Automatic wooden product carbonizing machine

A wood product, carbonizing machine technology, applied in the direction of charcoal burning/combustion, opening and dipping, etc., can solve the problems of high labor intensity and affect production efficiency, and achieve the effect of reducing labor intensity, improving work efficiency, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

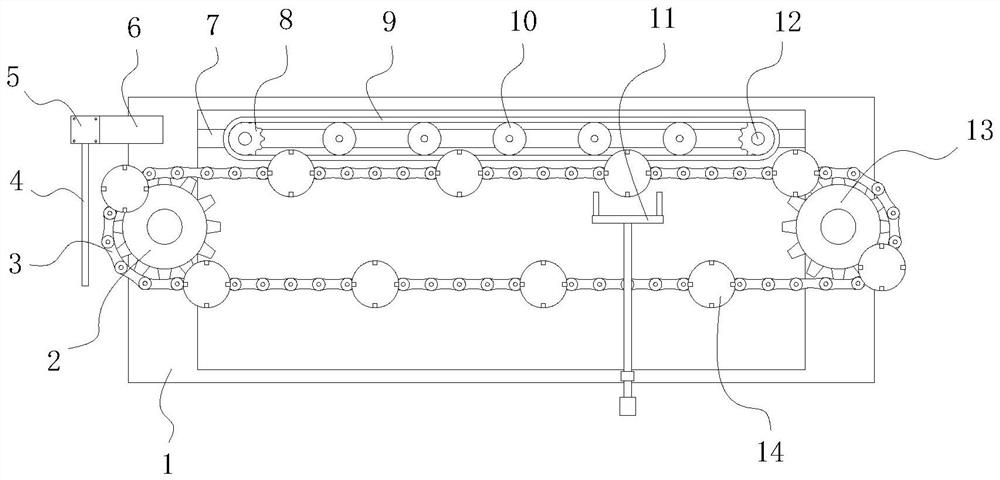

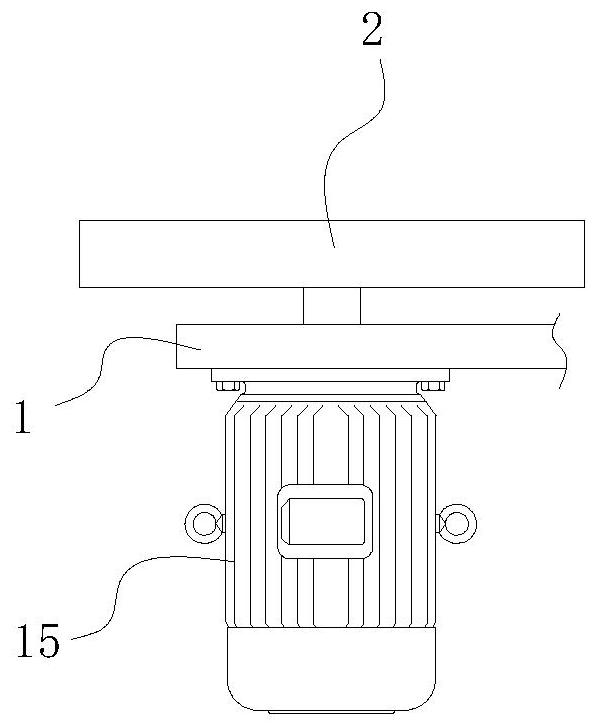

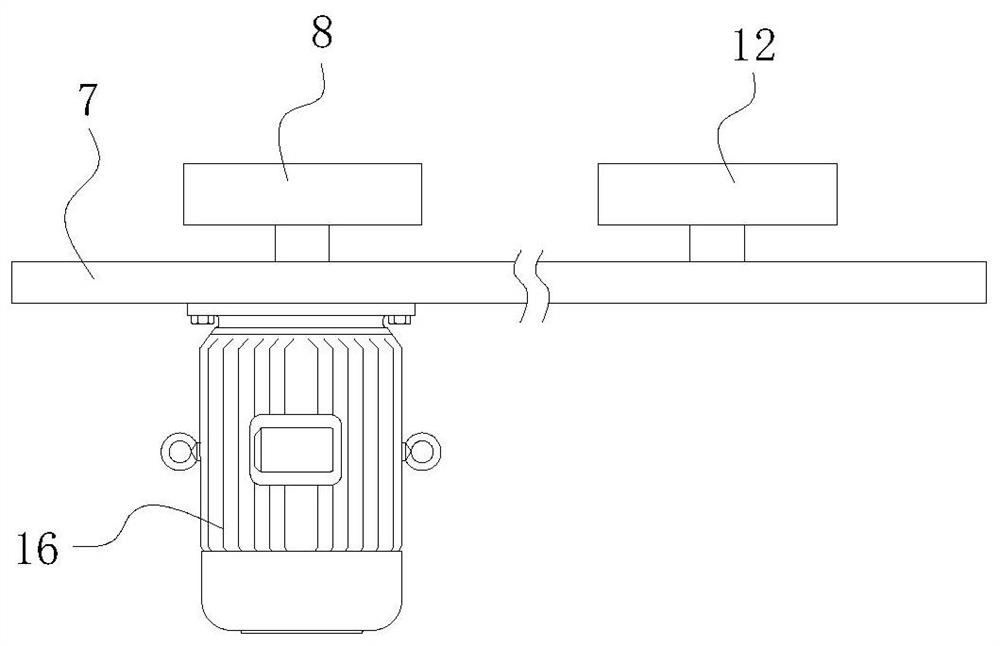

[0037] The specific embodiment: use the robot manipulator to clamp the wood products that need to be carbonized between the four jaws 21 on the pallet 14. When the first drive motor 15 is started, the first drive motor 15 drives the chain 3 to rotate, and the chain 3 drives The tray 14 and the wooden products on the tray 14 rotate together. When the tray 14 storing the wooden products moves to the torch 11, the flame ejected from the torch 11 will barbecue and carbonize the wooden products, so as to realize the purpose of mechanical carbonization and improve Work efficiency, reduce labor intensity, when starting the second driving motor 16, the second driving motor 16 drives the driving gear 8 to rotate, and the driving gear 8 drives the rubber belt 9 to rotate between the driving gear 8 and the driven gear 12, and the rotating rubber The belt ring 9 drives the cylinder 18 to rotate, and the cylinder 18 drives the tray 14 and the wood products in the tray 14 to rotate, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com