Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

627results about How to "Shorten the working cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

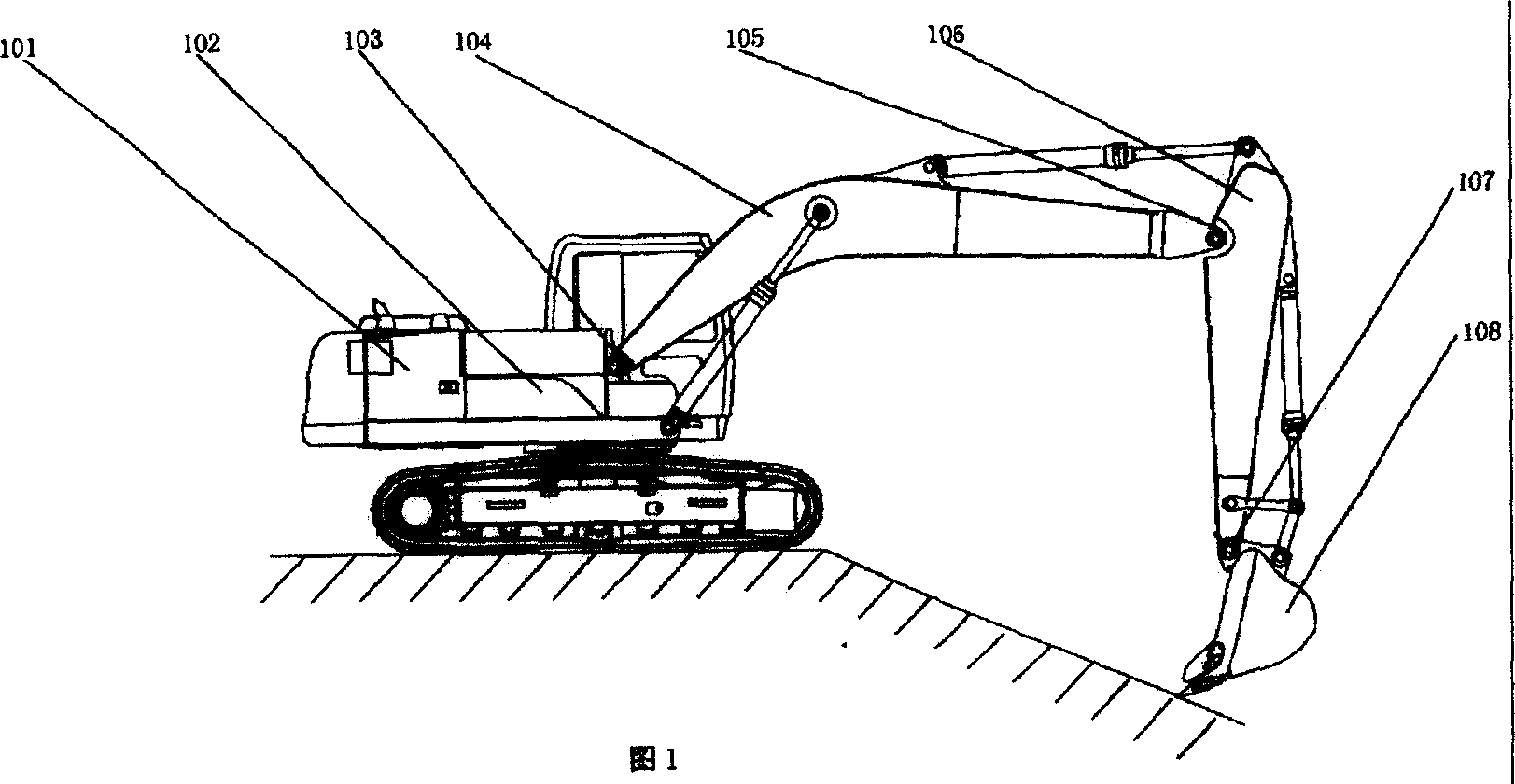

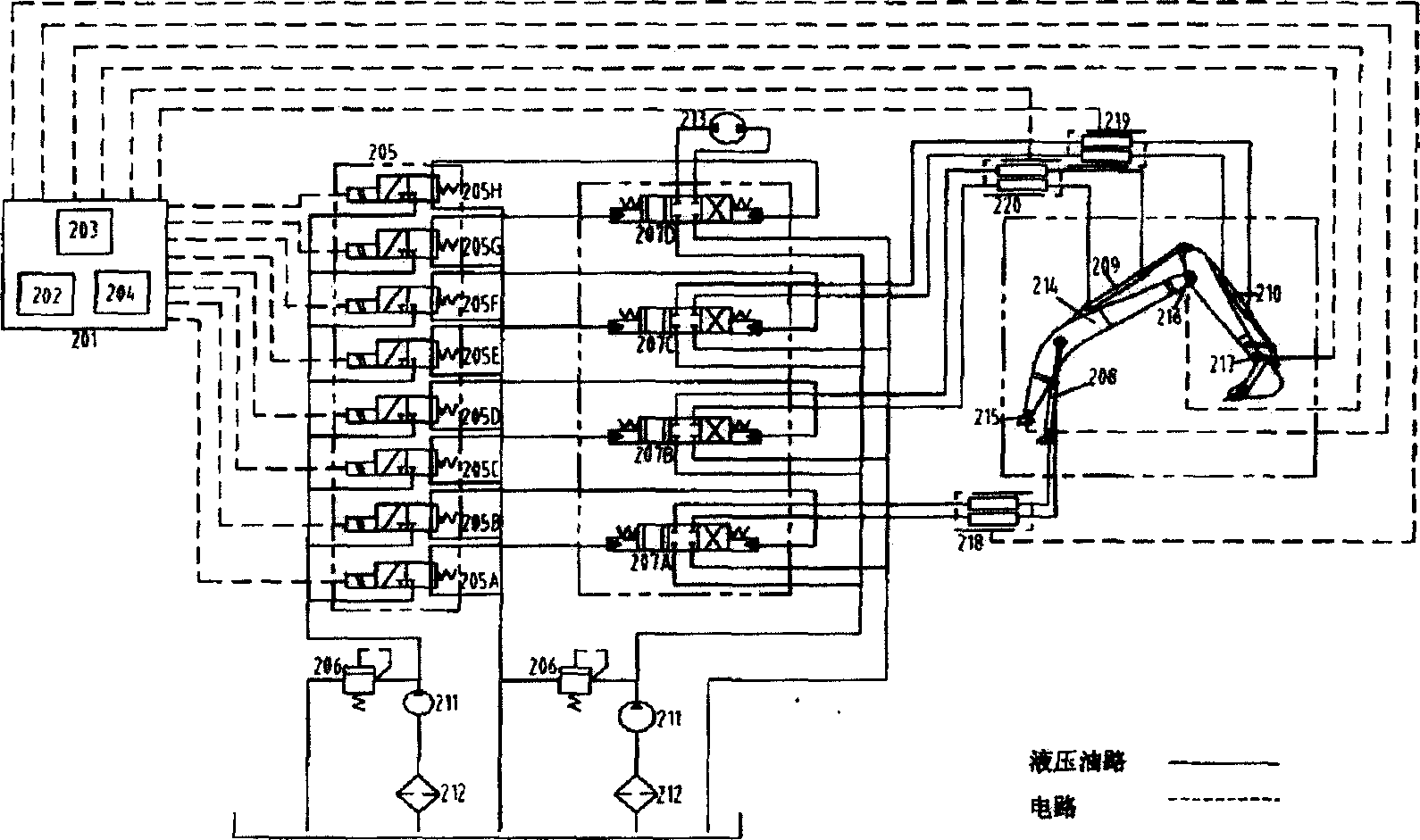

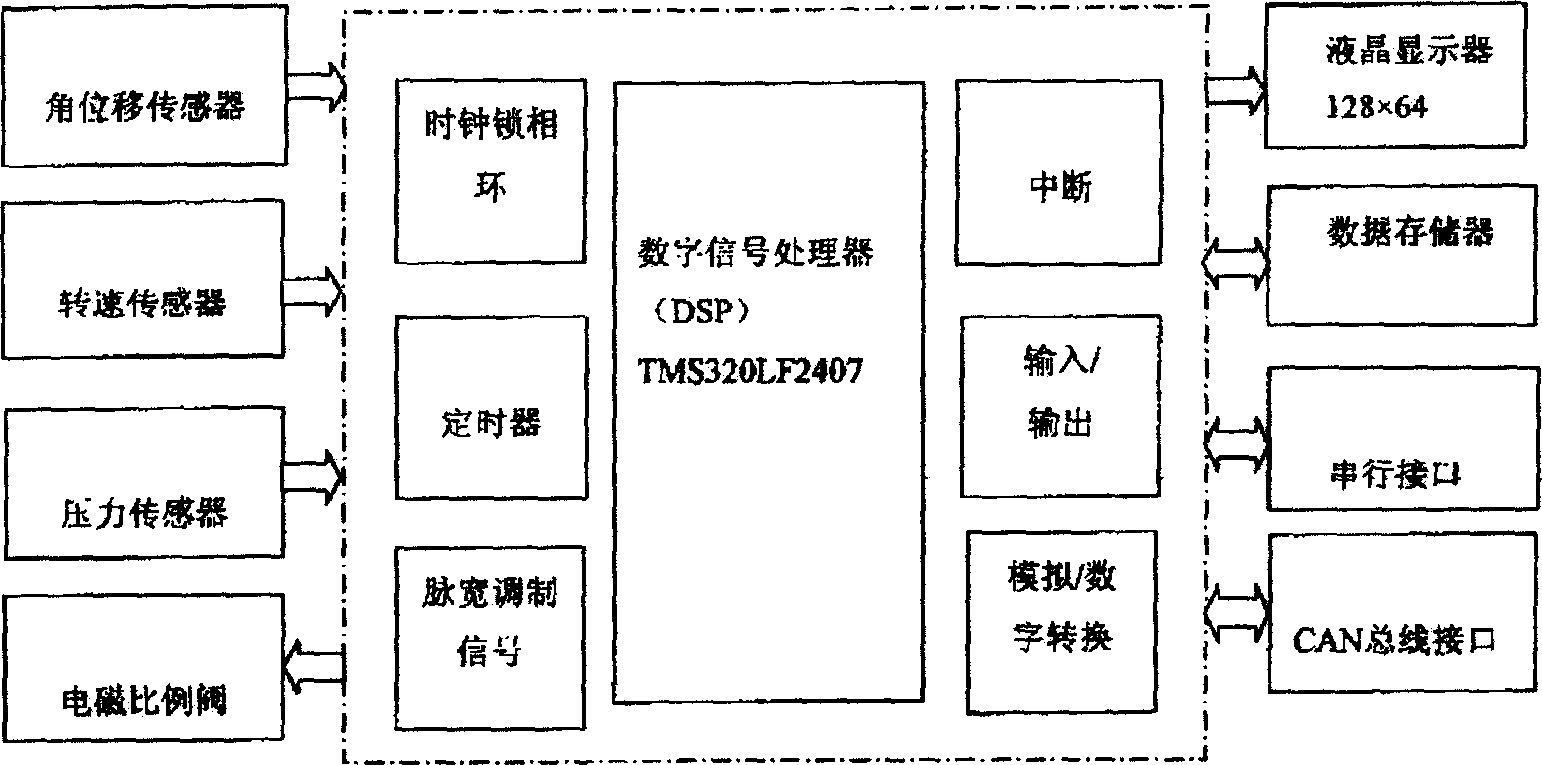

Path control system used for hydraulic digger operating device and its method

InactiveCN1651666ARealize automatic manipulationPrecise and stable positionSoil-shifting machines/dredgersPosition/direction controlHydraulic cylinderAutomatic control

The present invention relates to a track control system for hydraulic excavator working equipment and its method. Said system includes the following main components: DSP, moving arm angle detection mechanism, bucket arm angle detection mechanism, bucket angle detection mechanism, hydraulic cylinder, engine, working equipment and its driving cylinder and CAN bus. Said invention also provides the concrete steps of said control method. It can implement automatic control of hydraulic excavator working equipment, and can accurately and stably control the position and attitute of said hydraulic excavator working equipment so as to raise its working efficiency.

Owner:GUANGXI LIUGONG MASCH CO LTD

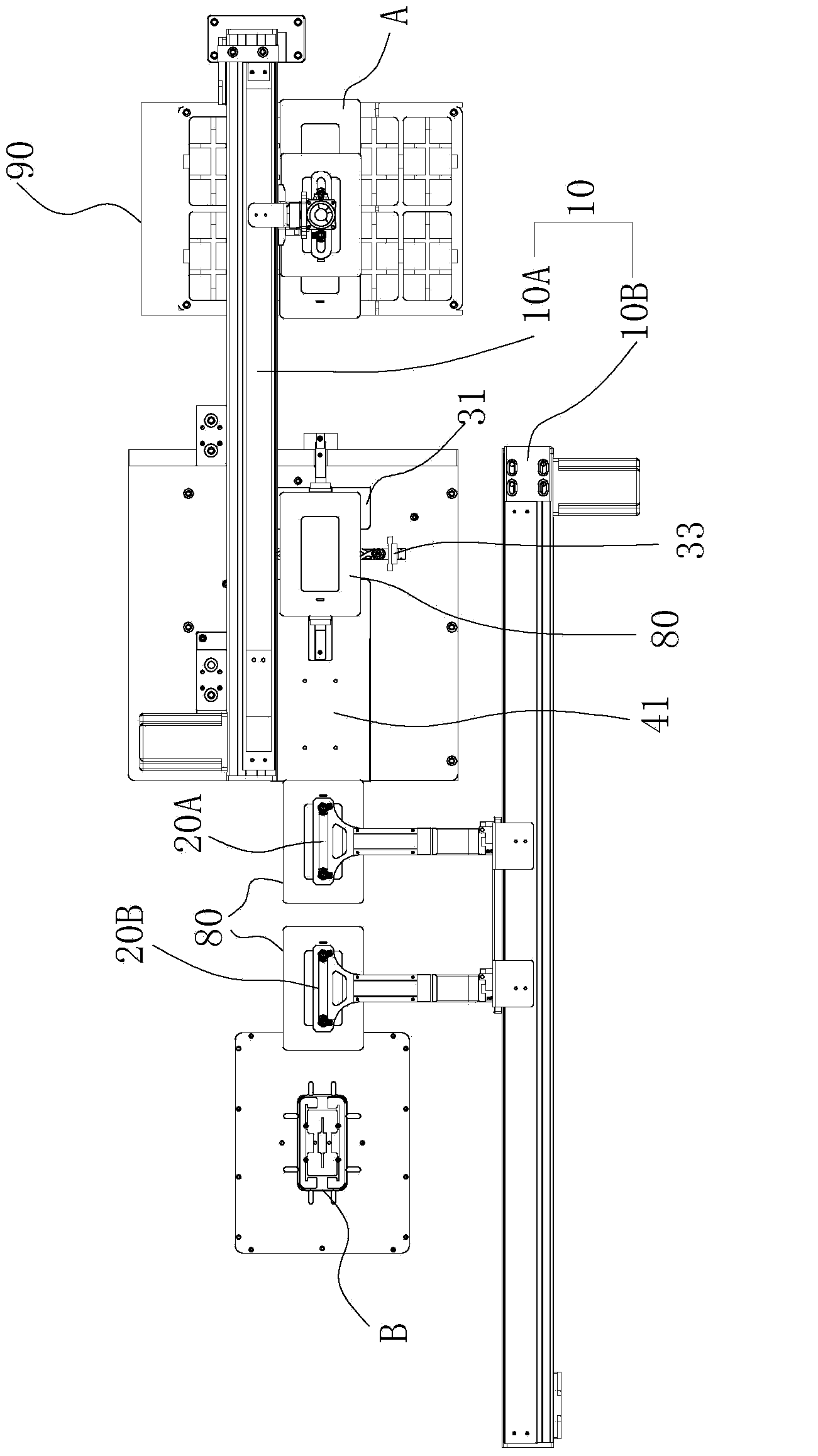

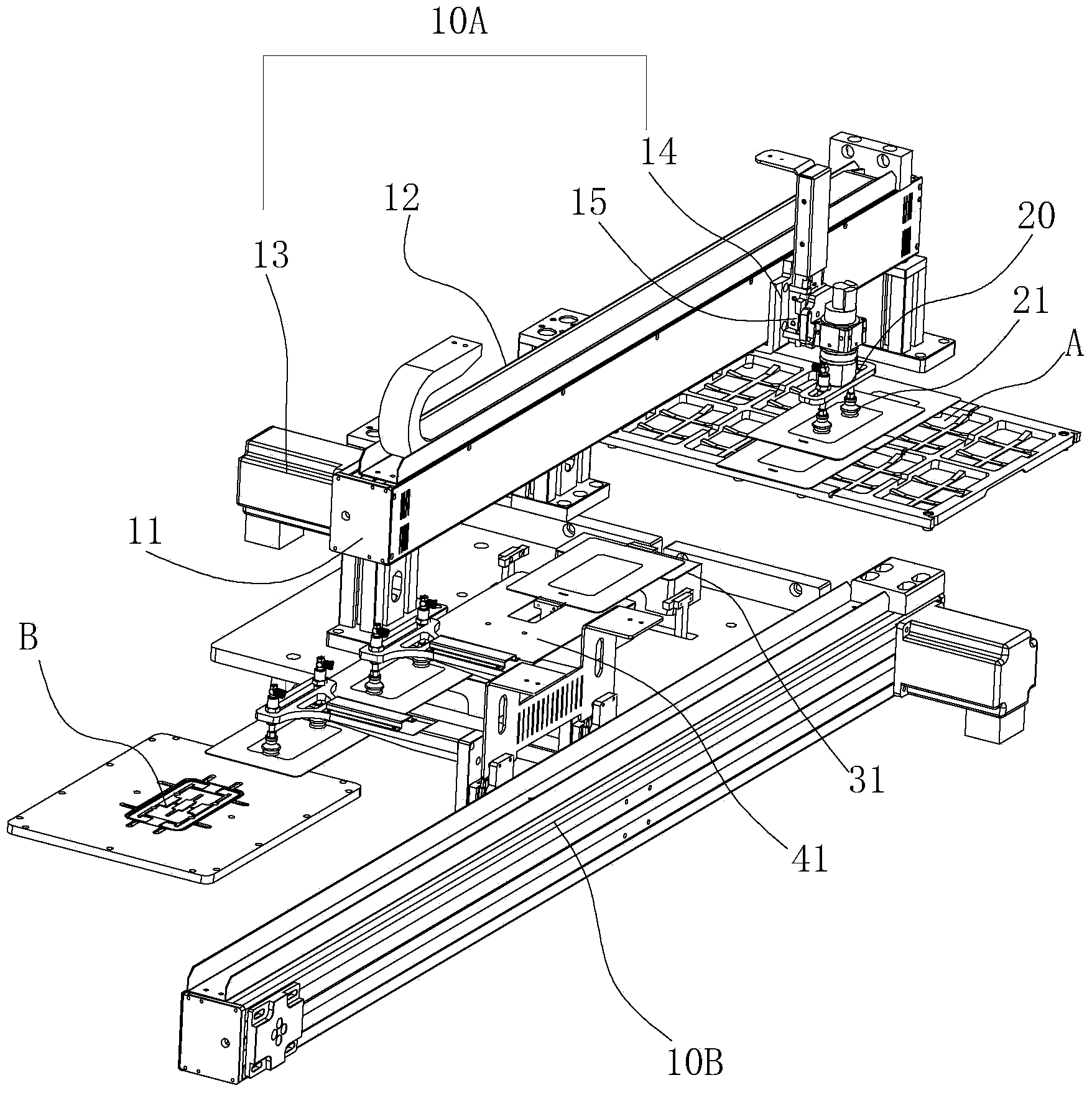

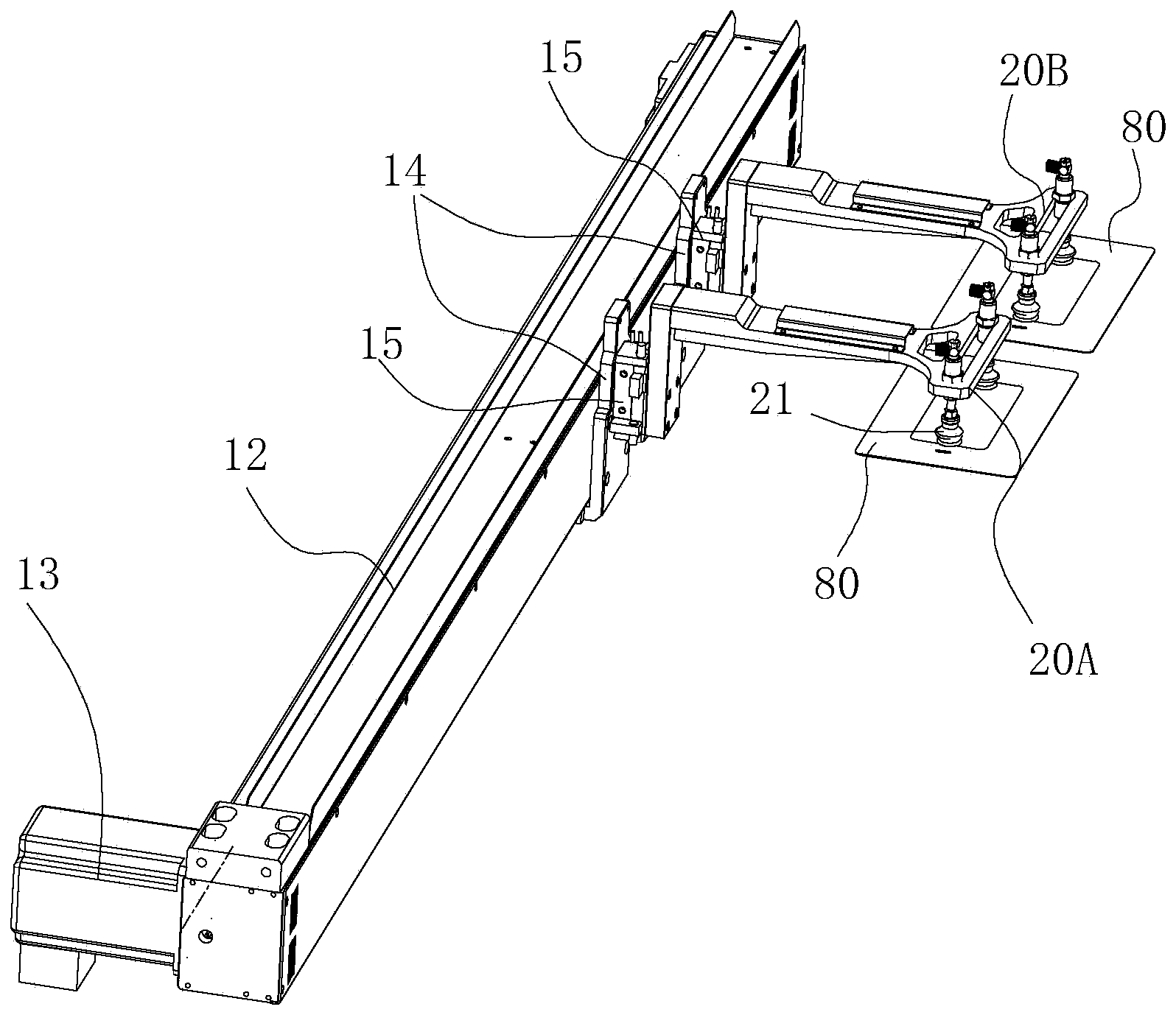

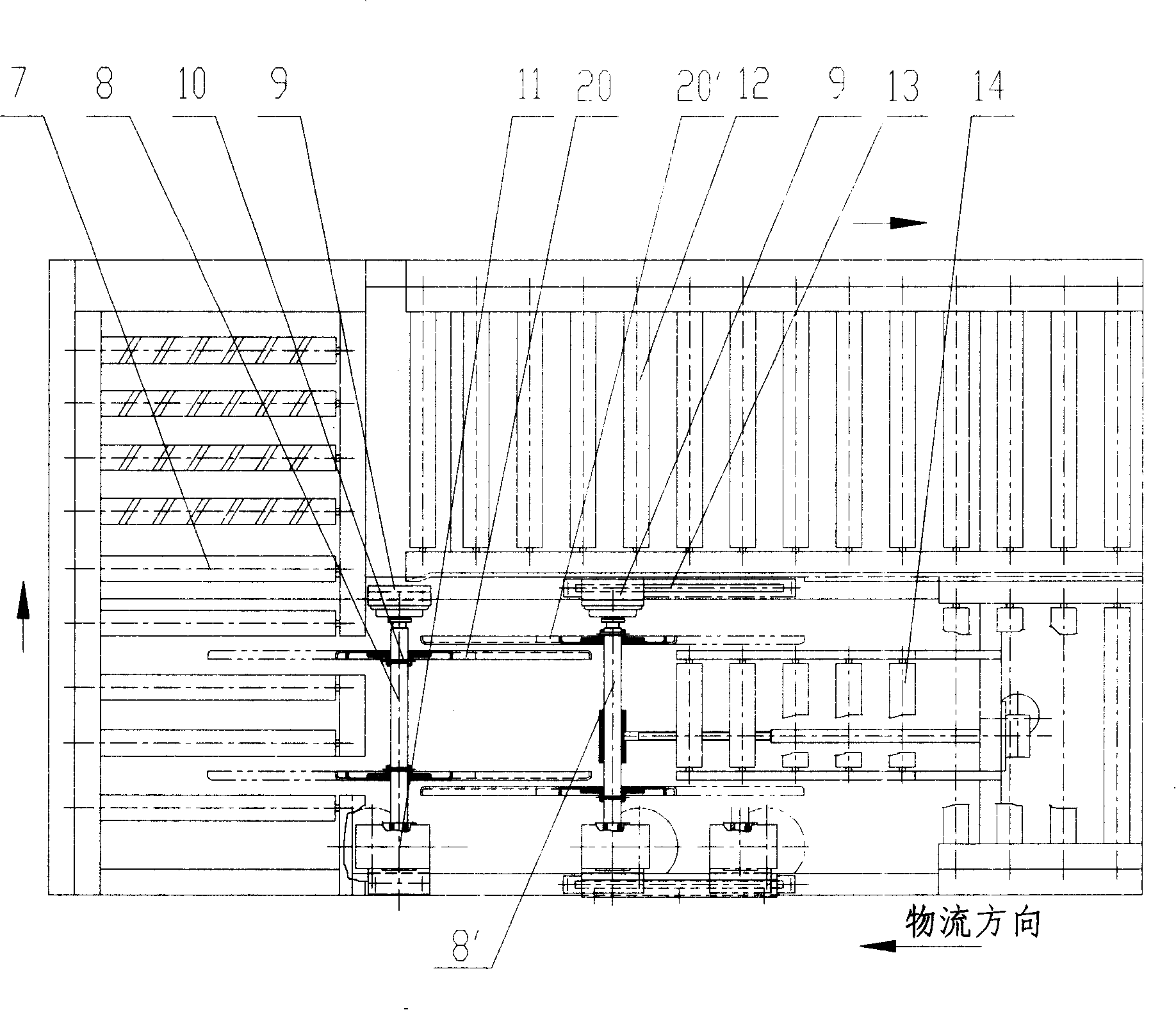

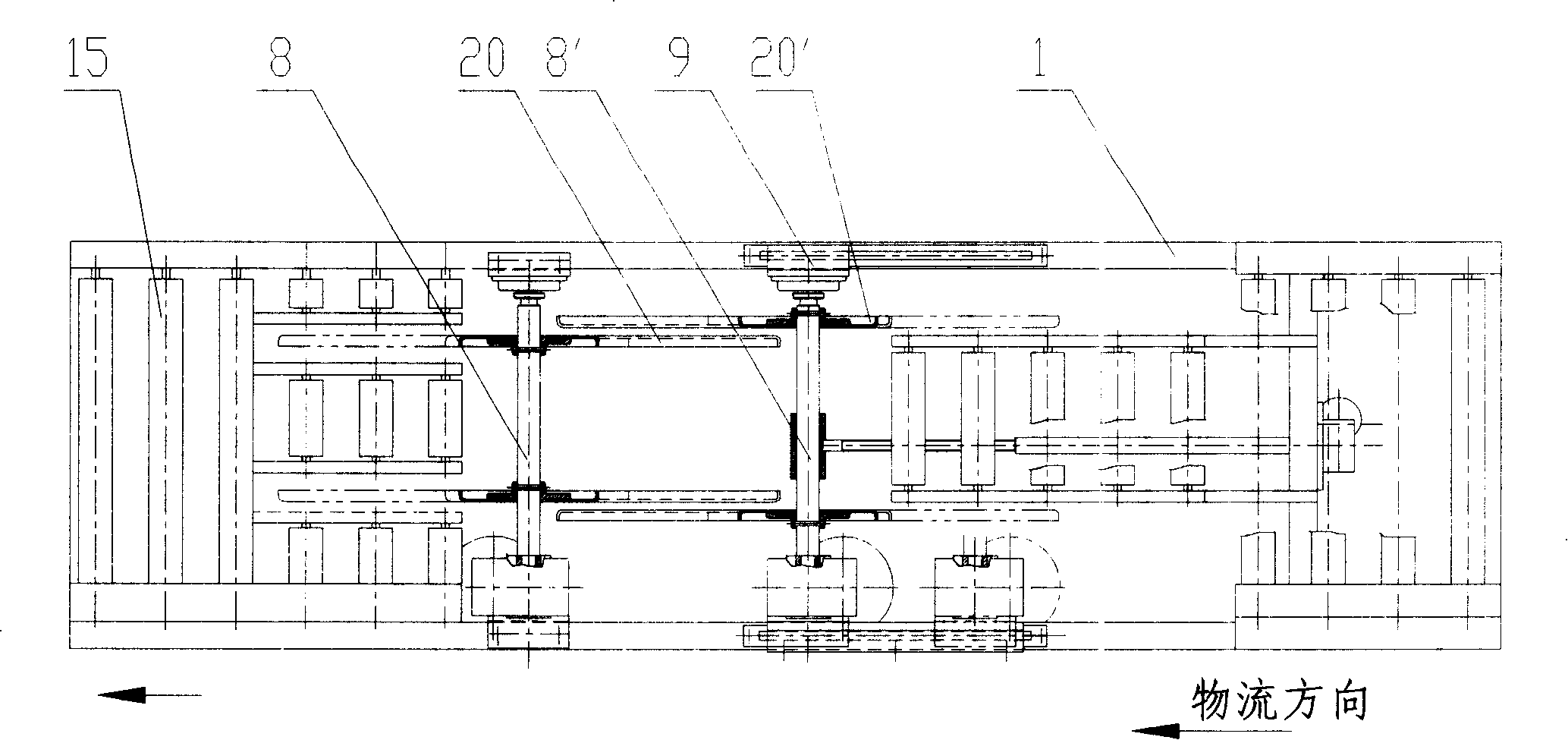

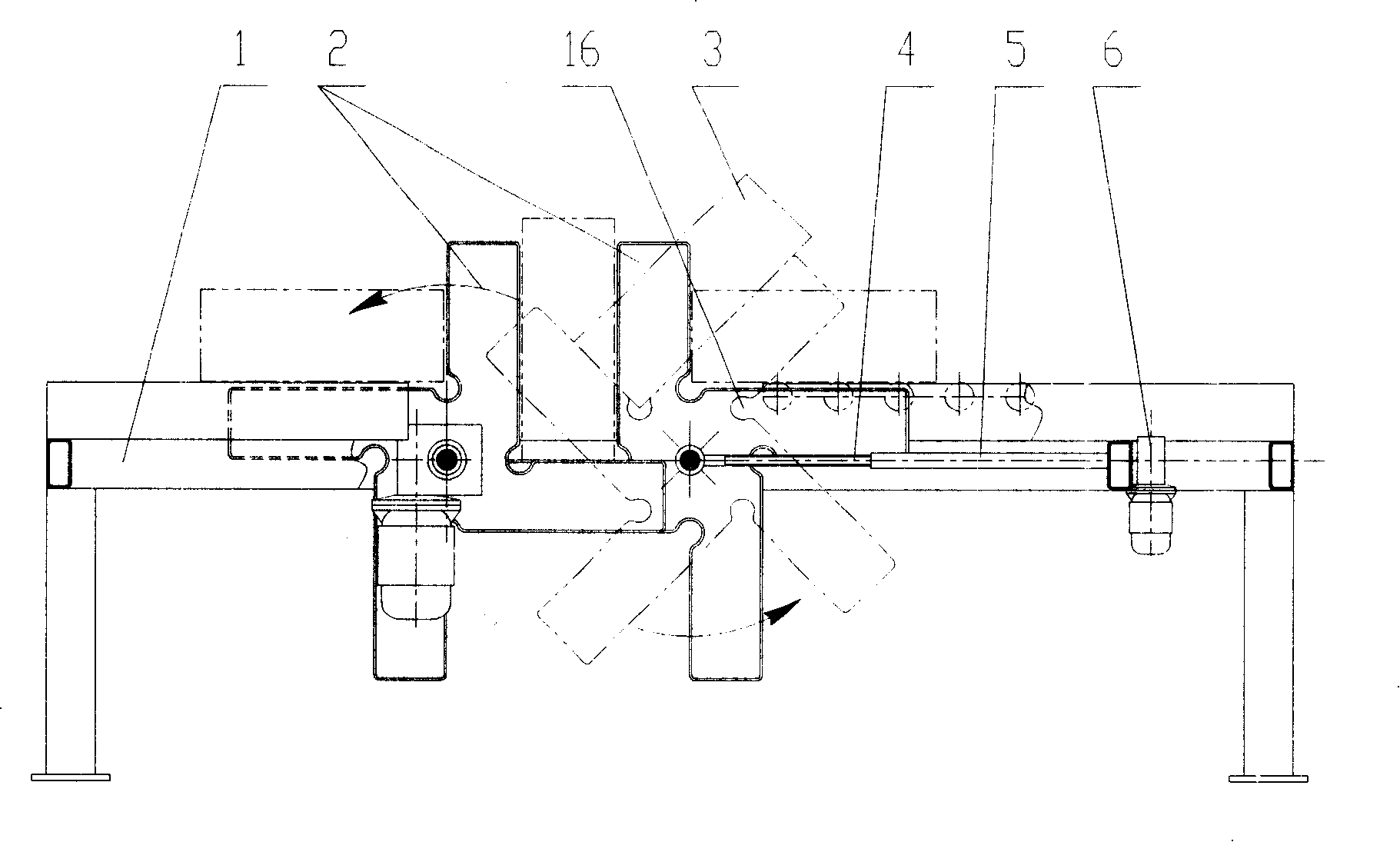

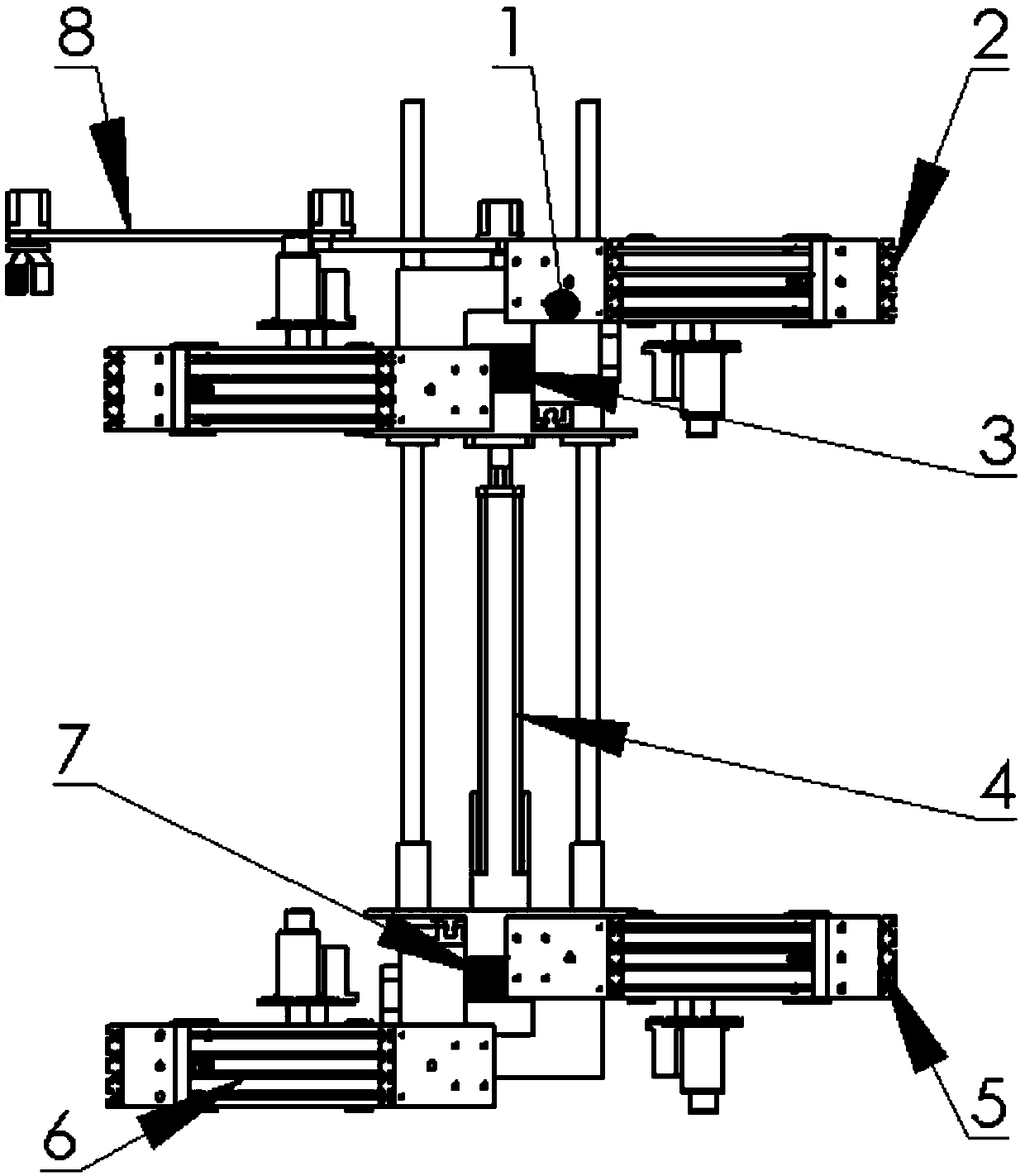

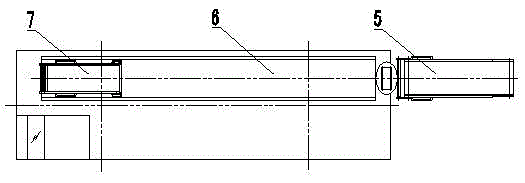

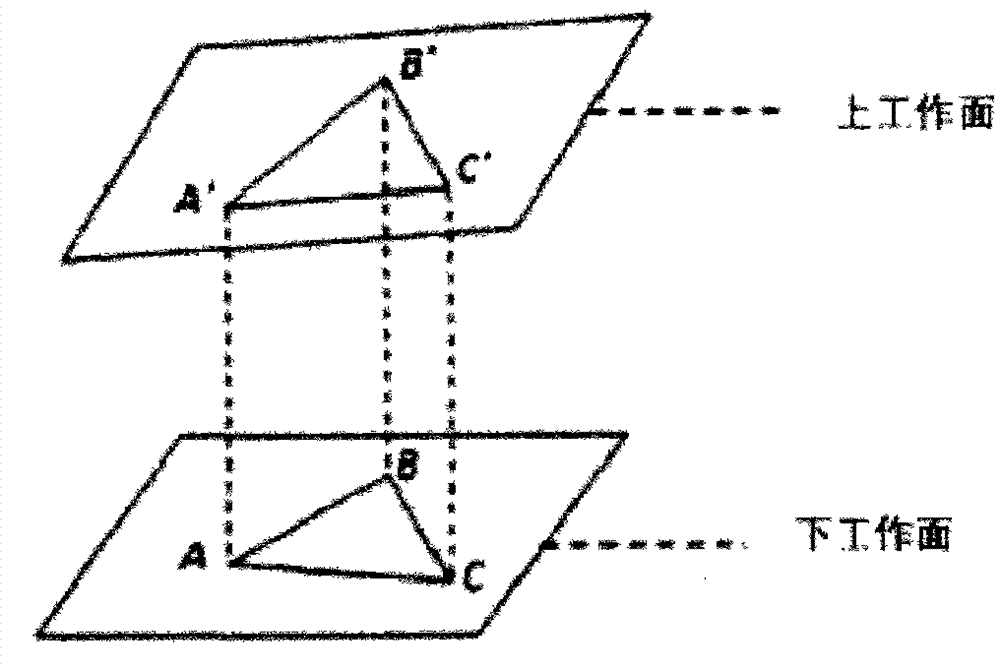

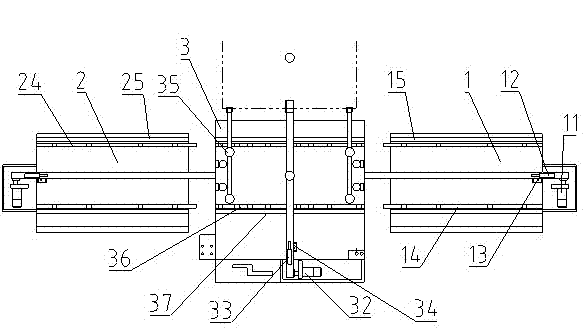

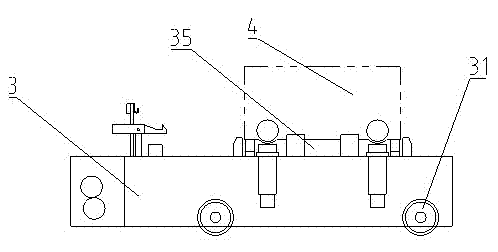

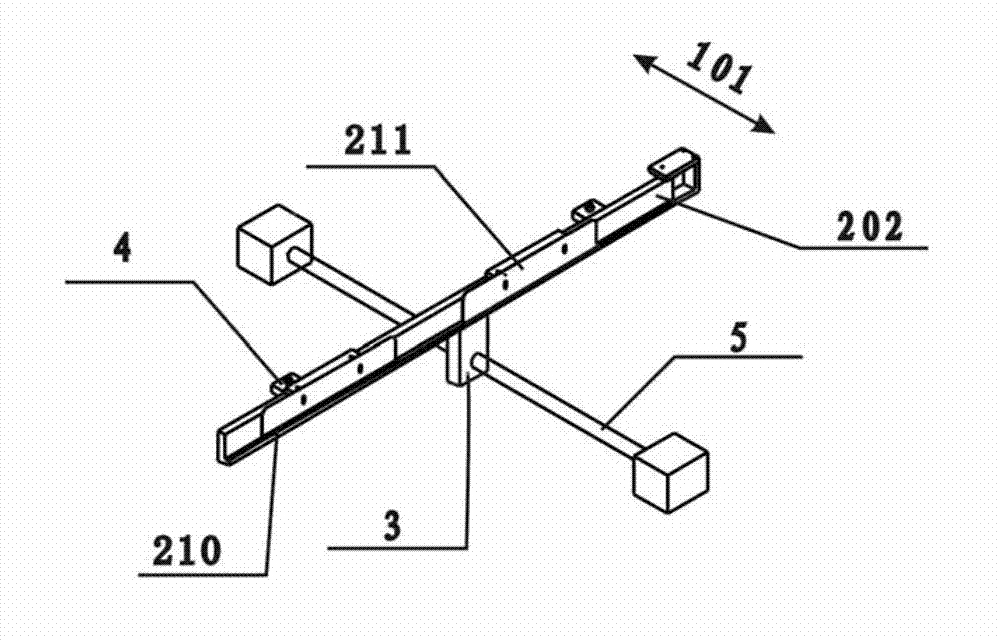

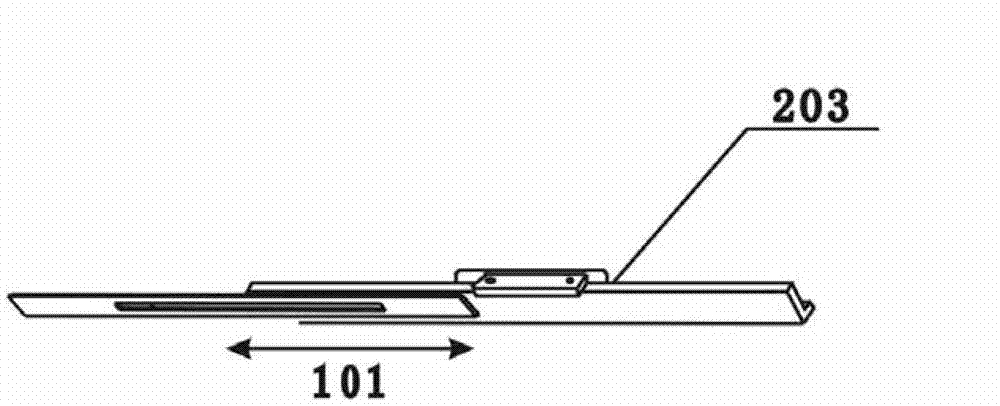

Material reciprocating transferring device and method

ActiveCN103863818AShorten the working cycleGuaranteed location consistencyCharge manipulationConveyor partsEngineeringLarge distance

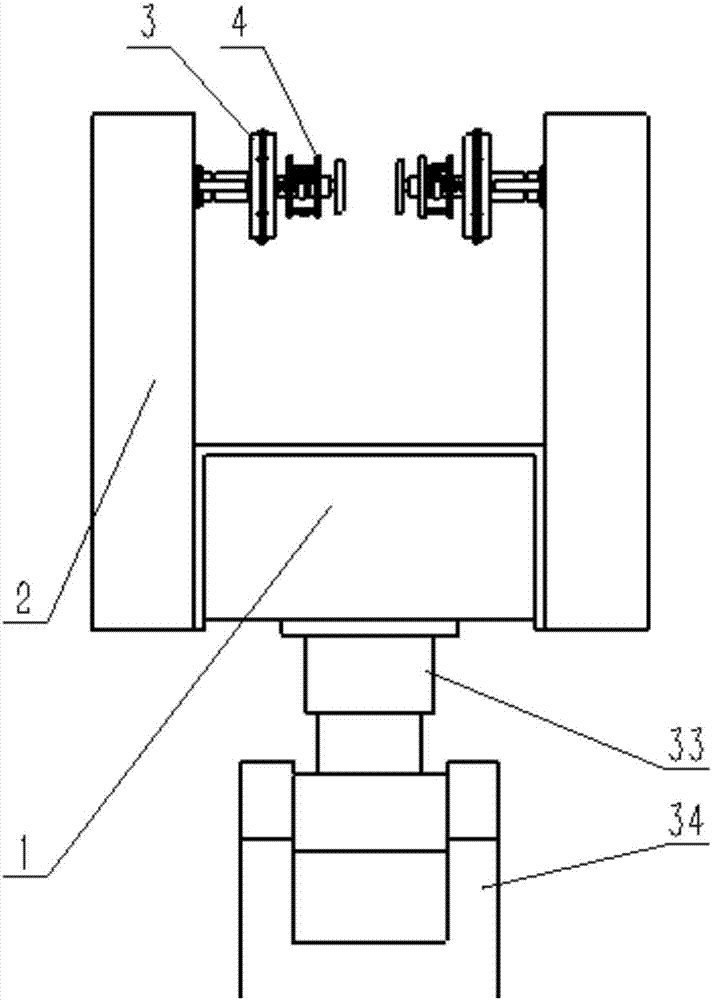

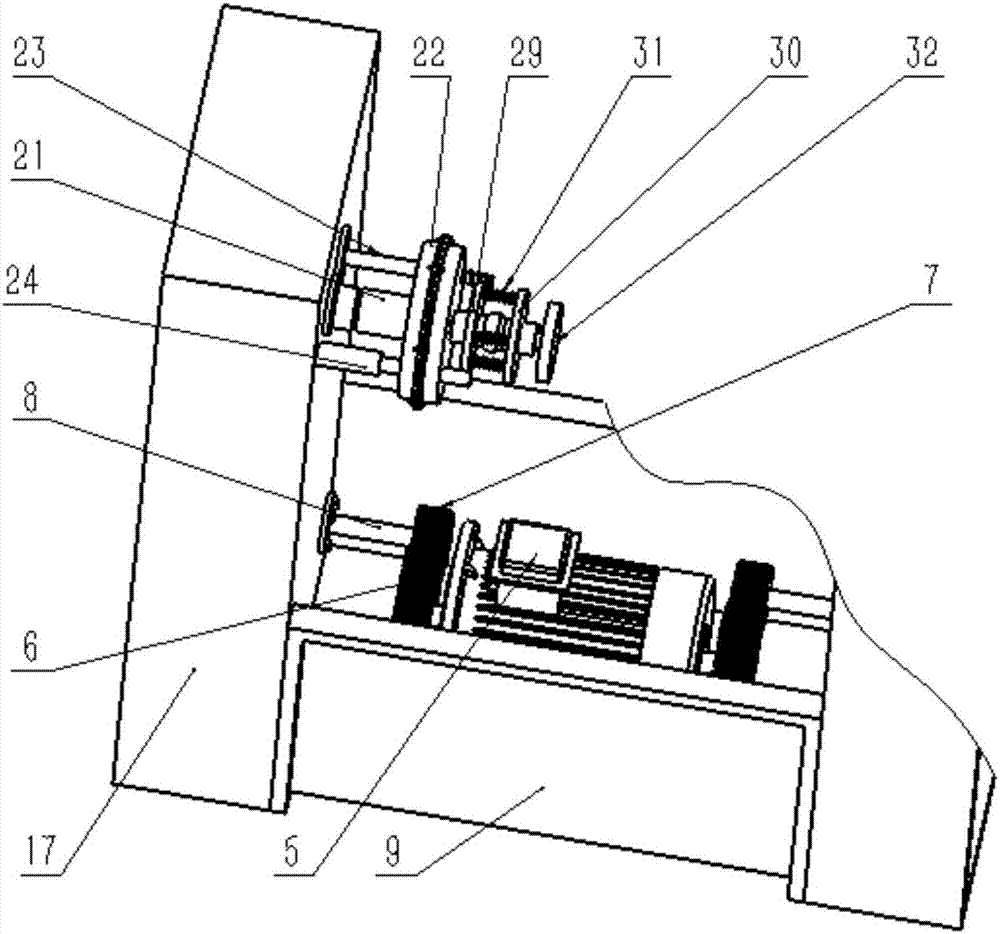

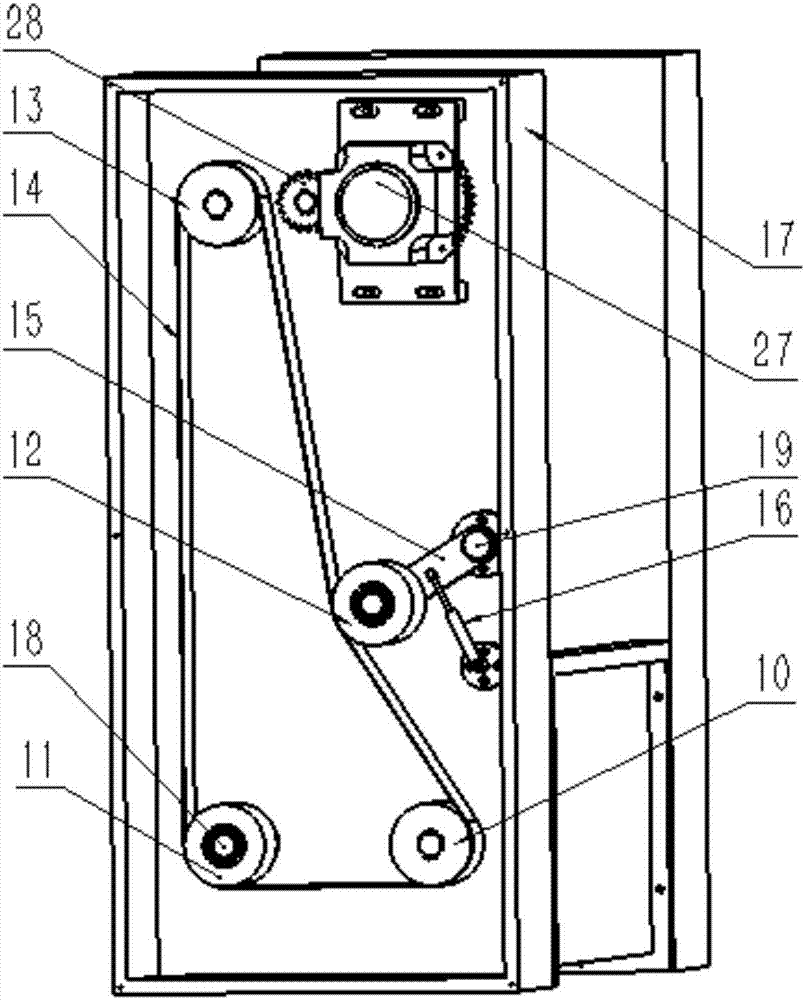

The invention discloses a material reciprocating transferring device and method. The material reciprocating transferring device comprises a transferring mechanism arranged between the material position of a material device and the machining position of a machining device. The transferring mechanism is movably connected with a downward fetching mechanism. The material reciprocating transferring device further comprises a primary locating mechanism located below the middle section of the transferring mechanism. Materials are fed for the first time and for the second time. When fetched for the first time, the materials move from the material position to the primary locating mechanism. When fetched for the second time, the materials move from the primary locating mechanism to the machining position. The primary locating mechanism is adopted, so that a work piece is roughly located at the material position; due to the locating function of the primary locating mechanism, the materials can be accurately placed at the machining position and can be accurately machined. The transferring mechanism adopts two mechanical arms moving linearly for feeding materials, so that the transferring period of the work piece is greatly shortened, and production efficiency is improved. The material reciprocating transferring device is suitable for the application environment with large distance between the material position and the machining position.

Owner:湖南三兴精密工业股份有限公司

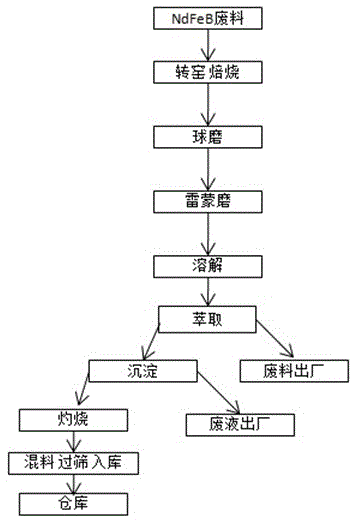

Method for extracting rare earth from oxidized neodymium iron boron waste

InactiveCN102719674AAvoid harmStop pollutionProcess efficiency improvementRare-earth elementElectrolysis

The invention discloses a method for extracting rare earth from oxidized neodymium iron boron waste. The method comprises the following steps of: mixing the neodymium iron boron waste with water and then grinding; oxidizing the ground neodymium iron boron waste; performing primary grinding of the oxidation product; adding acid and leaching; separating solid from liquid; extracting to remove iron; chloridizing rare earth; extracting and separating rare earth; extracting to remove aluminum; precipitating; and firing. By adopting the method disclosed by the invention to recover the rare earth, the rare earth recovery rate is increased by 5-8%; and moreover, the use value of the recovered rare earth is increased, the production cost of further processing is lowered, the problem of muddy objects of the molten salt when in single rare earth electrolysis is effectively solved, the electrolysis efficiency when in the electrolysis of the rare earth metal is improved, the power consumption can be effectively reduced, and the content of the non-rare earth elements in metal such as C, S, O and the like is reduced.

Owner:赣州市永莱宝高新材料有限公司

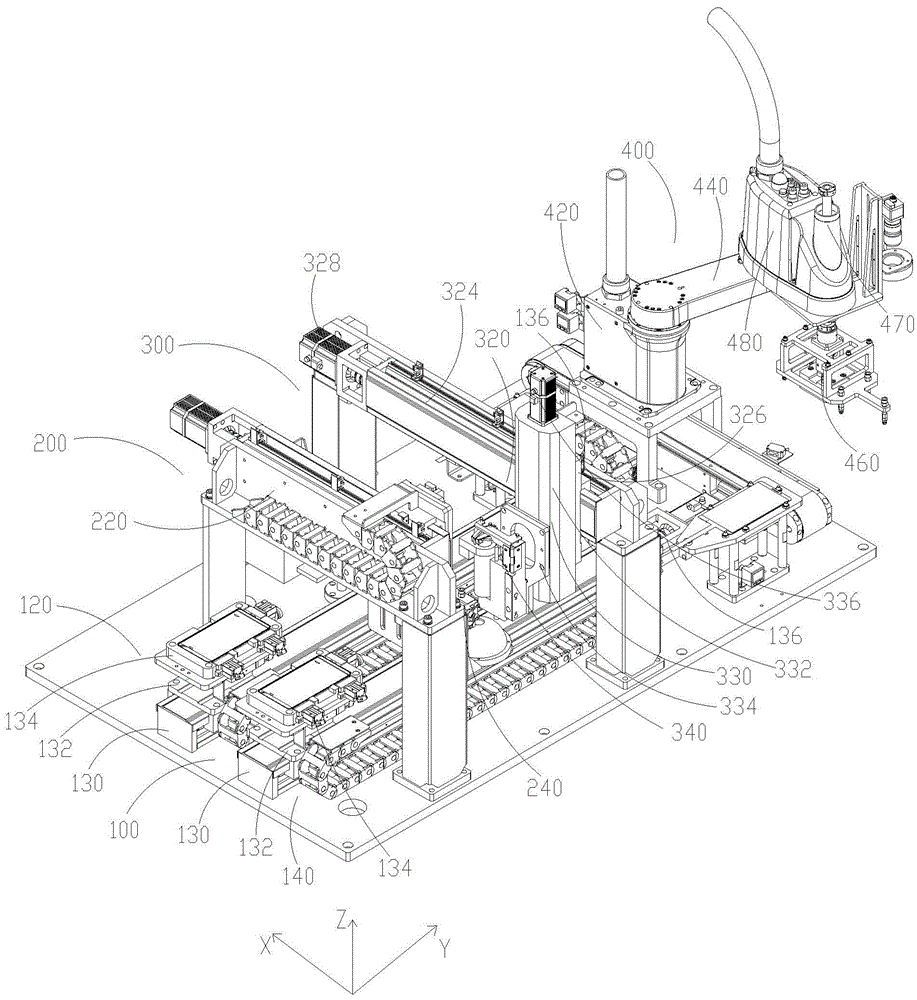

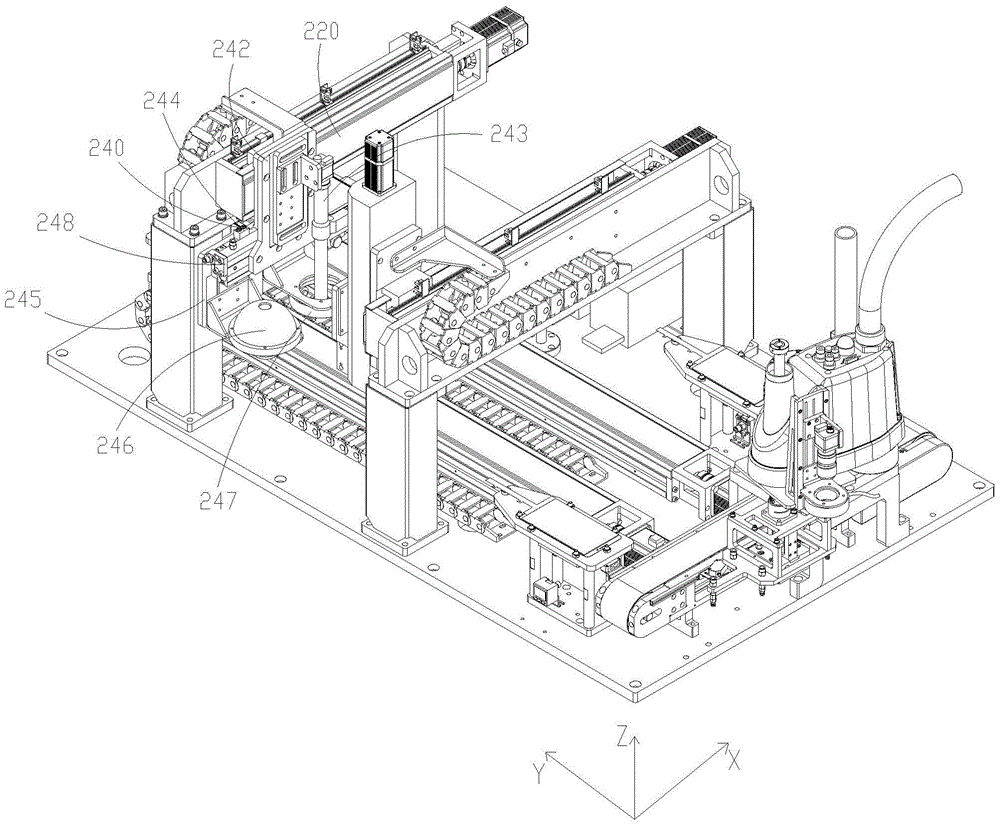

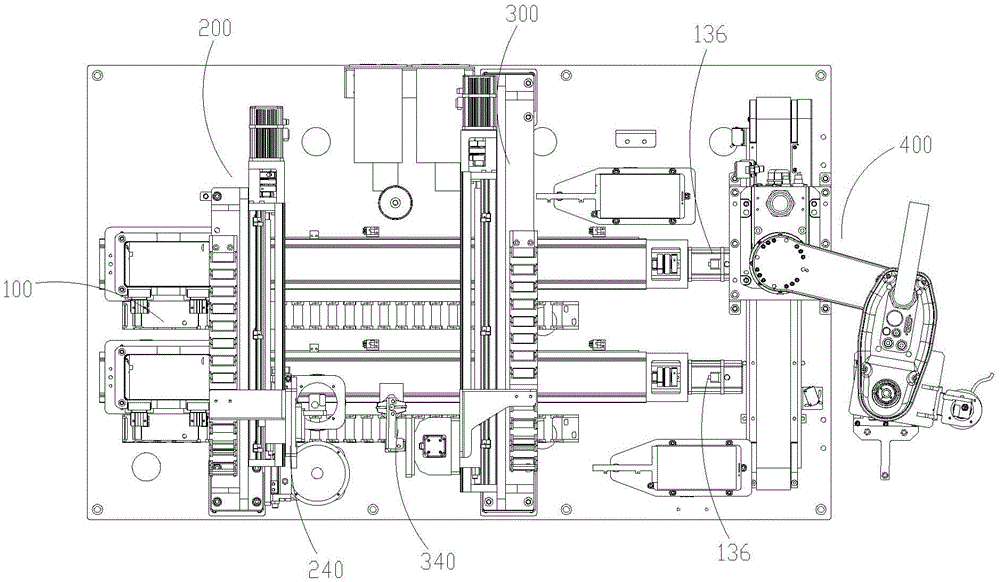

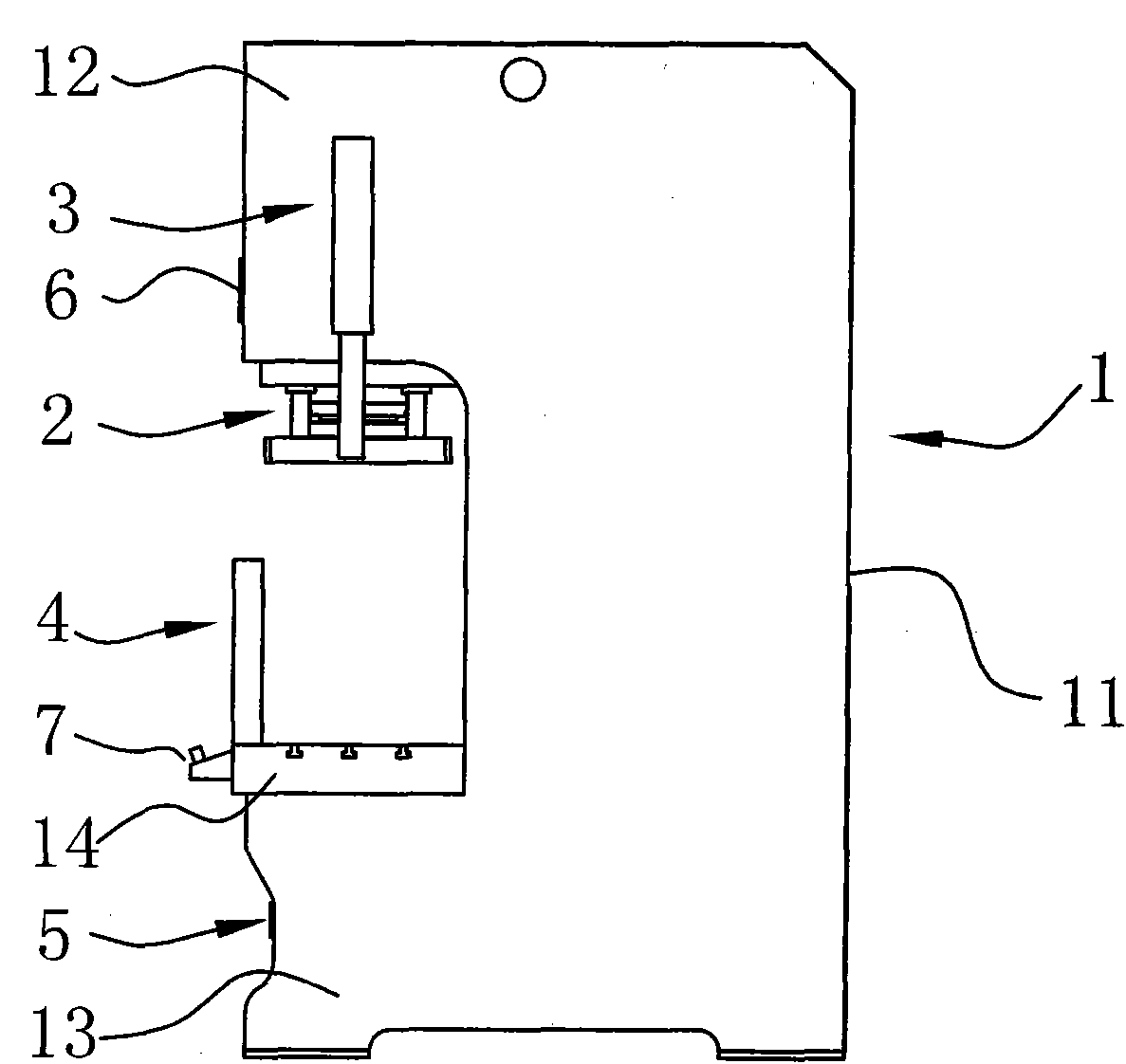

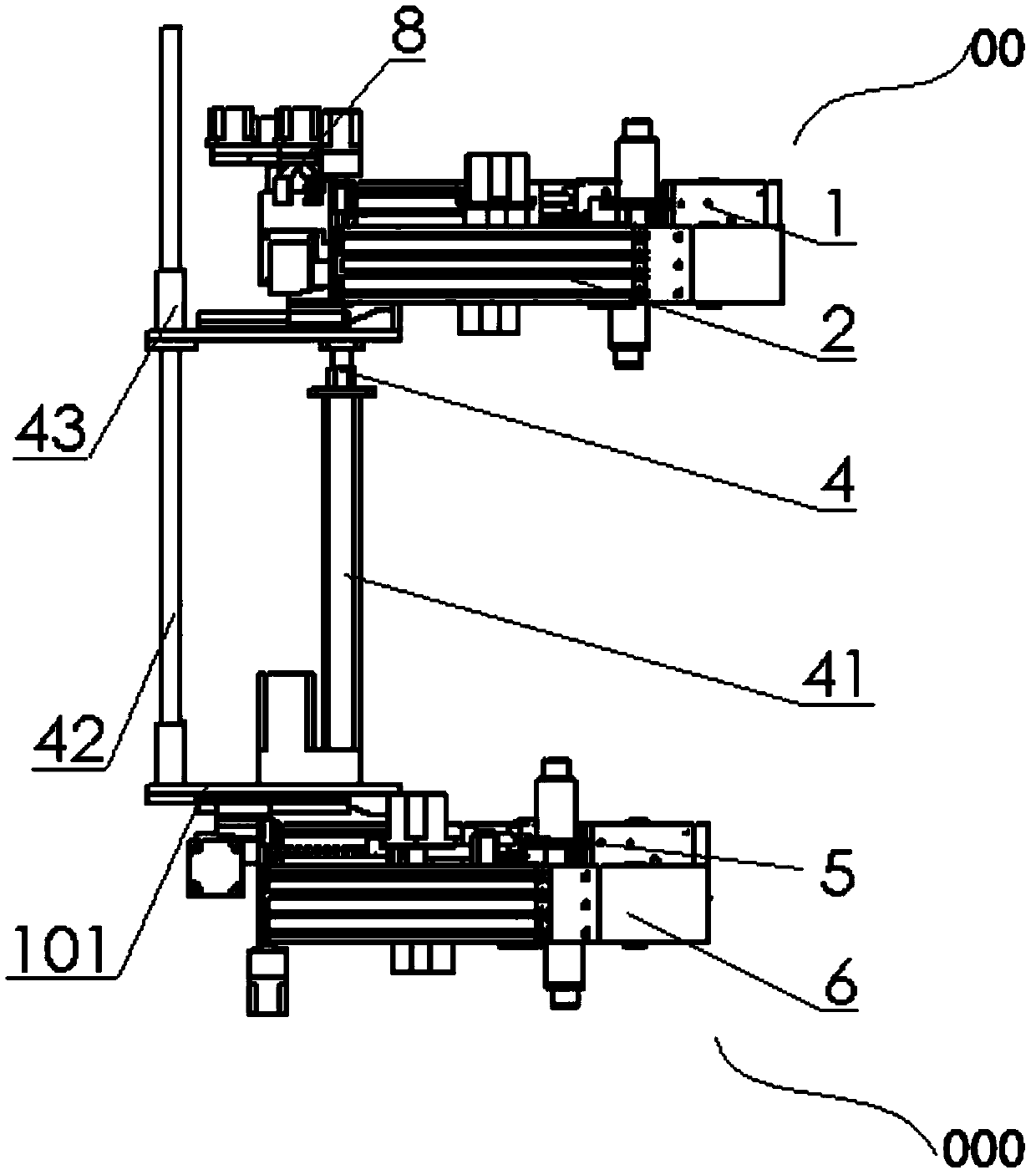

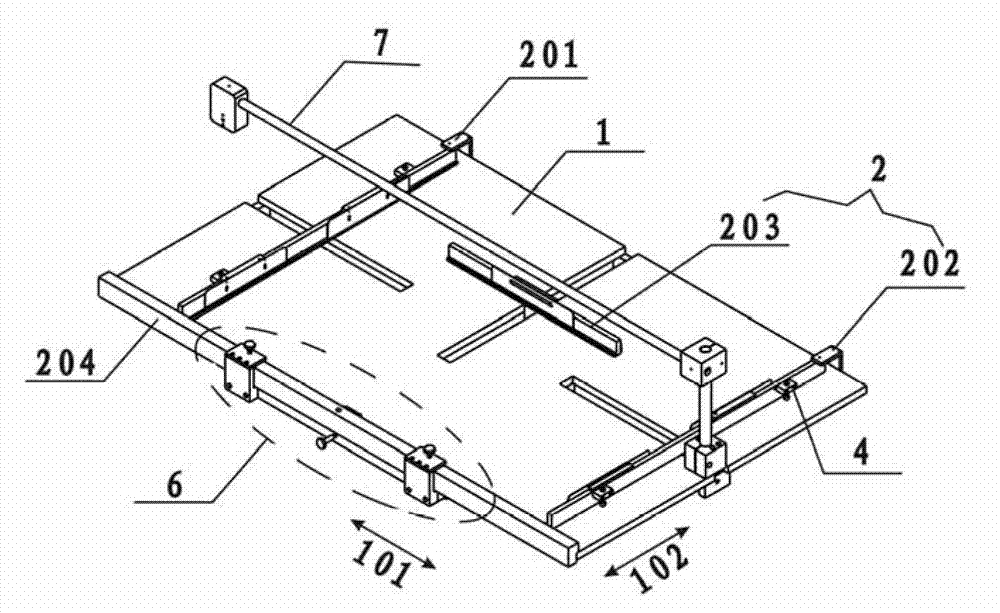

Adhesive dispensing machine and adhesive dispensing method thereof

ActiveCN105457840AShorten the working cycleIncrease productivityLiquid surface applicatorsCoatingsAdhesiveControl system

The invention discloses an adhesive dispensing machine and an adhesive dispensing method thereof. The adhesive dispensing machine comprises a control system, a charge system, and a visual inspection system and an adhesive dispensing system which are both located above the charge system. The charge system adopts a double-charge module comprising a first charge device and a second charge device, and matches with the visual inspection system and the adhesive dispensing system, thus the work of adhesive path planning, adhesive dispensing and adhesive path recheck carried out on production for products which are sequentially loaded and charged by the charge system, is realized; the adhesive path planning is carried out on products on the second charge device by virtue of time for adhesive dispensing for products on the first charge device, the work of adhesive dispensing is carried out on the products on the second charge device while recheck is carried out on the products on the first charge device, and the operation is circulated, thus the work cycle of the whole machine can be greatly saved, and the production efficiency of the whole machine is increased; and meanwhile, the labor cost can also be greatly reduced, and the adhesive dispensing quality is improved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Extraction method of platinum in high-concentration platinum solution

ActiveCN103468967AShort processReduce processing timeProcess efficiency improvementChemistryHigh concentration

The invention relates to an extraction method of platinum in a high-concentration platinum solution. The method comprises the following steps of 1) diluting a high-concentration platinum waste dissolving solution with a hydrochloric acid solution with the concentration being 4mol / L; and 2) preparing the platinum solution on which the first-grade extraction is performed by an extraction agent in a dilution manner by taking normal octane as a diluent and N-normal-butyl valnoctamide as a solute and discharging a raffinate so as to obtain an extract containing the platinum. By utilizing the method, the concentration of the platinum in the material solution can be improved to 20g / L; the first-grade extraction rate E is greater than or equal to 99.5%; the technological process is reduced; and the treatment time is shortened. Thus, the method is efficient.

Owner:CHONGQING MATERIALS RES INST

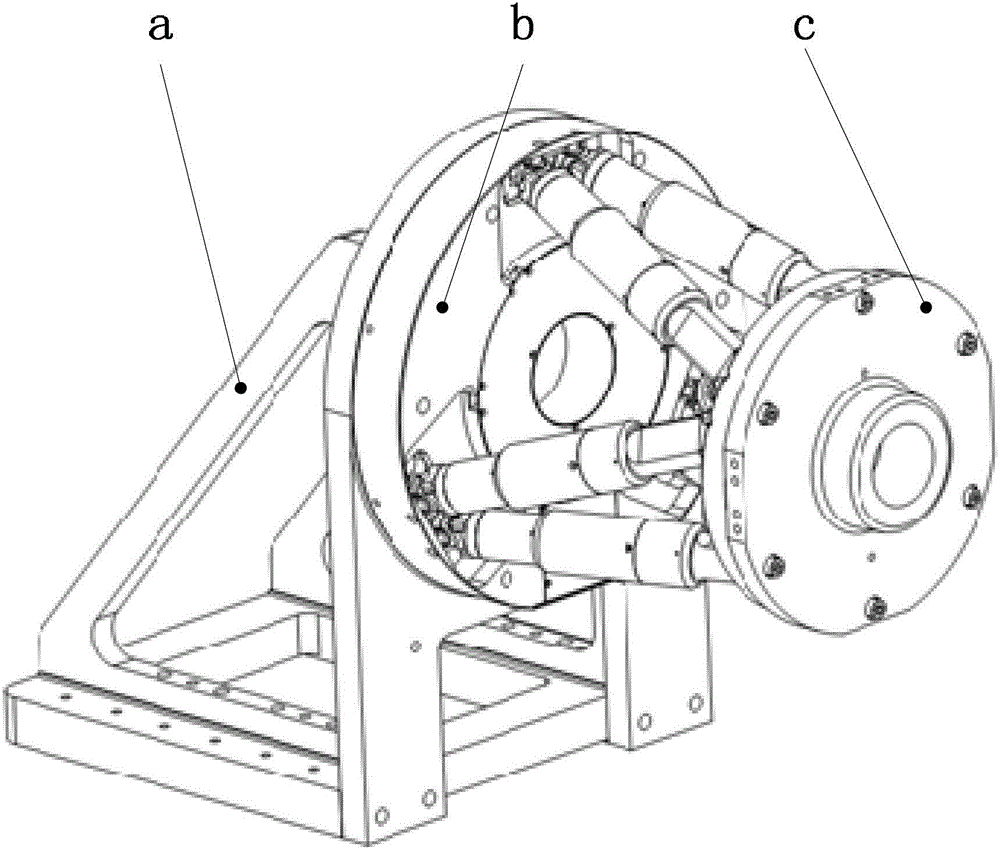

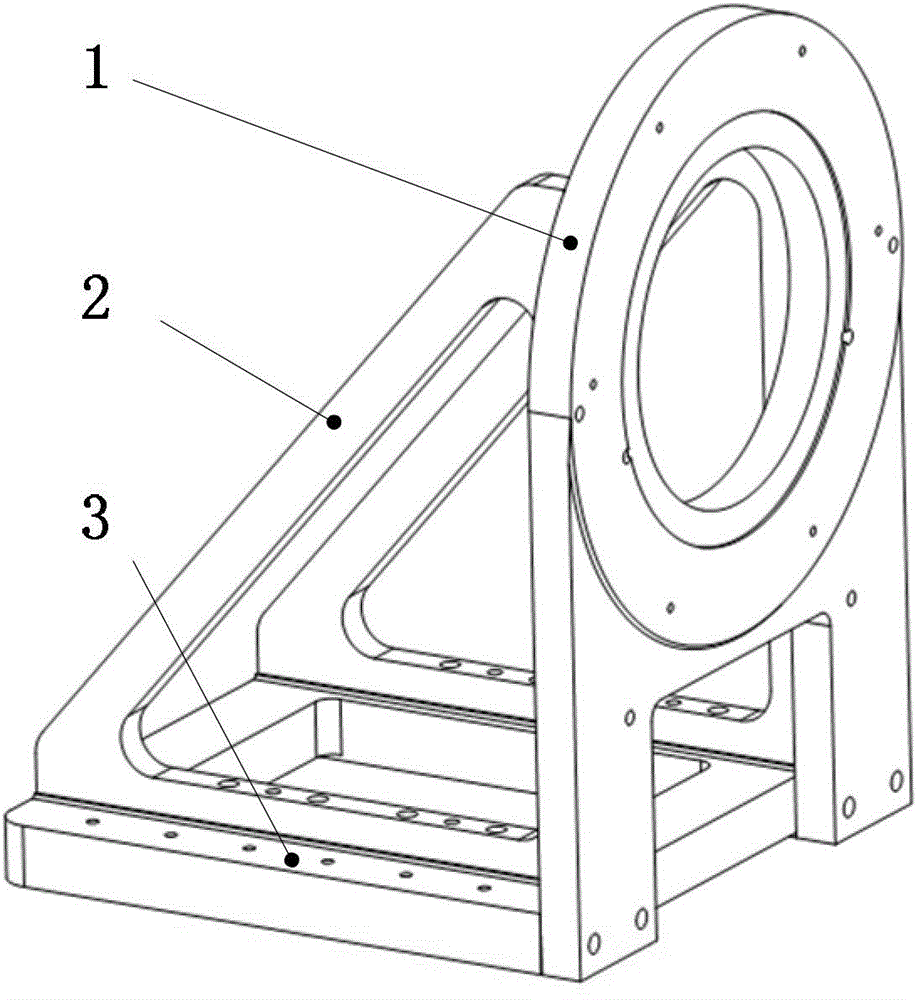

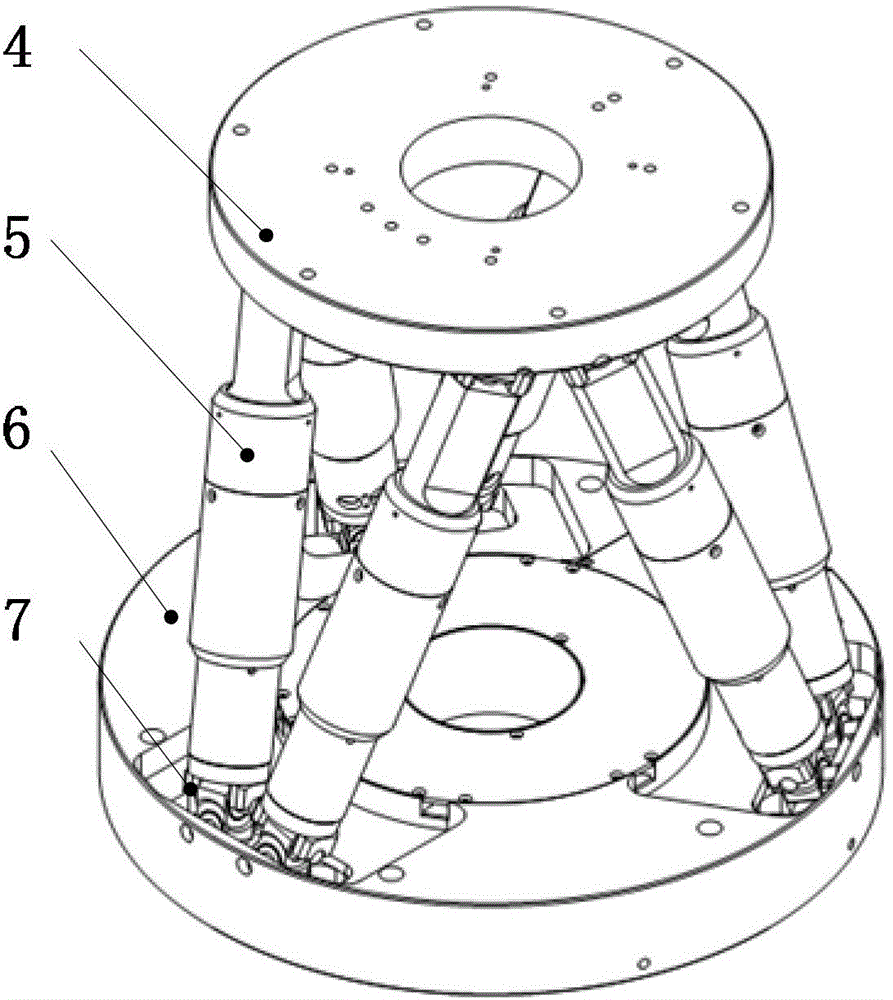

High-precision vibration simulation system based on multi-axis multi-degree of freedom

InactiveCN103335801AAdjustable vibration frequencyWide adaptabilityVibration testingWork cycleMulti degree of freedom

The invention discloses a high-precision vibration simulation system based on multi-axis multi-degree of freedom. The high-precision vibration simulation system comprises a mounting base, a shunt-wound multi-degree-of-freedom motion platform and a mechanical changeover panel, wherein the bottom of the mounting base is connected with a mounting connection platform, and the side surface of the mounting base is connected with the shunt-wound multi-degree-of-freedom platform; the mechanical changeover panel is fixed on a mobile platform of the shunt-wound multi-degree-of-freedom platform. The high-precision vibration simulation system greatly simplifies the design process under the premise of improving the system performance, improves the system positioning accuracy, besides, shortens the work cycle, and lowers various costs, as well as unnecessary expenditures in case of repeated design, manufacture, installation, debugging and the like after the design does not meet the requirements.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

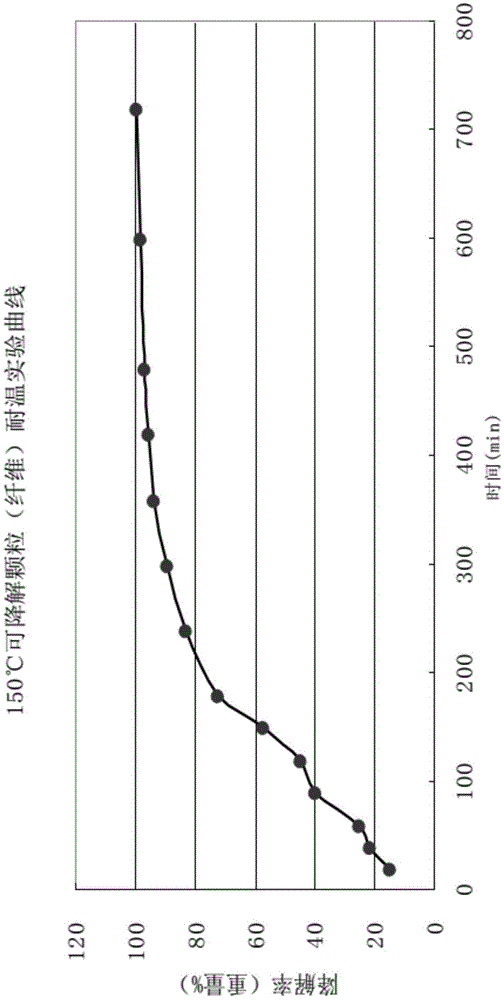

Process for repairing ancient books, paintings and calligraphy and paper literatures by using paper pulp

ActiveCN1844574AFast patchingEasy to operateNon-fibrous pulp additionPaper/cardboardFiberPulp and paper industry

The invention relates to a pulp repair method of ancient book, painting and calligraphy, which comprises: 1, according to the material of repaired book, painting and calligraphy, selecting pulp material, and adding the raw paper of selected pulp material into mixer, adding water and suspending agent, to mix and break uniformly; the mass ratios between raw paper, suspending agent, and water are: raw paper in 5-20; suspending agent in 5-15; and water in 500-1000, while the mixing time is 30-90s, then getting out the pulp; 2, spreading the book, painting and calligraphy on the repair support that made from paper shade; filling prepared pulp into repair pen to repair them that dropping pulp into the damaged part to use the combine force generated when the pulp becomes paper, the interlace force of fiber, and the adhesive function of suspending agent to complete said process; 3, removing repaired book, painting and calligraphy from the repair support, to be laid on the water-adsorption paper, to be dried.

Owner:邱晓刚

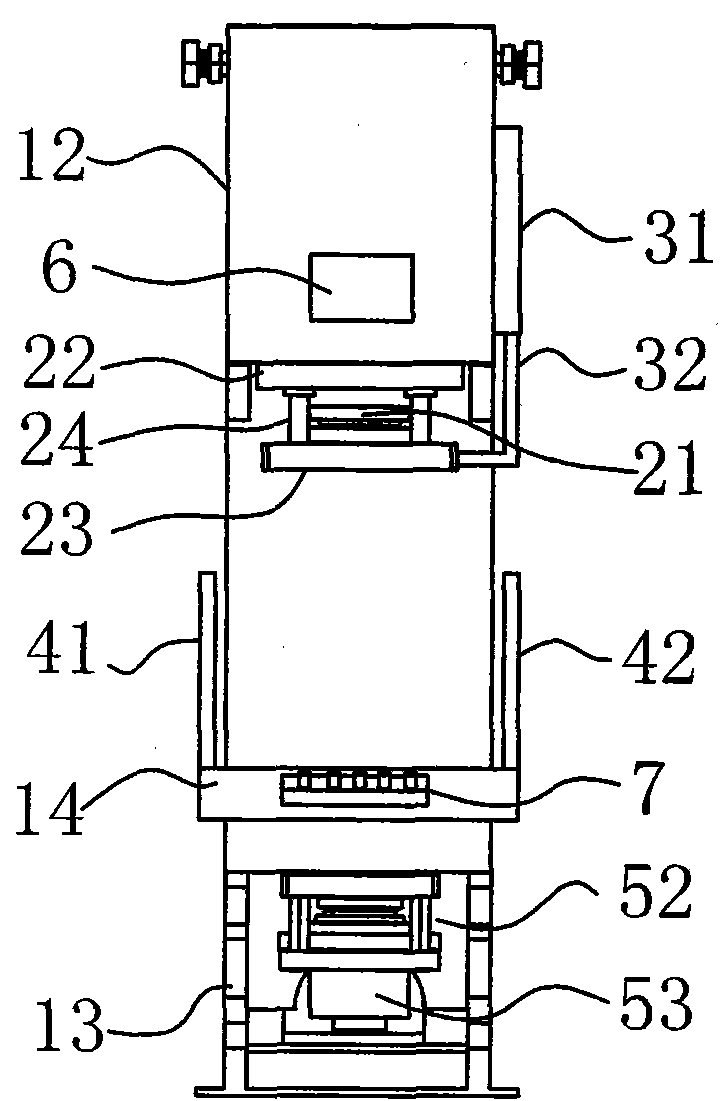

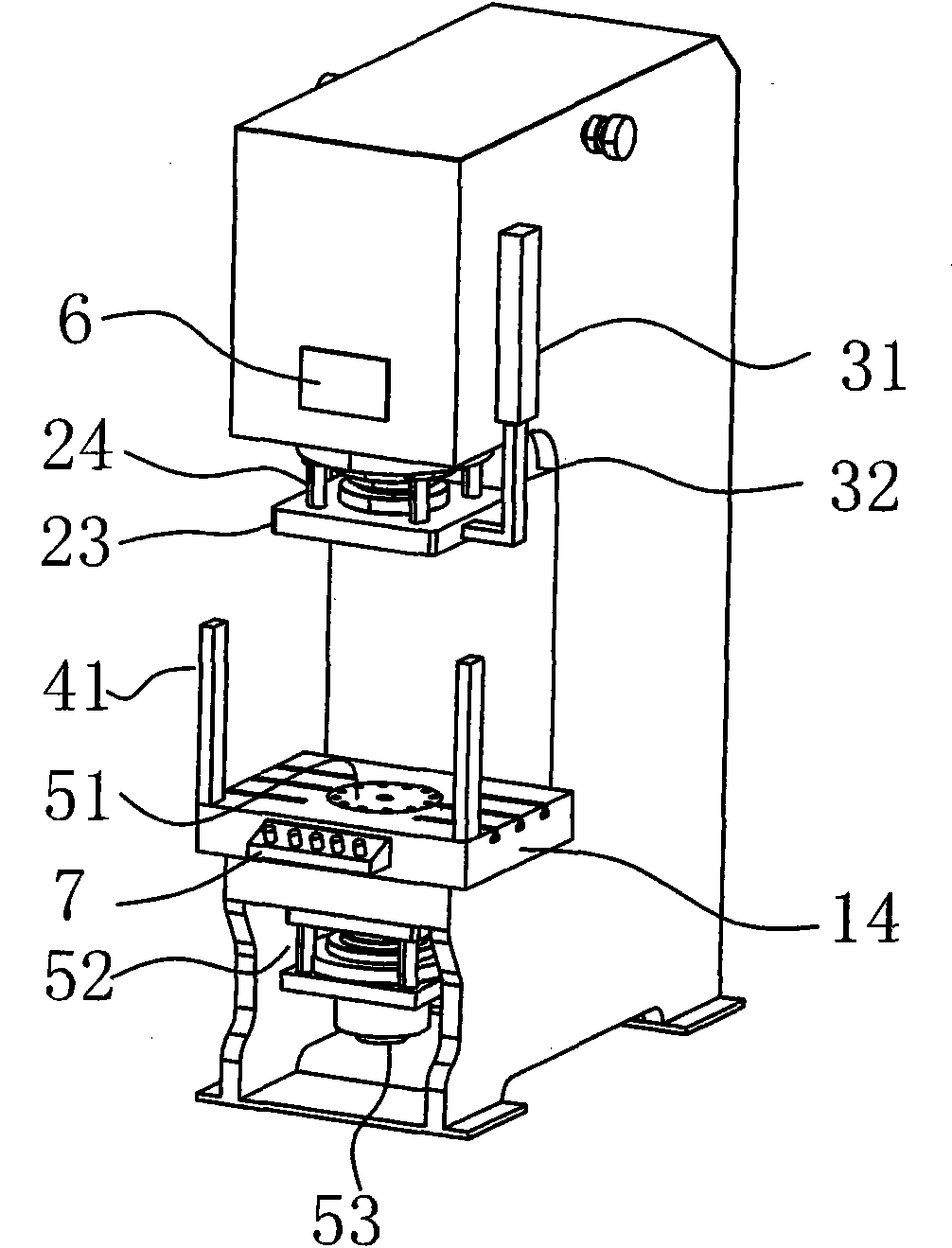

Servo electrohydraulic composite pressure method and press machine thereof

InactiveCN101927578AImprove performanceReduce energy consumptionPress ramNumerical controlPunch press

The invention discloses a servo electrohydraulic composite pressure method, comprising the following steps: 1) arranging a stander; 2) arranging an upper hydraulic device on the stander, 3) arranging a closed ring servo electrohydraulic control system, wherein the closed ring servo electrohydraulic control system is connected with the upper hydraulic device, and controls the work situation of the upper hydraulic device; the invention further discloses a press machine which implements the method; the method provided by the invention uses a servo electrohydraulic technology to replace the traditional electrohydraulic control technology, which has simple manufacturing, high efficiency, little power consumption and high control precision; the position control precision can reach to 0.01 to 0.02 millimeters; the pressing, the tensioning, the de-molding, the full deciding and other functions can be realized simultaneously, so the method has a comparatively high processing flexibility; the press machine provided by the invention is rational in structure, little in volume, stable in work, high in capacity, little in noise, and wide in application range. The advantages of a mechanical punching machine, a hydraulic punching machine and a numerical control are integrated, so the press machine has the advantages of multi-function, low cost, large pressure tonnage, etc.

Owner:东莞市得力仕机械科技有限公司

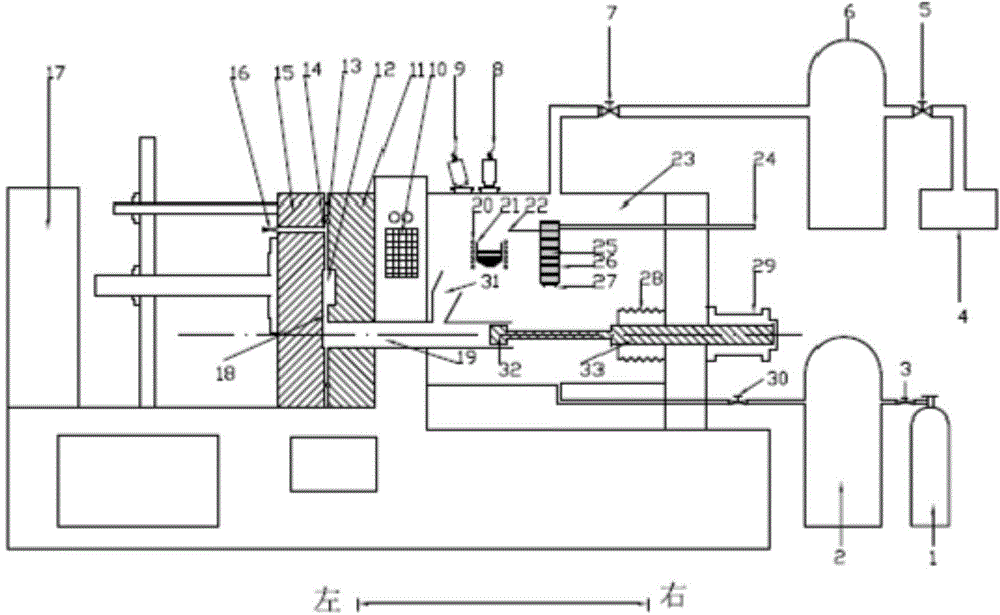

Casting forming equipment and process for amorphous alloy component

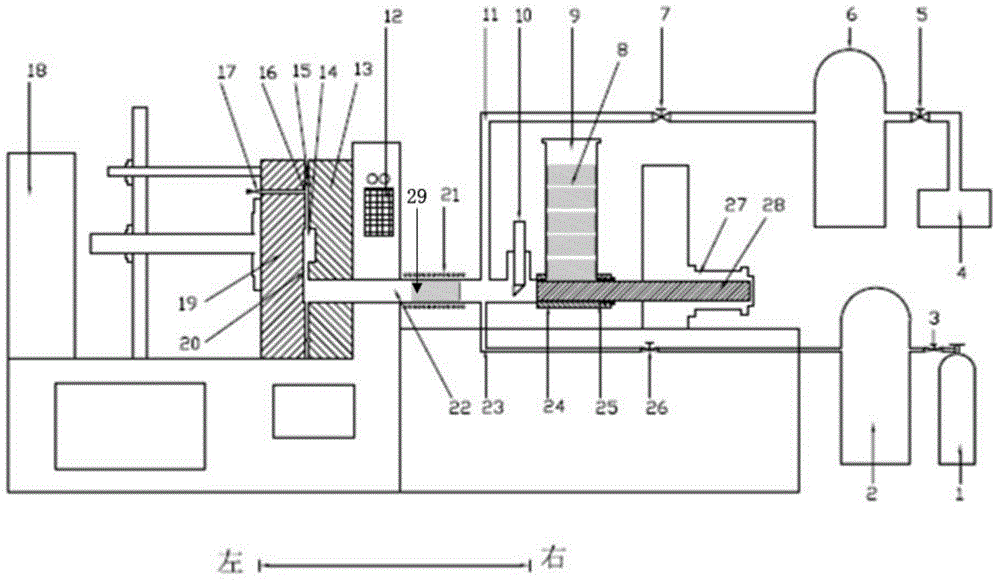

ActiveCN104668504ALong cycleShorten the working cycleElectric heating for furnacesManufactured materialSqueeze casting

Provided is a device for the casting forming of amorphous alloy components. The device comprises an injection system, an alloy smelting system, a raw material feeding system, a mould system, a vacuum system and a protective atmosphere system, which are used for the preparation of the amorphous alloy components, and can realize the formation by squeezing casting of the amorphous alloy components under a vacuum or a protective atmosphere with a positive pressure. The device is provided with an exhaust port on the mould to effectively solve the problem of forming micro shrinkage cavities on the surface in the process of forming the alloy components so as to improve the quality of the amorphous alloy components. Also provided is a process for the casting forming of the amorphous alloy components. A high vacuum tank or a protective atmosphere tank is used to reach an acquisition time of the vacuum or protective atmosphere with a positive pressure so as to shorten the forming period, save the production cost, and improve the production efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

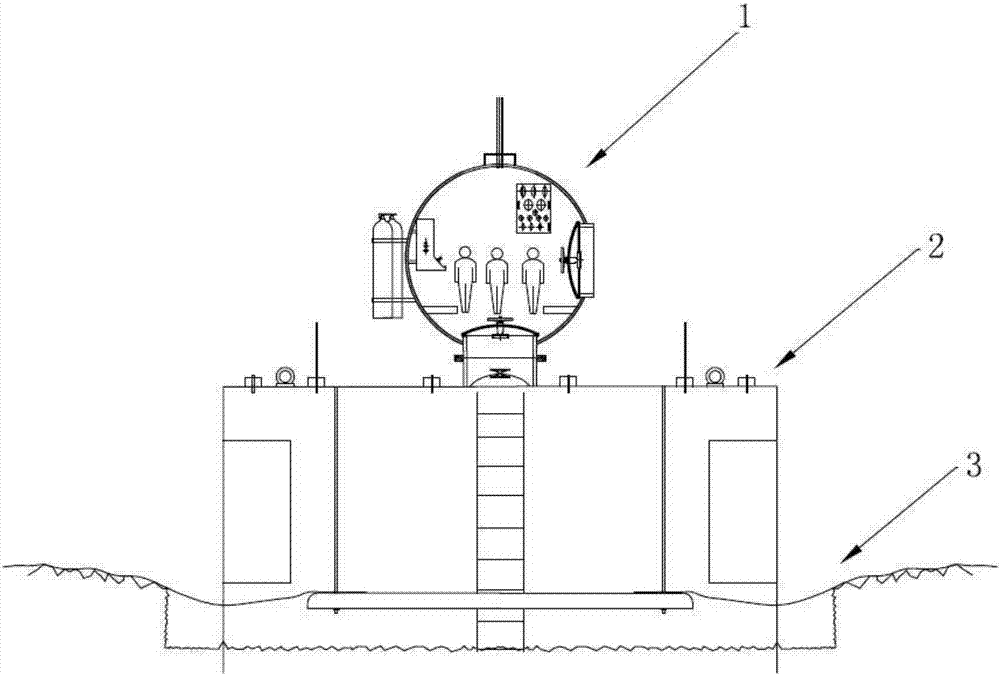

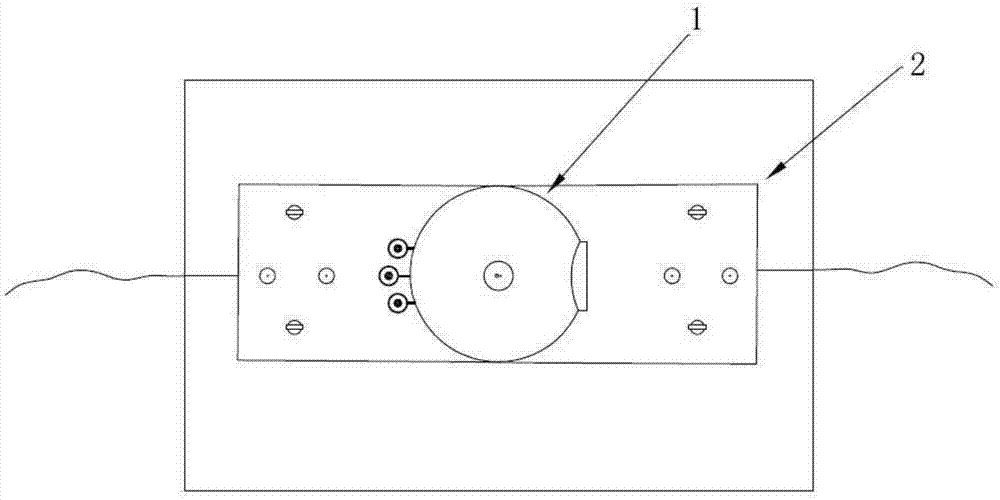

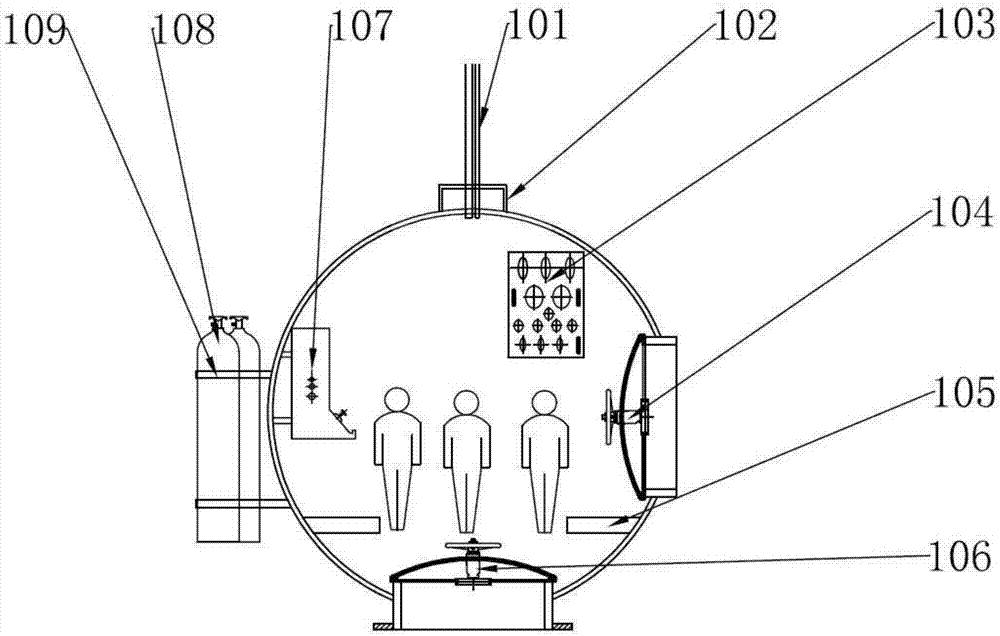

Deep-sea high-pressure dry type maintenance device

The invention relates to a deep-sea high-pressure dry type maintenance device. The deep-sea high-pressure dry type maintenance device comprises a diving bell, and one end of the diving bell is in butt joint with a high-pressure dry type maintenance chamber in an airtight or watertight mode. The deep-sea high-pressure dry type maintenance device is reasonable in design and convenient to use; and by adoption of the modular structural design, the diving bell and the high-pressure dry type maintenance chamber can be connected and separated rapidly on a deck, and therefore the deep-sea high-pressure dry type maintenance device has the advantages of being easy to assemble and reliable in connection. By adoption of the deep-sea high-pressure dry type maintenance device, the integral hanging and recycling of the diving bell and the maintenance chamber is achieved, so that maintenance workers can keep staying in a high-pressure and dry environment in the whole maintenance process, a wet working environment is avoided, and the range of working objects is expanded; and meanwhile, the maintenance workers are provided with a safe and comfortable working space. By adoption of the deep-sea high-pressure dry type maintenance device, the requirement for saturation diving can be met, working time can be effective prolonged for the maintenance workers by providing high pressure gas in the diving bell and the maintenance chamber, so that long-time underwater working is achieved, working efficiency is improved, and the whole working period is shortened.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

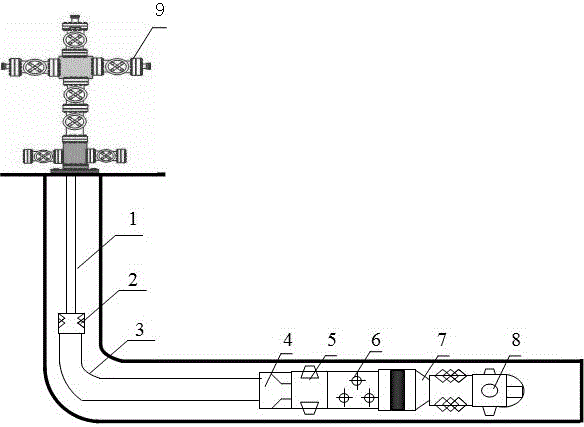

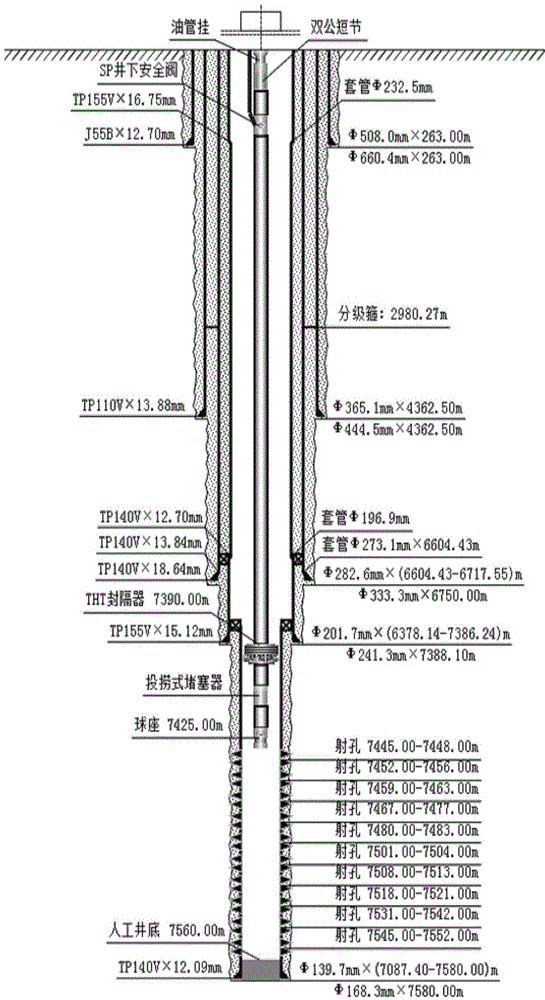

Fracturing and completion integrated method adopting coiled tubing and production tubing combined tubing string

ActiveCN104695927AReservoir damage is smallShorten the working cycleFluid removalSealing/packingWellheadEnvironmental geology

The invention belongs to the technical field of oil and gas field fracturing, particularly relates to a fracturing and completion integrated method adopting a coiled tubing and production tubing combined tubing string. The method specially comprises steps as follows: 1) placing the combined tubing string down to a shaft; 2) setting a first section; 3) performing sand blasting perforation on the first section; 4) fracturing the first layer section; 5) injecting a fracturing fluid; 6) lifting up a fracturing tubular column to a designed perforation position of a second section after the first section is fractured, and repeating Steps 2)-5) to finish the fracturing construction of all construction sections; 7) after construction, placing the fracturing tubular column at the bottom of an artificial well, and throwing steel balls from the wellhead to enable a hydraulic releasing tool to realize release; 8) draining the fluid and putting the oil and gas into production. With adoption of the method, after fracturing, the production tubular column can be placed one less time, so that damage to a reservoir is reduced while the working cycle is shortened.

Owner:PETROCHINA CO LTD

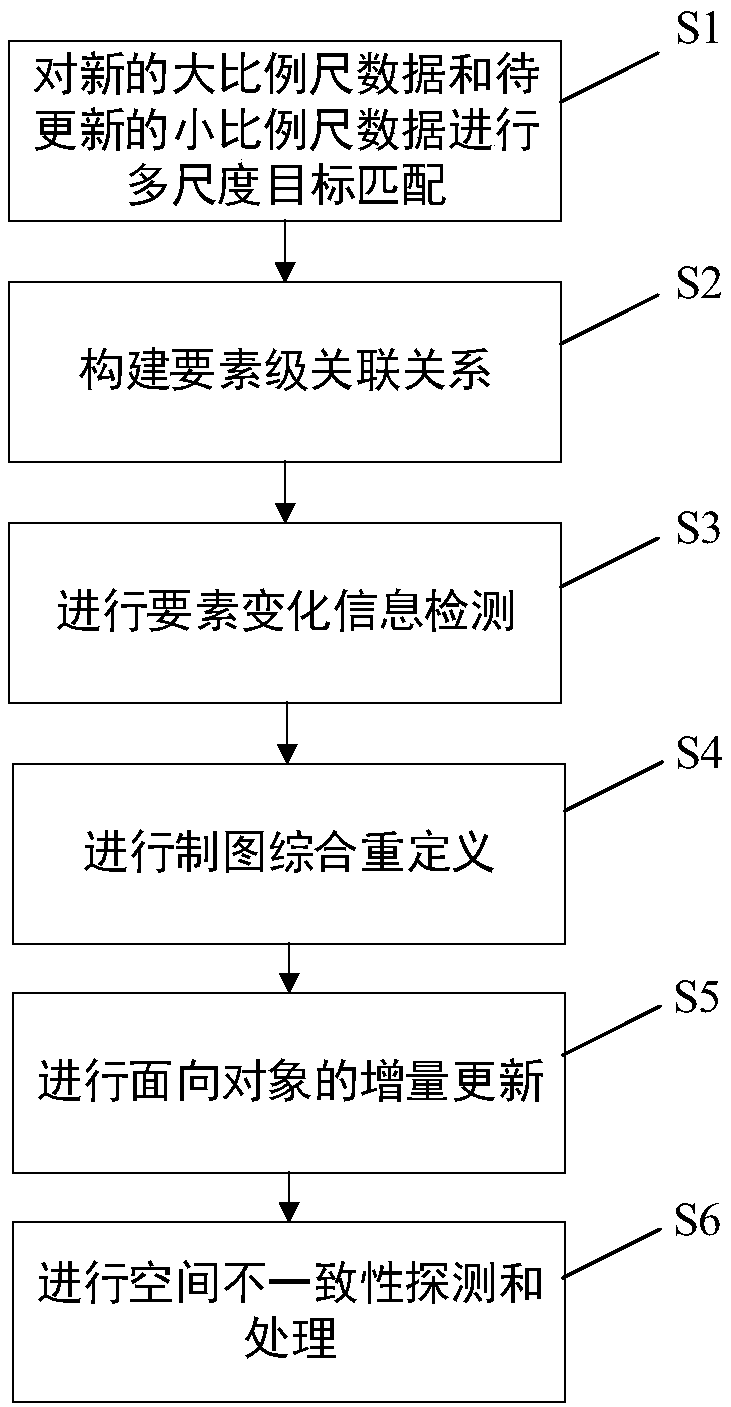

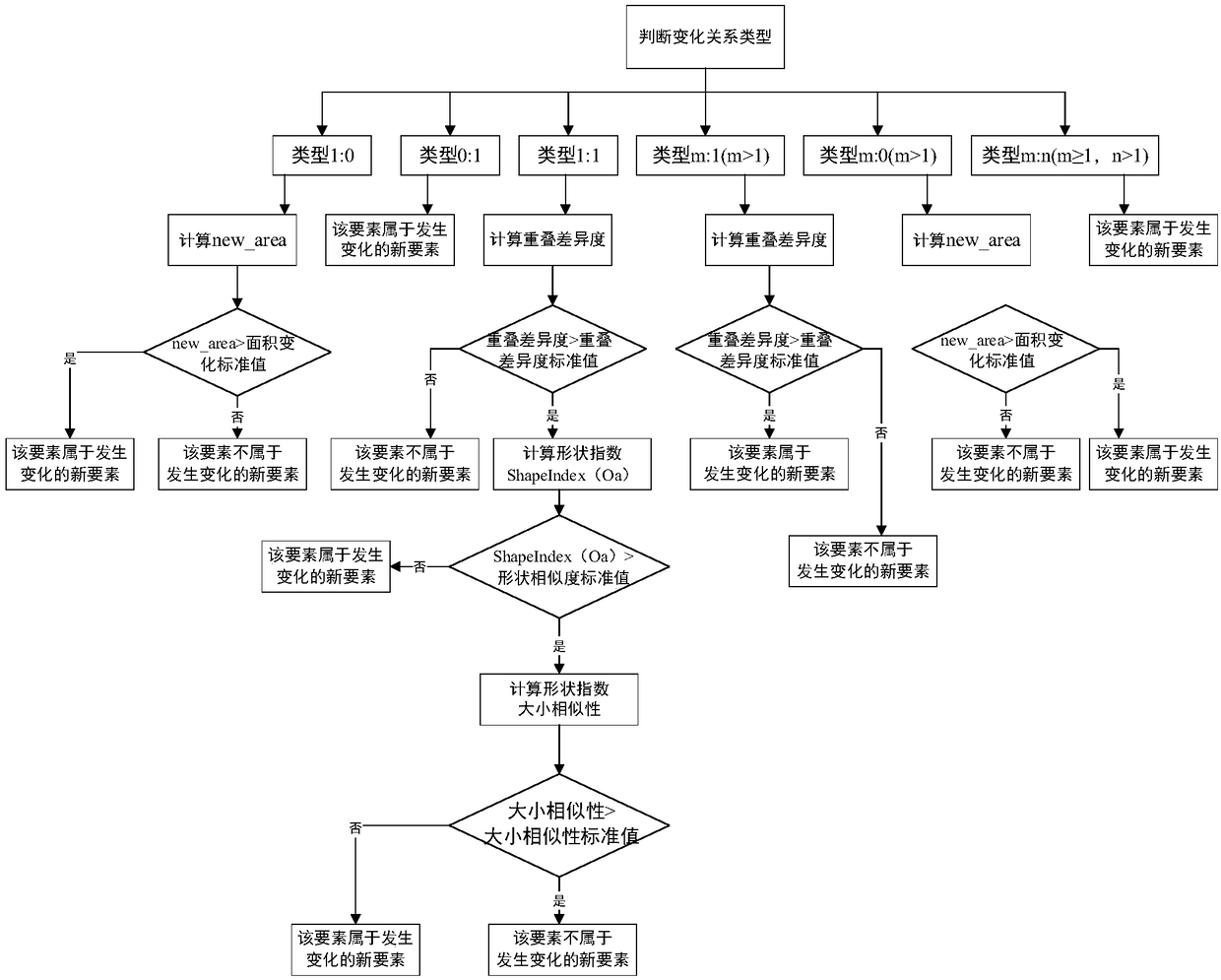

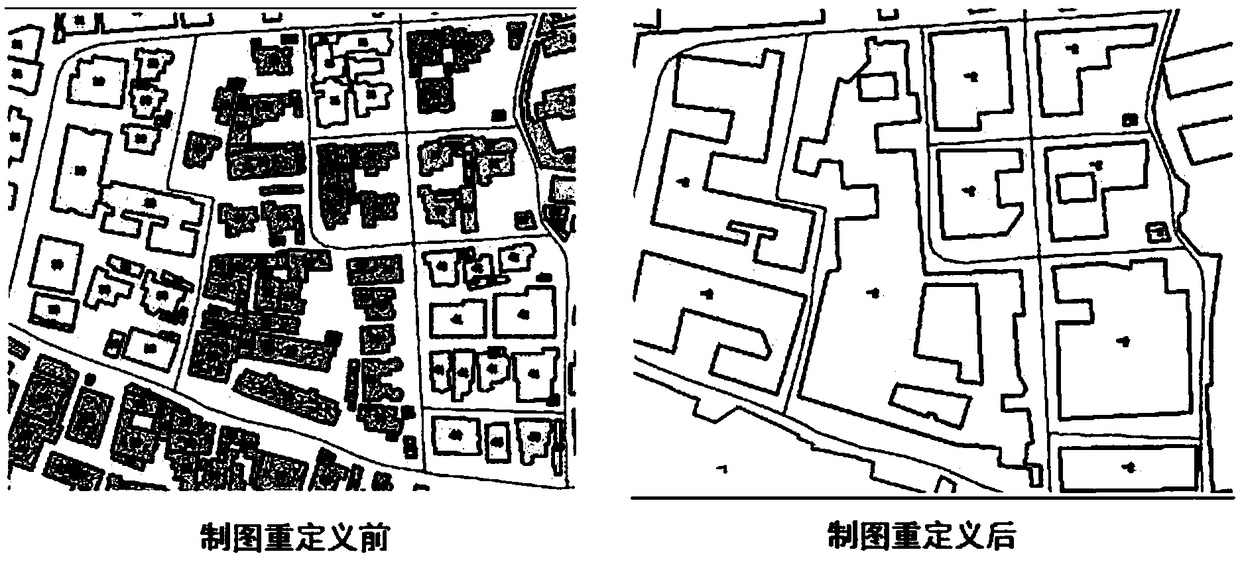

A method for updating multi-scale map data

ActiveCN109145171AImprove matching efficiencyThe matching operation is conciseDatabase updatingSemantic analysisCartographic generalizationLarge scale data

The invention discloses a multi-scale map data updating method, which comprises the following steps: matching the new large-scale data and the small-scale data to be updated with multi-scale targets;constructing element-level relationship; conducting element change information detection; cartographic generalization and redefinition; object-oriented incremental updating; spatial inconsistency detection and processing. The multi-scale map data updating method disclosed by the invention can effectively solve the problems that the prior art is unable to accurately identify the change informationand predict the transmission scale of the change element updating, the matching range of the element is small, and the efficiency of the map element updating is low.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

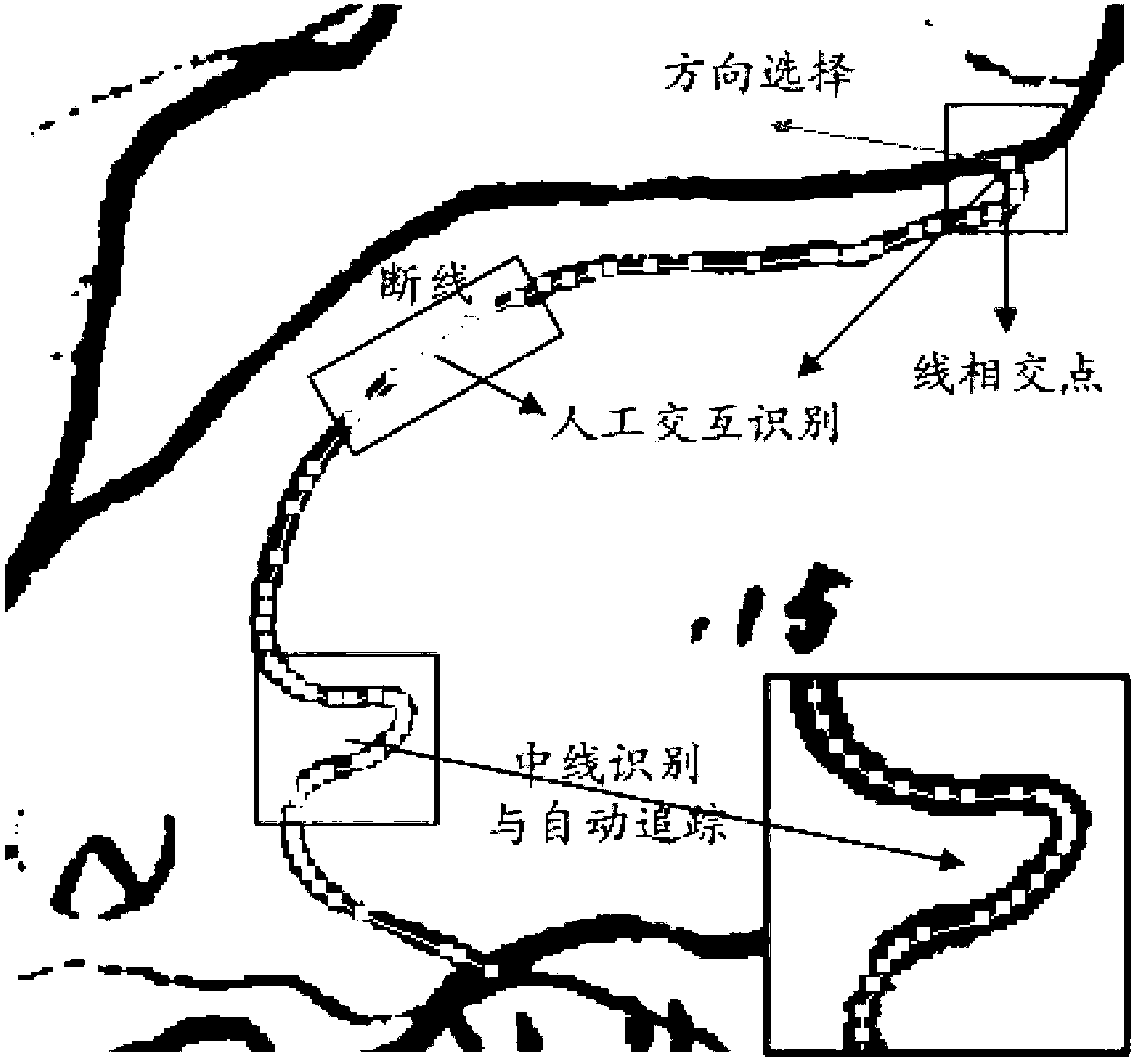

Semi-automatic digital method of non-standard map

InactiveCN102800052AAddress usability issuesSolve the accuracy problemImage enhancementPictoral communicationImaging processingSemi automatic

The invention discloses a semi-automatic digital method of a non-standard map. The method comprises the following steps of: 1) scanning to obtain a grid image, and performing geographical space registration and correction and binarization; 2) establishing a linear vector layer and assigning a geographical space reference system consistent with the corrected grid image; 3) overlapping the linear vector layer on the grid image after the binarization, identifying and capturing the center lines of the lines in the grid image, automatically tracking the captured center lines of the lines in the grid image one by one, and performing line breakage and endpoint artificial judgment on each automatically tracked line, and performing vectorization to obtain a vector image; 4) performing attribute assignment, check and correction; and 5) re-establishing the topological relation of the vector image, and checking and correcting the topological errors such as overlapping and gap to obtain a vector image after digitalization. The method disclosed by the invention has the advantages of good image processing accuracy, high image processing efficiency, low processing workload, short processing period and wide application range.

Owner:ZHEJIANG UNIV

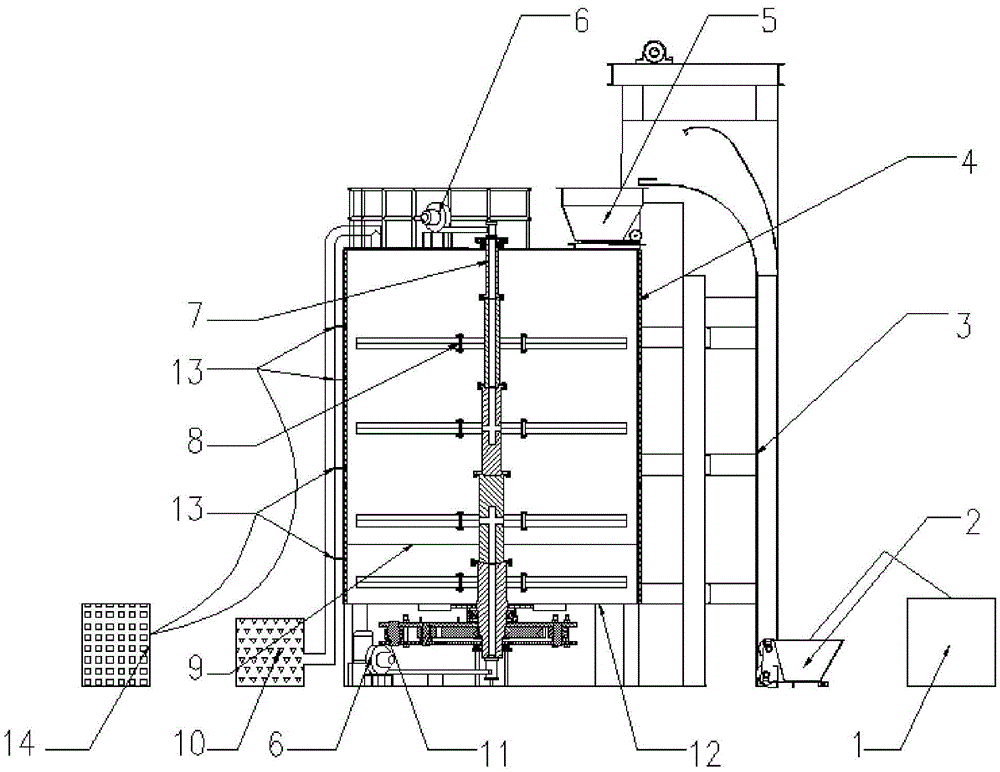

Continuous aerobic composting device and disposal method for dead livestock and poultry on livestock and poultry farm

ActiveCN105541420AImprove filtration efficiencyFully even air distributionBio-organic fraction processingAnimal corpse fertilisersAgricultural engineeringParameter control

The invention discloses a continuous aerobic composting device and a disposal method for dead livestock and poultry on a livestock and poultry farm and belongs to the field of hazardous waste harmless utilization and recycling. The continuous aerobic composting device comprises a crushing device, a fermentation tank body and a main shaft driving device, wherein a feed opening is formed in the top of the fermentation tank body, a discharge opening is formed in the bottom of the fermentation tank body, and a bushing with leak holes is arranged at the inner lower part of the fermentation tank body; a main shaft is arranged in the fermentation tank body, and stirring blades are arranged on the main shaft; the lower end of the main shaft extends out of the bottom of the fermentation tank body and then is connected with the main shaft driving device; a feeding device is arranged on the outer side of the fermentation tank body; the crushing device is connected with the feed opening of the fermentation tank body by the feeding device. The continuous aerobic composting device can realize continuous automatic aerobic composting of dead livestock and poultry, is low in energy consumption and free of secondary pollution, realizes recycling of harmful wastes, is uniform in air distribution, avoids local oxygen deficit, and has the advantages of being low in cost, accurate in parameter control, sufficient in fermentation, high in degree of automation and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

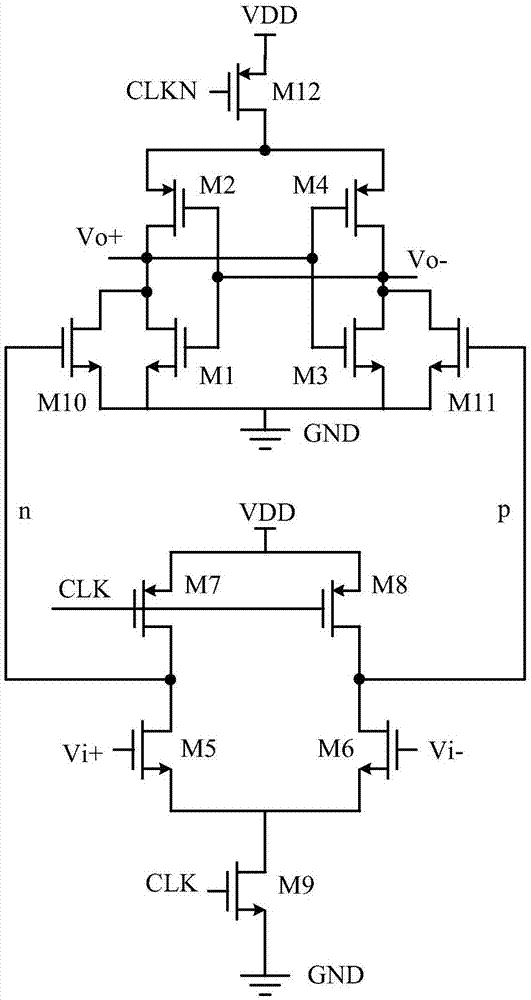

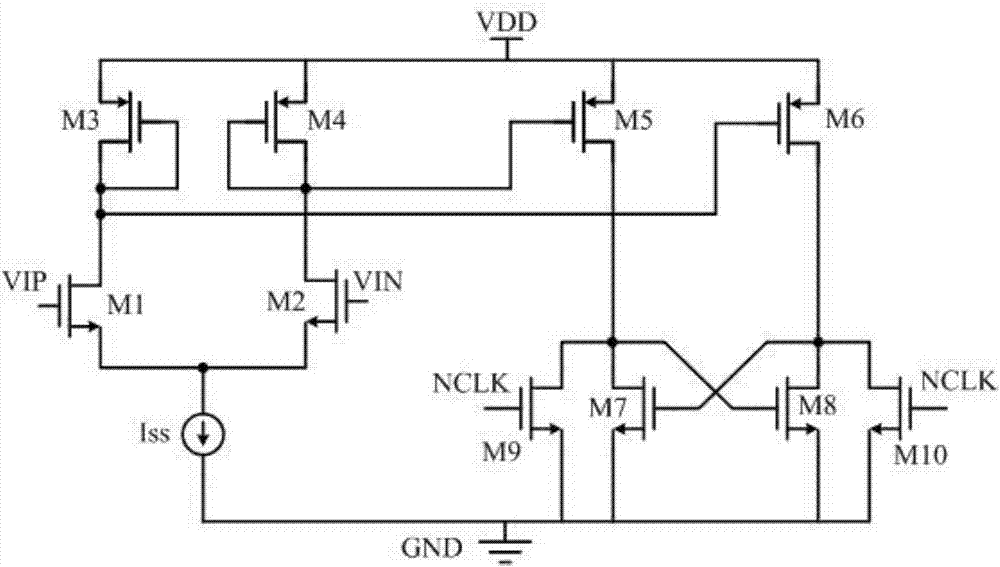

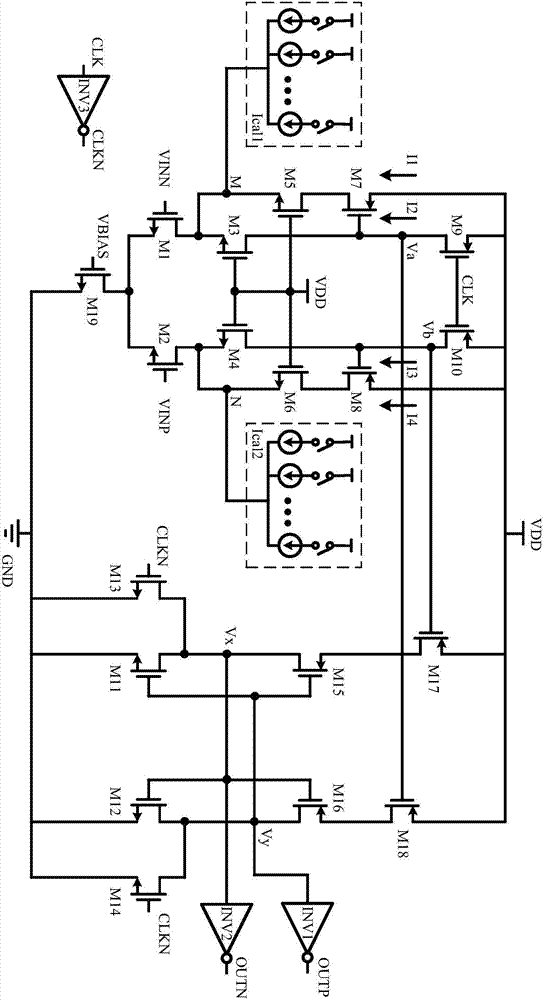

High-speed low-kickback-noise dynamic comparer and circuit

InactiveCN107888171AReduce reset timeShorten the working cycleMultiple input and output pulse circuitsUltrasound attenuationDynamic noise

The invention discloses a dynamic comparator with high speed and low kick noise, which belongs to the field of analog integrated circuits. Its structure includes: pre-amplification stage, current compensation branch for suppressing kickback noise, positive feedback regeneration stage composed of N-channel transistor and P-channel transistor cross-coupling unit, current between pre-amplification stage and positive feedback regeneration stage A control unit, a reset control unit, an offset calibration unit, and an inverter output driver stage. The two current compensation branches that suppress the kickback noise compensate the current attenuation of the main channel to ensure a constant working current of the input pair tube, thereby suppressing the influence of the kickback noise on the input signal, thereby increasing the size of the input pair tube and reducing offset voltage, increasing the response speed. Compared with the traditional comparator, the invention satisfies the requirement of high speed and low power consumption, and exhibits excellent kickback noise suppression ability.

Owner:SHANGHAI RES INST OF MICROELECTRONICS SHRIME PEKING UNIV

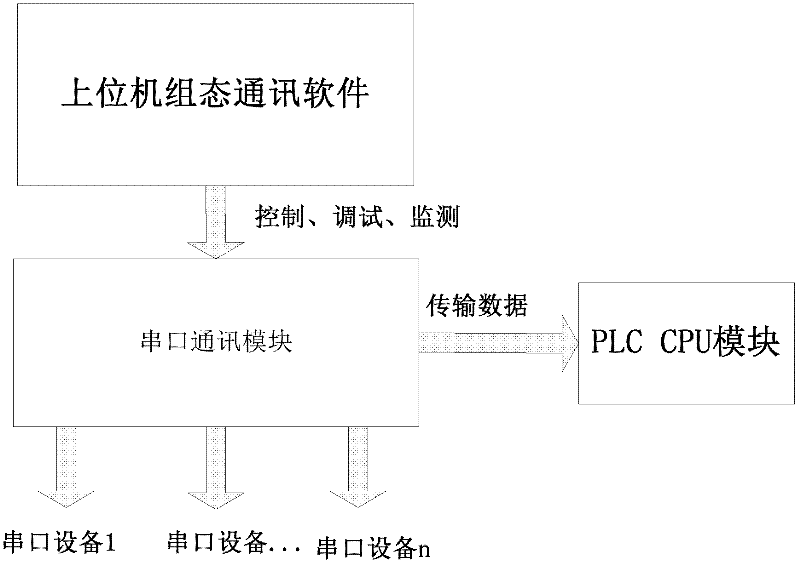

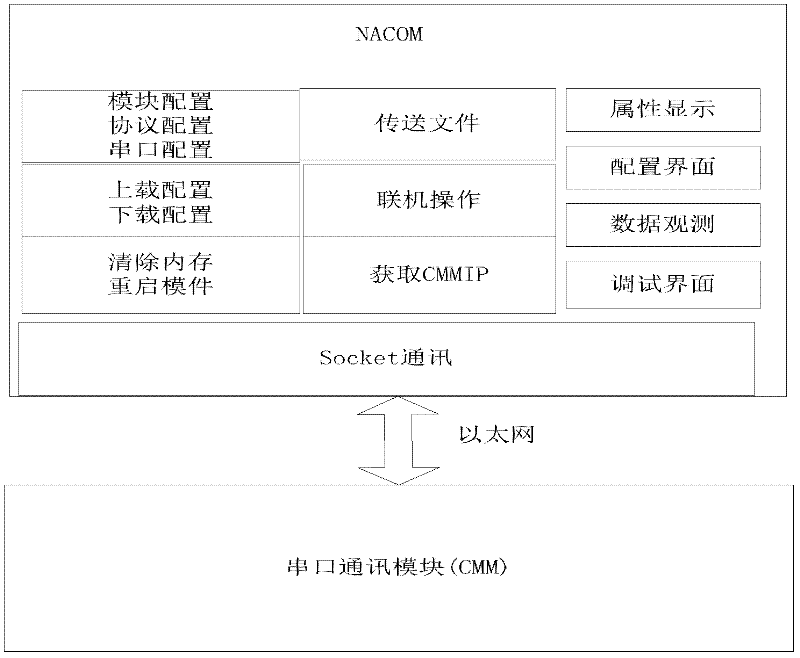

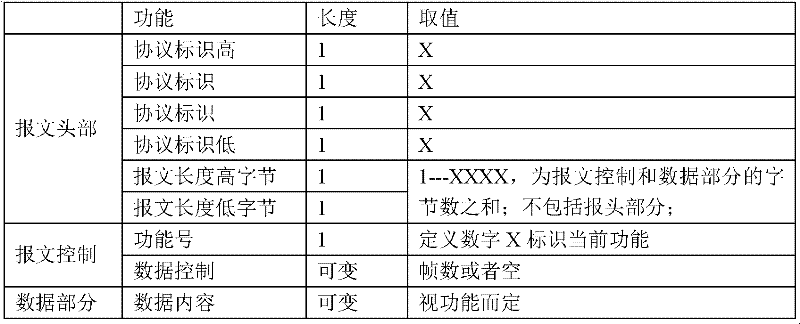

Serial communication configuration and debugging method based on Ethernet communication protocol

ActiveCN102694695AEasy to monitorEase of workData switching networksComputer terminalFunctional requirement

The invention provides a serial communication configuration and debugging method based on Ethernet communication protocols. The method performs configuration, surveillance, monitoring, debugging and other operations on a lower computer by using the software of an upper computer, users do not have to care about the system architecture of the hardware of a serial communication module, and configuration, monitoring, debugging and other operations on serial information of the lower computer can be realized by simply configuring the upper computer instead of using a hyper terminal and other complex operations to monitor each serial device. Meanwhile, the software communication is based on the Ethernet communication protocols, most communication requirements of PLC communication modules can be satisfied, and the method has good universality.

Owner:傲拓科技股份有限公司

Reservoir stratum transformation method for cleaning steering material blocking shot hole temporarily to form fracture net

ActiveCN104963672AGood effectSegmentally reliableFluid removalDrilling compositionFracturing fluidEnvironmental geology

The invention provides a reservoir stratum transformation method for cleaning steering material blocking a shot hole temporarily to form a fracture net. The reservoir stratum transformation method for the cleaning steering material blocking the shot hole temporarily to form the fracture net comprises the following steps that 1 fracturing fluid is injected into stratum; 2 active fluid is injected into the stratum; 3 acid liquor or the fracturing fluid is injected into the stratum; 4 carrying fluid containing with cleaning steering material fluid is injected into the stratum, and an artificial fracture fractured in the step 1 is blocked temporarily; 5 the carrying fluid containing with the cleaning steering material fluid is injected into the stratum, and the shot hole corresponding to the artificial fracture fractured in the step 1 is blocked temporarily; 6 the acid liquor or the fracturing fluid is injected into the stratum; 7 when deep transformation is needed, the steps 3 to 6 are repeated; 8 the fracturing fluid is used for replacing to achieve section fracture net transformation of the reservoir stratum. The reservoir stratum transformation method for the cleaning steering material blocking the shot hole temporarily to form the fracture net has the advantages that the section fracture net transformation can be achieved without a tool, the complexity degree of an underground tool is reduced, the engineering risk is reduced, the working difficulty is reduced, the working period is shortened, and the cost is reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

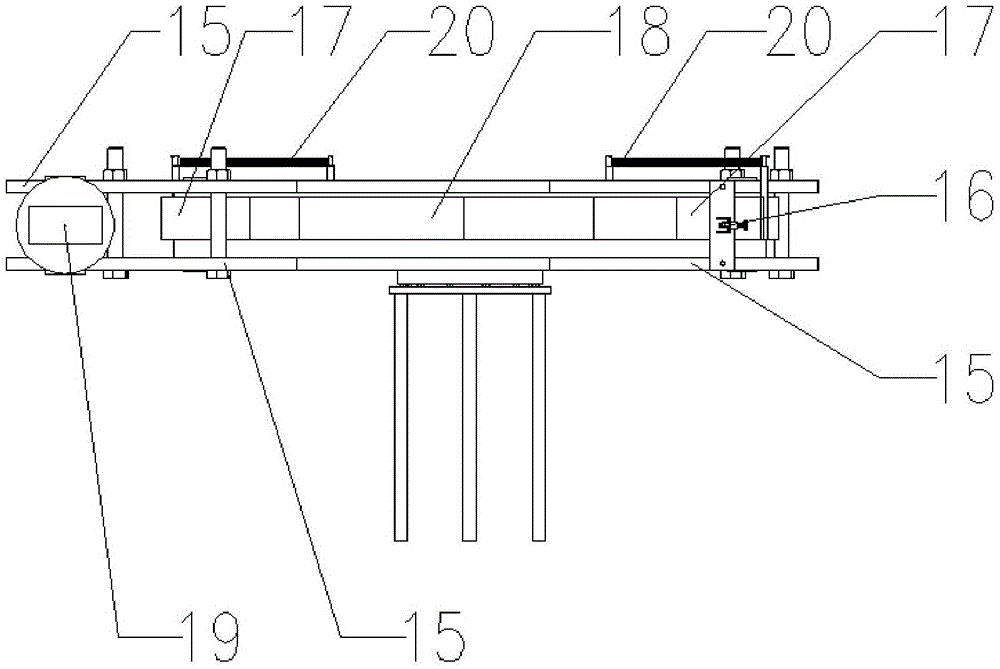

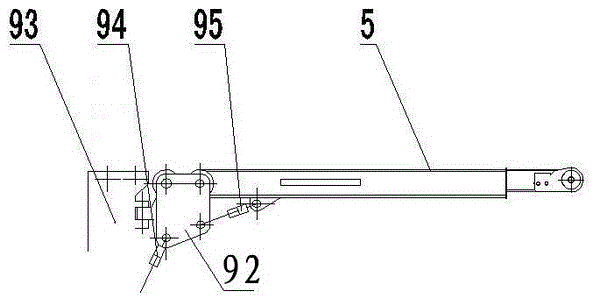

Turn-over device

InactiveCN101209778APlay a protective effectPrevent dumpingConveyor partsMaterial analysis by transmitting radiationWork cycleEngineering

The invention provides an overturning device used on a transportation line under the irradiation of an electron beam which consists of two rotary shafts rotatably arranged in parallel on a frame and two overturning retarding motors fixed on the frame. The two ends of each rotary shaft are fixedly provided with a pair of tumblers. The two pairs of tumblers on two rotary shafts have same structures which consist of a middle body and four overturning arms fixed that is combined with the middle body to be a whole or fixed on the middle body and the axle wires of the four overturning arms are all uniformly arranged on the tangent direction of a same circumference. The corresponding overturning arms of the tumblers on the two rotary shafts are arranged mutually parallel and overlapped. The invention has simple structure, can adopt 90 DEG overturning for twice, shorts one time of the working period and improves the working efficiency and simultaneously ensures reliable transportation.

Owner:NUCTECH CO LTD

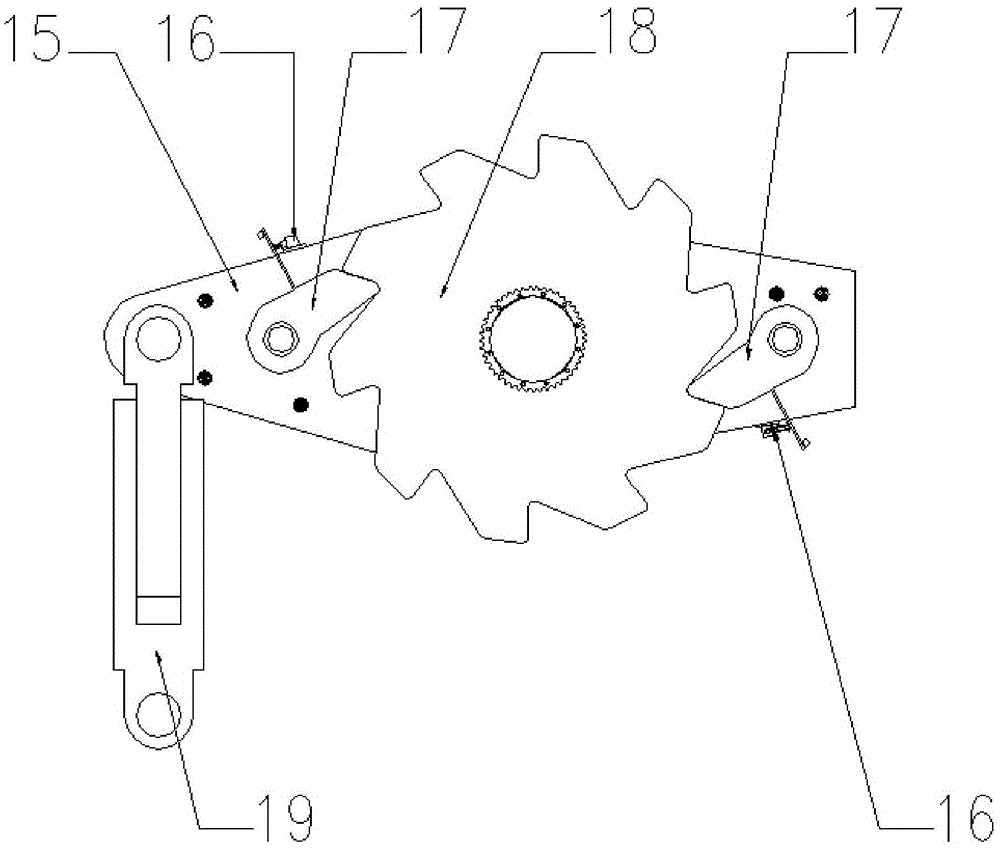

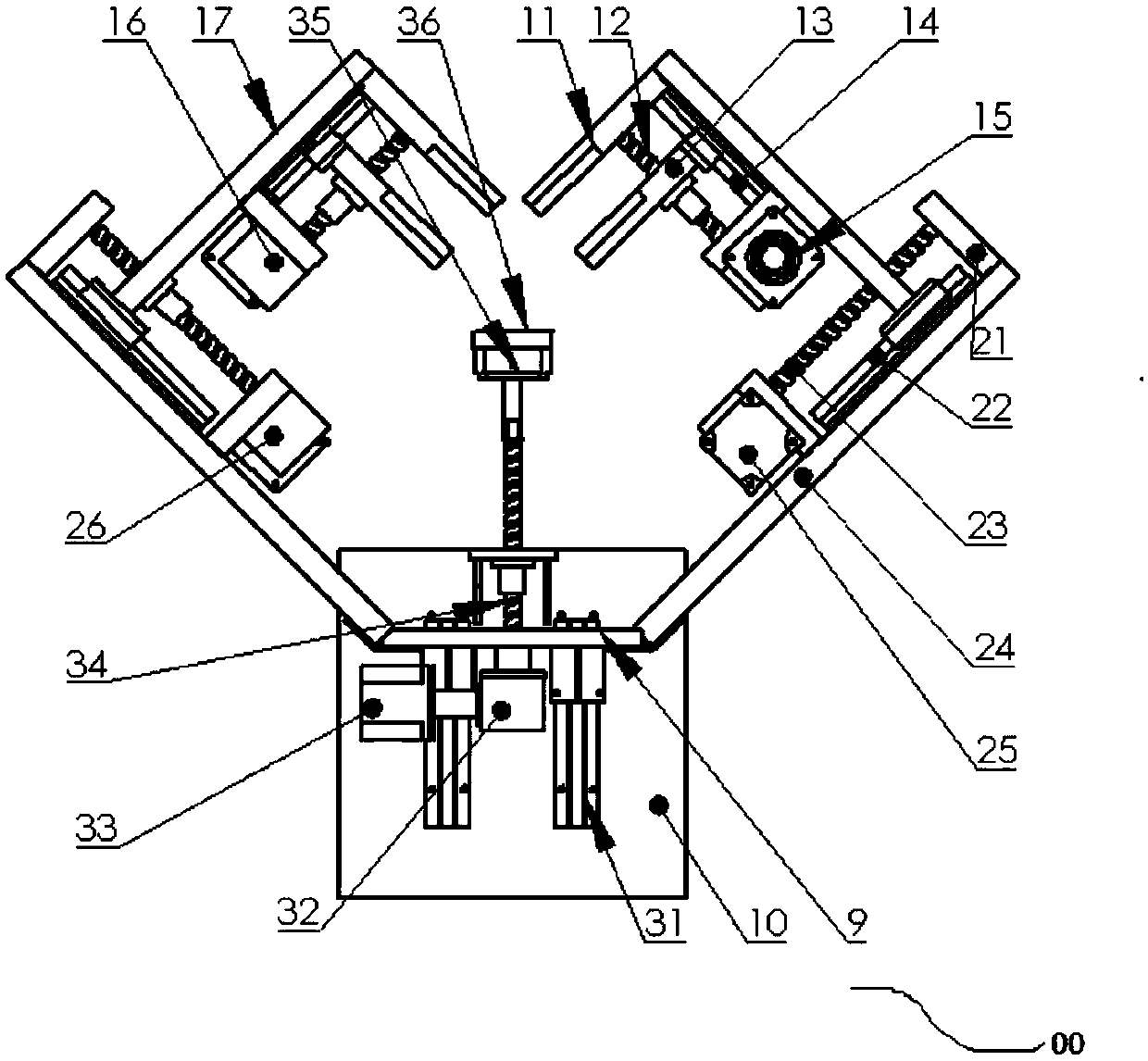

Clamping mechanisms of robot used for transmission tower and climbing robot

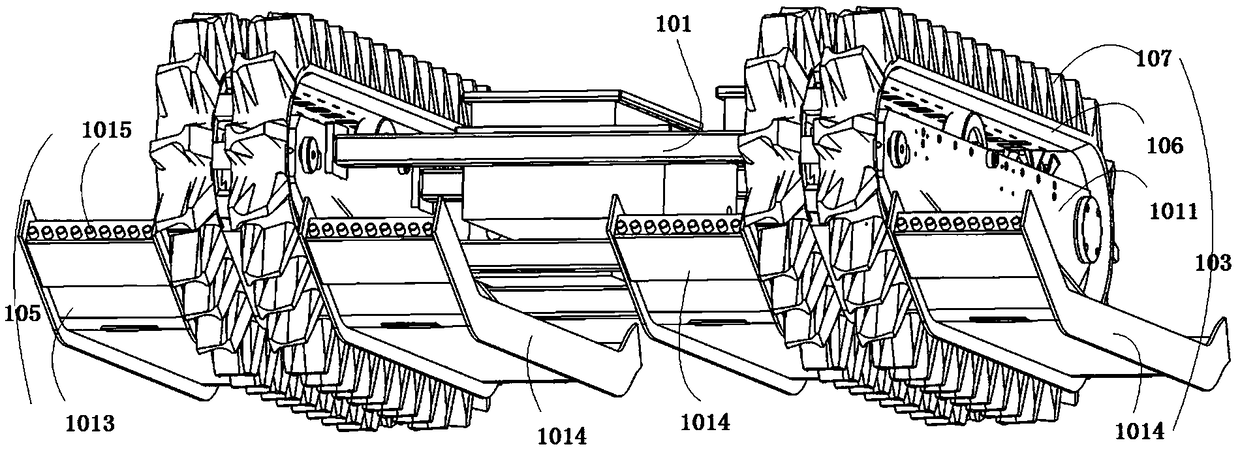

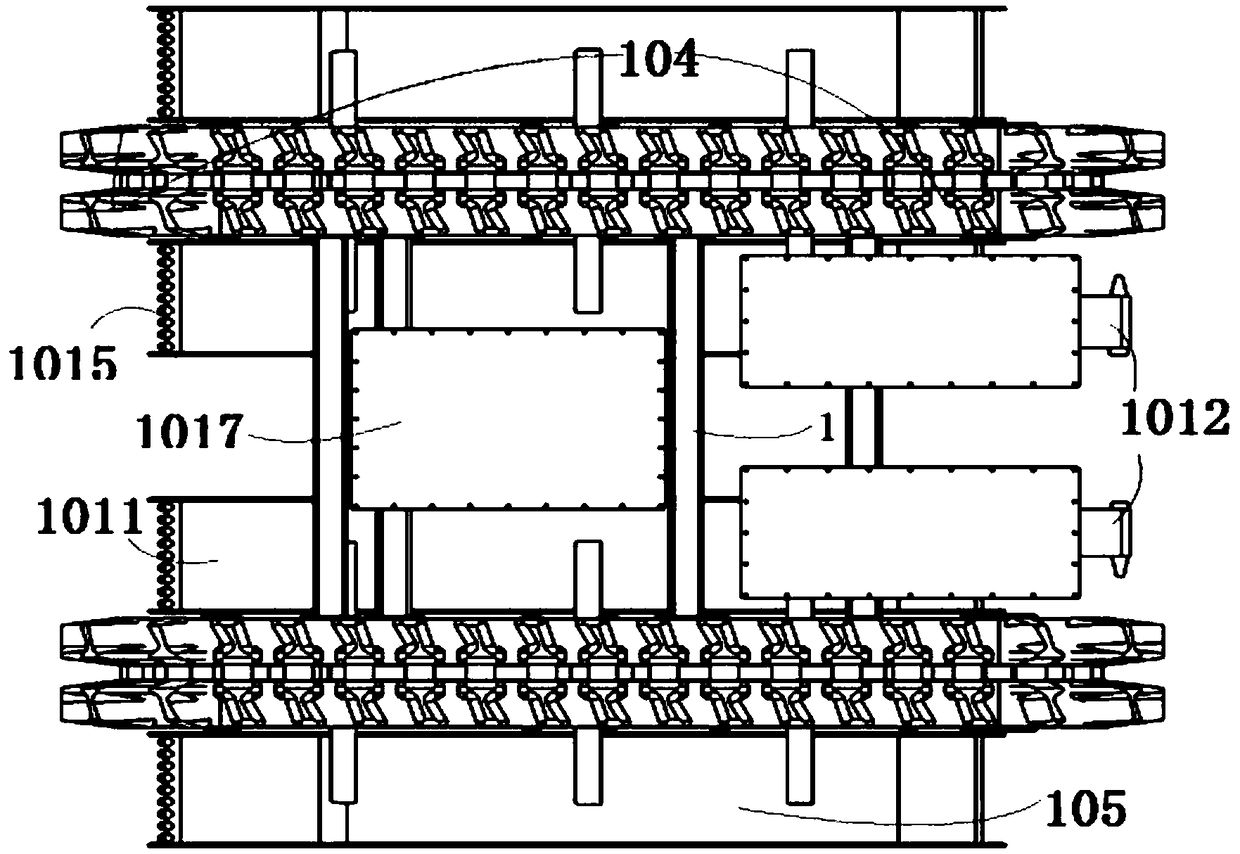

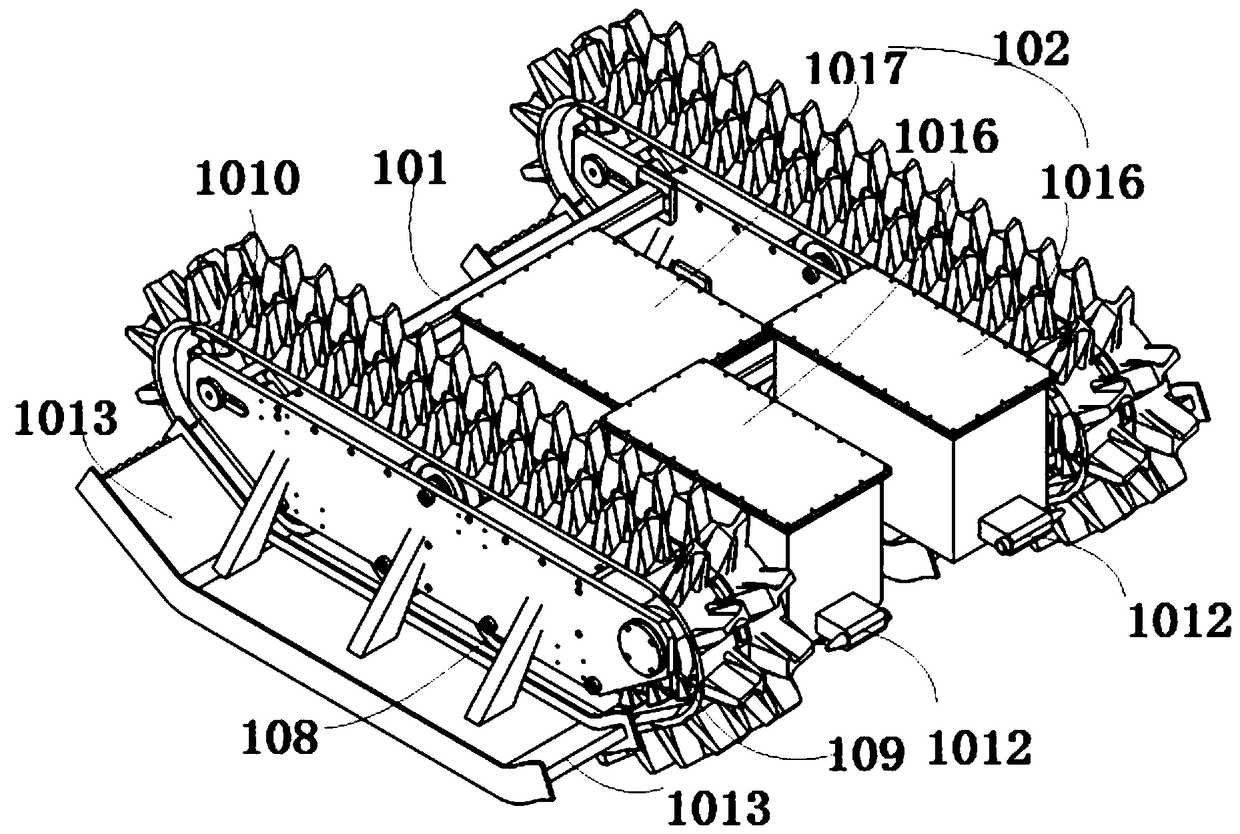

ActiveCN109572849ACompact structureIncrease clamping forceApparatus for overhead lines/cablesVehiclesTransmission towerReciprocating motion

The invention discloses clamping mechanisms of a robot used for a transmission tower and the climbing robot. The clamping mechanisms of the robot used for the transmission tower and the climbing robotsolve the problem in the prior art of high safety risk in the process of manually climbing the transmission tower, and have the beneficial effects of allowing the robot to climb the transmission tower, and providing a safety guarantee for climbing workers during follow-up operations. According to the technical solution, the robot used for the transmission tower consists of the clamping mechanisms, a lifting mechanism and a mechanical arm, wherein the clamping mechanisms comprise clamping components; the clamping components comprise clamping blocking plates and clamping plates; the clamping plates move back and forth relative to the clamping blocking plates through second telescopic units so as to clamp one side of the transmission tower through the clamping blocking plates and the clamping plates; extension components are provided with first telescopic units; the first telescopic units are connected to the clamping components so as to drive the clamping components to approach or get away from the side of the transmission tower; the top end and the bottom end of the lifting mechanism are separately connected to an upper clamping mechanism and a lower clamping mechanism; and the movement of the robot along a linear guideway is realized through the extension and retraction of the lifting mechanism.

Owner:SHANDONG JIANZHU UNIV

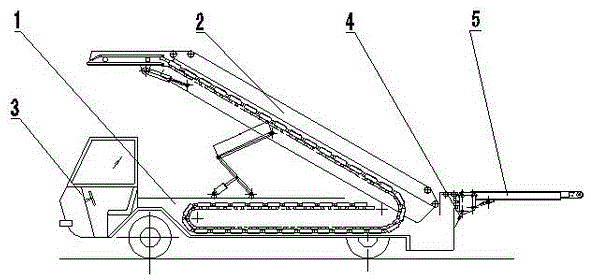

Movable loading and unloading machine with deflecting conveying function

ActiveCN105858269AReduce labor intensityRealize seamless dockingConveyorsLoading/unloadingEngineeringElectric control

The invention provides a movable loading and unloading machine with a deflecting conveying function and relates to the field of conveying equipment. The movable loading and unloading machine is composed of a vehicle chassis, a conveying device, an electric control system and a hydraulic system. The conveying device is arranged on the vehicle chassis and composed of a feeding conveyor, a middle conveyor and a front end conveyor. The vehicle chassis is driven to travel, steer and brake by controlling the electric control system and the hydraulic system, and accordingly the feeding conveyor can ascend, descend, stretch, retract, swing and turn, amplitude variation of the middle conveyor is achieved, the middle conveyor can carry objects of the feeding conveyor and convey the objects to the front end conveyor, and height adjustment, movable and inclinable belt conveying, and turnable conveying, formed by a plurality of conveying units, of the front end conveyor are achieved. By the adoption of the movable loading and unloading machine, nearby loading and unloading can be achieved to the maximum extent, the feeding conveyor and the front end conveyor can enter the internal operation environment of a compartment, the positions and states can be adjusted at any time according to the variation requirements for cargo loading and unloading points, the labor intensity of operators can be relieved, the cost can be reduced, the operation environment is improved, the operation efficiency is improved, and the personnel safety and cargo transferring safety are improved.

Owner:襄阳忠良工程机械有限责任公司

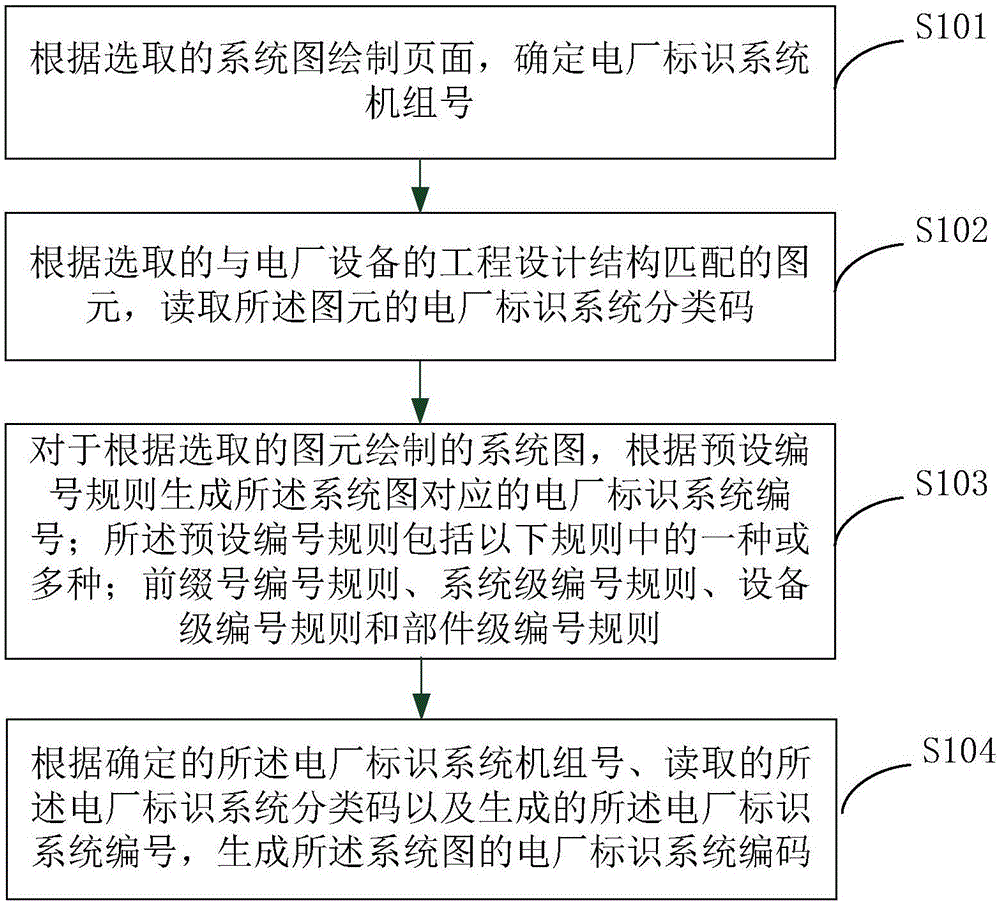

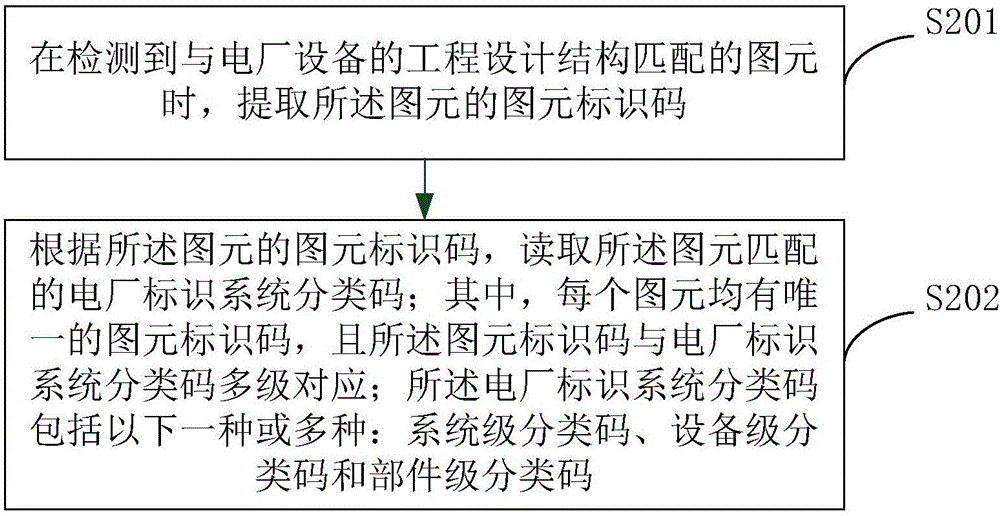

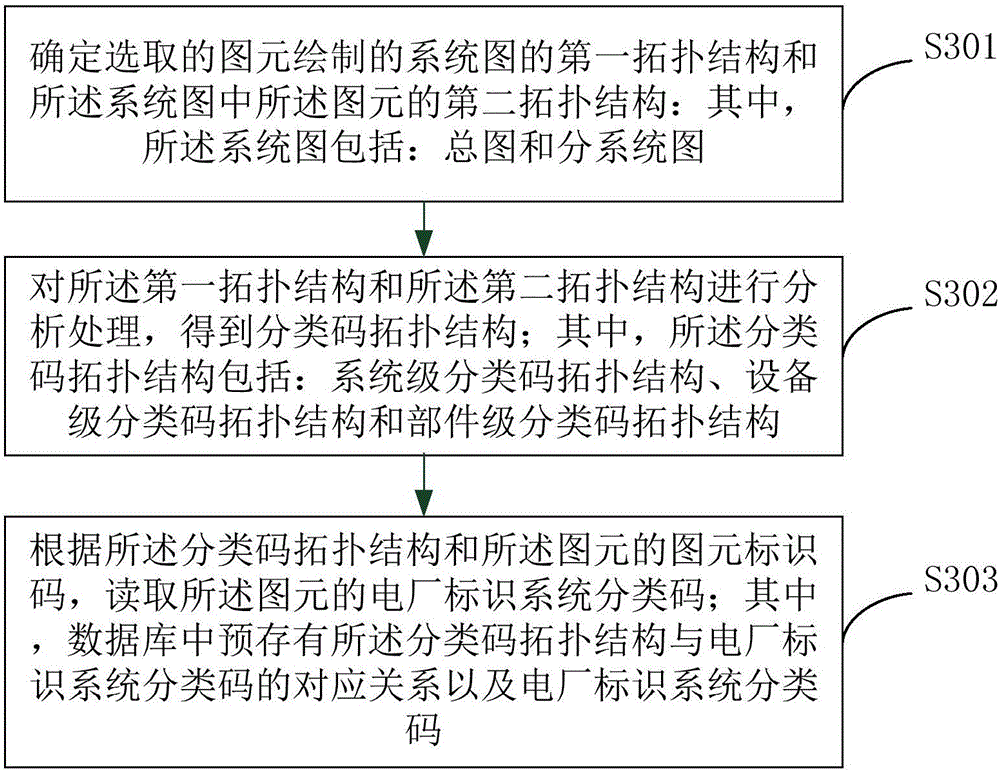

Automatically generating method and device of power plant identification system code

ActiveCN106777644ALow costReduce labor costsData processing applicationsSpecial data processing applicationsGraphicsComputerized system

The invention provides an automatically generating method and device of a power plant identification system code. The method includes the following steps that according to a selected system diagram, a page is drawn, and the machine group number of a power plant identification system is determined; according to a selected graphic primitive matched with the engineering design structure of power plant equipment, a power plant identification system classification code of the graphic primitive is read; for the system diagram drawn by the graphic primitive, a power plant identification system number corresponding to the system diagram is generated; according to the machine group number of the power plant identification system, the power plant identification system classification code and the power plant identification system number, the power plant identification system code of the system diagram is generated. According to the method and the device, automatic generation and automatic labeling of the power plant identification system code of the system diagram can be achieved through a computer system, the coding error rate, the repeat code rate and the labor cost are reduced, the digital management and safety operation level of an enterprise are improved, the working efficiency is improved, unified, scientific, correct and complete power plant identification system code data is provided for the application of the method and the device, and the integrated cost of the enterprise is largely reduced.

Owner:HUANENG POWER INTERNATIONAL

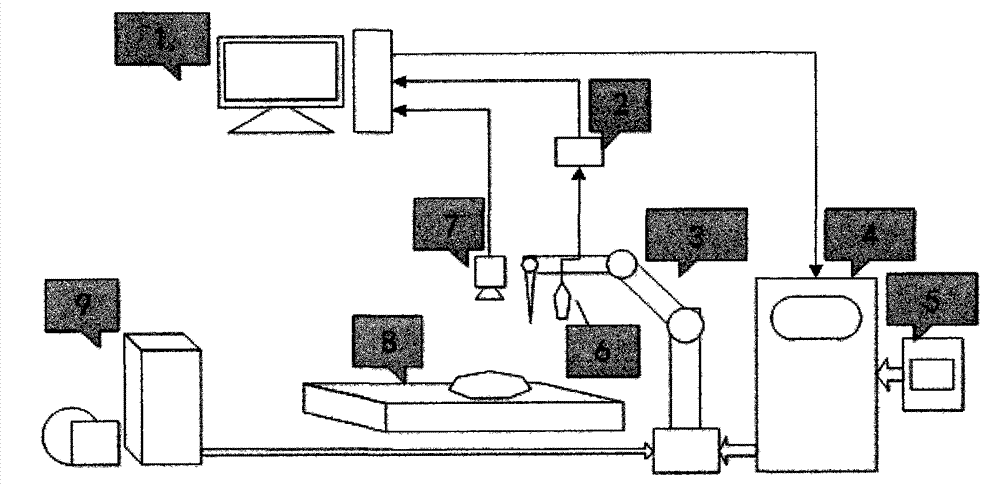

Position correcting system of welding robot

InactiveCN104741739AImprove accuracyImprove work efficiencyArc welding apparatusLaser rangingSimulation

The invention discloses a visual system of a welding robot capable of automatically correcting position deviation of a welding gun. Before the first work piece is welded, a welding plane and a visual plane are subjected to parallel measurement by a laser ranging sensor, thus the position of the visual plane is adjusted to be parallel with the welding plane. Then, the placing position of the work piece is obtained by an industrial camera and precise demonstration operation is performed on the first work piece. Subsequent work pieces are welded in an identical way and the position of the welding gun is adjusted based on the deviation information obtained through images taken by the industrial camera. Therefore, a problem that an original demonstration program cannot work due to position deviation of the work pieces is solved, repeated demonstration operation is avoided, and working efficiency is improved greatly.

Owner:唐山长城电焊机总厂有限公司

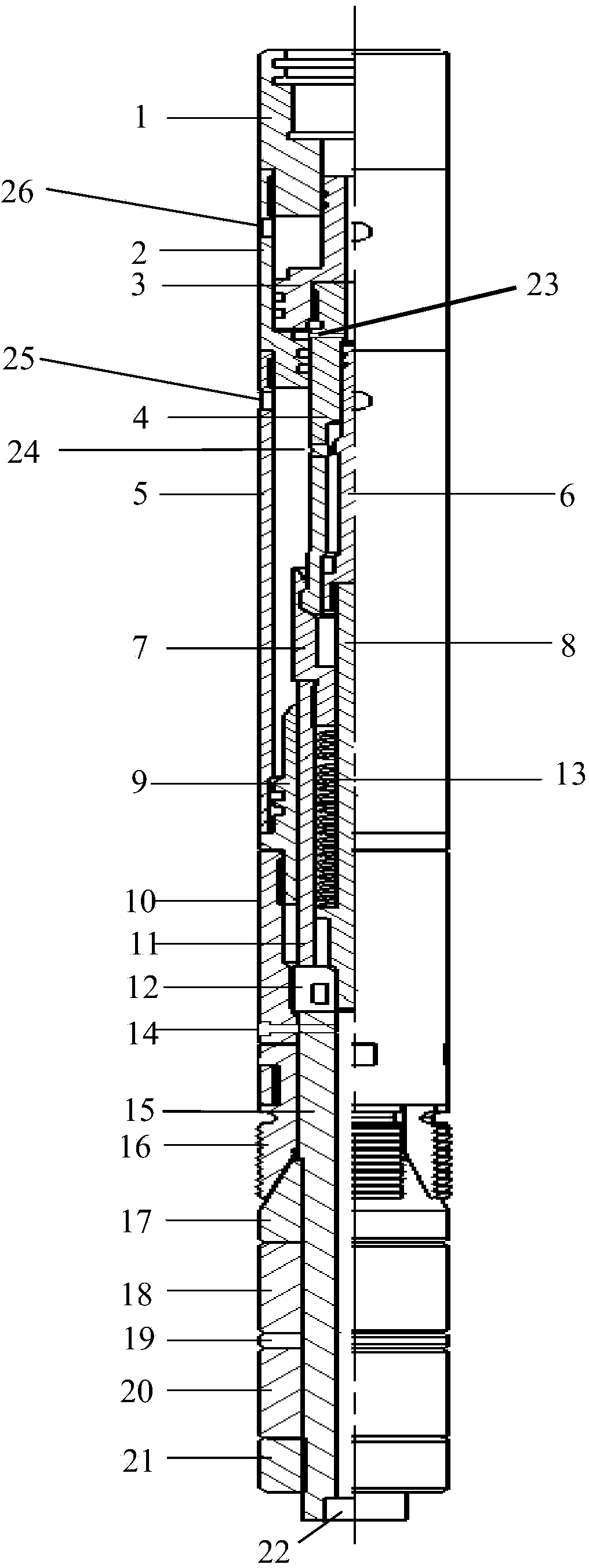

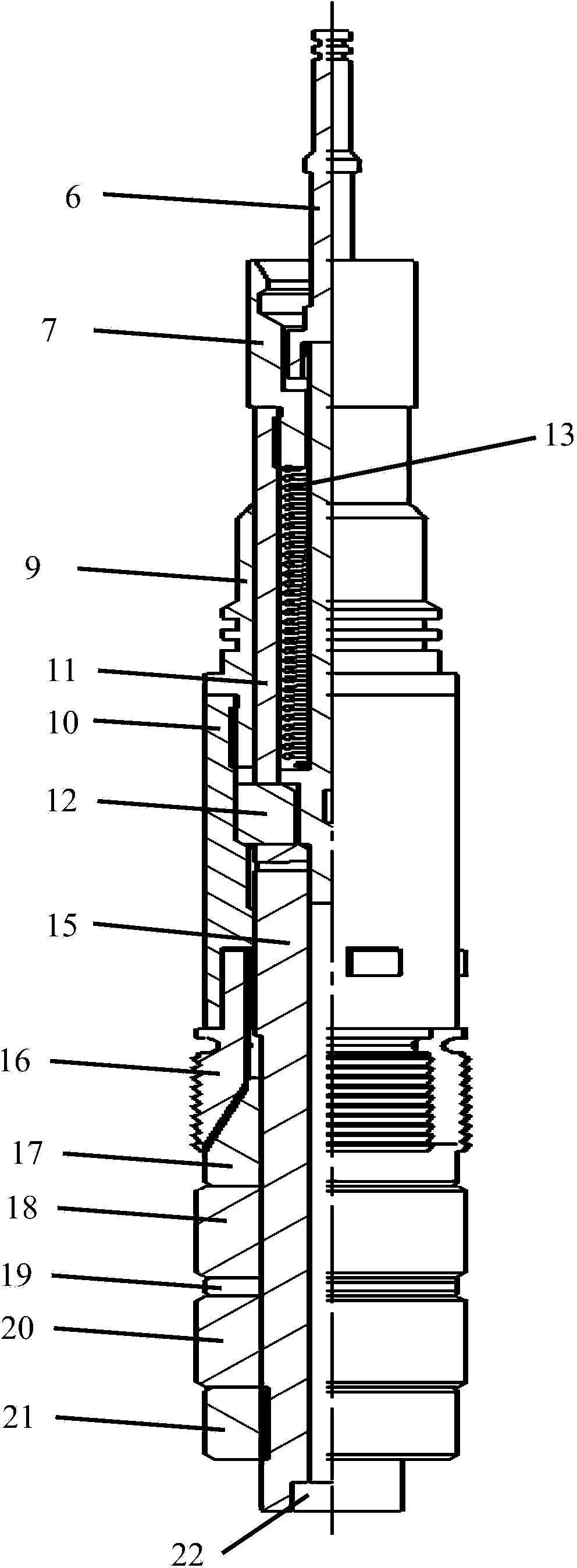

Oil pipe bridge plug

The invention discloses an oil pipe bridge plug, which is used for packing fluid and pressure in upper and lower spaces inside an oil pipe to realize the operation of changing a production tree upper hanging element with pressure. The oil pipe bridge plug mainly consists of two parts including a sealing mechanism and a setting releasing handle mechanism, wherein the sealing mechanism is a part remained in the oil pipe after the bridge plug plugging for achieving the packing effect, and comprises components including a center pipe, a lower releasing handle head, a fishing head, a sealing rod, a lock core, a lock block, a spring, a lower casing, a setting shear pin, a one-way slip, a cone body, a sealing rubber tube, a rubber tube retainer, a back cap and the like. The setting releasing handle mechanism is a part for enabling the bridge plug to complete the setting action and realizing the handle releasing, and comprises components including an upper joint, a piston cylinder, an upper casing, a setting piston, an elastic lifting clamp claw, an upper releasing handle head and the like. The oil pipe bridge plug is conveyed into the oil pipe through the hollow rod; through the pressurization into the center pipe, the piston generates ascending thrust, and the center pipe and the lock block are driven to upwards move; and the actions of rubber tube compression, slip anchoring, setting state locking, handle releasing and the like are realized. The oil pipe bridge plug is used for packing the upper and lower spaces of the oil pipe under pressure and achieving the goal of changing the production tree upper hanging element with pressure.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Die changing device

The invention discloses a die changing device, and belongs to the technical field of a conveying device. The die changing device comprises a first fixed die storing platform for storing a backup die, a second fixed die storing platform for storing a replaced die, and a lead rail die changing trolley for bearing the backup die or the replaced die in each working position of an equipment working table, wherein the lead rail die changing trolley can be operated among the equipment working table, the first fixed die storing platform and the second fixed die storing platform; and the die changing device further comprises a die seat for fixing the backup die or the replaced die in each working position of the equipment working table. The technical scheme provided by the invention has the beneficial effects that a die replacing operation and a die installing operation can be individually carried out, so that disassembling time can be saved, and a working cycle is reduced; the backup die can be precisely conveyed from a die storing table to the equipment working table, and an error in positioning precision is avoided; dies can be assembled in a plurality of working positions, thus, the error in positioning among different working positions can be avoided, working intensity of workers can be reduced, and danger is reduced.

Owner:SUOTE TRANSMISSION EQUIP

Fixing device and detection system

InactiveCN103032838ALow costShorten the working cycleLighting support devicesDisplay deviceStructural engineering

The invention provides a fixing device and a detection system, relating to the field of detection of a display device and solving the problem that the detection can only be performed by connecting and assembling all components of a backlight module into a model in the prior art. The fixing device comprises a supporting platform, at least two limiting side walls, a sliding part and a fixing part, wherein the limiting side walls are arranged on the supporting platform for limiting the position of the edge of an object carried by the supporting platform; at least one limiting side wall is a movable limiting side wall; the sliding part is connected with the movable limiting side wall for moving along the vertical direction of the movable limiting side wall; and the fixing part is arranged on the movable limiting side wall or the sliding part for fixing the movable limiting side wall at a certain position. The fixing device and the detection system are suitable for design and manufacturing of a detection part.

Owner:BOE TECH GRP CO LTD +1

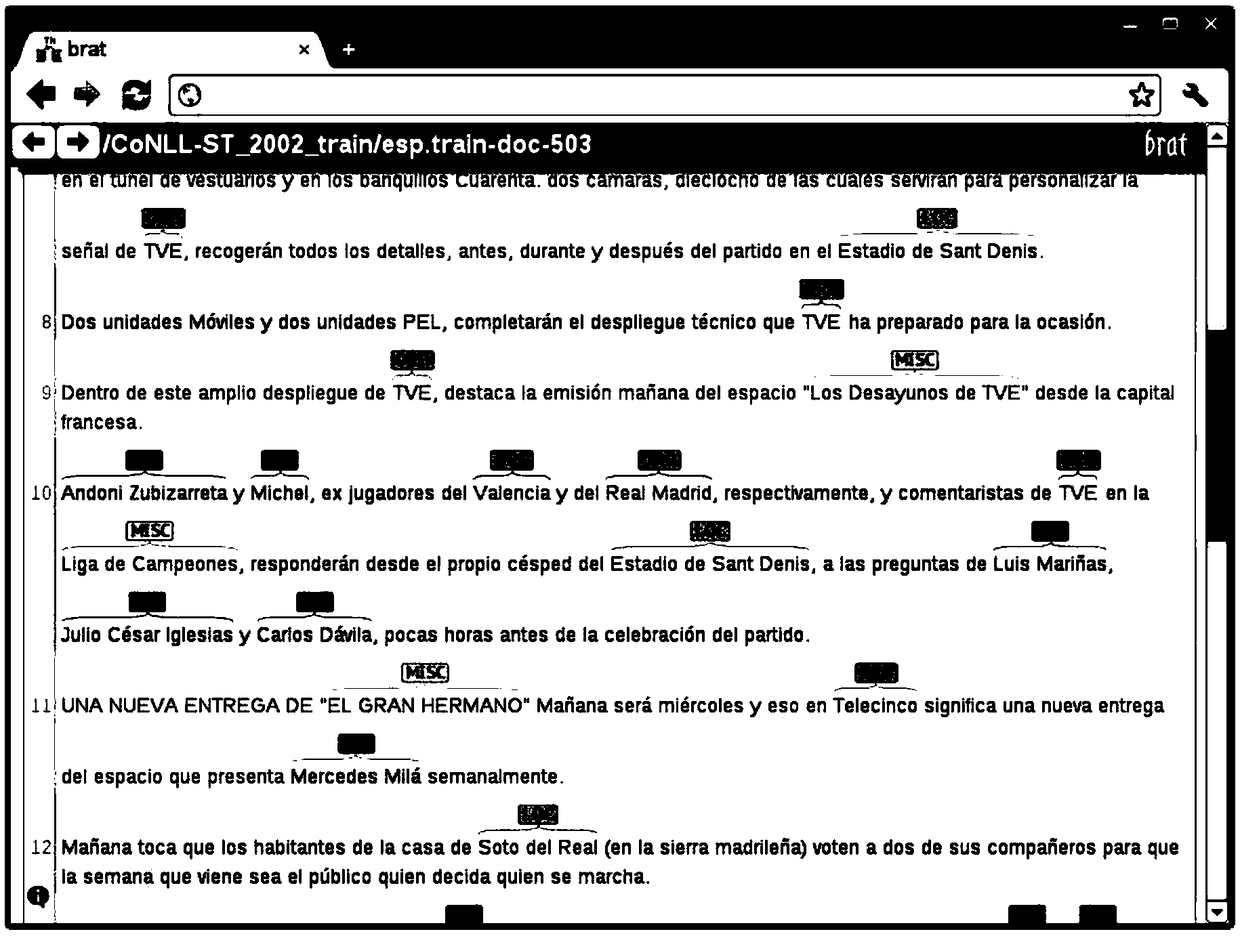

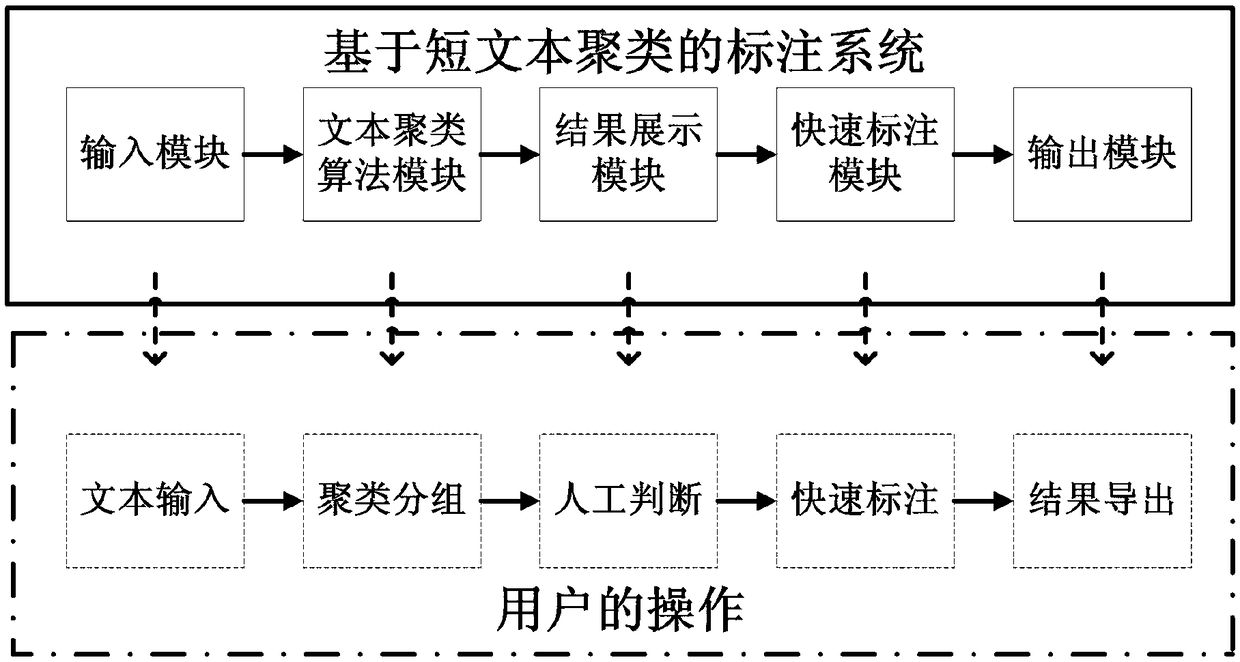

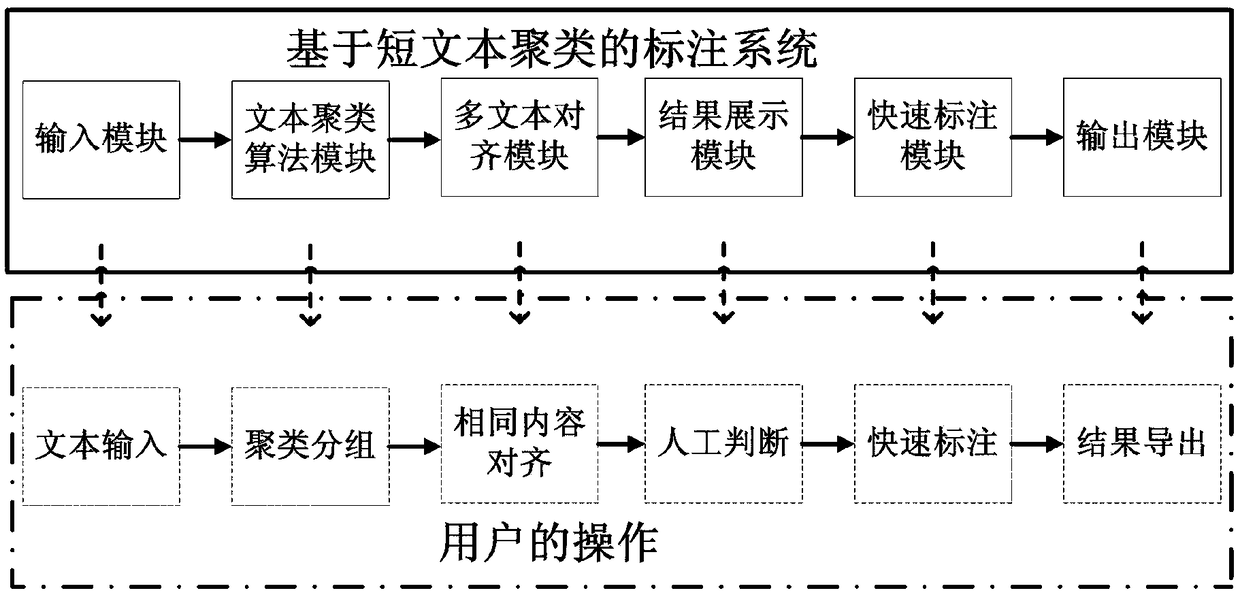

Short text clustering-based labeling system and method

ActiveCN108647319AImprove labeling efficiencyReduce reading workloadCharacter and pattern recognitionNatural language data processingText alignmentCluster algorithm

The invention relates to a short text clustering-based labeling system and method, belongs to the technical field of clinical medical labeling, and solves the problems of low labeling efficiency, difficult training, poor result accuracy and excessively high communication cost in the prior art. The short text clustering-based labeling system comprises an input module, a text clustering algorithm module, a multi-text alignment module, a result display module, a quick labeling module and an output module. Compared with the prior art, the labeling system and method has the advantages that a text clustering algorithm and a multi-text alignment algorithm are adopted, so that the reading quantity of similar sub-texts is greatly reduced and the reading speed is increased; longitudinal multi-text comparative browsing is adopted, so that the great convenience is provided for a user to perform manual comparison; and furthermore, algorithm training can be performed without any training set, and ITpersonnel do not need to perform algorithm modification for different medical texts, so that the communication cost is extremely low.

Owner:思派(北京)网络科技有限公司

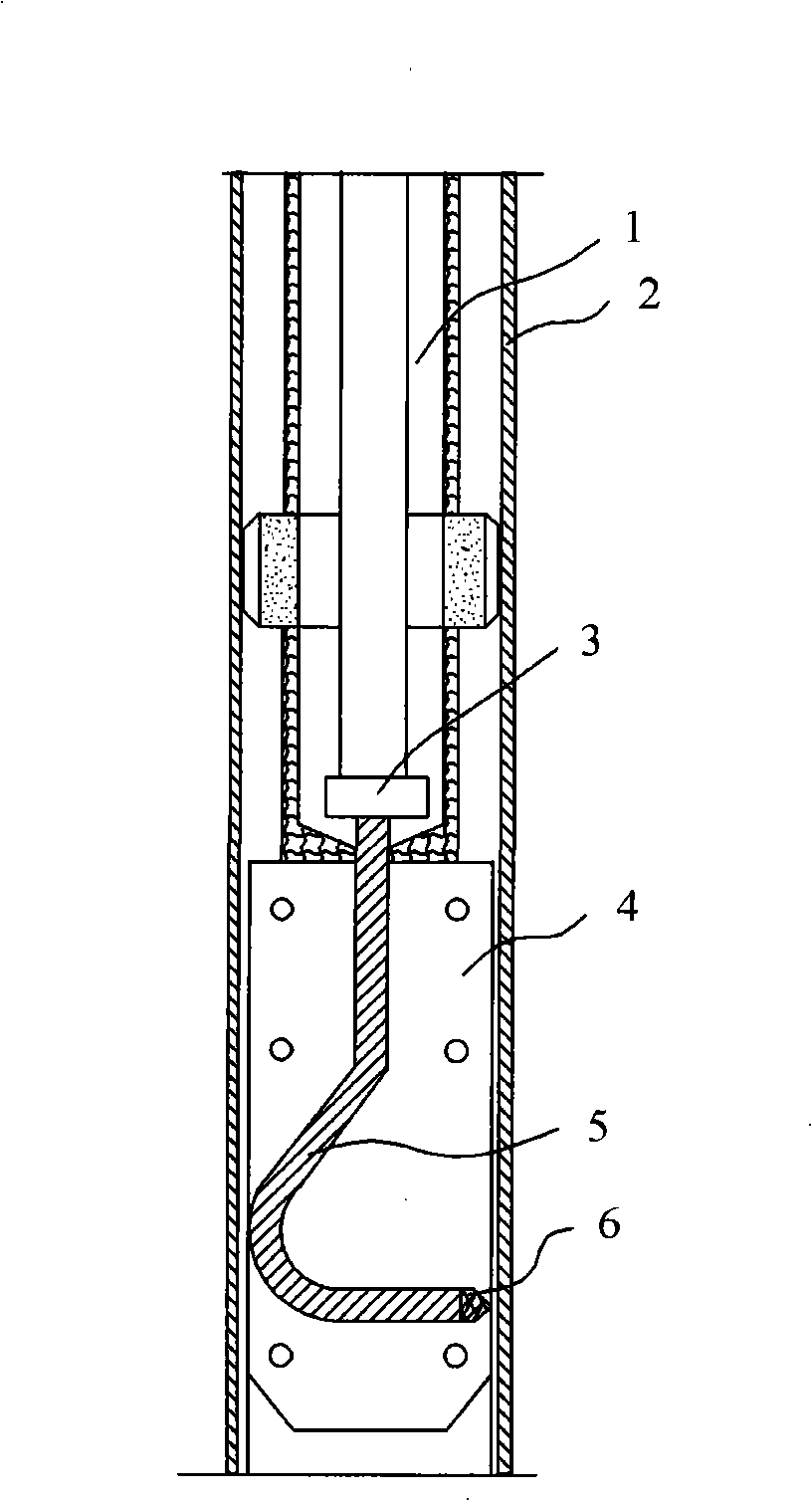

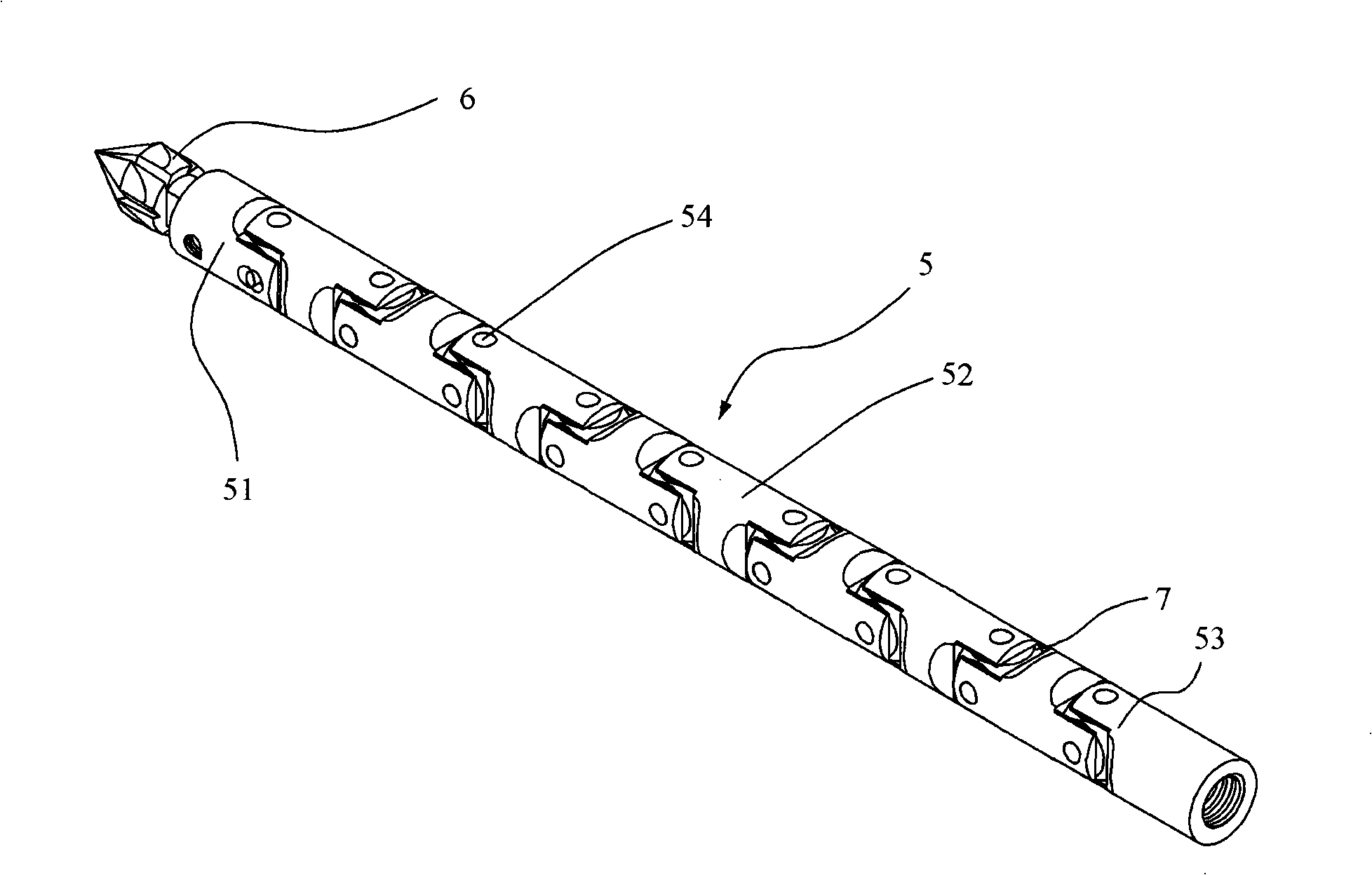

Device for drilling miniature borehole on ultra-short radius of coiled tubing

InactiveCN101294480AIncrease axial areaExtended service lifeDirectional drillingBorehole drivesDrive shaftCoiled tubing

The invention discloses a device for drilling minimal borehole on one coiled tubing side with ultra-short radius, which comprises a guider, a flexible transmission shaft, a driving motor and a bit. The flexible transmission shaft is arranged inside the guider, the bit is arranged at the output end of the flexible transmission shaft, and the driving motor is arranged at the input end of the flexible transmission shaft. The flexible transmission shaft includes more than three transmission sections which are connected with each other through ball heads, and the transmission sections are in surface contact with the ball heads. The invention increases the axial area of the flexible transmission shaft by using the ball heads to connect the transmission sections of the flexible transmission shaft and designing the surface contact between the transmission sections and the ball heads, thus prolonging the service time of the flexible transmission shaft and improving the device stability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Double-face polishing arm device for polishing propeller of large-sized ship

ActiveCN107253123AReduce vibrationShorten the working cycleGrinding drivesGrinding machinesPropellerWork period

The invention belongs to the field of manufacturing industry polishing and machining, and particularly relates to a double-face polishing robot arm device for polishing a propeller blade of a large-sized ship. The double-face polishing arm device comprises a power module, and two sets of polishing components which are arranged symmetrically. Each set of polishing component comprises a belt transmission module, a polishing head telescopic mechanism module and a self-adaption polishing head module. The double-face polishing device can achieve corresponding and simultaneous polishing of two side positions in the polishing process of the propeller blade of the large-sized ship, so that the vibration when the edge of the blade of the propeller is polished is reduced effectively. By adoption of a self-adoption attaching mechanism, rapid response to change of the surface shape of a workpiece can be made, and the working period of a polishing robot is shortened; and compared with single-face polishing, the double-face polishing arm device improves the polishing efficiency.

Owner:NORTHEASTERN UNIV

Amorphous alloy member cast forming device and process

ActiveCN104668503ASimple structureReduce usageElectric heating for furnacesGas cylinderManufactured material

Provided is a device for casting forming of amorphous alloy components. The device comprises an injection system, an alloy smelting system, a raw material feeding system, a mould system, a vacuum system and a protective atmosphere system. The vacuum system comprises a vacuum tank (6). The protective atmosphere system comprises a gas cylinder (1) for a protective atmosphere. The vacuum tank or the gas cylinder for a protective atmosphere is provided to effectively realize the acquisition of a vacuum or a protective atmosphere with a positive pressure in the forming process so as to achieve the casting forming of the amorphous alloy components under the protection of the vacuum and the protective atmosphere with a positive pressure. The mould is provided with an exhaust port to prevent the formation of micro shrinkage cavities on the surface in the process of forming the alloy components. Also provided is a process for the casting forming of the amorphous alloy components. The device and process substantially reduce the space of the vacuum or the protective atmosphere with a positive pressure, and can improve the quality of the amorphous alloy components, save on cost and improve the production efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com