Carbon powder preparation method

A production method and carbon powder technology, which are used in special forms of dry distillation, petroleum industry, biofuels, etc., can solve the problems of non-continuous operation, uneven carbonization, and low carbon powder yield, so as to improve product quality, uniform carbonization, The effect of improving the rate of carbon powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

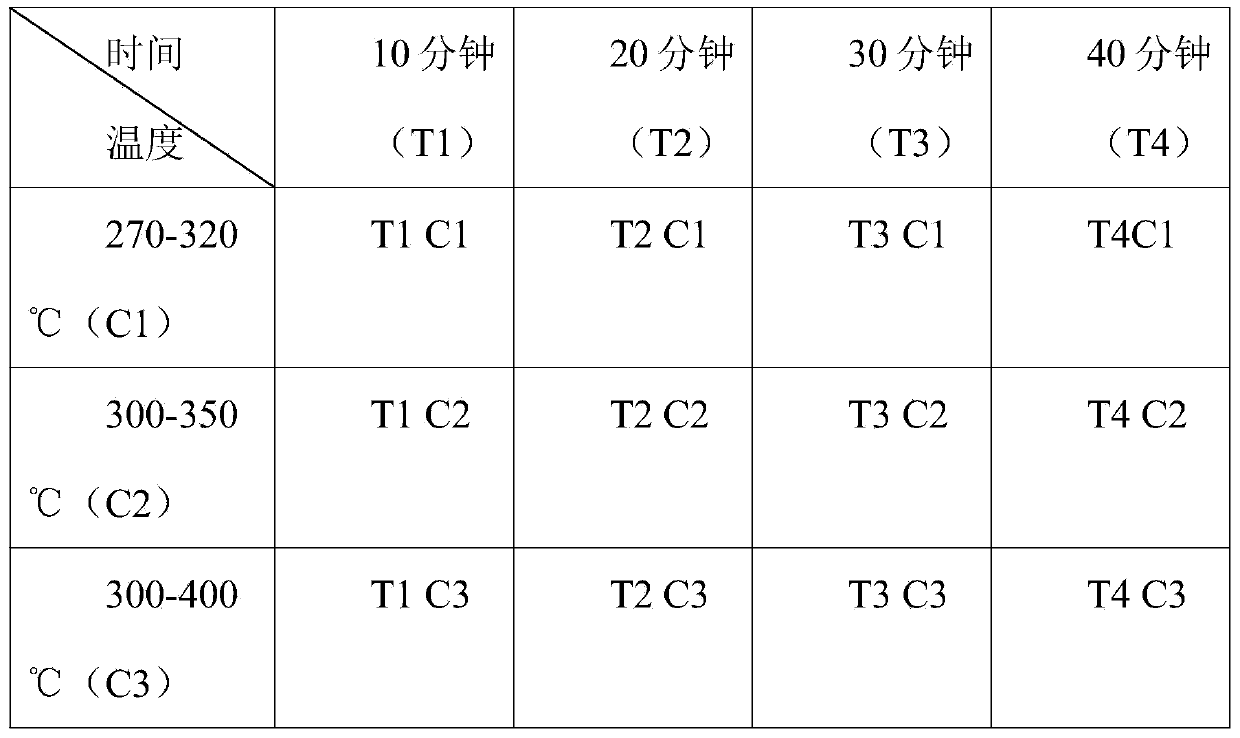

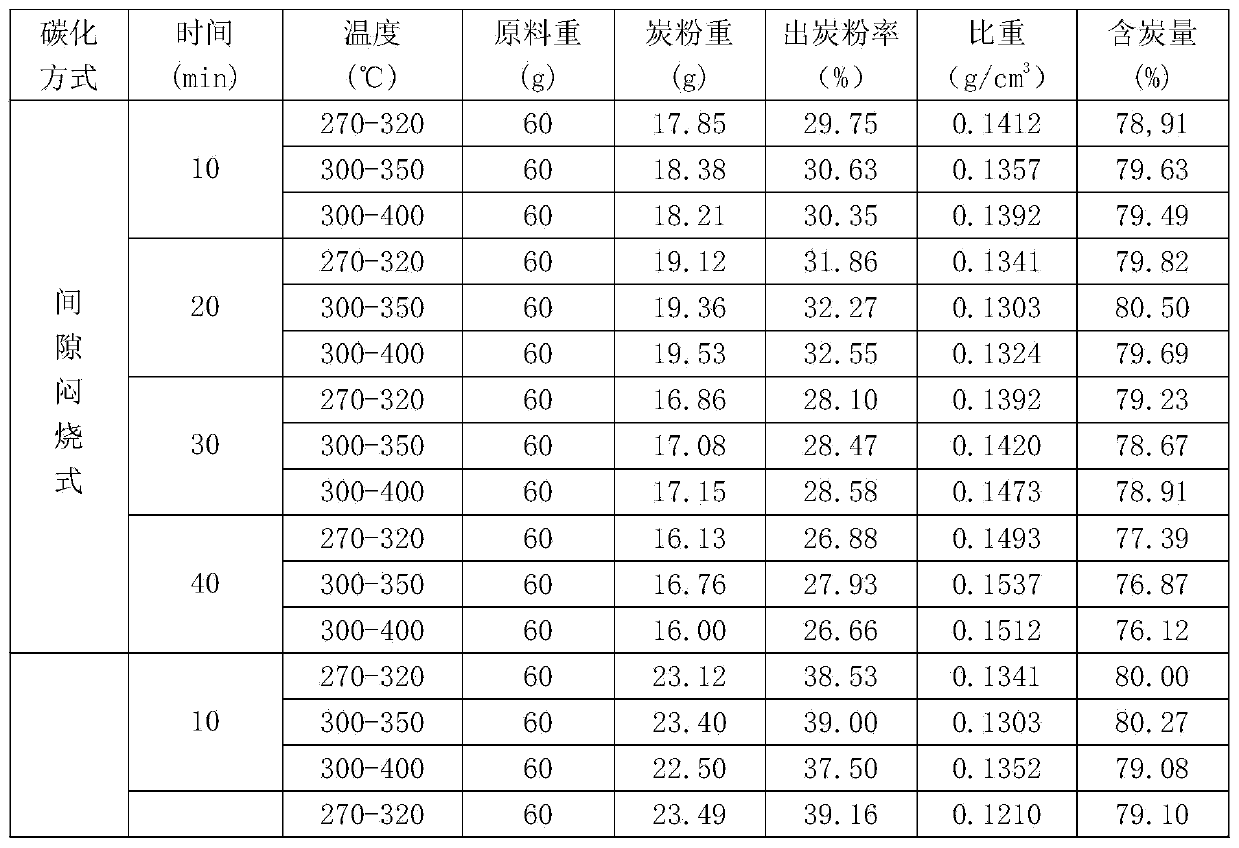

[0036] Embodiment 1, flax stalk carbonization experiment

[0037] From Table 2 of the flax stalk carbonization experiment, it can be concluded that among the 12 experimental treatment combinations, the charcoal output rate of the smoldering experiment is between 26.66-32.55%, with a difference of 5.89 percentage points, and the rotary type is between 33.83-40.80%, with a difference of 6.97 percentage points percentage points, the rotary type is 7.17-8.25 percentage points higher than the smoldering type. Both carbonization methods show that the carbon powder output rate decreases gradually with the increase of carbonization temperature and carbonization time; the carbon content of carbon powder is stuffy The burning type is between 76.12-80.50%, and the rotary type is between 76.12-80.87%. There is little difference between the 12 experimental treatment combinations, and there is little difference between the two carbonization methods. As the carbonization temperature increase...

Embodiment 2

[0042] Embodiment 2, Chinese fir sawdust carbonization experiment

[0043] It can be seen from Table 3 of the fir sawdust carbonization experiment that among the 12 experimental treatment combinations, the charcoal output rate of the smoldering experiment is between 36.86-39.90%, with a difference of 3.04 percentage points, and the rotary type is between 43.15-45.26%, with a difference of 1.76%. percentage points, the carbon powder output rate of the rotary type and the smoldering type is 5.12-6.14 percentage points higher than that of the same period last year. Both carbonization methods show that as the carbonization temperature increases and the carbonization time increases, the carbon powder output rate is "high in the middle and low at both ends." "; the carbon content of carbon powder is between 79.81-81.77% for the smoldering type and 79.49-81.92% for the rotary type. There is little difference between the 12 experimental treatment combinations, and the comparison betwee...

Embodiment 3

[0047] Embodiment 3, kenaf stalk carbonization experiment

[0048] From Table 4 of the kenaf stalk carbonization experiment, it can be seen that among the 12 experimental treatment combinations, the charcoal output rate of the smoldering experiment is between 24.16-29.10%, with a difference of 4.94 percentage points, and the rotary type is between 33.48-38.60%, with a difference of 4.94%. 5.12 percentage points, the carbon powder output rate of the rotary type and the smoldering type is 9.32-9.50 percentage points higher than that of the same period last year. Both carbonization methods show that as the carbonization temperature increases and the carbonization time increases, the carbon powder output rate shows "middle high at both ends" "Low" change; the carbon content of carbon powder is between 81.36-85.50% for the smoldering type, with a difference of 4.14 percentage points. The carbonization time of 20 minutes is the highest, followed by 10 minutes, 30 minutes, and 40 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com