A kind of positive electrode material of lithium ion battery and preparation method thereof

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as increased manufacturing costs, poor material performance, and inapplicability, and achieve improved fluidity, small internal voids, and structural Not easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

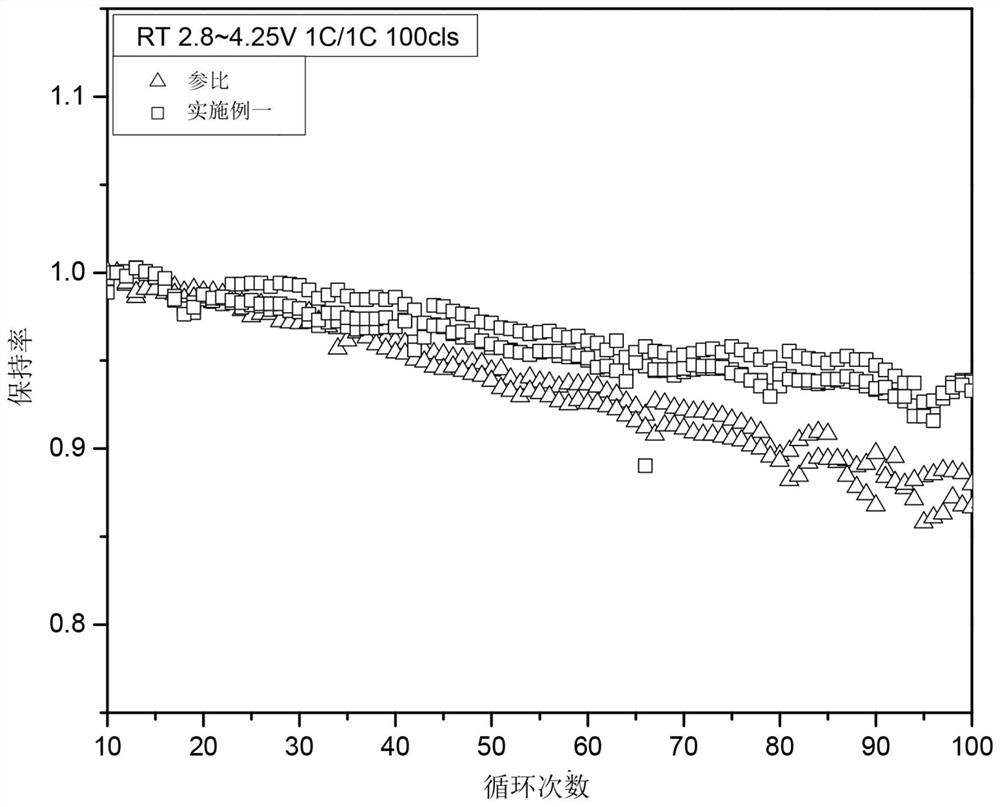

Embodiment 1

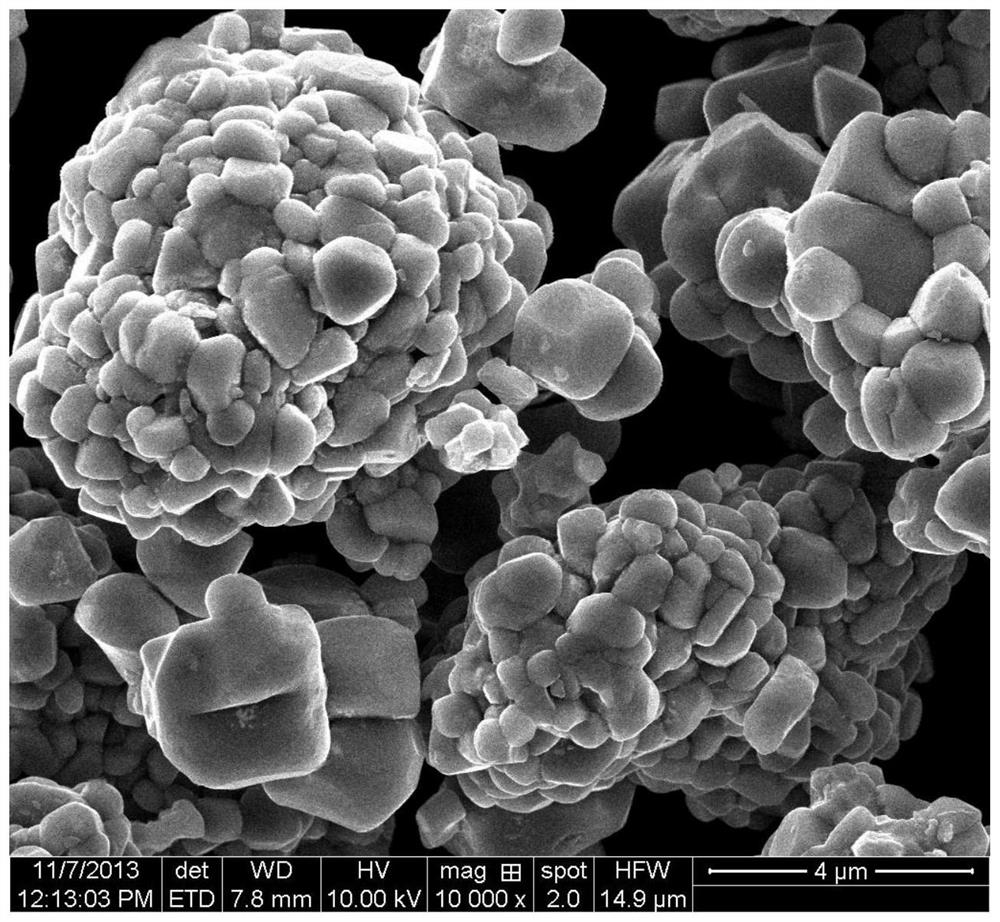

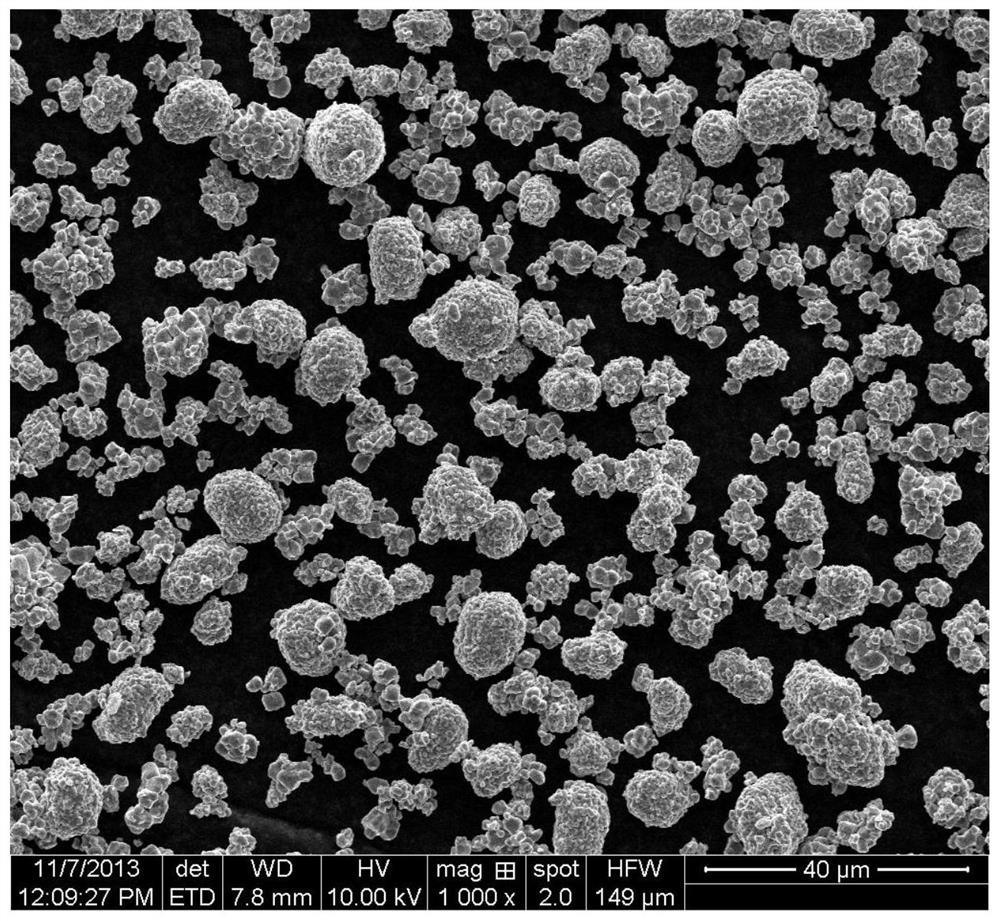

[0029] This embodiment provides a method for preparing a lithium-ion battery positive electrode material, the steps are as follows:

[0030] Ni with a median diameter of about 10 μm 0.815 co 0.15 Al 0.035 (OH) 2 Precursor (that is, nickel-cobalt-aluminum co-precipitation precursor A) and LiOH at a ratio of 1:1.05 (equivalent to the molar ratio of the sum of all metal ions of nickel-cobalt-aluminum co-precipitation precursor A to the lithium ion of LiOH, the same below) Mix evenly, place the mixture in a sintering furnace under an oxygen atmosphere, raise the temperature to 520°C at 5°C / min, keep it for 3 hours, then raise the temperature to 760°C at 1°C / min, keep it for 10 hours, and finally cool naturally to room temperature to obtain a spherical shape Morphology of nickel-cobalt-lithium-aluminate particles.

[0031] Ni with a median diameter of about 3 μm 0.88 co 0.09 Al 0.03 (OH) 2Precursor (that is, nickel-cobalt-aluminum co-precipitation precursor B) and LiOH at a...

Embodiment 2

[0035] This embodiment provides a method for preparing a lithium-ion battery positive electrode material, the steps are as follows:

[0036] Ni with a median diameter of about 12 μm 0.85 co 0.12 Al 0.03 (OH) 2 The precursor (i.e. nickel-cobalt-aluminum co-precipitation precursor A) and LiOH were mixed uniformly at a ratio of 1:1.04, and the mixture was placed in a sintering furnace under an oxygen atmosphere, and the temperature was raised to 500 °C at 5 °C / min, kept for 3 h, and then The temperature was raised to 770°C at 1°C / min, kept for 10 hours, and finally cooled to room temperature naturally to obtain spherical nickel-cobalt-lithium aluminate particles.

[0037] Ni with a median diameter of about 5 μm 0.85 co 0.12 Al 0.03 (OH) 2 The precursor (i.e. nickel-cobalt-aluminum co-precipitation precursor B) and LiOH were mixed uniformly at a ratio of 1:1.04, and the mixture was placed in a sintering furnace under an oxygen atmosphere, and the temperature was raised to 5...

Embodiment 3

[0041] This embodiment provides a method for preparing a lithium-ion battery positive electrode material, the steps are as follows:

[0042] Ni with a median diameter of about 9 μm 0.88 co 0.09 Al 0.03 (OH) 2 The precursor (i.e. nickel-cobalt-aluminum co-precipitation precursor A) and LiOH were mixed uniformly at a ratio of 1:1.10, and the mixture was placed in a sintering furnace under an oxygen atmosphere, and the temperature was raised to 540 °C at 5 °C / min, kept for 3 h, and then The temperature was raised to 780°C at 1°C / min, kept for 10h, and finally cooled to room temperature naturally to obtain spherical nickel-cobalt-lithium aluminate particles.

[0043] Ni with a median diameter of about 5 μm 0.85 co 0.12 Al 0.03 (OH) 2 The precursor (i.e. nickel-cobalt-aluminum co-precipitation precursor B) and LiOH were mixed uniformly at a ratio of 1:0.9, and the mixture was placed in a sintering furnace under an oxygen atmosphere, and the temperature was raised to 530 °C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com