Amorphous alloy member cast forming device and process

A casting molding and amorphous alloy technology, which is applied in the field of casting molding equipment and technology of amorphous alloy components, can solve the problem of easy formation of pores or shrinkage cavities in amorphous alloy components, prolonging the working cycle of amorphous alloy workpieces, and forming of amorphous alloy components. Efficiency reduction and other problems, to achieve the effect of continuous automatic production, solve the micro shrinkage cavity on the surface, and shorten the working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by specific embodiments.

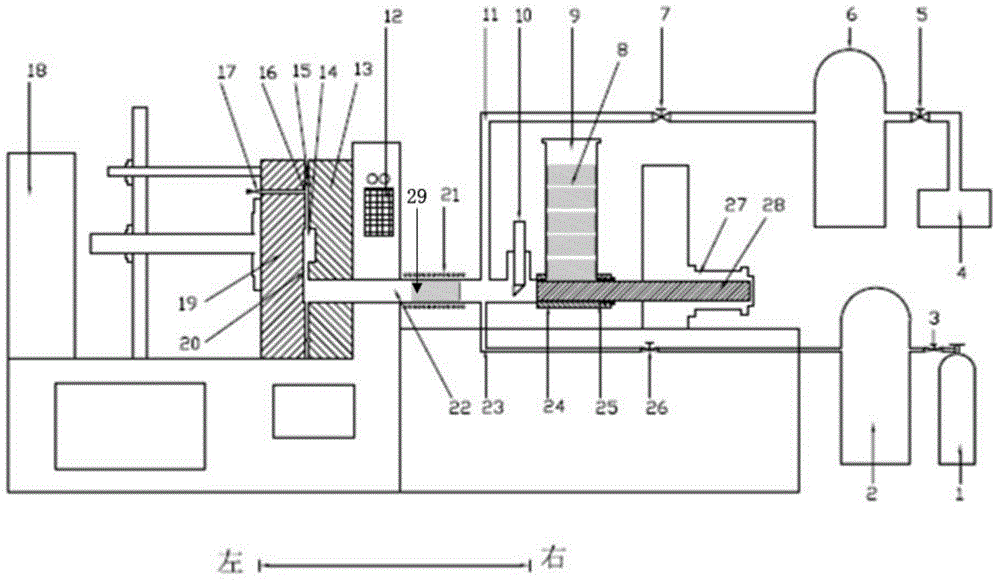

[0045] Such as figure 1 As shown, the casting molding equipment of the present invention includes an injection system, an alloy smelting system, a raw material feeding system, a mold system, a vacuum system and a protective atmosphere system, wherein:

[0046] Injection system: including injection cylinder 22, injection mechanism 27 and injection rod 28, the injection rod 28 can move along the direction of the inner wall of the injection cylinder 22, and the movement of the injection rod 28 is controlled by the injection mechanism 27 direction and speed.

[0047] Alloy smelting system: used for alloy smelting, including a smelting chamber 29 and a heating device 21, the heating device 21 is used to melt the alloy material 8 in the smelting chamber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com