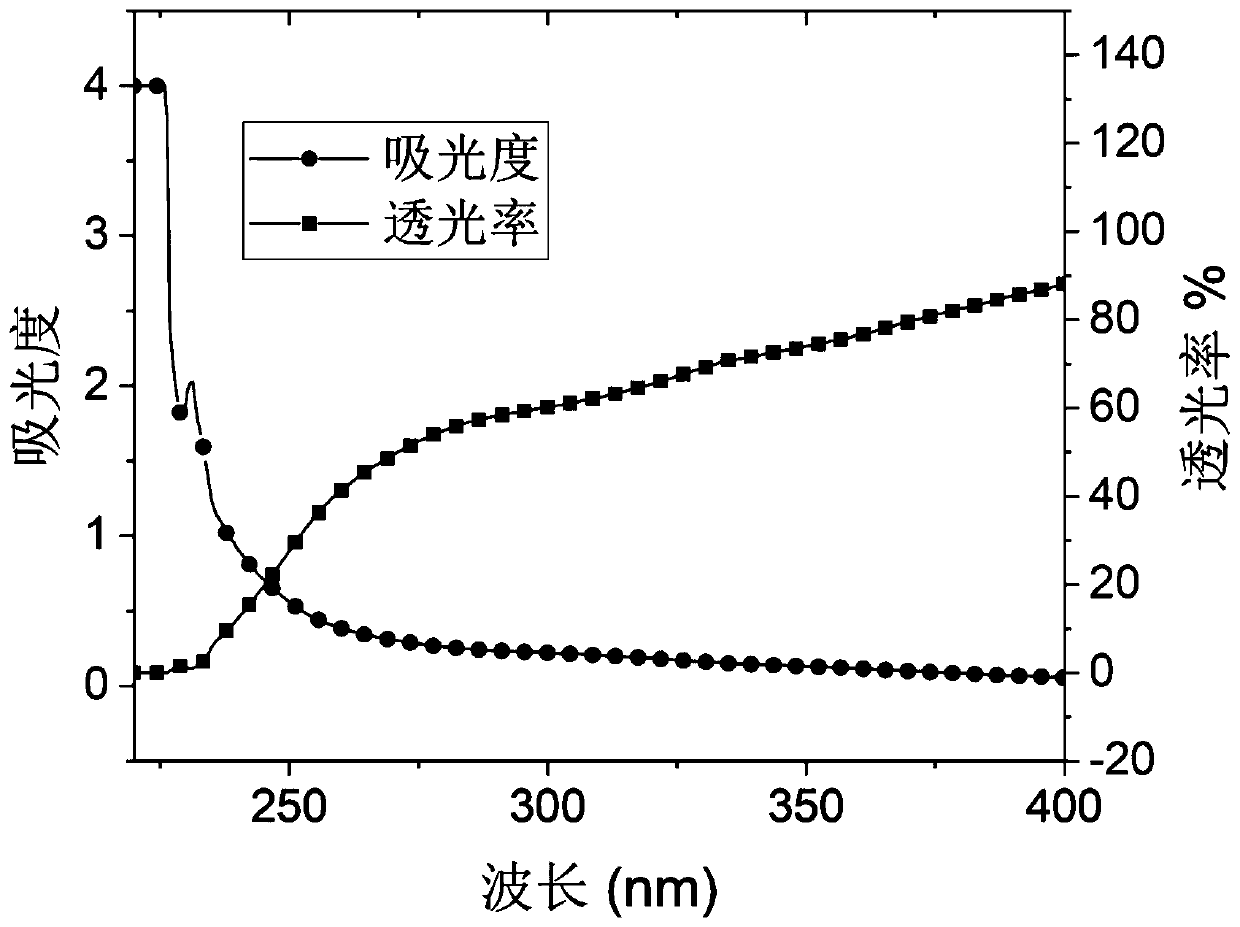

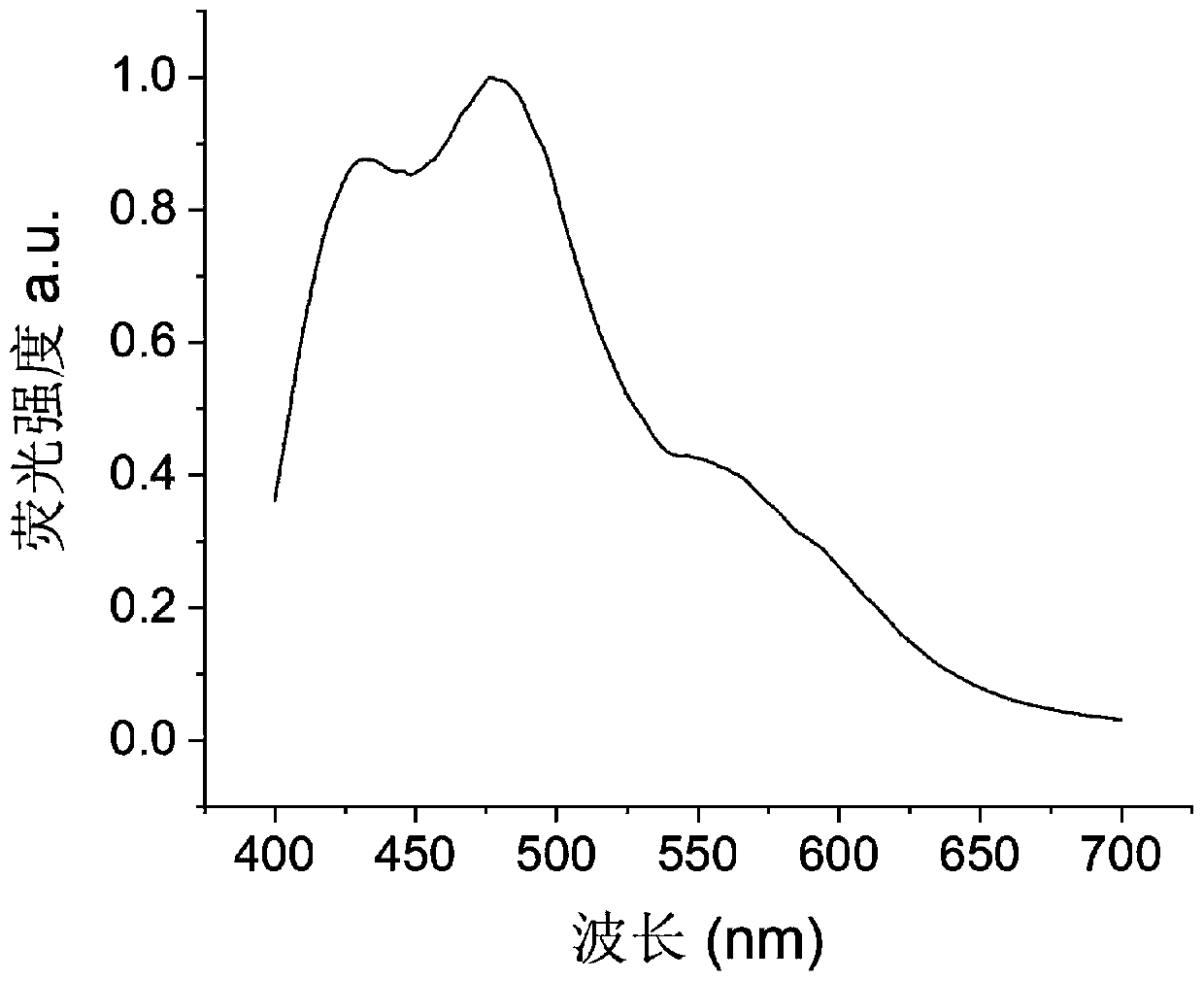

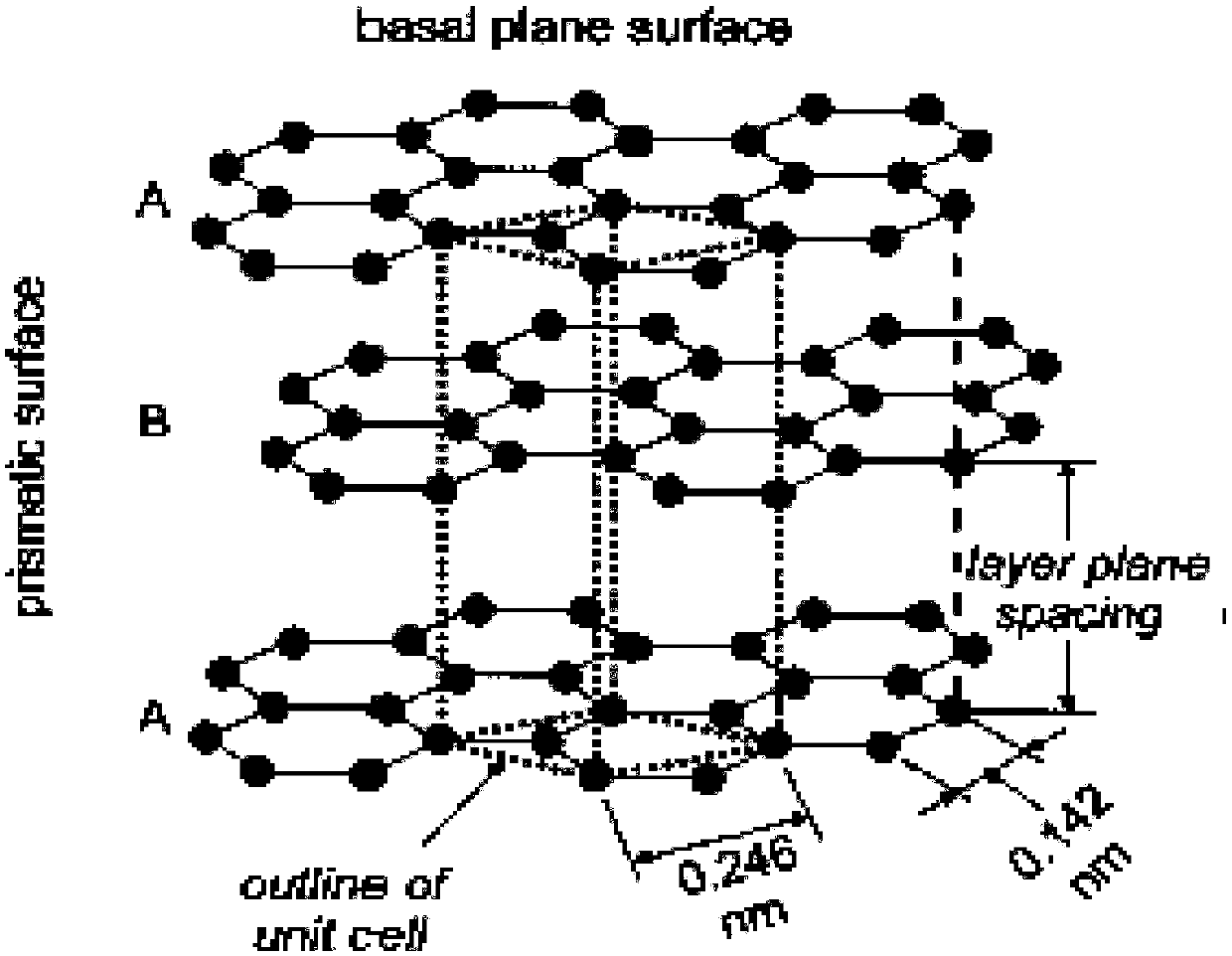

Graphene quantum dot material with high ultraviolet absorption characteristics and lipophilicity and preparation method of graphene quantum dot material

ActiveCN110697691AHigh boiling pointHigh degree of carbonationGrapheneNanoopticsCarbonizationSolvent free

The invention discloses a graphene quantum dot material with high ultraviolet absorption characteristics and lipophilicity and a preparation method of the graphene quantum dot material. The preparation method prepares the graphene quantum dot material with the high ultraviolet absorption characteristics and the lipophilic characteristics by using an ester of a polycarboxylic acid molecule as a carbon source through heat carbonization; the ester of the polycarboxylic acid molecule used in the method is in a liquid state under normal temperature or heating conditions and has a high boiling point, by using the feature, uniform carbonization of the carbon source can be realized through a simple heating manner without using any solvent, no special requirements for a heating atmosphere and carbonization pressure are needed in the solventless carbonization process, the carbonization efficiency is high, the environmental friendliness is realized, possible side reactions between the solvent andthe carbon source are prevented, the product separation and purification process is greatly simplified, and in the subsequent reaction process, a crude product can be purified only by dispersing andprecipitating treatment; and the prepared material has good lipophilicity and high ultraviolet absorption characteristics.

Owner:XI AN JIAOTONG UNIV

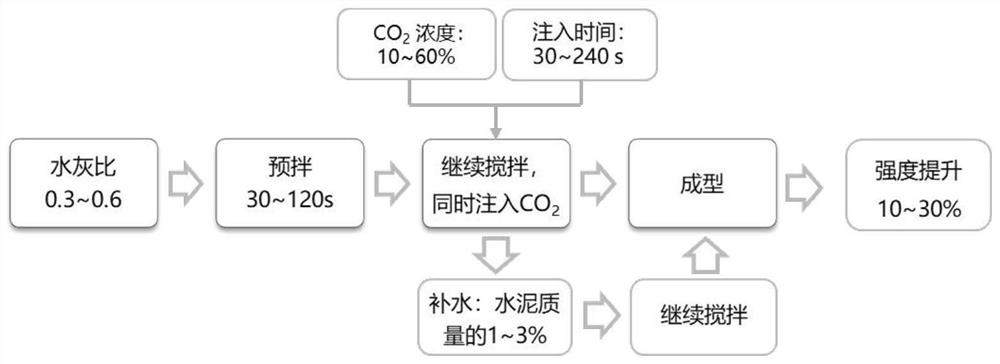

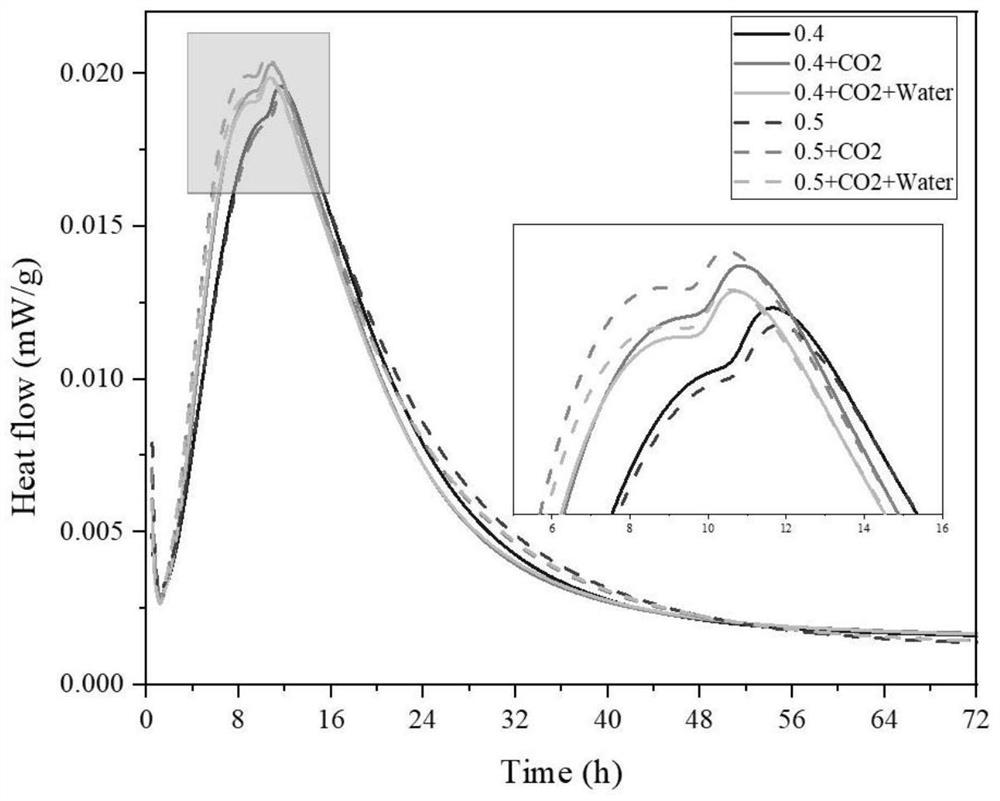

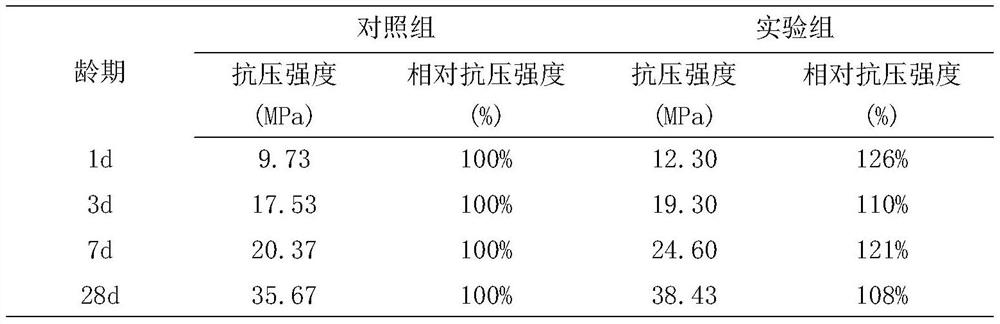

Preparation method of carbon dioxide premixed cement-based composite material

The invention discloses a preparation method of a carbon dioxide premixed cement-based composite material. The method comprises the following steps: 1, introducing gas containing carbon dioxide into cement paste which is stirred in a closed state for 30-240 seconds; 2, when the fluidity of the cement paste is obviously reduced, water accounting for 1%-3% of the mass of the cement is added into the cement paste so as to restore the original fluidity of the cement paste. The method has the characteristics of improving the material strength, reducing the cement consumption, relieving the greenhouse effect and being high in economic benefit.

Owner:HUNAN UNIV

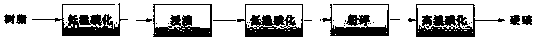

Method for producing environment-friendly coal from straws

InactiveCN102504907APrevent excessive carbonationIncrease carbon densityBiofuelsSolid fuelsRural areaCarbon density

The invention discloses a method for producing environment-friendly coal from straws. The method comprises the following steps of: preparing raw materials, grinding, primarily forming, pre-heating, grinding again, heating, activating, cooling, sieving and packaging. The invention has the benefits that the method effectively prevents excessive carbonization, increases carbon density and reduces defective rate; and the coal product is characterized in having a smooth surface and being not liable to fracture and uniformly carbonized. The method utilizes waste straws in rural areas to produce straw-derived coal, so as to achieve the purpose of turning waste into treasure, prevent environmental pollution and save resources.

Owner:TONGREN HUIMIN GASIFIER

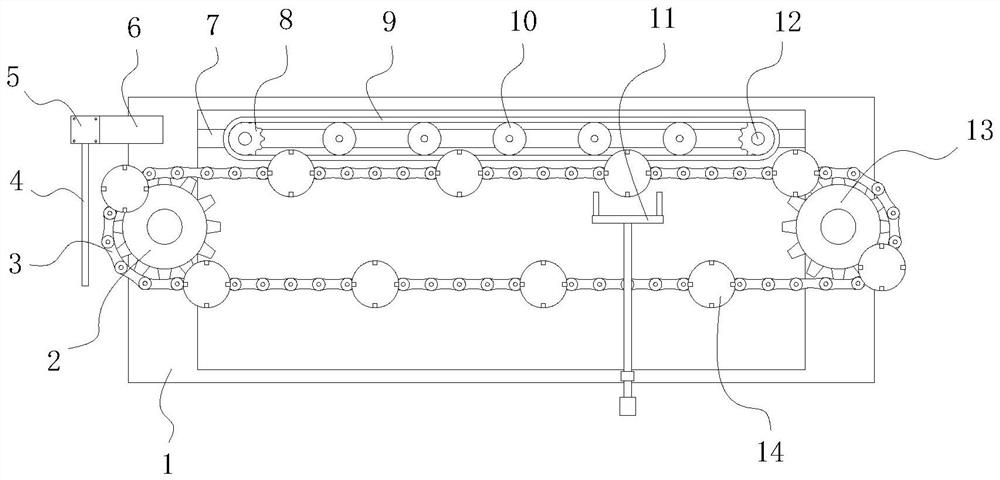

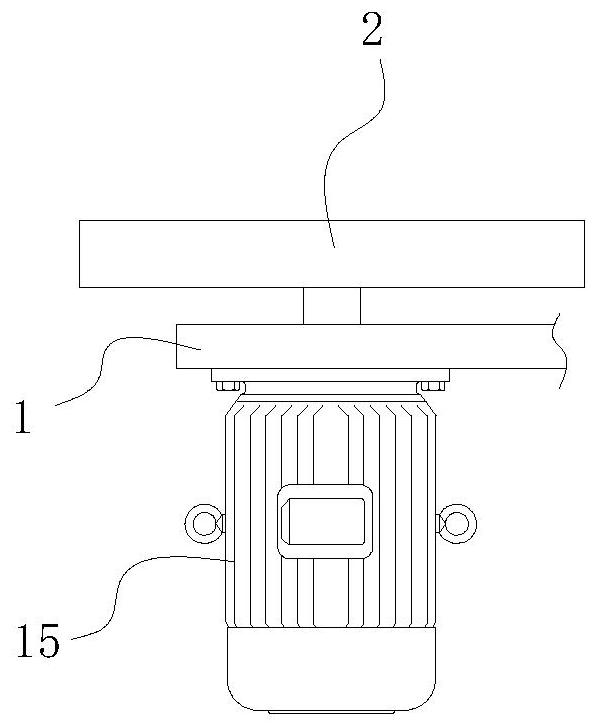

Automatic wooden product carbonizing machine

ActiveCN112792943AImprove work efficiencyReduce labor intensityOpen tank impregnationWood charring/burningSprocketManufacturing engineering

The invention provides an automatic wooden product carbonizing machine which comprises a rack. A driving chain wheel and a driven chain wheel are symmetrically installed on the upper surface of the rack, a chain is installed between the driving chain wheel and the driven chain wheel, a plurality of supporting rods are evenly installed on the upper surface of the chain, and cylinders are rotationally connected to the upper ends of the supporting rods correspondingly. A vertical rod is fixedly connected to the upper end of each cylinder. Trays used for lifting wooden products are fixedly connected to the upper ends of the vertical rods correspondingly. Four clamping jaws used for limiting the position of the corresponding wooden product are evenly fixed to the edge of the upper surface of each tray. A carrying plate arranged in the length direction of the rack is fixed in the rack. A driving gear and a driven gear are symmetrically installed on the upper surface of the carrying plate. A rubber belt ring attached to the outer surfaces of the cylinders is installed between the driving gear and the driven gear. Compared with the prior art, the automatic wooden product cabonizing machine has the following beneficial effects that the purpose of mechanical carbonization is realized, the working efficiency is improved, and the labor intensity is relieved.

Owner:临海市格林邦泰木业有限公司

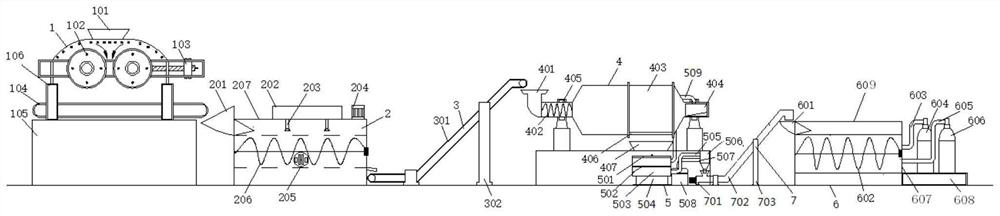

Integrated industrial preparation device for carbonized regenerated micro-powder

ActiveCN112028521AHigh degree of automationImprove preprocessing efficiencyFan bladeElectrical and Electronics engineering

The invention provides an integrated industrial preparation device of carbonized regenerated micro-powder, wherein the device comprises a crushing device, a performance improvement pretreatment device, a first conveying device, a ball milling device, a screening device, a second conveying device and a low-humidity pressurization carbonization system device which are connected in sequence, the ballmilling device comprises a support, and a barrel body is arranged on the support; a second spiral fan blade mechanism is arranged in a second feeding port of the barrel body, a first powder suction device is arranged at the tail end of the barrel body, a discharging port is formed in the bottom of the barrel body, and a transfer bin is arranged below the discharging port; the screening device comprises a vibrator, a screen barrel is arranged on the vibrator, a screen cover is arranged on the screen barrel, a screen is arranged in the screen barrel, and a first connecting pipe is arranged below a part, corresponding to the screen, in the screen barrel; the first connecting pipe is connected with a cyclone barrel, the cyclone barrel is connected with a second powder suction device through asecond connecting pipe, a third connecting pipe is arranged in the position, corresponding to the upper portion of the screen, in the screen barrel, and the third connecting pipe is connected with the first powder suction device. The invention provides the integrated industrial preparation device for carbonized regenerated micro-powder with high production efficiency.

Owner:绍兴市城投再生资源有限公司

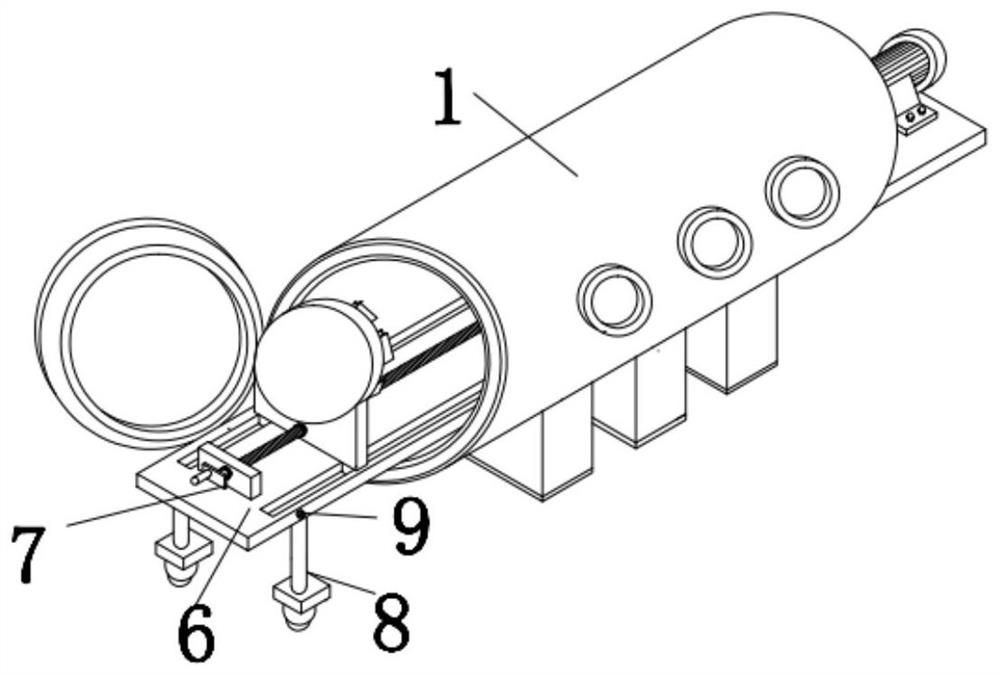

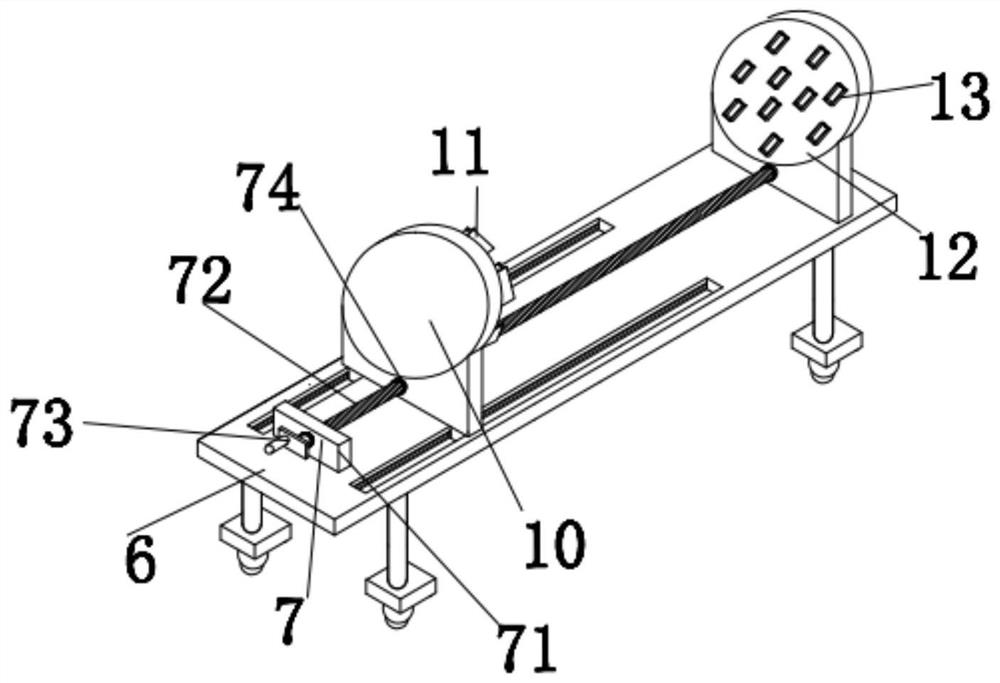

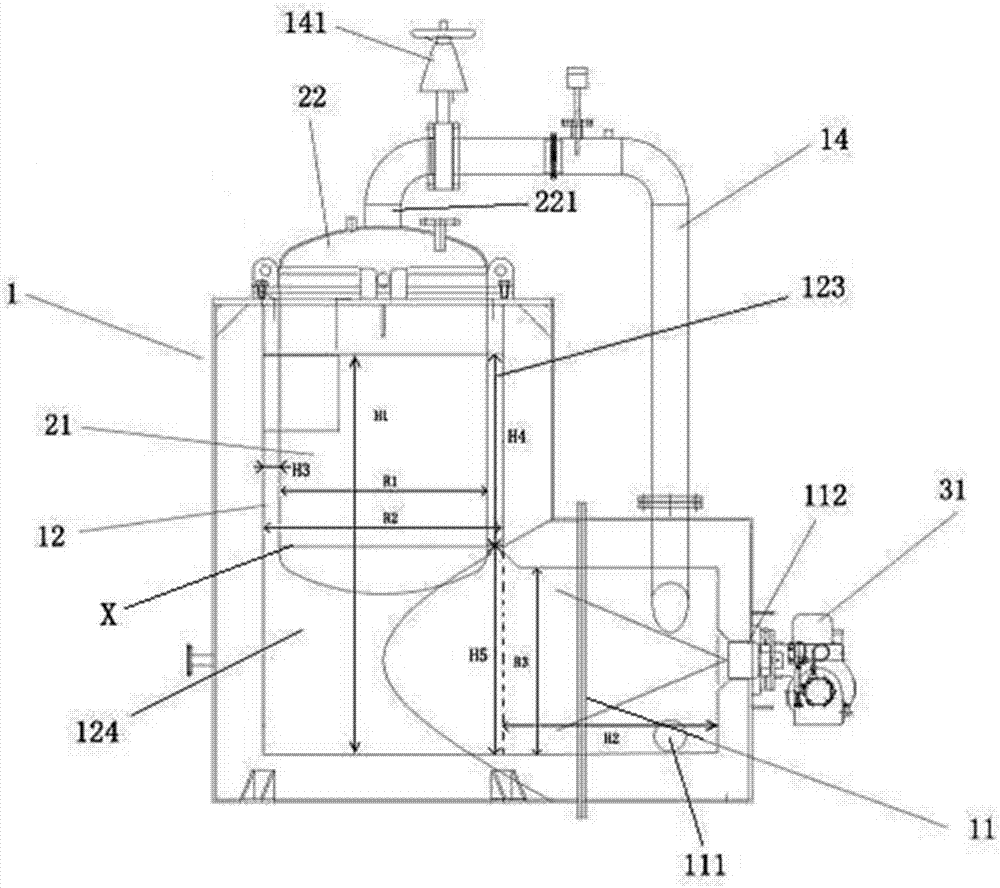

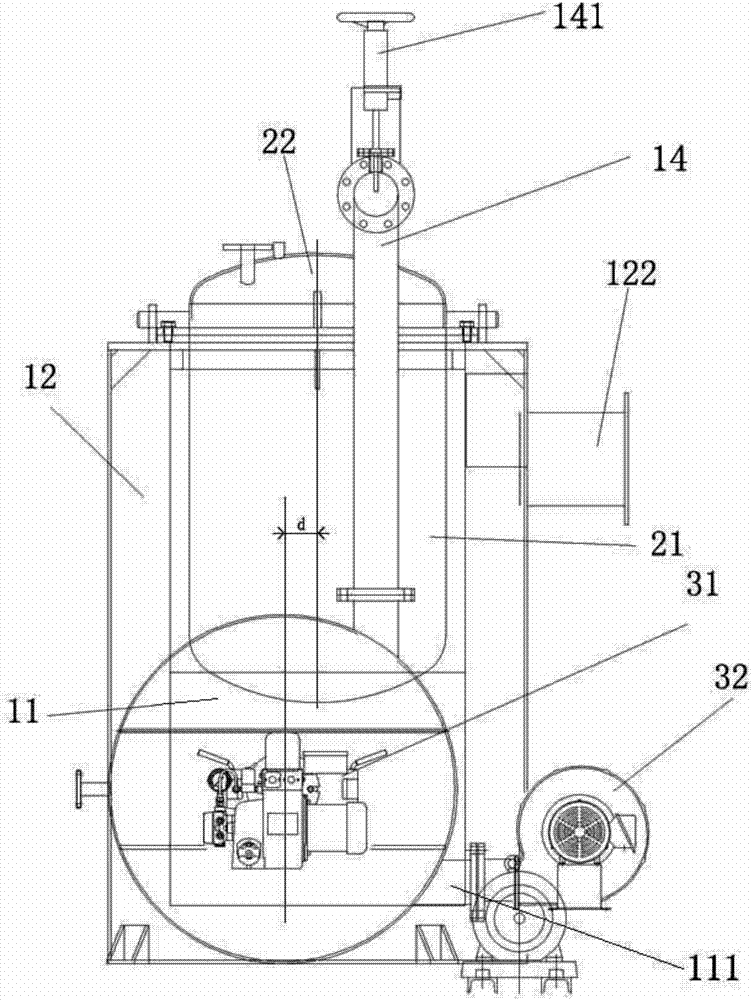

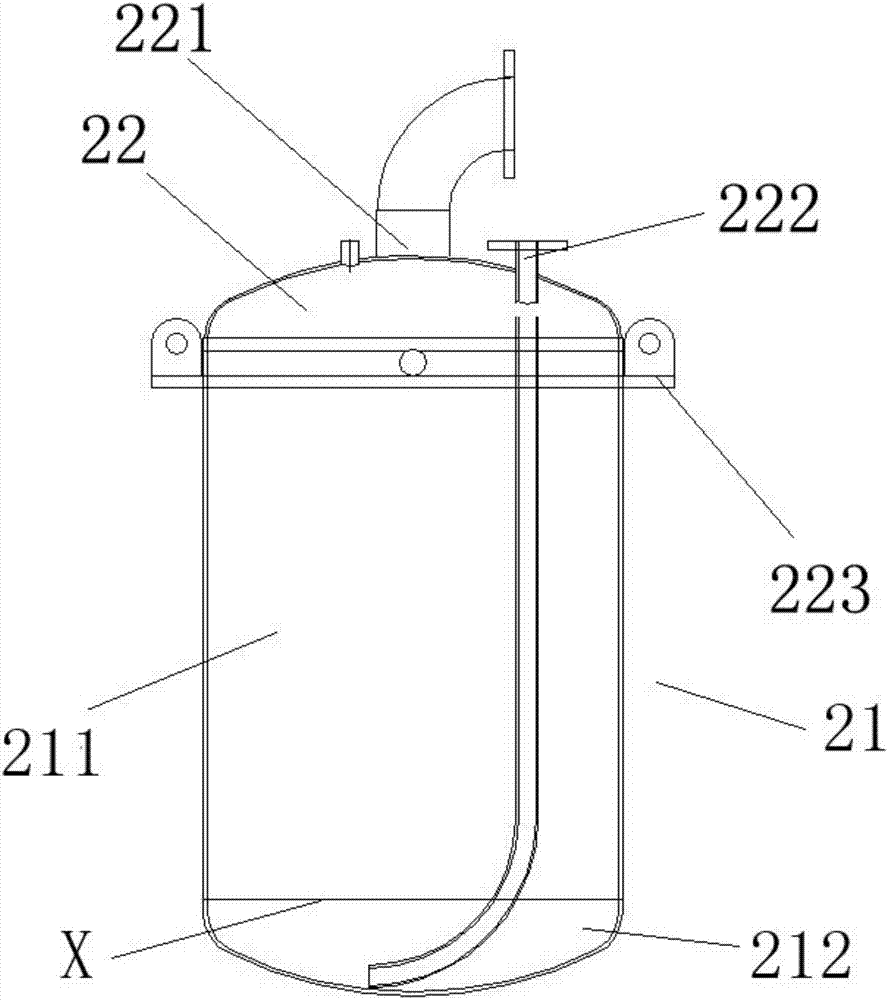

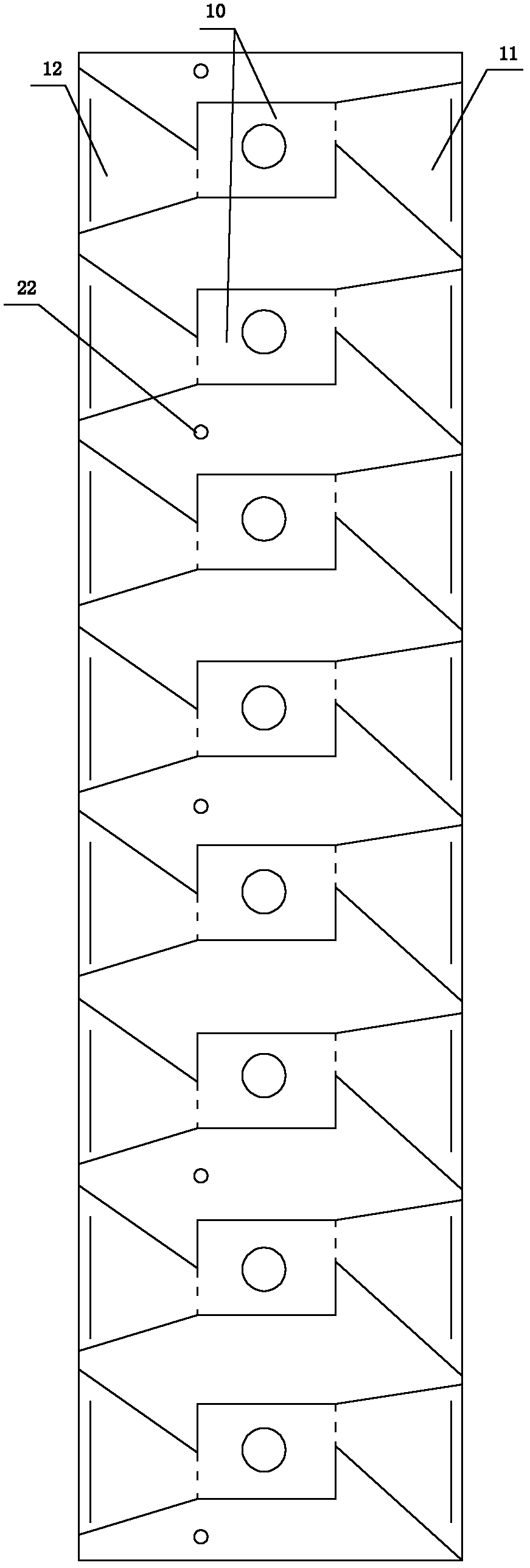

A wood batch deep carbonization device

ActiveCN111086080BUniform carbonizationEasy to put awayWood charring/burningCarbonizationEngineering

Owner:日照益尔居木业股份有限公司

Wood carbonizing process

ActiveCN106827136AWith fire performanceEndothermicWood treatment detailsThermal wood treatmentPulp and paper industry

The invention discloses a wood carbonizing process. The wood carbonizing process comprises the steps of: (1) cutting; (2) carbonizing box building; (3) electrification; (4) wood wrapping; (5) wood fixation; (6) carbonizing; and (7) ventilation. The process not only can prevent excessive temperature in a carbonizing box from causing fire, but also can greatly improve the wood carbonizing efficiency, and improves the wood heating uniformity.

Owner:MINGFENG DOORS

An organic waste treatment furnace

ActiveCN105003916BIncrease pressureSmall footprintCremation furnacesIncinerator apparatusCombustion chamberBiochemical engineering

The invention relates to an organic waste processing furnace. The organic waste processing furnace is provided with an L-shaped outer furnace body with a horizontally-extending cavity and a vertically-extending cavity, a tank body is arranged on the vertically-extending cavity, and a burning chamber is directly connected with a heating chamber, so that the occupation space of the L-shaped outer furnace body is greatly reduced, and the structure is more compact. In addition, the outer lateral wall of the tank body is surrounded by a lateral heating channel, and the bottom of the tank body is wrapped and heated by a bottom heating channel; and after high-temperature gas coming from the horizontally-extending cavity enters the vertically-extending cavity, the bottom of the tank body is heated through the bottom heating channel, and meanwhile the lateral wall of the tank body is synchronously heated through a lateral heating channel surrounding the outer lateral wall of the tank body in the circumferential direction, so that all outer walls, located in the vertically-extending cavity, of the tank body can be evenly heated by the high-temperature gas, and meanwhile carbonization of the organic waste in the tank body is more uniform.

Owner:江苏碧诺环保科技有限公司

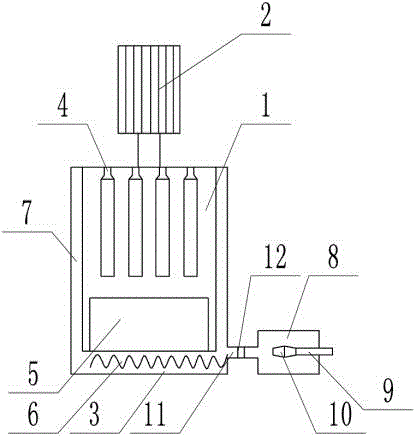

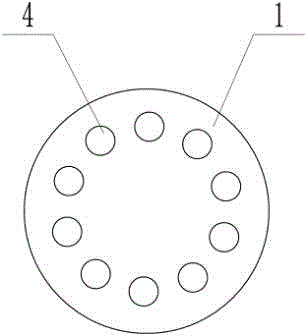

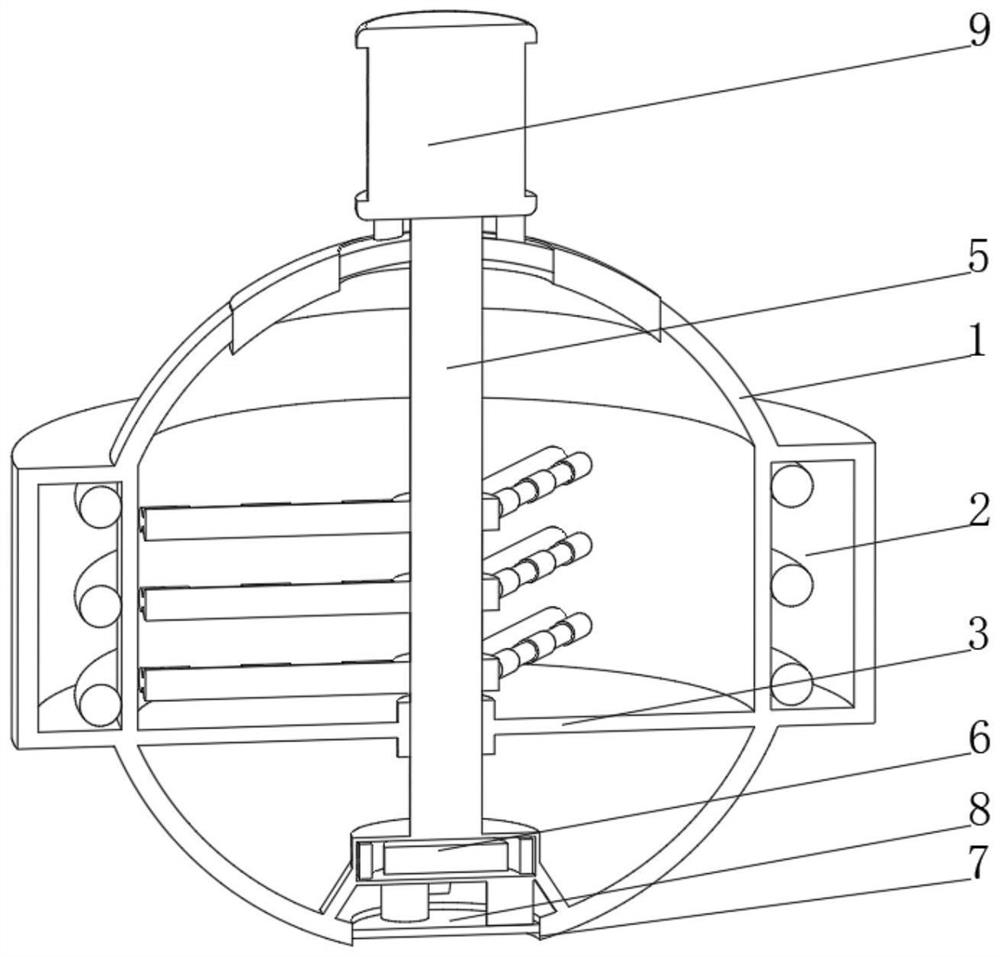

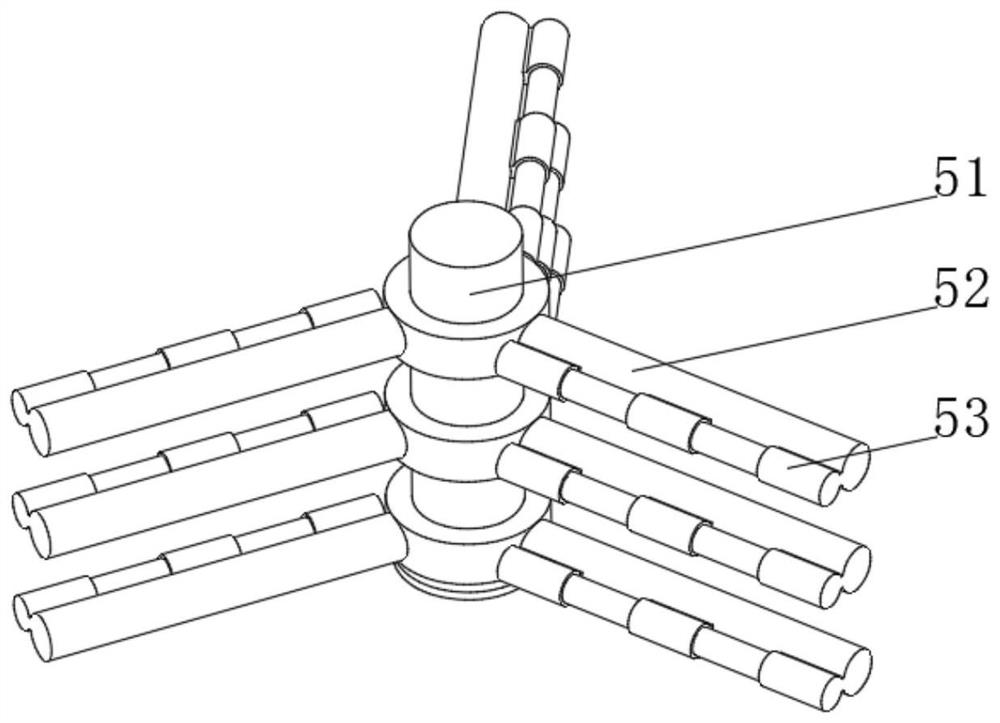

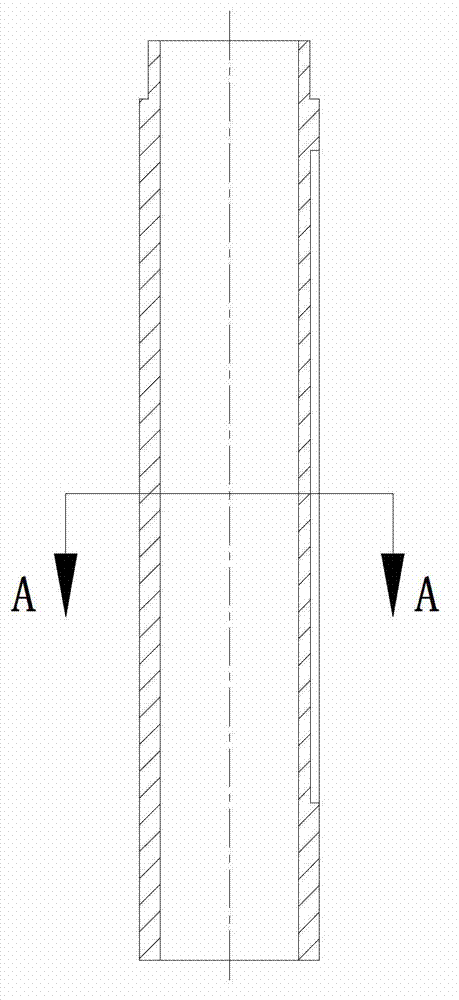

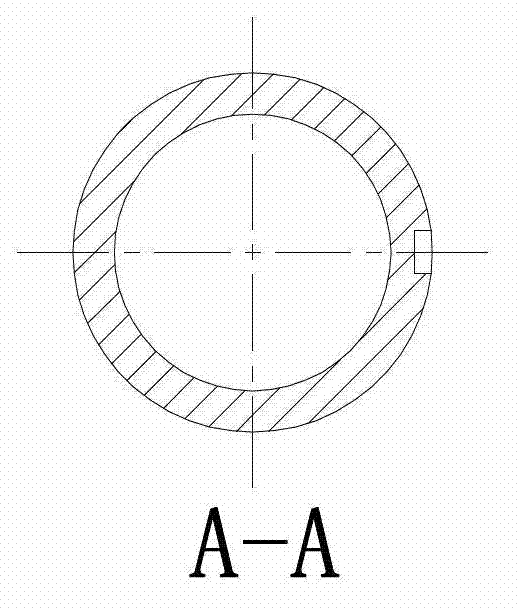

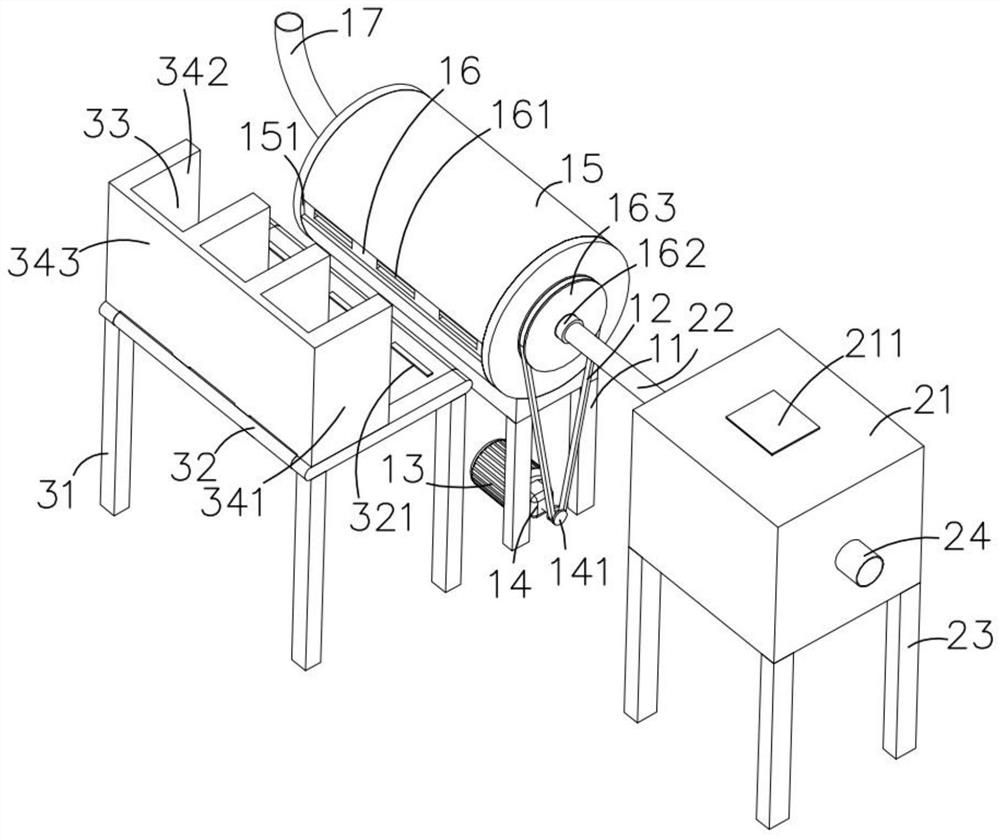

Internal heating type reduction activated carbon production converter

ActiveCN103130220AUniform carbonizationGood activation effectCarbon compoundsActivated carbonRetaining ring

The invention relates to an internal heating type reduction activated carbon production converter which comprises a combustion room, a first retaining ring, an activation chamber, heat-insulating / energy-storing refractory bricks, a second retaining ring, a carbonization chamber, a multi-inclination-angle raising plate, a push type multi-inclination-angle raising plate, a drying and plasticization chamber and a feeding spiral conveyer, wherein the drying and plasticization chamber, the carbonization chamber, the activation chamber and the combustion room are sequentially communicated and connected; the inner diameters of the drying and plasticization chamber, the carbonization chamber and the activation chamber are sequentially reduced; the feeding spiral conveyer is arranged at the inlet of the drying and plasticization chamber; the push type multi-inclination-angle raising plate is arranged in the drying and plasticization chamber; the multi-inclination-angle raising plate is arranged in the carbonization chamber; the inner walls of the carbonization chamber and the activation chamber are respectively provided with a layer of heat-insulating / energy-storing refractory bricks; and the retaining rings are respectively arranged at discharge ports of the carbonization chamber and the activation chamber. The internal heating type reduction activated carbon production converter can prevent the material from falling at the tail part of the converter, realizes uniform carbonization, achieves favorable activation effect, can maximize the activated carbon yield and fully utilize heat in the converter, and is stable in product quality, energy-saving and environment-friendly.

Owner:徐州天正活性炭厂

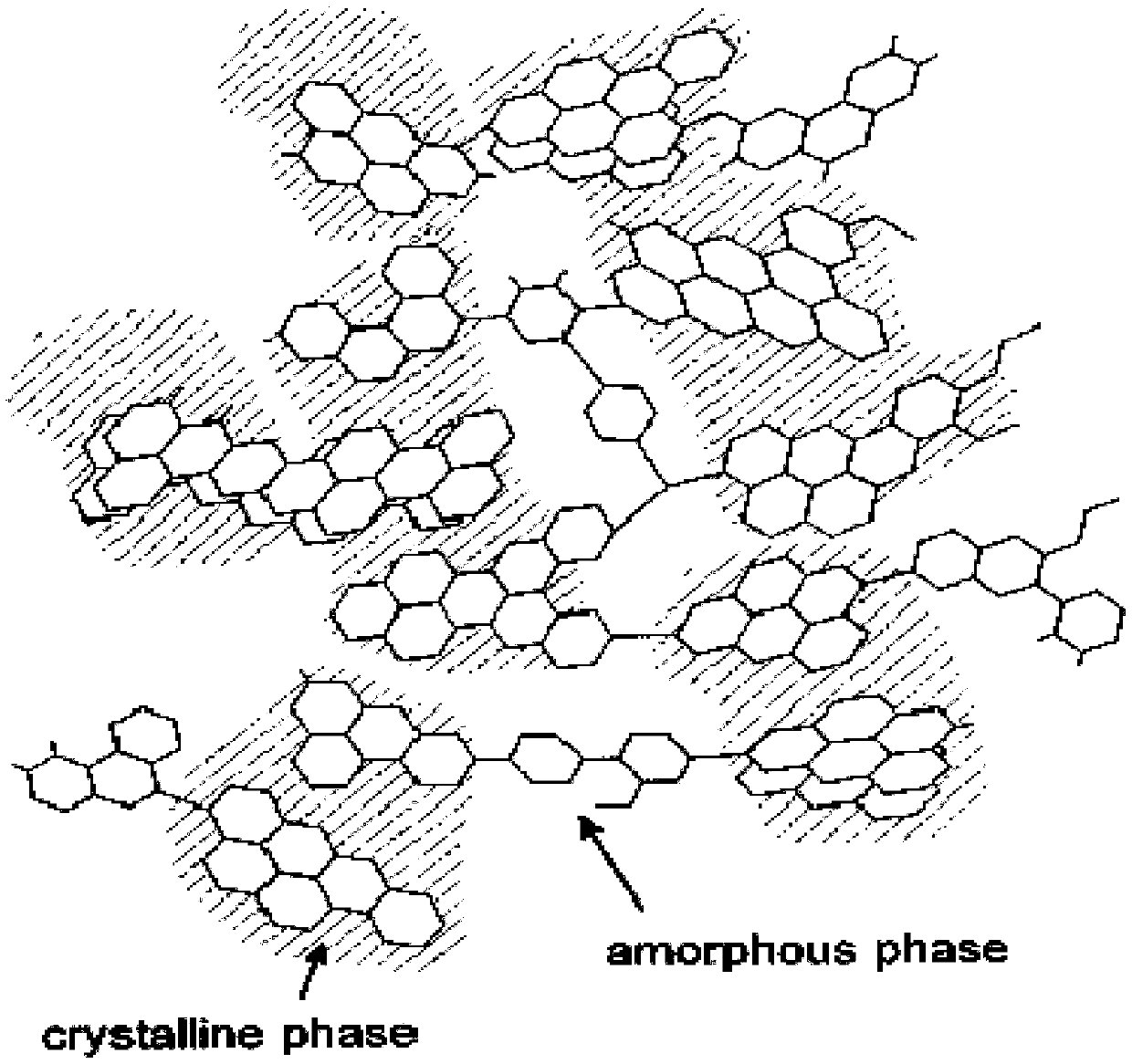

Preparation method of resin-based hard carbon negative electrode material

InactiveCN110817833AReduce intensityLow densityNegative electrodesSecondary cellsPetroleum resinCarbonization

The invention relates to a preparation method of a resin-based hard carbon negative electrode material. The method comprises the following steps of S1, carbonizing a resin raw material at 350-500 DEGC, putting the resin raw material into an impregnant, and carrying out impregnation at 60-100 DEG C; S2, taking out the resin raw material, carbonizing the resin raw material at 450-500 DEG C, and crushing the resin raw material until the median particle size is 10-40 [mu]m; and S3, carrying out carbonization at 1,000-1,400 DEG C to obtain the resin-based hard carbon negative electrode material. Compared with the prior art, the production method of the resin-based hard carbon negative electrode material has the advantage that based on molecular structures of coumarone resin, petroleum resin, phenolic resin and the like, the softening points and the market demands, hard carbon negative electrode materials with different particle sizes are obtained through carbonization, impregnation, crushing and high-temperature carbonization.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

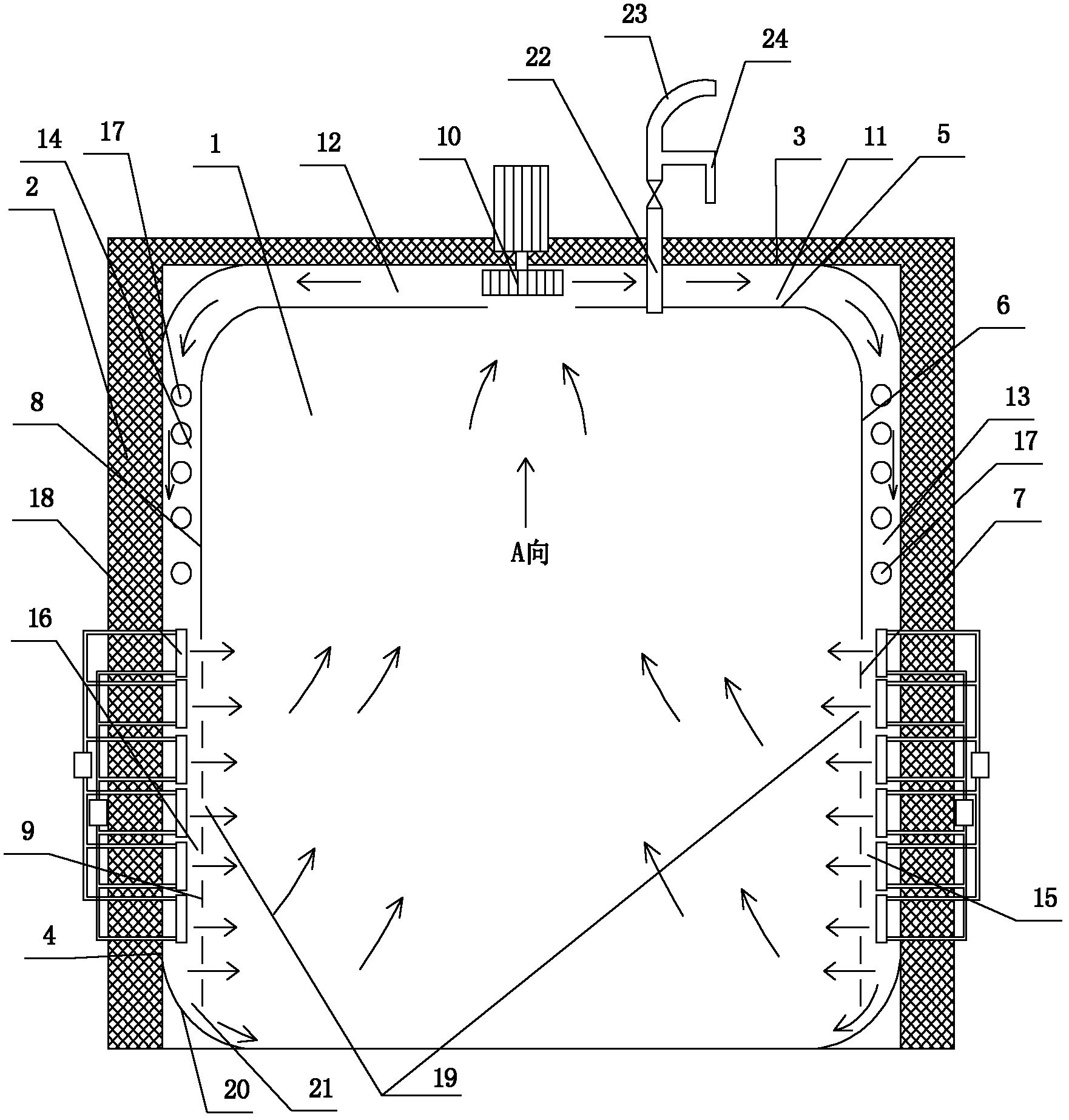

Intelligent carbonization furnace

InactiveCN102277177AUniform heating temperatureUniform carbonizationBiofuelsEfficient propulsion technologiesCold airCarbonization

The invention discloses an intelligent carbonization furnace. The furnace comprises a furnace body and a furnace body inner cavity. The furnace is characterized in that draught fans are arranged between a left top wall and a right top wall at the top of the furnace body; electric heaters are arranged in a left heating air duct and a right heating air duct; condensers with heat sinks are arranged in a left heat-sink cooling air duct and a right heat-sink cooling air duct; and air outlets are arranged on a left lower inner wall and a right lower inner wall. The furnace has the following beneficial effects: the drought fans rotate to suck the cold air in the furnace body inner cavity in which materials are placed, the cold air is led into a left upper air duct and a right upper air duct via left and right air outlets at the two sides of the drought fans and then enters the left and right heating air ducts provided with the electric heaters to be heated, the hot air obtained after heatingthe cold air is homogenized and then enters the furnace body inner cavity to heat the materials placed in the furnace body inner cavity, and the air going up through the materials is led to the left and right heating air ducts by the drought fans to be heated; therefore the materials such as bamboo wood, timbers and the like in the furnace body inner cavity are uniformly carbonized under the controlled uniform temperature through the cycles.

Owner:FUJIAN JIANOU CHANGLONG INDAL

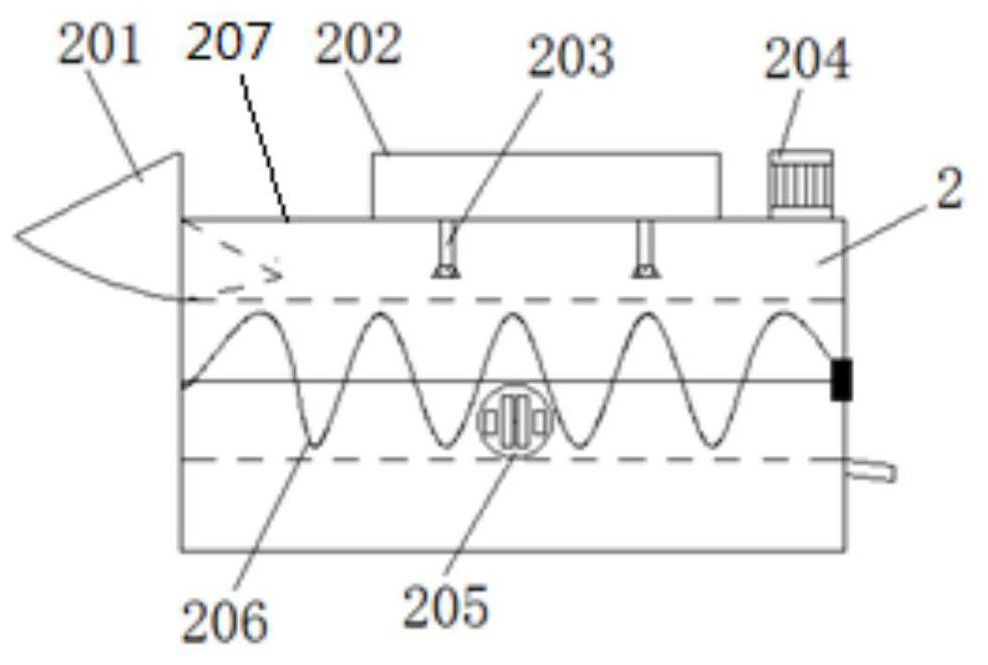

Hard carbon material production pretreatment device

ActiveCN113813852AAvoid uneven heatingUniform carbonizationSievingScreeningElectric machineCarbonization

The invention discloses a hard carbon material production pretreatment device. The device specifically comprises a treatment shell, wherein an annular heating device is arranged on the outer side of the treatment shell, a supporting plate is arranged on the portion, located below the annular heating device, of the inner wall of the treatment shell, leakage holes are formed in the supporting plate, a discharging opening is formed in the bottom of the treatment shell, and a filter screen is arranged on the inner wall of the discharge hole; a stirring device, wherein the top of the stirring device penetrates through the treatment shell and is fixedly connected with a driving motor, and the bottom of the stirring device penetrates through the supporting plate and is rotationally connected with the supporting plate; and a cleaning device, wherein the top of the cleaning device is fixedly connected with the stirring device, and the bottom of the cleaning device extends to the top of the filter screen and is in sliding connection with the top of the filter screen. The invention relates to the technical field of hard carbon material production. According to the device, the carbonization degree of raw materials of all parts is more uniform, smashing operation is easier, the pretreatment device can adapt to different carbonized raw materials, and adjustability is better.

Owner:深圳盘古钠祥新能源有限责任公司

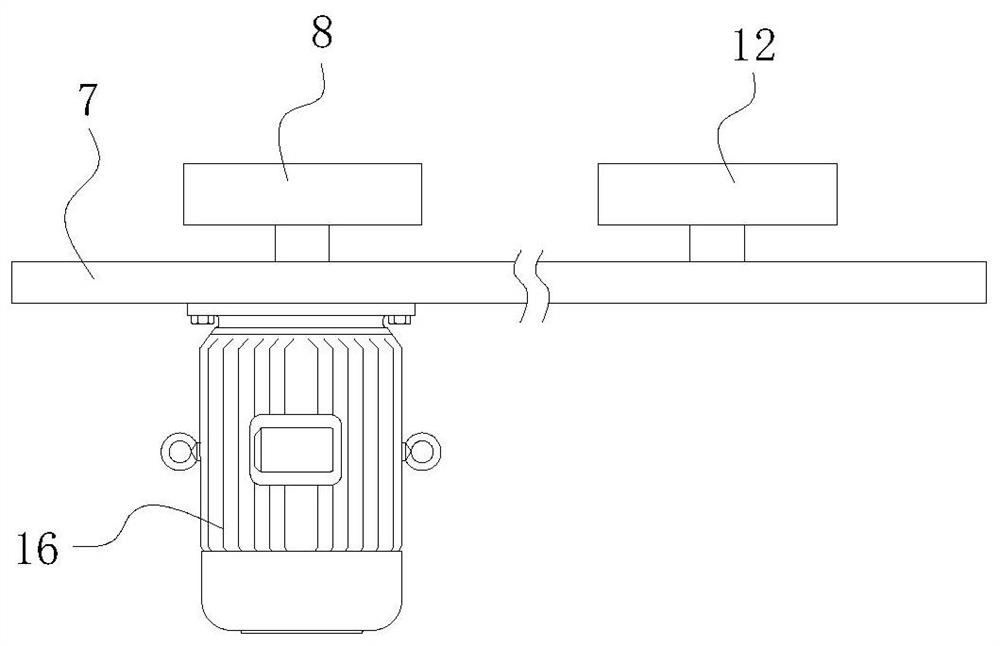

Material sorting device

The invention provides a material sorting device which comprises a rotary sleeve, a lifting sleeve, a furnace rake, a regular polygon prism and a transmission gear; a first keyway is formed in the external circumferential surface of the rotary sleeve, a key is matched with the keyway, and the rotary sleeve is sleeved on a fixed shaft; a second keyway which is matched with the key is formed in theinternal circumferential surface of the lifting sleeve, and the lifting sleeve is sleeved on the rotary sleeve through the key; the furnace rake is fixedly connected with the external circumferentialsurface of the lifting sleeve, and the regular polygon prism is fixedly connected with the external circumferential surface of the lifting sleeve; and the transmission gear connects a motor with the rotary sleeve, and is fixedly connected with a carbonization furnace body. The material sorting device can enable materials in a carbonization furnace to be uniformly burnt and carbonized; the material sorting device has a function of compacting materials, the materials are carbonized in an appropriate compactness state, so the carbonization quality and production efficiency of straws are ensured;moreover, a limit switch plays the role of automatic feeding of the carbonization furnace; and the material sorting device also has the advantages of simplicity and reasonability in structure, safetyand reliability, and is worth being applied and popularized.

Owner:天津德塔生态炭发展有限公司

Carbonization furnace for secondary utilization of crude coal flue gas

ActiveCN112852449AEfficient collectionTake advantage ofIndirect heating destructive distillationStationary retortsSpontaneous combustionCombustion chamber

The invention discloses a carbonization furnace for secondary utilization of crude coal flue gas. The carbonization furnace comprises a tubular carbonization cavity and a combustion furnace, the combustion furnace and a flue gas collecting bin are arranged at the two ends of the carbonization cavity respectively, a lattice wall is arranged in the combustion furnace, the combustion furnace communicates with a heat radiation pipe, a screen drum for layering carbonized materials and a turbine for driving the carbonized materials to move are arranged in the carbonization cavity in the axis direction, the heat radiation pipe penetrates through the carbonization cavity and extends to the outside, and the screen drum and the turbine are driven by a driving mechanism to rotate along with the carbonization cavity. According to the invention, an axial flow fan is used for guiding the crude coal flue gas into a combustion chamber for sufficient combustion, so that the crude coal flue gas replaces natural gas or fire coal to reduce the production cost, and the carbonization cavity is in a sealed anaerobic state, so that the carbonized material cannot generate open fire in the carbonization cavity, spontaneous combustion of the carbonized material is avoided, the ignition loss rate of the carbonized material is effectively reduced, the carbonized material is prevented from generating an ash layer, and the product quality index and yield are improved.

Owner:阿拉善盟正杰环保科技研究有限公司

Method for large-scale on-site production of biochar from crop straws

InactiveCN103265962BReduce investmentReduce manufacturing costBiofuelsSpecial form destructive distillationEngineeringLow oxygen

Owner:ZHEJIANG UNIV

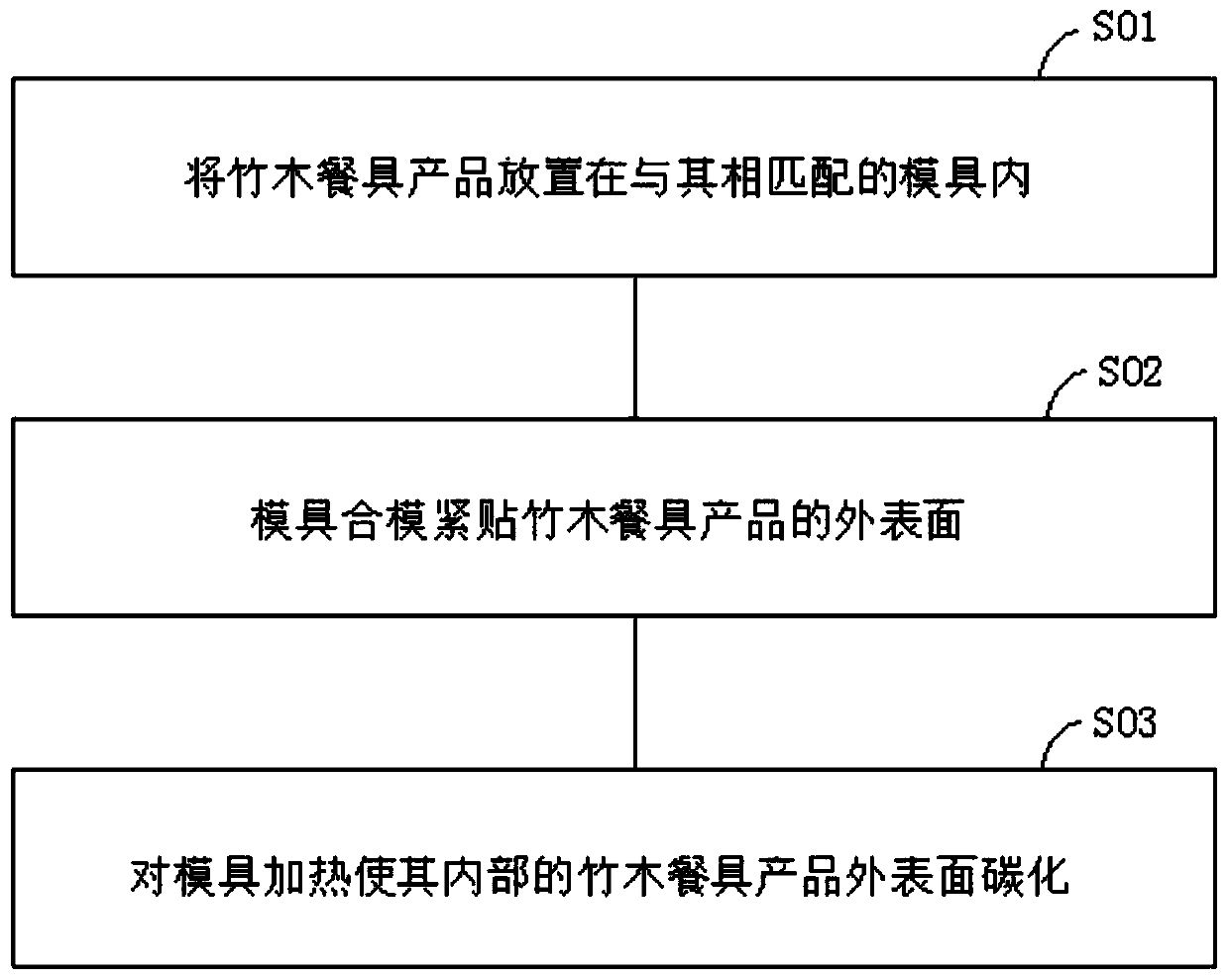

Semi-carbonization method and equipment for single-layer bamboo tableware

InactiveCN111015879ACreate pollutionDetrimental to healthWood charring/burningCarbon layerBatch manufacturing

The invention relates to a semi-carbonization method for single-layer bamboo tableware. The method comprises the following steps: putting a bamboo tableware product into a mold matched with the bambootableware product; the mold is closed and clings to the outer surface of the bamboo tableware product; heating the mold to carbonize the outer surface of the bamboo tableware product in the mold; method according to the invention, the outer surface of the bamboo tableware can be quickly and uniformly carbonized to form a compact protective carbon layer, the processing speed is high, the bamboo tableware is suitable for batch production, the mildew-proof, insect-proof and deformation-proof effects are good, additives such as chemicals and the like do not need to be additionally added, the tableware cannot pollute the environment, and the health of a user cannot be damaged.

Owner:深圳市山峰智动科技有限公司 +1

Preparation method for basalt ware

The invention discloses a preparation method of the black pottery, which is characterized in that yellow clay is selected to be ground, and water is added into the yellow clay so as to mix the yellow clay into mud, then the mud is filtered and deposited to be made into strip shape, and the strip- shaped mud is made into a green body in needed shape; the made green body is shady dried for a first time, modified, polished for a first time, drawn, engraved, polished for a second time and shady dried for a second time, then vegetable oil is smeared on the surface of the green body to process the surface of the green body; after that, the green body is put into the kiln body to be fired; when the green body is fired, a fume material of asphalt is added so that the smoke carbon produced by the asphalt is fully absorbed by the green body inside the kiln body. The preparation method has the following advantages: before the black pottery is fired, the surface of the green body is smeared with the vegetable oil so that fine channels are formed in the green body when the vegetable oil is infiltrated into the green body, and the fine channels facilitate the smoke carbon to be infiltrated intothe green body, thereby making the handicraft of the black pottery black and bright from the inside to the outside; at the same time, the pottery smoked by the smoke carbon formed by the asphalt is colorized evenly and has primitive and simple and natural color with smooth and bright surface and fastened color, and does not have the peculiar smell and impurities of the asphalt; and additionally, the preparation method shortens the firing time and saves the energy.

Owner:临沂高新城乡发展有限公司

Equipment and method for preparing graphene film through laser grading carbonization of polyimide film

The equipment is characterized in that electric appliance bodies are fixedly connected to the inner walls of the front face and the back face of a preparation box of the equipment, a square groove is formed in the top of the preparation box, openings are formed in the top and the bottom of the square groove, and a precise rolling conveying mechanism is fixedly connected to the interior of the preparation box; the precise rolling conveying mechanisms are arranged on the left side and the right side of the electric appliance body, a laser mechanism for heating, carbonizing and graphitizing is fixedly connected into the preparation box, each precise rolling conveying mechanism comprises a discharging roller, and the discharging rollers are rotationally connected to the inner walls of the front face and the back face of the preparation box and arranged on the left side of the electric appliance body. Through laser power selection and laser action time control, polyimide film damage occurring in the laser carbonization process is reduced, and in addition, the patterned graphene heat conduction film can be customized by adjusting the laser path according to customer requirements.

Owner:GUANGZHOU UNIVERSITY

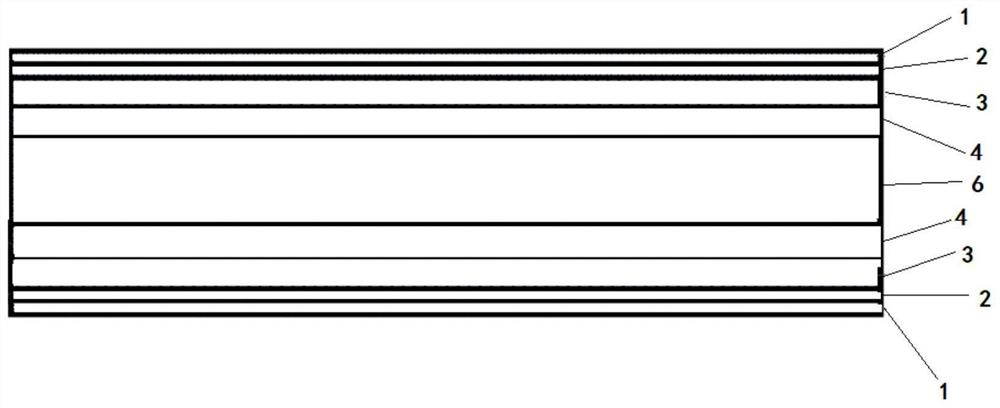

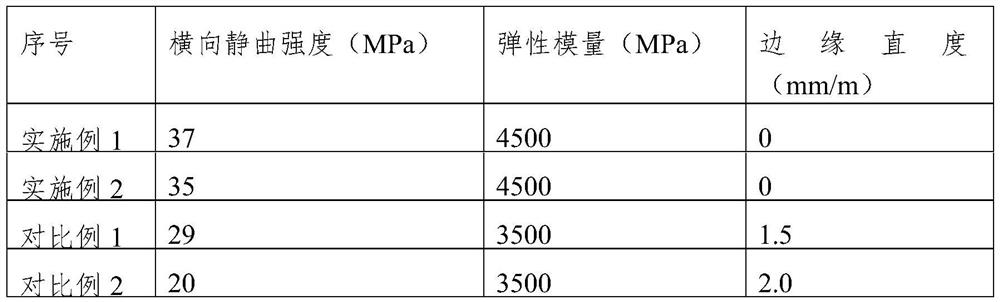

A heat-modified anti-deformation home door panel and its production process

ActiveCN113815080BEnsure stabilityReduce brittlenessLamination ancillary operationsLaminationWood fibreCarbonization

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

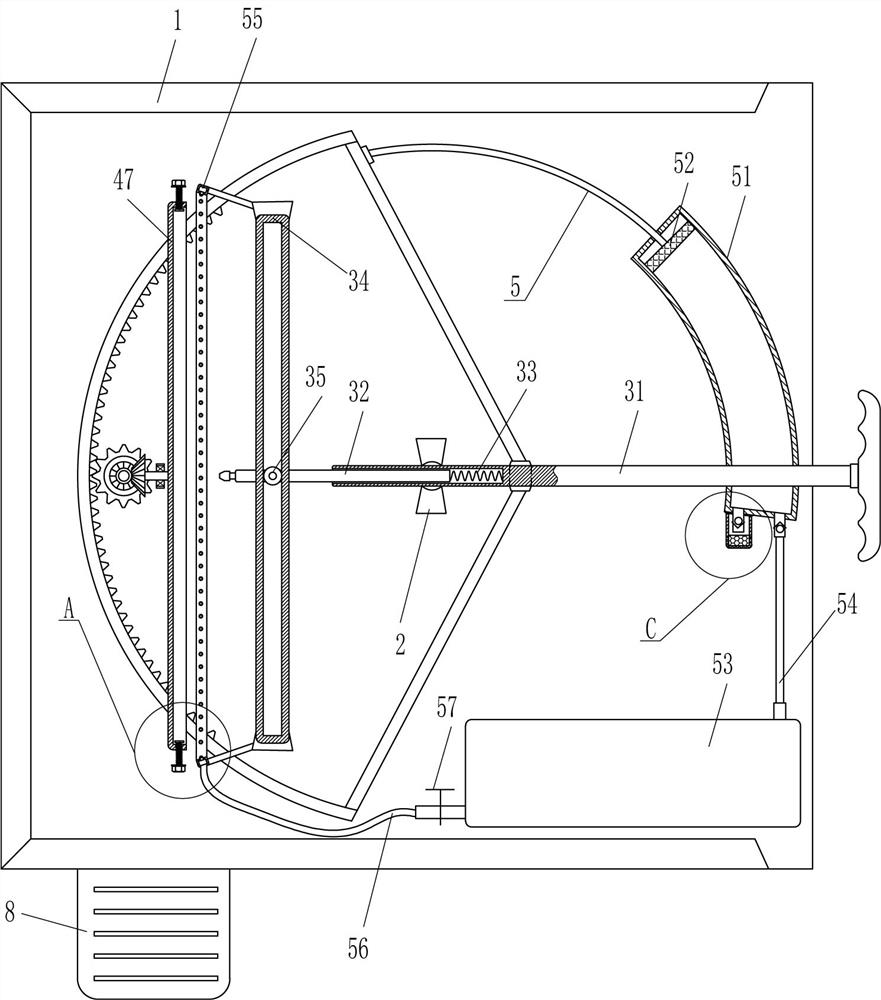

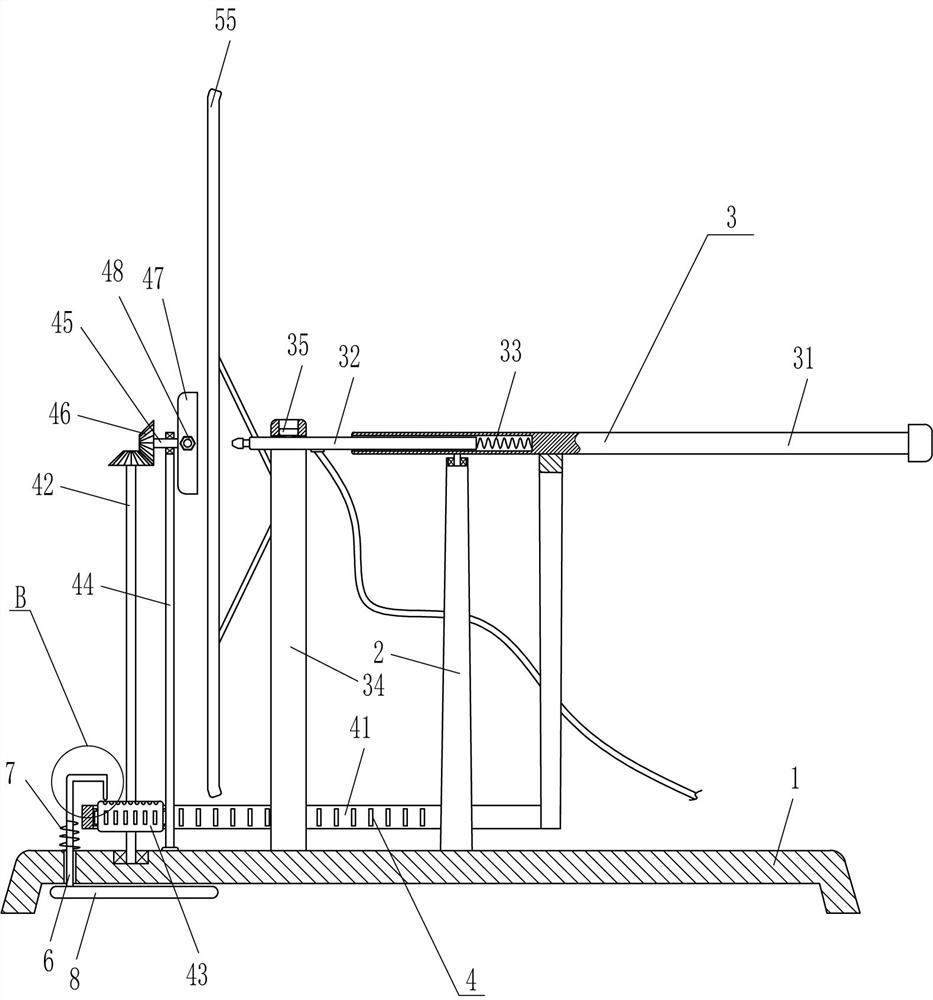

A shallow layer carbonization device for carbonized wood

ActiveCN110978191BUniform carbonizationEasy to removeDomestic cooling apparatusLighting and heating apparatusPolymer scienceCarbonization

The invention relates to a carbonization device, in particular to a shallow-layer carbonization device for process carbonized wood. The technical problem is how to provide a shallow layer carbonization device for carbonized wood that can keep a certain distance between the oxygen torch and the wood board, control the time and intensity of spraying fire on the surface of the wood board, and cool down the carbonized wood board. A shallow layer carbonization device for technical carbonized wood, comprising a base, a support rod, etc.; the base is fixedly connected with a support rod. The present invention fixes the wooden board in the placement frame by fastening bolts, and swings the hollow swing rod to drive the telescopic fire spray pipe to swing. The wooden boards keep a consistent distance, so that the wooden boards can be evenly carbonized. When the hollow swing rod swings, it can drive the arc-shaped rack to swing. Through the cooperation of the column gear and the bevel gear, the wooden boards in the frame can be driven to rotate. The surface of the board is evenly and reasonably shallowly carbonized.

Owner:赵正芽

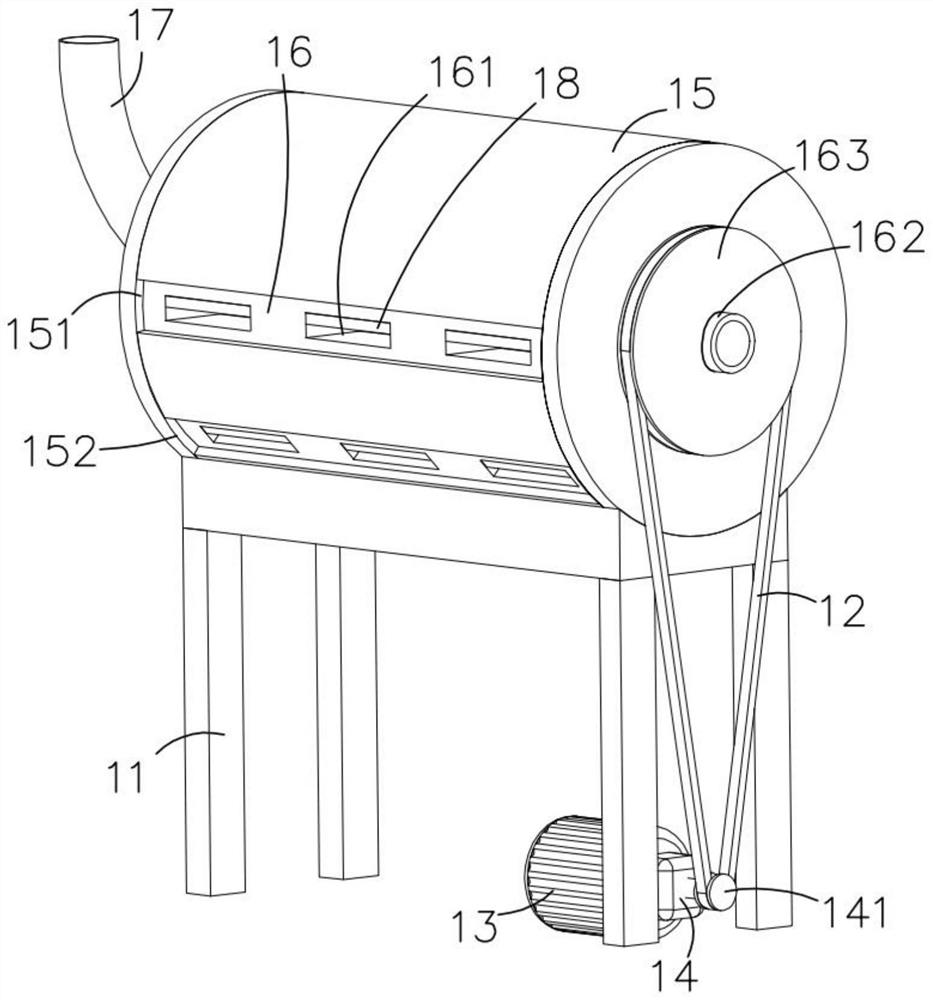

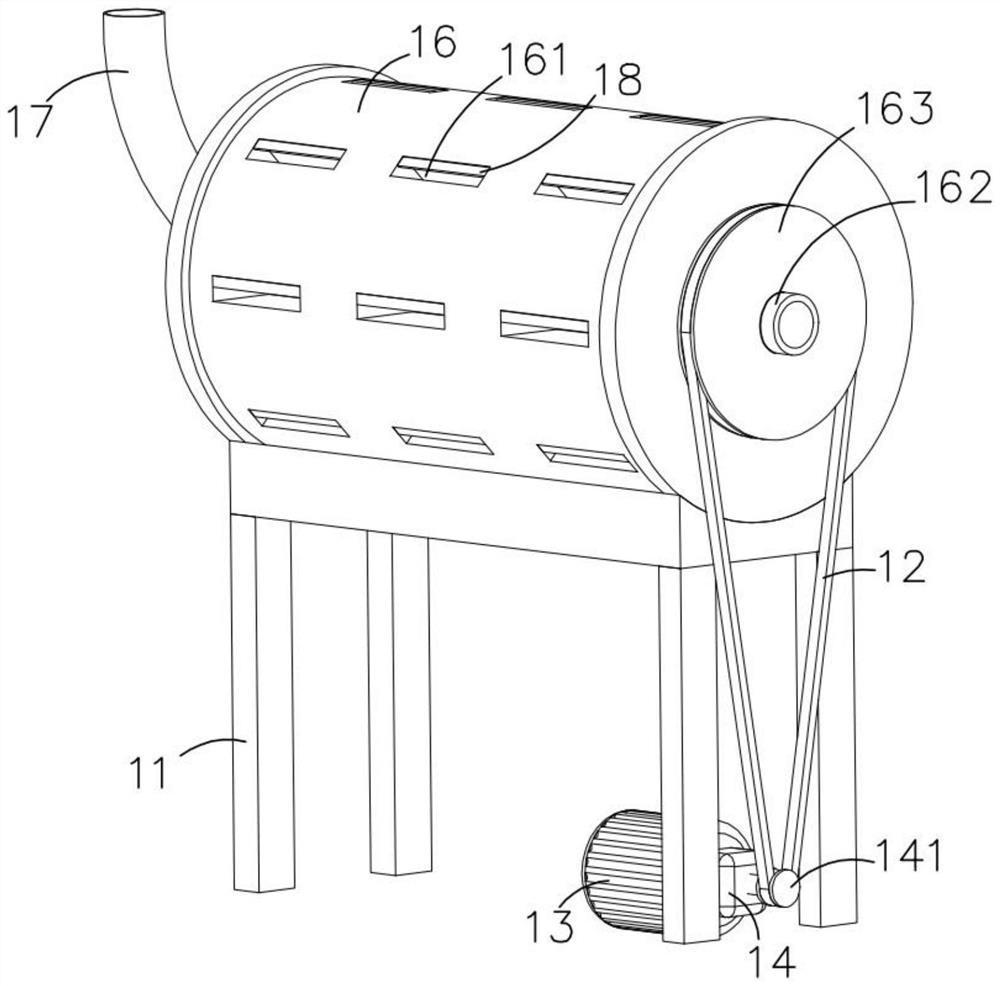

A pencil board carbonization device

ActiveCN109352783BUniform carbonizationImprove carbonization qualityWood charring/burningElectric machineryEngineering

The invention discloses a pencil board carbonization device, which includes a carbonization furnace and a blast furnace. The blast furnace includes a first support frame, a belt, a motor, a reducer and a furnace body. The furnace body includes an outer furnace and an inner furnace. A first connecting pipe and a second connecting pipe are provided respectively, the first connecting pipe and the second connecting pipe communicate with the interior of the inner furnace, the first connecting pipe is coaxially fitted with a first pulley, the speed reducer has a second pulley, and the first The pulley and the second pulley are connected by a belt. The inner furnace has a plurality of rectangular grooves sunken into the furnace on the peripheral wall. The first connecting pipe and the second connecting pipe pass through the two ends of the outer furnace. The second connecting pipe and the outer furnace A second bearing is arranged therebetween to realize the relative rotation between the second connecting pipe and the outer furnace. The outer furnace is placed on the first supporting frame, and one side of the outer furnace is provided with a first opening and a second opening. Compared with the prior art, the invention can realize the uniform carbonization of the pencil board and effectively improve the carbonization quality of the pencil board.

Owner:靖州县金心笔业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com