Ultrahigh nickel single-crystal positive electrode material and preparation method thereof

A positive electrode material and single crystal-like technology, which is applied in the field of ultra-high nickel single crystal positive electrode material and its preparation, can solve the problems of difficult preparation, high see content, serious nickel precipitation, etc., and achieve simple preparation process, high particle strength, Effect of Reducing Residual Alkali Content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

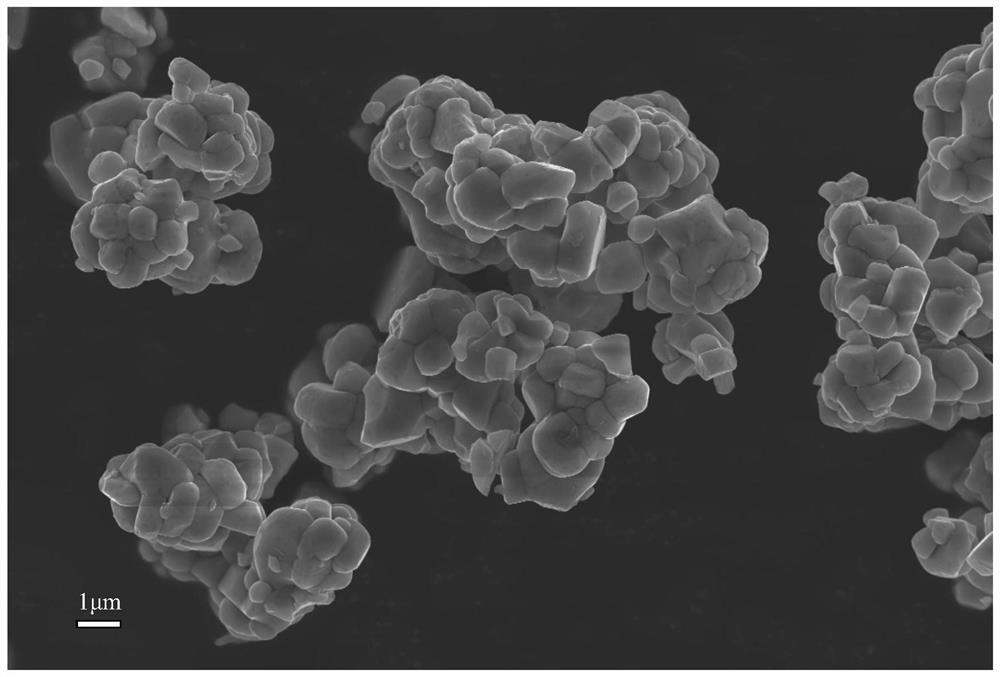

[0034] This embodiment provides an ultra-high nickel-based single crystal positive electrode material, and the specific preparation steps are as follows:

[0035] (1) 100g of nickel-cobalt-manganese-aluminum hydroxide (wherein the molar ratio of metal elements: Ni:Co:Mn:Al=90:7:2:1, the same below) is placed in an ultracentrifugal grinder, at a pressure of 1MPa, Stir at 10000r / min for 45 minutes.

[0036] (2) LiOH, strontium carbonate and nickel cobalt manganese aluminum hydroxide (molar ratio: Ni:Co:Mn:Al=90:7:2:1) according to the molar ratio of 1.025:0.001:1 (Li / Metal= 1.025, Sr / Metal=0.001, the same below) was poured into an ultracentrifugal grinder, and the rotation speed was adjusted to 7000r / min to continue stirring for 45 minutes.

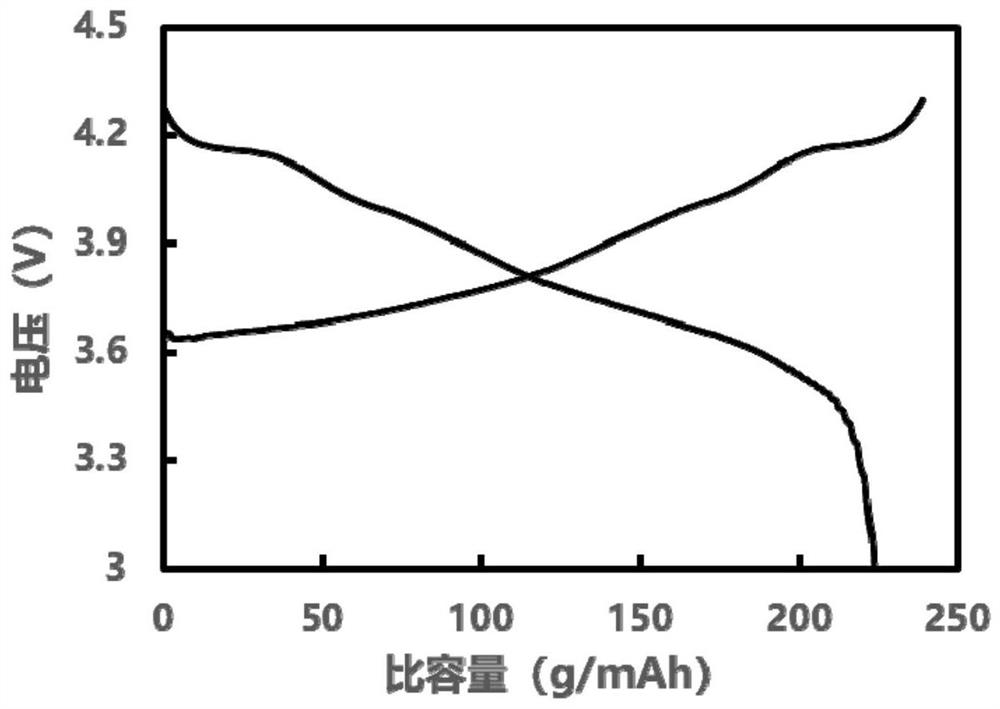

[0037] (3) Finally, the mixed material was calcined in an ordinary box-type furnace at 750° C. in an oxygen atmosphere with a purity of 98% for 8 hours, then cooled, crushed and passed through a 300-mesh sieve to obtain an ultra-high nicke...

Embodiment 2

[0040] This embodiment provides an ultra-high nickel-based single crystal positive electrode material, and the specific preparation steps are as follows:

[0041] (1) Put 100g of nickel-cobalt-manganese-aluminum hydroxide (the molar ratio of metal elements: Ni:Co:Mn:Al=90:7:2:1) in an ultracentrifugal grinder, at a pressure of 0.5MPa, 10000r / min stirring for 45 minutes.

[0042](2) LiOH, strontium carbonate and nickel cobalt manganese aluminum hydroxide (molar ratio: Ni:Co:Mn:Al=90:7:2:1) according to the molar ratio of 1.05:0.001:1 (Li / Metal= 1.05, Sr / Metal=0.001) was poured into an ultracentrifugal grinder, and the rotating speed was adjusted to 7000r / min to continue stirring for 45 minutes.

[0043] (3) Finally, the mixed material was calcined in an ordinary box-type furnace at 750° C. in an oxygen atmosphere with a purity of 98% for 8 hours, then cooled, crushed and passed through a 300-mesh sieve to obtain an ultra-high nickel single crystal positive electrode material....

Embodiment 3

[0045] This embodiment provides an ultra-high nickel-based single crystal positive electrode material, and the specific preparation steps are as follows:

[0046] (1) Put 100g of nickel-cobalt-manganese-aluminum hydroxide (molar ratio: Ni:Co:Mn:Al=90:7:2:1) in an ultracentrifugal grinder, stir at 1.5MPa, 10000r / min for 45 minute.

[0047] (2) LiOH, strontium carbonate and nickel cobalt manganese aluminum hydroxide (molar ratio: Ni:Co:Mn:Al=90:7:2:1) according to the molar ratio of 1:0.001:1 (Li / Metal= 1) Pour into an ultracentrifugal grinder, adjust the speed to 7000r / min and continue stirring for 45 minutes.

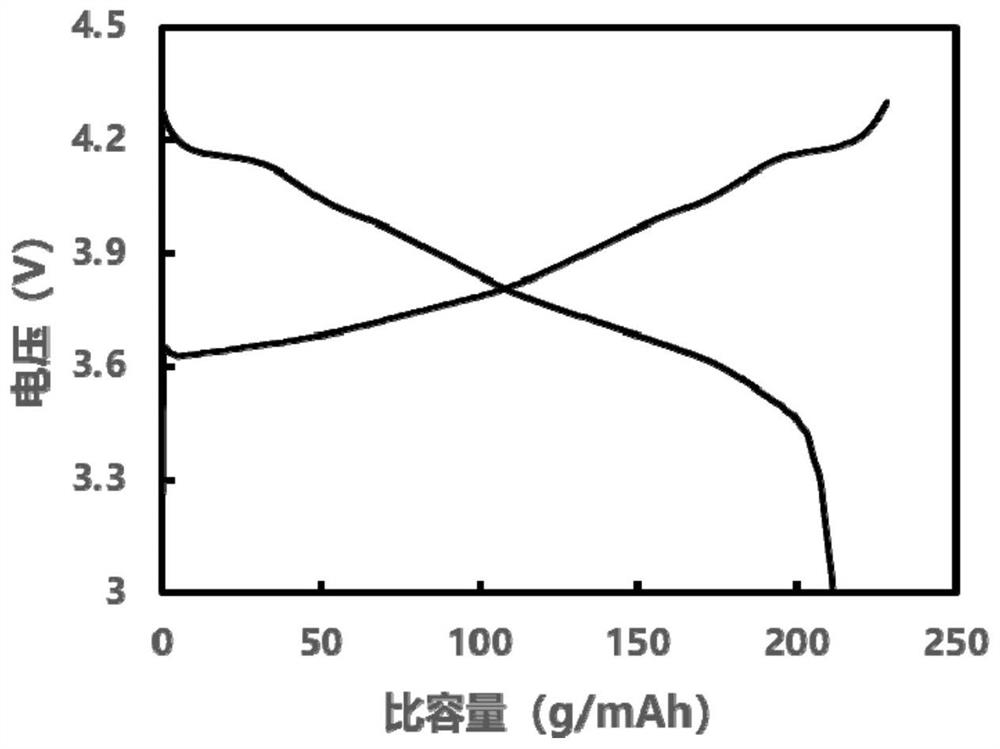

[0048] (3) Finally, the mixed material was calcined in an ordinary box-type furnace at 750° C. in an oxygen atmosphere with a purity of 98% for 8 hours, then cooled, crushed and passed through a 300-mesh sieve to obtain an ultra-high nickel single crystal positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com