Method for reducing residual alkali content of high-nickel material and prepared low-residual-alkali high-nickel material

A technology with high nickel and residual alkali, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problem of high residual alkali, achieve the effect of reducing damage, reducing complexity and shortening the process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

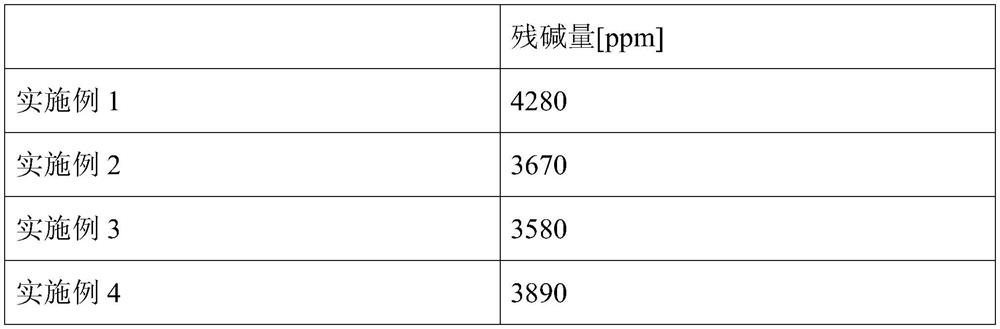

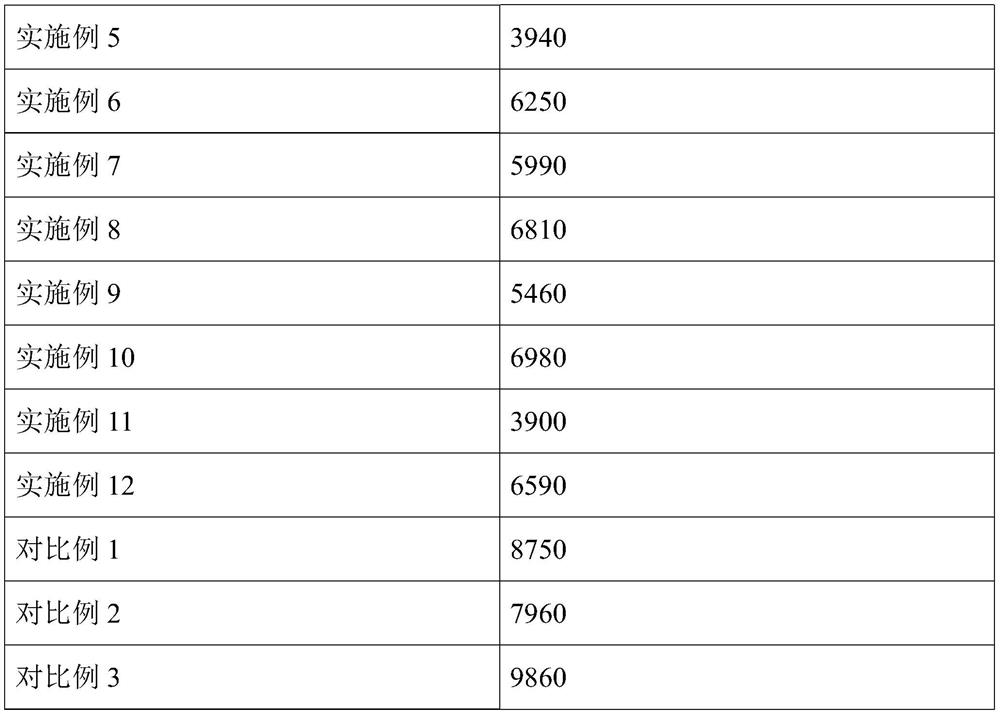

Examples

Embodiment 1

[0039] This embodiment provides a method for reducing the residual alkali content of high-nickel materials, and the method specifically includes the following steps:

[0040] (1) High-nickel ternary cathode material precursor Ni 0.6 co 0.3 mn 0.1 (OH) 2 , Lithium hydroxide and additives are mixed evenly to obtain a mixed material. The molar ratio of the lithium element in lithium hydroxide to the nickel-cobalt-manganese element in the precursor of the high-nickel ternary positive electrode material is 1.02. The additives include lithium sulfate and ammonium dihydrogen phosphate, lithium sulfate The addition amount of the ammonium dihydrogen phosphate accounts for 0.1wt% of the mass of the high-nickel ternary cathode material precursor, and the addition amount of ammonium dihydrogen phosphate accounts for 0.4wt% of the mass of the high-nickel ternary cathode material precursor;

[0041] (2) The mixed material is heated to 700°C at a heating rate of 1°C / min, and kept for 10 h...

Embodiment 2

[0045] This embodiment provides a method for reducing the residual alkali content of high-nickel materials, and the method specifically includes the following steps:

[0046] (1) High-nickel ternary cathode material precursor Ni 0.65 co 0.15 mn 0.2 (OH) 2 , Lithium hydroxide and additives are mixed evenly to obtain a mixed material. The molar ratio of the lithium element in lithium hydroxide to the nickel-cobalt-manganese element in the precursor of the high-nickel ternary positive electrode material is 1.03, and the additives include ammonium sulfate and lithium metaphosphate, ammonium hydrogen sulfate The addition amount of lithium metaphosphate accounts for 0.1wt% of the mass of the high-nickel ternary cathode material precursor, and the addition amount of lithium metaphosphate accounts for 0.2wt% of the mass of the high-nickel ternary cathode material precursor;

[0047] (2) The mixed material is heated to 800°C at a heating rate of 2°C / min, and kept for 8 hours; then c...

Embodiment 3

[0051] This embodiment provides a method for reducing the residual alkali content of high-nickel materials, and the method specifically includes the following steps:

[0052] (1) High-nickel ternary cathode material precursor Ni 0.7 co 0.1 mn 0.2 (OH) 2 , Lithium hydroxide and additives are mixed uniformly to obtain a mixed material, the molar ratio of lithium element in lithium hydroxide to nickel-cobalt-manganese element in the precursor of high-nickel ternary positive electrode material is 1.04, and additives include ammonium hydrogen sulfate and lithium metaphosphate, hydrogen sulfate The amount of ammonia added accounts for 0.3wt% of the mass of the precursor of the high-nickel ternary cathode material, and the amount of lithium metaphosphate added accounts for 0.2wt% of the mass of the precursor of the high-nickel ternary cathode material;

[0053] (2) The mixed material is heated to 850°C at a heating rate of 3°C / min, and kept for 8 hours; then cooled to 400°C at a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com