Hard carbon material production pretreatment device

A technology of pretreatment device and cleaning device, which is applied in grain treatment, dyeing physical treatment, fibrous filler, etc., can solve the problems of difficult crushing operation and low processing efficiency, achieve easy crushing operation, improve production efficiency, and avoid wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

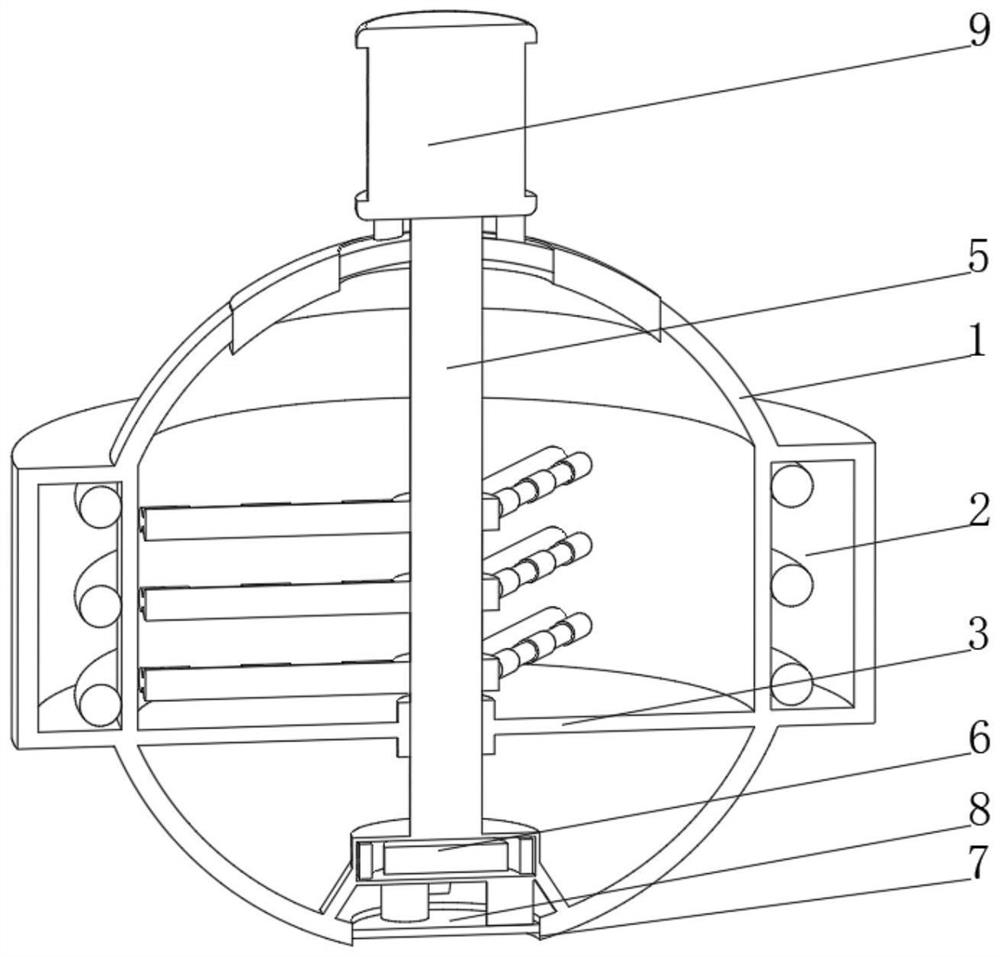

[0036] see Figure 1-3 , the present invention provides a technical solution: a hard carbon material production pretreatment device, specifically comprising:

[0037] Processing shell 1, the outer side of the processing shell 1 is provided with an annular heating device 2, the part of the inner wall of the processing shell 1 below the annular heating device 2 is provided with a support plate 3, a leak hole is opened on the support plate 3, and an outlet is provided at the bottom of the processing shell 1. The feed port 7 and the inner wall of the discharge port 7 are provided with a filter screen 8;

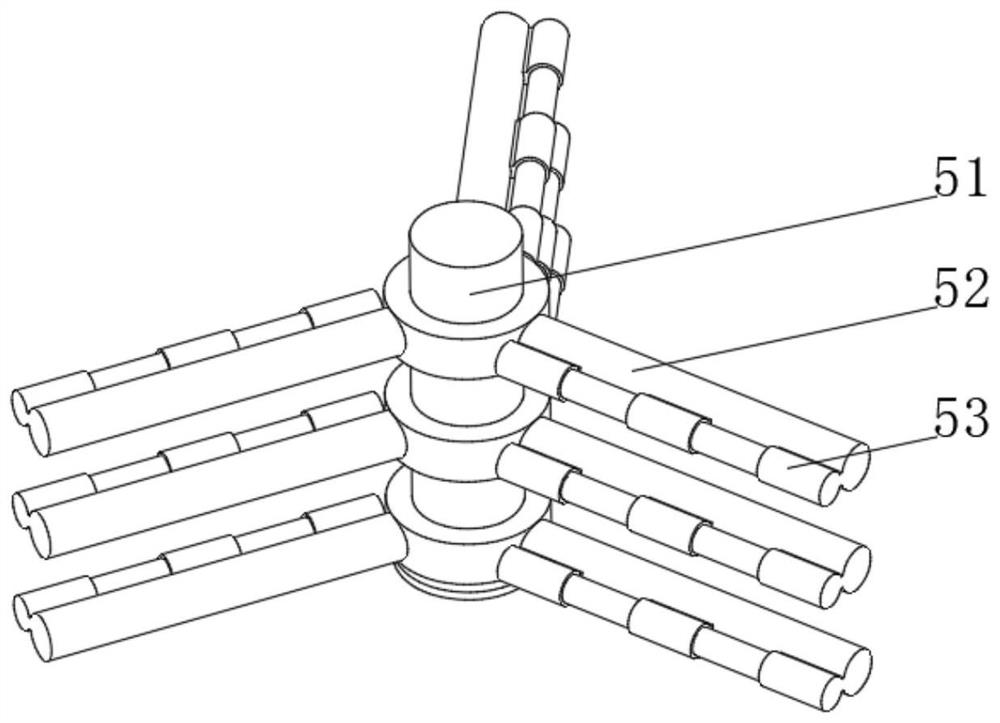

[0038] Stirring device 5, the top of the stirring device 5 runs through the processing shell 1 and is fixedly connected with a drive motor 9, the bottom of the stirring device 5 runs through the support plate 3 and is rotatably connected with the support plate 3;

[0039] Cleaning device 6, the top of the cleaning device 6 is fixedly connected to the stirring device 5, the botto...

Embodiment 2

[0045] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a technical solution: the cleaning device 6 includes a cleaning casing 61, the top of the cleaning casing 61 is penetrated and rotatably connected to a rotating shaft 62, and one end of the rotating shaft 62 located inside the cleaning casing 61 is fixedly connected to a planetary gear Group 63, the bottom of the planetary pinion inside the planetary gear set 63 is fixedly connected with a buffer casing 64, and the inner wall of the buffer casing 64 is connected with a cleaning brush 65 through a spring piece. Sliding hole 532, a return spring 533 is fixedly connected to one end of the inner wall of the storage tube 531, a slider 534 is fixedly connected to an end of the back spring 533 away from the inner wall of the storage tube 531, and a cutting plate 535 is fixedly connected to the side of the slider 534 close to the return spring 533, The top and bottom of one end of the cutting plate 5...

Embodiment 3

[0048] see Figure 1-5 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the cleaning device 6 includes a cleaning shell 61, the top of the cleaning shell 61 penetrates and is connected with a rotating shaft 62 for rotation, and one end of the rotating shaft 62 located inside the cleaning shell 61 is fixed. A planetary gear set 63 is connected, and the bottom of the planetary pinion gear inside the planetary gear set 63 is fixedly connected with a buffer housing 64, and the inner wall of the buffer housing 64 is connected with a cleaning brush 65 through a spring piece, and the top of the rotating shaft 62 is fixedly connected with the bottom of the stirring shaft 51 to clean the housing. The outer side of 61 is fixed on the inner wall of the processing shell 1 through a bracket. When in use, the stirring shaft 51 drives the planetary gear set 63 to rotate through the rotating shaft 62, and the planetary gear set 63 drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com