Preparation method of resin-based hard carbon negative electrode material

A negative electrode material and resin-based technology, which is applied in the field of preparation of power supply negative electrode materials and resin hard carbon negative electrode materials, can solve the problems of low initial Coulombic efficiency and capacity of hard carbon, difficult industrialization, poor uniformity, etc., to achieve uniform impregnation, Uniform carbonization and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

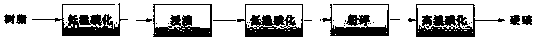

Method used

Image

Examples

Embodiment 1

[0032] Such as Figure 4 As shown, use coumarone resin (softening point 130°C, carbon residue 10%) as the skeleton, fully carbonize at 420°C for 5 hours, and then use impregnating agent pitch (softening point 25°C, QI 2.5%, carbon residue 30%) %) impregnation, the ratio of resin to impregnating agent is 1:2, continue to carbonize at 450°C, after the carbonized material is crushed, the median particle size D 50 The negative electrode material is 10 μm, and then carbonized at 1400°C at high temperature. The obtained negative electrode material has a high initial Coulombic efficiency (83%) and a first reversible capacity of 310.8mAh / g. The material was tested for 50 charge-discharge cycles at 5C. Reversible capacity retention The rate is 97.2%.

Embodiment 2

[0034] Use petroleum resin (softening point 150°C, carbon residue 15%) as the skeleton, fully carbonize at 450°C for 5 hours, and then use impregnating agent pitch (softening point 25°C, QI 3.0%, carbon residue 35%) impregnation, resin The ratio with the impregnating agent is 1:2, continue to carbonize at 450°C, after the carbonized material is crushed, the median particle size D 50 The negative electrode material is 15μm, and then carbonized at 1400°C. The obtained negative electrode material has a high first-time Coulombic efficiency (85%) and a first-time reversible capacity of 324.3mAh / g. The material was tested for 50 charge-discharge cycles at 5C. Reversible capacity retention The rate is 98.9%.

Embodiment 3

[0036] Use phenolic resin (softening point 115°C, carbon residue 20%) as the skeleton, fully carbonize at 500°C for 5 hours, and then use impregnating agent pitch (softening point 30°C, QI 3.5%, carbon residue 40%) impregnation, resin The ratio with the impregnating agent is 1:2, continue to carbonize at 450, and the carbonized material is crushed to obtain a median particle size D 50 The negative electrode material is 20μm, and then carbonized at 1400°C. The obtained negative electrode material has a high first-time Coulombic efficiency (90%) and a first-time reversible capacity of 332.5mAh / g. The material was tested for 50 charge-discharge cycles at 5C. Reversible capacity retention The rate is 99.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com