Equipment and method for drying-carbonizing combined treatment of wood material heated by electric heating plate in negative pressure environment

A technology of wood drying and combined treatment, applied in the direction of pressurized wood treatment, wood drying, wood treatment, etc., can solve the problems of low production efficiency, unsuitable drying, labor-intensive and labor-intensive, etc., to reduce procurement costs, speed up drying, temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

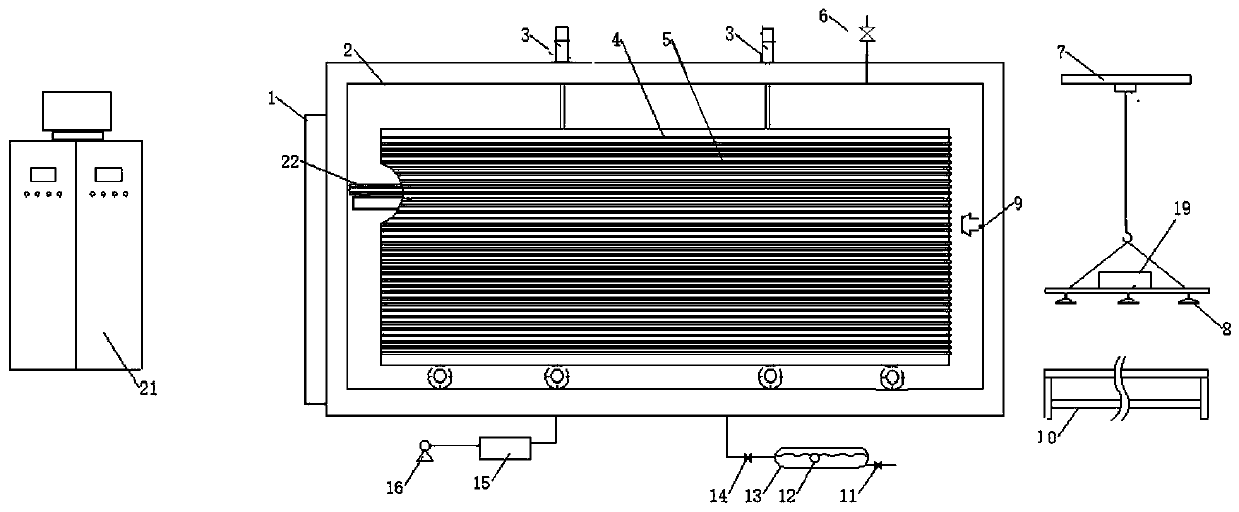

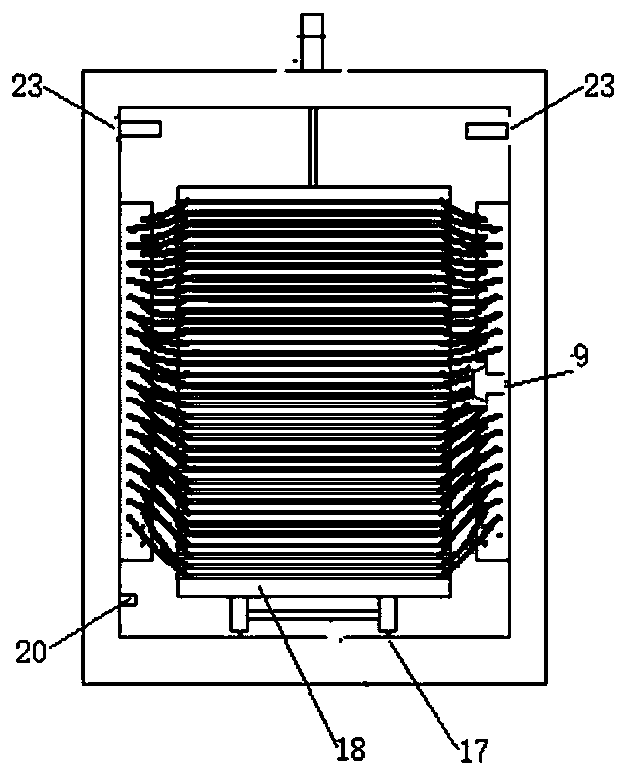

[0043] as attached figure 1 And attached figure 2 As shown, an electric heating plate heating wood drying-carbonization joint treatment equipment in a negative pressure environment includes a vacuum tank body 2, a vacuum acquisition device, an electric heating device in the tank, an electric control cabinet 21 and a control device, and the vacuum tank body 2 is also provided with A high-pressure fine water atomization humidification device 23 is arranged.

[0044] The electric heating device in the vacuum tank body 2 is composed of several electric heating plates 4, and the electric heating plates 4 are composed of a heat dissipation aluminum plate, a high temperature resistant insulating material and an inner conductive heating element. When in use, the electric heating plates 4 and the wood to be processed 5 are alternately placed in parallel to form a stack, the uppermost and lowermost electric heating plates 4 of the stack are provided with heat insulation layers, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com